Abstract

Within electrical contacts, poor electrical conductivity of lubricants can lead to triboelectric charging, causing electrostatic currents and thermal effects, which accelerate lubrication failure. This study aimed to address these challenges by producing and testing three greases with different base oils: ionic liquid ([Oley][Oleic]), synthetic oil (PAO4), and vegetable oil-based synthetic ester (trimethylolpropane oleate). Each grease was prepared with polytetrafluoroethylene powder as the thickener. The greases were tested using a custom-made tribometer, integrated with a grounded electrical current system, with friction tests conducted with up to a 2 A electrical current flow at a constant voltage supply of 4.5 V. Under triboelectric friction testing, [Oley][Oleic] grease outperformed a commercial perfluoropolyether grease by 27.7% in friction and 16.3% in wear. This grease also showed better performance than formulated lithium grease with extreme pressure additives. The study demonstrates that greases with low interfacial resistance can retain their lubrication capacity under triboelectric conditions. These results indicate that [Oley][Oleic] grease, with its ionic liquid base oil, offers a promising solution for applications involving electrical contacts. This study highlights the potential of using advanced base oils and thickeners to enhance the performance and sustainability of lubricants in demanding environments.

1. Introduction

Greases are widely used in various industries, including automotive, steel, machinery, food, and textiles, due to their ability to reduce friction and wear between moving parts. They are crucial in electrical contacts, minimizing electrical resistance and preventing overheating [1,2]. Electrical contacts are prone to triboelectric charging, where frictional contact between surfaces leads to electrostatic charge accumulation and thermal effects [3,4]. This can deteriorate friction and wear performance, accelerate oxidation, and cause damage through electrostatic discharge. Furthermore, electrical current flow can cause contact electrification, exacerbating these issues by increasing the potential difference between surfaces with different electron affinities [5,6]. To address these challenges, electrically conductive lubricants are often designed with additives, such as metallic fillers and carbon substances, to facilitate current flow through contacts [7].

Greases of a base oil and a thickener flow when shear stress exceeds their yield point. The bonding between the base oil and the thickener is facilitated by mechanical occlusion, capillary forces, and polar attraction [8]. Grease performance is heavily influenced by this interaction [9,10], and the choice of base oil is integral for maintaining viscosity and thermal stability [11,12]. To counteract triboelectric charging, greases in electrical contacts must have sufficient electrical resistance and dielectric strength to prevent high permittivity and current leakage [7]. These properties ensure that the grease manages better the electron transfers between surfaces, maintaining balanced charge distribution and preventing property alterations. Thus, selecting the right grease is vital for the reliability and longevity of electrical systems.

Traditionally, mineral oils have been used as lubricants due to their suitable viscosity and high oxidation stability [5,13]. However, they are non-biodegradable, non-renewable, and prone to evaporation, causing separation from thickeners in greases [1,14]. Synthetic oils, such as polyalphaolefin (PAO), exhibit outstanding oxidative and thermal stability with low volatility [15]. These properties make PAO-based grease compatible with a wide temperature range and stable under shear stress [16]. Even though PAO offers better properties, it remains non-renewable and expensive [17,18].

Given the environmental concerns with traditional oils, research has focused on eco-friendly alternatives. Vegetable oils, having similar hydrocarbon structures to mineral oils [11], offer biodegradability, renewability, low toxicity, and good lubricity [11,19]. Studies on non-edible vegetable oils in greases, such as castor and coconut oil thickened with lithium soap, show superior tribological performance compared to commercial lithium greases [20]. Fatty acids in these oils enhance lubrication properties, and thickeners absorb vegetable oil better than mineral oil, making vegetable oil-based grease a better sealant [21]. However, their low oxidative stability and susceptibility to hydrolysis are significant drawbacks [18]. Chemical modifications, like esterification and transesterification, can improve these properties, but high costs limit their viability [22,23,24].

Ionic liquids (ILs) are emerging as potential base oils for greases due to their non-flammability, low volatility, biodegradability, high thermal stability, and dispersibility [25,26,27]. The strong bonds between ion molecules result in good performance under high shear forces [28]. IL-based greases have shown better anti-wear properties and friction reduction than mineral oil-based greases at various temperatures [29,30]. Studies have shown that ILs, such as imidazolium added to polyurea grease, reduce wear by up to 12 times [31]. Lithium salt ILs mixed with a polytetrafluoroethylene (PTFE) thickener exhibit excellent tribological properties under triboelectric conditions, owing to the conductive properties of IL-based greases [7,29,32]. However, selecting the right ILs to avoid corrosion and ensure good tribological performance is challenging [28,33].

In heavy industries, thickeners made from aluminium, calcium, and lithium are used to withstand extreme conditions [8,34], with lithium-based greases dominating the grease industry [35]. However, the demand for electric vehicles (EVs) has created a supply imbalance, as lithium is critical for battery production [5,36]. Polyurea grease is also commonly used in the high-performance automotive industry [37], having better structural strength and yield stress compared to lithium-thickened grease [38]. Recent studies highlight the use of PTFE micro powder as a thickener for its ability to withstand high temperatures and reduce friction and wear [39,40], which is particularly useful in electronic and semiconductor industries [41,42]. Under triboelectric conditions, PTFE is known for its electrical insulation properties, which can help to avoid arcing in electrical contacts [42]. PTFE’s high negative triboelectric charge density and strong electron affinity enhance its insulation properties, making it an excellent electron acceptor material [43]. However, base oils can oxidize and decompose under high temperatures, making the selection of both the base oil and the thickener critical for optimal performance, especially in managing triboelectric effects in electrical contacts.

This study addresses the challenges of triboelectric performance in greases by exploring various base oils, including conventional synthetic hydrocarbons, vegetable oil-based synthetic esters, and ionic liquids (ILs), all using polytetrafluoroethylene (PTFE) micro powder as the thickener. The transition from traditional to eco-friendly alternatives aims to benchmark their performance against established greases. By evaluating friction and wear under triboelectric conditions, this study highlights the importance of selecting polar base oils, with good thermal stability and low interfacial resistance, to ensure optimal grease performance in triboelectric environments.

Oleic acid was chosen for producing IL in this study due to its stable dispersibility [44,45]. It is cost-effective and has a simple production process when mixed with oleylamine. Trimethylolpropane oleate (TMPO), produced via esterification of oleic acid, is used for its excellent lubricity and biodegradability [46]. PAO4 was selected for its superior thermal and oxidative stability [15], making it beneficial under triboelectric conditions, where elevated temperatures are expected. All base oils were thickened using PTFE micro powder, chosen for its effectiveness at high temperatures, up to 260 °C, without degradation, while also reducing friction and wear [39,40]. This combination ensures a comprehensive evaluation of triboelectric performance across different base oils, each with proven benefits in high-temperature and high-friction environments.

2. Experimental Approach

2.1. Material and Sample Preparation

This study examines three types of greases using different base oils: (1) ionic liquid (IL), (2) synthetic oil, polyalphaolefin (PAO4), and (3) vegetable oil-based synthetic ester, trimethylolpropane oleate (TMPO). PAO4, also known as Durasyn 16X PAO, was obtained from DNA Petrochem Sdn Bhd, Selangor, Malaysia. TMPO was sourced from Wilmar Oleochemicals, China. The thickener used was 5 to 10 μm polytetrafluoroethylene (PTFE) powder with over 98% purity. This was supplied by HDD Technology Sdn. Bhd, Johor, Malaysia.

For IL synthesis, oleic acid and oleylamine, both sourced from Sigma-Aldrich (Product no. 364525, CAS no. 112-80-1 for oleic acid; Product no. O7805, CAS no. 112-90-3 for oleylamine), were used. The neutralization process followed methods from previous works [47,48]. Oleic acid and oleylamine, in a 1:1 equimolar ratio, were stirred with a magnetic stirrer at 400 rpm for 24 h, resulting in the product [Oley][Oleic] [25].

The grease production process was adapted from previous studies [49,50]. To ensure a consistent comparative analysis, the PTFE thickener was fixed at 50 wt%. The base oil was mechanically stirred at room temperature (27 °C) for five minutes at 200 rpm. The stirrer speed was then increased to 400 rpm, and the PTFE powder was added slowly over 10 min. The mixture was heated to 80 °C and stirred for an additional 30 min at 1000 rpm. It was then left to cool at room temperature without further stirring. The cooled mixture was rolled through a two-roller mill three times to ensure homogeneity. Representative photos of the produced greases are shown in Figure 1a–c. A series of tests, detailed in Table 1, were conducted to characterize the grease samples and determine their properties according to international standards.

Figure 1.

PTFE greases with base oils: (a) [Oley][Oleic], (b) TMPO, and (c) PAO4.

Table 1.

Characterization of PTFE grease with different base oils.

2.2. Friction Test

The friction tests used AISI 304 stainless steel disks (⊘ 50 mm, 1 mm thickness, 304 2B finish) with a hardness of 80 HRB (160 HV) and AISI 52100 steel balls (⊘ 6 mm) with a hardness of 62 HRC. The arithmetic surface roughness of the disk and ball used in this study was measured at 0.3 and 0.15 μm, respectively, using a surface profilometer. Before testing, the stainless steel disks underwent a cleaning process: rinsing with water, ultrasonic cleaning in acetone, soaking in ethanol for four hours, and air drying for 30 min to ensure complete ethanol evaporation. This procedure optimized the stainless steel surface’s wettability for reliable results as detailed in reference [22]. After cleaning, the disks were rinsed with distilled water, oven-dried, and cooled to room temperature. The steel balls were stored in an airtight bag with silicone gel to prevent rust.

Each grease was then uniformly applied to the disk surface using a modified blade coating technique. The blade had an adjustable gap set to achieve the desired thickness of 7 mm. The grease was applied in multiple passes, allowing each layer to settle before applying the next, to ensure uniform coverage. The thickness of the grease layer was measured using an optical microscope to ensure it ranged between 7.0 and 8.0 mm to achieve a fully-flooded condition.

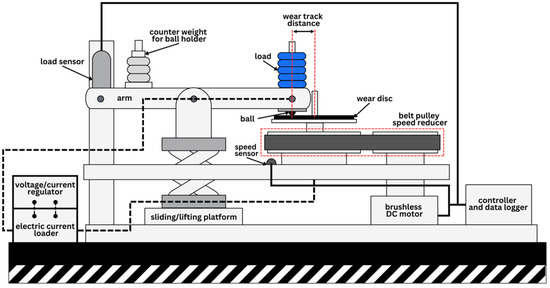

Friction tests were conducted using a custom-made tribometer, configured for a ball-on-disk contact, as shown in Figure 2. The tribometer had a grounded electrical current flow path through the point contact between the ball and the disk. At a rotational speed of 500 rpm, the normal load was adjusted from 80 g to 160 g in 20 g increments. Each test took approximately 255 s to cover a distance of 200 m, with a new set of balls and disks for each configuration. Before each main friction measurement, an initial run-in trial was conducted on each ball and disk using a 60 g load at 1000 rpm for 60 s. This run-in process stabilizes the contact surfaces and ensures consistent and reliable results in the subsequent friction tests [51].

Figure 2.

Custom-made ball-on-disk tribometer integrated with a grounded electrical current system.

Friction tests were conducted under three conditions: no current, 1 A, and 2 A, all using identical configurations at a constant supplied voltage of 4.5 V. The voltage of 4.5 V was specifically chosen to prevent arcing at the contacts, which can occur at higher voltages and disrupt the lubricant film, thereby allowing the study to focus accurately on lubricant performance. Each test was repeated three times, yielding results with less than 5% deviation. Additionally, two commercial greases were tested for benchmarking: synthetic perfluoropolyether (PFPE)-based grease with PTFE (denoted as PFPE grease), and EAJ 7000 EP (denoted as LI grease), a commonly used automotive grease with extreme pressure (EP) additive, obtained from Toyo Holdings Sdn Bhd. After each friction test, an optical microscope was used to measure the wear scar diameter on the steel ball.

2.3. Interfacial Resistance

Considering electrical contact problems with smooth surfaces, electrical resistance between contacts can be classified into two components: interfacial resistance and constriction resistance [52]. Interfacial resistance, , occurs due to a layer of film, which in the present study is taken to be influenced by the lubricant film thickness () and resistivity () over the contact area (A) as described in Equation (1).

On the other hand, constriction resistance, , results from microscopic gaps between contacts. Following Holm’s electrical contact theory, resistance between a sphere and a half-space can be calculated using the contact electrical resistance in Equation (2) [53], where and are the resistivity values of the sphere and the half-space, respectively.

In this study, the resistivity values used are 0.22 and 0.72 for the ball and disk, respectively [54]. The Hertzian contact radius (a) is calculated using , where R is the radius of curvature, and is the effective Young’s Modulus of the ball and disk.

The electrical setup for this study is a series connection, where the potential drop, , of the system is measured using a voltage/current regulator with a constant supplied voltage (V) of 4.5 V during the friction test. Subsequently, the interfacial resistance can be obtained using Equation (3) [52]. It is assumed that a higher potential drop within the system is attributed by higher interfacial resistance ().

3. Results and Discussion

3.1. Sample Characterization

The base oils and their properties are listed in Table 2. At 40 °C, [Oley][Oleic] base oil has the highest viscosity, followed by TMPO and PAO4. Generally, grease with a higher viscosity base oil is necessary for high load and temperature conditions to ensure adequate lubrication and film thickness formation. However, it is essential to strike a balance in choosing a highly viscous base oil to avoid low flowability of the grease, which is critical for reaching the lubrication point [55]. The viscosity index (VI) was calculated using ASTM D2270. Among the studied base oils, TMPO (VI = 194) is expected to provide better lubrication under high-temperature conditions.

Table 2.

Properties of PTFE greases with different base oils.

The consistency of the greases was determined using the National Lubricating Grease Institute (NLGI) scale, which ranges from 000 (very soft) to 6 (very firm). Higher NLGI-grade greases are firm and stay in place under extreme conditions. Greases with NLGI grades from 1 to 3 are typically used in bearing systems due to their pumpability [1], while grades 00 to 0 are more suitable for enclosed gearing systems [50]. From Table 2, TMPO grease is considered fluid to semi-fluid, while the other samples are categorized as medium to hard greases. The oil separation test involved storing samples in an airtight container for over a month, at room temperature. No oil separation was observed in any of the samples. This is attributed to the PTFE micro powder thickener, which creates a strong, sponge-like structure between the thickener and base oil molecules [56].

3.2. Thermal Stability

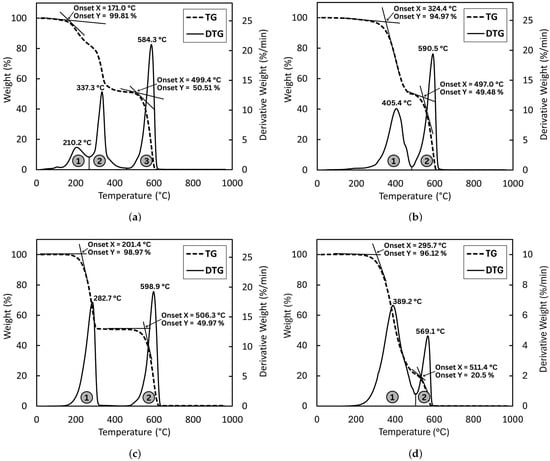

Based on the thermogravimetric (TG) plot in Figure 3, the thermal decomposition onset temperature () can be determined to evaluate the oxidative stability of the grease samples and their suitability as lubricants. This onset temperature indicates the minimum temperature before the vaporization of volatile components [49]. For all samples, the initial weight loss is less than 5 wt% before , indicating minimal water content and contributing to their stability as lubricants. Generally, the for each sample occurs within 171.0 to 324.4 °C. The decomposition of grease typically occurs in two weight loss steps, as shown in the derivative TG (DTG) plot in Figure 3. The first step represents the evaporation of lower molecular weight compounds, such as hydrocarbons or base oil, while the second step corresponds to the decomposition of higher molecular weight compounds, often the thickener [57,58]. Thus, the extended thermal stability beyond 400 °C is attributed to the presence of the PTFE thickener, similar to reported results in the literature [30].

Figure 3.

TGA Thermogram for PTFE greases with base oils: (a) [Oley][Oleic], (b) TMPO, (c) PAO4, and (d) PFPE.

TMPO grease in Figure 3b has the highest thermal stability, with a around 324.4 °C before significant weight loss begins, resulting in a total mass loss of approximately 45.5 wt%. Following TMPO grease, the commercial PFPE grease in Figure 3d has an onset temperature of 295.7 °C and degrades with a total mass loss of up to 75.6 wt%. PAO4 grease in Figure 3c having a at 201.4 °C experience thermal degradation of 49.0 wt% mass loss. For [Oley][Oleic] grease in Figure 3a, the is approximately 171.0 °C, consistent with reported values for the base oil [25]. However, [Oley][Oleic] grease exhibits three decomposition steps because the first two steps represent the decomposition of the [Oley][Oleic] base oil components, oleylamine and oleic acid, occurring at 210.2 °C and 337.3 °C, respectively.

Overall, the results indicate that the greases tested in this study can be categorized as medium volatile, as they can withstand temperatures above 150 °C without evaporating or decomposing [49]. However, under elevated temperatures, base oils could eventually oxidize even though the thickeners can withstand high temperatures, necessitating frequent relubrication.

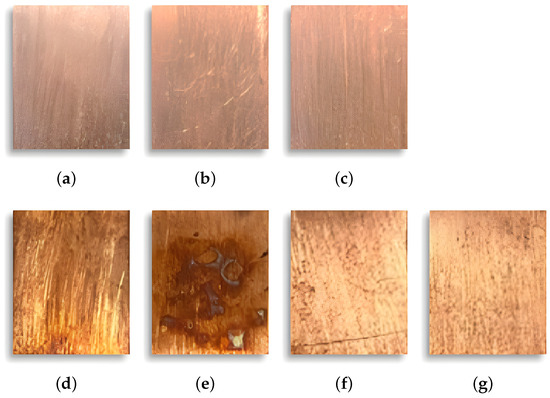

3.3. Corrosion

The copper strip corrosion test was conducted to evaluate the anti-corrosion properties of the grease samples, and the results are shown in Figure 4. The corrosion test for each base oil was performed simultaneously with the corresponding grease samples. Comparing the shiny surface of the polished strip in Figure 4a, [Oley][Oleic] base oil in Figure 4b showed no obvious colour changes, indicating minimal corrosion. This is due to the non-acidic mixture with oleic acid’s polar carboxylic acid group (-COOH), which forms a protective layer on the metal surface, reducing oxidation and corrosion [59]. In contrast, TMPO base oil in Figure 4d exhibited significant colour changes, indicating corrosion. Meanwhile, PAO4 base oil exhibits slight corrosion as shown in Figure 4f, similar to reported study [60]. The corrosion grades for all base oils, determined using the standard copper corrosion control shade guide as per ASTM D4048, are listed in Table 3.

Figure 4.

Corrosion test comparisons for (a) freshly polished copper strip, and tested strips using (b) [Oley][Oleic] base oil, (c) [Oley][Oleic] grease, (d) TMPO base oil, (e) TMPO grease, (f) PAO4 base oil, and (g) PAO4 grease.

Table 3.

Corrosiveness comparison for PTFE greases and their respective base oils.

PTFE powder, used as a thickener, is known for its excellent anti-corrosion properties under extreme temperatures and pressures due to its chemical inertness and thermal stability [2]. Mixing base oil with PTFE powder can enhance or maintain the lubricant’s anti-corrosive properties. For [Oley][Oleic] grease in Figure 4c and PAO4 grease in Figure 4g, the presence of PTFE powder maintains the corrosion ratings at 1a and 1b, respectively, consistent with previous studies [60,61]. For TMPO grease, PTFE improves the corrosion rating from 3a to 2c, as in Figure 4d and Figure 4e, respectively. Additionally, the corrosion tests confirm that the commercial PFPE grease provides effective corrosion protection to surfaces in contact, as reported in reference [62].

3.4. Friction and Wear Performance

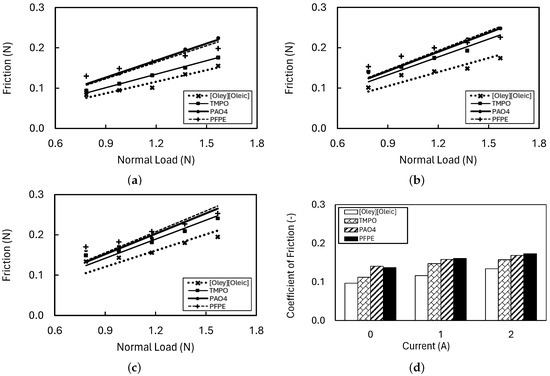

The friction force against the normal load for each grease sample, at 500 rpm under all electrical current conditions, is shown in Figure 5a–c. All samples follow Amonton’s friction law, displaying a linear relationship between friction force and normal load, with R2 values ranging from 0.98 to 0.99. The friction force was averaged over a 255 s running time for each load, with a standard deviation below 5%, ensuring reliable data. [Oley][Oleic] grease consistently generates lower friction than the other samples, with the commercial PFPE grease being the least desirable under most tested conditions. Figure 5d summarizes the coefficient of friction (CoF) values for the PTFE grease samples under increasing electrical currents, derived from the slope of the friction force against normal load. The measured CoF value under dry conditions is around 0.36 [63]. All samples showed lower CoF values, indicating lubricated conditions rather than direct metal-to-metal contact.

Figure 5.

Friction against load for PTFE greases with different base oils at 4.5 V and 500 rpm: (a) no current, (b) 1 A, (c) 2 A, and (d) the coefficient of friction (CoF).

For all samples, friction force increases with the introduction of electrical current. A current of 1 A increases the friction of the samples by 12.6 to 31.5% compared to their respective no-current condition. When 2 A current is introduced, the friction increases by 20.1 to 40.4%. Both trends highlight the significant impact of electrical current discharge on frictional properties. Among these samples, PAO4 grease shows the smallest increase in friction for both currents, while TMPO grease experiences the largest increase when a current is introduced. The data show that the presence of current increases the friction force between contacts, with the magnitude of the current heavily influencing this behaviour. The introduction of current alters the resistivity properties of the samples, leading to increased friction force [64]. Using the commercial PFPE grease sample as the baseline, [Oley][Oleic] grease produces the lowest friction, with CoF values 22.5% and 27.7% lower at 1 and 2 A, respectively.

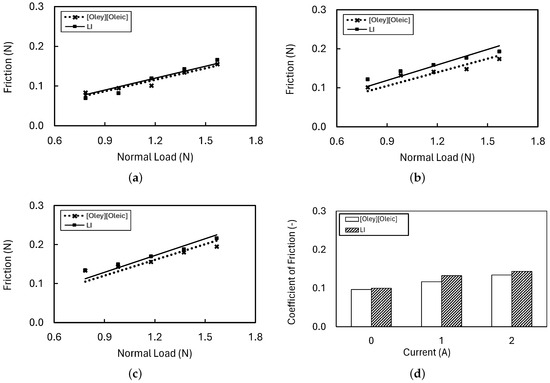

Given [Oley][Oleic] grease’s effectiveness as a friction reducer, even under triboelectric conditions, additional friction tests were conducted using a fully formulated lithium grease for further comparison. Figure 6a–c shows the friction force against the normal load for [Oley][Oleic] grease compared to the commercial lithium grease, with Figure 6d summarising the CoF. The measured friction force against normal load for all configurations consistently resulted in a standard deviation of less than 5% across repeated measurements, so error bars are not included.

Figure 6.

Friction against load for [Oley][Oleic] and LI greases at 4.5 V and 500 rpm: (a) no current, (b) 1 A, (c) 2 A, and (d) coefficient of friction (CoF).

Comparing the overall frictional performance in Figure 6, [Oley][Oleic] grease performs similarly to LI grease under no-current conditions. When 1 A current is introduced, [Oley][Oleic] grease shows a friction force increase of 20.6%, while LI grease shows a 32.3% increase compared to their respective no-current condition. At 2 A, the CoF values for [Oley][Oleic] and LI greases increase by 39.0% and 43.4%, respectively, compared to their no-current condition. Despite similar trends, [Oley][Oleic] grease slightly outperforms LI grease in the presence of electrical current, generating up to 12.1% lower friction. This demonstrates [Oley][Oleic] grease’s lubrication efficiency in electrical conditions, highlighting the ability of its IL base oil to maintain low friction without additives [65,66]. It could be surmised that the IL mixture improves a lubricant’s polarity [67], allowing it to perform better across various operating conditions without additives, compared to the commercially available lithium grease.

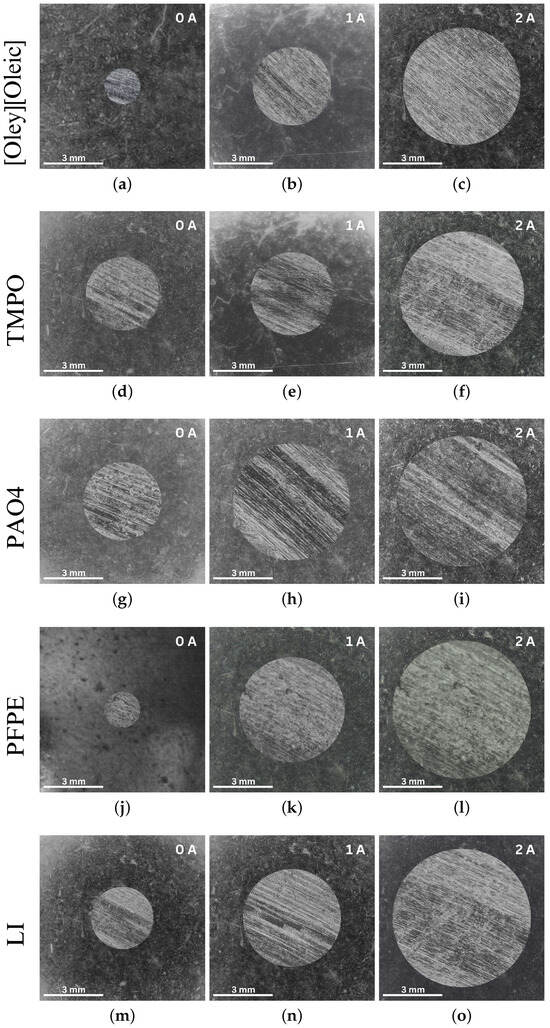

To further elucidate the tribological performance, wear measurements for each configuration are reported. Figure 7a–o show the ball wear scar diameter for all samples under no current, 1 A, and 2 A conditions. The ball scar diameter increases for all samples when current is introduced. Without current, [Oley][Oleic] and PFPE greases exhibit better wear-reducing properties, while TMPO, PAO4, and LI greases show larger wear scar diameters.

Figure 7.

Ball wear scar images for PTFE greases under different current conditions at 4.5 V: [Oley][Oleic] at (a) no current, (b) 1 A, and (c) 2 A; TMPO at (d) no current, (e) 1 A, and (f) 2 A; PAO4 at (g) no current, (h) 1 A, and (i) 2 A; PFPE at (j) no current, (k) 1 A, and (l) 2 A; LI at (m) no current, (n) 1 A, and (o) 2 A.

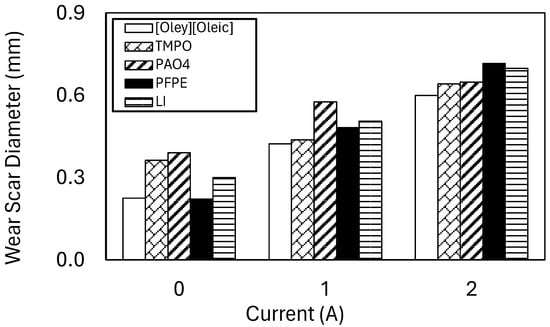

The wear scar diameter data for the studied greases are summarized in Figure 8. For all samples, the wear scar diameter is below 0.4 mm without electrical current. [Oley][Oleic] grease consistently shows the smallest wear values across all tested conditions. While wear increases with current, [Oley][Oleic] grease remains the smallest, being 12.2% and 16.3% lower than commercial PFPE grease at 1 and 2 A, respectively. Additionally, [Oley][Oleic] grease shows a reduction in wear by 16.4% and 14.1% compared to LI grease at 1 and 2 A, respectively. This trend aligns with the frictional performance and can be attributed to the polar amine group in [Oley][Oleic] base oil, which enhances the adsorption of IL molecules to the surface [68], even with electrical current, thereby reducing wear. The standard deviation of all data is less than 5%, explaining the exclusion of error bars in the plot.

Figure 8.

Ball wear scar diameter for PTFE greases with different base oils and LI grease under various electrical current conditions at 4.5 V.

3.5. Evaluating Friction and Wear Properties

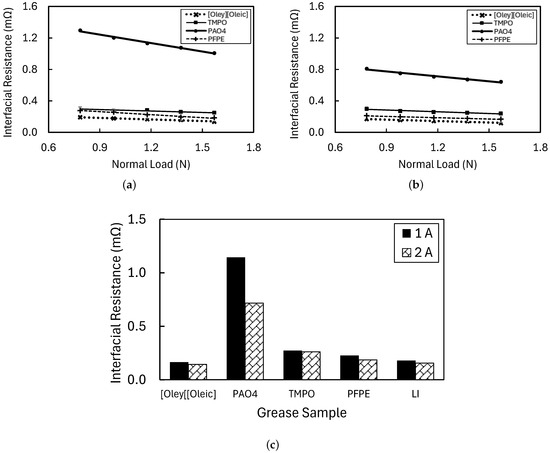

The analysis of greases under triboelectric conditions shows that [Oley][Oleic] grease outperforms other greases, including commercial PFPE and LI greases, in terms of friction and wear characteristics, especially with electrical current present. To elucidate this observation, the interfacial resistance () of each sample was determined using Equation (3) from the measured potential drop (), as shown in Figure 9.

Figure 9.

Interfacial resistance for PTFE greases with different base oils at (a) 1 A, (b) 2 A, and (c) their average values, compared with LI grease, under various electrical current conditions at 4.5 V.

The interfacial resistance decreases with increasing load for all PTFE greases at 1 and 2 A currents, as shown in Figure 9a,b. The smallest resistance is achieved using the [Oley][Oleic] grease sample. Referring to Equation (1), assuming constant resistivity for a given grease sample, the change in interfacial resistance is proportional to the thickness of the film layer () and inversely proportional to the contact area (A). In this study, the contact area is computed from the Hertzian contact radius (a). When the load increases, the contact area increases, while the film thickness decreases. This coupled effect explains the reduced interfacial resistance trend with increasing loads.

Figure 9c shows that the average interfacial resistance, over the load range, for all samples, decreases at higher electrical currents. The smaller interfacial resistance for all samples at 2 A indicates a thinner film layer. This reduced film thickness at 2 A, compared to 1 A, can be attributed to Joule heating [52], which lowers the lubricant’s viscosity, leading to reduced film thickness and load-carrying capacity. This reduced film thickness, from Joule heating, also explains the increased friction force with higher electrical current.

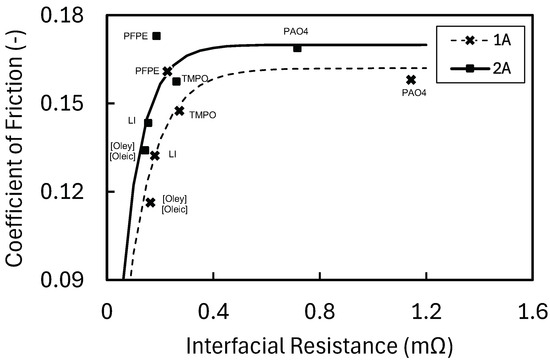

Table 4 presents the non-linear correlation analysis of the interfacial resistance, CoF, and wear scar diameter measured for the grease samples. The Spearman correlation coefficient was chosen for this analysis because it assesses the strength and direction of the association between two ranked variables, making it suitable for non-linear relationships. The results show that the CoF has a moderate positive correlation with the interfacial resistance (), while the wear scar diameter has an almost negligible correlation with the interfacial resistance (). The moderate positive correlation between CoF and wear scar diameter () is expected, as an increase in CoF tends to lead to increased wear.

Table 4.

Non-linear correlation analysis of electrical and tribological properties using the Spearman coefficient for the grease samples.

The correlation between interfacial resistance and CoF yields a p-value of 0.060, while the correlation between CoF and wear scar diameter has a p-value of 0.117. The correlation between interfacial resistance and wear scar diameter shows a p-value of 0.960. Given these probabilities, the only potentially statistically significant correlation is between interfacial resistance and CoF, which is close to the statistically recommended threshold value of 0.05. This marginal significance suggests a potential relationship between these factors, which warrants further investigation.

To illustrate this relationship, Figure 10 plots the change of CoF with interfacial resistance for all grease samples. The CoF increases, and then saturates at higher interfacial resistance values. PAO4 grease exhibited high resistance, due to its non-polar and non-conductive nature [55], consistent with its less desirable frictional performance under triboelectric conditions. In contrast, [Oley][Oleic] grease showed the lowest average interfacial resistance, at 0.165 and 0.145 mΩ under 1 and 2 A electrical currents, respectively. Compared to commercial PFPE grease, [Oley][Oleic] grease had 27.5% and 22.7% lower resistance at 1 and 2 A, respectively.

Figure 10.

Coefficient of friction against average interfacial resistance for PTFE greases with different base oils and LI grease, under various electrical current conditions at 4.5 V.

Overall, both [Oley][Oleic] and LI grease demonstrated better electrical conductivity, contributing to superior friction-reducing and anti-wear properties [29,69]. [Oley][Oleic] grease showed 8.9% and 6.8% lower resistance than LI grease at 1 and 2 A, respectively. Notably, despite lacking additives, [Oley][Oleic] grease marginally outperformed LI grease, which relies on additives to enhance dispersibility and conductivity [70]. This demonstrates the effectiveness of [Oley][Oleic] grease in triboelectric applications, highlighting the importance of interfacial resistance in determining triboelectric lubrication performance.

The better friction and wear properties of [Oley][Oleic] grease under triboelectric conditions are attributed to its base oil’s high polarity, derived from the mixture of oleic acid and oleylamine, which contains polar carboxylic acid (-COOH) and amine (-NH2) groups [68]. These polar molecules create strong intermolecular forces, forming stable lubricating films under electrical conditions. The carboxylic acid group interacts with metal surfaces to form a protective layer, reducing oxidation and corrosion, while the amine group enhances adsorption to the surfaces, reducing wear [59]. This behaviour aligns with the observed friction results and demonstrates how polar greases improve conductivity and interfacial resistance in electrical conditions.

4. Conclusions

This study investigated three greases—ionic liquid ([Oley][Oleic]), synthetic oil (PAO4), and vegetable oil-based synthetic ester (TMPO)—all using PTFE micro powder as a thickener. The key findings demonstrate that [Oley][Oleic] grease offers significant friction reduction and anti-wear properties, especially under electrical conditions.

- The [Oley][Oleic] grease outperformed commercial perfluoropolyether (PFPE) grease and formulated lithium grease by 27.7% and 12.1% in frictional performance, respectively, with up to 16.4% better wear.

- Despite a thermal decomposition onset temperature () of 171.0 °C, [Oley][Oleic] grease is categorized as medium volatile and can withstand temperatures above 150 °C.

- The [Oley][Oleic] base oil and PTFE powder contribute to excellent anti-corrosion properties.

- The synergistic combination of oleic acid and oleylamine as the base oil enhances the grease’s polarity, resulting in lower interfacial resistance (0.165 mΩ at 1 A and 0.145 mΩ at 2 A), which is 27.5% and 22.7% better than PFPE grease, and 8.9% and 6.8% better than lithium grease, respectively.

- Correlation analysis revealed a significant relationship between the coefficient of friction and interfacial resistance, with a Spearman coefficient of , indicating that lower interfacial resistance leads to better lubrication performance.

[Oley][Oleic] grease represents a sustainable and high-performance alternative for industrial applications involving electrical contacts. Its ionic nature and superior lubrication properties, demonstrated by its quantitative performance metrics, offer a viable solution to the limitations and environmental concerns associated with traditional greases.

Author Contributions

Conceptualization, N.A.A.M.A. and W.W.F.C.; data curation, N.A.A.M.A. and C.T.L.; formal analysis, N.A.A.M.A., K.J.W. and W.W.F.C.; funding acquisition, W.W.F.C.; investigation, N.A.A.M.A., C.T.L. and W.W.F.C.; methodology, N.A.A.M.A. and C.T.L.; project administration, A.T., K.J.W. and W.W.F.C.; resources, K.J.W. and W.W.F.C.; supervision, A.T., K.J.W. and W.W.F.C.; validation, N.A.A.M.A. and C.T.L.; visualization, N.A.A.M.A. and W.W.F.C.; writing—original draft, N.A.A.M.A. and W.W.F.C.; writing—review & editing, A.T., K.J.W. and W.W.F.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research project received financial support from both Universiti Teknologi Malaysia and the Ministry of Higher Education (MOHE), Malaysia, under the Fundamental Research Grant Scheme (FRGS) with the reference number FRGS/1/2023/TK10/UTM/02/3 and the UTM Fundamental Research Grant with the reference number Q.J130000.3851.22H02 (PY/2022/00419).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Japar, S.A.; Aizudin, M.; Aziz, A.; Razali, N.; Waheeda, N.; Rahman, A. Grease and its Application on Electrical Equipment: A Review. Int. J. Eng. Technol. 2018, 7, 23–29. [Google Scholar] [CrossRef]

- Ge, X.; Xia, Y.; Feng, X. Influence of carbon nanotubes on conductive capacity and tribological characteristics of poly (ethylene glycol-ran-propylene glycol) monobutyl ether as base oil of grease. J. Tribol. 2016, 138, 011801. [Google Scholar] [CrossRef]

- Lee, W.B.; Orr, D.E. The TriboElectric Effect Series. AlphaLab, Inc. 2022. Available online: https://www.alphalabinc.com/wp-content/uploads/2024/02/The-Triboelectric-Effect-Series-AlphaLab-Inc.pdf (accessed on 30 June 2024).

- Wang, J.; Zhou, L.; Zhang, C.; Wang, Z.L. Small-Scale Energy Harvesting from Environment by Triboelectric Nanogenerators. In Small-Scale Energy Harvesting; Manyala, R., Ed.; IntechOpen: London, UK, 2019; Chapter 4; pp. 63–94. [Google Scholar]

- Andrew, J.M. The future of lubricating greases in the electric vehicle era. Tribol. Lubr. Technol. 2019, 75, 38–44. [Google Scholar]

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance characteristics of lubricants in electric and hybrid vehicles: A review of current and future needs. Front. Mech. Eng. 2020, 6, 571464. [Google Scholar] [CrossRef]

- Bustami, B.; Rahman, M.M.; Shazida, M.J.; Islam, M.; Rohan, M.H.; Hossain, S.; Nur, A.S.; Younes, H. Recent Progress in Electrically Conductive and Thermally Conductive Lubricants: A Critical Review. Lubricants 2023, 11, 331. [Google Scholar] [CrossRef]

- Donahue, C.J. Lubricating grease: A chemical primer. J. Chem. Educ. 2006, 83, 862. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Synergism or antagonism in tribo-performance of nano-greases using combinations of nanoparticles of graphite and PTFE. Appl. Nanosci. 2021, 11, 2525–2536. [Google Scholar] [CrossRef]

- Saxena, A.; Kumar, D.; Tandon, N. Dynamic performance of newly developed environmentally friendly greases containing polysaccharide gums in rolling bearing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 4124–4138. [Google Scholar] [CrossRef]

- Hamnas, A.; Unnikrishnan, G. Bio-lubricants from vegetable oils: Characterization, modifications, applications and challenges–Review. Renew. Sustain. Energy Rev. 2023, 182, 113413. [Google Scholar] [CrossRef]

- Liu, Z.; Xue, W.; Shi, J.; Han, S.; Yan, J. Recent advances in polyalkylene glycol base oil. In Research on Chemical Intermediates; Springer: Berlin, Germany, 2024; pp. 1–25. [Google Scholar]

- Singh, T. Grease production survey report. In Proceedings of the 22nd Lubricating Grease Conference, NLGI India-Chapter, NLGI Missouri, Marriott Hotel, Indore, India, 1–3 February 2020. [Google Scholar]

- Hybská, H.; Mitterpach, J.; Samešová, D.; Schwarz, M.; Fialová, J.; Veverková, D. Assessment of ecotoxicological properties of oils in water. Arc. Environ. Protect. 2018, 44, 31–37. [Google Scholar]

- Cousseau, T.; Graça, B.; Campos, A.; Seabra, J. Grease aging effects on film formation under fully-flooded and starved lubrication. Lubricants 2015, 3, 197–221. [Google Scholar] [CrossRef]

- Hope, K. Polyalphaolefin Lubricant Applications. In Friction, Lubrication, and Wear Technology; Totten, G.E., Ed.; ASM International: Almere, The Netherlands, 2017; Volume 18, pp. 207–212. [Google Scholar]

- Tian, C.; Xu, H.; Dong, J. Development of environmentally friendly lubricant using natural resources: Layered double hydroxide gels. Ind. Crops Prod. 2024, 208, 117879. [Google Scholar] [CrossRef]

- Antonov, S.; Bartko, R.; Nikul’shin, P.; Kilyakova, A.Y.; Tonkonogov, B.; Danilov, A. The Current State of Development of Greases. Chem. Technol. Fuels Oils 2021, 57, 279–288. [Google Scholar] [CrossRef]

- Saxena, A.; Kumar, D.; Tandon, N. Development of lubricious environmentally friendly greases using synergistic natural resources: A potential alternative to mineral oil-based greases. J. Clean. Prod. 2022, 380, 135047. [Google Scholar] [CrossRef]

- Rawat, S.S.; Harsha, A. The lubrication effect of different vegetable oil-based greases on steel-steel tribo-pair. Biomass Convers. Biorefinery 2024, 14, 1993–2005. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Li, F. Comparative study on mechanical properties of sealing grease composed of different base oils for shield tunnel. Materials 2020, 13, 692. [Google Scholar] [CrossRef]

- Lee, C.T.; Lee, M.B.; Chong, W.W.F.; Ng, J.H.; Wong, K.J.; Chong, C.T. Boundary Lubricity of Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester. Lubricants 2022, 10, 346. [Google Scholar] [CrossRef]

- Perera, M.; Yan, J.; Xu, L.; Yang, M.; Yan, Y. Bioprocess development for biolubricant production using non-edible oils, agro-industrial byproducts and wastes. J. Clean. Prod. 2022, 357, 131956. [Google Scholar] [CrossRef]

- Kamyab, B.; Beims, R.; Chambers, D.W.; Bassi, A.S.; Xu, C. Sustainable production of high-performance bio-based hydraulic fluids from vegetable oils: Recent advances, current challenges, and future perspectives. Biomass Bioenergy 2024, 183, 107160. [Google Scholar]

- Shi, Y.; Larsson, R. Non-corrosive and biomaterials protic ionic liquids with high lubricating performance. Tribol. Lett. 2016, 63, 1–7. [Google Scholar] [CrossRef]

- Song, J. Research progress of ionic liquids as lubricants. ACS Omega 2021, 6, 29345–29349. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.K.; Savoy, A.W. Ionic liquids synthesis and applications: An overview. J. Mol. Liquids 2020, 297, 112038. [Google Scholar] [CrossRef]

- Cai, M.; Yu, Q.; Liu, W.; Zhou, F. Ionic liquid lubricants: When chemistry meets tribology. Chem. Soc. Rev. 2020, 49, 7753–7818. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Xia, Y.; Wang, L.; Pu, J.; Chen, T.; Zhang, H. Study of the conductivity and tribological performance of ionic liquid and lithium greases. Tribol. Lett. 2014, 53, 281–291. [Google Scholar] [CrossRef]

- Wang, Z.; Xia, Y.; Liu, Z.; Wen, Z. Conductive lubricating grease synthesized using the ionic liquid. Tribol. Lett. 2012, 46, 33–42. [Google Scholar] [CrossRef]

- Cai, M.; Liang, Y.; Zhou, F.; Liu, W. Tribological properties of novel imidazolium ionic liquids bearing benzotriazole group as the antiwear/anticorrosion additive in poly (ethylene glycol) and polyurea grease for steel/steel contacts. ACS Appl. Mater. Interfaces 2011, 3, 4580–4592. [Google Scholar] [CrossRef]

- Millar, W.; Aman, Z.M.; Atkin, R.; Li, H. Graphite infused ionic liquid greases. Colloids Surf. A Physicochem. Eng. Asp. 2022, 653, 130017. [Google Scholar] [CrossRef]

- Xiao, H. Ionic liquid lubricants: Basics and applications. Tribol. Trans. 2017, 60, 20–30. [Google Scholar] [CrossRef]

- Amin, A.A.E.R.; Salah, H.M.; Kandile, N.G. Fabrication and Evaluation of New Multi-Purpose Grease Using Local Raw Materials. Egypt. J. Chem. 2023, 66, 1033–1041. [Google Scholar] [CrossRef]

- Larsson, E.; Westbroek, R.; Leckner, J.; Jacobson, S.; Rudolphi, Å.K. Unraveling the lubrication mechanisms of lithium complex (LiX)-and polypropylene (PP)-thickened greases in fretting–Part I: Fretting experiments and surface analysis. Wear 2022, 490, 204192. [Google Scholar] [CrossRef]

- Neumann, J.; Petranikova, M.; Meeus, M.; Gamarra, J.D.; Younesi, R.; Winter, M.; Nowak, S. Recycling of lithium-ion batteries—Current state of the art, circular economy, and next generation recycling. Adv. Energy Mater. 2022, 12, 2102917. [Google Scholar] [CrossRef]

- Jopen, M.; Degen, P.; Henzler, S.; Grabe, B.; Hiller, W.; Weberskirch, R. Polyurea thickened lubricating grease—The effect of degree of polymerization on rheological and tribological properties. Polymers 2022, 14, 795. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, P.; Lin, J.; Gao, X. Rheological and tribological properties of lithium grease and polyurea grease with different consistencies. Coatings 2022, 12, 527. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Performance properties of lithium greases with PTFE particles as additive: Controlling parameter-size or shape? Tribol. Int. 2020, 148, 106302. [Google Scholar] [CrossRef]

- Dhanumalayan, E.; Joshi, G.M. Performance properties and applications of polytetrafluoroethylene (PTFE)—A review. Adv. Compos. Hybrid Mater. 2018, 1, 247–268. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I. Tribology of electric vehicles: A review of critical components, current state and future improvement trends. Tribol. Int. 2019, 138, 473–486. [Google Scholar] [CrossRef]

- Vyavhare, K.; Aswath, P.B. Tribological properties of novel multi-walled carbon nanotubes and phosphorus containing ionic liquid hybrids in grease. Front. Mech. Eng. 2019, 5, 15. [Google Scholar] [CrossRef]

- Zhang, R.; Olin, H. Material choices for triboelectric nanogenerators: A critical review. EcoMat 2020, 2, e12062. [Google Scholar] [CrossRef]

- Liao, Y.; Hao, X.; An, M.; Yang, Z.; Ma, L.; Ren, H. Enhancing low-rank coal flotation using mixed collector of dodecane and oleic acid: Effect of droplet dispersion and its interaction with coal particle. Fuel 2020, 280, 118634. [Google Scholar] [CrossRef]

- Marino, F.; Lopez, E.R.; Arnosa, A.; Gómez, M.A.G.; Pineiro, Y.; Rivas, J.; Alvarez-Lorenzo, C.; Fernandez, J. ZnO nanoparticles coated with oleic acid as additives for a polyalphaolefin lubricant. J. Mol. Liquids 2022, 348, 118401. [Google Scholar] [CrossRef]

- Kiriliauskaitė, V.; Bendikienė, V.; Juodka, B. Synthesis of trimethylolpropane esters of oleic acid by Lipoprime 50T. J. Ind. Microbiol. Biotechnol. 2011, 38, 1561–1566. [Google Scholar] [CrossRef] [PubMed]

- Cota, I.; Gonzalez-Olmos, R.; Iglesias, M.; Medina, F. New short aliphatic chain ionic liquids: Synthesis, physical properties, and catalytic activity in aldol condensations. J. Phys. Chem. B 2007, 111, 12468–12477. [Google Scholar] [CrossRef] [PubMed]

- Álvarez, V.H.; Dosil, N.; Gonzalez-Cabaleiro, R.; Mattedi, S.; Martin-Pastor, M.; Iglesias, M.; Navaza, J.M. Brønsted ionic liquids for sustainable processes: Synthesis and physical properties. J. Chem. Eng. Data 2010, 55, 625–632. [Google Scholar] [CrossRef]

- Sofi, S.N.A.M.; Aziz, M.A.A.; Japar, N.S.A.; Rahman, N.W.A.; Abdulhalim, A.R.; Yunus, M.Y.M. Preparation and characterization of grease formulated from waste transformer oil. IOP Conf. Ser. Mater. Sci. Eng. 2019, 702, 012034. [Google Scholar] [CrossRef]

- Rahman, N.W.A.; Ying, S.S.Y.; Aziz, M.A.A. Grease formulation and characterization from waste automotive engine oil with the use of complex thickener. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1195, 012014. [Google Scholar] [CrossRef]

- Mohamed Ariffin, N.A.A.; Foong, S.Y.; Chong, W.W.F.; Lam, S.S.; Ng, J.H.; Zhang, H. Ionic liquid lubricity enhancement with bio-oil derived from microwave pyrolysis of bamboo. Ind. Crops Prod. 2024, 214, 118543. [Google Scholar] [CrossRef]

- Li, Y.H.; Shen, F.; Ke, L.L. Multi-physics electrical contact analysis considering the electrical resistance and Joule heating. Int. J. Solids Struct. 2022, 256, 111975. [Google Scholar] [CrossRef]

- Holm, R. Electric Contacts: Theory and Application; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Harvey, P.D. Engineering Properties of Steels; American Society for Metals: Detroit, MI, USA, 1982. [Google Scholar]

- Shah, R.; Tung, S.; Chen, R.; Miller, R. Grease performance requirements and future perspectives for electric and hybrid vehicle applications. Lubricants 2021, 9, 40. [Google Scholar] [CrossRef]

- Hairunnaja, M.A.; Aziz, M.A.A.; Abdu Rahman, N.W.; Arifin, M.A.; Isa, K.M.; Ali, U.F.M. Innovative Formulation and Characterisation of Grease Made from Waste Engine Oil. Pertanika J. Sci. Technol. 2023, 31, 2375–2387. [Google Scholar] [CrossRef]

- Tripathi, A.K.; Vinu, R. Characterization of thermal stability of synthetic and semi-synthetic engine oils. Lubricants 2015, 3, 54–79. [Google Scholar] [CrossRef]

- Santos, J.C.; Santos, I.M.; Souza, A.G. Thermal degradation of synthetic lubricating oils: Part III–TG and DSC studies. Pet. Sci. Technol. 2017, 35, 540–546. [Google Scholar] [CrossRef]

- Al-Amiery, A.A.; Isahak, W.N.R.W.; Al-Azzawi, W.K. Corrosion inhibitors: Natural and synthetic organic inhibitors. Lubricants 2023, 11, 174. [Google Scholar] [CrossRef]

- Su, H.; Zhao, Q.; Chen, Y.; Zhao, Q.; Jiang, C.; Lou, W. Synthesis and investigation of phosphorus-free ionic liquids as multifunctional lubricating additives. RSC Adv. 2022, 12, 25134–25142. [Google Scholar] [CrossRef]

- Kreivaitis, R.; Gumbytė, M.; Kupčinskas, A.; Kazancev, K.; Makarevičienė, V. Investigating the tribological properties of PILs derived from different ammonium cations and long chain carboxylic acid anion. Tribol. Int. 2020, 141, 105905. [Google Scholar] [CrossRef]

- Grechin, A.; Schott, V.; Kling, R. PFPE-Greases: Modern trends and perspectives. In Proceedings of the Conference ELGI AGM, London, UK, 21–24 April 2018; pp. 1–11. [Google Scholar]

- Mohamed Ariffin, N.A.A.; Lee, C.T.; Lee, M.B.; Halid, I.; Hamdan, S.H.; Ismail, M.I.; Chong, W.W.F.; Zhang, H. Enhancing boundary friction and wear reduction through adsorption control in protic ionic liquid and carbon mixtures. J. Mater. Sci. 2024, 59, 794–809. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Li, X.; Li, A.; Lu, Z.; Zhang, G.; Wu, Z. The Friction and Wear Properties of Metal-Doped DLC Films under Current-Carrying Condition. Tribol. Trans. 2019, 62, 1119–1128. [Google Scholar] [CrossRef]

- Bermúdez, M.D.; Jiménez, A.E.; Sanes, J.; Carrión, F.J. Ionic liquids as advanced lubricant fluids. Molecules 2009, 14, 2888–2908. [Google Scholar] [CrossRef]

- Verma, D.K.; Dewangan, Y.; Singh, A.K.; Mishra, R.; Susan, M.A.B.H.; Salim, R.; Taleb, M.; Hajjaji, F.E.; Berdimurodov, E. Ionic liquids as green and smart lubricant application: An overview. Ionics 2022, 28, 4923–4932. [Google Scholar] [CrossRef]

- Yalcin, D.; Drummond, C.J.; Greaves, T.L. Solvation properties of protic ionic liquids and molecular solvents. Phys. Chem. Chem. Phys. 2020, 22, 114–128. [Google Scholar] [CrossRef]

- Fry, B.M.; Chui, M.Y.; Moody, G.; Wong, J.S. Interactions between organic friction modifier additives. Tribol. Int. 2020, 151, 106438. [Google Scholar] [CrossRef]

- Reddy, A.B.; Shah, F.U.; Leckner, J.; Rutland, M.W.; Glavatskih, S. Ionic liquids enhance electrical conductivity of greases: An impedance spectroscopy study. Colloids Surf. A Physicochem. Eng. Asp. 2024, 683, 132875. [Google Scholar] [CrossRef]

- Nyholm, N.; Espallargas, N. Functionalized carbon nanostructures as lubricant additives—A review. Carbon 2023, 201, 1200–1228. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).