Fabrication and Characterization of SnSb11Cu6 Babbitt-Infiltrated Open-Cell AlSn6Cu-SiC Matrix Composites

Abstract

1. Introduction

2. Materials and Methods

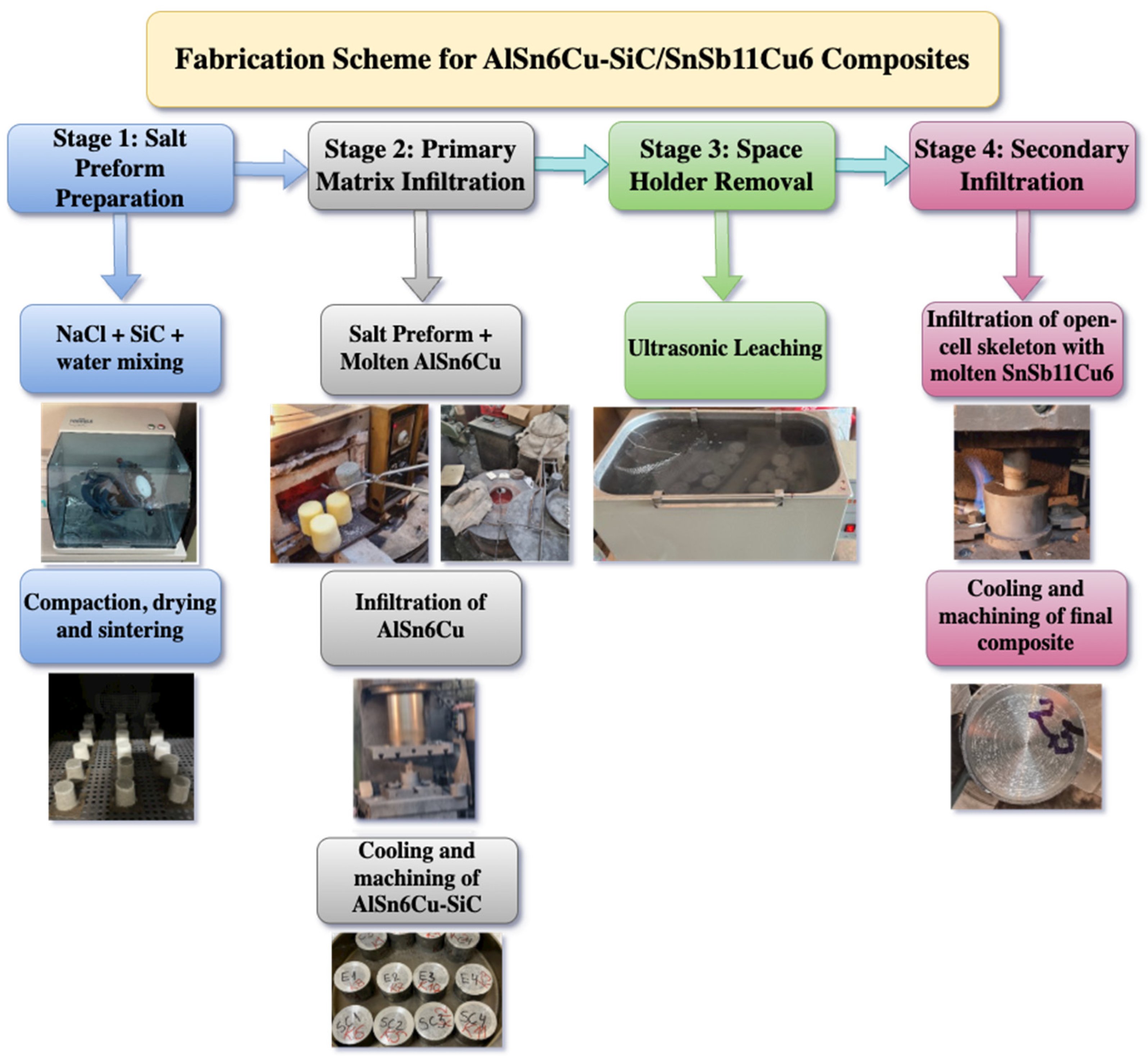

2.1. Fabrication

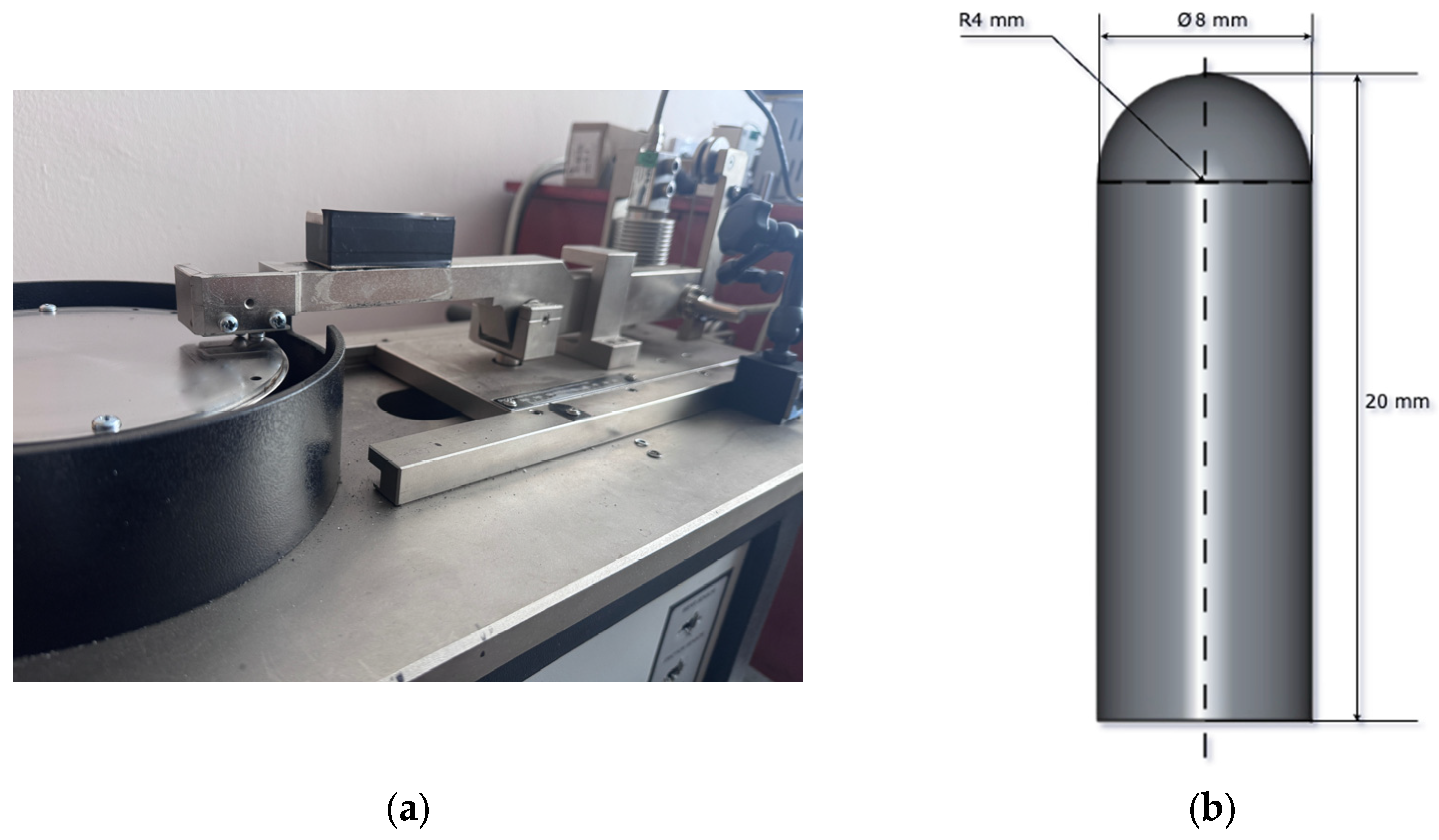

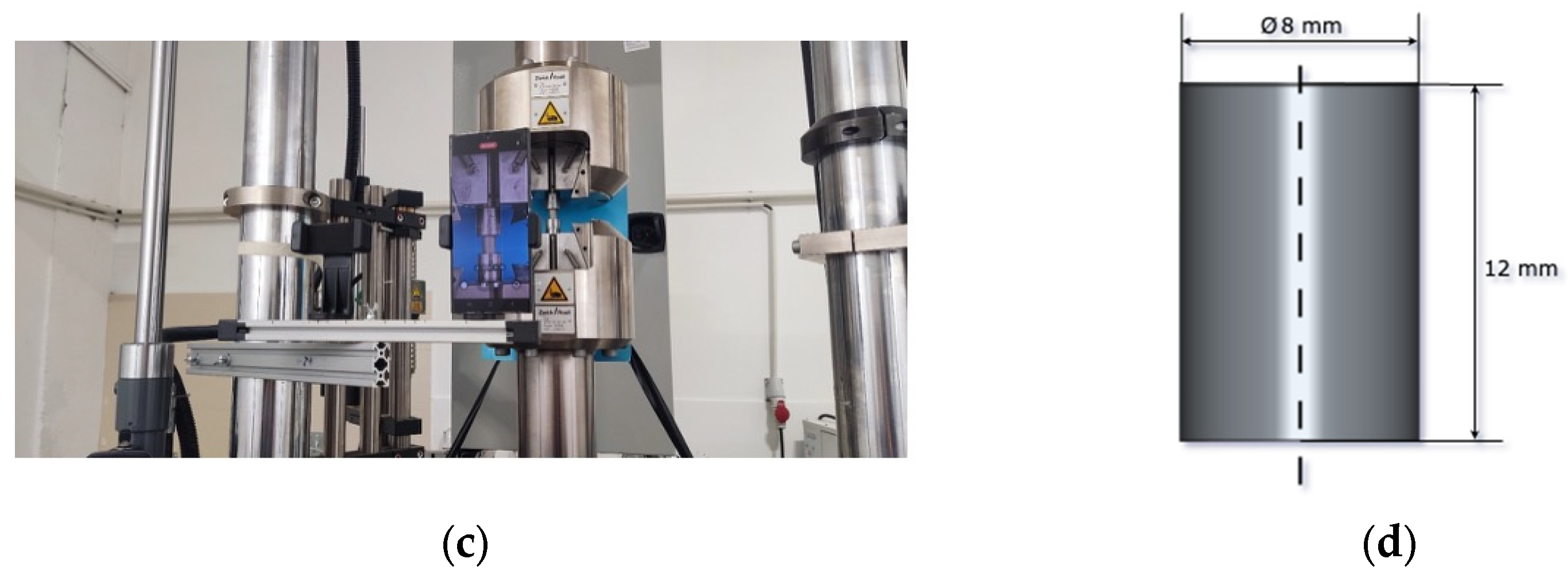

2.2. Characterization

3. Results and Discussion

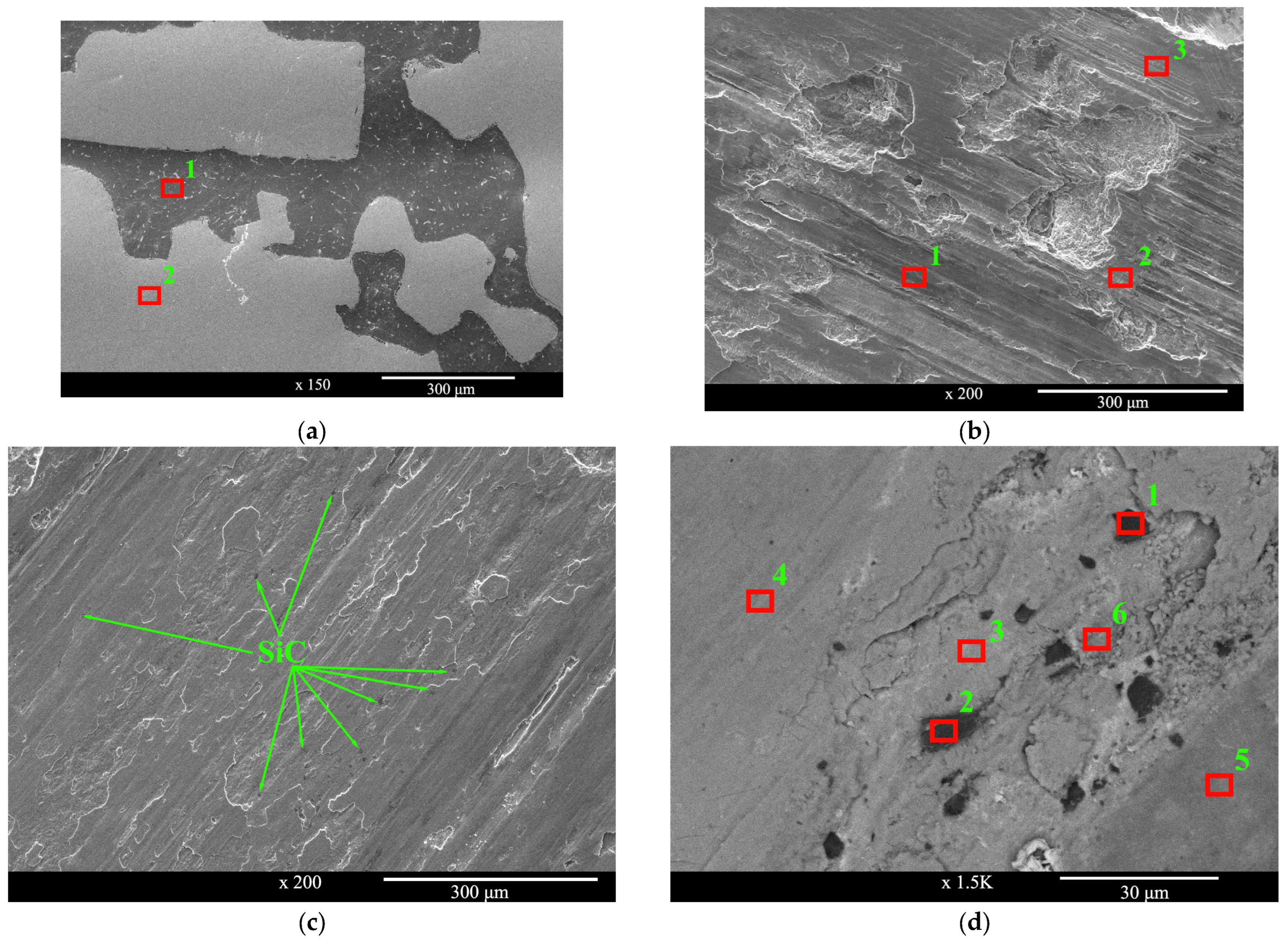

3.1. Microstructural Analysis

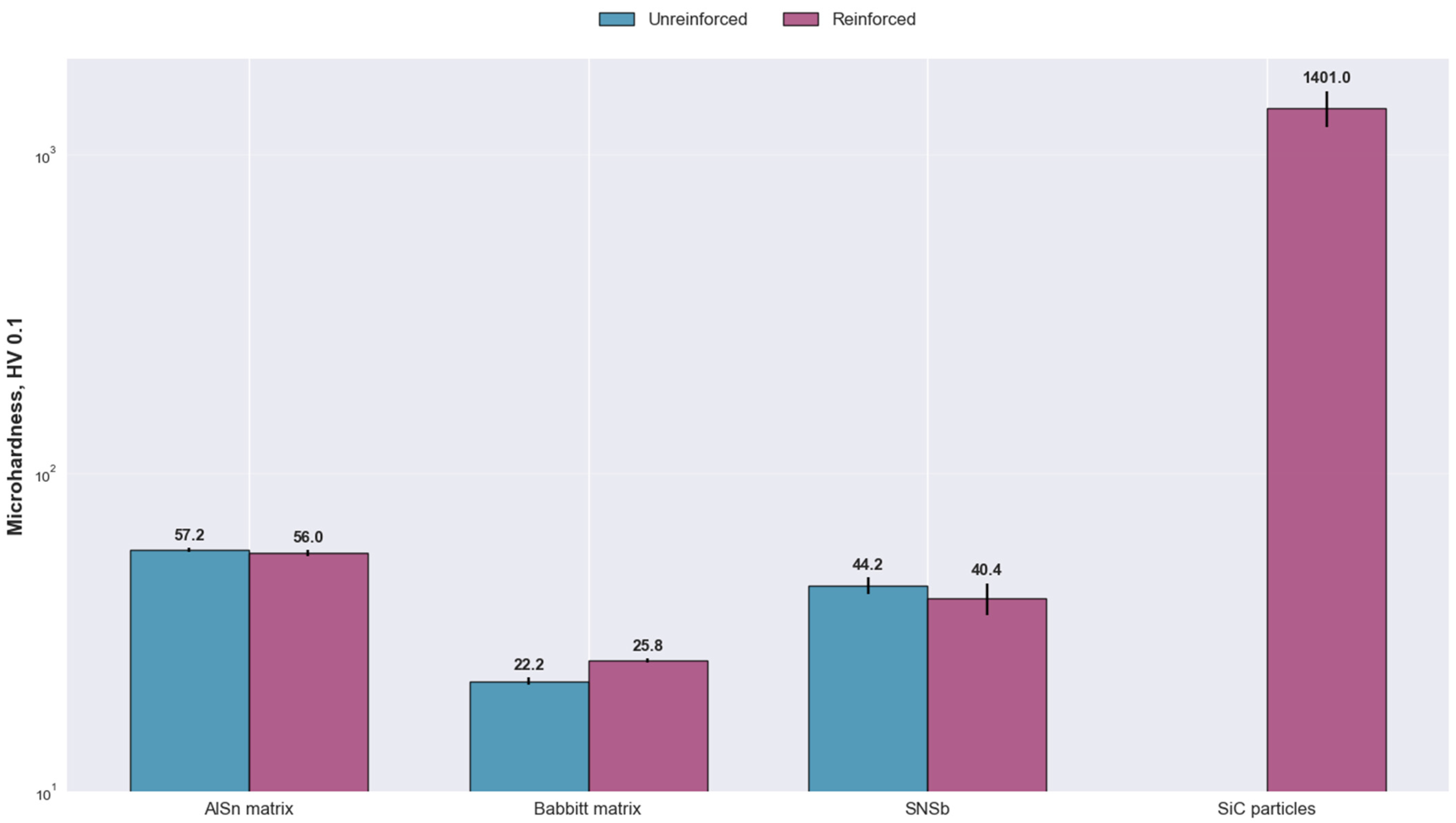

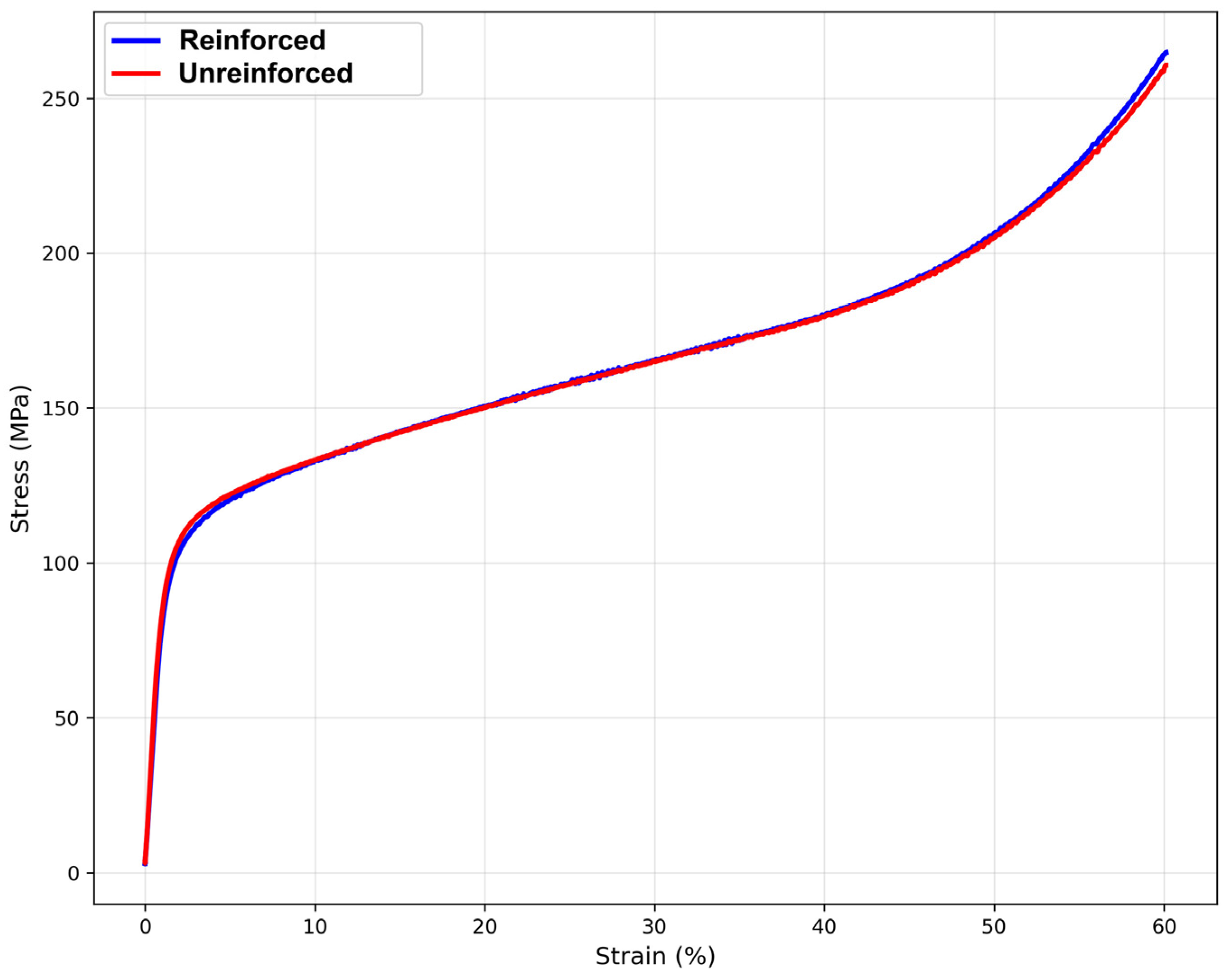

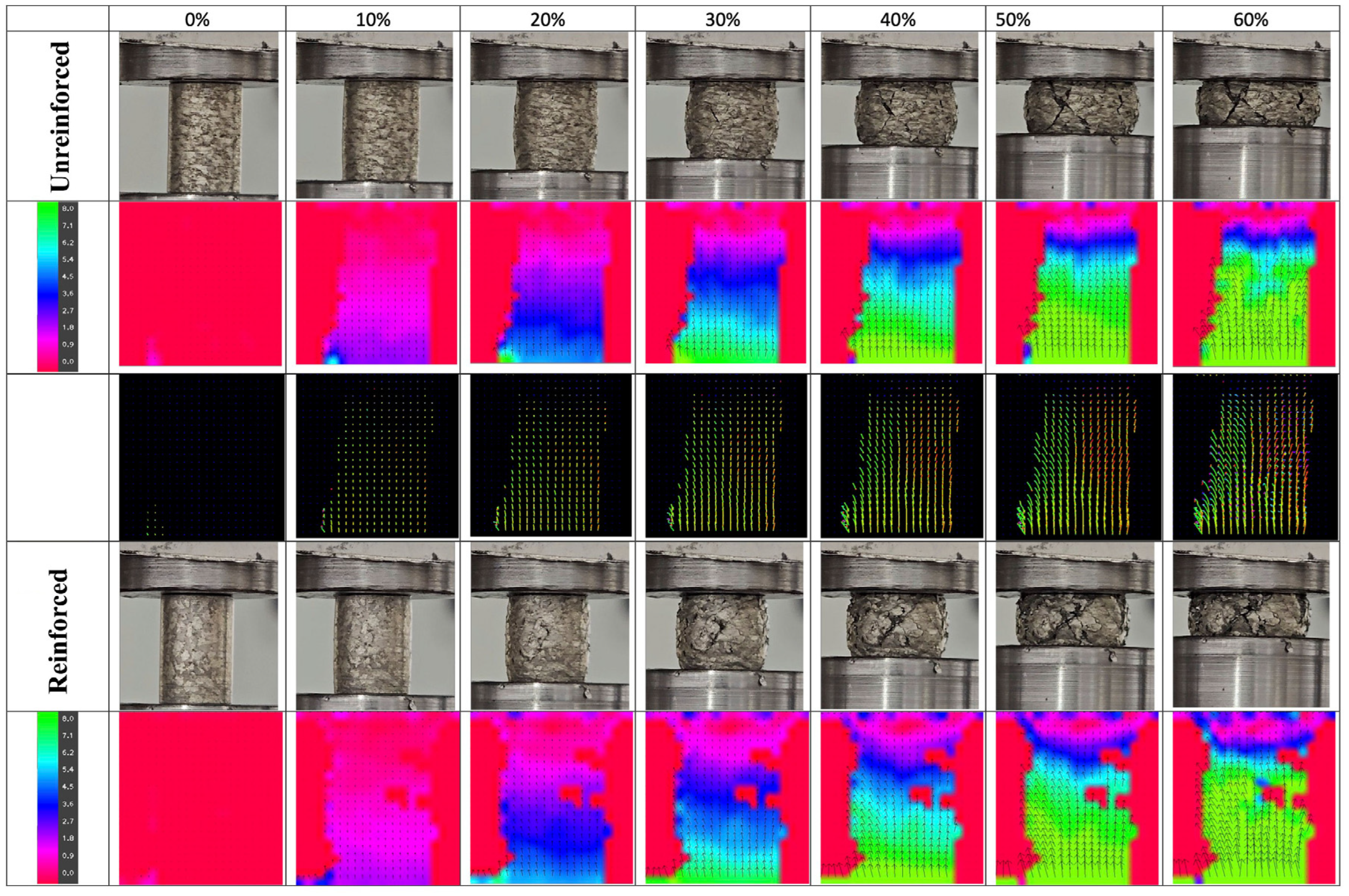

3.2. Mechanical Behavior

3.3. Wear Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Talluri, B.K.; Narasimha Rao, R.; Özcan, M.; Syam Prasad, P. Evaluating Mechanical and Tribological Performance of B4C Reinforced Aluminum Composites with Predictive Machine Learning Models. Results Eng. 2025, 27, 106503. [Google Scholar] [CrossRef]

- Beder, M.; Varol, T.; Akçay, S.B. Impact of High Al2O3 Content on the Microstructure, Mechanical Properties, and Wear Behavior Al–Cu–Mg/Al2O3 Composites Prepared by Mechanical Milling. Ceram. Int. 2024, 50, 38610–38631. [Google Scholar] [CrossRef]

- Sadhu, K.K.; Prajapati, P.K.; Mandal, N.; Sahoo, R.R. Tribo-Mechanical Evaluation of SiC-Reinforced Wear-Resistant Aluminium Composite Fabricated through Powder Metallurgy. Mater. Today Commun. 2025, 42, 111184. [Google Scholar] [CrossRef]

- Maleki, K.; Alizadeh, A.; Hajizamani, M. Compressive Strength and Wear Properties of SiC/Al6061 Composites Reinforced with High Contents of SiC Fabricated by Pressure-Assisted Infiltration. Ceram. Int. 2021, 47, 2406–2413. [Google Scholar] [CrossRef]

- Abdelbary, A.; Chang, L. Principles of Engineering Tribology; Academic Press: San Diego, CA, USA, 2023; ISBN 9780323991155. [Google Scholar]

- Sharifi, H.; Ostovan, K.; Tayebi, M.; Rajaee, A. Dry Sliding Wear Behavior of Open-Cell Al-Mg/Al2O3 and Al-Mg/SiC-Al2O3 Composite Preforms Produced by a Pressureless Infiltration Technique. Tribol. Int. 2017, 116, 244–255. [Google Scholar] [CrossRef]

- Aktar Zahid Sohag, M.; Gupta, P.; Kondal, N.; Kumar, D.; Singh, N.; Jamwal, A. Effect of Ceramic Reinforcement on the Microstructural, Mechanical and Tribological Behavior of Al-Cu Alloy Metal Matrix Composite. Mater. Today 2020, 21, 1407–1411. [Google Scholar] [CrossRef]

- Alizadeh, A.; Khayami, A.; Karamouz, M.; Hajizamani, M. Mechanical Properties and Wear Behavior of Al5083 Matrix Composites Reinforced with High Amounts of SiC Particles Fabricated by Combined Stir Casting and Squeeze Casting; A Comparative Study. Ceram. Int. 2022, 48, 179–189. [Google Scholar] [CrossRef]

- Shaikh, M.B.N.; Aziz, T.; Arif, S.; Ansari, A.H.; Karagiannidis, P.G.; Uddin, M. Effect of Sintering Techniques on Microstructural, Mechanical and Tribological Properties of Al-SiC Composites. Surf. Interfaces 2020, 20, 100598. [Google Scholar] [CrossRef]

- Bhatti, T.M.; Wang, Y.; Baig, M.M.A.B.; Zhou, Z.F.; Hussain, A.; Jamal, S.; Shehzadi, F. Influence of Processing Routes and SiC Volume Percentage on Microstructure, Thermophysical, and Mechanical Properties of SiCp/Al-6061 Composites. J. Alloys Compd. 2025, 1041, 183797. [Google Scholar] [CrossRef]

- Tan, Z.; Chen, Z.; Fan, G.; Ji, G.; Zhang, J.; Xu, R.; Shan, A.; Li, Z.; Zhang, D. Effect of Particle Size on the Thermal and Mechanical Properties of Aluminum Composites Reinforced with SiC and Diamond. Mater. Des. 2016, 90, 845–851. [Google Scholar] [CrossRef]

- Teng, F.; Yu, K.; Luo, J.; Fang, H.-J.; Shi, C.-L.; Dai, Y.-L.; Xiong, H.-Q. Microstructures and Properties of Al–50%SiC Composites for Electronic Packaging Applications. Trans. Nonferrous Met. Soc. China 2016, 26, 2647–2652. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Du, Y.H.; Zhang, P.; Wang, Y.J. Air-Isolated Stir Casting of Homogeneous Al-SiC Composite with No Air Entrapment and Al4C3. J. Mater. Process. Technol. 2019, 271, 226–236. [Google Scholar] [CrossRef]

- Sankhla, A.M.; Patel, K.M.; Makhesana, M.A.; Giasin, K.; Pimenov, D.Y.; Wojciechowski, S.; Khanna, N. Effect of Mixing Method and Particle Size on Hardness and Compressive Strength of Aluminium Based Metal Matrix Composite Prepared through Powder Metallurgy Route. J. Mater. Res. Technol. 2022, 18, 282–292. [Google Scholar] [CrossRef]

- El-Kady, O.; Fathy, A. Effect of SiC Particle Size on the Physical and Mechanical Properties of Extruded Al Matrix Nanocomposites. Mater. Eng. 2014, 54, 348–353. [Google Scholar] [CrossRef]

- Soltani, S.; Azari Khosroshahi, R.; Taherzadeh Mousavian, R.; Jiang, Z.-Y.; Fadavi Boostani, A.; Brabazon, D. Stir Casting Process for Manufacture of Al–SiC Composites. Rare Met. 2017, 36, 581–590. [Google Scholar] [CrossRef]

- Ren, X.R.; Chang, Y.C.; Chen, S.C.; Chen, N.C.; Shi, Z.S.; Zhang, Y.Z.; Chen, H.C.; Guo, Z.G.; Hu, J.H.; Zhang, G.Z.; et al. Effect of Rare Earth Y on the Microstructure, Mechanical Properties and Friction of Sn-Babbitt Alloy. Coatings 2024, 14, 1325. [Google Scholar] [CrossRef]

- Флегентoв, И.А.; Старшинoв, Д.М.; Михеев, Ю.Б.; Рябцев, Е.А. Improving reliability of main pumping unit by improving bearing units. Sci. Technol. OIL OIL Prod. Pipeline Transp. 2023, 12, 569–575. [Google Scholar] [CrossRef]

- Dong, Q.; Yin, Z.; Li, H.; Zhang, X.; Jiang, D.; Zhong, N. Effects of Ag Micro-Addition on Structure and Mechanical Properties of Sn-11Sb-6Cu Babbitt. Mater. Sci. Eng. A Struct. Mater. 2018, 722, 225–230. [Google Scholar] [CrossRef]

- Abioye, T.E.; Zuhailawati, H.; Azlan, M.A.I.; Anasyida, A.S. Effects of SiC Additions on the Microstructure, Compressive Strength and Wear Resistance of Sn-Sb-Cu Bearing Alloy Formed via Powder Metallurgy. J. Mater. Res. Technol. 2020, 9, 13196–13205. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, M.; Wang, B.; Zhang, L.; Zhu, T.; Li, N.; Zhou, J.; Jia, F. Effect of Co Addition on the Microstructure and Mechanical Properties of Sn-11Sb-6Cu Babbitt Alloy. Materials 2024, 17, 5494. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Petkov, V.; Dimitrova, R.; Kovacheva, D. Open-Cell AlSn6Cu-SiC Composites: Fabrication, Dry-Sliding Wear Behavior, and Machine Learning Methods for Wear Prediction. Materials 2023, 16, 6208. [Google Scholar] [CrossRef]

- Elizondo Luna, E.M.; Barari, F.; Woolley, R.; Goodall, R. Casting Protocols for the Production of Open Cell Aluminum Foams by the Replication Technique and the Effect on Porosity. J. Vis. Exp. 2014, 11, e52268. [Google Scholar] [CrossRef] [PubMed]

- Belov, N.A.; Akopyan, T.K.; Gershman, I.S.; Stolyarova, O.O.; Yakovleva, A.O. Effect of Si and Cu Additions on the Phase Composition, Microstructure and Properties of Al-Sn Alloys. J. Alloys Compd. 2017, 695, 2730–2739. [Google Scholar] [CrossRef]

- Lu, Z.C.; Gao, Y.; Zeng, M.Q.; Zhu, M. Improving Wear Performance of Dual-Scale Al–Sn Alloys: The Role of Mg Addition in Enhancing Sn Distribution and Tribolayer Stability. Wear 2014, 309, 216–225. [Google Scholar] [CrossRef]

- Demir, M.E.; Okumuş, M. Investigation of Microhardness, Microstructural, Tribological, and Thermal Properties of Al7075/TiO2/Kaoline Hybrid Metal Matrix Composites Produced by Powder Metallurgy Process. Adv. Eng. Mater. 2024, 26, 2401343. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Petkov, V.; Dimitrova, R.; Kolev, K.; Simeonova, T. Fabrication and Dry-Sliding Wear Characterization of Open-Cell AlSn6Cu–Al2O3 Composites with LSTM-Based Coefficient of Friction Prediction. Metals 2024, 14, 428. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Simeonova, T.; Krastev, R.; Kavardzhikov, V. Data on Mechanical Properties of Open-Cell AlSi10Mg Materials and Open-Cell AlSi10Mg-SiC Composites with Different Pore Sizes and Strain Rates. Data Brief 2023, 49, 109461. [Google Scholar] [CrossRef]

| Specimen | Analysis No. | Sn | Al | Fe | Sb | Cu | Si | C |

|---|---|---|---|---|---|---|---|---|

| AlSn6Cu material infiltrated with SnSb11Cu6 babbitt alloy before the wear test (Figure 2a) | 1 | 6.31 | 93.69 | – | – | – | – | – |

| 2 | 90.55 | – | – | 8.29 | 1.16 | – | – | |

| AlSn6Cu material infiltrated with SnSb11Cu6 babbitt alloy after the wear test (Figure 2b) | 1 | 59.11 | 20.13 | 14.19 | 5.79 | 0.78 | – | – |

| 2 | 74.40 | 11.31 | 7.72 | 5.89 | 0.68 | – | – | |

| 3 | 85.64 | 4.81 | 2.01 | 6.37 | 1.17 | – | – | |

| Zoomed zone of AlSn6Cu-SiC composite infiltrated with SnSb11Cu6 babbitt alloy after the wear test (Figure 2d) | 1 | 7.84 | 1.27 | 1.95 | 0.50 | – | 57.56 | 30.88 |

| 2 | 2.03 | 1.53 | 0.98 | 0.32 | – | 69.50 | 29.24 | |

| 3 | 66.65 | 10.95 | 15.46 | 6.28 | 0.66 | – | – | |

| 4 | 58.62 | 15.99 | 19.61 | 4.87 | 0.91 | – | – | |

| 5 | 45.33 | 34.72 | 12.94 | 6.13 | 0.89 | – | – | |

| 6 | 52.26 | 23.44 | 17.45 | 5.19 | 1.67 | – | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolev, M.; Lazarova, R.; Petkov, V.; Dimitrova, R.; Simeonova, T.; Krastev, R.; Stoilov, G.; Kolev, K.; Atanasov, I. Fabrication and Characterization of SnSb11Cu6 Babbitt-Infiltrated Open-Cell AlSn6Cu-SiC Matrix Composites. Lubricants 2025, 13, 435. https://doi.org/10.3390/lubricants13100435

Kolev M, Lazarova R, Petkov V, Dimitrova R, Simeonova T, Krastev R, Stoilov G, Kolev K, Atanasov I. Fabrication and Characterization of SnSb11Cu6 Babbitt-Infiltrated Open-Cell AlSn6Cu-SiC Matrix Composites. Lubricants. 2025; 13(10):435. https://doi.org/10.3390/lubricants13100435

Chicago/Turabian StyleKolev, Mihail, Rumiana Lazarova, Veselin Petkov, Rositza Dimitrova, Tatiana Simeonova, Rumen Krastev, Georgi Stoilov, Krasimir Kolev, and Ilian Atanasov. 2025. "Fabrication and Characterization of SnSb11Cu6 Babbitt-Infiltrated Open-Cell AlSn6Cu-SiC Matrix Composites" Lubricants 13, no. 10: 435. https://doi.org/10.3390/lubricants13100435

APA StyleKolev, M., Lazarova, R., Petkov, V., Dimitrova, R., Simeonova, T., Krastev, R., Stoilov, G., Kolev, K., & Atanasov, I. (2025). Fabrication and Characterization of SnSb11Cu6 Babbitt-Infiltrated Open-Cell AlSn6Cu-SiC Matrix Composites. Lubricants, 13(10), 435. https://doi.org/10.3390/lubricants13100435