An Analysis on Negative Effects of Shaft Deflection on Angular Misalignment of Rollers Inside Tapered Roller Bearing

Abstract

1. Introduction

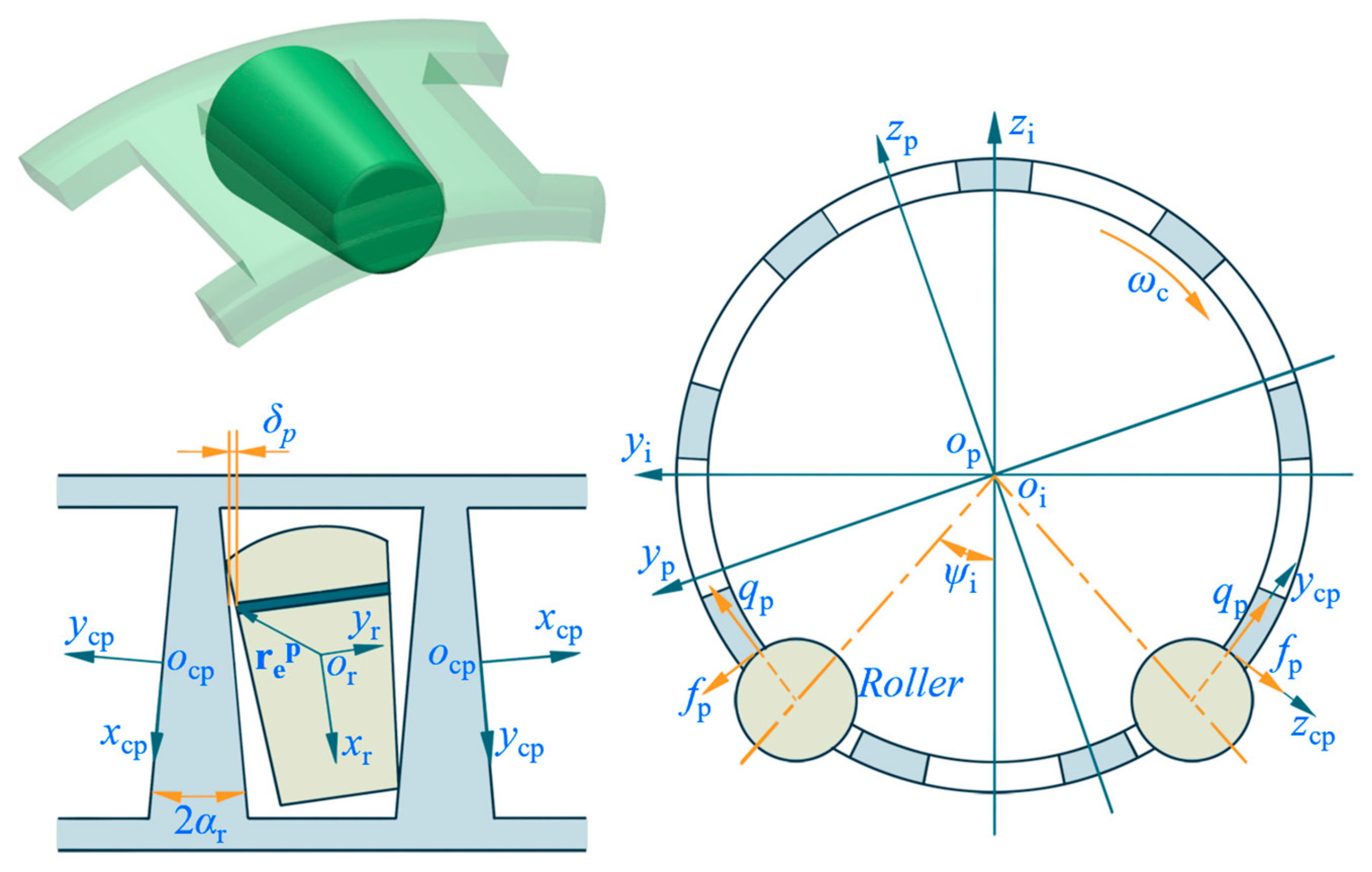

2. Theoretical Formulation

2.1. Roller/Raceway Interaction

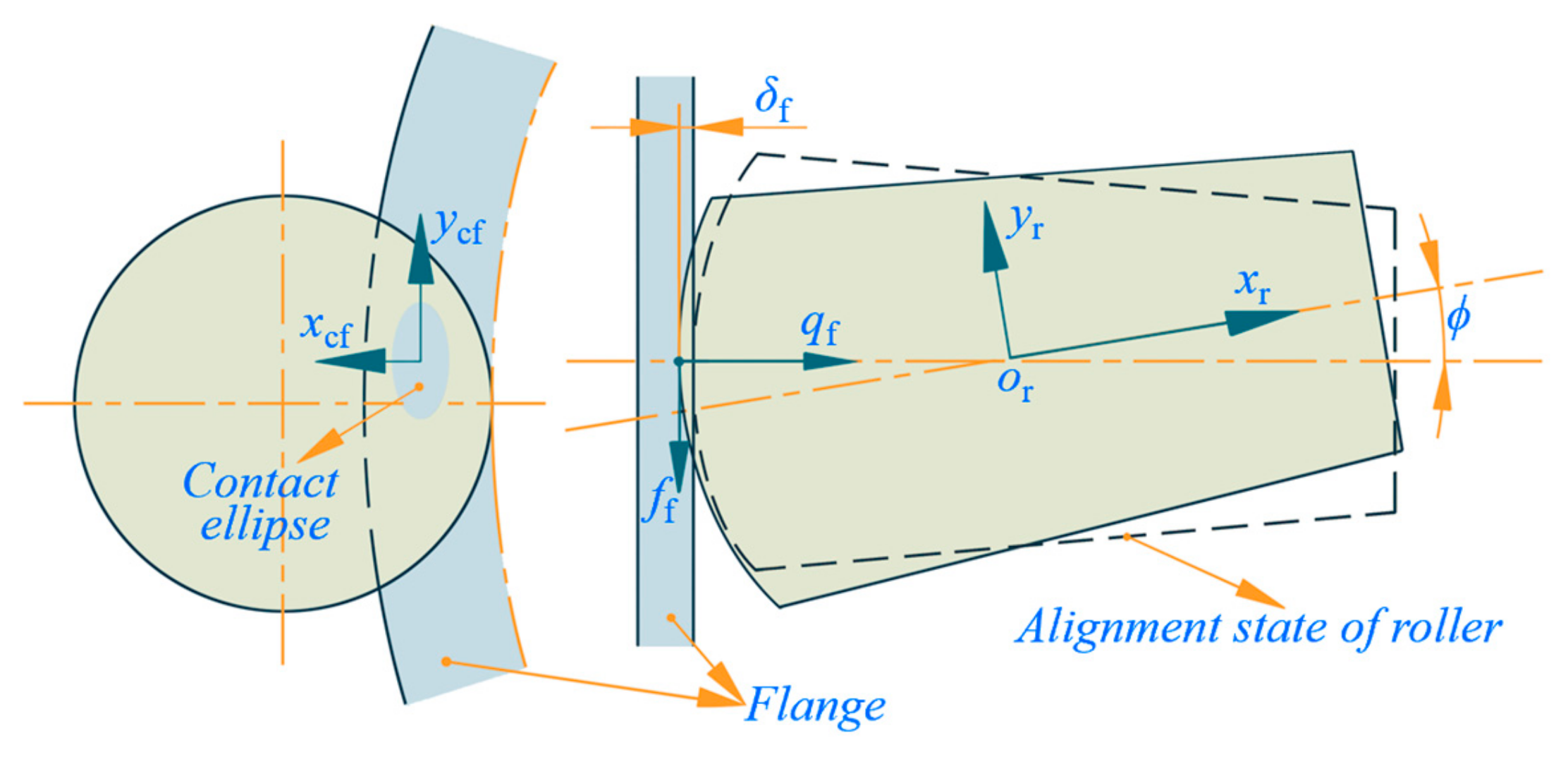

2.2. Flange/Roller-End Interaction

2.3. Roller/Cage Interaction

2.4. Cage/Guiding-Ring Interaction

2.5. Differential Equations of TRB Dynamics

3. Numerical Method

4. Results and Discussions

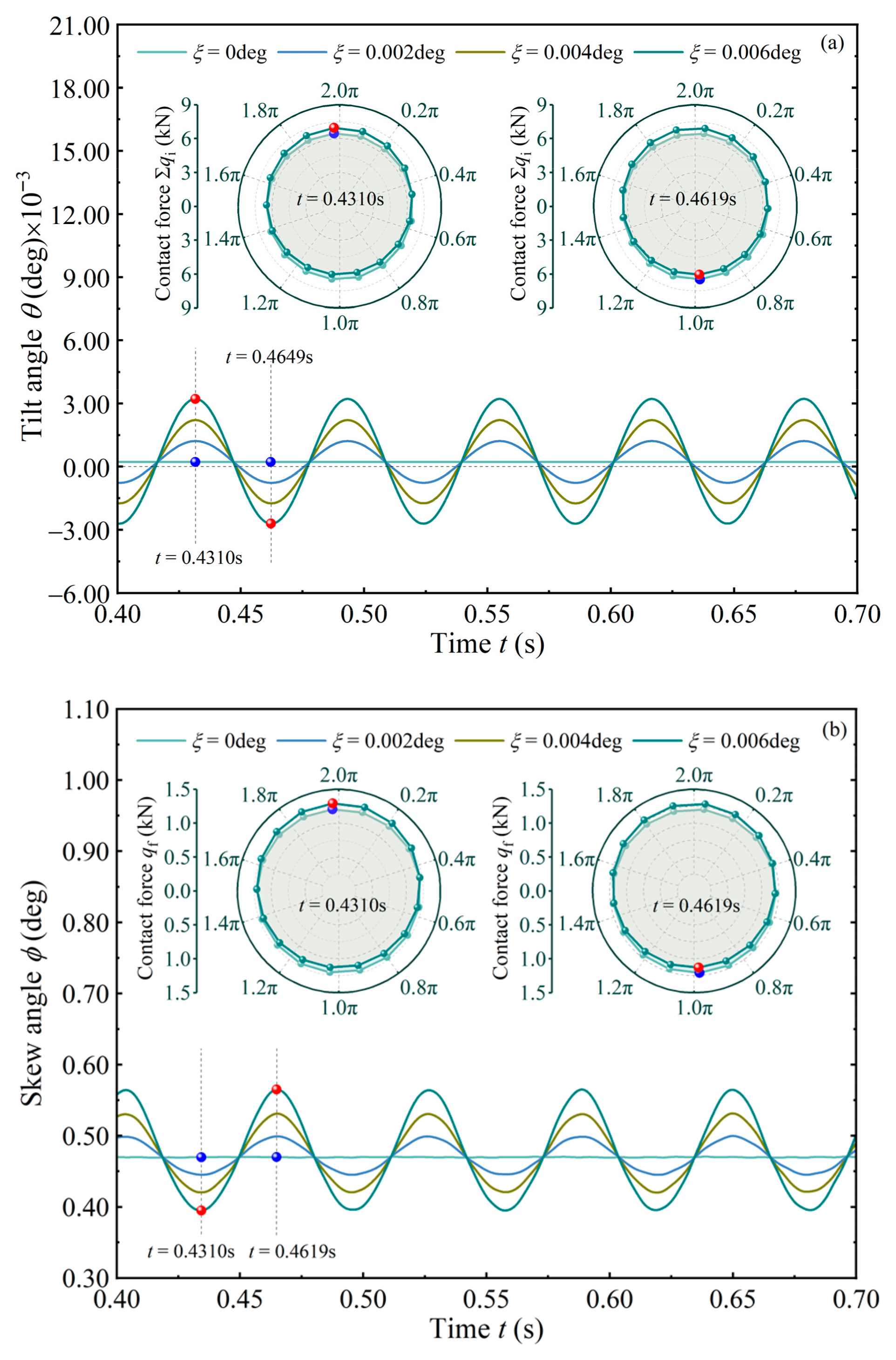

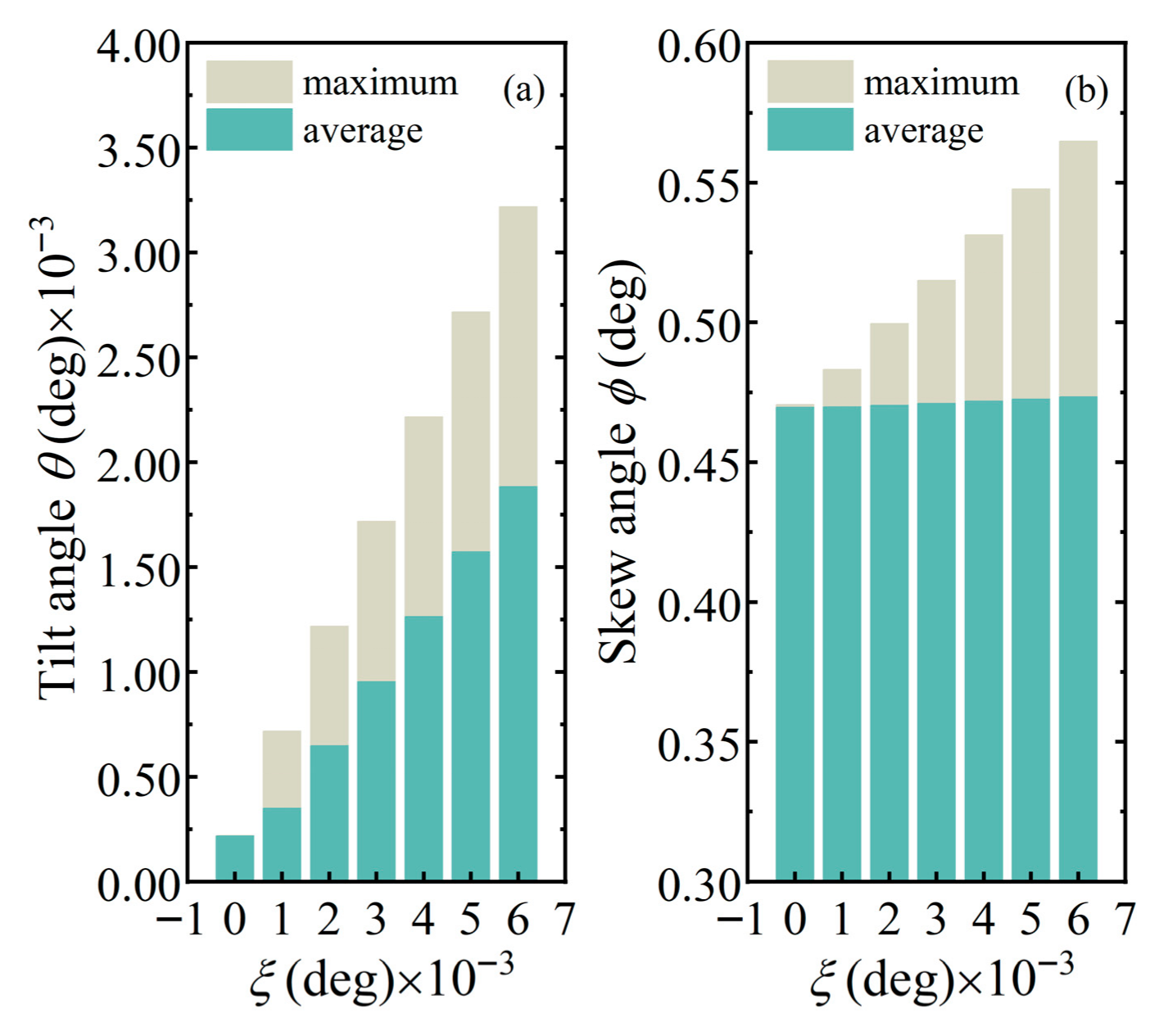

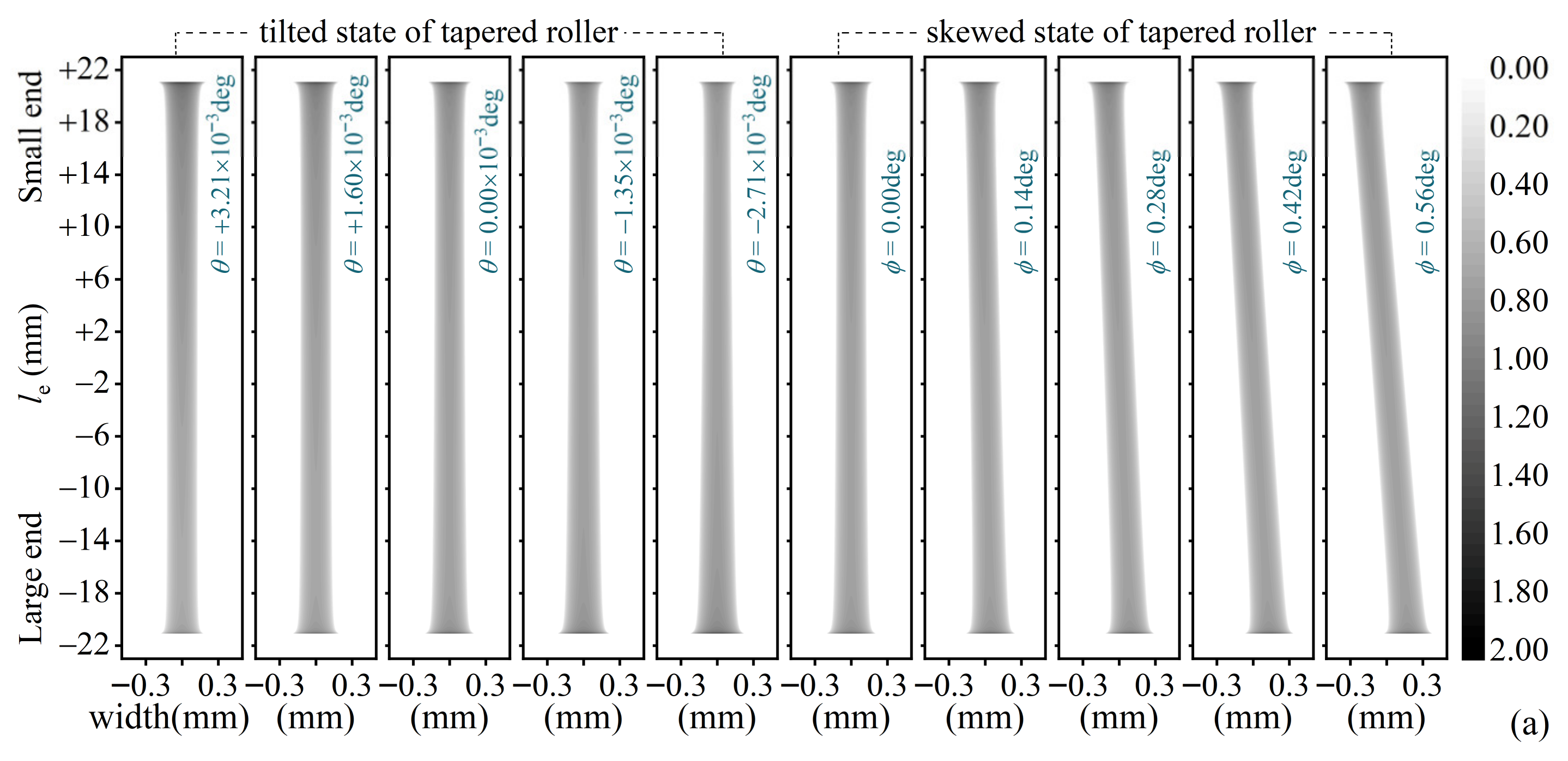

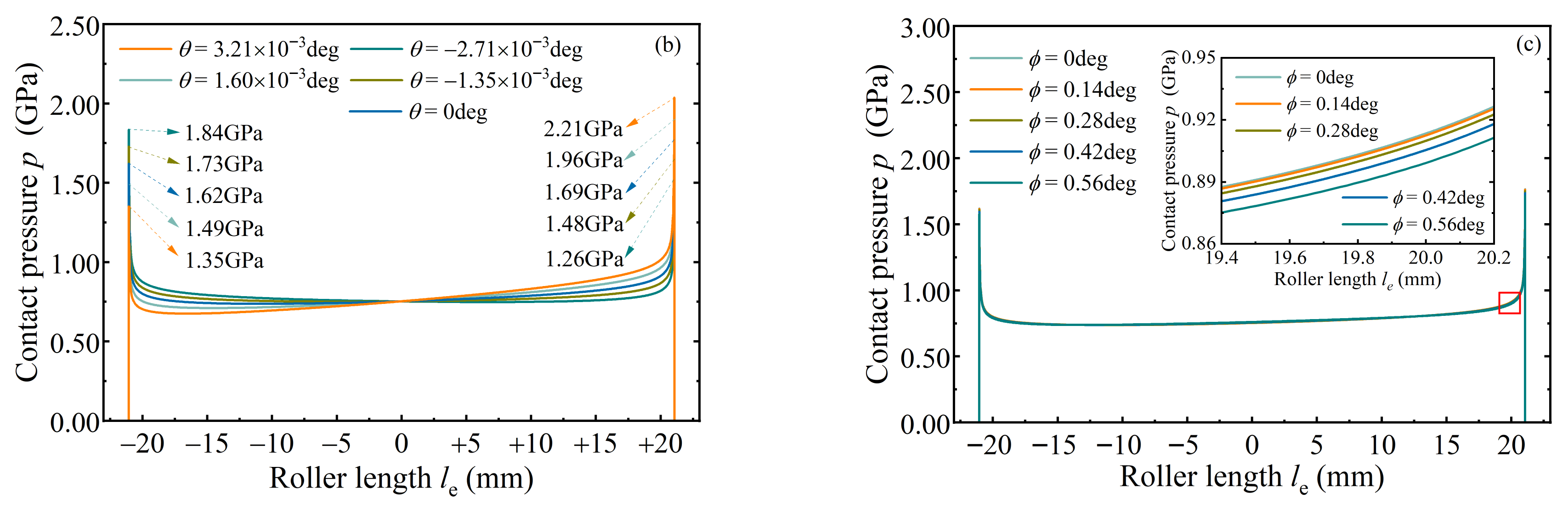

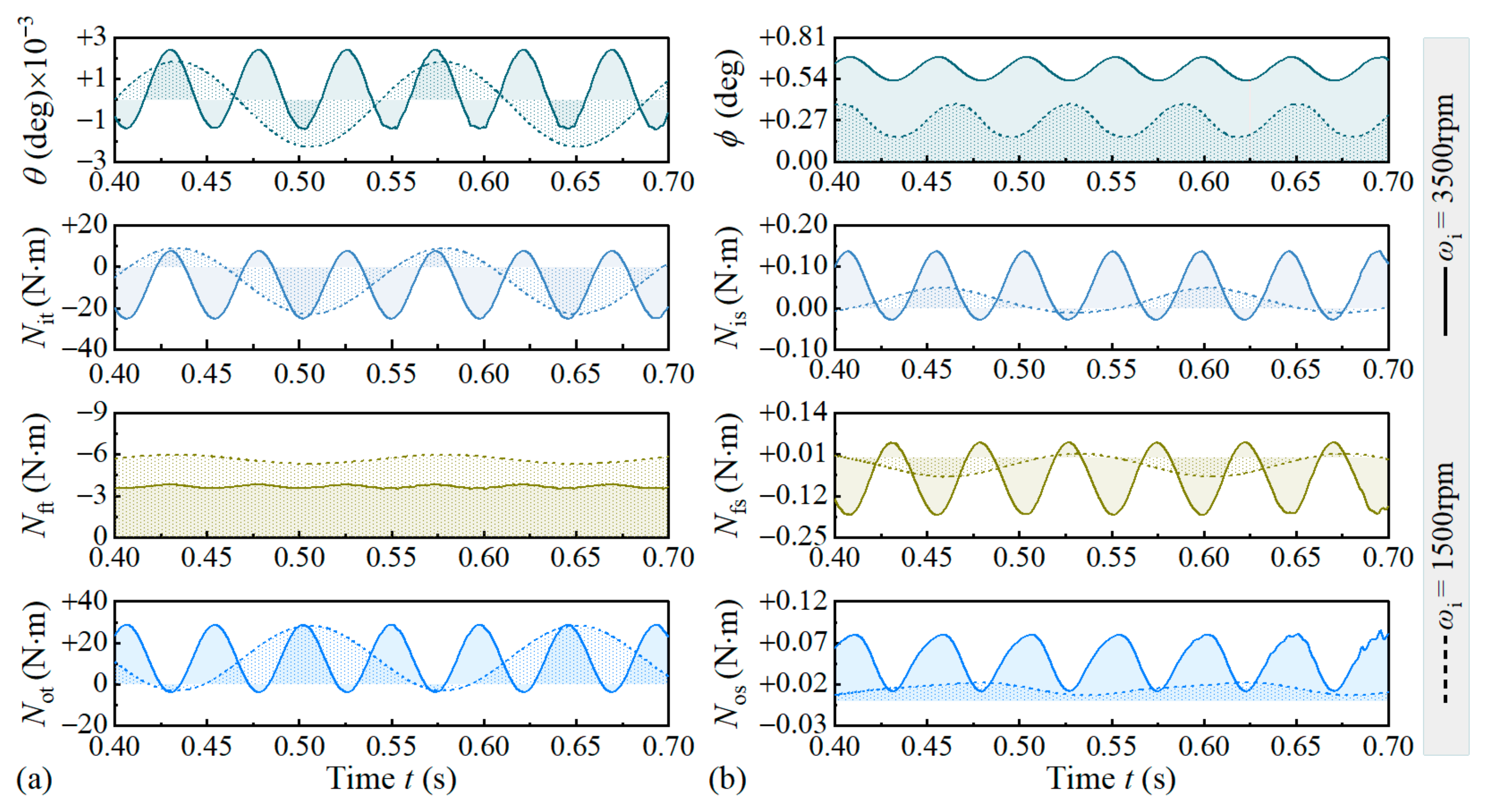

4.1. Effects of Shaft Deflection on Roller Behavior

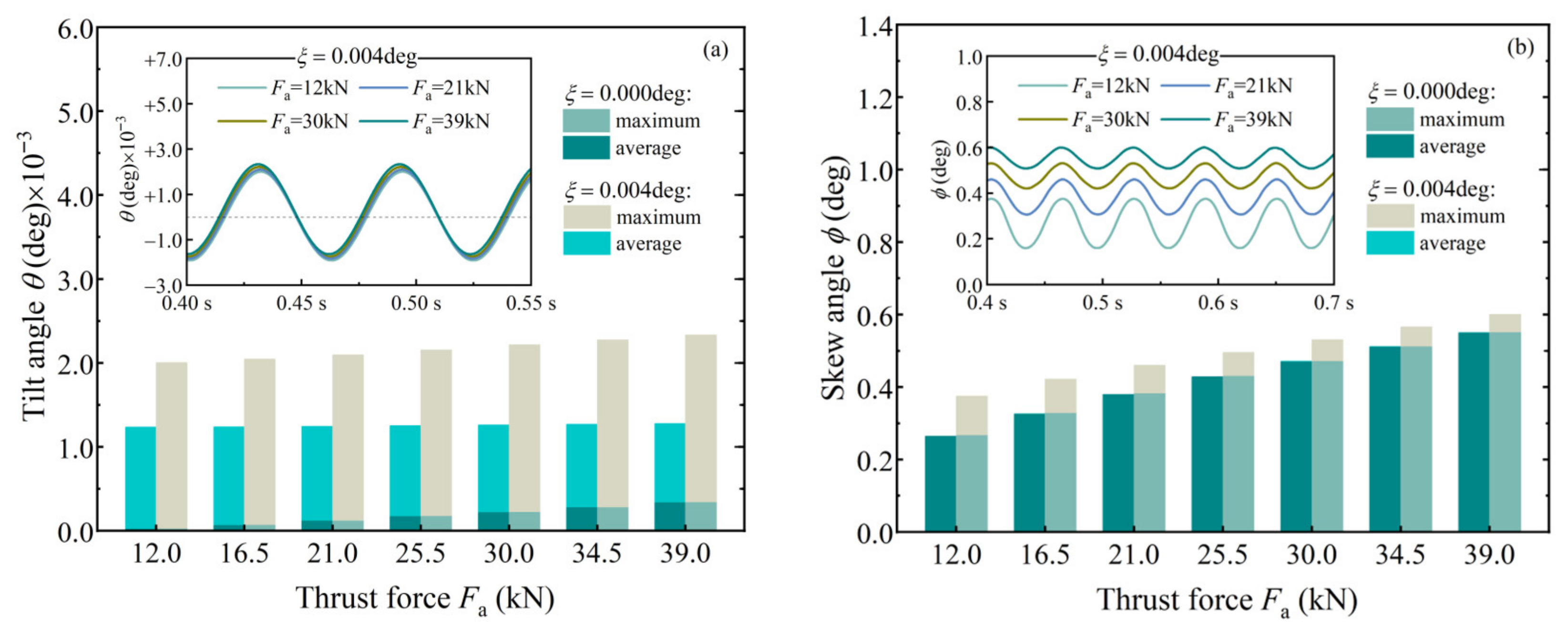

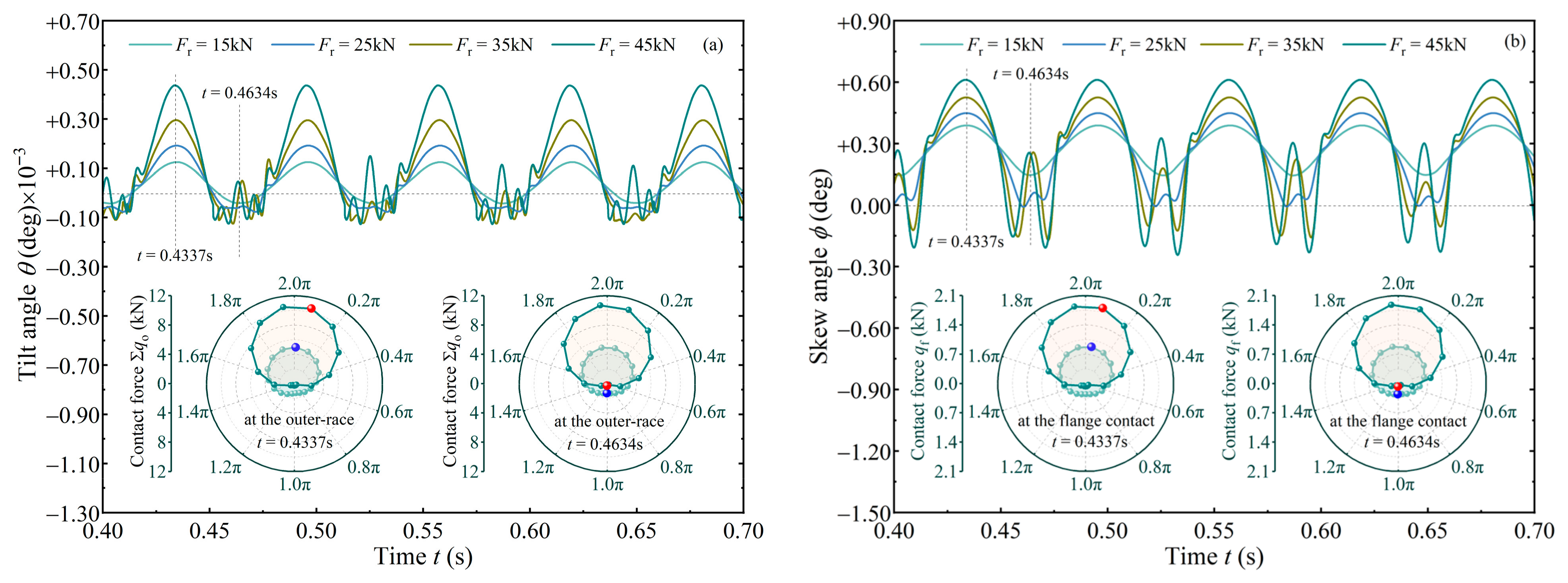

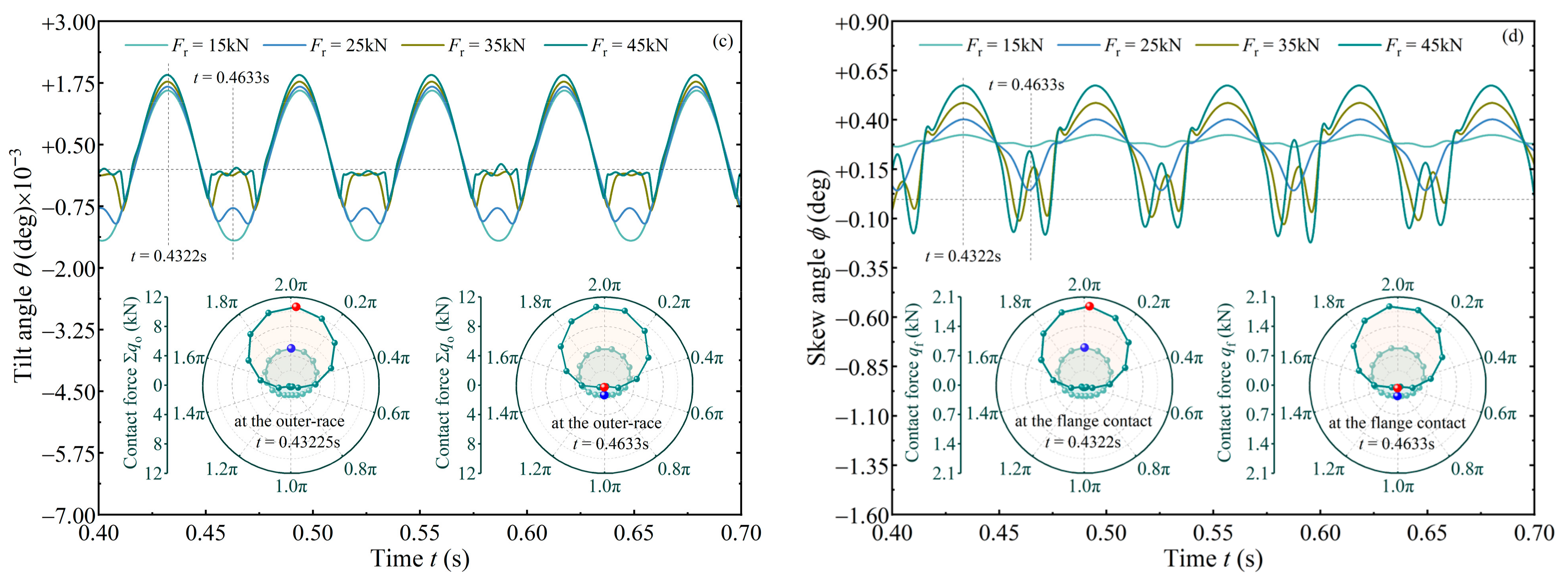

4.2. Effects of Operating Parameters on Roller Behavior Under Shaft Deflection

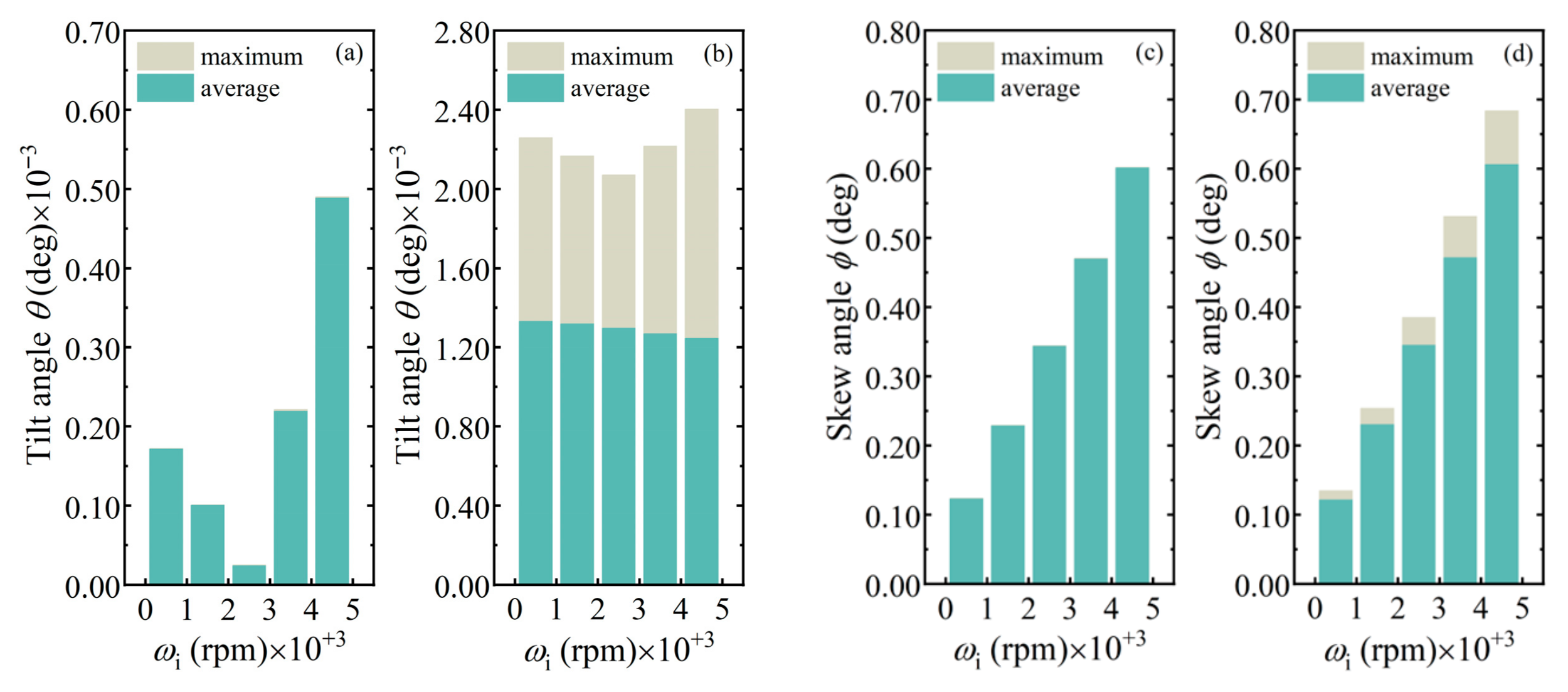

4.2.1. At Different Bearing Speeds

4.2.2. Under Different Force Loading Conditions

5. Conclusions

- (1)

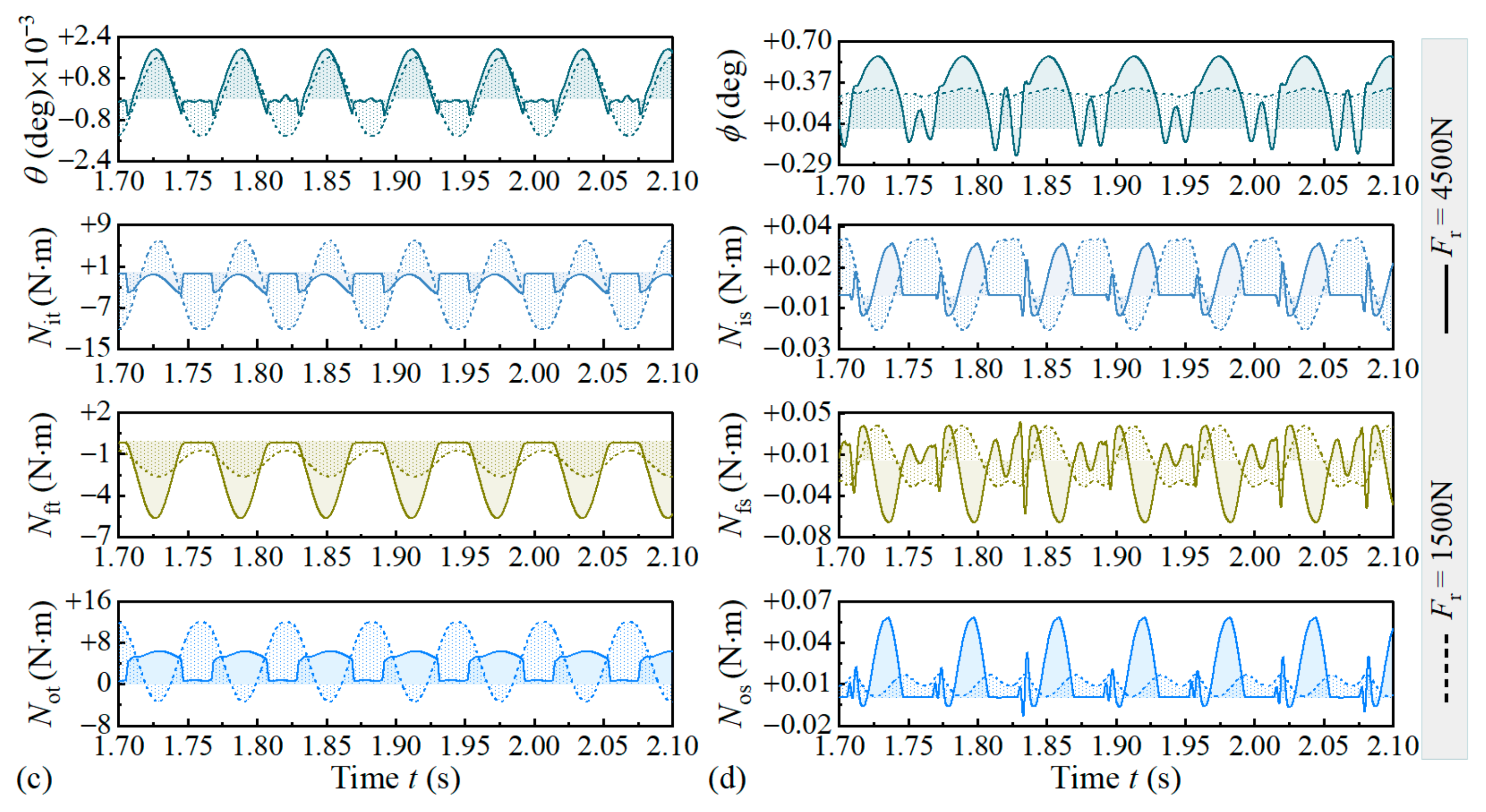

- The amplitude of the tilt moment borne by the roller is 2~3 orders of magnitude higher than the skew moment, but the tilt angle is several orders of magnitude lower than the skew angle. Compared with skew motion, tilt motion is more likely to aggravate the stress edge effect at the roller-end.

- (2)

- The deflected shaft increases tilt and skew amplitudes of the tapered roller. Tilt amplitude may exceed the deflected angle.

- (3)

- In aligned and misaligned states of the shaft, both bearing speed and axial force significantly affect roller skew, while slightly affecting tilt motion. These factors similarly influence the moments exerted on the roller by the cone and cup.

- (4)

- Within the load conditions analyzed, flange drives the roller to tilt toward the negative direction and prevents roller skew most of the time, whereas both raceways may drive the roller to tilt/skew toward either the positive or negative direction.

- (5)

- When a major and a minor load-carrying zone distinctly exists inside the TRB, the roller will exhibit a pronounced angular vibration when it is in the minor zone or just orbited to the major zone.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TRB | Tapered roller bearing |

Nomenclature

| General Variables | δp | Pocket clearance | |

| a | Semi-major axis of contact ellipse | ε | Eccentricity of cage, ε = e/c |

| b | Semi-minor axis of contact ellipse | η0 | Oil viscosity at atmospheric pressure |

| bc | Width of centering surface | σ | Comprehensive roughness |

| c | Radius gap, c = Rc − Rg | τ | Shear stress of oil film |

| cph | Viscous damping | υr, υb, υc | Poisson’s ratio of roller, ring, and cage, respectively |

| cv | Sum of principal curvatures | Δp, Δg | Critical film thickness at the cage pocket and the guiding ring, respectively |

| e | Eccentric distance of cage | χ | Elliptical ratio |

| Ec, Eb, Er | Young’s modulus of cage, rings, and roller, respectively | δi, δo, δf | Contact deformation at inner raceway, outer raceway, and flange, respectively |

| hc | Film thickness at the flange | Matrix and Vector | |

| hm | Film thickness at the raceways | H | Angular momentum |

| kph | Contact stiffness | r | Position vector of contact location |

| le | Total length of straight generatrix of roller | T | Transformation matrix |

| mr | Mass of roller | u | Linear displacement of cone or cup |

| mp | Mass of cage | v | Linear displacement of roller |

| n | Number of rollers | ω | Angular velocity |

| ph | Hertzian contact pressure | Superscript | |

| Rc | Radius of cage centering surface | a | Inertial cylindrical frame |

| Rg | Radius of flange guiding surface | c | Contact frame |

| Ri | Radius of inner raceway | i | Inertial frame |

| Ro | Radius of outer raceway | j | The *j*-th roller |

| Rr | Radius of roller | k | The *k*-th roller slice |

| Rs | Radius of spherical roller-end | p | Body-fixed frame of cage |

| s | Number of slices of roller | r | Body-fixed frame of roller |

| sr | Slide-to-roll ratio | Subscript | |

| ue | Entrainment speed of lubricant | f | Flange |

| z0 | Coefficient in Roelands pressure–viscosity model | g | Guiding ring |

| α | Coefficient in Barus pressure–viscosity model | i | Cone or inner raceway |

| αh | Half-cone angle of roller | o | Cup or outer raceway |

| αf | Flange contact angle | p | Cage |

| δg | Clearance between centering and guiding surfaces | r | Roller |

References

- Litwin, W.; Olszewski, A.; Wodtke, M. Influence of shaft misalignment on water lubricated turbine sliding bearings with various bush modules of elasticity. Key Eng. Mater. 2011, 490, 128–134. [Google Scholar] [CrossRef]

- Hili, M.A.; Fakhfakh, T.; Hammami, L.; Haddar, M. Shaft misalignment effect on bearings dynamical behavior. Int. J. Adv. Manuf. Technol. 2005, 26, 615–622. [Google Scholar] [CrossRef]

- Matsubara, M.; Rahnejat, H.; Gohar, R. Computational modelling of precision spindles supported by ball bearings. Int. J. Mach. Tools Manuf. 1988, 28, 429–442. [Google Scholar] [CrossRef]

- Jagadeesha, T.; Salunkhe, V.G.; Desavale, R.G.; Patil, P.B.; Kumbhar, M.B.; Koli, A.R. Investigation of Crack Detection Technique in a Rotating Shaft by Using Vibration Measurement. In Advances in Industrial Automation and Smart Manufacturing. Lecture Notes in Mechanical Engineering; Arockiarajan, A., Duraiselvam, M., Raju, R., Eds.; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Desavale, R.G. An intelligent prediction for detecting bearing vibration characteristics using machine learning model. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2021, 4, 031004. [Google Scholar] [CrossRef]

- Gupta, P.K. Advanced Dynamics of Rolling Elements; Springer Verlag: New York, NY, USA, 1984. [Google Scholar] [CrossRef]

- Creju, S.; Bercea, I.; Mitu, N. A dynamic analysis of tapered roller bearing under fully flooded conditions part 1, 2. Wear 1995, 188, 11–18. [Google Scholar] [CrossRef]

- Deng, S.; Gu, J.; Cui, Y.; Zhang, W.; Gachot, C. Dynamic analysis of a tapered roller bearing. Ind. Lubr. Tribol. 2017, 70, 191–200. [Google Scholar] [CrossRef]

- Rahnejat, H.; Gohar, R. Design of profiled taper roller bearings. Tribol. Int. 1979, 12, 269–275. [Google Scholar] [CrossRef]

- Harris, T.A.; Kotzalas, M.N. Advanced Concepts of Bearing Technology: Rolling Bearing Analysis, 5th ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Fujiwara, H.; Kawase, T. Logarithmic profile of rollers in roller bearing and optimization of the profile. Trans. Jpn. Soc. Mech. Eng. 2006, 72, 3022–3029. [Google Scholar] [CrossRef]

- Sakaguchi, T.; Harada, K. Dynamic analysis of cage behavior in a tapered roller bearing. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005. [Google Scholar] [CrossRef]

- Wang, Z.; Song, J.; Li, X.; Yu, Q. Modeling and dynamic analysis of cylindrical roller bearings under combined radial and axial loads. J. Tribol. 2022, 144, 121203. [Google Scholar] [CrossRef]

- Nelias, D.; Bercea, I.; Paleu, V. Prediction of Roller Skewing in Tapered Roller Bearings. Tribol. Trans. 2008, 51, 128–139. [Google Scholar] [CrossRef]

- Johns, P.M.; Gohar, R. Roller bearings under radial and eccentric loads. Tribol. Int. 1981, 14, 131–136. [Google Scholar] [CrossRef]

- Li, Y.; Gao, Y. Internal load distribution of single-row tapered roller bearings doubly supporting main shaft of wind turbine. Adv. Mech. Eng. 2022, 14, 105960. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Y.; Wang, J.; Xu, L. Fatigue life analysis of double-row tapered roller bearings for heavy trucks. J. Phys. Conf. Ser. 2025, 3043, 012061. [Google Scholar] [CrossRef]

- Kim, T.; Suh, J.; Lee, J.; Lee, B.; Yu, Y. Fatigue life prediction of double-row tapered roller bearings considering thermal effect. Adv. Mech. Eng. 2023, 15, 168781322311540. [Google Scholar] [CrossRef]

- Zhang, F.; Lv, H.; Han, Q.; Li, M. The effects analysis of contact stiffness of double-row tapered roller bearing under composite loads. Sensors 2023, 23, 4967. [Google Scholar] [CrossRef]

- Xia, X.; Li, Y.; Dong, S.; Zhu, W.; Chen, T. Based on ANSYS crown tapered rolling bearings dynamics simulation analysis. J. Intell. Fuzzy Syst. 2018, 34, 1121–1131. [Google Scholar] [CrossRef]

- Yang, L.; Xu, T.; Xu, H.; Wu, Y. Mechanical behavior of double-row tapered roller bearing under combined external loads and angular misalignment. Int. J. Mech. Sci. 2018, 142–143, 561–574. [Google Scholar] [CrossRef]

- Razpotnik, M.; Bischof, T.; Boltezar, M. The dynamics of tapered-roller bearings—A bottom-up validation study. J. Mech. Eng. 2023, 69, 289–298. [Google Scholar] [CrossRef]

- Zhou, L.; Yang, X.; Luo, Z.; Zhang, J.; Li, Z.; Wang, X. Research on the lubrication state of the contact interface under the tilt and skew state of the roller of the aviation bearing. Lubricants 2025, 13, 174. [Google Scholar] [CrossRef]

- Liu, X.; Li, S.; Yang, P.; Yang, P. On the lubricating mechanism of roller skew in cylindrical roller bearings. Tribol. Trans. 2013, 56, 929–942. [Google Scholar] [CrossRef]

- Yang, Y.; Danyluk, S.; Hoeprich, M. A study on rolling element skew measurement in a tapered roller bearing with a specialized capacitance probe. J. Tribol. 2000, 122, 534–538. [Google Scholar] [CrossRef]

- Yang, Y.; Danyluk, S.; Hoeprich, M. Rolling Element Skew in Tapered Roller Bearings. Tribol. Trans. 2000, 43, 564–568. [Google Scholar] [CrossRef]

- Falodi, A.; Chen, Y.K.; Caspall, M.; Earthrowl, B.; Dell, D. On the Measurement of Roller Skew of Tapered Roller Bearings. Appl. Mech. Mater. 2012, 217–219, 2328–2331. [Google Scholar] [CrossRef]

- Majdoub, F.; Mevel, B. Kinematic Equilibrium of Rollers in Tapered Roller Bearings. Tribol. Trans. 2019, 62, 567–579. [Google Scholar] [CrossRef]

- Majdoub, F.; Saunier, L.; Sidoroff-Coicaud, C.; Mevel, B. Experimental and numerical roller skew in tapered roller bearings. Tribol. Int. 2020, 145, 106142. [Google Scholar] [CrossRef]

- Shafiee, A.; Russell, T.; Lorenz, S.J.; Sadeghi, F.; Wilmer, M.G. Optical measurement of roller slip, tilt, and skew in a spherical roller bearing. J. Tribol. 2022, 145, 044302. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: London, UK, 1985. [Google Scholar] [CrossRef]

- Kragelskii, I.V. Friction and Wear; Butterworths: London, UK, 1965; pp. 178–184. [Google Scholar] [CrossRef]

- Wang, Y.S.; Yang, B.Y.; Wang, L.Q. Investigation into the traction coefficient in elastohydrodynamic lubrication. Tribotest 2004, 11, 113–124. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Schmid, S.R.; Jacobson, B.O. Fundamentals of Fluid Film Lubrication, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar] [CrossRef]

- Roelands, C.J.A. Correlational Aspects of the Viscosity-Temperature-Pressure Relationship of Lubricating Oils. Ph.D. Thesis, Technische Hogeschool Delft, Delft, The Netherlands, 1966. Available online: https://resolver.tudelft.nl/uuid:1fb56839-9589-4ffb-98aa-4a20968d1f90 (accessed on 27 August 2025).

- Chittenden, R.J.; Dowson, D.; Dunn, J.F.; Taylor, C.M. A theoretical analysis of the isothermal elastohydrodynamic lubrication of concentrated contacts. I. Direction of lubricant entrainment coincident with the major axis of the Hertzian contact ellipse. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1985, 397, 245–269. [Google Scholar] [CrossRef]

- Cameron, A. The Principles of Lubrication; Longmans Green and Co., Ltd.: London, UK, 1966; Available online: http://scholar.google.com/scholar_lookup?&title=Principles%20of%20Lubrication&publication_year=1966&author=Cameron%2CA (accessed on 27 August 2025).

- Alves, J.; Peixinho, N.; Silva, M.T.; Flores, P.; Lankarani, H. A comparative study on the viscoelastic constitutive laws for frictionless contact interfaces in multibody dynamics. Mech. Mach. Theory 2015, 85, 172–188. [Google Scholar] [CrossRef]

- Herbert, R.G.; Mcwhannell, D.C. Shape and frequency composition of pulses from an impact pair. J. Eng. Ind. 1977, 99, 513–518. [Google Scholar] [CrossRef]

- Tong, V.C.; Hong, S.W. The effect of angular misalignment on the running torques of tapered roller bearings. Tribol. Int. 2016, 95, 76–85. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Bearing bore diameter [mm] | 130.00 |

| Bearing outside diameter [mm] | 230.00 |

| Bearing width [mm] | 70.00 |

| Number of rollers | 17 |

| Roller length [mm] | 42.06 |

| Roller average diameter [mm] | 21.37 |

| Roller half-cone angle [deg] | 5.00 |

| Radius of roller spherical end [mm] | 153.95 |

| Pitch diameter of roller set [mm] | 177.91 |

| Outer contact angle [deg] | 15.00 |

| Inner contact angle [deg] | 5.00 |

| Flange contact angle [deg] | 83.00 |

| Young’s modulus of roller and rings [GPa] | 201.00 |

| Poisson’s ratio of roller and rings | 0.28 |

| Young’s modulus of cage [GPa] | 8.30 |

| Poisson’s ratio of cage | 0.30 |

| Lubricant brand | 4109 |

| Dynamic viscosity [Pa∙s] | 0.0330 |

| Pressure–viscosity coefficient [Pa−1] | 1.28 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Kang, J.; Deng, S. An Analysis on Negative Effects of Shaft Deflection on Angular Misalignment of Rollers Inside Tapered Roller Bearing. Lubricants 2025, 13, 438. https://doi.org/10.3390/lubricants13100438

Wu Z, Kang J, Deng S. An Analysis on Negative Effects of Shaft Deflection on Angular Misalignment of Rollers Inside Tapered Roller Bearing. Lubricants. 2025; 13(10):438. https://doi.org/10.3390/lubricants13100438

Chicago/Turabian StyleWu, Zhenghai, Junmin Kang, and Sier Deng. 2025. "An Analysis on Negative Effects of Shaft Deflection on Angular Misalignment of Rollers Inside Tapered Roller Bearing" Lubricants 13, no. 10: 438. https://doi.org/10.3390/lubricants13100438

APA StyleWu, Z., Kang, J., & Deng, S. (2025). An Analysis on Negative Effects of Shaft Deflection on Angular Misalignment of Rollers Inside Tapered Roller Bearing. Lubricants, 13(10), 438. https://doi.org/10.3390/lubricants13100438