A Comparison of the Tribological Properties of SiC Coatings Prepared via Atmospheric Plasma Spraying and Chemical Vapor Deposition for Carbon/Carbon Composites

Abstract

1. Introduction

2. Experimental

2.1. Coating Preparation

2.2. Characterization and Analysis

2.3. Tribological Test

3. Results and Discussion

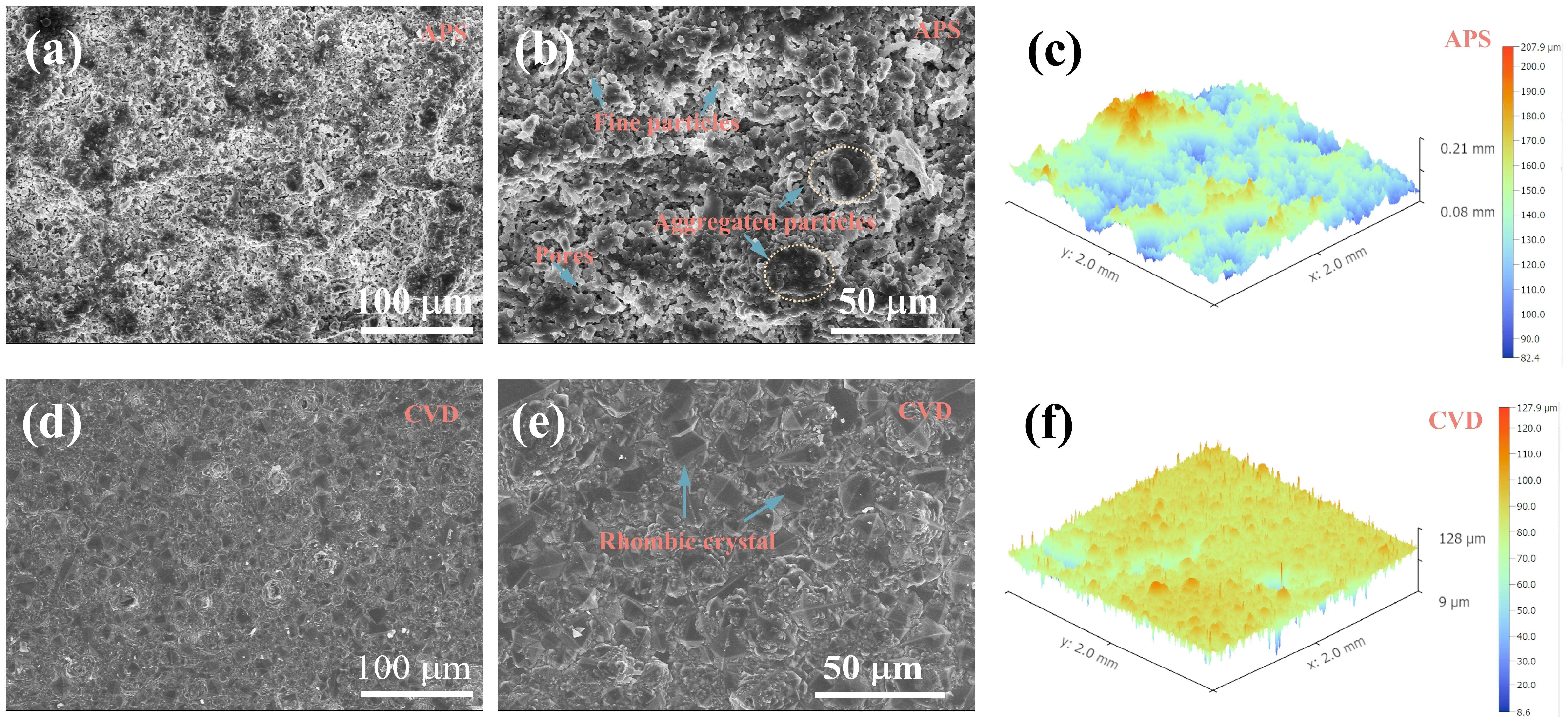

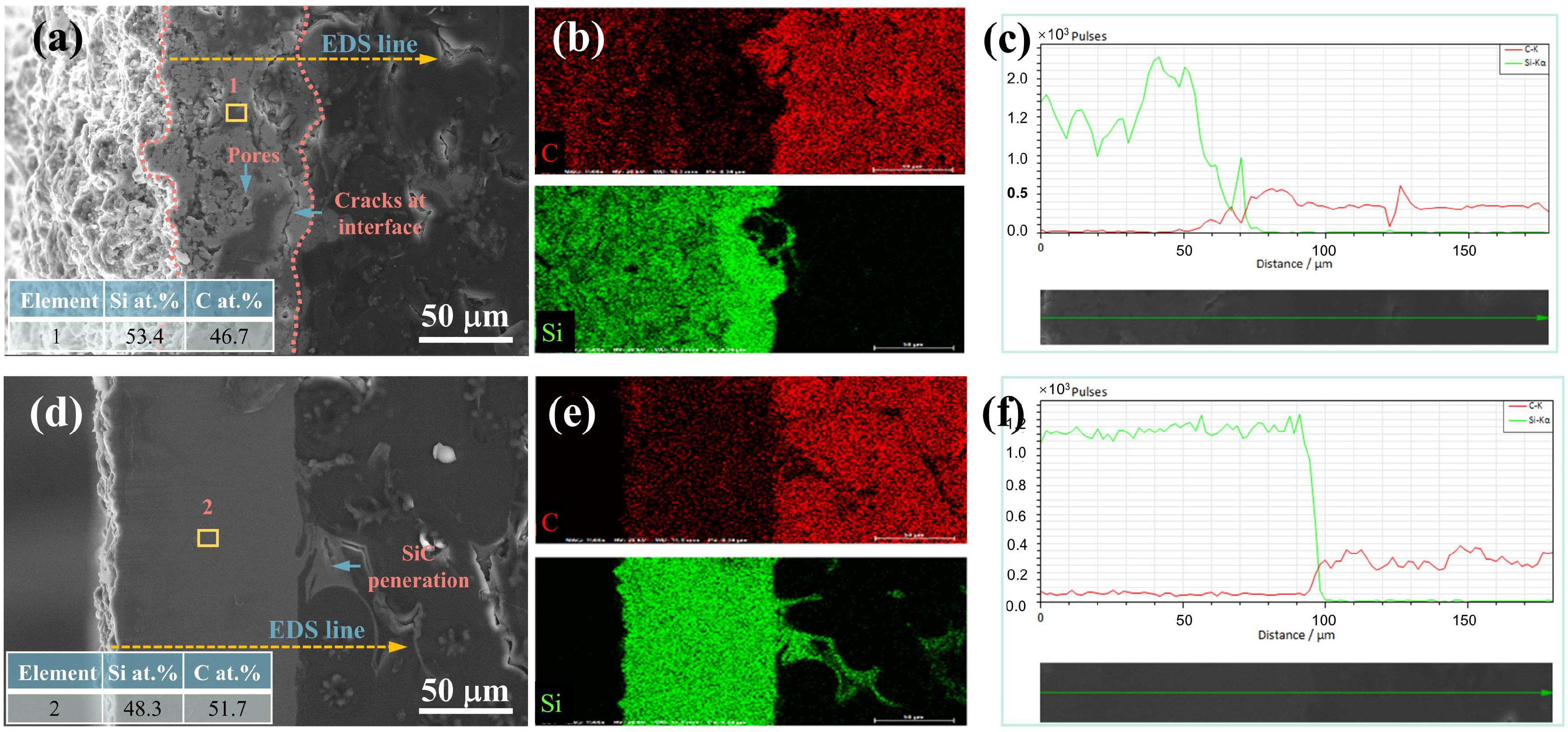

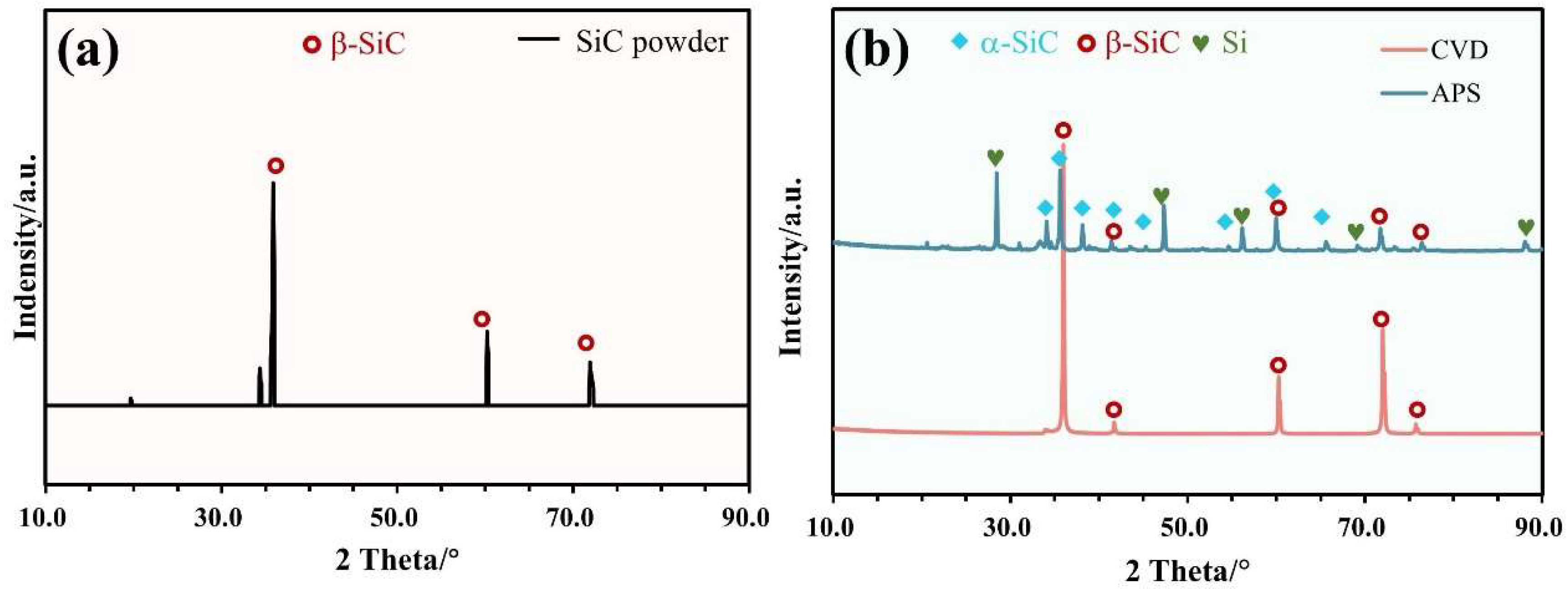

3.1. Characteristics of SiC Coating

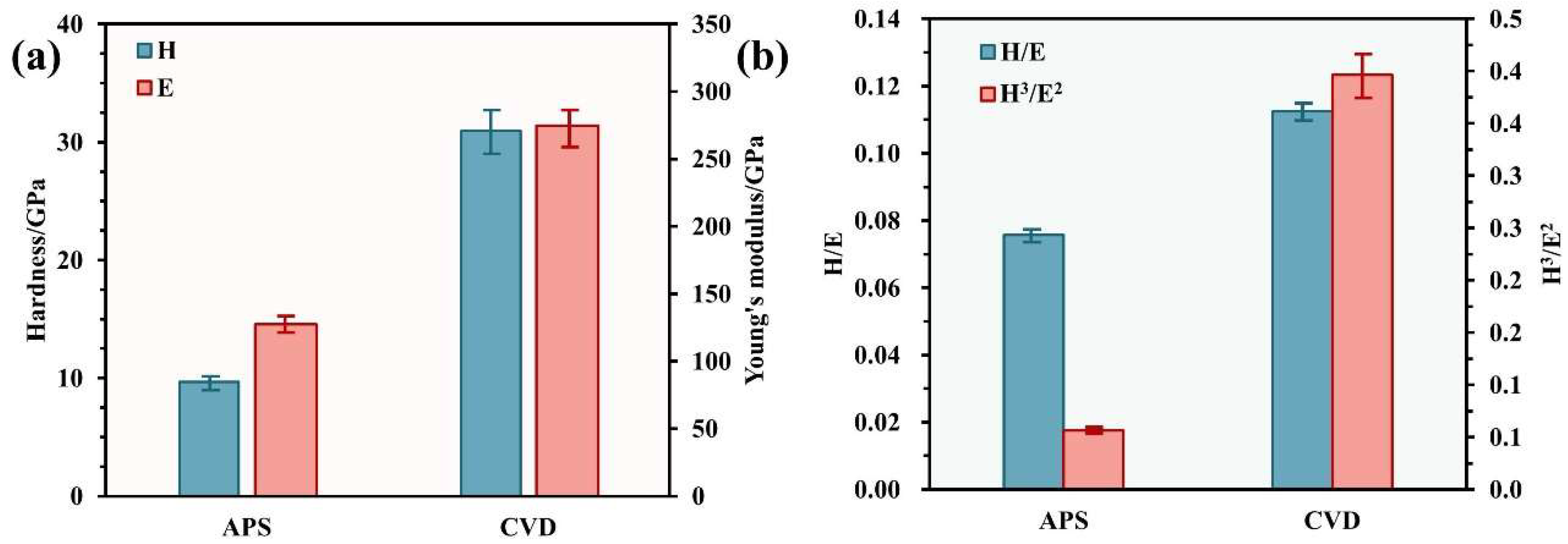

3.2. Mechanical Properties and Adhesive Strength

3.3. Tribological Performance

4. Conclusions

- (1)

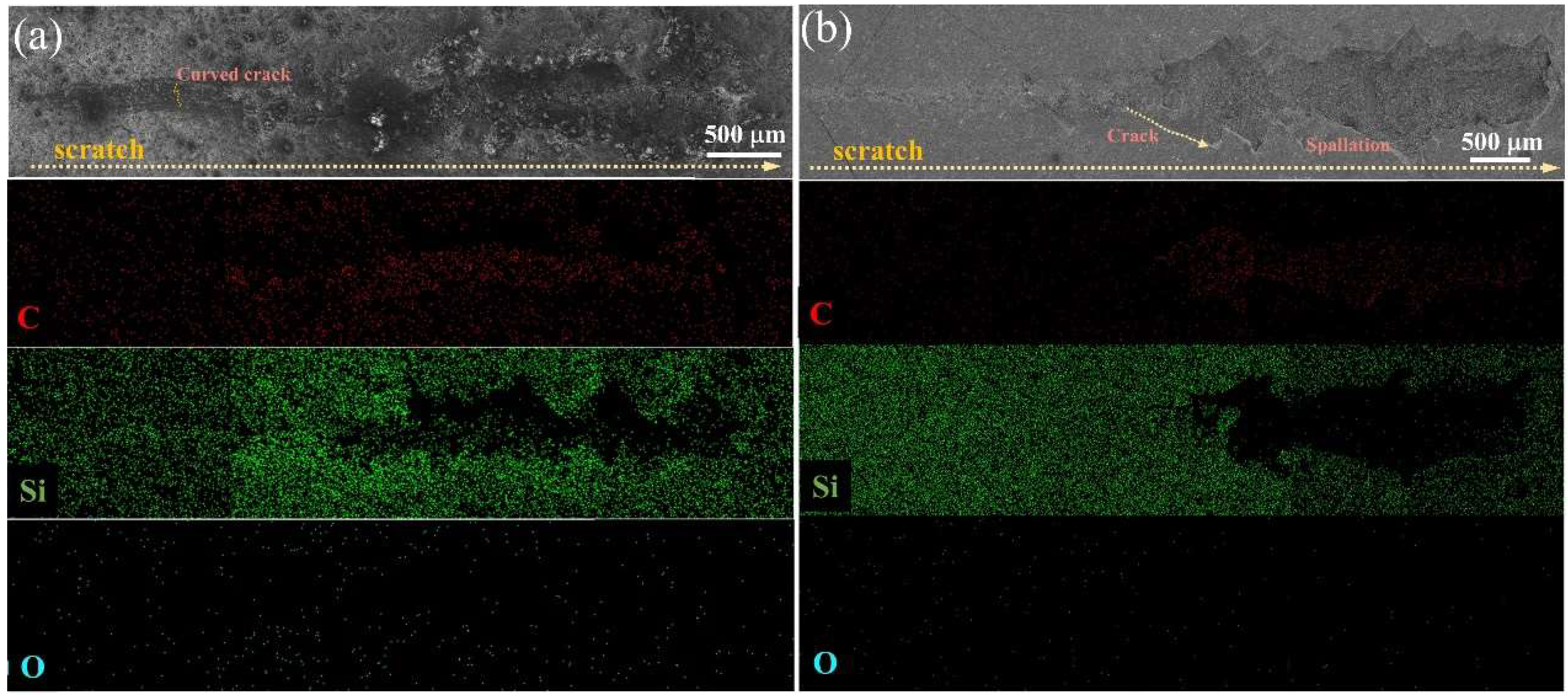

- The surface morphology of the APS-SiC coating was characterized by a porous structure, while the CVD-SiC coating displayed a surface composed of many pyramidal-shaped crystals. The APS-SiC coating is predominantly composed of the α-SiC phase, with a small fraction of the Si phase, whereas the XRD pattern of the CVD-SiC coating is primarily indicative of the β-SiC phase.

- (2)

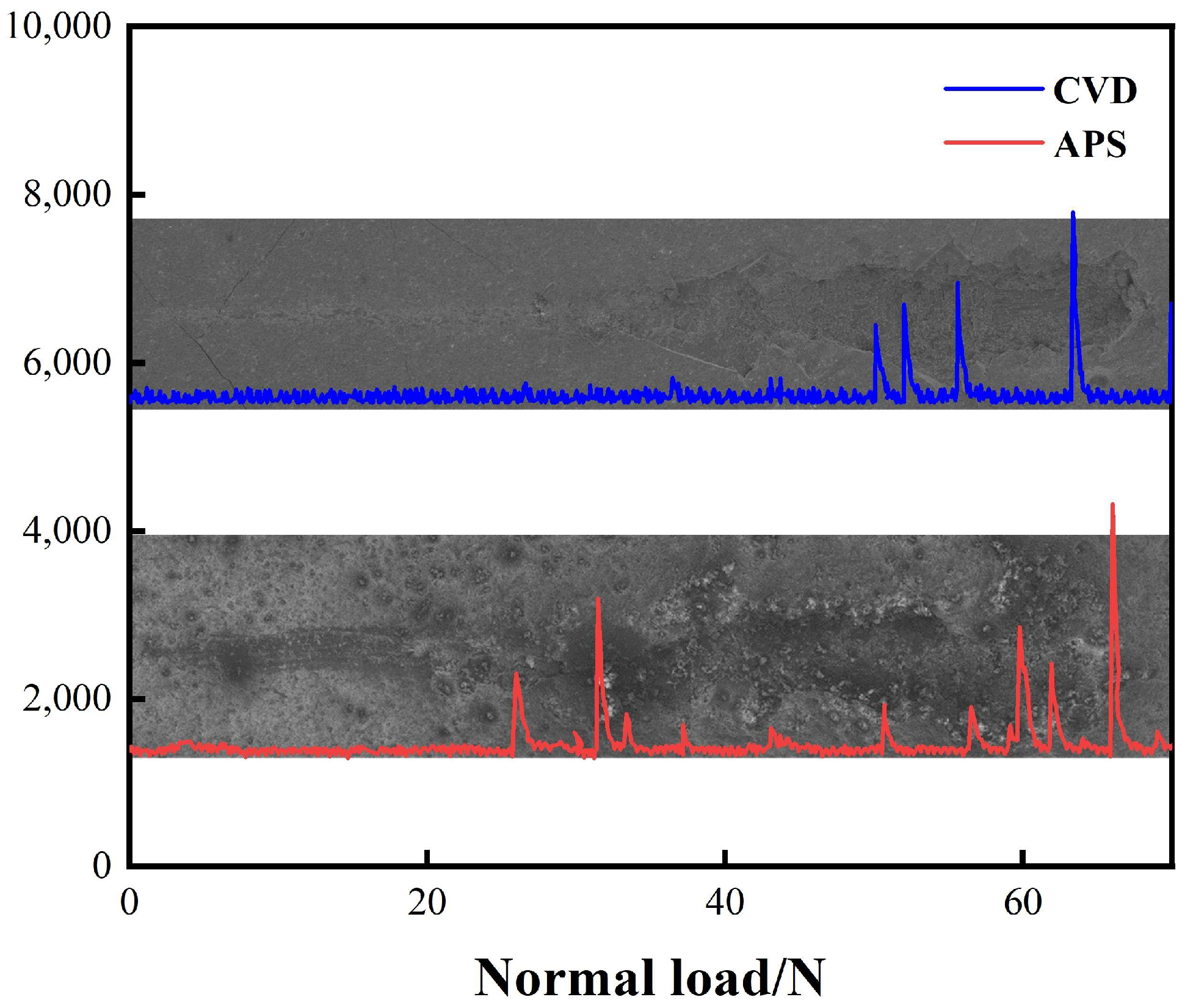

- The hardness and Young’s modulus of the CVD-SiC coating were 31.0 GPa and 275 GPa, respectively. The higher H/E and H3/E2 parameters of the CVD-SiC coating suggested superior plastic resistance, which is also significant for its anti-wear properties. The critical loads for the spallation of the APS-SiC coating and CVD-SiC coating were determined to be approximately 25.9 N and 36.4 N, respectively, indicating that the CVD-SiC coating possesses greater adhesive strength.

- (3)

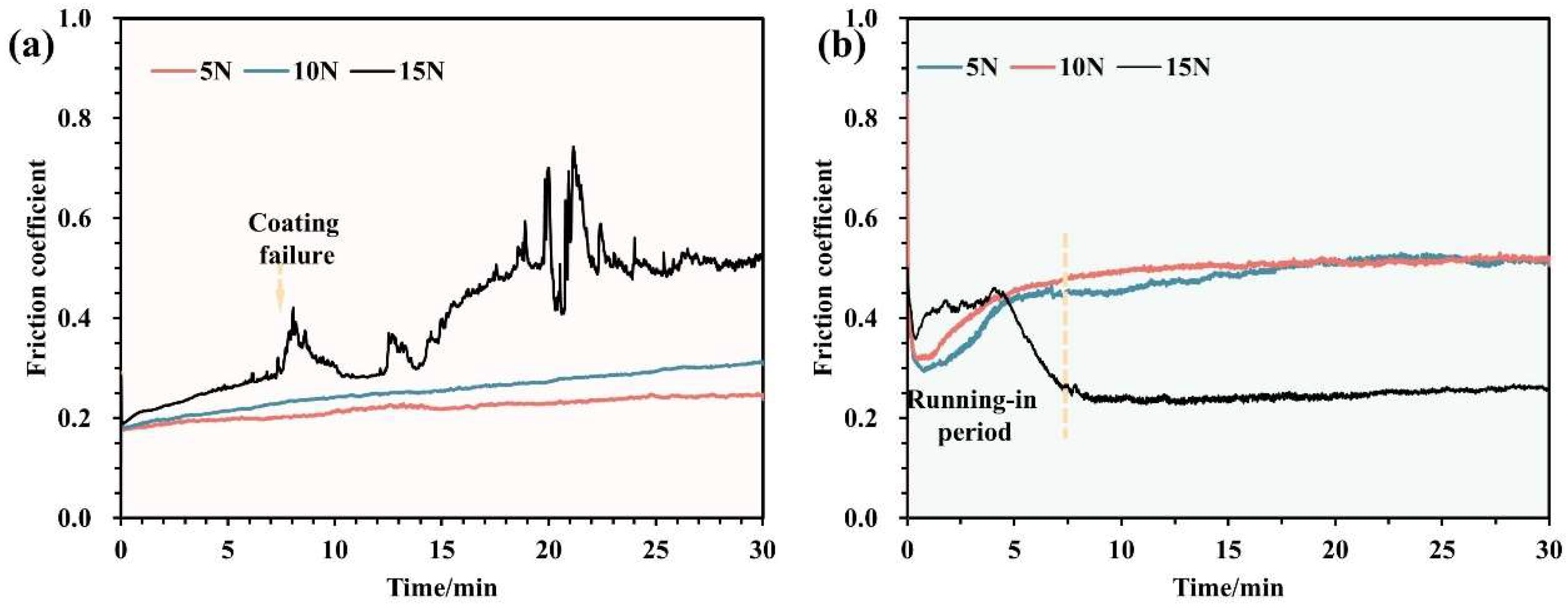

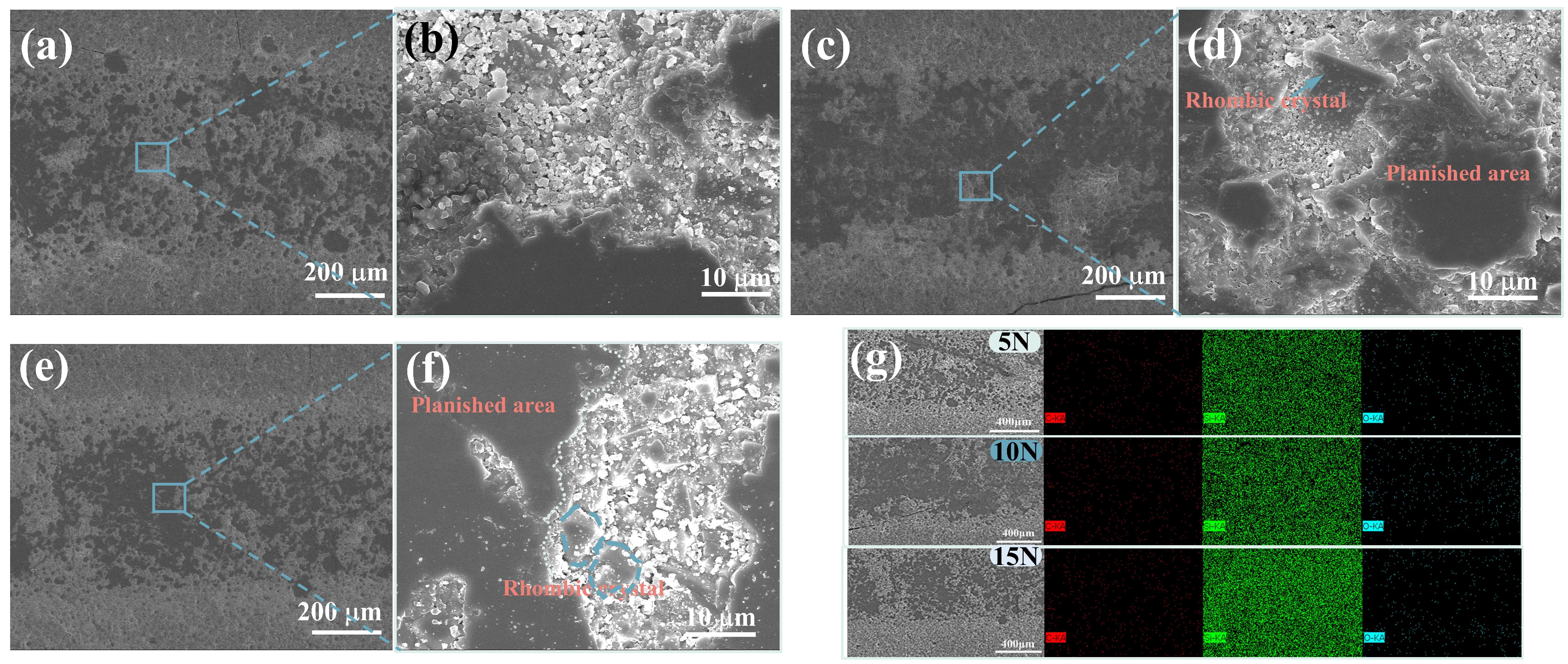

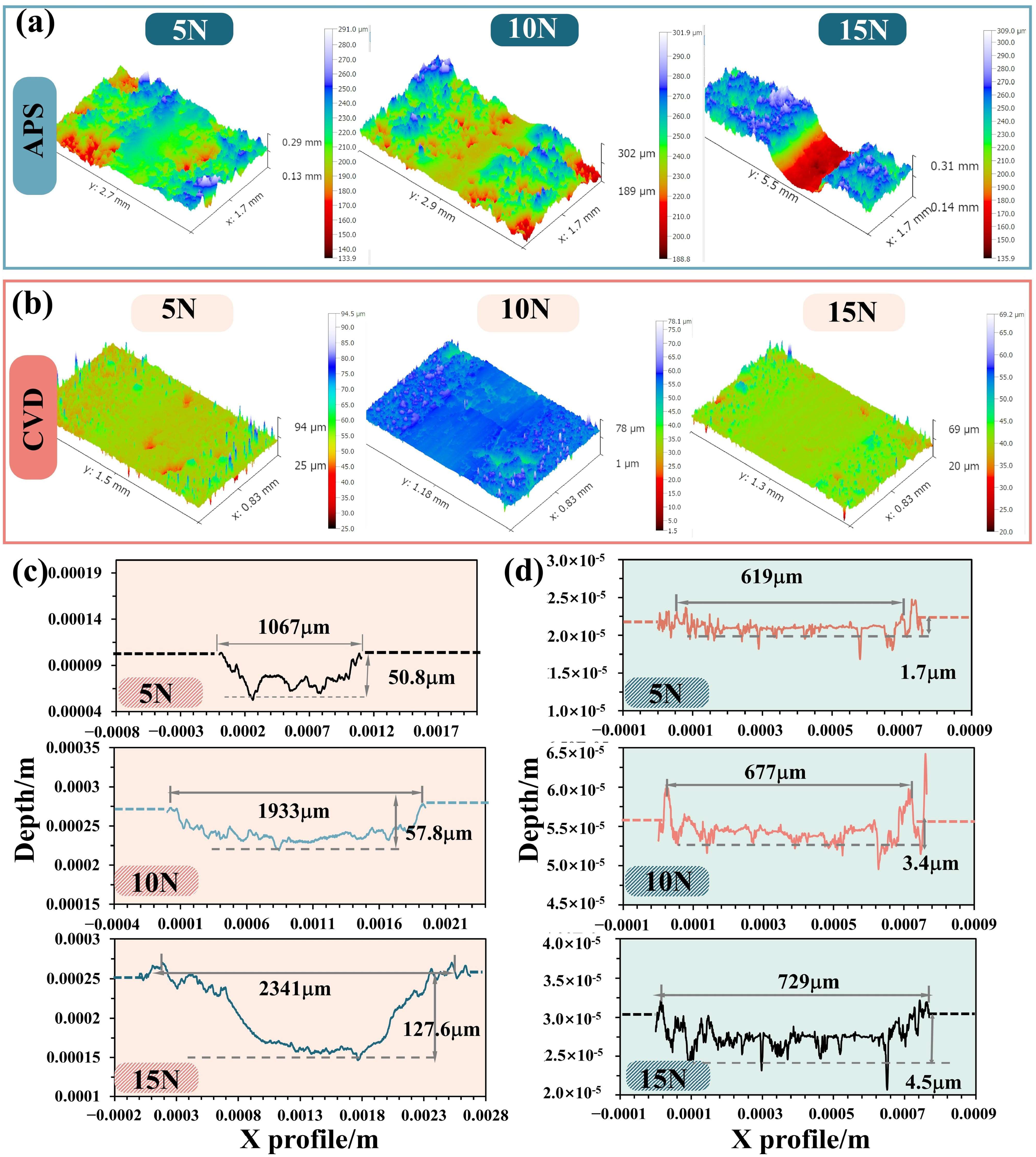

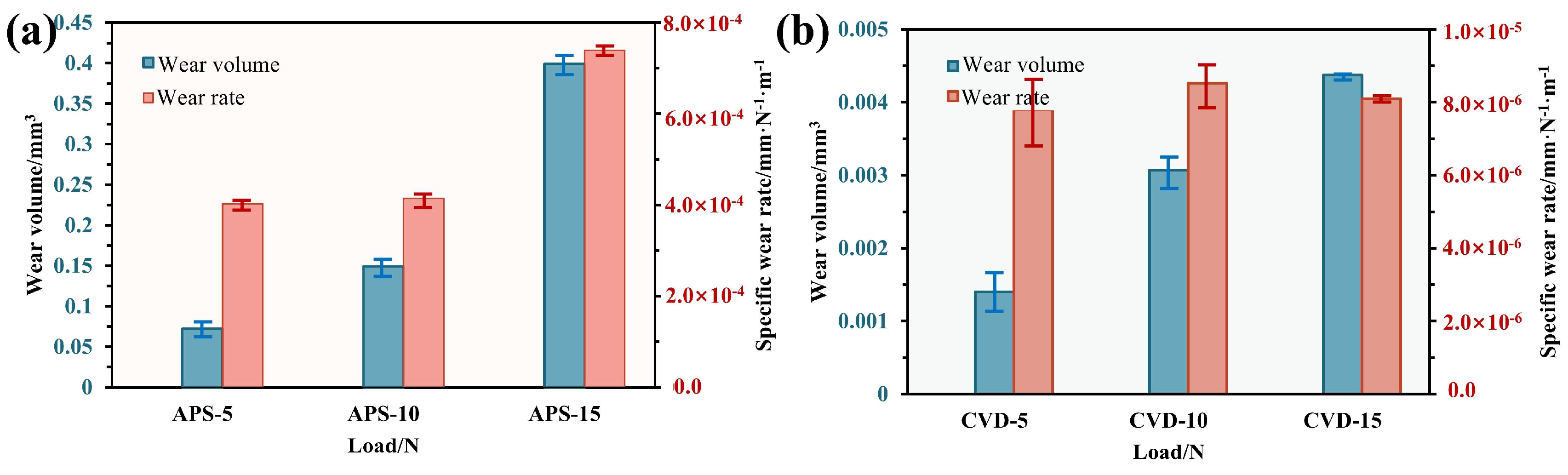

- During the tribological test, the friction coefficient of the APS-SiC coating exhibited significant fluctuations under high load conditions due to the damage to the SiC coating. The CoF of CVD-SiC was higher than that of the APS-SiC coating at loads of 5 and 10 N, but it stabilized at approximately 0.2 at 15 N. The wear morphology of the APS-SiC coatings under all tested loads revealed numerous cracks and wear debris, indicating that abrasive and fatigue wear were the dominant mechanisms. In contrast, the worn tracks of the CVD-SiC coating showed planished asperities and some untouched areas. The wear rate of the CVD-SiC coating was significantly lower than that of the APS-SiC coating, suggesting the superior wear resistance of the CVD-SiC coating.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Guo, L. SiC coating with high crack resistance property for carbon/carbon composites. Ceram. Int. 2022, 48, 1740–1744. [Google Scholar] [CrossRef]

- Kang, K.; Yu, B.; Deng, G.; Wang, P.; Yin, J.; Zhang, H.; Luo, G.; Song, H. Effect of counterpart materials on tribological behaviors of copper impregnated carbon/carbon composite under electric current condition. Ceram. Int. 2023, 49, 30008–30018. [Google Scholar] [CrossRef]

- Buchgraber, W. Carbon/Carbon Composite Friction Discs for Aerospace. Mater. Und Werkst. 2003, 34, 317–321. [Google Scholar] [CrossRef]

- Kogo, Y.; Iijima, Y.; Igata, N.; Ota, K.I. Internal friction of carbon–carbon composites at elevated temperatures. J. Alloys Compd. 2003, 355, 148–153. [Google Scholar] [CrossRef]

- Ju, C.P.; Lin, J.C.; Lee, K.J.; Kuo, H.H. Mulyi-braking tribological behavior of PAN-pitch, PAN-CVI and pitch-resin-CVI carbon-carbon composites. Mater. Chem. Phys. 2000, 64, 196–214. [Google Scholar] [CrossRef]

- Kasem, H.; Bonnamy, S.; Berthier, Y.; Dufrénoy, P.; Jacquemard, P. Tribological, physicochemical and thermal study of the abrupt friction transition during carbon/carbon composite friction. Wear 2009, 267, 846–852. [Google Scholar] [CrossRef]

- Kasem, H.; Bonnamy, S.; Rousseau, B.; Estrade-Szwarckopf, H.; Berthier, Y.; Jacquemard, P. Interdependence between wear process, size of detached particles and CO2 production during carbon/carbon composite friction. Wear 2007, 263, 1220–1229. [Google Scholar] [CrossRef]

- Feng, L.; Guo, L.; Chen, Q.; Tian, R.; Zhang, J.; Song, Q.; Wei, P.; Xiao, C.; Fu, Q. Tailoring the geometry of silicon nitride nanofillers to simultaneously strengthen and toughen carbon/carbon composites. J. Mater. Sci. Technol. 2024, 202, 183–191. [Google Scholar] [CrossRef]

- Zishan, C.; Hejun, L.; Qiangang, F.; Yanhui, C.; Shaolong, W.; Zibo, H. Tribological behavior of SiC coating on C/C composites against SiC and WC under unlubricated sliding. Ceram. Int. 2013, 39, 1765–1773. [Google Scholar] [CrossRef]

- Kumar, P.; Srivastava, V.K. A Review on Wear and Friction Performance of Carbon–Carbon Composites at High Temperature. Int. J. Appl. Ceram. Technol. 2016, 13, 702–710. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, Y.; Su, Y.; Fu, Y.; Zhang, P. SiC-Si coating with micro-pores to protect carbon/carbon composites against oxidation. J. Eur. Ceram. Soc. 2021, 41, 114–120. [Google Scholar] [CrossRef]

- Wu, Q.; Yu, S.; Zhong, H.; Li, X.; Xiao, T.; Liu, L.; Guo, X.; Li, Y.; Nie, Y. Preparation of silicon carbide coating by chemical vapor deposition by using hexamethyldisilylamine precursor. Surf. Coat. Technol. 2018, 334, 78–83. [Google Scholar] [CrossRef]

- Liu, Y.; Miao, Q.; Liang, W.; Lin, H.; Ma, H.; Shi, W.; Xu, X. Effect of Al2O3 addition on the microstructure and oxidation behavior of SiC coating prepared by pack cementation on C/C composites. Ceram. Int. 2021, 47, 29309–29319. [Google Scholar] [CrossRef]

- Huang, J.-F.; Zeng, X.-R.; Li, H.-J.; Xiong, X.-B.; Fu, Y.-W. Influence of the preparation temperature on the phase, microstructure and anti-oxidation property of a SiC coating for C/C composites. Carbon 2004, 42, 1517–1521. [Google Scholar]

- Yang, X.; Huang, Q.; Su, Z.; Chai, L.; Wang, X.; Zhou, L. A double layer nanostructure SiC coating for anti-oxidation protection of carbon/carbon composites prepared by chemical vapor reaction and chemical vapor deposition. Ceram. Int. 2013, 39, 5053–5062. [Google Scholar] [CrossRef]

- Li, N.; Wang, K.; Xu, T.; Gao, J.; Wang, Y.; Wang, W.; Sun, H. Effect of rapid thermal annealing on microstructure, mechanical and tribological properties of amorphous SiC hard coatings. J. Non-Cryst. Solids 2024, 632, 122939. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Basu, D.; Bose, S.; Bandyopadhyay, A. Laser processing of SiC-particle-reinforced coating on titanium. Scr. Mater. 2010, 63, 438–441. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, G.; Bi, Y.; He, J.; Qin, Y.; Yin, F.; Zhao, H. Plasma sprayed TiC–Ti5Si3–Ti3SiC2–SiC composite coatings using annealed Ti–SiC composite powders based on SiC content. Ceram. Int. 2023, 49, 11433–11441. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R. Effect of surface engineering on wear and fatigue behavior of thermally sprayed SiC coating. Surf. Coat. Technol. 2022, 445, 128751. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, Q.; Hu, D.; Wei, Y.; Tong, M.; Zhang, J. Oxidation protective SiC-Si coating for carbon/carbon composites by gaseous silicon infiltration and pack cementation: A comparative investigation. J. Eur. Ceram. Soc. 2021, 41, 194–203. [Google Scholar] [CrossRef]

- Mubarok, F.; Espallargas, N. Tribological behaviour of thermally sprayed silicon carbide coatings. Tribol. Int. 2015, 85, 56–65. [Google Scholar] [CrossRef]

- Krenkel, W.; Heidenreich, B.; Renz, R. C/C-SiC Composites for Advanced Friction Systems. Adv. Eng. Mater. 2002, 4, 427–436. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, Y.; Dong, D.; Yang, Q.; Hu, M. Tribological performance of SiC coating for carbon/carbon composites at elevated temperatures. Ceram. Int. 2018, 44, 11233–11238. [Google Scholar] [CrossRef]

- Berdoyes, I.; Plaisantin, H.; Danet, J.; Lepetitcorps, Y.; Roger, J. The corrosion behavior of various CVD SiC coatings in molten silicon. Ceram. Int. 2024, 50, 3877–3886. [Google Scholar] [CrossRef]

- Hao, K.; Huo, C.; Tu, J.; Sun, L.; Zhang, F.; Li, A.; Du, S. Cl2 corrosion resistance of SiC coatings with different morphologies. Mater. Today Commun. 2024, 39, 108997. [Google Scholar]

- Zhang, Y.-T.; Chen, G.-H.; Sun, J.; Shi, X.-H.; Li, N.; Li, H.-J. Atomic simulation and experimental: Oxidation protective SiC coating produced by chemical vapor deposition and pack cementation for carbon/carbon composites. Surf. Interfaces 2024, 46, 104170. [Google Scholar] [CrossRef]

- Tang, Z.; Yi, M.; Wu, H.; Zhou, Y.; Liu, R.; Jiang, J.; Peng, K. A novel approach for preparing a SiC coating on a C/C-SiC composite by slurry painting and chemical vapor reaction. J. Eur. Ceram. Soc. 2022, 42, 1884–1892. [Google Scholar] [CrossRef]

- Katsui, H.; Shimoda, K.; Hotta, M. Preparation of silicon carbide and tantalum carbonitride composite with high hardness and moderate elastic modulus by laser chemical vapor deposition for anti-erosion protective coatings. Ceram. Int. 2023, 49, 38813–38823. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Amanov, A.; Berkebile, S.P. Enhancement of sliding wear and scratch resistance of two thermally sprayed Cr-based coatings by ultrasonic nanocrystal surface modification. Wear 2023, 512–513, 204555. [Google Scholar] [CrossRef]

- Hogmark, S.; Jacobson, S.; Larsson, M. Design and evaluation of tribological coatings. Wear 2000, 246, 20–33. [Google Scholar] [CrossRef]

- Xu, B.; Guo, P.; Wang, Z.; Chen, R.; Ye, Y.; Shuai, J.; Wang, A.; Ke, P. Anti-wear Cr-V-N coating via V solid solution: Microstructure, mechanical and tribological properties. Surf. Coat. Technol. 2020, 397, 126048. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction and Wear of Materials, 2nd ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Effect of roughness on the wear behavior of HVOF coatings dry sliding against a friction material. Wear 2016, 368–369, 326–334. [Google Scholar] [CrossRef]

- Podgursky, V.; Adoberg, E.; Surženkov, A.; Kimmari, E.; Viljus, M.; Mikli, V.; Hartelt, M.; Wäsche, R.; Šíma, M.; Kulu, P. Dependence of the friction coefficient on roughness parameters during early stage fretting of (Al,Ti)N coated surfaces. Wear 2011, 271, 853–858. [Google Scholar] [CrossRef]

- Chang, K.; Dong, Y.; Zheng, G.; Jiang, X.; Yang, X.; Cheng, X.; Liu, H.; Zhao, G. Friction and wear properties of TiAlN coated tools with different levels of surface integrity. Ceram. Int. 2022, 48, 4433–4443. [Google Scholar] [CrossRef]

- Perfilyev, V.; Moshkovich, A.; Lapsker, I.; Laikhtman, A.; Rapoport, L. The effect of vanadium content and temperature on stick–slip phenomena under friction of CrV(x)N coatings. Wear 2013, 307, 44–51. [Google Scholar] [CrossRef]

| Current /A | Voltage /V | Spray Distance /mm | Plasma Gas (Ar) /L·min−1 | Plasma Gas (H2) /L·min−1 | |

|---|---|---|---|---|---|

| APS | 600 | 90 | 100 | 40 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Y.; Gao, J.; Liang, W.; Miao, Q.; Jia, F.; Chang, X.; Lin, H. A Comparison of the Tribological Properties of SiC Coatings Prepared via Atmospheric Plasma Spraying and Chemical Vapor Deposition for Carbon/Carbon Composites. Lubricants 2024, 12, 301. https://doi.org/10.3390/lubricants12090301

Qi Y, Gao J, Liang W, Miao Q, Jia F, Chang X, Lin H. A Comparison of the Tribological Properties of SiC Coatings Prepared via Atmospheric Plasma Spraying and Chemical Vapor Deposition for Carbon/Carbon Composites. Lubricants. 2024; 12(9):301. https://doi.org/10.3390/lubricants12090301

Chicago/Turabian StyleQi, Yan, Jiumei Gao, Wenping Liang, Qiang Miao, Feilong Jia, Xiangle Chang, and Hao Lin. 2024. "A Comparison of the Tribological Properties of SiC Coatings Prepared via Atmospheric Plasma Spraying and Chemical Vapor Deposition for Carbon/Carbon Composites" Lubricants 12, no. 9: 301. https://doi.org/10.3390/lubricants12090301

APA StyleQi, Y., Gao, J., Liang, W., Miao, Q., Jia, F., Chang, X., & Lin, H. (2024). A Comparison of the Tribological Properties of SiC Coatings Prepared via Atmospheric Plasma Spraying and Chemical Vapor Deposition for Carbon/Carbon Composites. Lubricants, 12(9), 301. https://doi.org/10.3390/lubricants12090301