Microstructural, Mechanical and Tribological Behaviors of Cu/LLDPE-Based Composite Coatings for Lightweight Applications

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

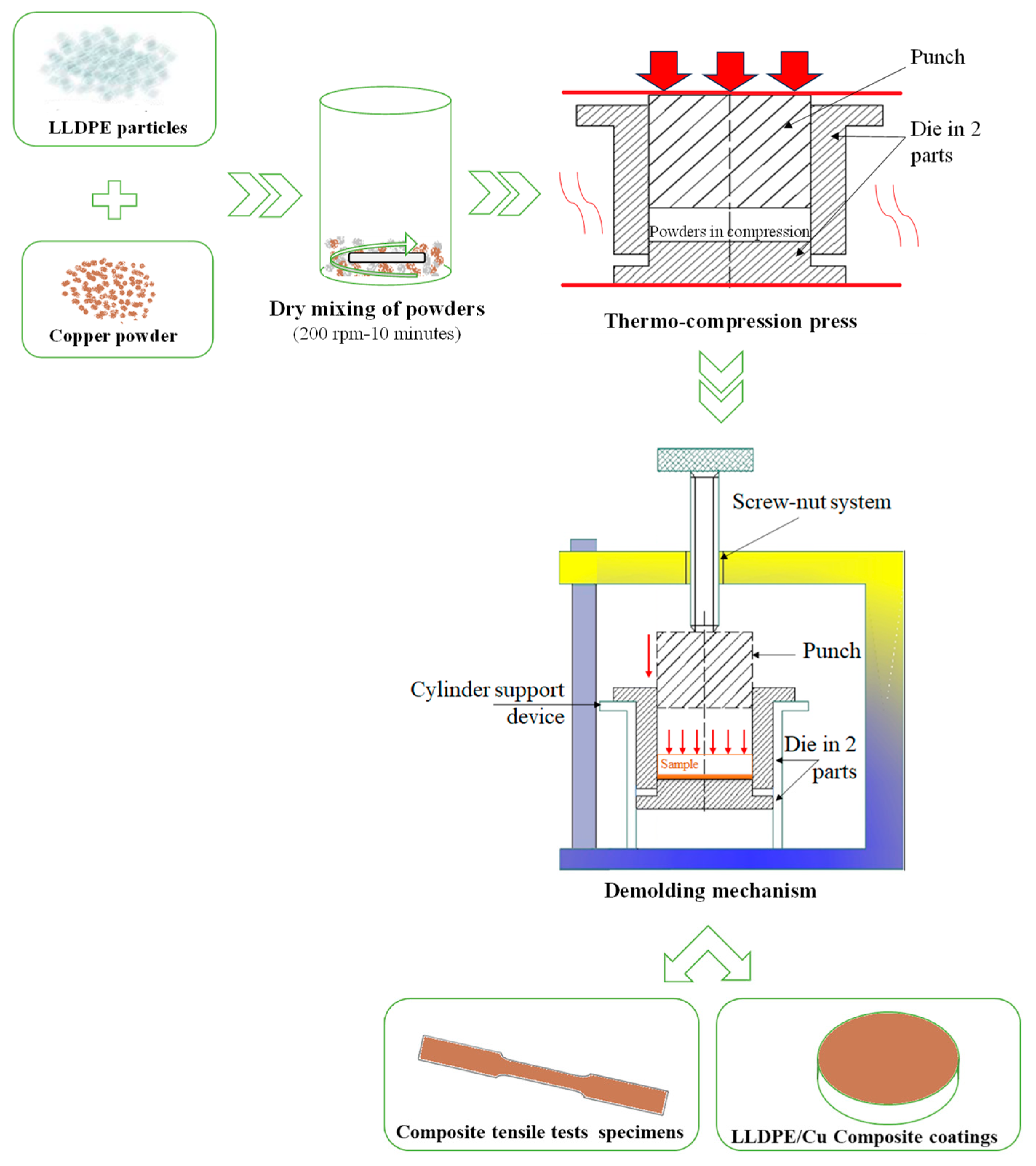

2.2. Sample Preparation

2.3. Mechanical and Microstructural Characterizations

2.4. Friction and Wear Testing

3. Results and Discussion

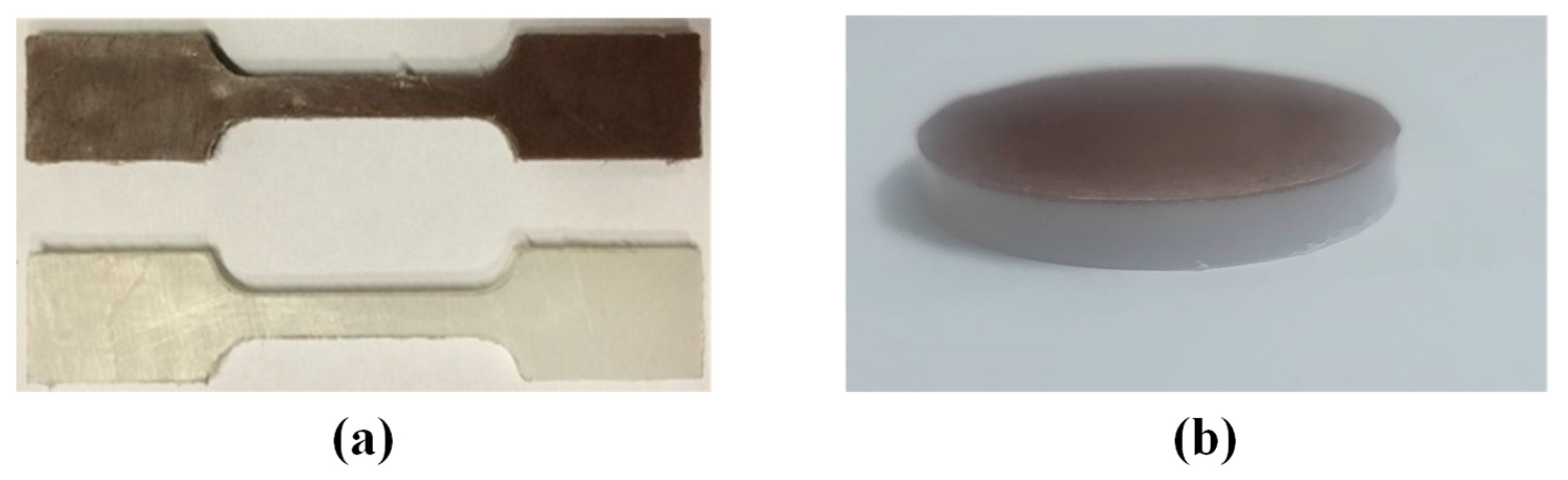

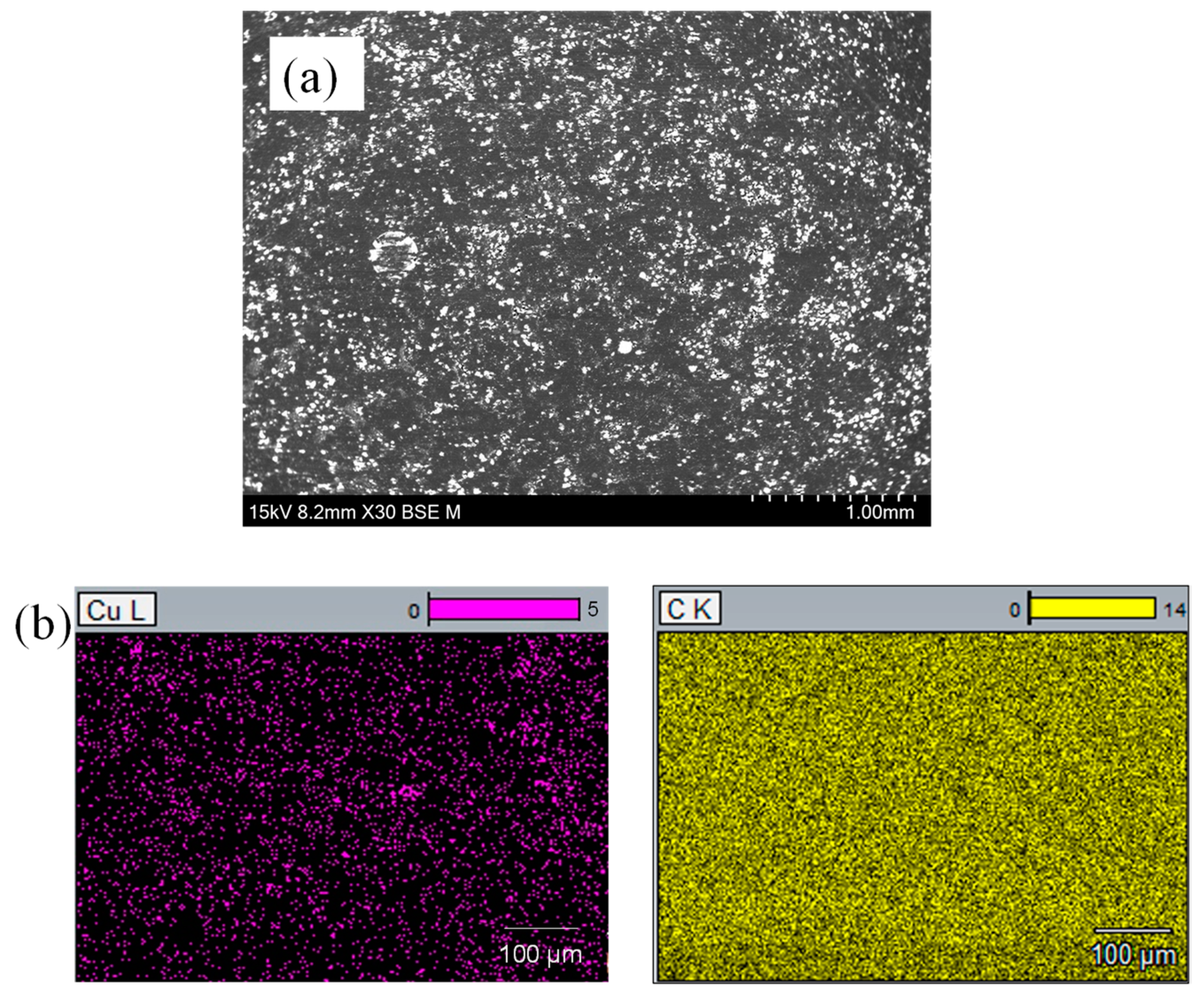

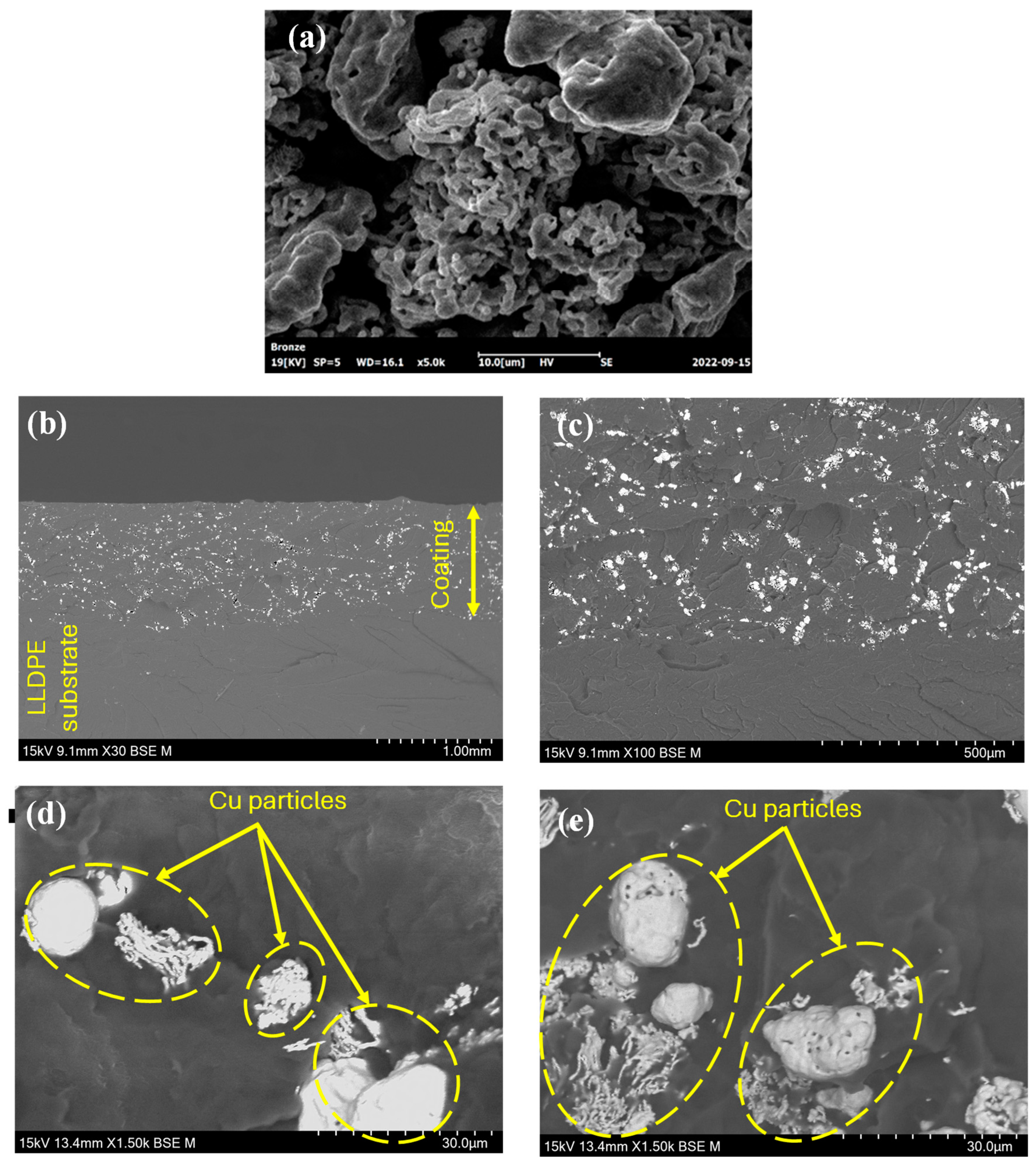

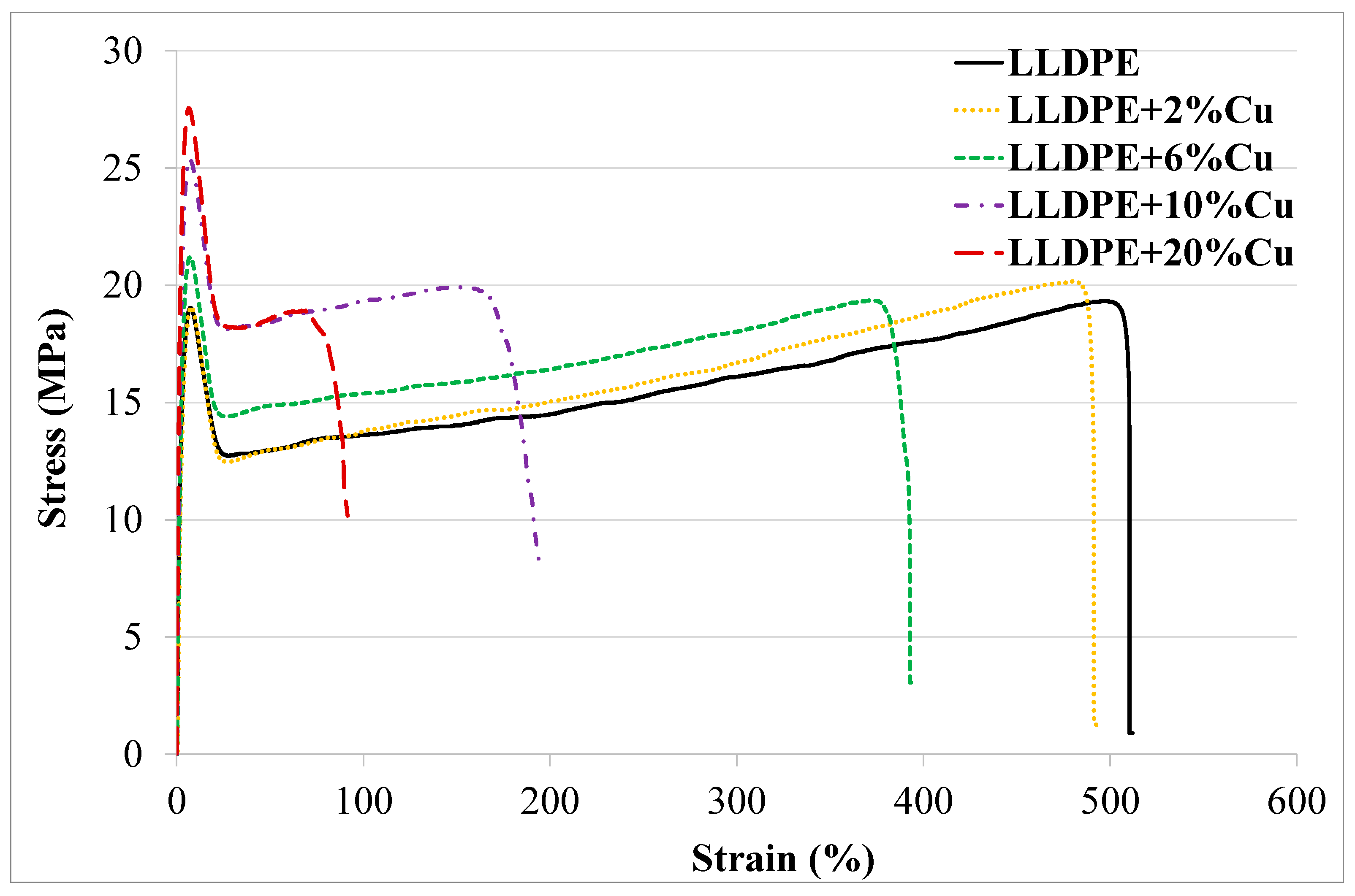

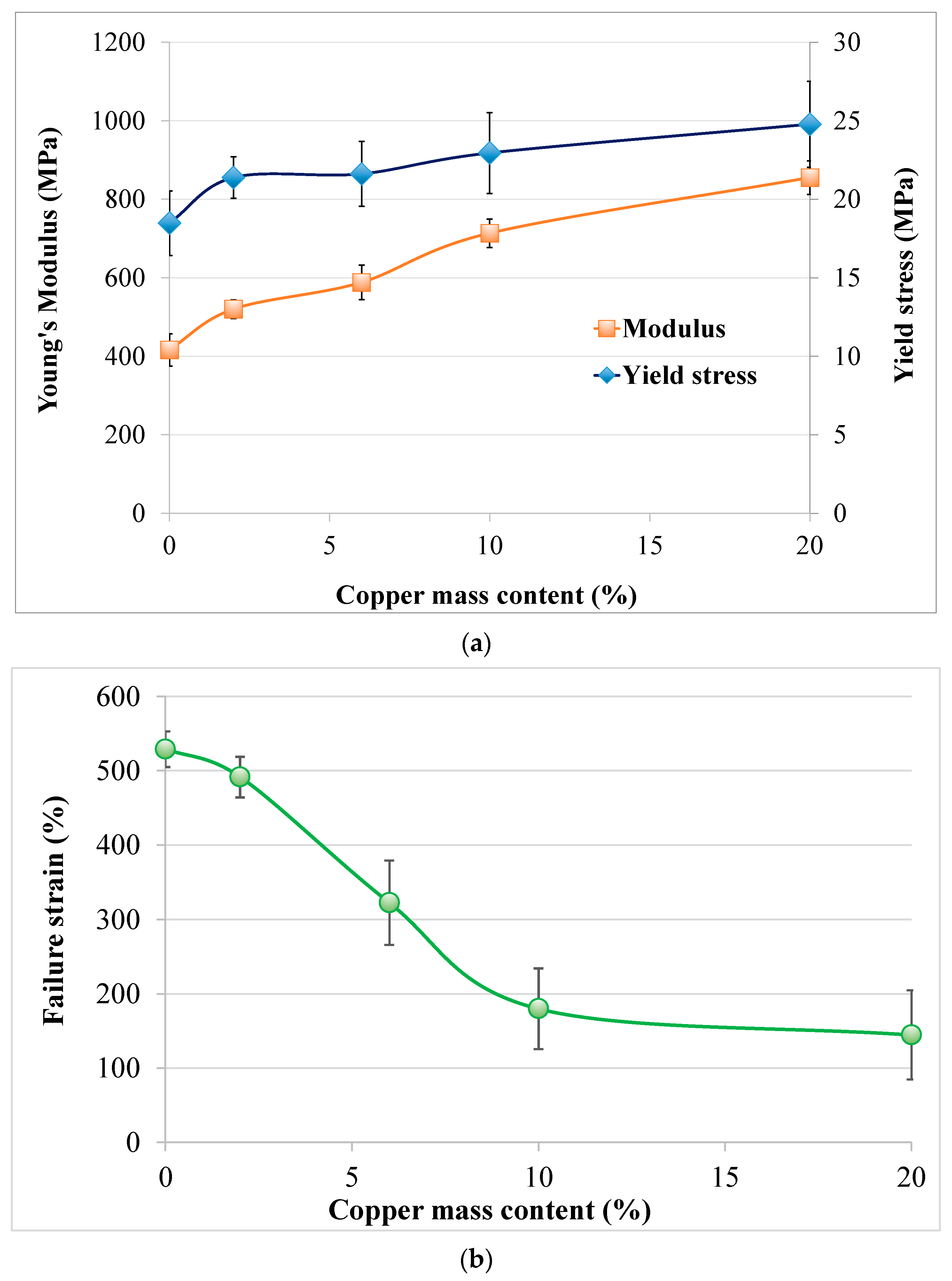

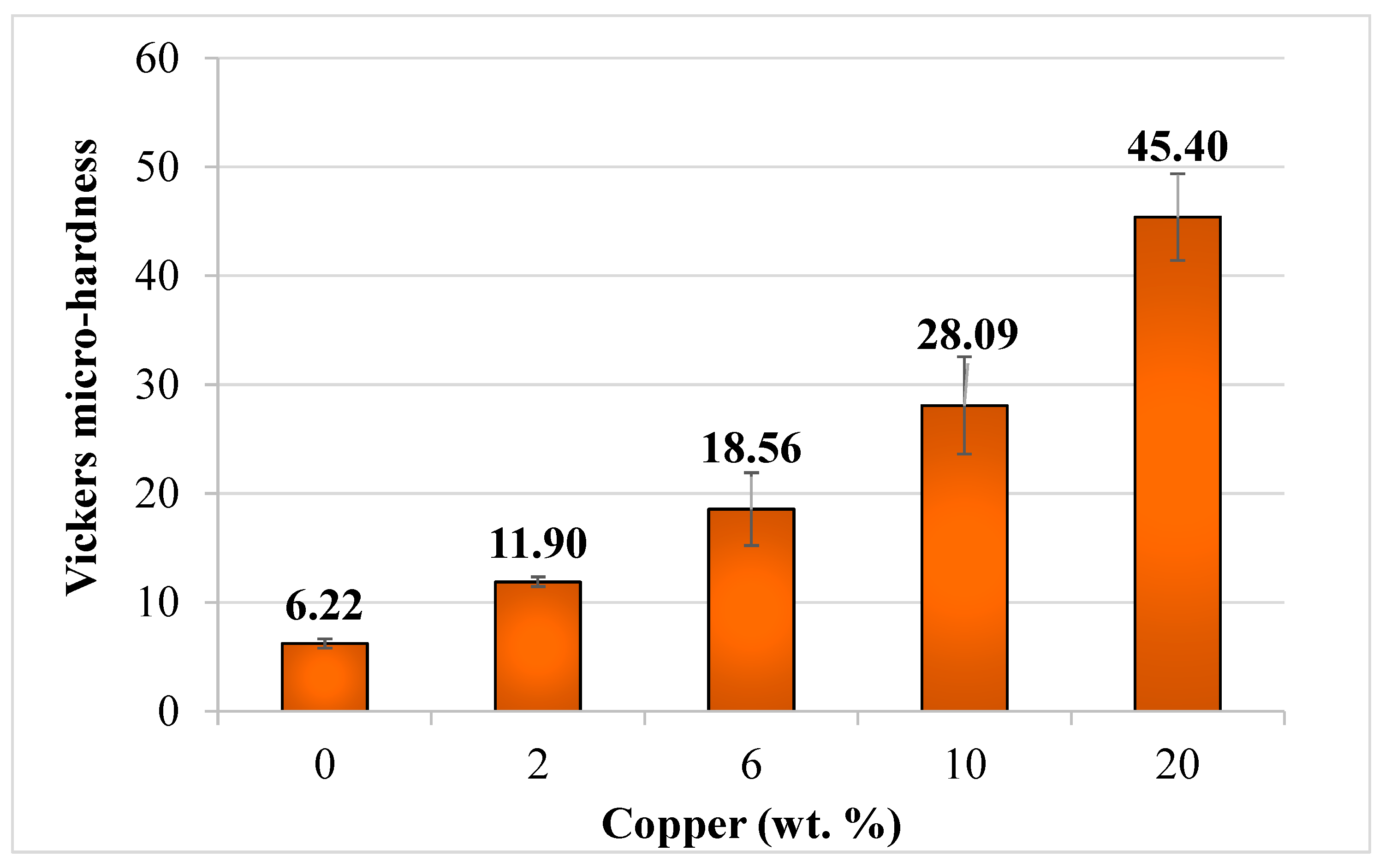

3.1. Morphological and Mechanical Properties

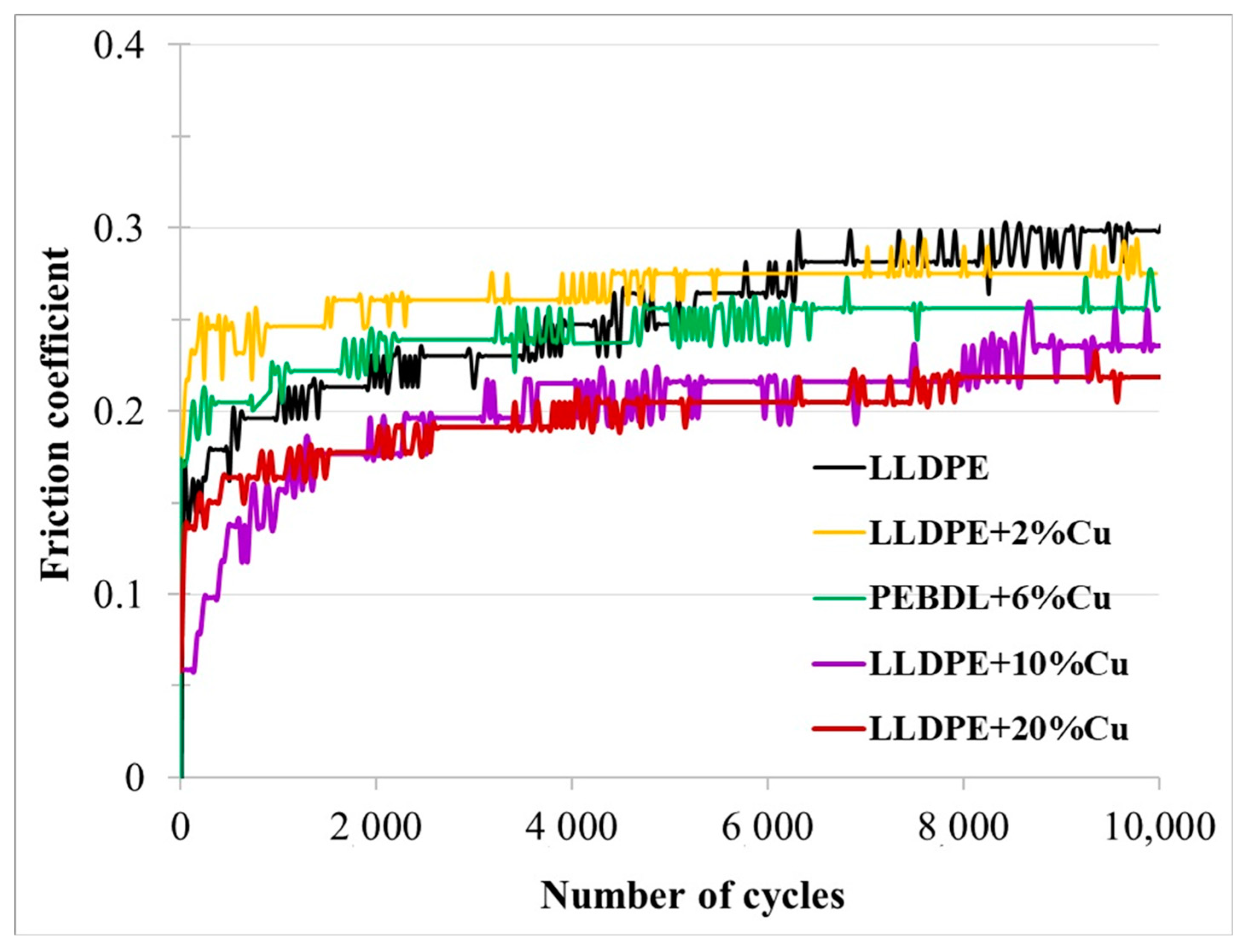

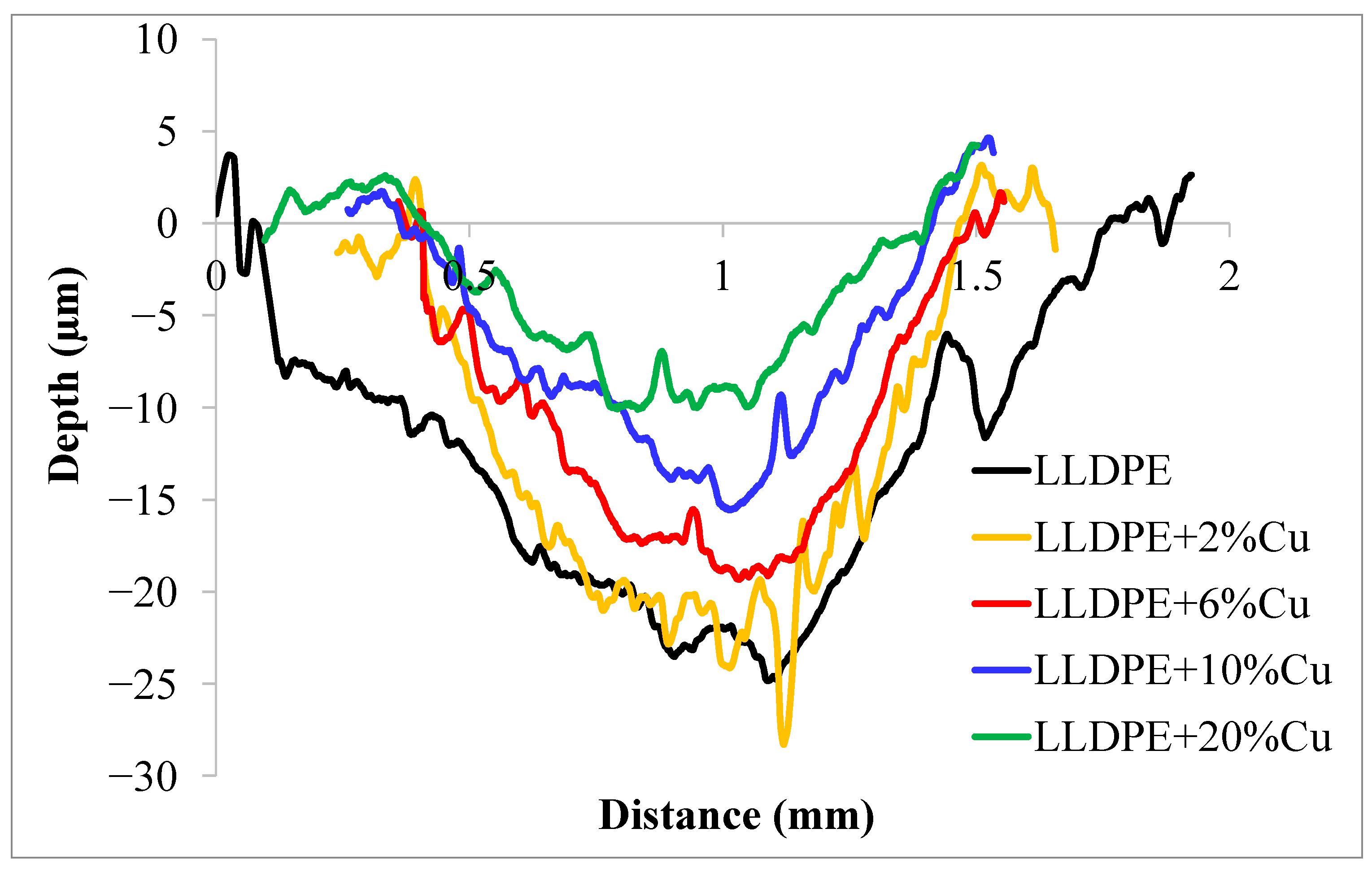

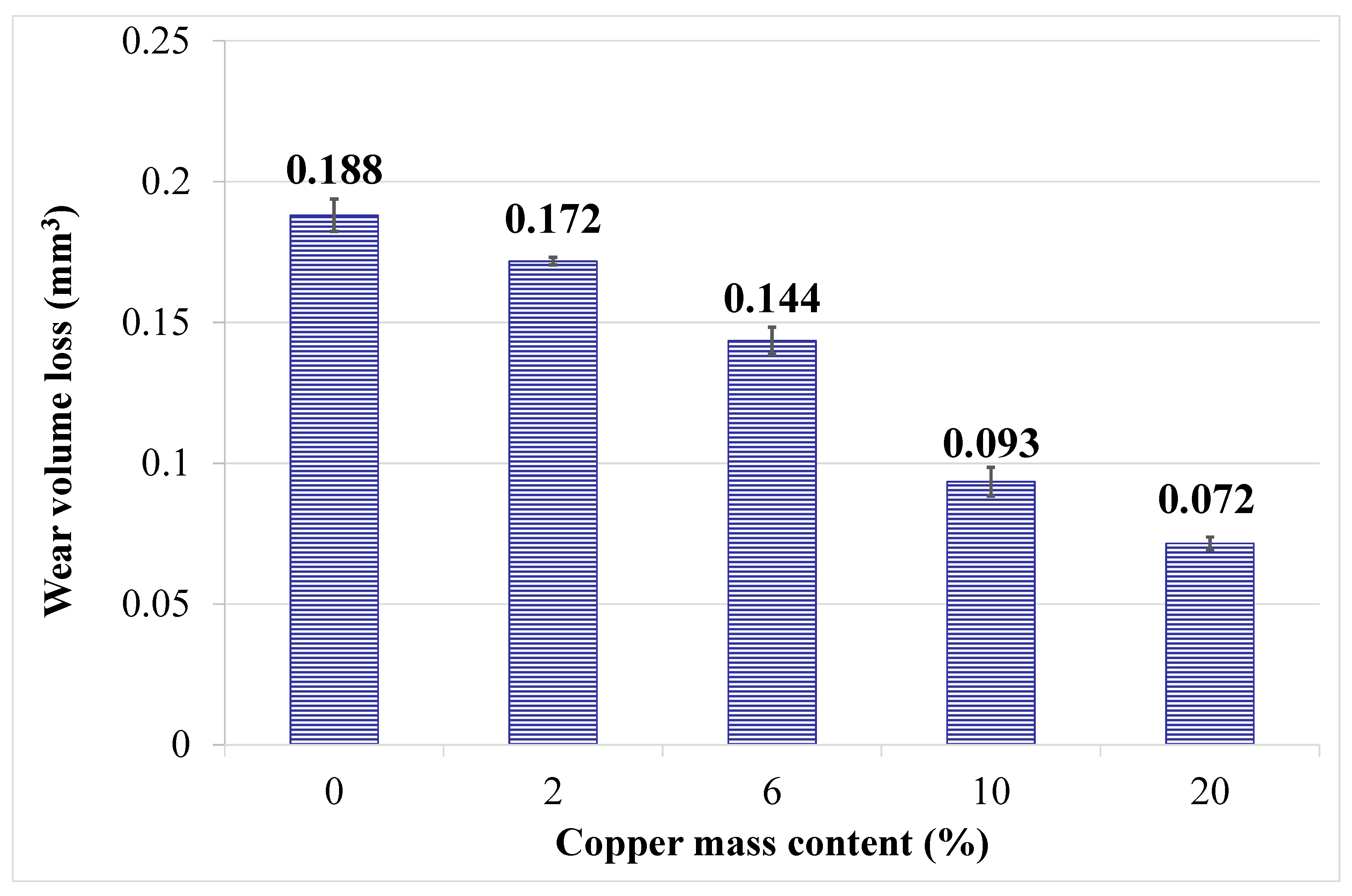

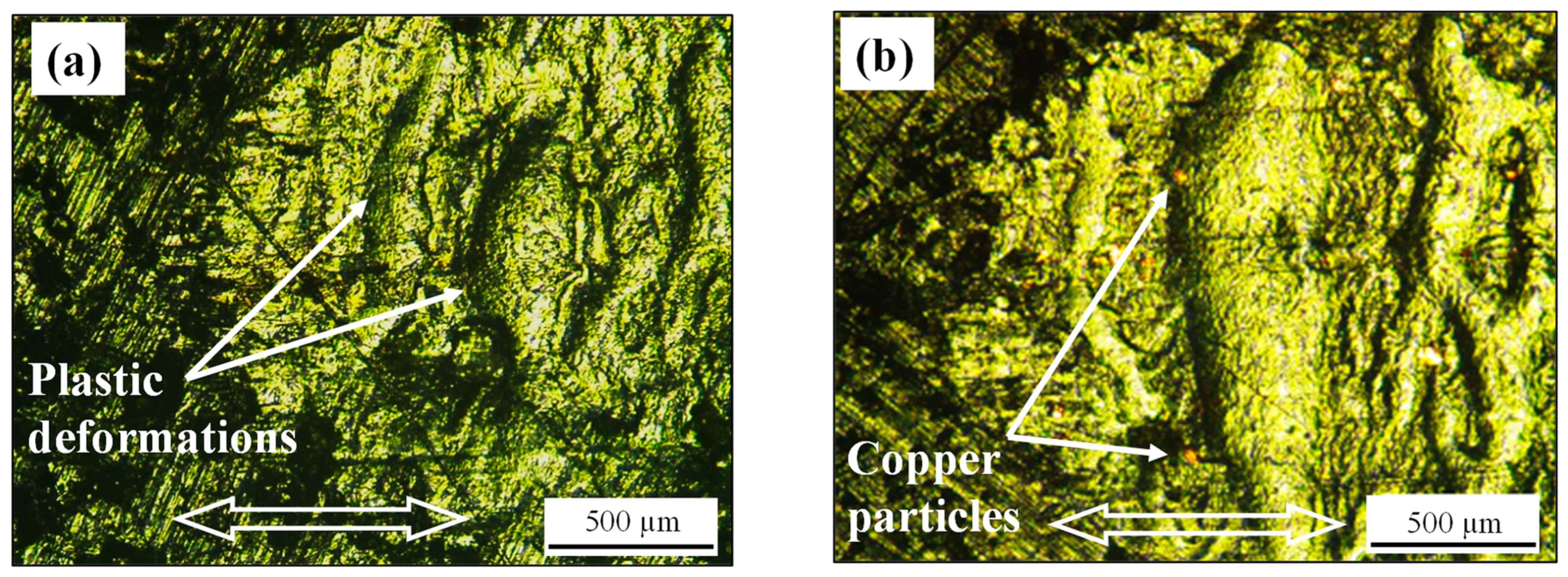

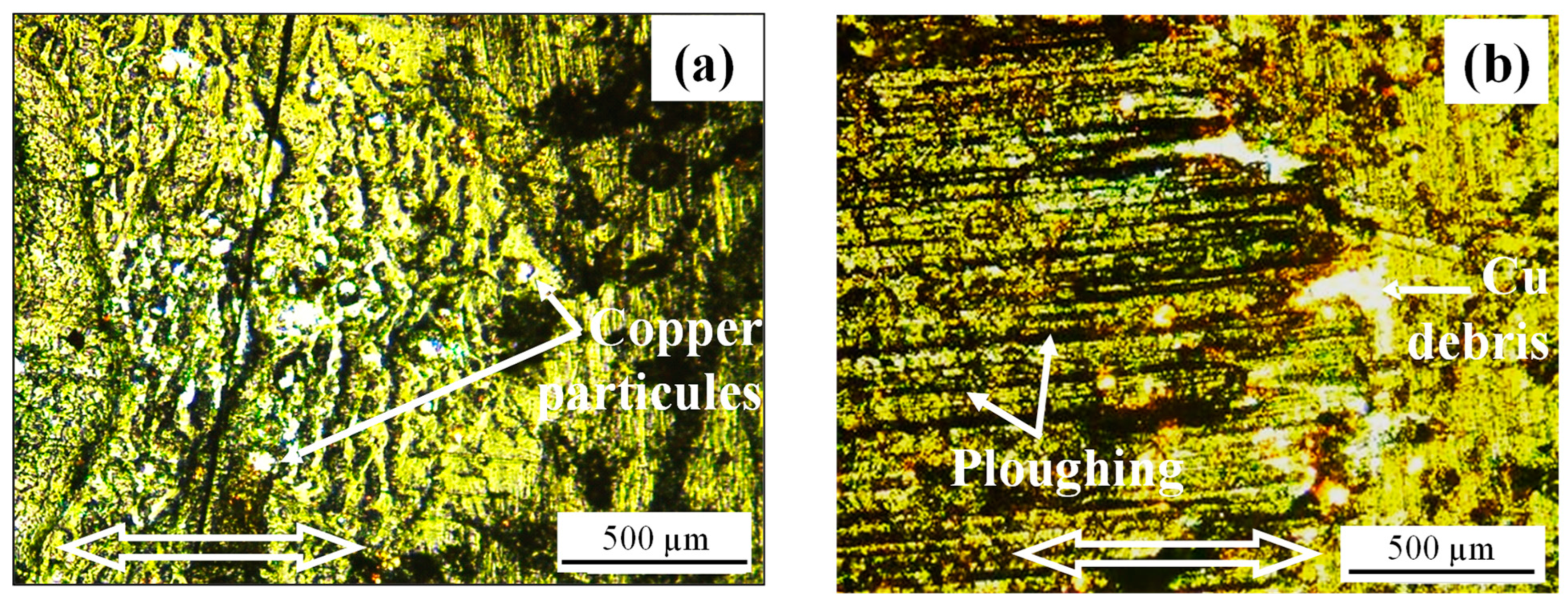

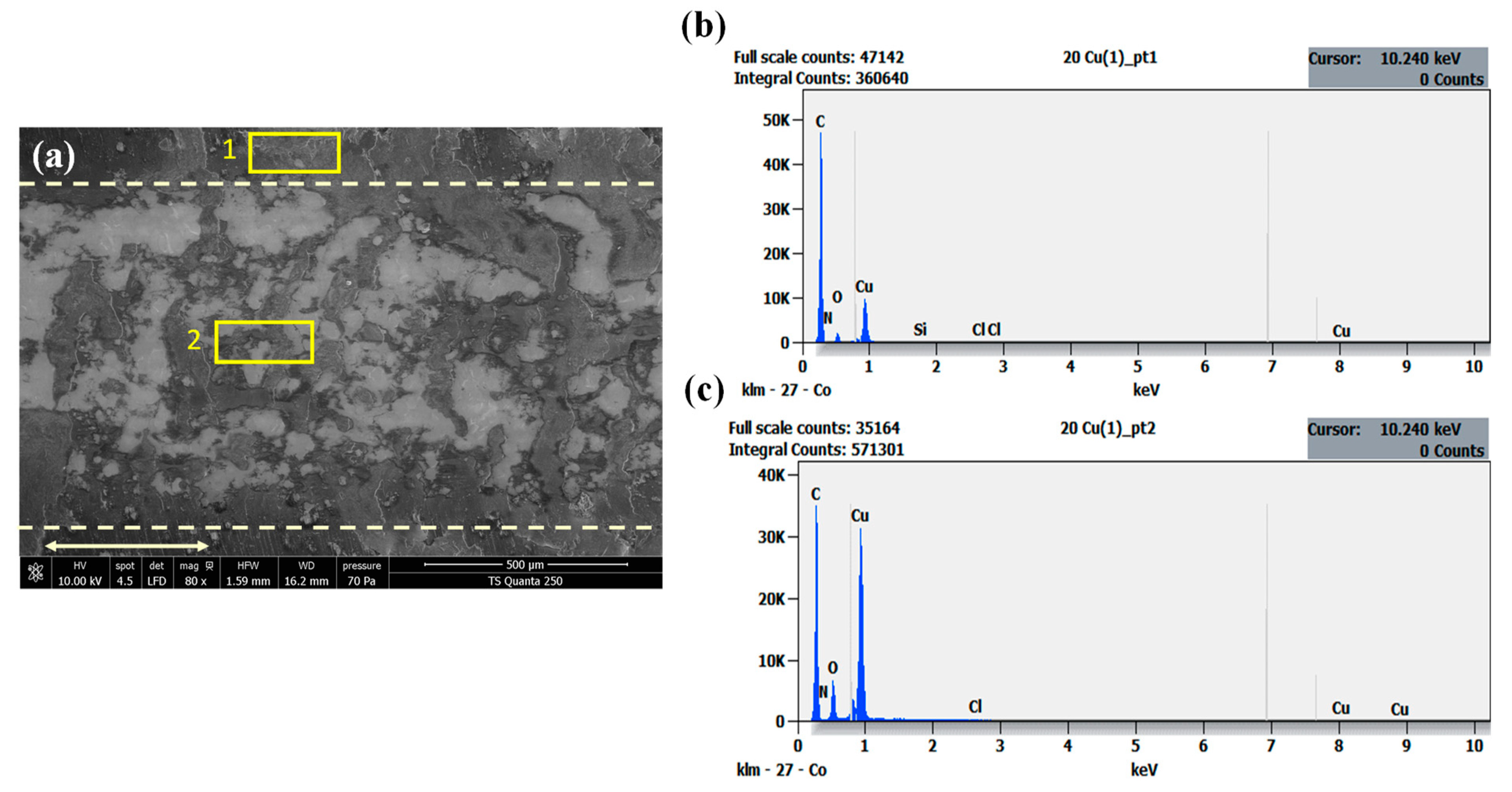

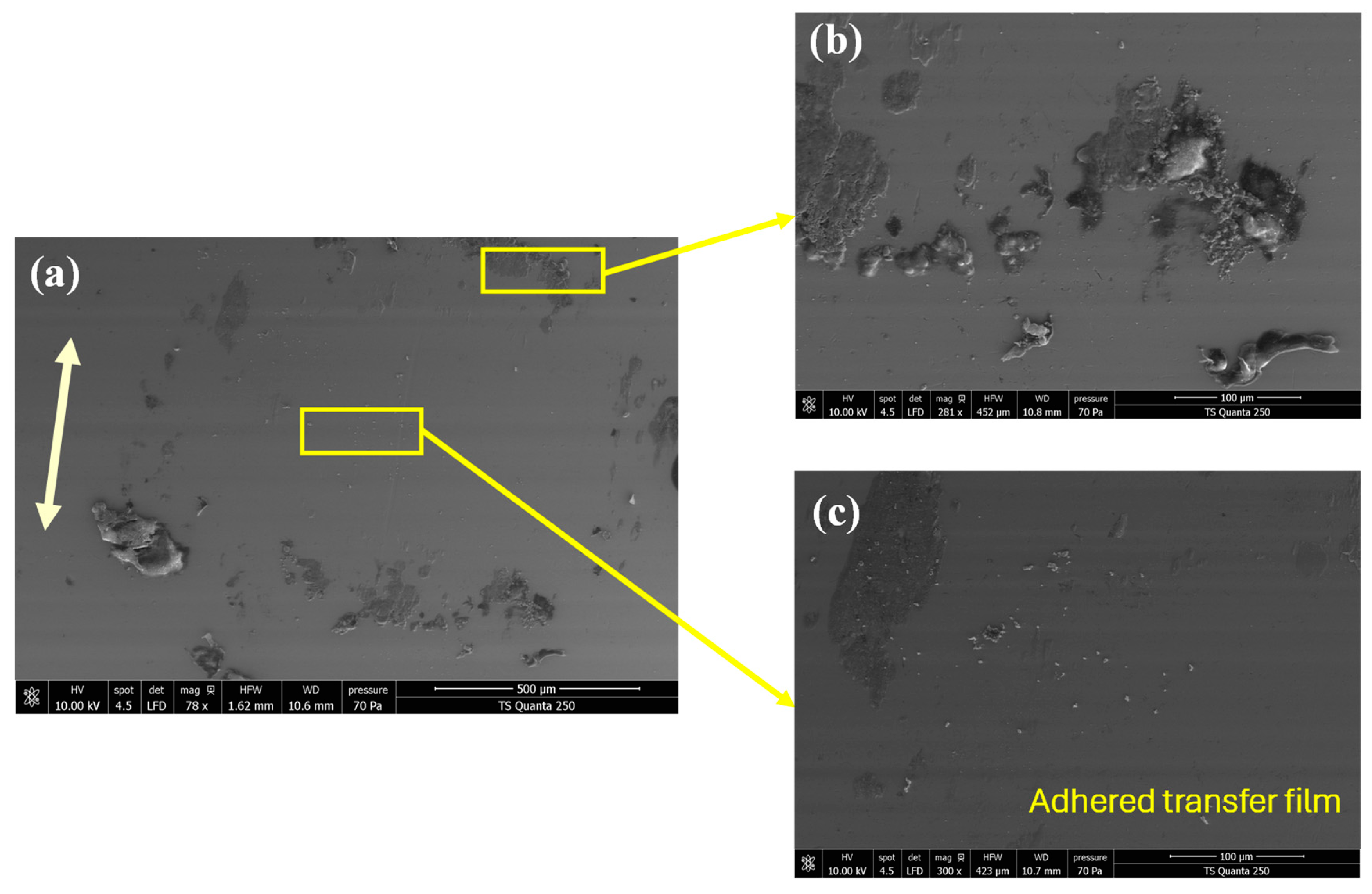

3.2. Friction and Wear Behaviors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Robinson, D.N.; Binienda, W.K.; Ruggles, M.B. Creep of Polymer Matrix Composites. I: Norton/Bailey Creep Law for Transverse Isotropy. J. Eng. Mech. 2003, 129, 310–317. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. B 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Gungor, A. Mechanical properties of iron powder filled high density polyethylene composites. Mater. Des. 2007, 28, 1027–1030. [Google Scholar] [CrossRef]

- Kim, M.H.; Park, C.I.; Choi, W.M.; Lee, J.W.; Lim, J.G.; Park, O.O. Synthesis and material properties of syndiotactic polystyrene/organophilic clay nanocomposites. J. Appl. Polym. Sci. 2004, 92, 2144–2150. [Google Scholar] [CrossRef]

- Hua, Y.; Yang, Y.-C.; Yamanaka, A.; Ni, Q.-Q. Low Friction Coefficient Property of Super Fiber-Reinforced Composites. Adv. Compos. Mater. 2011, 20, 133–147. [Google Scholar] [CrossRef]

- Ben Difallah, B.; Cornualt, P.H.; Kharrat, M.; Dammak, M.; Monteil, G. On the Role of Solid Lubricant Fillers in the Tribological, Micromechanical, and Morphological Properties of PA66 Composites. J. Tribol. 2020, 142, 051901. [Google Scholar] [CrossRef]

- Trabelsi, M.; Kharrat, M.; Dammak, M. On the Friction and Wear Behaviors of PTFE Based Composites Filled with MoS2 and/or Bronze Particles. Trans. Indian. Inst. Met. 2016, 69, 1119–1128. [Google Scholar] [CrossRef]

- Huang, G.; Zhang, T.; Chen, Y.; Yang, F.; Huang, H.; Zhao, Y. Graphite Fluoride as a Novel Solider Lubricant Additive for Ultra-High-Molecular-Weight Polyethylene Composites with Excellent Tribological Properties. Lubricants 2023, 11, 403. [Google Scholar] [CrossRef]

- Aydemir, T.; Burlakova, V.E.; Drogan, E.G.; Dzhardimalieva, G.I.; Uflyand, I.E.; Shershneva, I.N.; Kydralieva, K.A. Mechanical and Tribological Properties of Polymer Materials Based on Heterometallic Fe (III) Co (II) Polyacrylamide Complexes. Compos. Mech. Comput. Appl. 2021, 12, 81–92. [Google Scholar] [CrossRef]

- Tsetlin, M.B.; Teplov, A.A.; Belousov, S.I.; Chvalun, S.N.; Golovkova, E.A.; Krasheninnikov, S.V.; Golubev, E.K.; Presnyakov, M.Y.; Orekhov, A.S.; Vasiliev, A.L. Effect of a quasicrystalline filler on the tribological properties of a composite based on ultrahigh-molecular-weight polyethylene. J. Synch. Investig. 2015, 9, 1077–1084. [Google Scholar] [CrossRef]

- Pasha, B.M.; Budan, D.A.; Basavarajappa, S.; Yadav, S.M.; Nizamuddin, B.A. Studies on wear resistance of PTFE filled with glass and bronze particles based on Taguchi technique Nizamuddin. J. Thermoplasc. Compos. Mater. 2012, 26, 243–259. [Google Scholar] [CrossRef]

- Faujdar, E.; Singh, R.K. Amide polymers based on N-phenyl-p-phenylenediamine with α-olefins-co-maleic anhydride as multifunctional additives for lubricant application. Polym. Adv. Technol. 2022, 33, 2820–2834. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Darut, G.; Poirier, T.; Stella, J.; Wang, K.; Liao, H.; Planche, M.-P. A novel structured suspension plasma sprayed YSZ-PTFE composite coating with tribological performance improvement. Surf. Coat. Technol. 2019, 358, 108–113. [Google Scholar] [CrossRef]

- Khoddamzadeh, A.; Liu, R.; Wu, X. Novel polytetrafluoroethylene (PTFE) composites with newly developed tribaloy alloy additive for sliding bearings. Wear 2009, 266, 646–657. [Google Scholar] [CrossRef]

- Brostow, W.; Buchman, A.; Buchman, E.; Olea-Mejia, O. Microhybrids of Metal Powder Incorporated in Polymeric Matrices: Friction, Mechanical Behavior, and Microstructure. Polym. Eng. Sci. 2008, 48, 1977–1980. [Google Scholar] [CrossRef]

- Shamsuddin, M.S.M.; Othman, A.H.; Nasir, R.M.; Hassan, A.; Senawi, R.; Thirmizir, M.Z.A.; Ishak, Z.A.M. Influence of PTFE as a solid lubricant on the mechanical, electrical, and tribological properties of CF-reinforced PC composites. J. Appl. Polym. Sci. 2021, 138, e50346. [Google Scholar] [CrossRef]

- Bare, W.; Albano, C.; Reyes, J.; Dominguez, N. Effect of irradiation on the mechanical properties of high-density polyethylene reinforced with metallic fibres. Surf. Coat. Technol. 2002, 158/159, 404–407. [Google Scholar] [CrossRef]

- Muszynska, M.; Wycislik, H.; Siekierski, M. Composite polymeric electrolytes based on poly(ethylene oxide) matrix and metallic aluminum filler. Solid State Ion. 2002, 147, 281–287. [Google Scholar] [CrossRef]

- Nikkeshi, S.; Kudo, M.; Masuko, T. Dynamic viscoelastic properties and thermal properties of Ni powder-epoxy resin composites. J. Appl. Polym. Sci. 1998, 69, 2593–2598. [Google Scholar] [CrossRef]

- Jung-il, K.; Kang, P.H.; Nho, Y.C. Positive temperature coefficient behavior of polymer composites having a high melting temperature. J. Appl. Polym. Sci. 2004, 92, 394–401. [Google Scholar]

- Bazan, P.; Gajda, M.; Nosal, P.; Bąk, A.; Setlak, K.; Łach, M. The Influence of Copper Oxide Particle Size on the Properties of Epoxy Resin. Appl. Sci. 2024, 14, 2534. [Google Scholar] [CrossRef]

- Rajesh, J.J.; Bijwe, J. Influence of fillers on the low amplitude oscillating wear behaviour of poly amide 11. Wear 2004, 256, 1–8. [Google Scholar] [CrossRef]

- Zhansakova, K.S.; Eremin, E.N.; Russkikh, G.S. Tribological properties of polyethylene-based composites with fillers on iron based. J. Phys. Conf. Ser. 2019, 1260, 062028. [Google Scholar] [CrossRef]

- Tsetlin, M.B.; Teplov, A.A.; Belousov, S.I.; Chvalun, S.N.; Golovkova, Y.A.; Krasheninnikov, S.V.; Golubev, E.K.; Vasilyev, A.L.; Presnyakov, M.Y.; Dmitryakov, P.V. Tribological and Mechanical Properties of Composites Based on Ethylene-Tetrafluoroethylene and Quasicrystalline Al−Cu−Fe Filler. J. Surf. Investig. 2017, 11, 315–321. [Google Scholar] [CrossRef]

- Charfi, A.; Neili, S.; Kharrat, M.; Dammak, M. Tribological behaviors of PTFE-based composites filled with bronze microparticles. J. Thermoplast. Compos. Mater. 2019, 34, 1639–1653. [Google Scholar] [CrossRef]

- Keshavamurthy, R.; Tambrallimath, V.; Badari, A.; Krishna, R.; Kumar, G.S.; Jeevan, M.C. Friction and wear behaviour of copper reinforced acrylonitrile butadiene styrene based polymer composite developed by fused deposition modelling process. FME Trans. 2020, 48, 543–550. [Google Scholar] [CrossRef]

- 27. Akrout, M.; Ben Difallah, B.; Kharrat, M.; Dammak, M.; Pereira, A.; Bdikin, I.; Duarte, I. On the Structural, Thermal, Micromechanical and Tribological Characterizations of Cu-Filled Acrylonitrile Butadiene Styrene Micro-Composites. Materials 2023, 16, 6428. [Google Scholar] [CrossRef] [PubMed]

- Akrout, M.; Ben Difallah, B.; Kharrat, M.; Dammak, M.; Pereira, A.; Bdikin, I.; Duarte, I. Tribological, Micromechanical and Structural Characterizations of PA66 Composites Filled Cu Micro-particles. In Advances in Materials, Mechanics and Manufacturing, 3rd ed.; Ben Amar, M., Ben Souf, M.A., Beyaoui, M., Trabelsi, H., Ghorbel, E., Tounsi, D., El Mahi, A., Chaari, F., Haddar, M., Eds.; Springer Nature: Gewerbestrasse, Switzerland, 2024; pp. 303–310. [Google Scholar]

- Uflyand, I.E.; Drogan, E.G.; Burlakova, V.E.; Kydralieva, K.A.; Shershneva, I.N.; Dzhardimalieva, G.I. Testing the mechanical and tribological properties of new metal-polymer nanocomposite materials based on linear low-density polyethylene and Al65Cu22Fe13 quasicrystals. Polym. Test. 2019, 74, 178–186. [Google Scholar] [CrossRef]

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ASTM D638-08:2010; Plastics—Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2010.

- Petousis, M.; Ninikas, K.; Vidakis, N.; Mountakis, N.; Kechagias, J.D. Multifunctional PLA/CNTs nanocomposites hybrid 3D printing integrating material extrusion and CO2 laser cutting. J. Manuf. Process. 2023, 86, 237–252. [Google Scholar] [CrossRef]

- Luyt, A.S.; Molefi, J.A.; Krump, H. Thermal, mechanical and electrical properties of copper powder filled low-density and linear low-density polyethylene composites. Polym. Degrad. Stab. 2006, 91, 1629–1636. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Do Thi, V.V.; Grillet, A.-C.; Thuc, H.H.; Ha Thuc, C.N. Biodegradability of polymer film based on low density polyethylene and cassava starch. Int. Biodeterior. Biodegrad. 2016, 115, 257–265. [Google Scholar] [CrossRef]

- Nikzad, M.; Masood, S.H.; Sbarski, I. Thermo-mechanical properties of a highly filled polymeric composites for Fused Deposition Modeling. Mater. Des. 2011, 32, 3448–3456. [Google Scholar] [CrossRef]

- Brostow, W.; Chonkaew, W.; Rapoport, L.; Soifer, Y.; Verdyan, A. Grooves in scratch testing. J. Mater. Res. 2007, 22, 2483–2487. [Google Scholar] [CrossRef]

- Li, J.; Xia, Y.C. The Friction and Wear Properties of Thermoplastic PA6 Composites Filled with Carbon Fiber. J. Thermoplast. Compos. Mater. 2010, 23, 337–349. [Google Scholar] [CrossRef]

- Tsetlin, M.B.; Teplov, A.A.; Belousov, S.I.; Chvalun, S.N.; Golovkova, E.A.; Krasheninnikov, S.V.; Golubev, E.K.; Pichkur, E.B.; Dmitryakov, P.V.; Buzin, A.I. Composite Material Based on Polytetrafluoroethylene and Al–Cu–Fe Quasi-Crystal Filler with Ultralow Wear: Morphology, Tribological, and Mechanical Properties. J. Surf. Investig. 2018, 12, 277–285. [Google Scholar] [CrossRef]

- He, J.; Zhang, L.; Li, C. Thermal conductivity and tribological properties of POM-Cu composites. Polym. Eng. Sci. 2010, 50, 2153–2159. [Google Scholar] [CrossRef]

- Vasilev, A.P.; Dyakonov, A.A.; Danilova, S.N.; Makarov, I.S.; Okoneshnikova, A.V.; Okhlopkova, A.A. Effect of Nano-CuO and 2-Mercaptobenzothiazole on the Tribological Properties of Ultra-High Molecular Weight Polyethylene. Lubricants 2024, 12, 174. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Pesetskii, S.S.; Grigoriev, A.Y. Polymer Tribology: Current State and Applications. Tribol. Ind. 2015, 37, 284–290. [Google Scholar]

- Ji, K.; Shan, W.; Xia, Y.; Dai, Z. The Tribological Behaviors of Self-Lubricating Composites as Filler in Copper Foam. Tribol Trans. 2012, 55, 20–31. [Google Scholar] [CrossRef]

- Lin, Z.; Yue, H.; Gao, B. Enhancing tribological characteristics of PEEK by using PTFE composite as a sacrificial tribofilm-generating part in a novel dual-pins-on-disk tribometer. Wear 2020, 460–461, 203472. [Google Scholar] [CrossRef]

| Copper (wt.%) | 0 | 2 | 6 | 10 | 20 |

|---|---|---|---|---|---|

| Ra (µm) | 0.5 | 0.65 | 0.81 | 0.82 | 1.03 |

| Element | C | Al | Si | Cr | Fe | Cu | O |

|---|---|---|---|---|---|---|---|

| Weight % | 4.26 | 0.28 | 0.39 | 1.55 | 85.28 | 7.83 | 0.41 |

| Atom % | 17.19 | 0.50 | 0.67 | 1.45 | 73.96 | 5.97 | 0.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Difallah, B.; Bouaziz, A.; Horovistiz, A.; Kharrat, M.; Dammak, M.; Cardoso, C.; Pereira, A. Microstructural, Mechanical and Tribological Behaviors of Cu/LLDPE-Based Composite Coatings for Lightweight Applications. Lubricants 2024, 12, 231. https://doi.org/10.3390/lubricants12070231

Ben Difallah B, Bouaziz A, Horovistiz A, Kharrat M, Dammak M, Cardoso C, Pereira A. Microstructural, Mechanical and Tribological Behaviors of Cu/LLDPE-Based Composite Coatings for Lightweight Applications. Lubricants. 2024; 12(7):231. https://doi.org/10.3390/lubricants12070231

Chicago/Turabian StyleBen Difallah, Basma, Ayda Bouaziz, Ana Horovistiz, Mohamed Kharrat, Maher Dammak, César Cardoso, and António Pereira. 2024. "Microstructural, Mechanical and Tribological Behaviors of Cu/LLDPE-Based Composite Coatings for Lightweight Applications" Lubricants 12, no. 7: 231. https://doi.org/10.3390/lubricants12070231

APA StyleBen Difallah, B., Bouaziz, A., Horovistiz, A., Kharrat, M., Dammak, M., Cardoso, C., & Pereira, A. (2024). Microstructural, Mechanical and Tribological Behaviors of Cu/LLDPE-Based Composite Coatings for Lightweight Applications. Lubricants, 12(7), 231. https://doi.org/10.3390/lubricants12070231