Plant-Based Oils for Sustainable Lubrication Solutions—Review

Abstract

1. Introduction

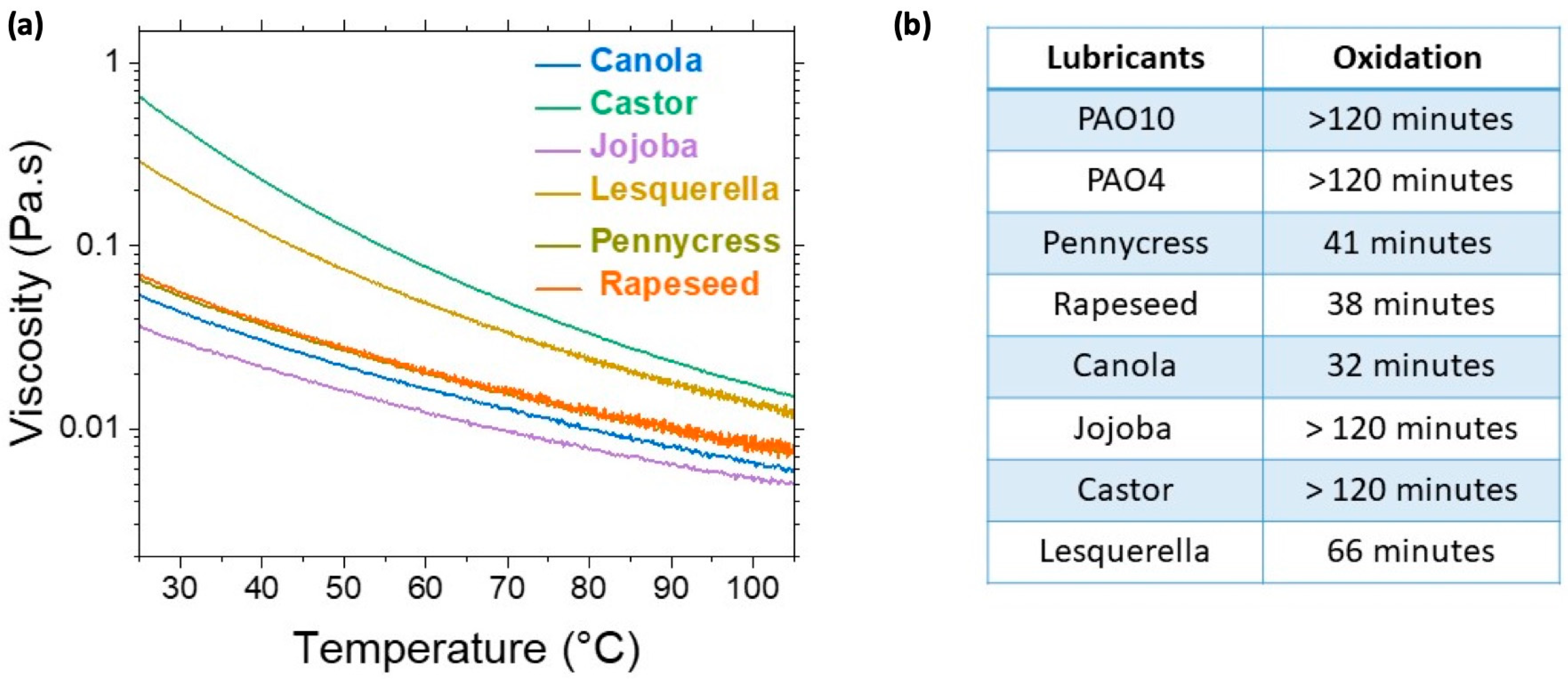

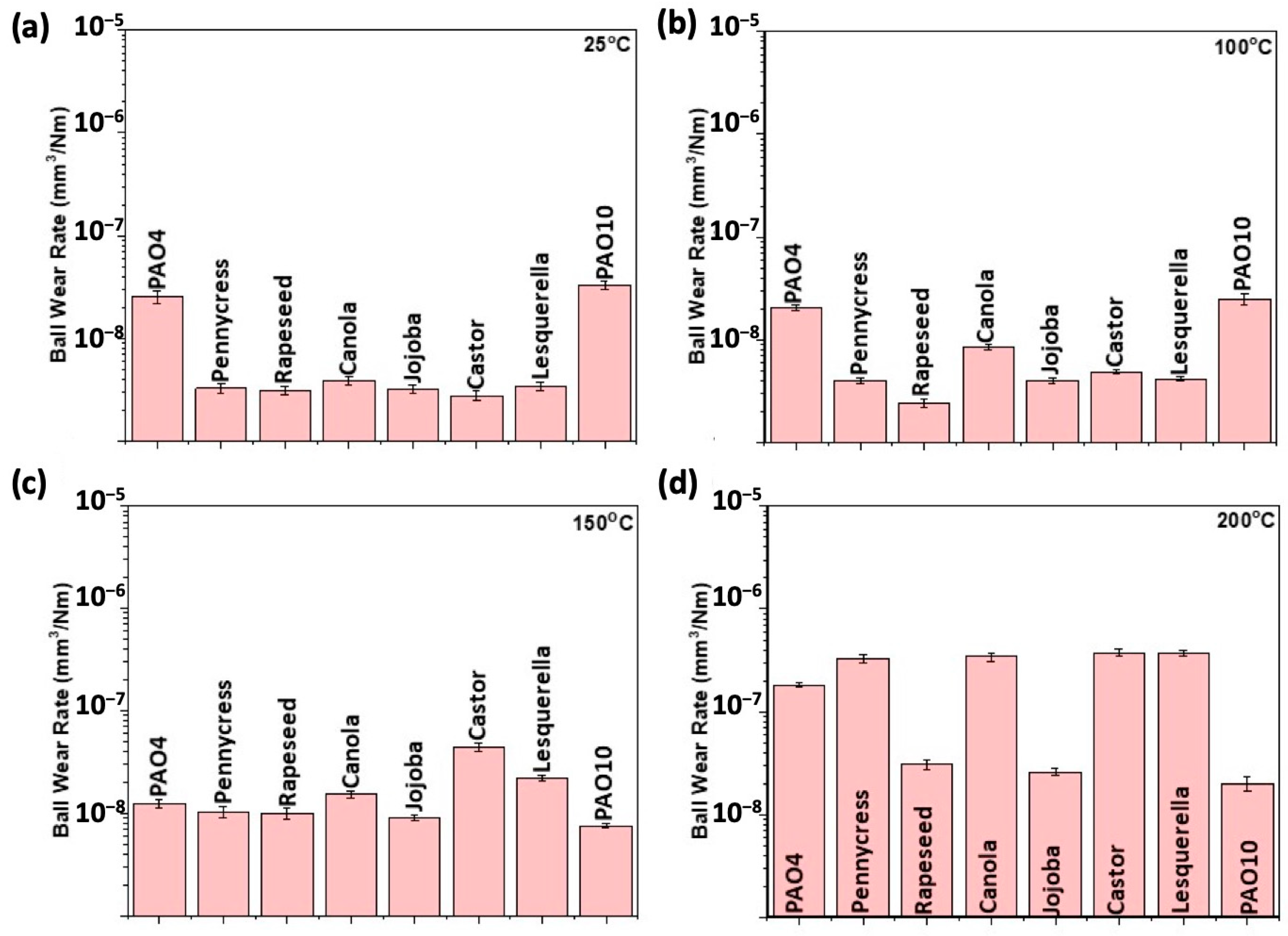

2. Physicochemical Characteristics of Liquid Lubricants

3. Plant-Based Oils and Their Evaluation

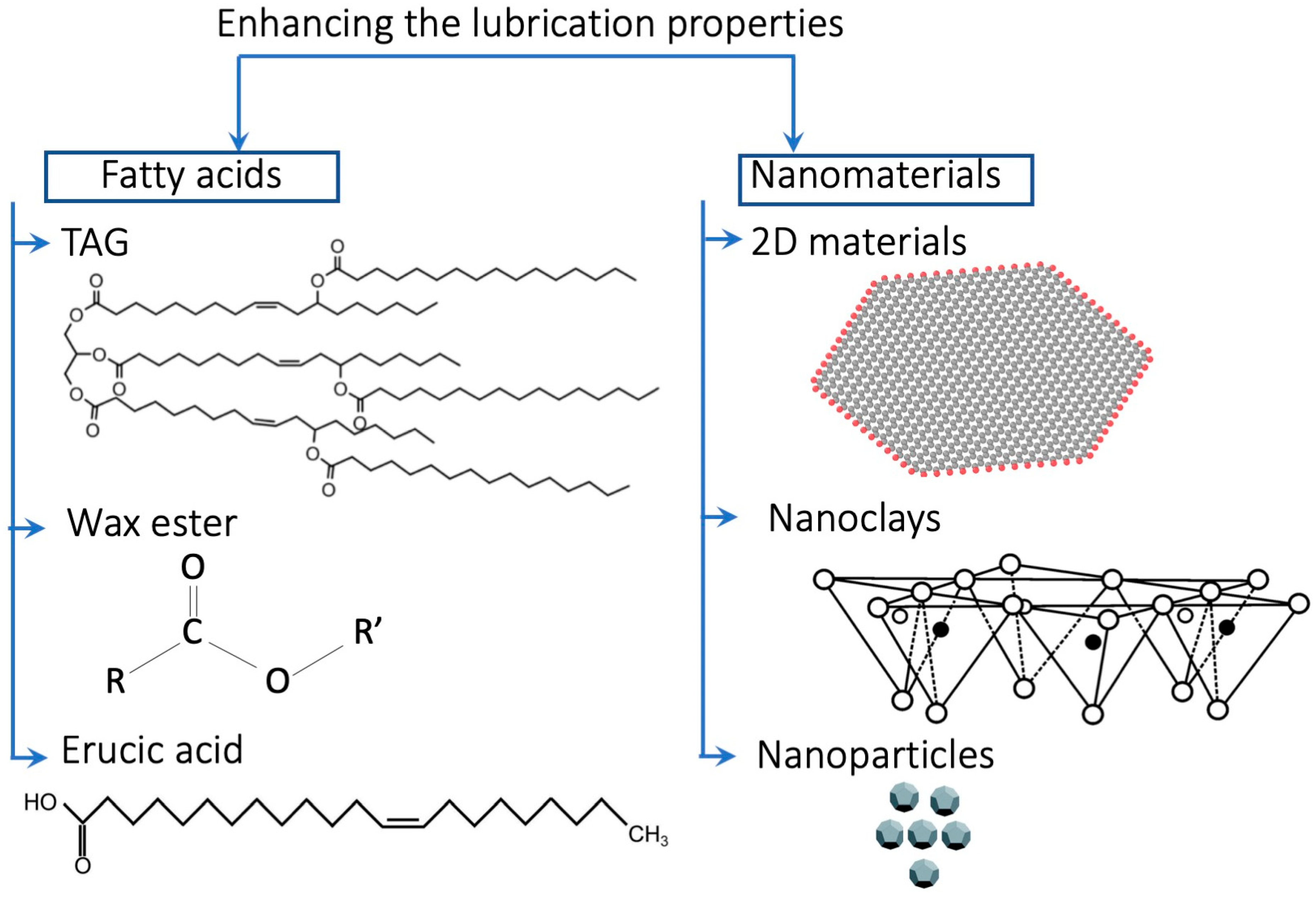

4. Novel Approaches for Lubrication Property Improvements

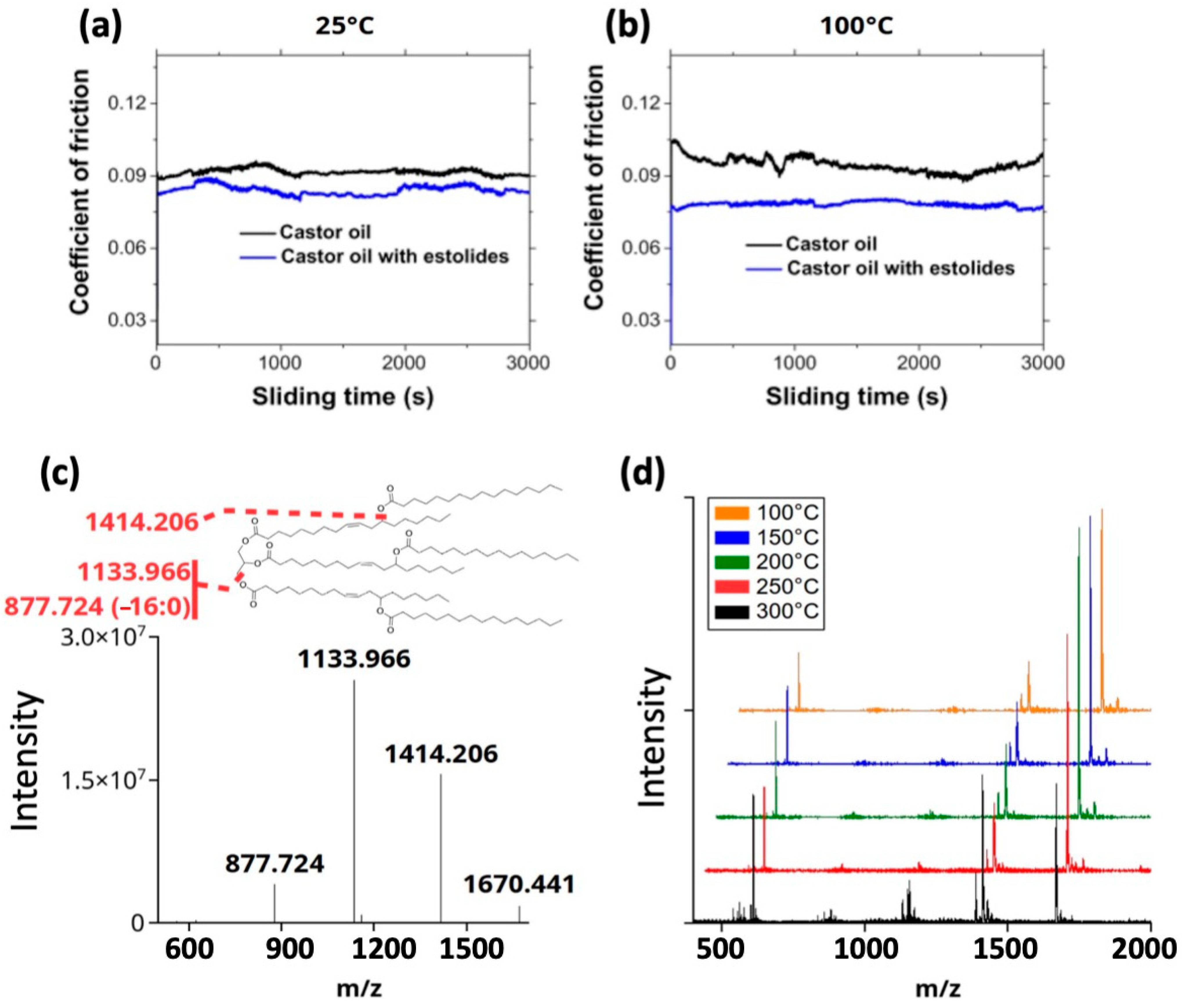

4.1. TAG Estolides

4.2. Wax Esters

4.3. Erucic Acid

4.4. Nanomaterials

5. Conclusions and Perspectives

Funding

Acknowledgments

Conflicts of Interest

References

- Wilson, B. Lubricants and functional fluids from renewable sources. Ind. Lubr. Tribol. 1998, 50, 6–15. [Google Scholar] [CrossRef]

- Bartz, W.J. Lubricants and the environment. Tribol. Int. 1998, 31, 35–47. [Google Scholar] [CrossRef]

- Chang, Q.; Rudenko, P.; Miller, D.J.; Wen, J.; Berman, D.; Zhang, Y.; Arey, B.; Zhu, Z.; Erdemir, A. Operando formation of an ultra-low friction boundary film from synthetic magnesium silicon hydroxide additive. Tribol. Int. 2017, 110, 35–40. [Google Scholar] [CrossRef]

- Jacques, K.; Joy, T.; Shirani, A.; Berman, D. Effect of Water Incorporation on the Lubrication Characteristics of Synthetic Oils. Tribol. Lett. 2019, 67, 105. [Google Scholar] [CrossRef]

- Macknojia, A.Z.; Montoya, V.L.; Cairns, E.; Eskandari, M.; Liu, S.; Chung, Y.-W.; Wang, Q.J.; Berkebile, S.P.; Aouadi, S.M.; Voevodin, A.A. Tribological Analysis of Steels in Fuel Environments: Impact of Alloy Content and Hardness. Appl. Sci. 2024, 14, 1898. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A. Achieving Ultralow Friction and Wear by Tribocatalysis: Enabled by In-Operando Formation of Nanocarbon Films. ACS Nano 2021, 15, 18865–18879. [Google Scholar] [CrossRef]

- Shirani, A.; Berkebile, S.; Berman, D. Promoted high-temperature lubrication and surface activity of polyolester lubricant with added phosphonium ionic liquid. Tribol. Int. 2023, 180, 108287. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of nanoparticles in lubricating oil: A critical review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Cermak, S.C.; Biresaw, G.; Isbell, T.A.; Evangelista, R.L.; Vaughn, S.F.; Murray, R. New crop oils—Properties as potential lubricants. Ind. Crops Prod. 2013, 44, 232–239. [Google Scholar] [CrossRef]

- Salimon, J.; Salih, N.; Yousif, E. Biolubricants: Raw materials, chemical modifications and environmental benefits. Eur. J. Lipid Sci. Technol. 2010, 112, 519–530. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, X.; Yang, S.; Chen, H.; Wang, D. The study of epoxidized rapeseed oil used as a potential biodegradable lubricant. J. Am. Oil Chem. Soc. 2000, 77, 561–563. [Google Scholar] [CrossRef]

- Liu, S.; Josephson, T.R.; Athaley, A.; Chen, Q.P.; Norton, A.; Ierapetritou, M.; Siepmann, J.I.; Saha, B.; Vlachos, D.G. Renewable lubricants with tailored molecular architecture. Sci. Adv. 2019, 5, eaav5487. [Google Scholar] [CrossRef] [PubMed]

- Balakrishnan, M.; Sacia, E.R.; Sreekumar, S.; Gunbas, G.; Gokhale, A.A.; Scown, C.D.; Toste, F.D.; Bell, A.T. Novel pathways for fuels and lubricants from biomass optimized using life-cycle greenhouse gas assessment. Proc. Natl. Acad. Sci. USA 2015, 112, 7645–7649. [Google Scholar] [CrossRef]

- Mobarak, H.M.; Niza Mohamad, E.; Masjuki, H.H.; Kalam, M.A.; Al Mahmud, K.A.H.; Habibullah, M.; Ashraful, A.M. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Panchal, T.M.; Patel, A.; Chauhan, D.; Thomas, M.; Patel, J.V. A methodological review on bio-lubricants from vegetable oil based resources. Renew. Sustain. Energy Rev. 2017, 70, 65–70. [Google Scholar] [CrossRef]

- Syahir, A.; Zulkifli, N.; Masjuki, H.; Kalam, M.; Alabdulkarem, A.; Gulzar, M.; Khuong, L.; Harith, M. A review on bio-based lubricants and their applications. J. Clean. Prod. 2017, 168, 997–1016. [Google Scholar] [CrossRef]

- Liew Yun Hsien, W.; Liew Yun Hsien, W. Utilization of vegetable oil as bio-lubricant and additive. In Towards Green Lubrication in Machining; Springer: Singapore, 2015; pp. 7–17. [Google Scholar] [CrossRef]

- Bio-lubricants Market Share, Size, Trends, Industry Analysis Report, By Base Oil Type (Vegetable Oils, Animal Fats, Others); By Application; By End-Use; By Region; Segment Forecast, 2022–2030. 2021. Available online: https://www.polarismarketresearch.com/industry-analysis/bio-lubricants-market (accessed on 22 July 2024).

- Nowak, P.; Kucharska, K.; Kamiński, M. Ecological and Health Effects of Lubricant Oils Emitted into the Environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef]

- Asadauskas, S.; Perez, J.H.; Duda, J.L. Lubrication properties of castor oil--potential basestock for biodegradable lubricants. Tribol. Lubr. Technol. 1997, 53, 35. [Google Scholar]

- Ghosh, P.; Hoque, M.; Karmakar, G. Castor oil as potential multifunctional additive in the formulation of eco-friendly lubricant. Polym. Bull. 2018, 75, 501–514. [Google Scholar] [CrossRef]

- Zulkifli, N.W.M.; Kalam, M.A.; Masjuki, H.H.; Shahabuddin, M.; Yunus, R. Wear prevention characteristics of a palm oil-based TMP (trimethylolpropane) ester as an engine lubricant. Energy 2013, 54, 167–173. [Google Scholar] [CrossRef]

- Masjuki, H.; Maleque, M.; Kubo, A.; Nonaka, T. Palm oil and mineral oil based lubricants—Their tribological and emission performance. Tribol. Int. 1999, 32, 305–314. [Google Scholar] [CrossRef]

- Arnšek, A.; Vižintin, J. Lubricating properties of rapeseed-based oils. J. Synth. Lubr. 2000, 16, 281–296. [Google Scholar] [CrossRef]

- Gryglewicz, S.; Muszyński, M.; Nowicki, J. Enzymatic synthesis of rapeseed oil-based lubricants. Ind. Crops Prod. 2013, 45, 25–29. [Google Scholar] [CrossRef]

- Zeng, Q. The lubrication performance and viscosity behavior of castor oil under high temperature. Green Mater. 2021, 10, 51–58. [Google Scholar] [CrossRef]

- Durak, E. A study on friction behavior of rapeseed oil as an environmentally friendly additive in lubricating oil. Ind. Lubr. Tribol. 2004, 56, 23–37. [Google Scholar] [CrossRef]

- Van Gerpen, J.; He, B. Biodiesel and renewable diesel production methods. Adv. Biorefineries 2014, 441–475. [Google Scholar] [CrossRef]

- Cecilia, J.A.; Ballesteros Plata, D.; Alves Saboya, R.M.; Tavares de Luna, F.M.; Cavalcante, C.L.; Rodríguez-Castellón, E. An Overview of the Biolubricant Production Process: Challenges and Future Perspectives. Processes 2020, 8, 257. [Google Scholar] [CrossRef]

- Trzepieciński, T. Tribological Performance of Environmentally Friendly Bio-Degradable Lubricants Based on a Combination of Boric Acid and Bio-Based Oils. Materials 2020, 13, 3892. [Google Scholar] [CrossRef] [PubMed]

- Rac, A.; Vencl, A. Ecological and technical aspects of the waste oils influence on environment. Ann. Univ. “Dunărea De Jos” Galaţi Fascicle VIII Tribol. 2012, 18, 5–11. [Google Scholar]

- Klaus, E.; Tewksbury, E. Liquid lubricants. Handb. Lubr. Theory Pract. Tribol. 1983, 2, 229–254. [Google Scholar]

- Berman, D.; Rosenkranz, A.; Marian, M. Fundamental and Practical Aspects of Tribology; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar]

- Luo, J.; Huang, P.; Wen, S.; Li, L.K. Characteristics of liquid lubricant films at the nano-scale. J. Tribol. 1999, 121, 872–878. [Google Scholar] [CrossRef]

- Ayyagari, A.; Alam, K.I.; Berman, D.; Erdemir, A. Progress in Superlubricity Across Different Media and Material Systems—A Review. Front. Mech. Eng. 2022, 8, 908497. [Google Scholar] [CrossRef]

- Torbacke, M.; Kassfeldt, E. Lubricants: Introduction to Properties and Performance; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Keeble, B.R. The Brundtland report:‘Our common future’. Med. War 1988, 4, 17–25. [Google Scholar] [CrossRef]

- Shashidhara, Y.M.; Jayaram, S.R. Vegetable oils as a potential cutting fluid—An evolution. Tribol. Int. 2010, 43, 1073–1081. [Google Scholar] [CrossRef]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Adediran, A.A.; Aliyu, S.J.; Akinlabi, S.A.; Jen, T.-C.; Akinlabi, E.T. Advances in the Application of Vegetable-Oil-Based Cutting Fluids to Sustainable Machining Operations—A Review. Lubricants 2022, 10, 69. [Google Scholar] [CrossRef]

- Ardizzon, G.; Cavazzini, G.; Pavesi, G. A new generation of small hydro and pumped-hydro power plants: Advances and future challenges. Renew. Sustain. Energy Rev. 2014, 31, 746–761. [Google Scholar] [CrossRef]

- Tripathy, D.B.; Mishra, A. Renewable plant-based raw materials for industry. Sustain. Inorg. Chem. 2016, 353, 156–157. [Google Scholar]

- Deuraseh, A.; Deuraseh, N. Halal Green from Plant-Based Product Perspective: Palm Oil as a Potential Source for Marine Engine Lubricant. J. Halal Sci. Technol. 2023, 2, 41–59. [Google Scholar] [CrossRef]

- Narayana Sarma, R.; Vinu, R. Current Status and Future Prospects of Biolubricants: Properties and Applications. Lubricants 2022, 10, 70. [Google Scholar] [CrossRef]

- Opia, A.C.; Abdollah, M.F.B.; Amiruddin, H.; Abdul Hamid, M.K.; Mohd Zawawi, F.B. Assessment on tribological responsiveness of different polymers on AISI 52100 steel using a sensitive reciprocating tribometer. Tribol.-Mater. Surf. Interfaces 2024, 18, 20–30. [Google Scholar] [CrossRef]

- Opia, A.C.; Abdollah, M.F.B.; Hamid, M.K.A.; Veza, I. A review on bio-lubricants as an alternative green product: Tribological performance, mechanism, challenges and future opportunities. Tribol. Online 2023, 18, 18–33. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, X.; Ma, Z.; Ma, S.; Zhou, F. An overview of functional biolubricants. Friction 2023, 11, 23–47. [Google Scholar] [CrossRef]

- Schneider, M.P. Plant-oil-based lubricants and hydraulic fluids. J. Sci. Food Agric. 2006, 86, 1769–1780. [Google Scholar] [CrossRef]

- Bart, J.C.; Gucciardi, E.; Cavallaro, S. Biolubricants: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. A review on the science and technology of natural and synthetic biolubricants. J. Bio-Tribo-Corros. 2017, 3, 11. [Google Scholar] [CrossRef]

- Salimon, J.; Abdullah, B.M.; Yusop, R.M.; Salih, N. Synthesis, reactivity and application studies for different biolubricants. Chem. Cent. J. 2014, 8, 16. [Google Scholar] [CrossRef]

- Al Sulaimi, R.; Macknojia, A.; Eskandari, M.; Shirani, A.; Gautam, B.; Park, W.; Whitehead, P.; Alonso, A.P.; Sedbrook, J.C.; Chapman, K.D. Evaluating the effects of very long chain and hydroxy fatty acid content on tribological performance and thermal oxidation behavior of plant-based lubricants. Tribol. Int. 2023, 185, 108576. [Google Scholar] [CrossRef]

- Yan, Z.; Jiang, D.; Fu, Y.; Qiao, D.; Gao, X.; Feng, D.; Sun, J.; Weng, L.; Wang, H. Vacuum tribological performance of WS 2–MoS 2 composite film against oil-impregnated porous polyimide: Influence of oil viscosity. Tribol. Lett. 2019, 67, 2. [Google Scholar] [CrossRef]

- Sharma, R.V.; Somidi, A.K.; Dalai, A.K. Preparation and properties evaluation of biolubricants derived from canola oil and canola biodiesel. J. Agric. Food Chem. 2015, 63, 3235–3242. [Google Scholar] [CrossRef]

- No, S.Y. Application of bio-oils from lignocellulosic biomass to transportation, heat and power generation—A review. Renew. Sustain. Energy Rev. 2014, 40, 1108–1125. [Google Scholar] [CrossRef]

- Li, X.; Teitgen, A.M.; Shirani, A.; Ling, J.; Busta, L.; Cahoon, R.E.; Zhang, W.; Li, Z.; Chapman, K.D.; Berman, D.; et al. Discontinuous fatty acid elongation yields hydroxylated seed oil with improved function. Nat. Plants 2018, 4, 711–720. [Google Scholar] [CrossRef]

- Luo, P.; Lan, Z.; Li, Z. Orychophragmus violaceus, a potential edible-oil crop. Plant Breed. 1994, 113, 83–85. [Google Scholar] [CrossRef]

- Pichler, J.; Maria Eder, R.; Besser, C.; Pisarova, L.; Dörr, N.; Marchetti-Deschmann, M.; Frauscher, M. A comprehensive review of sustainable approaches for synthetic lubricant components. Green Chem. Lett. Rev. 2023, 16, 2185547. [Google Scholar] [CrossRef]

- Kodali, D. Development, properties and applications of high-performance biolubricants. In Advances in Biorefineries; Elsevier: Amsterdam, The Netherlands, 2014; pp. 556–595. [Google Scholar]

- Honary, L.A. Biobased Automotive Lubricants; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Romsdahl, T.; Shirani, A.; Minto, R.E.; Zhang, C.; Cahoon, E.B.; Chapman, K.D.; Berman, D. Nature-Guided Synthesis of Advanced Bio-Lubricants. Sci. Rep. 2019, 9, 11711. [Google Scholar] [CrossRef] [PubMed]

- Cermak, S.C.; Isbell, T.A.; Bredsguard, J.W.; Thompson, T.D. Estolides: Synthesis and applications. In Fatty Acids; Elsevier: Amsterdam, The Netherlands, 2017; pp. 431–475. [Google Scholar]

- Chen, Y.; Biresaw, G.; Cermak, S.C.; Isbell, T.A.; Ngo, H.L.; Chen, L.; Durham, A.L. Fatty acid estolides: A review. J. Am. Oil Chem. Soc. 2020, 97, 231–241. [Google Scholar] [CrossRef]

- Bredsguard, J.W.; Thompson, T.D.; Cermak, S.C.; Isbell, T.A. Estolides: Bioderived synthetic base oils. In Environmentally Friendly and Biobased Lubricants; CRC Press: Boca Raton, FL, USA, 2016; pp. 35–49. [Google Scholar]

- Sanap, P.; Sonawane, D.; Thakur, R.; Agrawal, S.; Pratap, A. Estolide-Based Biolubricants. Lubr. Renew. Feedstocks 2024, 259–290. [Google Scholar] [CrossRef]

- Saleh, H.; Selim, M.Y. Improving the performance and emission characteristics of a diesel engine fueled by jojoba methyl ester-diesel-ethanol ternary blends. Fuel 2017, 207, 690–701. [Google Scholar] [CrossRef]

- Ohlrogge, J.; Pollard, M.; Stumpf, P. Studies on biosynthesis of waxes by developing jojoba seed tissue. Lipids 1978, 13, 203–210. [Google Scholar] [CrossRef]

- Ma, C.; Wen, R.; Zhou, F.; Zhao, H.; Bao, X.; Evelina, A.; Long, W.; Wei, Z.; Ma, L.; Liu, J. Preparation and application of an environmentally friendly compound lubricant based biological oil for drilling fluids. Arab. J. Chem. 2022, 15, 103610. [Google Scholar] [CrossRef]

- Fox, N.; Stachowiak, G. Vegetable oil-based lubricants—A review of oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Teerawanichpan, P.; Qiu, X. Fatty acyl-CoA reductase and wax synthase from Euglena gracilis in the biosynthesis of medium-chain wax esters. Lipids 2010, 45, 263–273. [Google Scholar] [CrossRef]

- Keng, P.; Basri, M.; Zakaria, M.; Rahman, M.A.; Ariff, A.; Rahman, R.A.; Salleh, A. Newly synthesized palm esters for cosmetics industry. Ind. Crops Prod. 2009, 29, 37–44. [Google Scholar] [CrossRef]

- Bell, E.W. Wax Esters of Vegetable Oil Fatty Acids Useful as Lubricants. U.S. Patent No. 4,152,278, 1 May 1979. [Google Scholar]

- Domergue, F.; Miklaszewska, M. The production of wax esters in transgenic plants: Towards a sustainable source of bio-lubricants. J. Exp. Bot. 2022, 73, 2817–2834. [Google Scholar] [CrossRef] [PubMed]

- Elongase, F.A. Producing wax esters in transgenic plants by expression of genes derived from jojoba. In Perspect. New Crops New Uses; ASHS Press: Alexandria, VA, USA, 1999; pp. 220–224. [Google Scholar]

- Bondioli, P.; Folegatti, L.; Lazzeri, L.; Palmieri, S. Native Crambe abyssinica oil and its derivatives as renewable lubricants: An approach to improve its quality by chemical and biotechnological processes. Ind. Crops Prod. 1998, 7, 231–238. [Google Scholar] [CrossRef]

- Zhu, L.-H.; Krens, F.; Smith, M.A.; Li, X.; Qi, W.; Van Loo, E.N.; Iven, T.; Feussner, I.; Nazarenus, T.J.; Huai, D. Dedicated industrial oilseed crops as metabolic engineering platforms for sustainable industrial feedstock production. Sci. Rep. 2016, 6, 22181. [Google Scholar] [CrossRef] [PubMed]

- Shirani, A.; Joy, T.; Lager, I.; Lindberg-Yilmaz, J.; Wang, H.-L.; Jeppson, S.; Cahoon, E.B.; Chapman, K.; Stymne, S.; Berman, D. Lubrication characteristics of wax esters from oils produced by a genetically-enhanced oilseed crop. Tribol. Int. 2020, 146, 106234. [Google Scholar] [CrossRef]

- Uniyal, P.; Gaur, P.; Yadav, J.; Khan, T.; Ahmed, O.S. A Review on the Effect of Metal Oxide Nanoparticles on Tribological Properties of Biolubricants. ACS Omega 2024, 9, 12436–12456. [Google Scholar] [CrossRef]

- Kurre, S.K.; Yadav, J. A review on bio-based feedstock, synthesis, and chemical modification to enhance tribological properties of biolubricants. Ind. Crops Prod. 2023, 193, 116122. [Google Scholar] [CrossRef]

- Chowdary, K.; Kotia, A.; Lakshmanan, V.; Elsheikh, A.H.; Ali, M.K.A. A review of the tribological and thermophysical mechanisms of bio-lubricants based nanomaterials in automotive applications. J. Mol. Liq. 2021, 339, 116717. [Google Scholar] [CrossRef]

- Zulkifli, N.W.M.; Kalam, M.A.; Masjuki, H.H.; Yunus, R. Experimental Analysis of Tribological Properties of Biolubricant with Nanoparticle Additive. Procedia Eng. 2013, 68, 152–157. [Google Scholar] [CrossRef]

- Mumtaz, M.; Baqar, Z.; Hussain, N.; Afifa; Bilal, M.; Azam, H.M.H.; Baqir, Q.-u.-a.; Iqbal, H.M.N. Application of nanomaterials for enhanced production of biodiesel, biooil, biogas, bioethanol, and biohydrogen via lignocellulosic biomass transformation. Fuel 2022, 315, 122840. [Google Scholar] [CrossRef]

- Ali, Z.A.A.A.; Takhakh, A.M.; Al-Waily, M. A review of use of nanoparticle additives in lubricants to improve its tribological properties. Mater. Today Proc. 2022, 52, 1442–1450. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiža, R.; Kreivaitis, R.; Asadauskas, S.J.; Bražinskienė, D. Tribologic behaviour and suspension stability of iron and copper nanoparticles in rapeseed and mineral oils. Tribol.-Mater. Surf. Interfaces 2009, 3, 97–102. [Google Scholar] [CrossRef]

- Shaari, M.Z.; Roselina, N.N.; Kasolang, S.; Hyie, K.M.; Murad, M.C.; Bakar, M.A.A. Investigation of tribological properties of palm oil biolubricant modified nanoparticles. J. Teknol. 2015, 76. [Google Scholar] [CrossRef]

- Nagabhooshanam, N.; Baskar, S.; Prabhu, T.R.; Arumugam, S. Evaluation of tribological characteristics of nano zirconia dispersed biodegradable canola oil methyl ester metalworking fluid. Tribol. Int. 2020, 151, 106510. [Google Scholar] [CrossRef]

- Shirani, A.; Hu, Q.; Su, Y.; Joy, T.; Zhu, D.; Berman, D. Combined tribological and bactericidal effect of nanodiamonds as a potential lubricant for artificial joints. ACS Appl. Mater. Interfaces 2019, 11, 43500–43508. [Google Scholar] [CrossRef] [PubMed]

- Xia, W.; Zhao, J.; Cheng, X.; Sun, J.; Wu, H.; Yan, Y.; Jiao, S.; Jiang, Z. Study on growth behaviour of oxide scale and its effects on tribological property of nano-TiO2 additive oil-in-water lubricant. Wear 2017, 376, 792–802. [Google Scholar] [CrossRef]

- Fernández-Silva, S.D.; García-Morales, M.; Ruffel, C.; Delgado, M.A. Influence of the Nanoclay Concentration and Oil Viscosity on the Rheological and Tribological Properties of Nanoclay-Based Ecolubricants. Lubricants 2021, 9, 8. [Google Scholar] [CrossRef]

- Ortega, J.A.; Sayeed Biswas, M.A.; Rahman, M.D.M.; Martinez, V.; Peña-Parás, L.; Maldonado-Cortés, D. Investigating the lubrication performance of vegetable oils reinforced with HNT and MMT nanoclays as green lubricant additives. Wear 2023, 523, 204859. [Google Scholar] [CrossRef]

- García-Morales, M.; Fernández-Silva, S.D.; Roman, C.; Olariu, M.A.; Cidade, M.T.; Delgado, M.A. Preliminary Insights into Electro-Sensitive Ecolubricants: A Comparative Analysis Based on Nanocelluloses and Nanosilicates in Castor Oil. Processes 2020, 8, 1060. [Google Scholar] [CrossRef]

- Biswas, M.A.S.; Rahman, M.M.; Ortega, J.A.; Peña-Parás, L.; Maldonado-Cortés, D.; González, J.A.; Cantú, R.; Campos, A.; Flores, E. Lubrication Performance of Sunflower Oil Reinforced with Halloysite Clay Nanotubes (HNT) as Lubricant Additives. Lubricants 2022, 10, 139. [Google Scholar] [CrossRef]

- Soltannia, B.; Martin-Alarcon, L.; Uhryn, J.; Govedarica, A.; Egberts, P.; Trifkovic, M. Enhanced rheological and tribological properties of nanoenhanced greases by tuning interparticle contacts. J. Colloid Interface Sci. 2023, 645, 560–569. [Google Scholar] [CrossRef] [PubMed]

- Mushtaq, Z.; Hanief, M. Enhancing the tribological characteristics of Jatropha oil using graphene nanoflakes. J. Tribol. 2021, 28, 129–143. [Google Scholar]

- Sadiq, I.O.; Suhaimi, M.A.; Sharif, S.; Mohd Yusof, N.; Hisam, M.J. Enhanced performance of bio-lubricant properties with nano-additives for sustainable lubrication. Ind. Lubr. Tribol. 2022, 74, 995–1006. [Google Scholar] [CrossRef]

- Liñeira del Río, J.M.; Guimarey, M.J.G.; Prado, J.I.; Lugo, L.; López, E.R.; Comuñas, M.J.P. Improving the tribological performance of a biodegradable lubricant adding graphene nanoplatelets as additives. J. Mol. Liq. 2022, 345, 117797. [Google Scholar] [CrossRef]

- Azman, S.S.N.; Zulkifli, N.W.M.; Masjuki, H.; Gulzar, M.; Zahid, R. Study of tribological properties of lubricating oil blend added with graphene nanoplatelets. J. Mater. Res. 2016, 31, 1932–1938. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Macknojia, A.; Ayyagari, A.; Zambrano, D.; Rosenkranz, A.; Shevchenko, E.V.; Berman, D. Superlubricity Induced by MXene MoS2 Nanocomposites on Rough Steel Surfaces under High Contact. ACS Nano 2023, 17, 2421–2430. [Google Scholar] [CrossRef]

- Macknojia, A.Z.; Ayyagari, A.; Shevchenko, E.; Berman, D. MXene/graphene oxide nanocomposites for friction and wear reduction of rough steel surfaces. Sci. Rep. 2023, 13, 11057. [Google Scholar] [CrossRef]

- Marian, M.; Berman, D.; Rota, A.; Jackson, R.; Rosenkranz, A. Layered 2D Nanomaterials to Tailor Friction and Wear in Machine Elements—A Review. Adv. Mater. Interfaces 2021, 9, 2101622. [Google Scholar] [CrossRef]

- Jacques, K.; Murthy, N.; Dixit, S.; Berman, D.; Berkebile, S. Method for Tribological Experiment to Study Scuffing Initiation on AISI 52100 Steel and Hard Ceramic Coatings. Tribol. Int. 2021, 160, 107001. [Google Scholar] [CrossRef]

- Omrani, E.; Siddaiah, A.; Moghadam, A.D.; Garg, U.; Rohatgi, P.; Menezes, P.L. Ball milled graphene nano additives for enhancing sliding contact in vegetable oil. Nanomaterials 2021, 11, 610. [Google Scholar] [CrossRef]

- Marian, M.; Berman, D.; Necas, D.; Emami, N.; Rosenkranz, A. Roadmap for 2D materials in biotribological/biomedical applications—A review. Adv. Coll. Interf. Sci. 2022, 307, 102747. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.S.; Foletto, E.L.; Alves, S.M.; de Castro Dantas, T.N.; Neto, A.A.D. New hydraulic biolubricants based on passion fruit and moringa oils and their epoxy. Ind. Crops Prod. 2015, 69, 362–370. [Google Scholar] [CrossRef]

- Yunus, R.; Fakhru’l-Razi, A.; Ooi, T.L.; Iyuke, S.E.; Perez, J.M. Lubrication properties of trimethylolpropane esters based on palm oil and palm kernel oils. Eur. J. Lipid Sci. Technol. 2004, 106, 52–60. [Google Scholar] [CrossRef]

- Kamalakar, K.; Rajak, A.K.; Prasad, R.; Karuna, M. Rubber seed oil-based biolubricant base stocks: A potential source for hydraulic oils. Ind. Crops Prod. 2013, 51, 249–257. [Google Scholar] [CrossRef]

- Singh, A. Castor oil-based lubricant reduces smoke emission in two-stroke engines. Ind. Crops Prod. 2011, 33, 287–295. [Google Scholar] [CrossRef]

- Arumugam, S.; Sriram, G.; Ellappan, R. Bio-lubricant-biodiesel combination of rapeseed oil: An experimental investigation on engine oil tribology, performance, and emissions of variable compression engine. Energy 2014, 72, 618–627. [Google Scholar] [CrossRef]

- Mannekote, J.K.; Kailas, S.V. Experimental investigation of coconut and palm oils as lubricants in four-stroke engine. Tribol. Online 2011, 6, 76–82. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A. Metalworking fluids from vegetable oils. J. Synth. Lubr. 2006, 23, 167–176. [Google Scholar] [CrossRef]

- John, J.; Bhattacharya, M.; Raynor, P.C. Emulsions containing vegetable oils for cutting fluid application. Colloids Surf. A Physicochem. Eng. Asp. 2004, 237, 141–150. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. Application of vegetable oil-based metalworking fluids in machining ferrous metals—A review. Int. J. Mach. Tools Manuf. 2012, 52, 1–12. [Google Scholar] [CrossRef]

- Muratori, M.; Alexander, M.; Arent, D.; Bazilian, M.; Cazzola, P.; Dede, E.M.; Farrell, J.; Gearhart, C.; Greene, D.; Jenn, A. The rise of electric vehicles—2020 status and future expectations. Prog. Energy 2021, 3, 022002. [Google Scholar] [CrossRef]

- Berman, D.; Farfan-Cabrera, L.I.; Rosenkranz, A.; Erdemir, A. 2D materials for durable and sustainable electric vehicles. Nat. Rev. Mater. 2024, 9, 527–529. [Google Scholar] [CrossRef]

| Property | Mineral Oils | Synthetic (PAO) Oils | Plant-Based Oils |

|---|---|---|---|

| Density, kg·m−3 at 20 °C | 830 to 910 | 800 to 850 | 850 to 950 |

| Viscosity index | 100 | 120 to 140 | 100 to 200 |

| Shear stability | Good | Good | Good |

| Pour point, °C | −15 | −73 to −30 | −20 to +10 |

| Miscibility with mineral oils | n/a | Good | Good |

| Solubility in water | No | No | No |

| Oxidation stability | Good | Good | Moderate |

| Biodegradability | Poor | Moderate | Good |

| Oil | Density at 25 °C, kg/m3 | Kinematic Viscosity at 40 °C, cSt | Oxidation Stability at 110 °C, h | Cloud Point, °C | Flash Point, °C |

|---|---|---|---|---|---|

| Non-edible oils | |||||

| Karanja | 918 | 4.8 | 6 | 9 | 150 |

| Castor | 898 | 15.25 | 1.2 | −14 | 260 |

| Neem | 885 | 5.2 | 7.2 | −6 | 44 |

| Jatropha | 878 | 4.82 | 2.3 | 3 | 136 |

| Tobacco | 887 | 4.25 | 0.8 | n/a | 166 |

| Mahua | 850 | 3.4 | n/a | n/a | 210 |

| Edible oils | |||||

| Coconut | 805 | 2.75 | 35.4 | 0 | 325 |

| Sunflower | 878 | 4.45 | 0.9 | 3 | 252 |

| Linseed | 890 | 3.74 | 0.2 | −4 | 178 |

| Soybean | 885 | 4.05 | 2.1 | 1 | 325 |

| Peanut | 882 | 4.92 | 2.1 | 5 | 177 |

| Olive | 892 | 4.52 | 3.4 | n/a | 318 |

| Rice bran | 886 | 4.95 | 0.5 | 0 | 318 |

| Rape seed | 880 | 4.45 | 7.5 | −3 | 252 |

| Palm | 875 | 5.72 | 4.0 | 13 | 165 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berman, D. Plant-Based Oils for Sustainable Lubrication Solutions—Review. Lubricants 2024, 12, 300. https://doi.org/10.3390/lubricants12090300

Berman D. Plant-Based Oils for Sustainable Lubrication Solutions—Review. Lubricants. 2024; 12(9):300. https://doi.org/10.3390/lubricants12090300

Chicago/Turabian StyleBerman, Diana. 2024. "Plant-Based Oils for Sustainable Lubrication Solutions—Review" Lubricants 12, no. 9: 300. https://doi.org/10.3390/lubricants12090300

APA StyleBerman, D. (2024). Plant-Based Oils for Sustainable Lubrication Solutions—Review. Lubricants, 12(9), 300. https://doi.org/10.3390/lubricants12090300