Real-World Fuel Consumption of a Passenger Car with Oil Filters of Different Characteristics at High Altitude

Abstract

1. Introduction

- How do oil filters with different physical and material characteristics influence fuel consumption in passenger vehicles under high-altitude conditions?

- What are the critical factors affecting oil filter efficiency in retaining particles at varying altitudes?

- Can specific oil filter designs be recommended to optimise fuel consumption and engine performance in high-altitude environments?

2. Materials and Methods

2.1. Materials

2.1.1. Oil Filters

2.1.2. Test Vehicle

2.1.3. Lubricant Oil

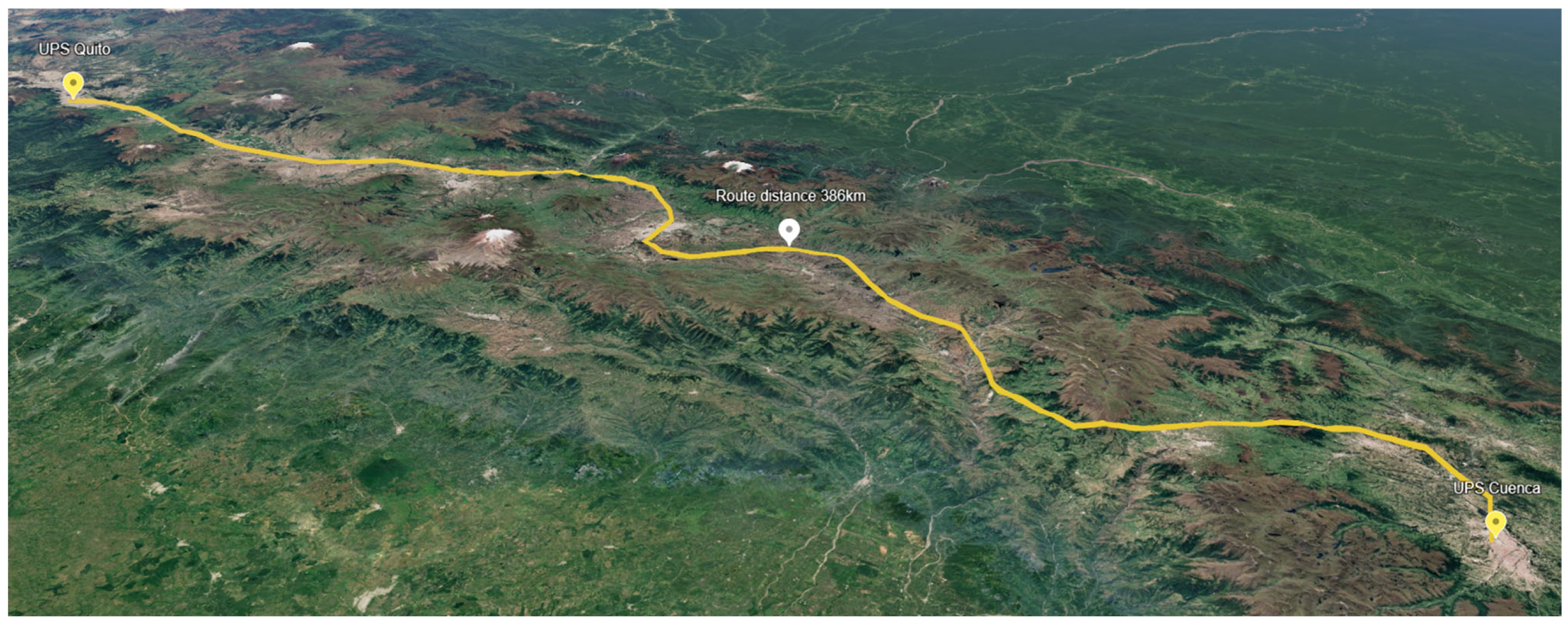

2.1.4. Driving Cycles

2.1.5. Data Acquisition Card

2.1.6. Measurement Protocols and Particle Counting Standard (ISO 4406) [43]

Statistics for Cleanliness Codes

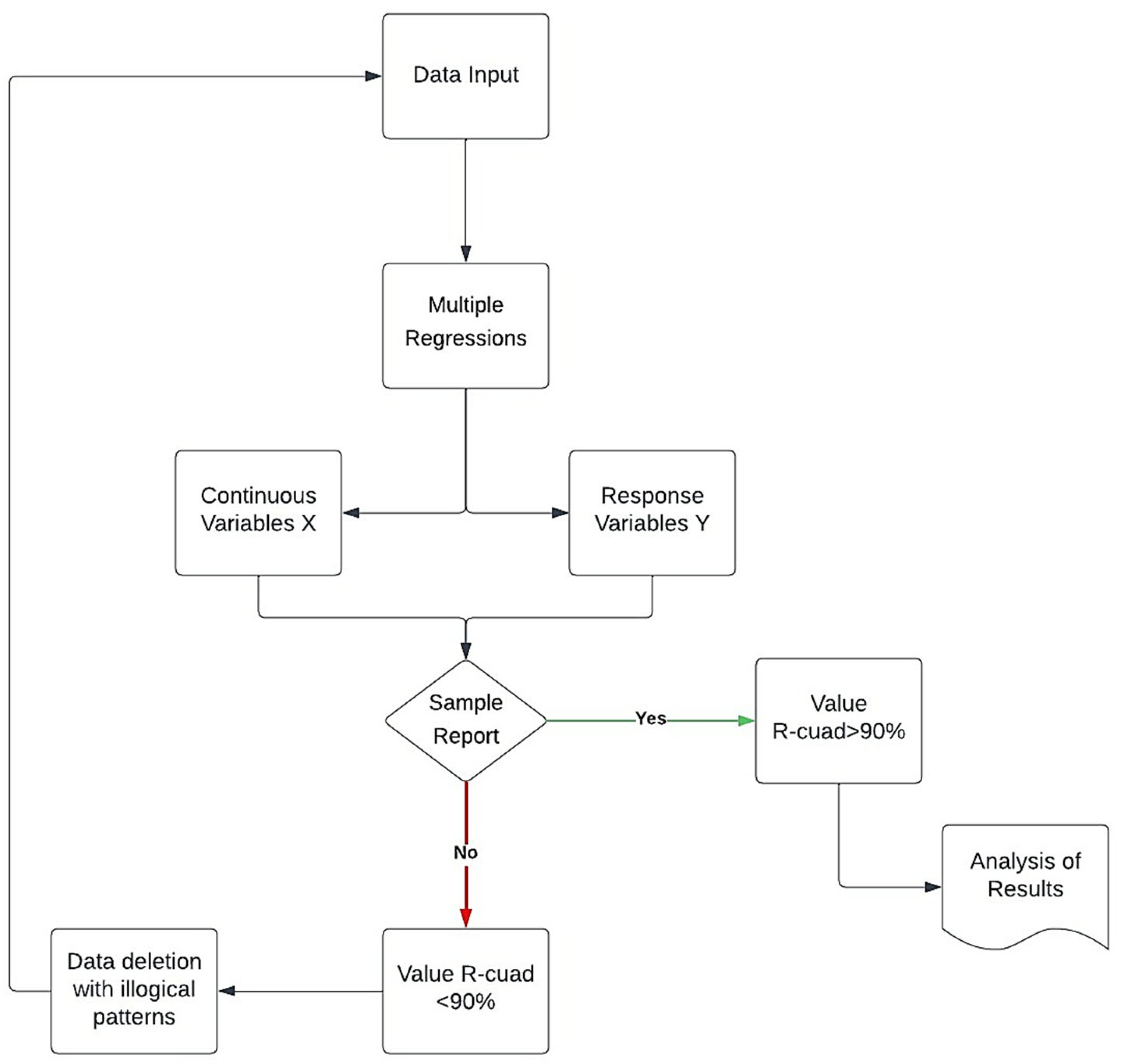

2.2. Methods

2.2.1. Experimental Design

- Geographical conditions: gradients of up to 10% and temperatures ranging between 15 °C and 25 °C.

- Road conditions: the asphalt is in good condition, with no rain or winds exceeding 20 km/h, to reduce environmental interference.

- Repeatability: each filter was tested in three complete repetitions of the route (a total of 960 km per type), carried out by the same operator following a set speed script (50 km/h in urban areas, 90 km/h on interurban roads, 100 km/h on straight sections, 60 km/h on wide bends and 40 km/h on sharp bends).

- In this way, variability in driving behaviour and environmental conditions is managed, reducing sources of bias that could jeopardise the internal validity of the study.

2.2.2. Methodology for Conducting Driving Tests

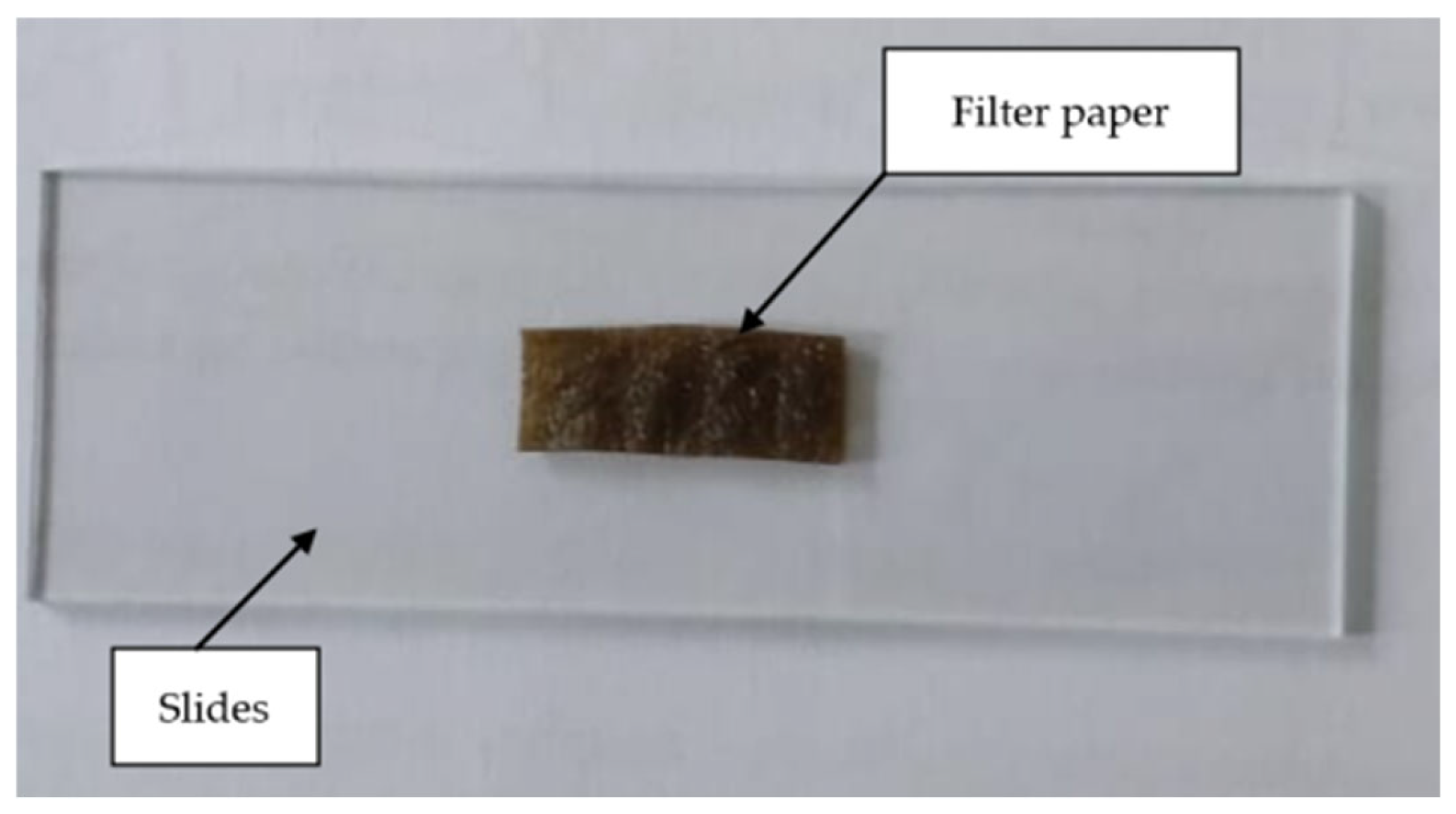

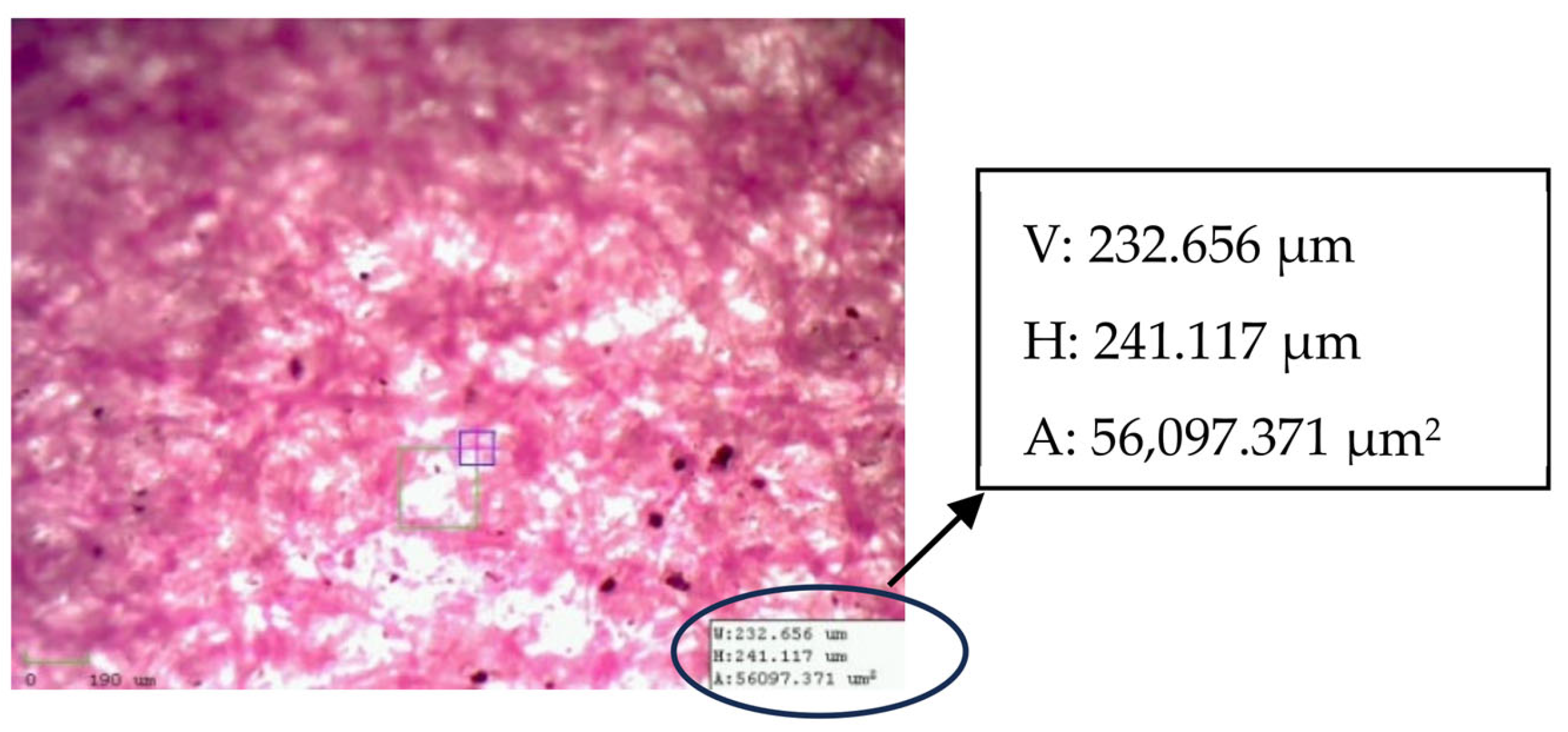

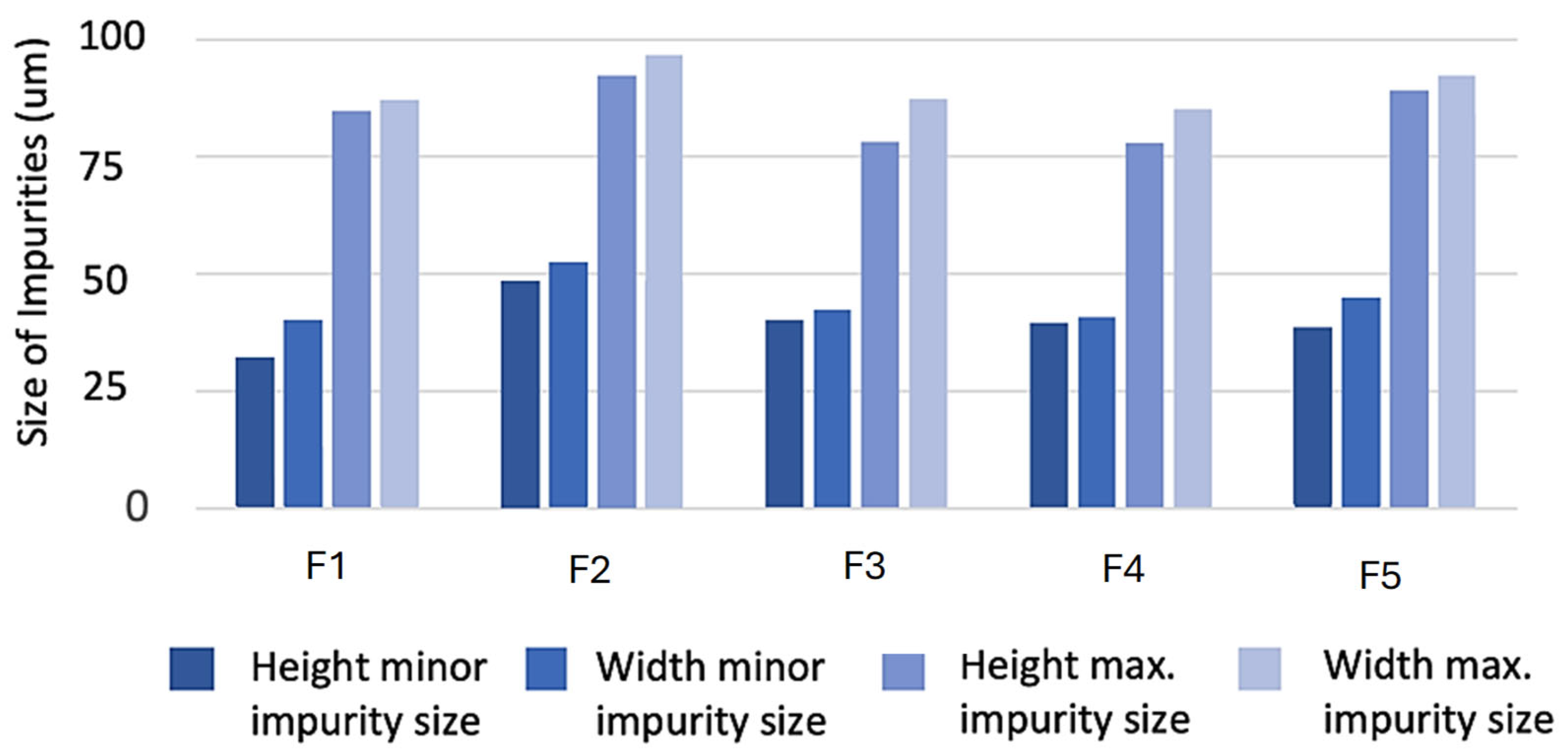

2.2.3. Determination of Pore Size and Impurities

2.2.4. Methodological Limitations

3. Results

3.1. Hydraulic Pressure Drop and Viscosity Stability

3.2. Filter-Media Integrity

3.3. Comparison Between Used Filter Papers and Lubricating Oil

ISO 4406 Cleanliness and Particle Concentration

3.4. Fuel Consumption

Measurement Uncertainty

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rovai, F.F.; Sartori, E.; Crepaldi, J.; Rajala, S. Engine Lubricant Impact in Light-Vehicle Fuel Economy: A Combined Numerical Simulation and Experimental Validation. Lubricants 2025, 13, 137. [Google Scholar] [CrossRef]

- Levendis, Y.; Johannesen, L.T. Recent Developments in the Design of a Ceramic Automotive OilFilter. In Proceedings of the SAE 2011 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2011. [Google Scholar] [CrossRef]

- Alie, A.; Darwito, P.A. Improve of Engine Oil Lifetime by Using Additional Filter A Case Study at PT Vale Indonesia TBK. AIP Conf. Proc. 2019, 2088, 020004. [Google Scholar] [CrossRef]

- Why Full Synthetic Media Is Important. Available online: https://www.purolatornow.com/en/resources/Why-Full-Synthetic-Media-is-Important.html (accessed on 28 September 2025).

- Botov, S.; Wooley, R. Investigation on Novel Polymer Filter Medium for Filtration of Automotive Lubricants. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2016. [Google Scholar]

- Devlin, M.T. Common Properties of Lubricants That Affect Vehicle Fuel Efficiency: A North American Historical Perspective. Lubricants 2018, 6, 68. [Google Scholar] [CrossRef]

- Feng, J.Y.; Zhang, J. The Property of Automobile Engine Oil Filtration Material and the Development of New Filter. J. Eng. Fiber Fabr. 2014, 9, 134–141. [Google Scholar] [CrossRef]

- Darcy, H. Les Fontaines Publiques de La Ville de Dijon Exposition et Application Des Principes a Suivre et Des Formulesa Employer Dans Les Questions de Distribution d’Eau; Dalmont, V., Ed.; Gallica: Paris, France, 1856; 647p. [Google Scholar]

- Carman, P.C. Flow of Gases through Porous Media; Butterworths Scientific Publications: London, UK, 1956; p. 5. [Google Scholar]

- Regulations to the Law on Land Transport, Traffic, and Road Safety. Available online: https://www.mit.gob.ec/wp-content/uploads/downloads/2015/03/Decreto-Ejecutivo-No.-1196-de-11-06-2012-REGLAMENTO-A-LA-LEY-DE-TRANSPORTE-TERRESTRE-TRANSITO-Y-SEGURIDAD-VIA.pdf (accessed on 28 September 2025).

- Tian, X.; Wei, H.; Wang, W.; Huang, Y.; Wang, H.; Pan, J.; Wang, R.; Li, Z. An Investigation of the Filtration Performance and Mechanism of Oil-Solid Mixed Particles on Filter Materials with Different Wettability. Sep. Purif. Technol. 2024, 349, 127903. [Google Scholar] [CrossRef]

- Tulík, J.; Kosiba, J.; Varga, F.; Bureš, Ľ.; Šinský, V. Analysis of Synthetic Oil Samples During an Operating Test. Acta Technol. Agric. 2013, 16, 22–25. [Google Scholar] [CrossRef][Green Version]

- Stanley, I.; Schmitz, S. Advances in Filtration in Automatic Lube Oil Filters. In Proceedings of the 2018 Joint Rail Conference, JRC 2018, Pittsburgh, PA, USA, 18–20 April 2018; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2018. [Google Scholar][Green Version]

- Nazarova, E.; Alimova, D.S.; Mikhaylov, V.I.; Krivoshapkina, E.F.; Krivoshapkin, P.V. Macroporous Ceramic Filters from Mineral Raw Materials for Machine Oils Filtration. Ceram. Int. 2019, 45, 8767–8773. [Google Scholar] [CrossRef]

- Wu, Y. An Analysis of Constant-Pressure Filtration. Chem. Eng. Sci. 1994, 49, 831–836. [Google Scholar] [CrossRef]

- Blanco-Rodríguez, J.; Simón-Montero, X.; Cortada-García, M.; Maroto, S.; Jacobo, P. Modelling the Impact of Reducing Lubricant Viscosity on a Conventional Passenger Car Fuel Economy and Wear Protection. Results Eng. 2024, 24, 103159. [Google Scholar] [CrossRef]

- Hoag, K.; Dondlinger, B. Vehicular Engine Design, 2nd ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Li, H.; Wang, S.; Liu, M.; Song, R.; Cui, K.; Chang, C. Study on Filtration Efficiency of Filter Elements for Lubricating Oil Separation. Processes 2025, 13, 2067. [Google Scholar] [CrossRef]

- Lamon, D.; Zhang, D. The Evaluation of Mechanical Design and Comparison of Automotive Oil Filters. SAE Int. J. Fuels Lubr. 2010, 3, 346–361. [Google Scholar] [CrossRef]

- Yang, Y.; Chang, C.; Liu, T.; Feng, Y.; Wang, Y.; Jin, J.; Cui, K.; Xie, P.; Wu, X. Effect of Liquid Properties on Filtration Performance of Filters for Lubricating Oil Separation from Natural Gas. Chem. Eng. Res. Des. 2025, 216, 282–292. [Google Scholar] [CrossRef]

- Gangopadhyay, A.; Liu, Z.; Simko, S.; Lam, W.; Devlin, M.T. The Effect of Friction Modifiers and Additive Packages on Friction Reduction Potential of Next Generation Engine Oils—Part II: Aged Oils. In Proceedings of the 72nd STLE Annual Meeting, Atlanta, GA, USA, 21–25 May 2017. [Google Scholar]

- Tejada Tovar, C.N.; Quiñones Bolaños, E.; Fong Silva, W. Physical-Chemical Caracterization of Spent Engine Oils for Its Recycling // Caracterización Físico-Química de Aceites Usados de Motores Para Su Reciclaje. Prospectiva 2017, 15, 135–144. [Google Scholar] [CrossRef][Green Version]

- Chen, X.; Wang, Z.; Pan, S.; Pan, B. A Novel Biomass Lubricant Filter and Its Effect on Gasoline Engine Emissions and Fuel Economy. J. Energy Inst. 2019, 92, 332–340. [Google Scholar] [CrossRef]

- Kushwaha, G.; Saraswati, S.; Paul, B. Effect of Different Lubricating Oil on the Adsorption/Desorption Process of Fuel in Oil Layer in an SI Engine. Lubr. Sci. 2017, 29, 73–91. [Google Scholar] [CrossRef]

- Jokinen, A.; Calonius, O.; Pietola, M.; Gorle, J.; Hannifin, P. Effects of Oil Contamination Level, Flow Rate and Viscosity on Pressure Drop Development and Dirt Holding Capacity of Hydraulic Filter. In Proceedings of the ASME/BATH 2019 Symposium on Fluid Power and Motion Control, FPMC 2019, Longboat Key, FL, USA, 7–9 October 2019; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2020. [Google Scholar]

- Peuchot, C.; Petillon, N.; Lynch, J. Filter Efficiency and Liquids: The Advantages of Cartridge Filters. Filtr. Sep. 2008, 45, 11–13. [Google Scholar] [CrossRef]

- Hujo, Ľ.; Michalides, M.; Nosian, J.; Simikić, M. Measurement of Flow and Pressure Characteristics of Combustion Engine Oil Filters. MATEC Web Conf. 2021, 351, 01004. [Google Scholar] [CrossRef]

- Peaslee, K.D. Recycling Used Automotive Oil Filters. JOM 1994, 46, 44–46. [Google Scholar] [CrossRef]

- Levendis, Y.A. Design and Testing of a Novel Environmentally-Benign Automotive Oil Filter. In Proceedings of the SAE 2011 World Congress and Exhibition, Detroit, MI, USA, 13–15 April 2010. [Google Scholar]

- Semjonovs, J.; Springis, G.; Leitans, A. Increasing of Engine Oil Change Interval by Using Additional Oil Filter in Diesel Engines; Riga Technical University: Riga, Latvia, 2014. [Google Scholar]

- Feng, J.Y.; Zhang, J.C.; Hua, Z.; Yang, D.X. Based on the Main Factor Mathematical Method to Study on the Structure and Performance of Automobile Engine Oil Filter Materials. Adv. Mater. Res. 2012, 507, 11–15. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Rizwanul Fattah, I.M. Oil Filter Modification for Biodiesel-Fueled Engine: A Pathway to Lubricant Sustainability and Exhaust Emissions Reduction. Energy Convers. Manag. 2015, 91, 168–175. [Google Scholar] [CrossRef]

- AEADE. Boletín Sector Automotor En Cifras; AEADE—Asociación de Empresas Automotrices Del Ecuador: Quito, Ecuador, 2024. [Google Scholar]

- ND ECOREPUESTOS Repuestos Automotrices Genuinos y Alternos. Available online: https://www.ecorepuestos.ec/ (accessed on 28 September 2025).

- Hyundai Santa Fe 2.7 Style Aut. 5 Plazas (2008–2009). Available online: https://www.km77.com/coches/hyundai/santa-fe/2006/estandar/style/santa-fe-27-style-aut-5-plazas2/datos (accessed on 28 September 2025).

- ASTM D445; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D4052; Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D97; Standard Test Method for Pour Point of Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D92; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D874; Standard Test Method for Sulfated Ash from Lubricating Oils and Additives. ASTM International: West Conshohocken, PA, USA, 2019.

- Select 20w-50 Engine Oil Product Description. Available online: www.acdelco.com.au (accessed on 21 September 2025).

- ISO 14230-4; Road vehicles—Diagnostic systems—Keyword Protocol 2000 — Part 4: Requirements for emission-related systems. ISO: Geneva, Switzerland, 2000.

- ISO 4406; Hydraulic fluid power—Fluids—Method for coding the level of contamination by solid particles. ISO: Geneva, Switzerland, 2021.

- ASTM D2896; Standard Test Method for Base Number of Petroleum Products by Potentiometric Perchloric Acid Titration. ASTM International: West Conshohocken, PA, USA, 2021.

- CEC L-14-93; Evaluation of the Mechanical Shear Stability of Lubricating Oils Containing Polymers (Fuel Injection Pump). CEC: United Kingdom, 1993.

- ASTM F316-03 (Reapproved 2019); Standard Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test. ASTM International: West Conshohocken, PA, USA, 2019.

- ISO 4548-12; Methods of test for full-flow lubricating oil filters for internal combustion engines—Part 12: Filtration efficiency using particle counting. ISO: Geneva, Switzerland, 2017.

- SAE J1858; Full-Flow Lubricating Oil Filters—Multipass Method for Evaluating Filtration Performance. SAE International: Warrendale, PA, USA, 2002.

| Attribute | F1 | F2 | F3 | F4 | F5 |

|---|---|---|---|---|---|

| Parameter-based identifier | Aftermarket, cellulose media | OEM-type, higher mean pore metric | OEM, lower mean pore metric | OEM, lowest mean pore metric | Aftermarket, intermediate pore metric |

| Commercial reference | ACDelco PF46 | Toyota 90915-YZZD2 (OEM) | Kia 26300-35503 | Hyundai 26300-35503 | Shogun W 610/3 |

| Equivalent Circular Diameter (µm, NFP 5×, min–max) | 97.20–166.76 | 113.94–252.53 | 65.53–120.54 | 67.49–139.01 | 109.90–135.45 |

| Mean pore diameter (µm) | 150 | 130 | 110 | 100 | 120 |

| Thread | 13/16-16 UN | 3/4-16 UNF | M20 × 1.5 | M20 × 1.5 | M20 × 1.5 |

| Anti-drainback valve | Yes | Yes | Nitrile | Nitrile | Yes |

| Bypass valve (setting) | Engine-mounted (no bypass in can) | 0.75–1.2 bar | 14 psi (~0.97 bar) | 14 psi (~0.97 bar) | 1.0 bar |

| Filter media (declared) | Cellulose + polyester + microglass | Cellulose | “NanoFiber (Donaldson Synteq)” | “NanoFiber (Donaldson Synteq)” | Cellulose |

| Efficiency (declared) | 98% @ 25–30 µm | 99% @ 40 µm (SAE J1858) | 20 µm absolute | 20 µm absolute | — |

| Filtering area/pleats | — | — | 497 cm2/35 | 497 cm2/35 | — |

| Collapse/burst | — | 100 psi (collapse, typical listing) | 330 psi (burst) | 330 psi (burst) | — |

| Max. flow | — | — | 34–42 L/min | 34–42 L/min | — |

| Parameter | Value | Units |

|---|---|---|

| Engine code | G6EA (Hyundai Mu/Delta V6) | 2.7 L, DOHC, 24 Valves. |

| Cylinders & layout | 6, V6 (60°), cross-cutting | — |

| Displacement | 2656 | cm3 |

| Bore × Stroke | 86.7 × 75.0 | mm × mm. |

| Compression ratio | 10.4:1 | — |

| Fuel system | Multi-port fuel injection (MPi) | — |

| Cooling system | Water-cooled | Pressurised water-glycol circuit. |

| Max. power | 138 kW @ 6000 min−1 | ≈185 HP |

| Max. torque | 247 Nm @ 4000 min−1 | ≈182.18 ft-lbs |

| Emissions standard | EURO 4 | — |

| Vehicle curb weight | 1780 | kg |

| Odometer at test | 180,000 | Kilometres |

| Property | Unit | Method | Typical Value |

|---|---|---|---|

| Density @15.6 °C | g/mL | ASTM D4052 | 0.89 |

| Kinematic viscosity @40 °C | cSt | ASTM D445 | 185 |

| Kinematic viscosity @100 °C | cSt | ASTM D445 | 20.5 |

| Pour point | °C | ASTM D97 | −33 |

| Flash point (open cup) | °C | ASTM D92 | 230 |

| Sulphated ash | wt% | ASTM D874 | 0.8 |

| Sierra Route | ||||

|---|---|---|---|---|

| Section | Distance | Height Max. | Height Min. | Duration Trip |

| Quito-Salcedo | 38.6 km | 3515 m | 2670 m | 1 h 17 min |

| Salcedo-Riobamba | 88.0 km | 3632 m | 2398 m | 2 h 38 min |

| Riobamba-Alausí | 89.2 km | 3390 m | 2374 m | 1 h 14 min |

| Alausí-Tambo | 95 km | 3094 m | 2256 m | 3 h 08 min |

| Tambo-Cuenca | 75.7 km | 3572 m | 2353 m | 1 h 07 min |

| Filter | Route | ΔP Range (bar) | Viscosity Before (cSt @100 °C) | Viscosity After (cSt @100 °C) | Stability (%) |

|---|---|---|---|---|---|

| 1 | Q–C | 0.10–0.13 | 20.5 | 19.6 | 95.6 |

| 1 | C–Q | 0.10–0.13 | 20.5 | 19.5 | 95.1 |

| 2 | Q–C | 0.12–0.14 | 20.5 | 19.0 | 92.7 |

| 2 | C–Q | 0.12–0.14 | 20.5 | 19.1 | 93.2 |

| 3 | Q–C | 0.09–0.12 | 20.5 | 19.8 | 96.6 |

| 3 | C–Q | 0.09–0.12 | 20.5 | 19.9 | 97.1 |

| 4 | Q–C | 0.09–0.12 | 20.5 | 19.7 | 96.1 |

| 4 | C–Q | 0.09–0.12 | 20.5 | 19.8 | 96.6 |

| 5 | Q–C | 0.11–0.13 | 20.5 | 19.2 | 93.7 |

| 5 | C–Q | 0.11–0.13 | 20.5 | 19.3 | 94.1 |

| Oil Filter | Min Pore ECD (NFP) | Min Pore ECD (UFP) | Max Pore ECD (NFP) | Max Pore ECD (UFP) |

|---|---|---|---|---|

| F1 | 97.20 | 120.54 | 166.76 | 236.85 |

| F2 | 113.94 | 127.09 | 252.53 | 354.42 |

| F3 | 65.53 | 120.42 | 120.54 | 219.96 |

| F4 | 67.49 | 124.62 | 139.01 | 198.77 |

| F5 | 109.90 | 169.90 | 135.45 | 175.48 |

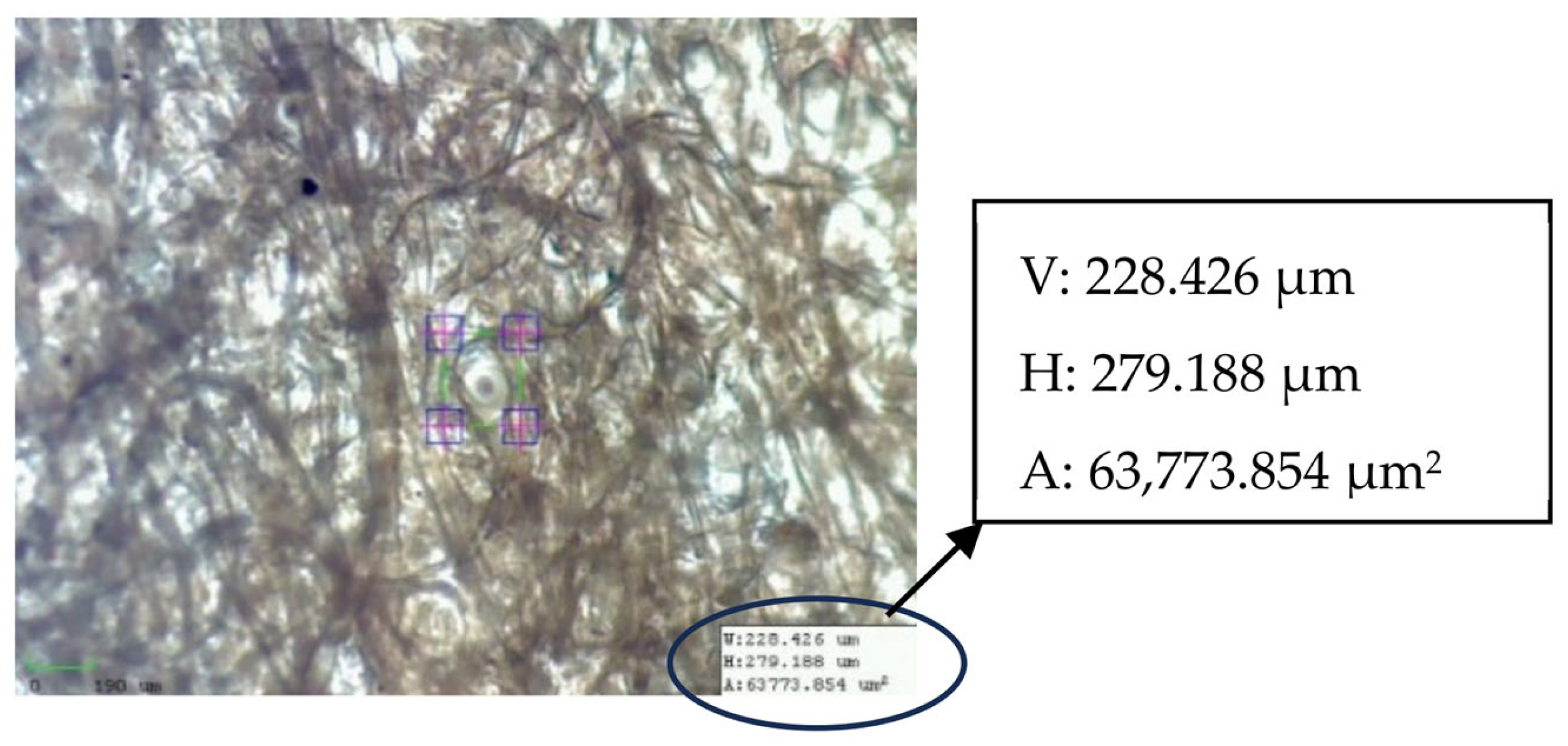

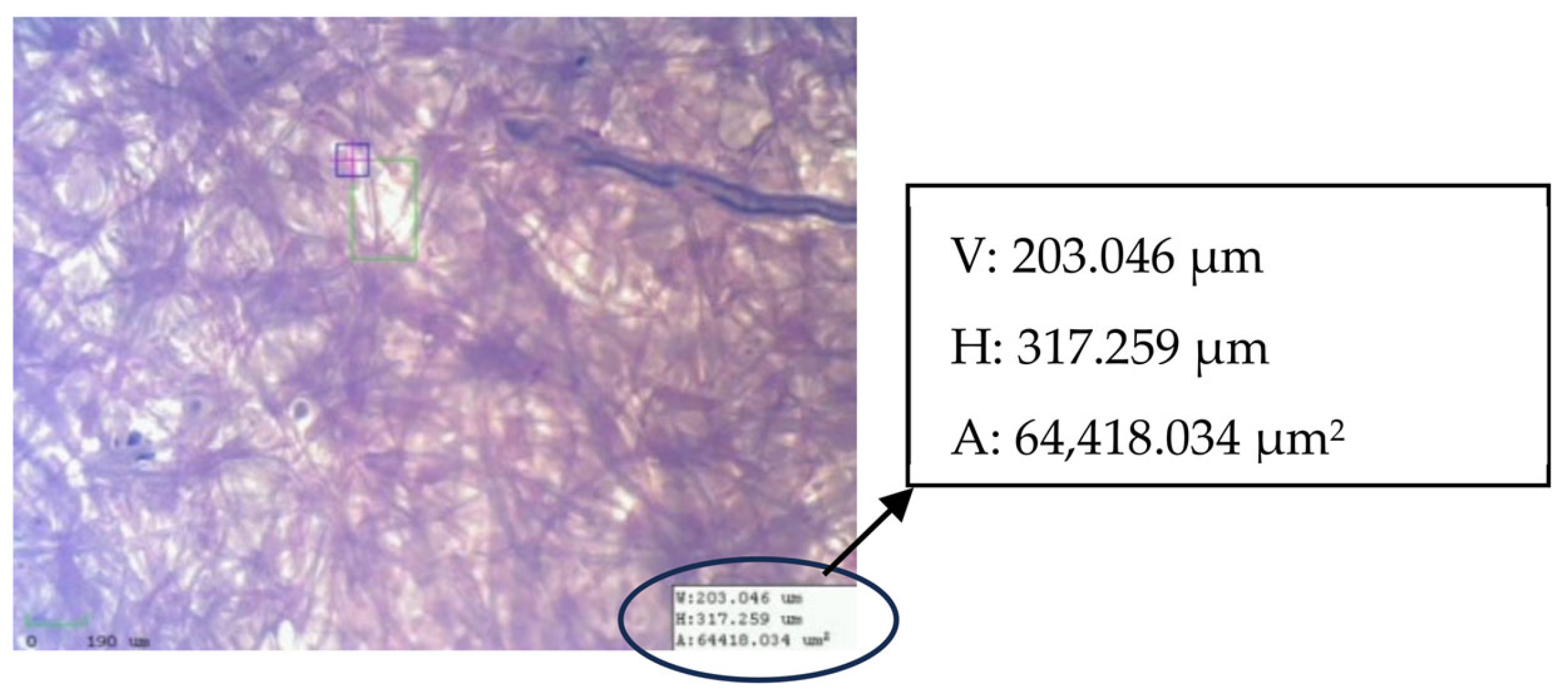

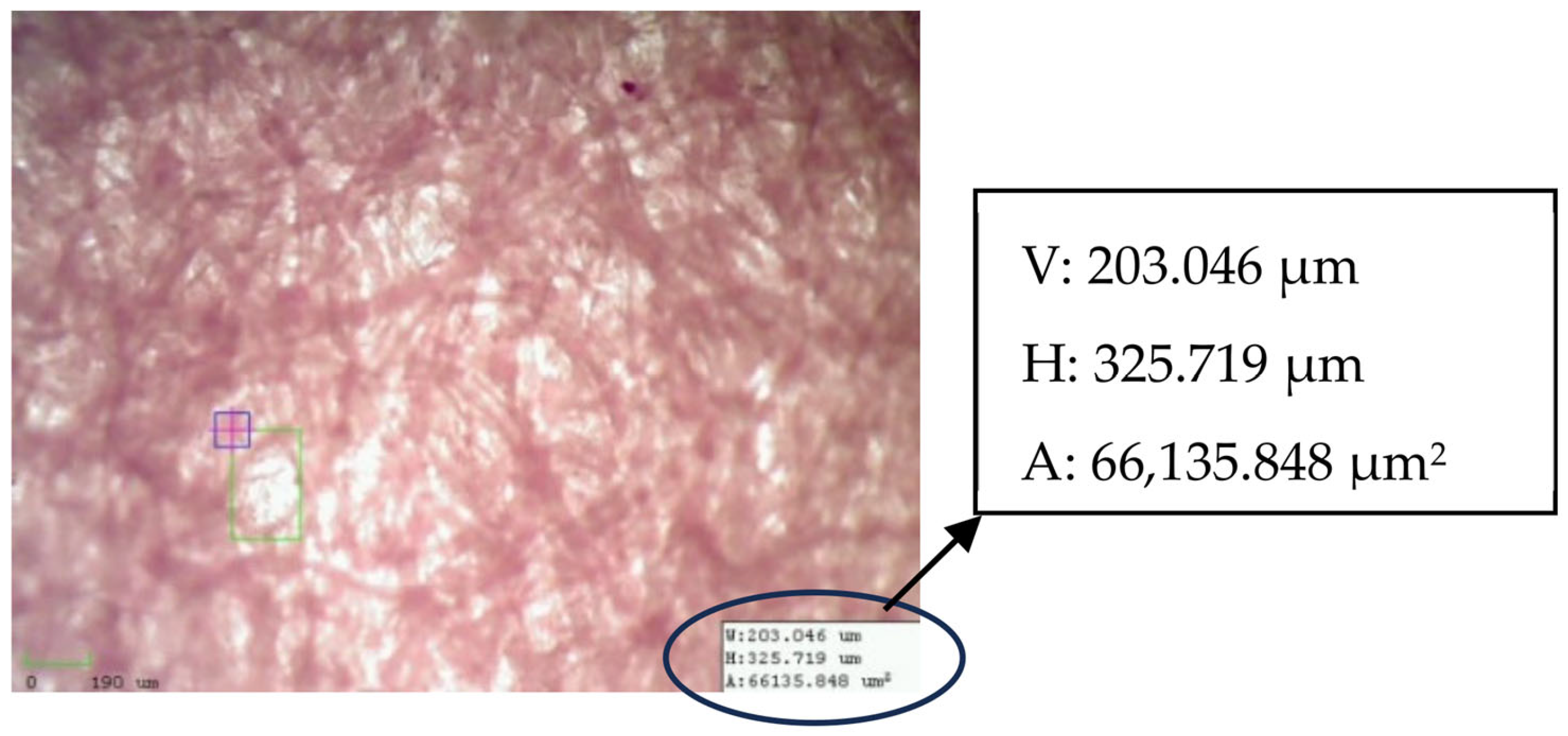

| Filter | Mean Equivalent Particle Diameter deq (µm) | Projected Area of the Particle |

|---|---|---|

| F1 | 267 | 56,097 µm2 |

| F2 | 285 | 63,774 µm2 |

| F3 | 286 | 64,418 µm2 |

| F4 | 290 | 66,136 µm2 |

| F5 | 192 | 28,934 µm2 |

| Filter | Routes | Number of Trips | Average km/gls |

|---|---|---|---|

| F1 | Quito-Cuenca | 3 | 28.861 |

| Cuenca-Quito | 3 | 35.478 | |

| F2 | Quito-Cuenca | 3 | 32.219 |

| Cuenca-Quito | 3 | 32.430 | |

| F3 | Quito-Cuenca | 3 | 29.062 |

| Cuenca-Quito | 3 | 33.011 | |

| F4 | Quito-Cuenca | 3 | 29.519 |

| Cuenca-Quito | 3 | 28.955 | |

| F5 | Quito-Cuenca | 3 | 32.847 |

| Cuenca-Quito | 3 | 27.838 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas-Reinoso, E.V.; Malla-Toapanta, C.; Plaza-Roldán, P.; Mata, C.; Barba, J.; Tipanluisa, L. Real-World Fuel Consumption of a Passenger Car with Oil Filters of Different Characteristics at High Altitude. Lubricants 2025, 13, 437. https://doi.org/10.3390/lubricants13100437

Rojas-Reinoso EV, Malla-Toapanta C, Plaza-Roldán P, Mata C, Barba J, Tipanluisa L. Real-World Fuel Consumption of a Passenger Car with Oil Filters of Different Characteristics at High Altitude. Lubricants. 2025; 13(10):437. https://doi.org/10.3390/lubricants13100437

Chicago/Turabian StyleRojas-Reinoso, Edgar Vicente, Cristian Malla-Toapanta, Paúl Plaza-Roldán, Carmen Mata, Javier Barba, and Luis Tipanluisa. 2025. "Real-World Fuel Consumption of a Passenger Car with Oil Filters of Different Characteristics at High Altitude" Lubricants 13, no. 10: 437. https://doi.org/10.3390/lubricants13100437

APA StyleRojas-Reinoso, E. V., Malla-Toapanta, C., Plaza-Roldán, P., Mata, C., Barba, J., & Tipanluisa, L. (2025). Real-World Fuel Consumption of a Passenger Car with Oil Filters of Different Characteristics at High Altitude. Lubricants, 13(10), 437. https://doi.org/10.3390/lubricants13100437