A Review on the Dynamic Performance Studies of Gas Foil Bearings

Abstract

1. Introduction

2. Dynamic Coefficients of GFB

2.1. Dynamic Stiffness and Damping of Foil Structures

2.1.1. Modeling Studies of Bump-Type Bearings

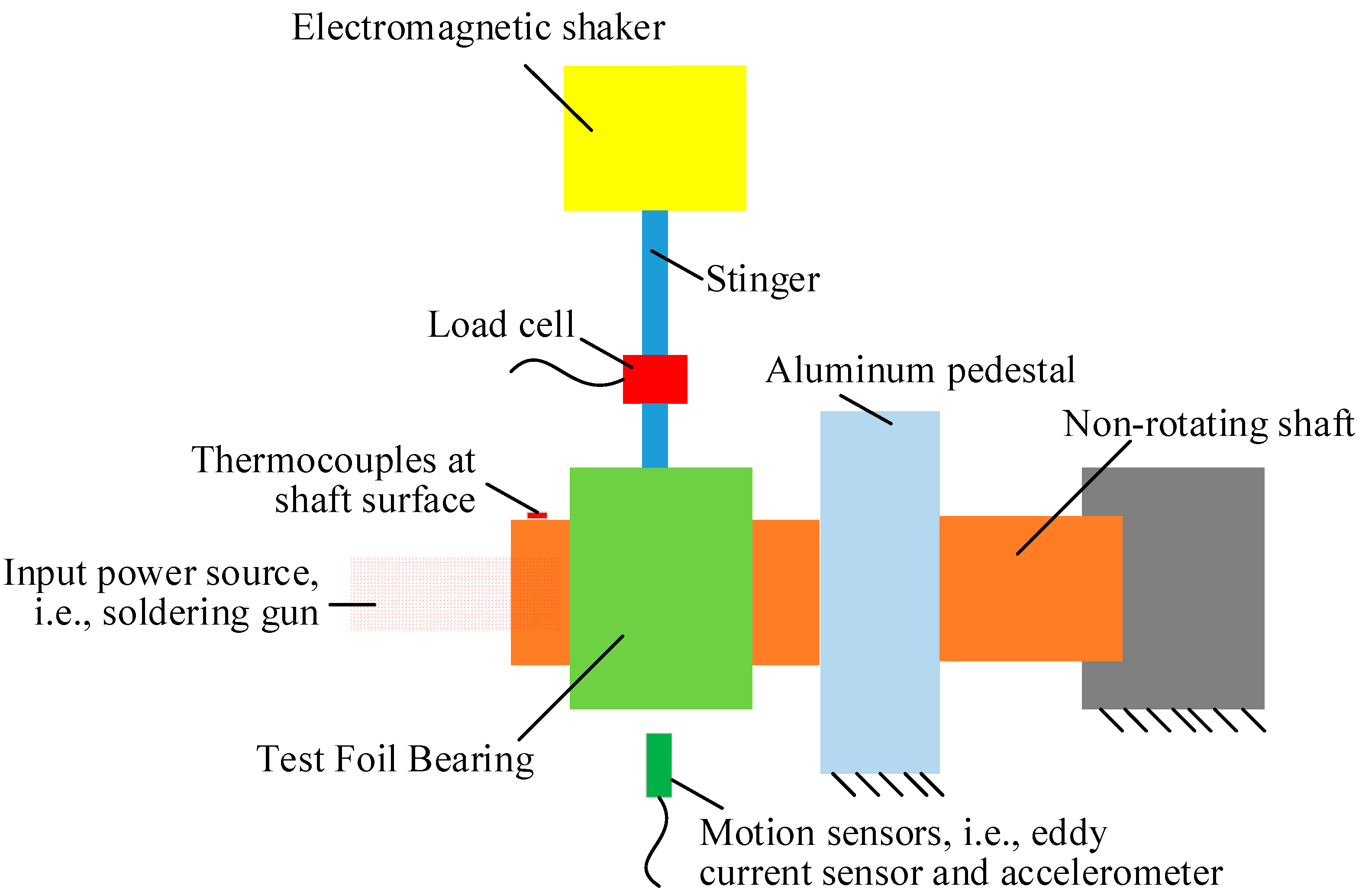

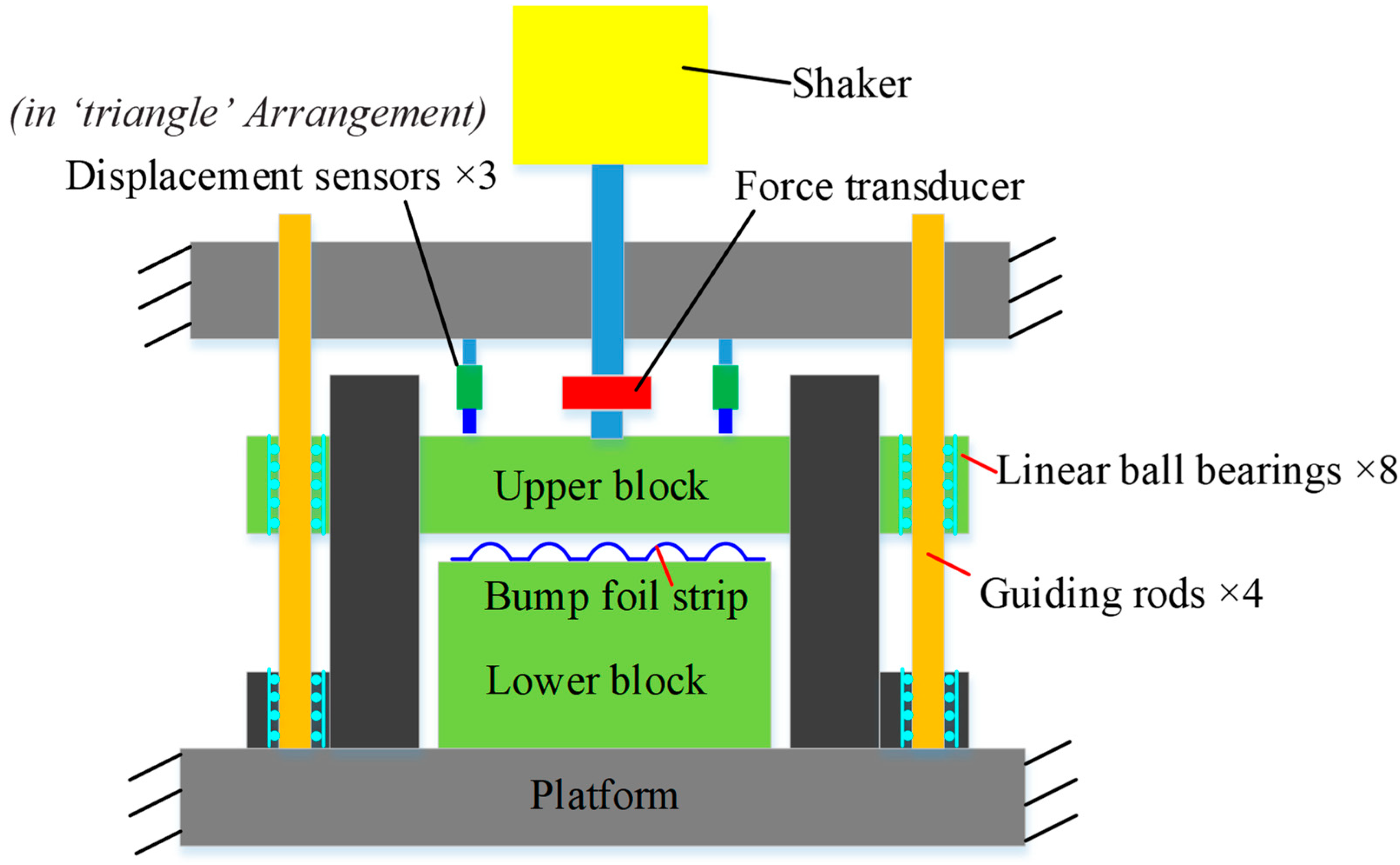

2.1.2. Experimental Studies of Bump-Type Bearings

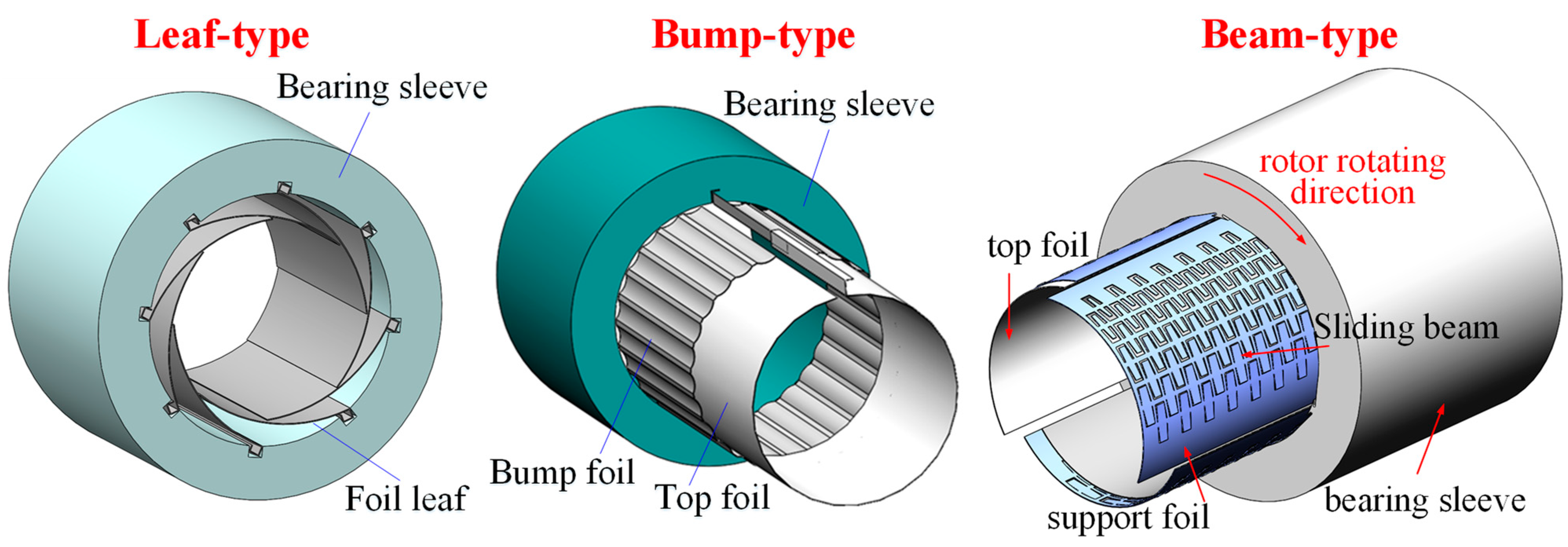

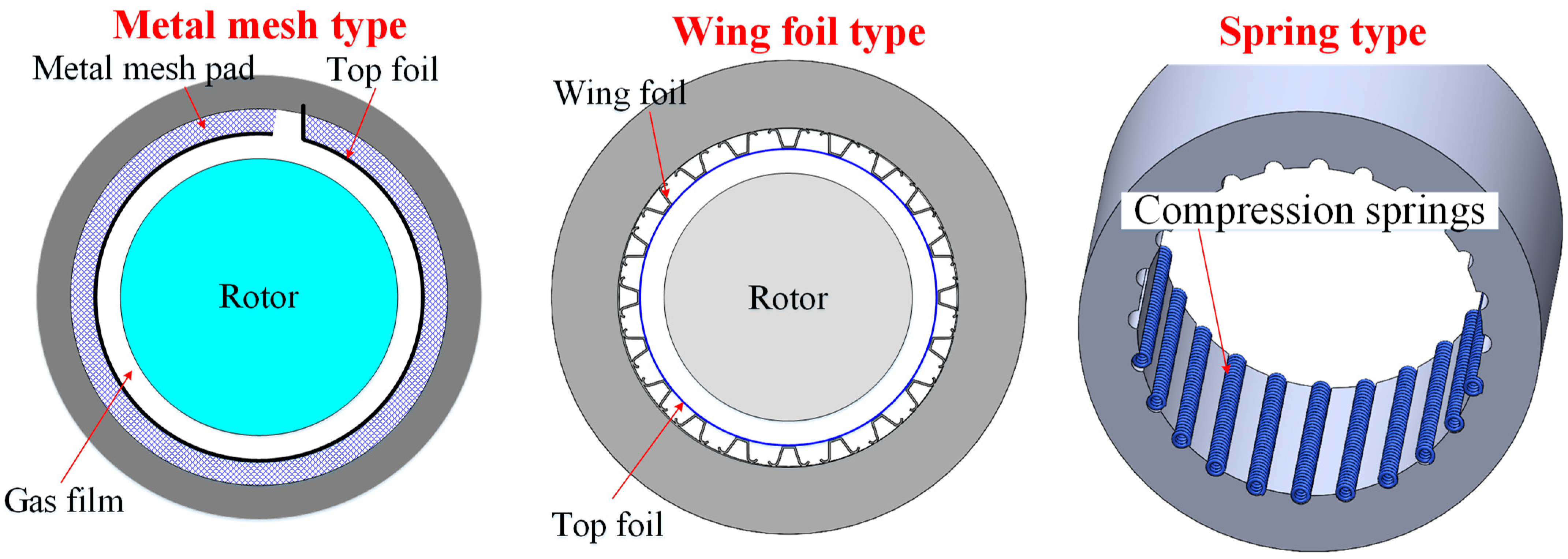

2.1.3. Studies of Other Types of Foil Bearings

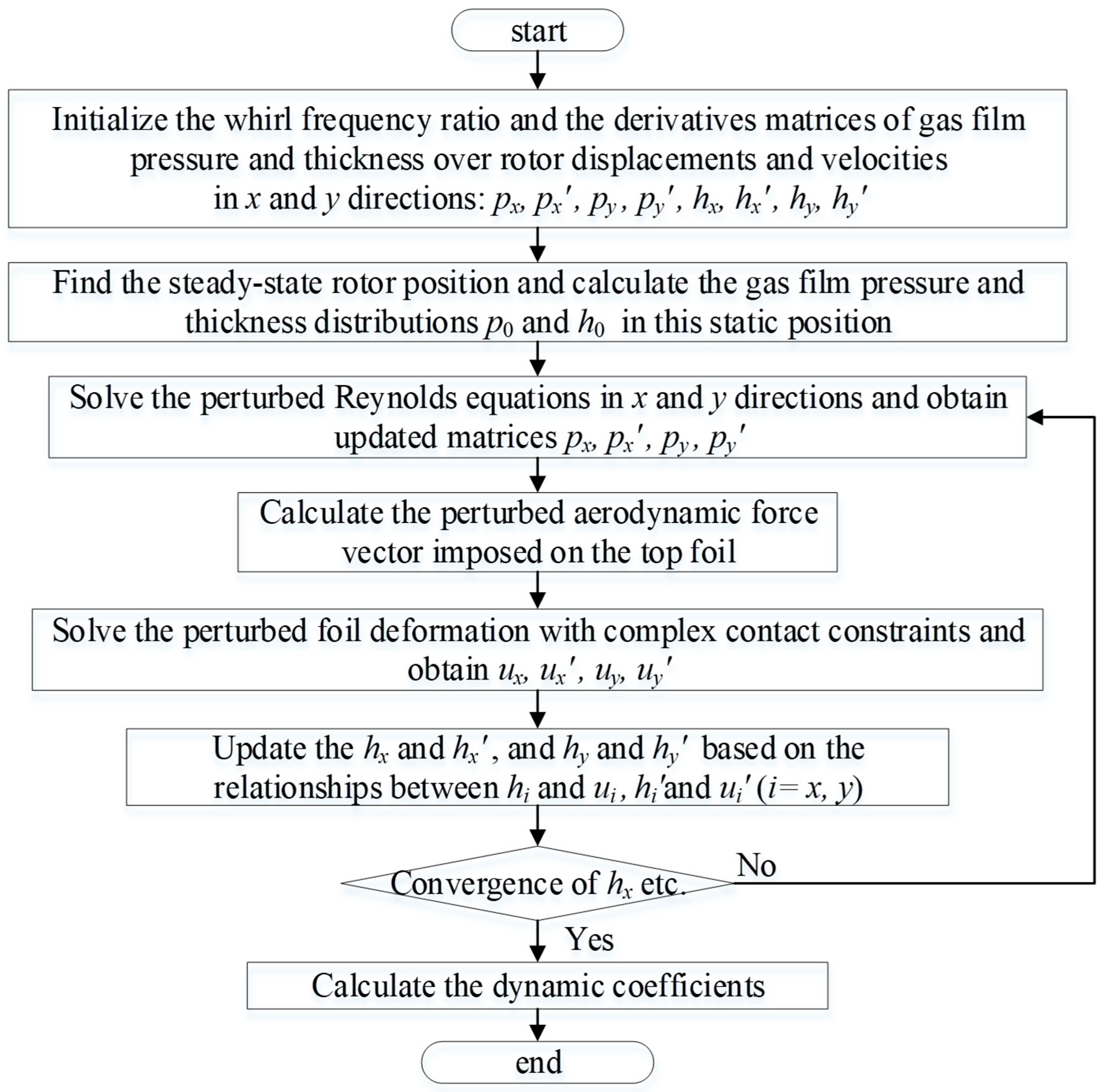

2.2. Dynamic Coefficients of the Aero-Elastic System and Linear Stability

3. Nonlinear Rotor Stability and Vibrations Supported by GFBs and Bifurcation Analyses

4. Active Methods of Controlling GFB Dynamic Performance

5. Conclusions

- (1)

- The dynamic excitation models of foil structures become more and more comprehensive and elaborate, including the full bearing structure, complex contact constraints, dynamic friction force, etc.

- (2)

- The perturbation methods experience significant improvements in dealing with simple to complex foil structures. In addition, different approaches such as multi-mode analyses applying eigenvalues and eigenvectors in the s-domain were proposed to increase the predicting accuracy of rotor instability speed.

- (3)

- The initial models for predicting nonlinear responses of the rotor–foil bearing system adopted the weak coupling method and the simple elastic foundation model of the foil structure, in which the Coulomb frictional damping is replaced by the equivalent viscous damping. After decades of developments, the latest models are able to solve the simultaneous coupling problem of multiple physic fields with complex foil structures and can also consider the real Coulomb friction effect as well as complex contact constraints.

- (4)

- The active gas foil bearings were proposed and studied in both dynamic modeling and control methods. Active bearings seem to have good potential in high-speed turbomachinery but still need validations in their applications.

Author Contributions

Funding

Conflicts of Interest

References

- Pattnayak, M.R.; Ganai, P.; Pandey, R.K.; Dutt, J.K.; Fillon, M. An overview and assessment on aerodynamic journal bearings with important findings and scope for explorations. Tribol. Int. 2022, 174, 107778. [Google Scholar] [CrossRef]

- Priyadarshini, S.; Behera, S.K. A comprehensive review on advancements in compliant structures of gas foil journal bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2024, 1–27. [Google Scholar] [CrossRef]

- Kumar, J.; Khamari, D.S.; Behera, S.K.; Sahoo, R.K. A review of thermohydrodynamic aspects of gas foil bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1466–1490. [Google Scholar] [CrossRef]

- Xu, Z.; Li, C.; Du, J.; Li, J.; Wang, Y. Load-carrying characteristics of bump-type gas foil thrust bearings. Int. J. Mech. Sci. 2023, 244, 108080. [Google Scholar] [CrossRef]

- Kumar, J.; Khamari, D.S.; Behera, S.K.; Sahoo, R.K. Influence of slip-flow phenomenon on thermohydrodynamic behaviour of gas foil thrust bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 15–30. [Google Scholar] [CrossRef]

- Agrawal, G.L. Foil Air/Gas Bearing Technology-An Overview. Am. Soc. Mech. Eng. 1997. [Google Scholar] [CrossRef]

- Khamari, D.S.; Behera, S.K. Numerical and experimental studies on feasibility of a cryogenic turboexpander rotor supported on gas foil bearings. Sadhana 2023, 48, 224. [Google Scholar] [CrossRef]

- Heshmat, H.; Walton, J.F.; Corte, C.D.; Valco, M. Oil-Free Turbocharger Demonstration Paves Way to Gas Turbine Engine Applications. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000. [Google Scholar]

- DellaCorte, C.; Bruckner, R.J. Remaining Technical Challenges and Future Plans for Oil-Free Turbomachinery. J. Eng. Gas Turbines Power 2011, 133, 042502. [Google Scholar] [CrossRef]

- Li, C.; Du, J.; Zhu, J.; Yao, Y. Effects of structural parameters on the load carrying capacity of the multi-leaf gas foil journal bearing based on contact mechanics. Tribol. Int. 2018, 131, 318–331. [Google Scholar] [CrossRef]

- Heshmat, H.; Walowit, J.; Pinkus, O. Analysis of Gas-Lubricated Foil Journal Bearings. J. Lubr. Technol. 1983, 105, 647–655. [Google Scholar] [CrossRef]

- Li, C.; Du, J.; Yao, Y. Study of load carrying mechanism of a novel three-pad gas foil bearing with multiple sliding beams. Mech. Syst. Signal Process. 2020, 135, 106372. [Google Scholar] [CrossRef]

- Suriano, F.J. Gas Foil Bearing Development Program; Garrett Turbine Engine Co.: Phoenix, AZ, USA, 1981. [Google Scholar]

- San Andres, L.; Abraham Chirathadam, T. A Metal Mesh Foil Bearing and a Bump-Type Foil Bearing: Comparison of Performance for Two Similar Size Gas Bearings. J. Eng. Gas Turbines Power 2012, 134, 102501. [Google Scholar] [CrossRef]

- Swanson, E.E.; O’Meara, P.S. The Wing Foil: A Novel Compliant Radial Foil Bearing Design. J. Eng. Gas Turbines Power 2018, 140, 082701.1–082701.7. [Google Scholar] [CrossRef]

- Song, J.H.; Kim, D. Foil Gas Bearing With Compression Springs: Analyses and Experiments. J. Tribol. 2007, 129, 628–639. [Google Scholar] [CrossRef]

- Feng, K.; Hu, J.; Liu, W.; Zhao, X.; Li, W. Structural Characterization of a Novel Gas Foil Bearing With Nested Compression Springs: Analytical Modeling and Experimental Measurement. J. Eng. Gas Turbines Power 2016, 138, 012504. [Google Scholar] [CrossRef]

- Feng, K.; Zhao, X.; Huo, C.; Zhang, Z. Analysis of novel hybrid bump-metal mesh foil bearings. Tribol. Int. 2016, 103, 529–539. [Google Scholar] [CrossRef]

- Yazdi, B.Z.; Kim, D. Rotordynamic Performance of Hybrid Air Foil Bearings with Regulated Hydrostatic Injection. J. Eng. Gas Turbines Power 2018, 140, 012506. [Google Scholar] [CrossRef]

- Hou, Y.; Zheng, Y.; Chen, S.; Liu, X.; Lai, T. The numerical study of static and dynamic characteristics of multi-layer protuberant foil bearing. J. Adv. Mech. Des. Syst. Manuf. 2015, 9, JAMDSM0058. [Google Scholar] [CrossRef]

- Feng, K.; Zhu, P.; Wu, Y.; Guan, Y.; Li, W. A novel gas foil bearing with negative Poisson’s ratio structure and embedded damping materials: Numerical and experimental investigations. Mech. Syst. Signal Process. 2023, 198, 110419. [Google Scholar] [CrossRef]

- Dellacorte, C.; Valco, M.J. Load Capacity Estimation of Foil Air Journal Bearings for Oil-Free Turbomachinery Applications. Tribol. Trans. 2008, 43, 795–801. [Google Scholar] [CrossRef]

- Zhao, X.; Xiao, S. A Finite Element Model for Static Performance Analysis of Gas Foil Bearings Based on Frictional Contacts. Tribol. Trans. 2021, 64, 275–286. [Google Scholar] [CrossRef]

- DellaCorte, C.; Radil, K.C.; Bruckner, R.J.; Howard, S.A. Design, Fabrication, and Performance of Open Source Generation I and II Compliant Hydrodynamic Gas Foil Bearings. Tribol. Trans. 2008, 51, 254–264. [Google Scholar] [CrossRef]

- Heshmat, H. High Load Capacity Compliant Foil Hydrodynamic Journal Bearing. US5902049A, 11 May 1999. [Google Scholar]

- Li, C.; Li, J.; Xu, Z.; Zhao, X.; Du, J. Load carrying performance of the 2nd and 3rd generation journal bump foil bearings including two dimensional stiffness variations. Tribol. Int. 2023, 190, 109016. [Google Scholar] [CrossRef]

- San Andrés, L.; Kim, T.H. Analysis of gas foil bearings integrating FE top foil models. Tribol. Int. 2009, 42, 111–120. [Google Scholar] [CrossRef]

- Le Lez, S.; Arghir, M.; Frene, J. A new bump-type foil bearing structure analytical model. J. Eng. Gas Turbines Power 2007, 129, 1047–1057. [Google Scholar] [CrossRef]

- Arghir, M.; Benchekroun, O. A simplified structural model of bump-type foil bearings based on contact mechanics including gaps and friction. Tribol. Int. 2019, 134, 129–144. [Google Scholar] [CrossRef]

- Feng, K.; Kaneko, S. Analytical model of bump-type foil bearings using a link-spring structure and a finite-element shell model. J. Tribol. 2010, 132, 021706. [Google Scholar] [CrossRef]

- Lee, D.-H.; Kim, Y.-C.; Kim, K.-W. The static performance analysis of foil journal bearings considering three-dimensional shape of the foil structure. J. Tribol. 2008, 130, 031102. [Google Scholar] [CrossRef]

- Zhao, X.; Xiao, S. A three-dimensional model of gas foil bearings and the effect of misalignment on the static performance of the first and second generation foil bearings. Tribol. Int. 2021, 156, 106821. [Google Scholar] [CrossRef]

- Xu, Z.; Li, C.; Du, J. Modeling and static characteristics study of the double-layer bump gas foil bearing. Tribol. Int. 2021, 164, 107202. [Google Scholar] [CrossRef]

- Li, C.; Du, J.; Li, J.; Xu, Z.; Zhao, C. Investigations on the Load Capacity of Multilayer Foil Thrust Bearing Based on an Updated Complete Model. J. Tribol. 2023, 145, 021202. [Google Scholar] [CrossRef]

- Li, C.; Du, J.; Yao, Y. Modeling of a multi-layer foil gas thrust bearing and its load carrying mechanism study. Tribol. Int. 2017, 114, 172–185. [Google Scholar] [CrossRef]

- Grau, G.; Iordanoff, I.; Bou Said, B.; Berthier, Y. An Original Definition of the Profile of Compliant Foil Journal Gas Bearings: Static and Dynamic Analysis. Tribol. Trans. 2004, 47, 248–256. [Google Scholar] [CrossRef]

- Iordanoff, I. Analysis of an Aerodynamic Compliant Foil Thrust Bearing: Method for a Rapid Design. J. Tribol. 1999, 121, 816–822. [Google Scholar] [CrossRef]

- Kim, T.H.; San Andrés, L. Heavily Loaded Gas Foil Bearings: A Model Anchored to Test Data. J. Eng. Gas Turbines Power 2008, 130, 012504. [Google Scholar] [CrossRef]

- Kumar, J.; Khamari, D.S.; Behera, S.K.; Sahoo, R.K. A methodology for performance prediction: Aerodynamic analysis of axially loaded gas foil bearing. Sadhana 2021, 46, 193. [Google Scholar] [CrossRef]

- Khamari, D.S.; Kumar, J.; Behera, S.K. A Review on Modeling and Stability Aspects of Gas Foil Bearing Supported Rotors. Tribol. Ind. 2023, 45, 12–33. [Google Scholar] [CrossRef]

- Ku, C.P.R.; Heshmat, H. Compliant Foil Bearing Structural Stiffness Analysis: Part I—Theoretical Model Including Strip and Variable Bump Foil Geometry. J. Tribol. 1992, 114, 394–400. [Google Scholar] [CrossRef]

- Ku CP, R.; Heshmat, H. Structural Stiffness and Coulomb Damping in Compliant Foil Journal Bearings: Theoretical Considerations. Tribol. Trans. 1994, 37, 525–533. [Google Scholar]

- Ku CP, R.; Heshmat, H. Structural Stiffness and Coulomb Damping in Compliant Foil Journal Bearings: Parametric Studies. Tribol. Trans. 1994, 37, 455–462. [Google Scholar]

- Swanson, E.E. Bump Foil Damping Using a Simplified Model. J. Tribol. 2006, 128, 542–550. [Google Scholar] [CrossRef][Green Version]

- Le Lez Sébastien Arghir, M.; Frene, J. A Dynamic Model for Dissipative Structures used in Bump-Type Foil Bearings. Tribol. Trans. 2008, 52, 36–46. [Google Scholar] [CrossRef]

- Petrov, E.P.; Ewins, D.J. Generic Friction Models for Time-Domain Vibration Analysis of Bladed Disks. J. Turbomach. 2004, 126, 184–192. [Google Scholar] [CrossRef]

- Feng, K.; Guo, Z. Prediction of Dynamic Characteristics of a Bump-Type Foil Bearing Structure with Consideration of Dynamic Friction. Tribol. Trans. 2014, 57, 230–241. [Google Scholar] [CrossRef]

- Armstrong-Helouvry, B.P. Control of Machines with Friction; Kluwer Academic Publishers: Boston, MA, USA, 1991. [Google Scholar]

- Hoffmann, R.; Liebich, R. Experimental and numerical analysis of the dynamic behavior of a foil bearing structure affected by metal shims. Tribol. Int. 2017, 115, 378–388. [Google Scholar] [CrossRef]

- Zywica, G.; Baginski, P.; Bogulicz, M.; Martowicz, A.; Roemer, J.; Kantor, S. Numerical identification of the dynamic characteristics of a nonlinear foil bearing structure: Effect of the excitation force amplitude and the assembly preload. J. Sound Vib. 2022, 520, 116663. [Google Scholar] [CrossRef]

- Heshmat, H.; Ku CP, R. Structural Damping of Self-Acting Compliant Foil Journal Bearings. J. Tribol. 1994, 116, 76–82. [Google Scholar] [CrossRef]

- Ku CP, R.; Heshmat, H. Effects of Static Load on Dynamic Structural Properties in a Flexible Supported Foil Journal Bearing. J. Vib. Acoust. 1994, 116, 257–262. [Google Scholar]

- Ku, C.P.R. Dynamic Structural Properties of Compliant Foil Thrust Bearings-Comparison between Experimental and Theoretical Results. J. Tribol. 1994, 116, 70–75. [Google Scholar] [CrossRef]

- Salehi, M.; Heshmat, H.; Walton, J.F. On the Frictional Damping Characterization of Compliant Bump Foils. J. Tribol. 2003, 125, 804–813. [Google Scholar] [CrossRef]

- Rubio, D.; San Andres, L. Structural Stiffness, Dry Friction Coefficient, and Equivalent Viscous Damping in a Bump-Type Foil Gas Bearing. J. Eng. Gas Turbines Power 2006, 129, 494–502. [Google Scholar] [CrossRef]

- Kim, T.H.; Breedlove, A.W.; San Andrés, L. Characterization of a Foil Bearing Structure at Increasing Temperatures: Static Load and Dynamic Force Performance. J. Tribol. 2009, 131, 041703. [Google Scholar] [CrossRef]

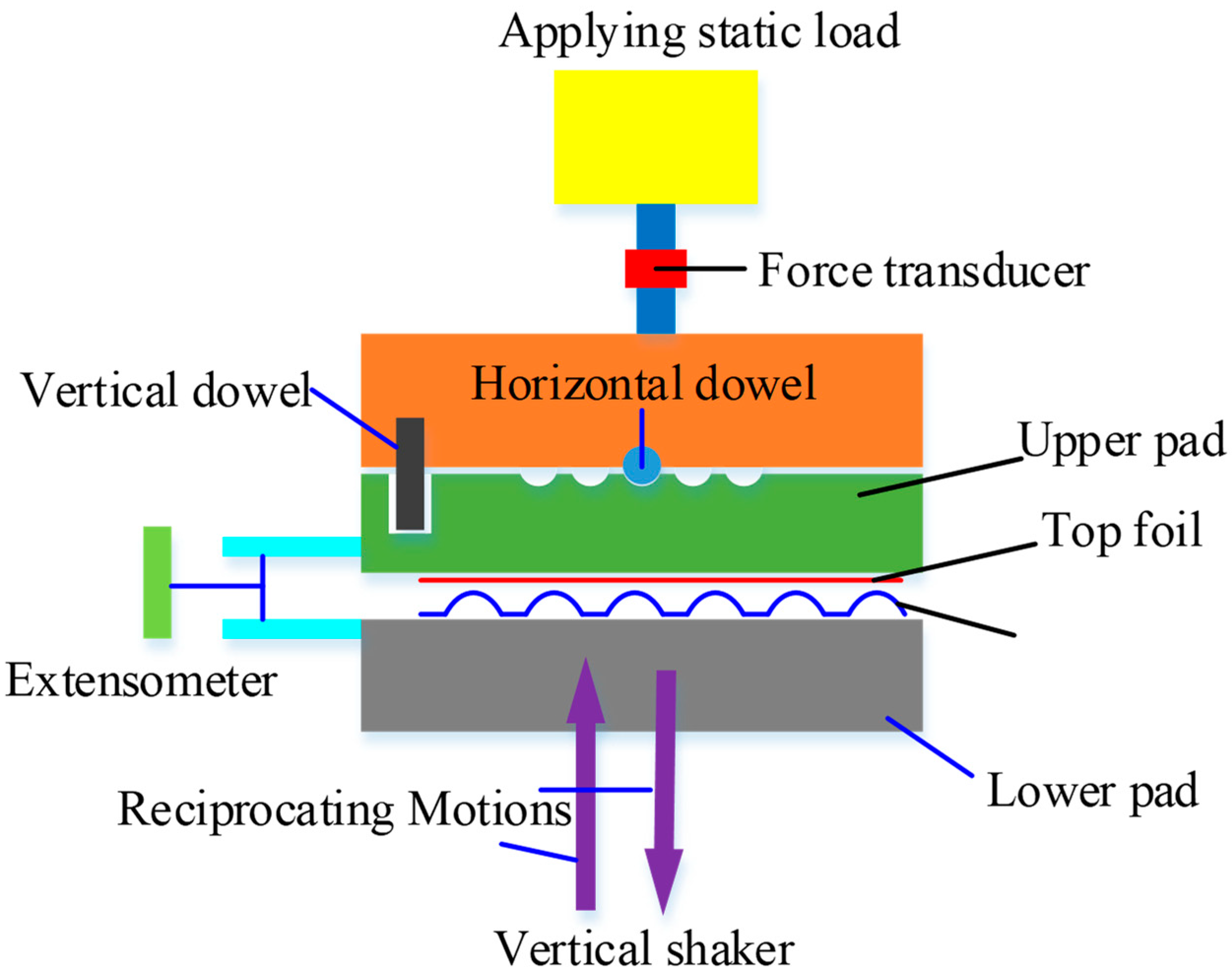

- Larsen, J.S.; Varela, A.C.; Santos, I.F. Numerical and experimental investigation of bump foil mechanical behaviour. Tribol. Int. 2014, 74, 46–56. [Google Scholar] [CrossRef]

- Schmiedeke, H.; Sinapius, M.; Prechavut, N. Experimental Investigation of the Leaf Type Bearing Structure with Undersprings Under Dynamic Excitation. Machines 2021, 9, 15. [Google Scholar] [CrossRef]

- Li, C.; Du, J.; Li, J.; Xu, Z. Investigations on the Frictional Hysteresis Effect of Multi-Leaf Journal Foil Bearing: Modeling, Predictions and Validations. Lubricants 2022, 10, 261. [Google Scholar] [CrossRef]

- Feng, K.; Zhao, X.; Guo, Z. Design and structural performance measurements of a novel multi-cantilever foil bearing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1830–1838. [Google Scholar] [CrossRef]

- Lund, J.W. Calculation of Stiffness and Damping Properties of Gas Bearings. J. Tribol. 1968, 90, 793–803. [Google Scholar] [CrossRef]

- Peng, J.P.; Carpino, M. Calculation of Stiffness and Damping Coefficients for Elastically Supported Gas Foil Bearings. J. Tribol. 1993, 115, 20–27. [Google Scholar] [CrossRef]

- Peng, J.P.; Carpino, M. Coulomb Friction Damping Effects in Elastically Supported Gas Foil Bearings. Tribol. Trans. 1994, 37, 91–98. [Google Scholar] [CrossRef]

- Peng, J.P.; Carpino, M. Finite Element Approach to the Prediction of Foil Bearing Rotor Dynamic Coefficients. J. Tribol. 1997, 119, 85–90. [Google Scholar] [CrossRef]

- Carpino, M.; Talmage, G. Prediction of Rotor Dynamic Coefficients in Gas Lubricated Foil Journal Bearings with Corrugated Sub-Foils. Tribol. Trans. 2006, 49, 400–409. [Google Scholar] [CrossRef]

- Howard, S.; Dellacorte, C.; Valco, M.J.; Prahl, J.M.; Heshmat, H. Dynamic Stiffness and Damping Characteristics of a High-Temperature Air Foil Journal Bearing. Tribol. Trans. 2001, 44, 657–663. [Google Scholar] [CrossRef]

- Kim, D. Parametric Studies on Static and Dynamic Performance of Air Foil Bearings with Different Top Foil Geometries and Bump Stiffness Distributions. J. Tribol. 2007, 129, 354–364. [Google Scholar] [CrossRef]

- Larsen, J.S.; Santos, I.F.; von Osmanski, S. Stability of rigid rotors supported by air foil bearings: Comparison of two fundamental approaches. J. Sound Vib. 2016, 381, 179–191. [Google Scholar] [CrossRef]

- von Osmanski, S.; Larsen, J.S.; Santos, I.F. Multi-domain stability and modal analysis applied to Gas Foil Bearings: Three approaches. J. Sound Vib. 2020, 472, 115174. [Google Scholar] [CrossRef]

- Pronobis, T.; Liebich, R. Comparison of stability limits obtained by time integration and perturbation approach for Gas Foil Bearings. J. Sound Vib. 2019, 458, 497–509. [Google Scholar] [CrossRef]

- Hoffmann, R.; Pronobis, T.; Liebich, R. Non-linear Stability Analysis of a Modified Gas Foil Bearing Structure. In Mechanisms and Machine Science: Proceedings of the 9th IFToMM International Conference on Rotor Dynamics; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Gu, Y.; Ren, G.; Zhou, M. A novel method for calculating the dynamic force coefficients of Gas Foil Bearings and its application in the rotordynamic analysis. J. Sound Vib. 2021, 515, 116466. [Google Scholar] [CrossRef]

- Zhou, R.; Gu, Y.; Ren, G.; Yu, S. Alternative linear dynamic analysis method for gas foil bearing rotor systems using bearing s-domain impedance. Mech. Syst. Signal Process. 2023, 205, 110844. [Google Scholar] [CrossRef]

- Bonello, P.; Pham, H.M. The efficient computation of the nonlinear dynamic response of a foil–air bearing rotor system. J. Sound Vib. 2014, 333, 3459–3478. [Google Scholar] [CrossRef]

- Bonello, P. The extraction of Campbell diagrams from the dynamical system representation of a foil-air bearing rotor model. Mech. Syst. Signal Process. 2019, 129, 502–530. [Google Scholar] [CrossRef]

- Bonello, P. The effects of air film pressure constraints and top foil detachment on the static equilibrium, stability and modal characteristics of a foil-air bearing rotor model. J. Sound Vib. 2020, 485, 115590. [Google Scholar] [CrossRef]

- Bonello, P.; Pourashraf, T. A comparison of modal analyses of foil-air bearing rotor systems using two alternative linearisation methods. Mech. Syst. Signal Process. 2022, 170, 108714. [Google Scholar] [CrossRef]

- Li, C.; Du, J.; Li, J.; Xu, Z. Linear stability and nonlinear rotor responses of the gas foil bearing with multiple sliding beams. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 5247–5272. [Google Scholar] [CrossRef]

- Yang, P.; Zhu, K.Q.; Wang, X.L. On the non-linear stability of self-acting gas journal bearings. Tribol. Int. 2009, 42, 71–76. [Google Scholar] [CrossRef]

- Wang, C.; Chen, C. Bifurcation Analysis of Self-Acting Gas Journal Bearings. J. Tribol. 2001, 123, 755–767. [Google Scholar] [CrossRef]

- Zhang, J.; Kang, W.; Liu, Y. Numerical Method and Bifurcation Analysis of Jeffcott Rotor System Supported in Gas Journal Bearings. J. Comput. Nonlinear Dyn. 2009, 4, 011007. [Google Scholar] [CrossRef]

- Andrés, L.S.; Rubio, D.; Kim, T.H. Rotordynamic Performance of a Rotor Supported on Bump Type Foil Gas Bearings: Experiments and Predictions. J. Eng. Gas Turbines Power 2006, 129, 850–857. [Google Scholar] [CrossRef]

- San Andrés, L.; Kim, T.H. Forced nonlinear response of gas foil bearing supported rotors. Tribol. Int. 2008, 41, 704–715. [Google Scholar] [CrossRef]

- Balducchi, F.; Arghir, M.; Gauthier, R. Experimental Analysis of the Unbalance Response of Rigid Rotors Supported on Aerodynamic Foil Bearings. J. Vib. Acoust. 2015, 137, 061014. [Google Scholar] [CrossRef]

- Guo, Z.; Peng, L.; Feng, K.; Liu, W. Measurement and prediction of nonlinear dynamics of a gas foil bearing supported rigid rotor system. Measurement 2018, 121, 205–217. [Google Scholar] [CrossRef]

- Guo, Z.; Feng, K.; Liu, T.; Lyu, P.; Zhang, T. Nonlinear dynamic analysis of rigid rotor supported by gas foil bearings: Effects of gas film and foil structure on subsynchronous vibrations. Mech. Syst. Signal Process. 2018, 107, 549–566. [Google Scholar] [CrossRef]

- Guo, Z.; Cao, Y.; Feng, K.; Guan, H.; Zhang, T. Effects of static and imbalance loads on nonlinear response of rigid rotor supported on gas foil bearings. Mech. Syst. Signal Process. 2019, 133, 106271. [Google Scholar] [CrossRef]

- Le Lez, S.; Arghir, M.; Frene, J. Nonlinear Numerical Prediction of Gas Foil Bearing Stability and Unbalanced Response. J. Eng. Gas Turbines Power 2009, 131, 012503. [Google Scholar] [CrossRef]

- IIordanoff, I.; Bou-Saïd, B.; Berthier, Y. Effect of friction in the dynamic behavior of aerodynamic foil bearing bearings. Tribol. Int. 2005, 41, 387–395. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, Y.C.; Kim, K.W. The Dynamic Performance Analysis of Foil Journal Bearings Considering Coulomb Friction: Rotating Unbalance Response. Tribol. Trans. 2009, 52, 146–156. [Google Scholar] [CrossRef]

- Bhore, S.P.; Darpe, A.K. Nonlinear dynamics of flexible rotor supported on the gas foil journal bearings. J. Sound Vib. 2013, 332, 5135–5150. [Google Scholar] [CrossRef]

- Hoffmann, R.; Liebich, R. Characterisation and calculation of nonlinear vibrations in gas foil bearing systems–An experimental and numerical investigation. J. Sound Vib. 2018, 412, 389–409. [Google Scholar] [CrossRef]

- Bonello, P.; Hassan, M.F.B. An experimental and theoretical analysis of a foil-air bearing rotor system. J. Sound Vib. 2018, 413, 395–420. [Google Scholar] [CrossRef]

- Bin Hassan, M.F.; Bonello, P. A new modal-based approach for modelling the bump foil structure in the simultaneous solution of foil-air bearing rotor dynamic problems. J. Sound Vib. 2017, 396, 255–273. [Google Scholar] [CrossRef]

- Bonello, P.; Pham, H. Nonlinear Dynamic Analysis of a Turbocharger on Foil-Air Bearings with Focus on Stability and Self-Excited Vibration. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Larsen, J.S.; Santos, I.F. On the nonlinear steady-state response of rigid rotors supported by air foil bearings—Theory and experiments. J. Sound Vib. 2015, 346, 284–297. [Google Scholar] [CrossRef]

- von Osmanski, S.; Larsen, J.S.; Santos, I.F. A fully coupled air foil bearing model considering friction—Theory & experiment. J. Sound Vib. 2017, 400, 660–679. [Google Scholar] [CrossRef]

- Leister, T.; Baum, C.; Seemann, W. On the Importance of Frictional Energy Dissipation in the Prevention of Undesirable Self-Excited Vibrations in Gas Foil Bearing Rotor Systems. Tech. Mech. 2017, 37, 280–290. [Google Scholar]

- Feng, K.; Guan, H.-Q.; Zhao, Z.-L.; Liu, T.-Y. Active bump-type foil bearing with controllable mechanical preloads. Tribol. Int. 2018, 120, 187–202. [Google Scholar] [CrossRef]

- Guan, H.-Q.; Feng, K.; Cao, Y.-L.; Huang, M.; Wu, Y.-H.; Guo, Z.-Y. Experimental and theoretical investigation of rotordynamic characteristics of a rigid rotor supported by an active bump-type foil bearing. J. Sound Vib. 2020, 466, 115049. [Google Scholar] [CrossRef]

- Guan, H.-Q.; Feng, K.; Yu, K.; Cao, Y.-L.; Wu, Y.-H. Nonlinear dynamic responses of a rigid rotor supported by active bump-type foil bearings. Nonlinear Dyn. 2020, 100, 2241–2264. [Google Scholar] [CrossRef]

- Guan, H.; Feng, K.; Yu, K.; Sun, D.; Cao, Y. Real-time control of rotor vibrations with active bump-type foil bearings. IEEE Trans. Ind. Electron. 2020, 68, 7412–7421. [Google Scholar] [CrossRef]

- Guan, H.; Wei, K.; Mao, W.; He, Q.; Zou, H. Study on the static and dynamic performance of active bump-metal mesh foil bearings. Mech. Syst. Signal Process. 2023, 184, 109690. [Google Scholar] [CrossRef]

- Park, J.; Sim, K. A Feasibility Study of Controllable Gas Foil Bearings with Piezoelectric Materials Via Rotordynamic Model Predictions. J. Eng. Gas Turbines Power 2019, 141, 021027. [Google Scholar] [CrossRef]

- Sadri, H.; Schlums, H.; Sinapius, M. Design Characteristics of an Aerodynamic Foil Bearing With Adaptable Bore Clearance. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Sadri, H.; Schlums, H.; Sinapius, M. Investigation of Structural Conformity in a Three-Pad Adaptive Air Foil Bearing With Regard to Active Control of Radial Clearance. J. Tribol. 2019, 141, 081701. [Google Scholar] [CrossRef]

- Breńkacz, Ł.; Kędra, R.; Janicki, W.; Maurin, A.; Bagiński, P.; Andrearczyk, A.; Zima, B. Research on Linear Actuators for Active Foil Bearings. Materials 2022, 15, 5694. [Google Scholar] [CrossRef]

- Feng, K.; Cao, Y.; Yu, K.; Guan, H.; Wu, Y.; Guo, Z. Characterization of a controllable stiffness foil bearing with shape memory alloy springs. Tribol. Int. 2019, 136, 360–371. [Google Scholar] [CrossRef]

| Bearing Type | Dynamic Characteristics |

|---|---|

| Leaf foil type | Rotor preload effect stabilizing the system [6]; adaption of multi-directional installation and shocking load |

| Bump foil type | High anti-shock ability resulting from the high stiffness bump structure |

| Beam foil type | Three converged initial clearances stabilizing the rotor; multiple sliding beams providing Coulomb damping [12]; resistance of beam elastic failure |

| Metal mesh type | Higher loss factor than bump bearing and relatively independent dynamic coefficients with excitation frequency [14] |

| Wing foil type | Low subsynchronous vibration and good damping through rigid shaft critical speed; extremely tunable design [15] |

| Isolated spring type | Sufficient damping of the underlying structure to effectively suppress maximum peak at the critical speed rather than the onset of hydrodynamic rotor–bearing instability [16] |

| Nested spring type | Larger loss factor than the bump foil bearing with similar linear stiffness; larger loss factor than the bearing with isolated springs; larger loss factor under axial preload [17] |

| Authors and Publication Information | Key Contributions |

|---|---|

| Ku and Heshmat [42] | A quasi-static enhanced model is developed to calculate hysteresis loops caused by friction in the journal GFBs |

| Ku and Heshmat [43] | The influences of bearing load, load angle, friction coefficient, and dynamic load on dynamic coefficients are investigated |

| Swanson [44] | A simplified model is developed with a single bump and single friction interface as well as the explicit inclusion of a load-dependent friction element |

| Le Lez and Arghir [45] | Friction force is regularized using Petrov’s model; bump motions are investigated in one loading cycle of one bump and of multiple bumps in a strip |

| Feng et al. [47] | A LuGre dynamic friction model is applied, and loading–unloading simulations are conducted on both a six-bump strip and a full bearing |

| Hoffmann et al. [49] | The influence of mechanical preload induced by metal shims is investigated |

| Zywica et al. [50] | Abaqus commercial software is used, and the influence of assembly preload is studied |

| Authors and Publication Information | Key Contributions |

|---|---|

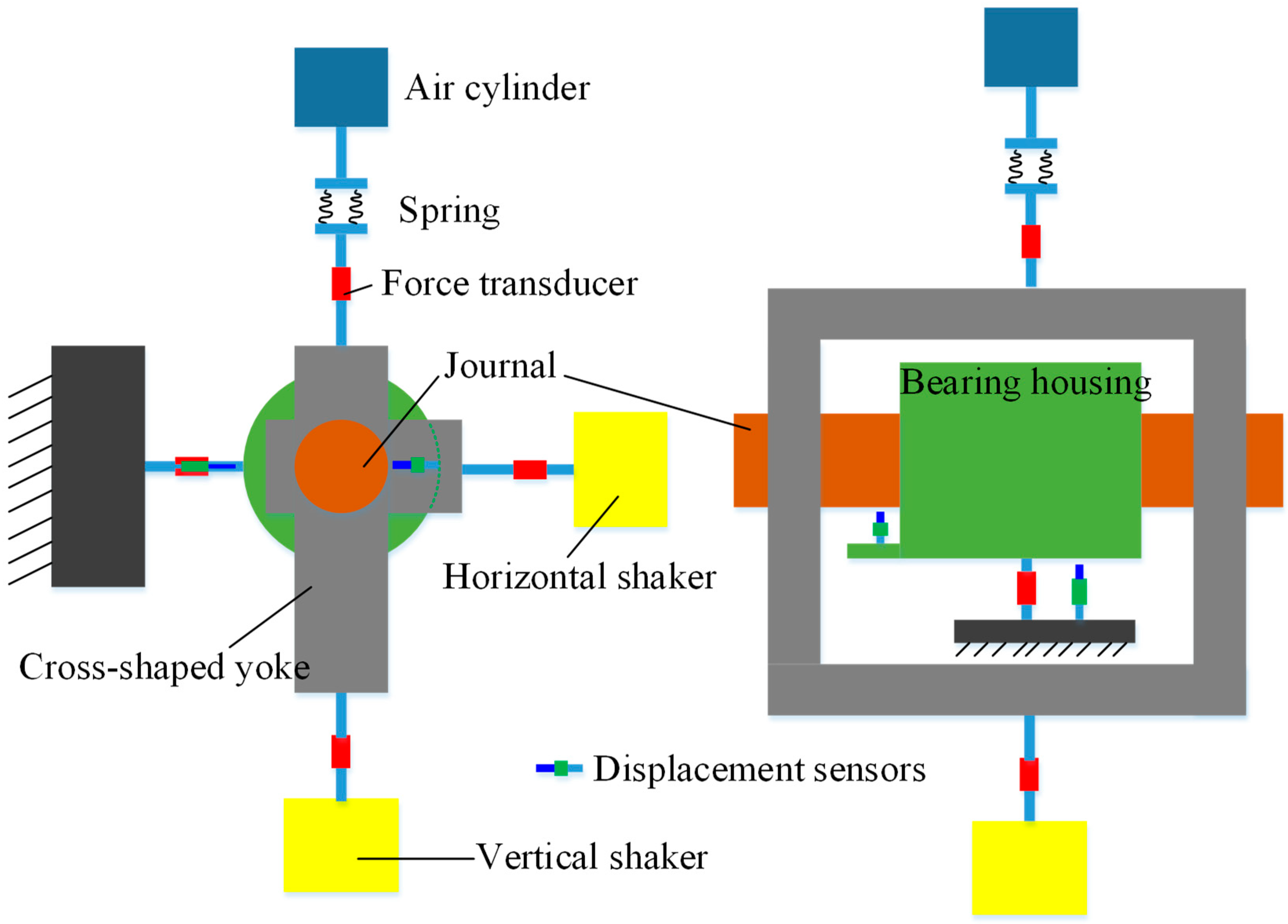

| Ku and Heshmat [51] | A test facility using two shakers on a full bearing was built for the first time, and algorithms of calculating dynamic coefficients from test data are presented |

| Ku and Heshmat [52] | Direct stiffness and damping coefficients in a gas foil bearing are found to increase with static load through experiments |

| Ku and Heshmat [53] | A test facility was built to study the influence of load distributions, friction coefficients, surface coatings, and lubricants on dynamic coefficients |

| Salehi and Heshmat [54] | Semi-empirical functions of the dynamic damping and friction coefficients were developed, and high-ambient temperature and vapor conditions were considered |

| Rubio and San Andres [55] | The dry friction coefficient was identified, and comprehensive investigations including various parameters were conducted |

| Kim and Breedlove [56] | The influence of temperature on the dynamic coefficients of foil structures were experimentally investigated |

| Larsen et al. [57] | The flatten phenomenon of hysteresis loops under higher excitation frequency were found, and reasonable explanations were presented |

| Authors and Publication Information | Key Contributions |

|---|---|

| Lund [61] | A perturbation method for calculating dynamic coefficients in gas bearings was developed for the first time |

| Peng and Carpino [62] | A perturbation method was applied in gas foil bearing for the first time, and aeroelastic dynamic coefficients were calculated |

| Peng and Carpino [63] | Viscous damping was introduced to equivalent Coulomb friction damping |

| Peng and Carpino [64] | Real foil configuration was considered in the perturbation method of gas foil bearings |

| Carpino and Talmage [65] | Real foil configuration was considered, and the influences of orbit size et al. were studied |

| Howard et. al [66] | The influence of temperature on aeroelastic dynamic coefficients was studied |

| Kim [67] | The perturbation and orbit methods were compared in terms of predicting rotor instability speed, and the influence of mechanical preload (3-pad structure) was investigated |

| Larsen et al. [68] | Errors between perturbation and orbit methods were found, and possible reasons were proposed by stating that the error tends to increase with the decrease in foil stiffness |

| Osmanski et al. [69] | Three approaches were adopted to predict the linear rotor instability supported by gas foil bearings: classical perturbation, extended perturbation, and the Jacobian eigenvalue |

| Pronobis and Liebich [70] | A revised foil structural perturbation model was developed by taking the self-excitated eigenfrequent vibration into account |

| Hoffmann et al. [71] | Close calculation results of perturbation and orbit methods were obtained, and the influences of bump pad number and metal shim on dynamic coefficients were studied |

| Gu et al. [72] | A perturbed finite element model of complex foil structures was developed, and close calculation results of perturbation and orbit methods were also obtained |

| Zhou and Gu et al. [73] | The multi-mode problem was solved by applying an s-domain (complete frequency domain) impedance |

| Bonello and Pham [74] | A method using eigenvalues extracted from the Jacobian matrix for predicting the static equilibrium stability of gas foil bearing was proposed for the first time |

| Bonello [75] | Campbell maps with whirl modes and mode-specific initial conditions were presented |

| Bonello [76] | The detachment of top foil from the bump foil in the dynamic model was considered to enable this frequency method to be more robust |

| Bonello et al. [77] | Two alternative approaches were adopted to conduct a linearized analysis |

| Li et al. [78] | A perturbed model of the complex foil structure with contact constraints was developed, and calculating algorithms for the dynamic coefficients were proposed for the complex model |

| Authors and Publication Information | Key Contributions |

|---|---|

| San Andres et al. [82] | 0.5 × rotor subsynchronous vibration was found to increase with unbalance level |

| San Andres et al. [83] | The whirl frequency ratio tended to bifurcate from one-half to one-third as rotor speed increases, similar to a Duffing oscillator with multi-frequency responses |

| Balducchi et al. [84] | Larger rotor speed and unbalance could excite more components of subsynchronous vibrations, including frequency-locked ones and nonlinear jump phenomena |

| Guo et al. [85] | Larger bearing radial clearance led to larger amplitudes of both synchronous and subsynchronous vibrations |

| Guo et al. [86] | Definitions of whip and whirl components of nonlinear rotor vibration supported by gas foil bearings were proposed |

| Guo et al. [87] | Higher levels of static and unbalance loads could increase the subsynchronous vibrations |

| Le Lez and Arghir [88] | A transient model of the foil structure was developed, and larger rotor unbalance could lead to a nonlinear jump |

| Iordanoff [89] | An optimal friction coefficient value exists for ensuring the best stability of the rotor–foil bearing system |

| Lee et al. [90] | A representative study of the weak coupling model was conducted, and optimum values were found for the friction coefficient, bump foil stiffness, and bump foil strips |

| Bhore et al. [91] | The rotor flexibility was considered, and comprehensive simulations of nonlinear rotor dynamics supported by gas foil bearings were conducted, including sufficient bifurcation analyses |

| Hoffmann et al. [92] | The vibration characteristics of high and low balance levels, corresponding to the features of Hopf bifurcation and Duffing system, were found |

| Bonello et al. [93] | A fully coupled dynamic model of the foil bearing–rotor system was established |

| Bonello et al. [94] | The Galerkin method was found to contain fewer state variables and had a higher solving efficiency |

| Hassan and Bonello [95] | The interactions between individual bumps was considered, and a dynamic model of a bump foil strip using modal superposition method was established |

| Larsen et al. [96] | Subsynchronous vibration was found to disappear when the rotor unbalance mass was small and it was different from the traditional linear instability mechanism |

| Osmanski et al. [97] | The theoretical model was found to overestimate the Coulomb damping |

| Leister et al. [98] | Foil structural stiffness was found to have certain influences on rotor instabilities |

| Authors and Publication Information | Key Contributions |

|---|---|

| Feng et al. [99] | A novel foil bearing with a piezoelectric actuator was proposed to actively adjust the mechanical preload |

| Guan et al. [100] | A larger mechanical preload caused by a higher driven voltage was able to suppress the subsynchronous vibrations through both experiments and simulations |

| Guan et al. [101] | Smaller initial clearance, softer hinge, and larger static load help increase the rotor stability supported by active gas foil bearings |

| Guan et al. [102] | Open-loop and closed-loop controlling methods of active gas foil bearing were proposed |

| Guan et al. [103] | Performance of active bump-metal mesh hybrid foil bearing is investigated |

| Park et al. [104] | A type of active foil bearing was proposed that applied circumferentially distributed piezo stacks to achieve real-time control of the bearing clearance |

| Sadri et al. [105,106] | Piezoelectric patches of the microfiber composite type were applied in combination with the supporting shell to adjust gas foil clearances |

| Brenkacz et al. [107] | Linear displacement actuators for active foil bearings were reviewed |

| Feng et al. [108] | A novel foil bearing using shape memory alloy to actively adjust bearing stiffness and damping was proposed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.; Li, C.; Du, J. A Review on the Dynamic Performance Studies of Gas Foil Bearings. Lubricants 2024, 12, 262. https://doi.org/10.3390/lubricants12070262

Jin C, Li C, Du J. A Review on the Dynamic Performance Studies of Gas Foil Bearings. Lubricants. 2024; 12(7):262. https://doi.org/10.3390/lubricants12070262

Chicago/Turabian StyleJin, Chaozhe, Changlin Li, and Jianjun Du. 2024. "A Review on the Dynamic Performance Studies of Gas Foil Bearings" Lubricants 12, no. 7: 262. https://doi.org/10.3390/lubricants12070262

APA StyleJin, C., Li, C., & Du, J. (2024). A Review on the Dynamic Performance Studies of Gas Foil Bearings. Lubricants, 12(7), 262. https://doi.org/10.3390/lubricants12070262