1. Introduction

Hydrodynamic linear guides (HDGs) are essential components in various engineering applications, facilitating precise and smooth linear motion due to good damping properties. They are successfully used not only in large machines but also in medium-sized machines [

1]. They have a good damping coefficient, are low cost [

2], and lead to high-quality machined surfaces. Therefore, this type of guideway remains crucial for the feed axes in numerous machine tools [

2]. Contrary to the constant supply of lubricant in hydrostatic bearing, the efficiency is better. The constant supply of lubricant in hydrostatic bearings increases the running cost, which reduces the efficiency; whereas, roller bearing leads to low-quality machine surfaces due to the dynamic excitation of rolling contact. The wear caused by friction is considered the main reason for the failure of mechanical systems and the major source of energy loss [

3]. Depending on the application, a static surface pressure of approximately p

stat = 0.5 MPa, corresponding to the weight load (F

stat), is recommended for the bearing surfaces of the guideways [

4]. However, significantly lower values are used for higher dynamics of the feed axis, such as in grinding machines [

5,

6]. The hydrodynamic (HD) pressure is generated due to wedge-shaped film and relative movement between the guide surfaces. The initial moment of floating and forming a lubrication wedge is due to oil inlet pressure [

6]. One of the key parameters in hydrodynamic guides is the oil film pressure, which influences the operation of guides [

2,

7]. The accuracy of the straight-line motion of machine tool tables with a hydrodynamic linear guide is influenced not only by the geometry of the guideway, but also the thickness of the lubricant films [

8]. The floating heights of a hydrodynamically lubricated guide are inconsistent depending on the speed and load, assuming a sufficient oil supply and constant viscosity of the lubricant. In machine tools, however, the change of state of friction is undesirable [

8]. Additionally, the presence of mixed friction regimes during start-up and deceleration phases introduces instability and potential wear, adversely affecting system accuracy and efficiency. Furthermore, issues such as air entrapment within the lubrication gap and variations in oil film pressure further compound the complexities of lubrication dynamics, leading to suboptimal performance and potential mechanical failure. Understanding lubrication conditions is crucial for mitigating challenges (adverse effects of dynamic changes in floating heights and mixed friction regimes) in hydrodynamic linear guides. Therefore, the primary objective of this study is to gain insight into the lubrication conditions (with the help of pressure sensors) within the lubrication gap and propose solutions to improve the lubrication conditions, which enhance the performance and reliability of hydrodynamic linear guides in engineering applications.

3. Literature Review

In the domain of hydrodynamic linear guides, this study pioneers the integration of sensors to measure oil film pressure within the lubrication gap, filling a significant gap in existing research. Despite decades of research in this area, there has been a notable absence of methods to measure oil film pressure in hydrodynamic linear guides. While experimental efforts dating back to 1969 have focused on measuring dynamic friction and floating heights/film thicknesses, the absence of a developed method for oil film pressure measurement underscores the novelty and importance of our research endeavor. Our research addresses this gap by introducing an innovative approach, aiming to deepen the understanding of lubrication dynamics in hydrodynamic linear guides. However, the existing literature was reviewed to examine variable dependencies, the design of lubrication grooves, pressure measurement for other applications, and types of lubrication.

In their experimental research, Shiozaki et al. [

5] investigated the effects of lubricant viscosity on film thickness and frictional resistance in models and surface grinding machines through an oil bath lubrication method. The study demonstrated that film thickness increases at the leading edge and decreases at the trailing edge as the table moves, with a minimum thickness exceeding 10 µm. A direct relationship between the table speed and the inclination was observed, indicating that speed influences system dynamics. Additionally, increased load slightly reduced film thickness, pointing to a complex relationship between lubricant efficiency and load. Remarkably, higher speeds ensured consistent frictional resistance, even with changes in slider inclination, and higher viscosity reduced the speeds at which frictional resistance was minimized. The findings emphasize the importance of selecting appropriate lubricants and operational parameters to minimize friction and enhance efficiency in surface grinding processes. The study, however, did not address oil film pressure in the lubrication gap, a crucial aspect for understanding lubrication conditions.

Kortendieck et al. [

8] explored the complexity of lubrication in hydrodynamically lubricated linear guides in machine tools, highlighting the importance of effective oil distribution for minimizing friction and ensuring smooth operations. Through an experimental setup involving a 900 mm long table with a maximum stroke of 150 mm and a feed rate of 3.8 m/min, the study underlines the necessity of optimizing lubricant distribution across sliding surfaces, considering surface smoothness, gap size, and viscosity. This study presents design recommendations for lubrication grooves, emphasizing perpendicular orientation, comprehensive coverage, and strategic placement. These recommendations aim to enhance oil supply and maintain lubrication film integrity, which are crucial for reducing losses and ensuring precision in machining applications. The research also examines the impact of motion sequences on lubricant behavior and the importance of accommodating gap height variations, concluding that a thorough understanding of lubrication dynamics and strategic design is vital for improving the performance and durability of machine tool sliding guides.

Gläser et al. [

9] developed a simulation model by applying the finite difference method to the Reynolds equation [

10] to estimate the floating angle. The conformity of the floating angle between the numerical and simulated results was good at velocities up to 40 m/min. On the one hand, they measured friction coefficients of sliding surfaces with very low variations and on the other hand, with a slight concavity deviation of the flatness. It has been realized that with concave sliding surfaces there is relatively 60% more friction and the floating angle showed irregular behavior.

Zhang et al. [

11] continued the work of Gläser et al. [

9] and estimated the oil film pressure and floating heights of HDGs using a 2D simulation model (single-phase) based on the Reynolds equation [

10]. However, due to the unavailability of a pressure measurement system, the simulation model was calibrated using only experimental floating heights (measured using eddy current sensors). The lubrication was adjusted subjectively by visual inspection. Both Gläser et. al. [

9] and Zhang et. al. [

11] used only two lubrication grooves close to the ends of the carriage. Neugebauer et al. [

12] have also studied various shapes of the lubrication gap and their effects on oil film pressure.

Optical sensors can be used as an alternative to eddy current sensors for measuring oil film thickness in hydrodynamically lubricated bearings, as demonstrated in [

13,

14]. These sensors work by transmitting light through the lubricant film and reflecting it from the shaft surface back to the sensor. However, they tend to be more expensive due to their use of advanced technologies such as Fiber Bragg Grating [

15] or Fabry–Perot interferometry [

16].

Previously, 16 manometer tubes were used by Sinanoglu et al. [

17] to study the pressure development in journal bearings under different velocity variations and various shaft surface textures [

17]. Additionally, Ichikawa et al. [

18], Mihara et al. [

19,

20], Mihara and Someya [

21], and Someya and Mihara [

22] used thin film sensors, consisting of thin material layers with a total thickness of 6 µm, on the sliding surface of bearings to measure the oil film pressure in journal bearings. Mihara and Someya [

21] conducted oil film pressure measurements, along with temperature and strain measurements, on the bearing surface in an engine test. Ronkanien et al. [

23] used optical pressure sensors to measure the oil film pressure in journal bearings. Iwata et al. [

24] displayed the successful implementation of a recently created thin film sensor for gauging the distribution of oil film pressure in the main bearings of high-speed motorcycle engines. The results of the study emphasize the significance of accurate oil film pressure measurement in optimizing engine performance, thereby offering valuable insights for further exploration and improvement in engine design and lubrication systems.

Previous research efforts have laid the groundwork for the current investigation, emphasizing the critical role of proper lubrication in achieving optimal performance and longevity in linear guide systems. Ibrar et al. [

25] and Wittstock et al. [

26] developed an integration method for strain gauge miniature pressure sensors into the rail to measure hydrodynamic pressure generated inside a lubrication gap. This method is further used in this study to understand the lubrication conditions and influencing parameters. These findings serve as a pertinent reference point for the advancement of similar technology in diverse applications. Firstly, based on [

27,

28], the pressure sensors were installed in an identical rail made of acrylic glass (Plexiglas) for easier fabrication. Different integration methods were tested in the Plexiglas rail to measure the pressure and observe the oil or trapped air [

25]. Subsequently, the finalized integration method, which showed a significant improvement in pressure measurement, was used to integrate pressure sensors into the steel rail [

25]. The author also calibrated the pressure sensors statically and dynamically before and after integrating them into the steel rail [

25]. This novel approach enables a comprehensive evaluation of lubrication dynamics and system behavior under dynamic operating conditions, paving the way for informed decisions in lubrication strategy optimization and maintenance practices.

4. Experimental Setup

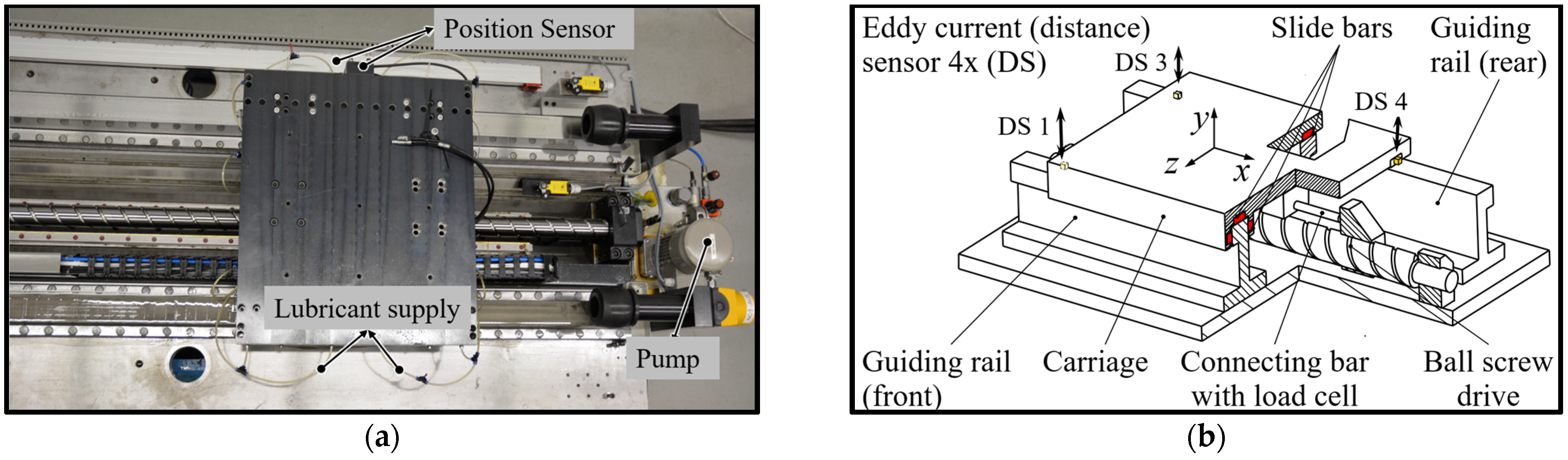

Figure 1 depicts the hydrodynamic linear guide system used in this study. The system features a carriage with two sliding bars that move over two parallel steel rails. Distance eddy current sensors are mounted at each of the four ends of the carriage to measure the lubrication gap, as well as the roll and pitch of the carriage. Shell Tonna S-68 lubricant is used, with a density of 879 kg/m

3 and a viscosity of 68 mm

2/s at 40 °C (8.6 mm

2/s at 100 °C). Pressure sensors have a round sensing surface with a diameter of 6 mm and a thickness of 0.6 mm. Seven strain gauge pressure sensors by Kyowa [

29] named “PS-5KD”, calibrated, are integrated into a steel rail (integration method is shown in

Figure 2c) to provide a detailed examination of the pressure within the lubricating gap. The pressure sensor comprises miniature strain gauge pressure sensors that can safely operate within a temperature range of −20 to 70 °C [

29], allowing for the measurement of oil film pressure inside the lubrication gap. The pressure rise rate is 213 bar/s.

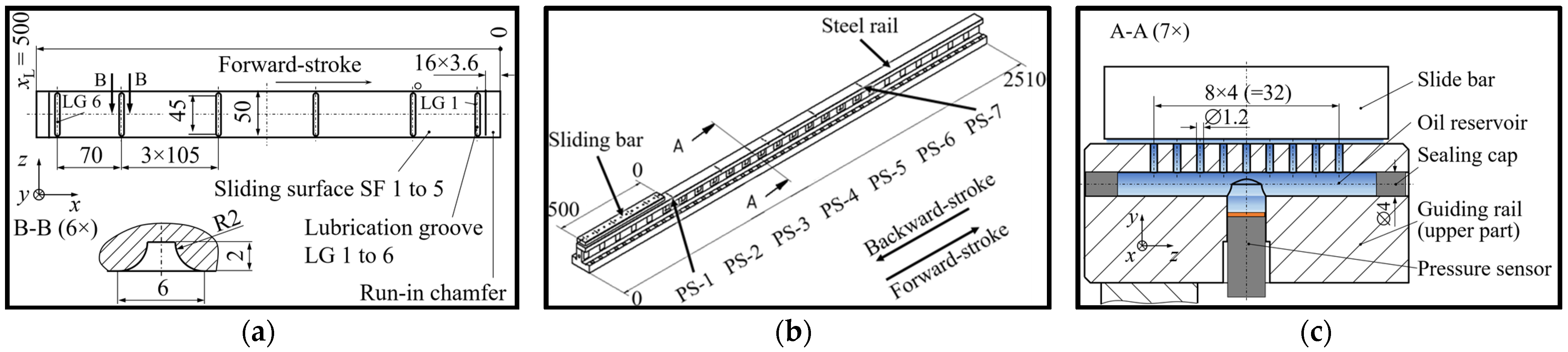

Figure 2a demonstrates the inclusion of six lubrication grooves, LG 1 to 6, in each sliding bar accompanied by four holes with a diameter of 1.8 mm in each groove to supply lubricant in the lubrication gap. The sliding bars have undergone precise machining to guarantee an optimal and seamless contact with the steel rails if no lubrication oil is supplied. This was assessed using contact paper. With the help of pressure sensors, it has been realized that two lubrication grooves (used in [

9,

10]) are not sufficient to lubricate the 500 mm long lubrication gap irrespective of the lubrication time. Contrary to [

9,

10], a combination of two, four, and six oil-supplied lubrication grooves have been compared using integrated pressure sensors to test which combination improves the lubrication conditions.

Figure 2b,c illustrates the inclusion of the pressure sensors PS 1 to PS 7 in the steel rail, allowing for accurate monitoring of the oil film pressure in a longitudinal manner along the length of the carriage. However, it is important to note that these sensor systems are unable to detect pressure variations across the width of the rail (average pressure in transverse direction). The distances between the pressure sensors are as follows: 5 mm from the start position of the sliding bar to PS1, 300 mm from PS1 to PS2, 200 mm from PS2 to PS3, 100 mm from PS3 to PS4 and from PS4 to PS5, 200 mm from PS5 to PS6, and 300 mm from PS6 to PS7.

Integrating sensors into the steel rail enables the full utilization of the 1.7 m stroke length, allowing for a maximum feed rate of 100 m/min in both forward and backward directions. The pressure data are obtained throughout the extensive range of constant velocity, acceleration, and deceleration of the carriage. Nevertheless, limitations such as the stick-slip effect and the necessity to minimize abrupt motion of the carriage restrict the attainable range of both acceleration and deceleration (3 m/s2).

The advantage of integrating pressure sensors in a steel rail is that both oil film pressure and floating heights can be measured simultaneously. The steel rail, composed of P20/1.2311 (40-CrMnMo-7) grade alloy tool steel, has undergone quenching and tempering procedures to achieve an impressive strength of 1000 N/mm2. Furthermore, gas-nitriding techniques have been applied, achieving a hardening depth of 0.3 mm and a hardness level of 600 HV.

Utilizing a screw-drive mechanism, the system operates with a force sensor strategically placed between the ball screw drive and carriage to gauge the applied force precisely. To eliminate any horizontal shifting, roller bearing side guiding is incorporated on rear side of the carriage, utilizing a steel rail without pressure sensors. In contrast, the carriage exclusively interfaces with one side of the front steel rail, which includes integrated sensors, ensuring optimal performance through hydrodynamic lubrication.

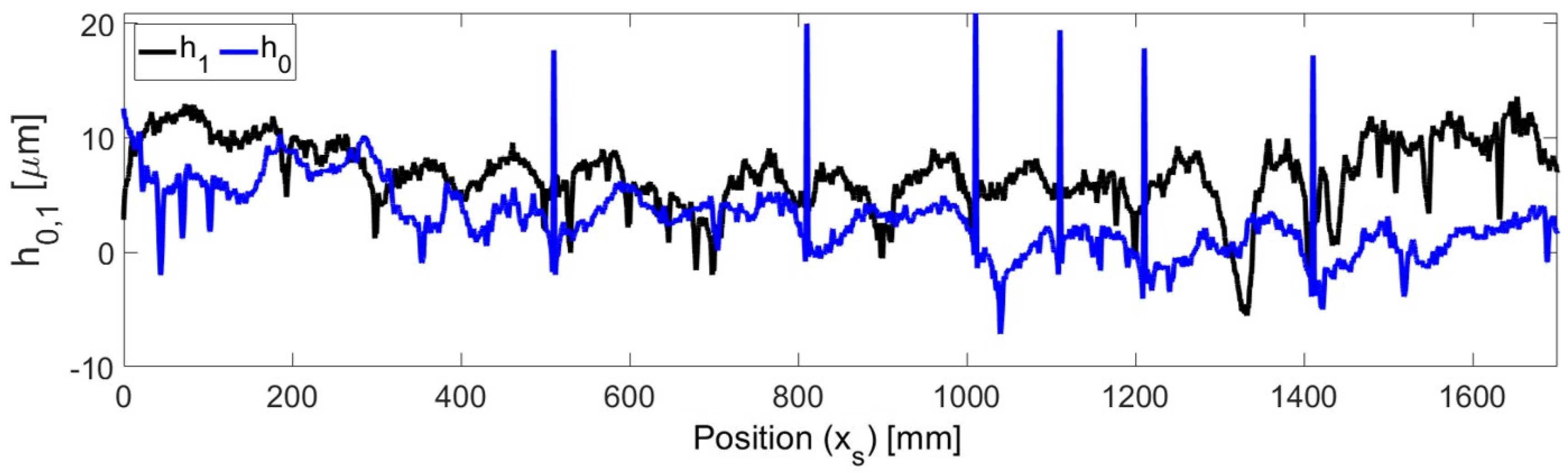

To obtain the rail surface profile, a dry run of the carriage was conducted without the application of lubricant, operating at a speed of 0.1 m/min, which is one-tenth of the minimum speed used for measurements. The detected profile (as shown in

Figure 3) is then subtracted from the actual measured floating heights and yields the absolute and realistic floating height values.

Before using the slide bars with six oil-supplied lubrication grooves to measure the pressure, it was necessary to evaluate the contact pattern between the sliding bar and the steel rail with integrated sensors [

25]. Ink spots were applied to the steel rail, and the bars were meticulously cleaned to remove any oil from the lubrication gap. The carriage was then placed on both steel rails and moved back and forth to examine the surface contact. This analysis uncovered an irregular and nonuniform contact pattern between the sliding bar and the steel rail, leading to low or negative pressure readings in areas with insufficient contact. Nevertheless, this situation accurately reflects the real-world conditions experienced in machine tools.

5. Experimental Design

In this research study, a series of experiments was meticulously designed as shown in

Table 1 to investigate the impact of various factors on pressure measurements within the lubrication system. Specifically, the experiments were structured to analyze the influence of different parameters, including feed rate variations (10, 20, 30, 40, and 50 m/min), lubrication time (duration of lubricant supply), pause time (interval between lubrication supply and measurement stroke), static pressure p

stat (ratio of the weight of the carriage to the contact surface area between the rail and the carriage), and the number of oil-supplied lubrication grooves present. By systematically altering these variables across multiple experimental setups, the study aimed to understand how each factor contributes to variations in pressure measurements. This approach allowed for a detailed examination of the intricate dynamics within the lubrication system, providing valuable insights into its behavior under diverse operating conditions.

Due to unidentified issues, the pressure sensor PS 3 displayed errors throughout from Exp. No. 10 to Exp. No. 18. As a result, the data collected from PS 3 during these experiments have been deemed unreliable and has been omitted from the analysis.

The lubrication cycle employed in the study consisted of several key phases as shown in

Figure 4. Initially, lubrication was applied to the system, followed by a variable pause time to allow for proper distribution and settling of the lubricant. Subsequently, measurements were taken during the forward stroke of the system to assess its performance under lubricated conditions. After this, the lubrication process was repeated, followed by another variable pause period, before measurements were taken during the system’s backward stroke. Each stroke is separated by the addition of the lubrication interval (t

L) and the pause time (t

P). This cycle was repeated five times to ensure thorough data collection and consistency in the experimental procedure.

In this study, the analysis of the influence of different static pressures on pressure measurement and system performance was not discussed, because this aspect was already covered by Ibrar et al. [

25] during the development of the integration method for pressure sensors.

6. Analysis and Findings

Analysis methodology of pressure and floating: Floating thicknesses of the oil film (h

0 and h

1) depend directly on lubrication cycle parameters. As the lubricant enters the gap between the slide bar and rail (see

Figure 1 and

Figure 2), the floating heights increase; when lubrication stops, the height decreases due to the squeezing effect. Initial floating heights significantly influence the pressure within the lubrication gap. Pressure sensors provide critical real-time data on lubrication conditions, essential for improving lubrication and preventing failure.

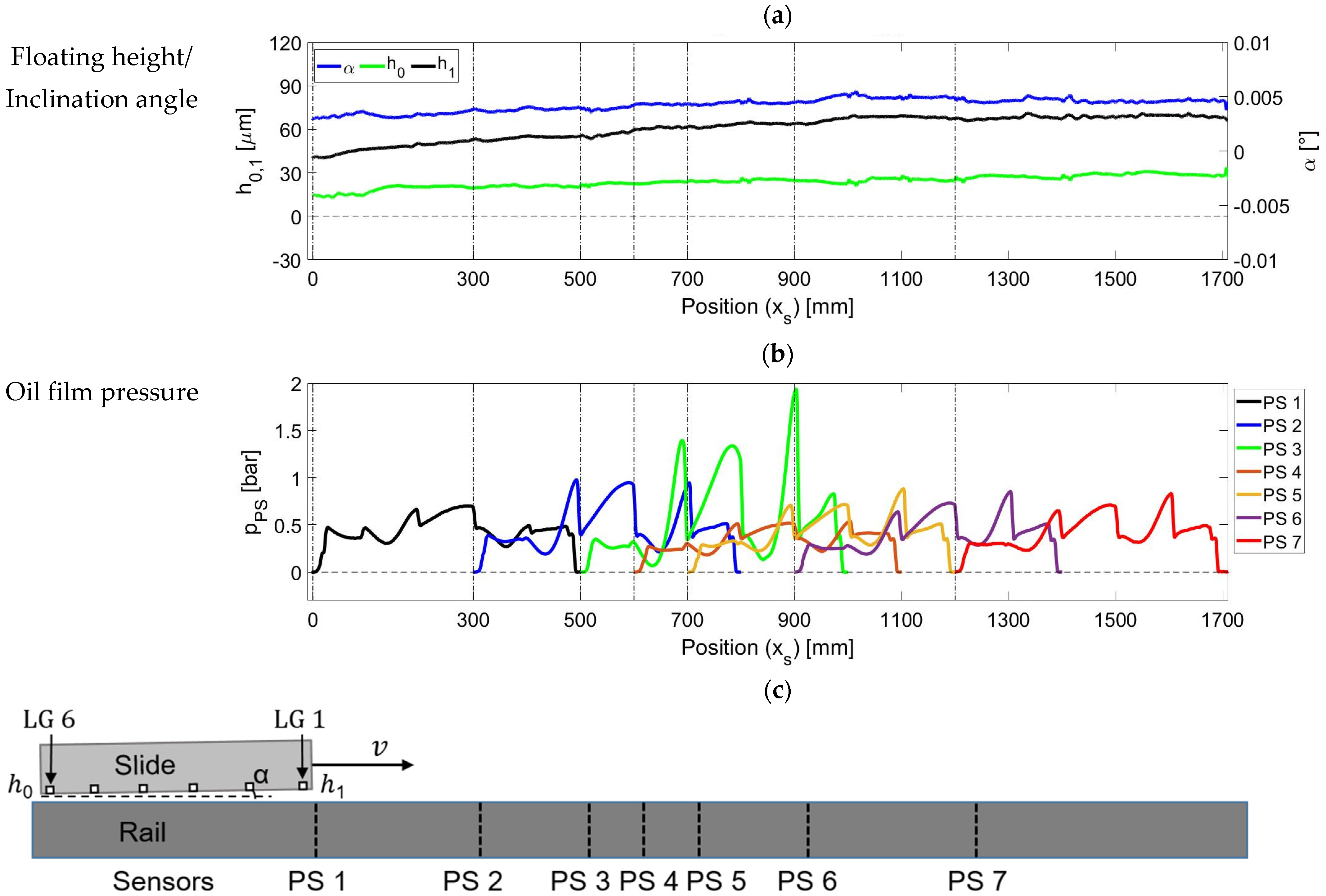

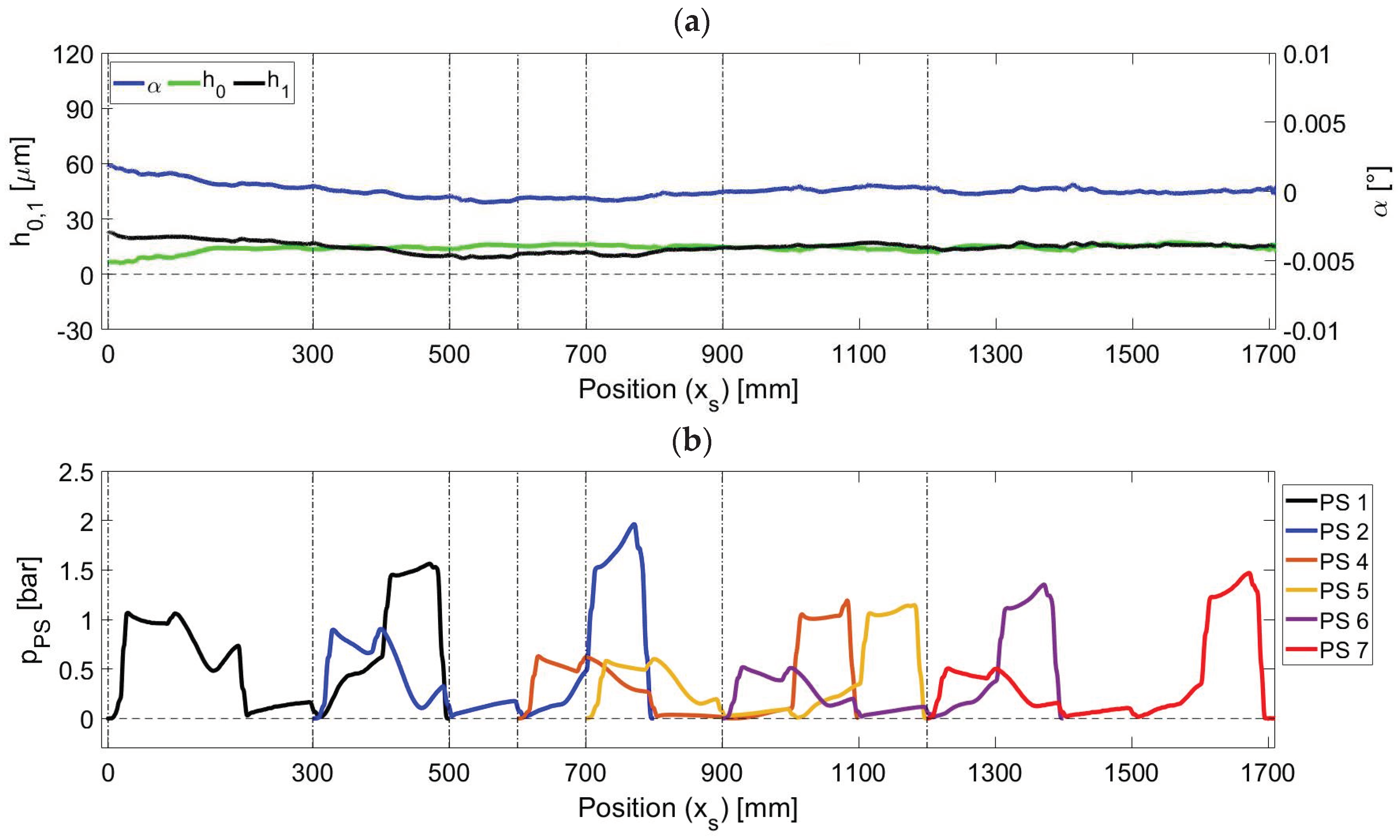

To grasp the pressure curves and floating heights measured, the data from Exp. No. 3 are presented in

Figure 5, where the pressure curves closely resemble the ideal scenario of an excellent floating behavior. The floating heights and pressure were measured during an exemplary forward stroke with relatively high feed rates of 30 m/min, with a static pressure of 0.7 bar and a 5 s pause time.

Figure 5a shows floating heights at both the trailing edge (h

0) and the leading edge (h

1) and the inclination angle (α) of the slide. It represents that at the start of the slide bar’s movement, the slide bar is lifted and runs relatively smoothly afterward.

Figure 5b shows the pressure curves measured through pressure sensors integrated into the steel rail. In

Figure 5c, the slide with lubrication grooves and the rail with the position of pressure sensors are schematically illustrated. Vertical dashed lines show the position of all seven pressure sensors; therefore, they represent the starting point of each pressure curve of PS 1 to PS 7.

The first pressure sensor PS 1 (as shown in

Figure 2) sits right outside the lubrication gap and beside the inlet floating height h

1 when the slide bar is at the rest position. As soon as the slide bar moves, the first sensor PS 1 comes inside the lubrication gap and the pressure sensor records the first pressure curve (shown by the black curve in

Figure 5 from the 0 to 500 mm position). The second pressure sensor PS 2 sits at a distance of 300 mm from the first sensor; therefore, the blue pressure curve starts from 300 mm and completes at 800 mm and so on. Six pressure maxima corresponding to six oil-supplied lubrication grooves can be clearly seen in the third pressure curve (from 500 to 1000 mm position) measured from the third pressure sensor PS 3. The variability of oil film pressure along the length of the slide bar (due to the difference between the floating thicknesses h

0 and h

1) can be validated with the help of the integrated pressure sensors as it passes over them. The pressure curve measured through PS 3 shows that at the leading edge, the pressure is minimal as the floating height h

1 is relatively large whereas the maximum pressure generated between the LG 5 and LG 6 is close to the trailing floating height (h

0), which is relatively small. The pressure curves measured by pressure sensors from PS 4 to PS 7 show similar curves with the same pressure values. This is because, after reaching maximum thickness, the pressure decreases, causing the slide bar to start sinking.

During the forward strokes, the floating height sensor h0 at the trailing edge runs over one of the small holes in the rail (which connects the pressure sensor and lubrication gap). The floating height h0 has seven peaks (small fluctuations) in all experimental results because when it runs over the small holes of the pressure measurement then it records the larger values as compared to the lubrication gap. Due to the assembly and disassembly of experimental setup during different experiments, perfect synchronization of position (xs) could not be achieved. This issue should be addressed by subtracting the surface profile of the steel rail (measured with same floating heights sensor before experimental run) from the actual floating height measurement. However, minor fluctuations in h0 are observed due to slight discrepancies of the position between the dry run measurement and the actual pressure measurements.

Variation of Feed Rate:![Lubricants 12 00287 i011 Lubricants 12 00287 i011]()

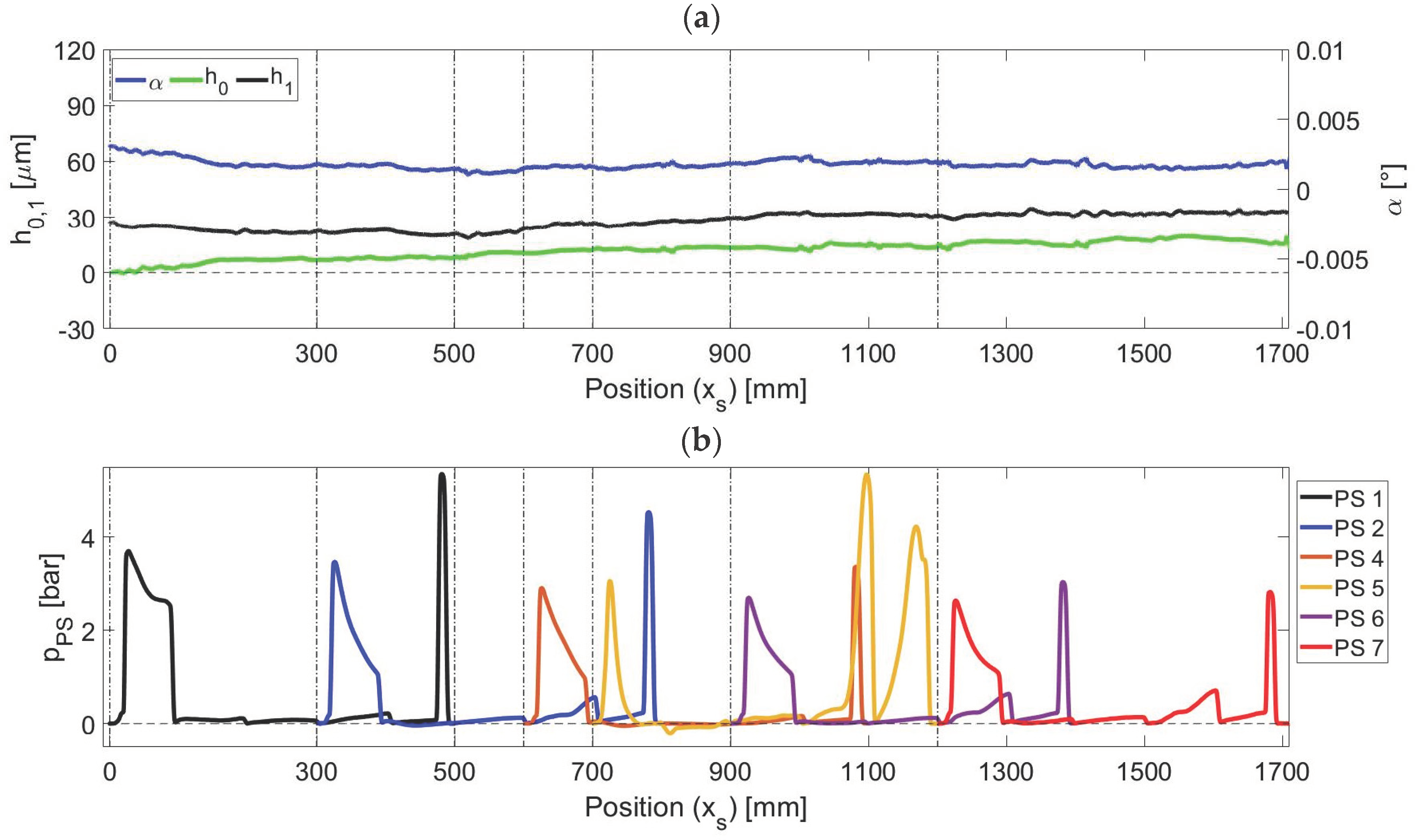

Comparing the pressure curves presented in

Figure 5 and

Figure 6, for feed rates of 30 m/min and 10 m/min, respectively, for a surface pressure of 0.7 bar, reveals slight differences. The pressure curves recorded by the sensors indicate slightly higher values at lower speeds, contrary to expectations. However, as the speed increases, there is a greater likelihood of air bubble formation within the oil reservoir (see

Figure 2c). However, the actual increase in pressure due to the increment of the feed rate cannot be measured through this setup. This is because of a very small sensor area as compared to the total lubrication gap and when the pressure inside the lubrication gap increases, then the floating heights will increase. The change of floating heights will neutralize the pressure generated and the pressure inside the lubrication gap becomes equal to the weight of the carriage. In addition, if the pressure reduces inside the lubrication gap, then floating heights are reduced until the pressure becomes equal to the weight of the carriage. Therefore, to capture the actual increase in pressure, the floating heights should be kept constant, which is not realistically possible. However, if the slide bar moves at higher speed, then the floating heights have higher values as compared to lower feed rates, which proves that at higher speed, the pressure generated is also higher but cannot be measured with the pressure sensors. In addition, the minimum lubrication gap is influenced by both the feed rate and the surface pressure or load that the system must withstand.

Variation of the Number of Oil-Supplied Lubrication Grooves:![Lubricants 12 00287 i012 Lubricants 12 00287 i012]()

To compare the different number of oil-supplied lubrication grooves, a slide bar with six lubrication grooves was used. However, oil was supplied through two, four, and six lubrication grooves for different tests. With the help of pressure sensors, it has been realized that two lubrication oil–supplied grooves are not sufficient to lubricate the 500 mm long lubrication gap irrespective of the lubrication interval. It is apparent that having fewer than six oil-supplied grooves was not sufficient to lubricate the lubrication gap properly, leading to poor lubrication during operation. This leads to irregular floating heights and an inappropriate pressure measurement, which is an undesirable outcome.

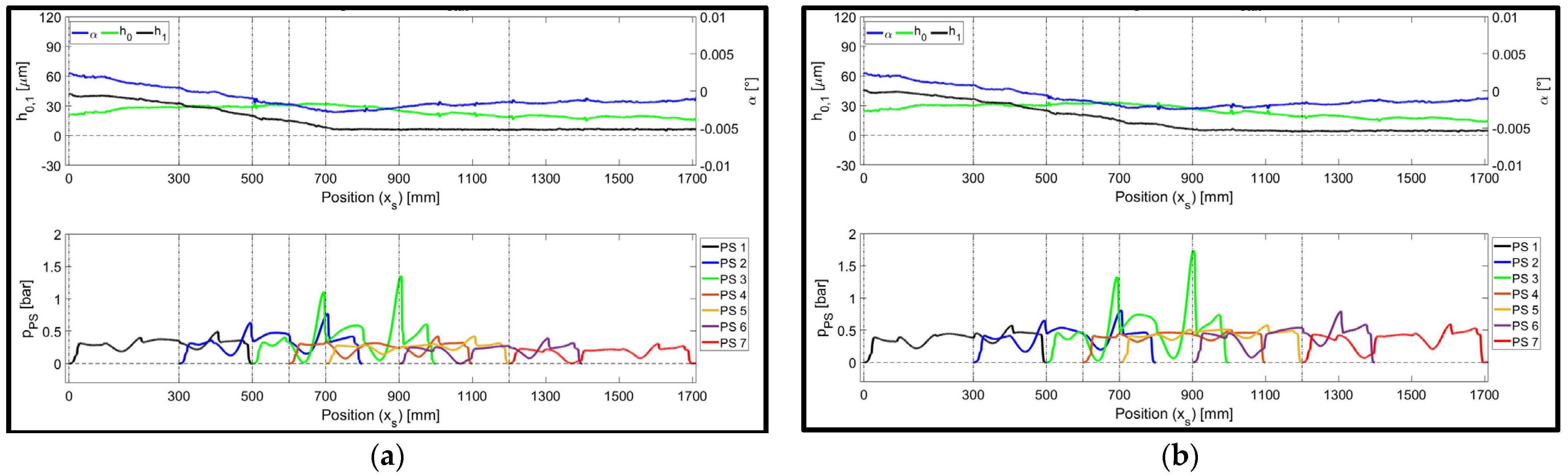

The different oil film pressures measured at a feed rate of 30 m/min with six, four, and two oil-supplied lubrication grooves, respectively, are shown in

Figure 5 (Exp. No. 3),

Figure 7 (Exp. No. 15), and

Figure 8 (Exp. No. 18). It is evident from the results that it is important to have six oil-supplied lubrication grooves because it shows promising results (pressure curves) and because it can lubricate the whole lubrication gap before each stroke, while the pressures measured with two and four oil-supplied lubrication grooves have zero-pressure regions due to poor lubrication between the lubrication grooves. However, the maximum values of pressure peaks corresponding to the lubrication grooves also increase with fewer grooves. This is understandable, as with fewer oil-supplied lubrication grooves, the guiding surfaces only separate in regions where the lubricant is provided. In other words, when lubricating with fewer grooves, the weight of the entire carriage is distributed over a smaller area, which leads to higher maximum pressure values over a relatively small area. The results clearly show that the floating thickness (h

0) decreases with fewer oil-supplied lubrication grooves; h

0 rises with the number of oil-supplied lubrication grooves from two to four and six. The differences in pressure and floating height measurements due to varying numbers of oil-supplied lubrication grooves are almost independent of feed rate, surface static pressure, pause time, and lubrication interval.

Variation of Lubrication Interval:![Lubricants 12 00287 i013 Lubricants 12 00287 i013]()

Different lubrication intervals (t

L) (Exp. No. 1 with 8 s t

L and Exp. No. 10 with 5 s t

L for static pressure of 0.24 bar) were tested to explore their effects on pressure distribution inside the lubrication gap and lubrication effectiveness. The difference between different pause times for other static pressures (0.454 and 0.7 bar) and a pause time of 5 s also show similar results. In other words, the pressure curves do not change their shape due to different static pressures, but only the maximum values in response to the weight of the carriage. This parameter is adjusted to thoroughly lubricate the lubrication gap and assess its influence on the system performance during operation. It is important to consider the number of oil-supplied lubrication grooves along with the lubrication interval time because the main goal is to lubricate the lubrication gap completely to achieve low friction and better lubrication conditions during operation. In

Figure 8, it can be seen that the pressure sensors showed two pressure peaks where the lubrication grooves meet the pressure sensors and in between two lubrication grooves, the sensors did not measure anything. This is due to poor lubrication inside the lubrication gap between both lubrication grooves. In

Figure 9, the pressure measured inside the lubrication gap is shown for a feed rate of 10 m/min and a static pressure of 0.24 bar for two different lubrication interval times of 5 and 8 s. It can be clearly seen that the pressure values recorded with sensors from PS 4 to PS 7 are relatively higher with a lubrication interval of 8 s. This is due to better lubrication conditions inside the lubrication gap before each stroke and more oil stays inside the lubrication gap until the end of the stroke.

The cavitation occurs inside the lubrication gap due to poor lubrication and relative motion between guiding surfaces, which draws the oil out from the oil reservoir. Initially, the integration method of pressure sensors was developed using a Plexiglas rail and carriage, enabling visual observation of flow and air entrapment in the lubrication gap. Later, when testing different lubrication grooves, the pressure sensors showed negative values between grooves due to increased air from poor lubrication conditions. This phenomenon, where pressure sensors indicated negative values in certain regions and increased with longer pause times, was also reported in [

19].

The presence of air bubbles inside the oil reservoir can reduce the pressure values measured due to the compressibility of air, which can be confirmed from the comparison of different lubrication intervals as shown in

Figure 9. To avoid these losses, it is important to keep the oil reservoir always filled with oil. In this experimental study, the oil reservoir was filled only before each experiment run, because it is not feasible or safe to refill it after every stroke. However, there is a possibility to avoid these losses by providing the oil to the reservoir before each stroke with the help of a pump in future experiments.

To avoid or reduce cavitation within the lubrication gap, it is important to optimize lubrication parameters. Increasing the number of lubrication grooves ensures that the entire lubrication gap is thoroughly filled with oil. Additionally, a longer lubrication time and a shorter pause time help maintain proper lubrication during strokes. Furthermore, the feed rate and floating heights are directly proportional to the generation of cavitation, meaning that higher feed rates and increased floating heights can increase cavitation.

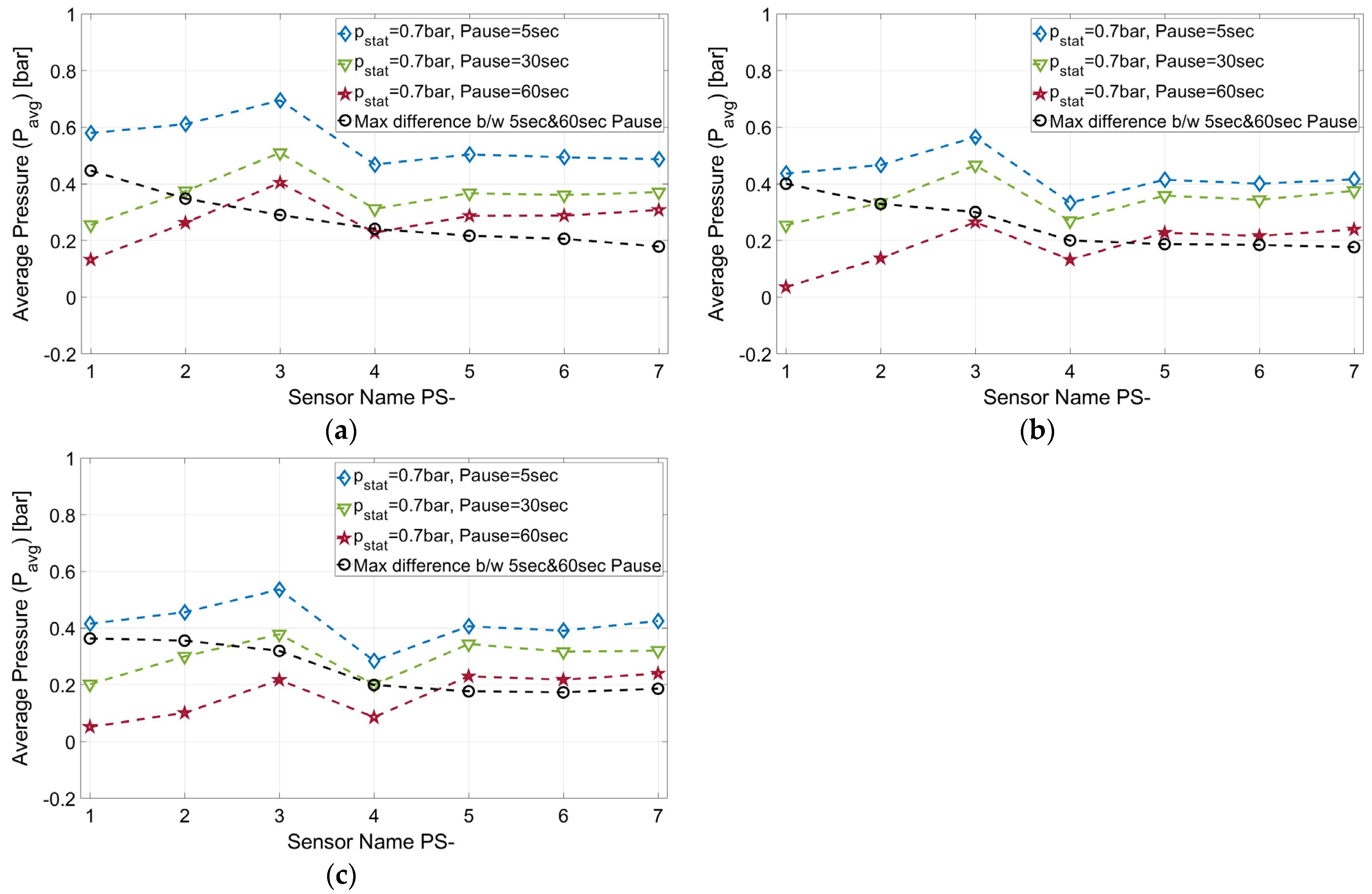

Variation of the Pause Time:![Lubricants 12 00287 i014 Lubricants 12 00287 i014]()

In real application, there is no specific pause time and the lubricant is supplied usually before or during strokes. It is not optimal to supply lubricant during machining or operation and if the lubricant is supplied before strokes then there will be a pause, which can be very short or long depending on the requirement. Therefore, it is important to understand the effects of pause duration on pressure measurement, and various pause durations (5 s (Exp. No. 3), 30 s (Exp. No. 6) and 60 s (Exp. No. 9)) are tested with a 0.7 bar static surface pressure to investigate their impact on the lubricant settling and its distribution within the lubrication gap.

To enhance the comprehension of oil film pressure across different scenarios, the average pressure by integrating pressure over the length (L) of the lubrication gap (sliding bar) has been derived as shown in equation 1. This aggregated value provides a useful benchmark for comparison, shedding light on lubrication conditions and potential enhancements.

In

Figure 10, the oil film pressure along with floating heights are shown for pause times of 5, 30, and 60 s for different feed rates (10, 30, and 50 m/min). It can be seen that the pressure measured after 60 s of pause time is comparatively small from all seven sensors and pressure curves go in a negative direction in some regions, which is not optimal. Whereas, the pressure with a 5 s pause time shows promising results (also shown in

Figure 5) because the pressure curves are in the positive region and the pressure measured through all seven sensors is also significant. However, with the 30 s pause time, the pressure sensors measured pressure curves with values between a 50 and 60 s pause time. All seven sensors measure similar pressure curves qualitatively, but quantitatively they are different due to speed variation, pause time, lubrication interval, and surface pressure. A short pause time causes the slide bar to descend during operation, leading to more irregular floating heights during operation and high friction. Conversely, a longer pause slows down the process, resulting in a decrease in lubricant volume within the gap. This can lead to increased friction due to a mixed lubrication regime and an increased angle of attack due to pressure variations along the length of the slide bar.

It is also evident that the sensors generate reproducible results as long as the floating heights or inclination angles are similar. From the results, it can also be observed that the pressure curves are highly sensitive to the slide bar’s inclination angle and the reason for instable floating heights is due to the varying pressure along the length of the slide bar.

7. Discussion

In the quest for improving the lubrication system of hydrodynamic linear guides, the integration of pressure sensors presents a promising opportunity to enhance functionality and efficiency. By utilizing pressure sensor technology, various significant advancements can be made as follows, with a specific focus on optimizing the lubrication system:

1. Real-Time Monitoring: Pressure sensors enable the continuous monitoring of oil film pressure within the lubrication gap. This constant feedback allows for dynamic adjustments to lubrication system parameters, such as flow rate and timing. As conditions change during operation, this real-time monitoring optimizes the distribution of the lubricant and ensures the ideal film thickness.

2. Detection of Lubrication Issues: With the presence of pressure sensors, it becomes possible to quickly identify and address any lubrication deficiencies or irregularities. Whether it is insufficient lubrication or the presence of air pockets, the data from pressure sensors empowers proactive interventions to ensure optimal lubrication performance.

3. Prevention of Failures: Pressure sensors have the capability to detect changes in pressure that indicate potential failures in the lubrication system, such as oil film breakdown or bearing overload. By promptly identifying these issues, pressure sensors facilitate preventive maintenance measures, reducing the risk of catastrophic failures and prolonging the lifespan of linear guides.

4. Enhanced Performance: Through precise monitoring and control of the lubrication process facilitated by pressure sensors, linear guides can achieve superior performance. Optimized lubrication parameters minimize friction, wear, and heat generation, resulting in smoother operation, reduced vibration, and improved accuracy and repeatability.

5. Optimizing Sensor Placement: One challenge is to minimize the number of sensors required while still obtaining accurate and comprehensive data. Reducing the sensor count can help lower costs and simplify the system without compromising performance.

6. Machine Learning Approaches: Implementing machine learning algorithms can significantly improve the analysis and interpretation of the data collected by pressure sensors and four floating height sensors (to measure the thickness of lubrication gap and machine table’s orientation). Additionally, the data from the current measurement of the motor to assess friction conditions can also enhance the overall monitoring capability. These algorithms can predict potential failures, optimize lubrication schedules, and adapt to changing operational conditions, thereby improving the efficiency and reliability of the lubrication system.

In brief, while the integration of pressure sensors in the lubrication system of hydrodynamic linear guides offers substantial benefits in monitoring, detecting issues, preventing failures, and enhancing performance, addressing challenges such as reducing the number of sensors and leveraging advanced technologies like multisensor systems and machine learning will be crucial for future advancements.

8. Conclusions

Using a newly developed pressure integration method, for the first time, this study provides an insight into the oil film pressure behavior of a hydrodynamic linear guide at various feed rates, different surface pressures, and various numbers of lubrication grooves, and different parameters of lubrication cycles have been measured. Pressure sensors are used in this study to comprehend the lubrication conditions inside the lubrication gap, which helps in taking appropriate actions to prevent failures. The measured transient pressure curve gives very important information regarding the lubricant conditions, the contact built between the sliding surfaces, the table inclination angle, the sliding surface conditions, and the presence of air pockets.

The study underscores the importance of minimizing the pause time for accurate pressure measurements, while acknowledging its impact on slide bar orientation. Pressure curves obtained with a 5 s pause time and longer lubrication intervals closely resemble the ideal scenario. However, longer pause times, coupled with an additional lubrication system to maintain a filled oil reservoir, could improve pressure measurements. Careful consideration of lubrication intervals and the number of lubrication grooves is crucial to ensure thorough lubrication before each stroke. In future research, it will be beneficial to compare three different slides featuring two, four, and six physical lubrication grooves.

Regarding feed rate variations, it is essential to note that pressure measurements may not precisely align with simulation results due to rapid changes in floating heights caused by pressure build-up in the lubrication gap. To obtain comparable simulation results, the instantaneous floating heights from the experimental results should be used in the simulation to calculate the pressure. The study emphasizes that the pressure sensors’ limited area may not capture instantaneous pressure rises within the lubrication gap. Ideally, the average pressure value of any pressure curve should be above or closely match the carriage’s static pressure.

The results presented in this paper demonstrate that the pressure sensors effectively measure the average oil film pressure, which closely approximates the carriage’s average static pressure. However, if lubrication parameters are not properly selected, the average oil film pressure can be significantly reduced, leading to less favorable outcomes. Additionally, the number of lubrication grooves influences the accuracy of oil film pressure measurements. To ensure the precise measurement of the oil film pressure, lubrication parameters are optimized to ensure that the entire lubrication gap is fully lubricated before each stroke.

The sensors measure average pressure across the width of the slide; however, the sensors still provide valuable information about the lubrication conditions of the hydrodynamic slide. While the results demonstrate promising potential for monitoring lubrication conditions, challenges such as air entrapment within the oil reservoir have been identified. To address this issue, future research will focus on further improvement of the existing lubrication system to ensure a reliable oil supply to the oil reservoir during measurements. There is a possibility if the reservoir is attached to a pump (which is used for lubrication through lubrication grooves) to obtain oil supply that fills the oil reservoir after each stroke. However, a nonreturning valve should be installed between the pump and the oil reservoir to prevent backflow toward the pump/tank during pressure measurement. The pressure requirement to keep the oil reservoir filled is very small (1/10 of the small pressure measured during operation) to avoid a large change in pressure measurement during operation.

The results outlined in this research are based on controlled laboratory experiments that were conducted with adequate lubrication. Furthermore, future research will concentrate on optimizing the deployment of sensors, potentially reducing their quantity. The objective is to utilize pressure sensors for the ongoing monitoring of linear guide lubrication in machine tools, ultimately enhancing efficiency and dependability without depending on float measurements.

Comparing the pressure curves presented in Figure 5 and Figure 6, for feed rates of 30 m/min and 10 m/min, respectively, for a surface pressure of 0.7 bar, reveals slight differences. The pressure curves recorded by the sensors indicate slightly higher values at lower speeds, contrary to expectations. However, as the speed increases, there is a greater likelihood of air bubble formation within the oil reservoir (see Figure 2c). However, the actual increase in pressure due to the increment of the feed rate cannot be measured through this setup. This is because of a very small sensor area as compared to the total lubrication gap and when the pressure inside the lubrication gap increases, then the floating heights will increase. The change of floating heights will neutralize the pressure generated and the pressure inside the lubrication gap becomes equal to the weight of the carriage. In addition, if the pressure reduces inside the lubrication gap, then floating heights are reduced until the pressure becomes equal to the weight of the carriage. Therefore, to capture the actual increase in pressure, the floating heights should be kept constant, which is not realistically possible. However, if the slide bar moves at higher speed, then the floating heights have higher values as compared to lower feed rates, which proves that at higher speed, the pressure generated is also higher but cannot be measured with the pressure sensors. In addition, the minimum lubrication gap is influenced by both the feed rate and the surface pressure or load that the system must withstand.

Comparing the pressure curves presented in Figure 5 and Figure 6, for feed rates of 30 m/min and 10 m/min, respectively, for a surface pressure of 0.7 bar, reveals slight differences. The pressure curves recorded by the sensors indicate slightly higher values at lower speeds, contrary to expectations. However, as the speed increases, there is a greater likelihood of air bubble formation within the oil reservoir (see Figure 2c). However, the actual increase in pressure due to the increment of the feed rate cannot be measured through this setup. This is because of a very small sensor area as compared to the total lubrication gap and when the pressure inside the lubrication gap increases, then the floating heights will increase. The change of floating heights will neutralize the pressure generated and the pressure inside the lubrication gap becomes equal to the weight of the carriage. In addition, if the pressure reduces inside the lubrication gap, then floating heights are reduced until the pressure becomes equal to the weight of the carriage. Therefore, to capture the actual increase in pressure, the floating heights should be kept constant, which is not realistically possible. However, if the slide bar moves at higher speed, then the floating heights have higher values as compared to lower feed rates, which proves that at higher speed, the pressure generated is also higher but cannot be measured with the pressure sensors. In addition, the minimum lubrication gap is influenced by both the feed rate and the surface pressure or load that the system must withstand. To compare the different number of oil-supplied lubrication grooves, a slide bar with six lubrication grooves was used. However, oil was supplied through two, four, and six lubrication grooves for different tests. With the help of pressure sensors, it has been realized that two lubrication oil–supplied grooves are not sufficient to lubricate the 500 mm long lubrication gap irrespective of the lubrication interval. It is apparent that having fewer than six oil-supplied grooves was not sufficient to lubricate the lubrication gap properly, leading to poor lubrication during operation. This leads to irregular floating heights and an inappropriate pressure measurement, which is an undesirable outcome.

To compare the different number of oil-supplied lubrication grooves, a slide bar with six lubrication grooves was used. However, oil was supplied through two, four, and six lubrication grooves for different tests. With the help of pressure sensors, it has been realized that two lubrication oil–supplied grooves are not sufficient to lubricate the 500 mm long lubrication gap irrespective of the lubrication interval. It is apparent that having fewer than six oil-supplied grooves was not sufficient to lubricate the lubrication gap properly, leading to poor lubrication during operation. This leads to irregular floating heights and an inappropriate pressure measurement, which is an undesirable outcome.  Different lubrication intervals (tL) (Exp. No. 1 with 8 s tL and Exp. No. 10 with 5 s tL for static pressure of 0.24 bar) were tested to explore their effects on pressure distribution inside the lubrication gap and lubrication effectiveness. The difference between different pause times for other static pressures (0.454 and 0.7 bar) and a pause time of 5 s also show similar results. In other words, the pressure curves do not change their shape due to different static pressures, but only the maximum values in response to the weight of the carriage. This parameter is adjusted to thoroughly lubricate the lubrication gap and assess its influence on the system performance during operation. It is important to consider the number of oil-supplied lubrication grooves along with the lubrication interval time because the main goal is to lubricate the lubrication gap completely to achieve low friction and better lubrication conditions during operation. In Figure 8, it can be seen that the pressure sensors showed two pressure peaks where the lubrication grooves meet the pressure sensors and in between two lubrication grooves, the sensors did not measure anything. This is due to poor lubrication inside the lubrication gap between both lubrication grooves. In Figure 9, the pressure measured inside the lubrication gap is shown for a feed rate of 10 m/min and a static pressure of 0.24 bar for two different lubrication interval times of 5 and 8 s. It can be clearly seen that the pressure values recorded with sensors from PS 4 to PS 7 are relatively higher with a lubrication interval of 8 s. This is due to better lubrication conditions inside the lubrication gap before each stroke and more oil stays inside the lubrication gap until the end of the stroke.

Different lubrication intervals (tL) (Exp. No. 1 with 8 s tL and Exp. No. 10 with 5 s tL for static pressure of 0.24 bar) were tested to explore their effects on pressure distribution inside the lubrication gap and lubrication effectiveness. The difference between different pause times for other static pressures (0.454 and 0.7 bar) and a pause time of 5 s also show similar results. In other words, the pressure curves do not change their shape due to different static pressures, but only the maximum values in response to the weight of the carriage. This parameter is adjusted to thoroughly lubricate the lubrication gap and assess its influence on the system performance during operation. It is important to consider the number of oil-supplied lubrication grooves along with the lubrication interval time because the main goal is to lubricate the lubrication gap completely to achieve low friction and better lubrication conditions during operation. In Figure 8, it can be seen that the pressure sensors showed two pressure peaks where the lubrication grooves meet the pressure sensors and in between two lubrication grooves, the sensors did not measure anything. This is due to poor lubrication inside the lubrication gap between both lubrication grooves. In Figure 9, the pressure measured inside the lubrication gap is shown for a feed rate of 10 m/min and a static pressure of 0.24 bar for two different lubrication interval times of 5 and 8 s. It can be clearly seen that the pressure values recorded with sensors from PS 4 to PS 7 are relatively higher with a lubrication interval of 8 s. This is due to better lubrication conditions inside the lubrication gap before each stroke and more oil stays inside the lubrication gap until the end of the stroke.  In real application, there is no specific pause time and the lubricant is supplied usually before or during strokes. It is not optimal to supply lubricant during machining or operation and if the lubricant is supplied before strokes then there will be a pause, which can be very short or long depending on the requirement. Therefore, it is important to understand the effects of pause duration on pressure measurement, and various pause durations (5 s (Exp. No. 3), 30 s (Exp. No. 6) and 60 s (Exp. No. 9)) are tested with a 0.7 bar static surface pressure to investigate their impact on the lubricant settling and its distribution within the lubrication gap.

In real application, there is no specific pause time and the lubricant is supplied usually before or during strokes. It is not optimal to supply lubricant during machining or operation and if the lubricant is supplied before strokes then there will be a pause, which can be very short or long depending on the requirement. Therefore, it is important to understand the effects of pause duration on pressure measurement, and various pause durations (5 s (Exp. No. 3), 30 s (Exp. No. 6) and 60 s (Exp. No. 9)) are tested with a 0.7 bar static surface pressure to investigate their impact on the lubricant settling and its distribution within the lubrication gap.

, 20,

, 20,  , 40, and 50

, 40, and 50