Effect of CeO2 Content on Microstructure and Wear Resistance of Laser-Cladded Ni-Based Composite Coating

Abstract

1. Introduction

2. Test Materials and Methods

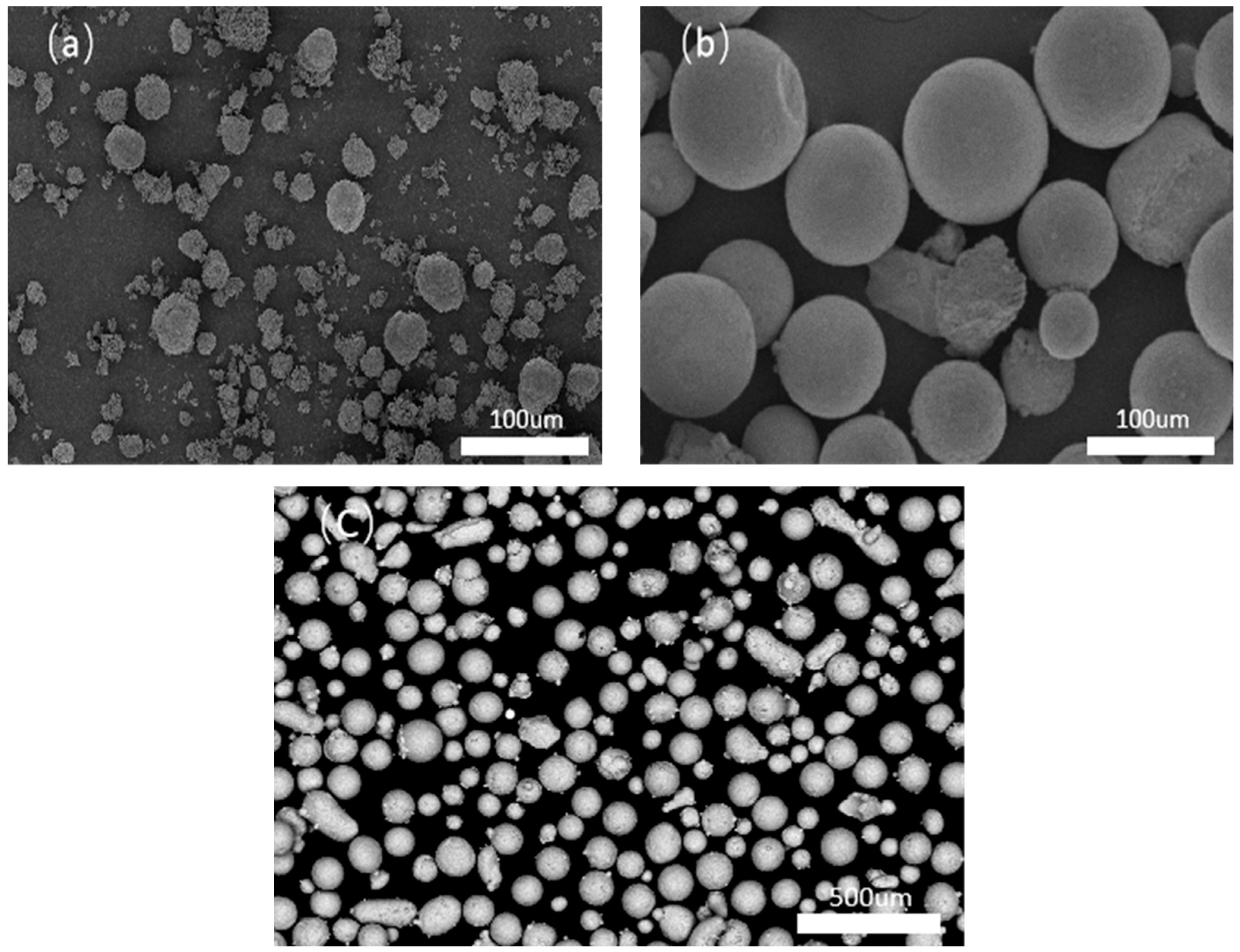

2.1. Test Materials

2.2. Test Method

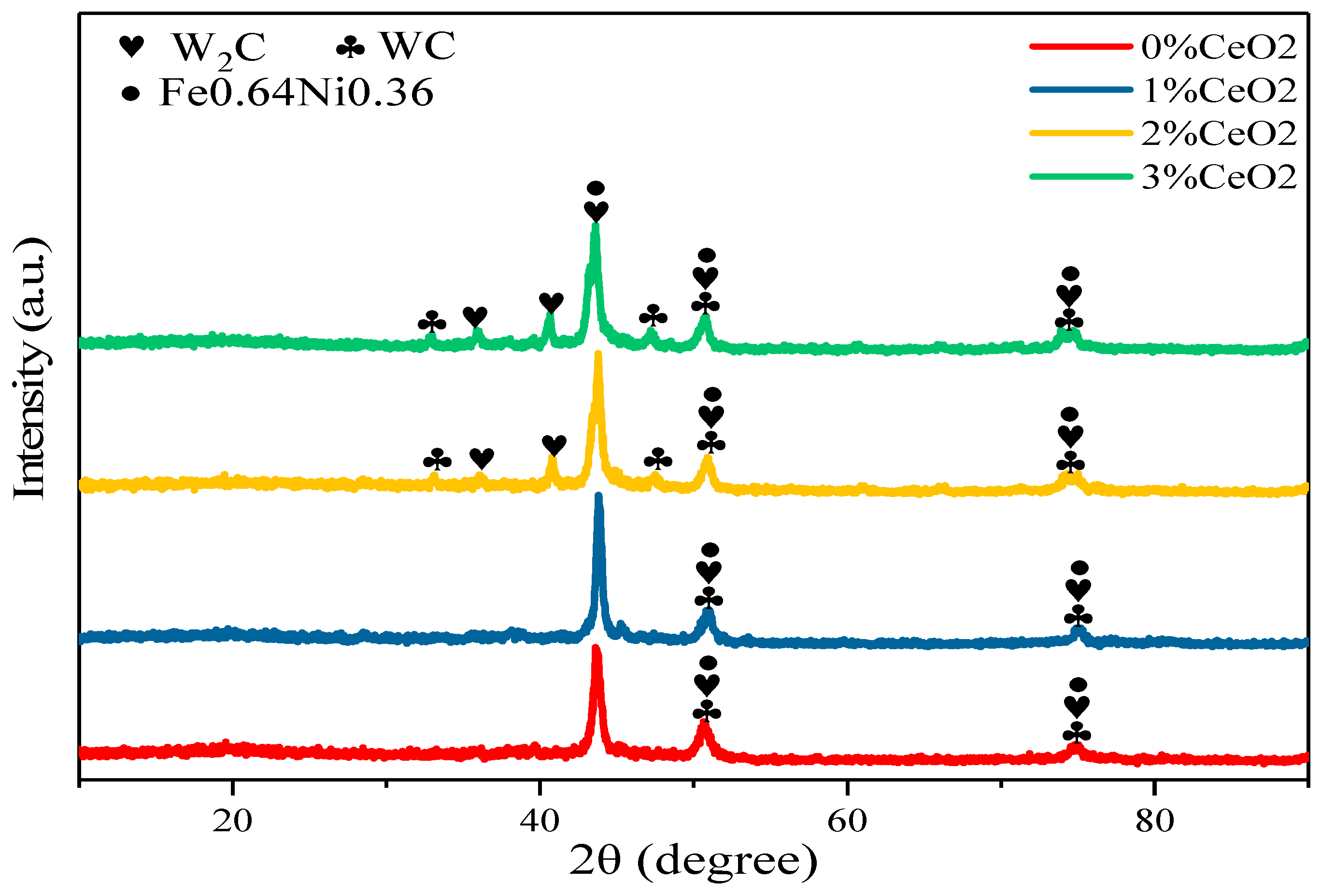

3. Results and Discussion

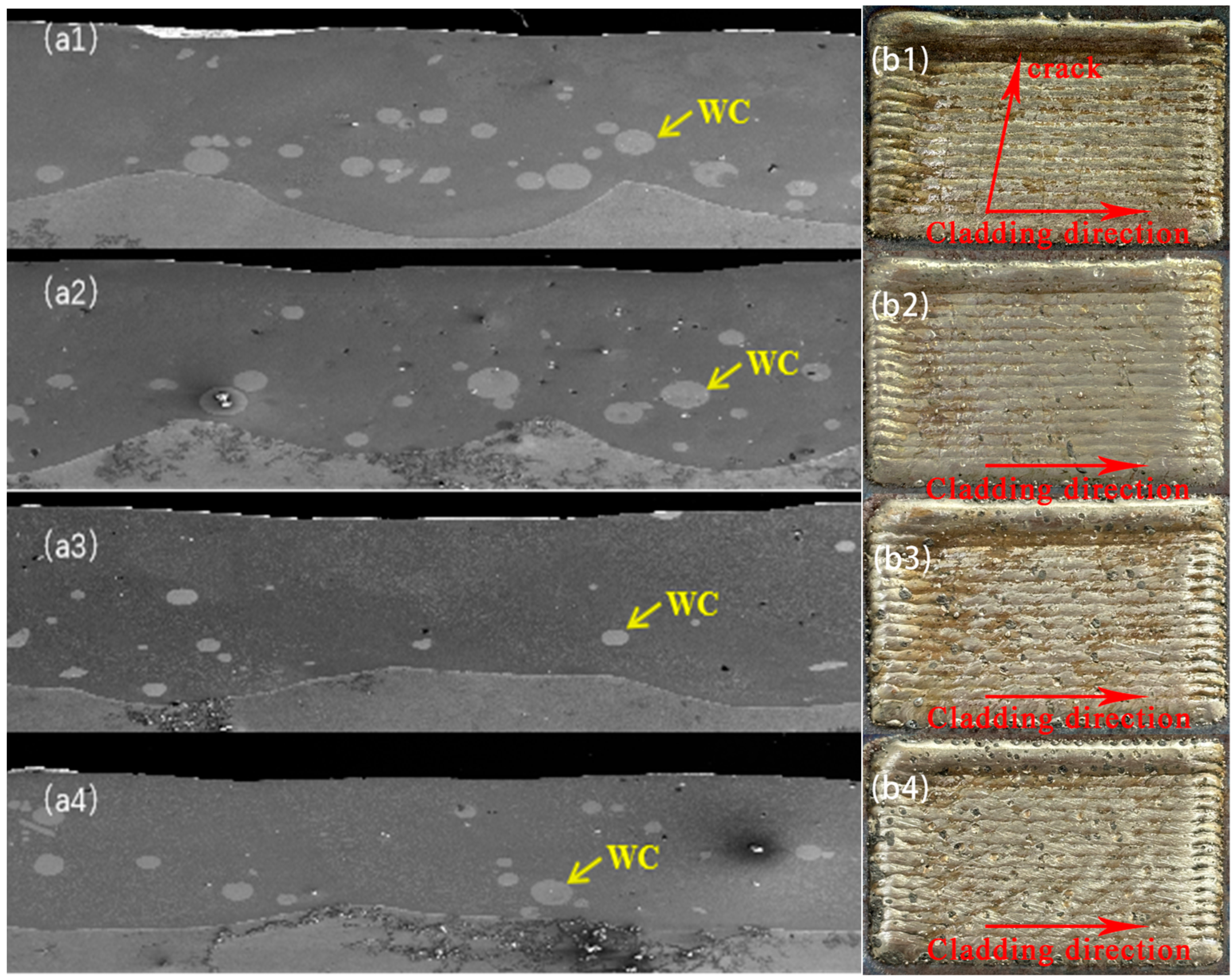

3.1. Coating Macromorphology Analysis

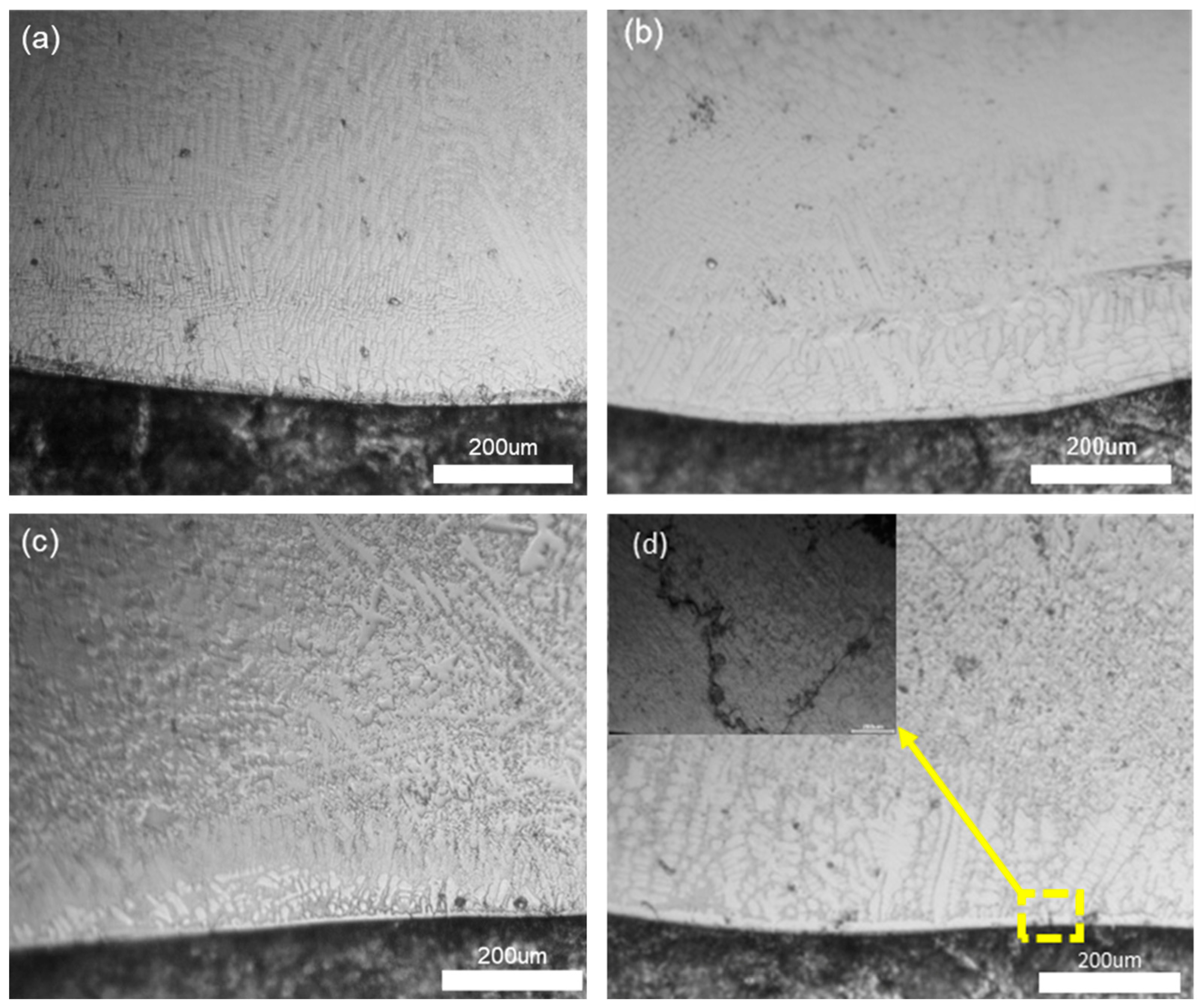

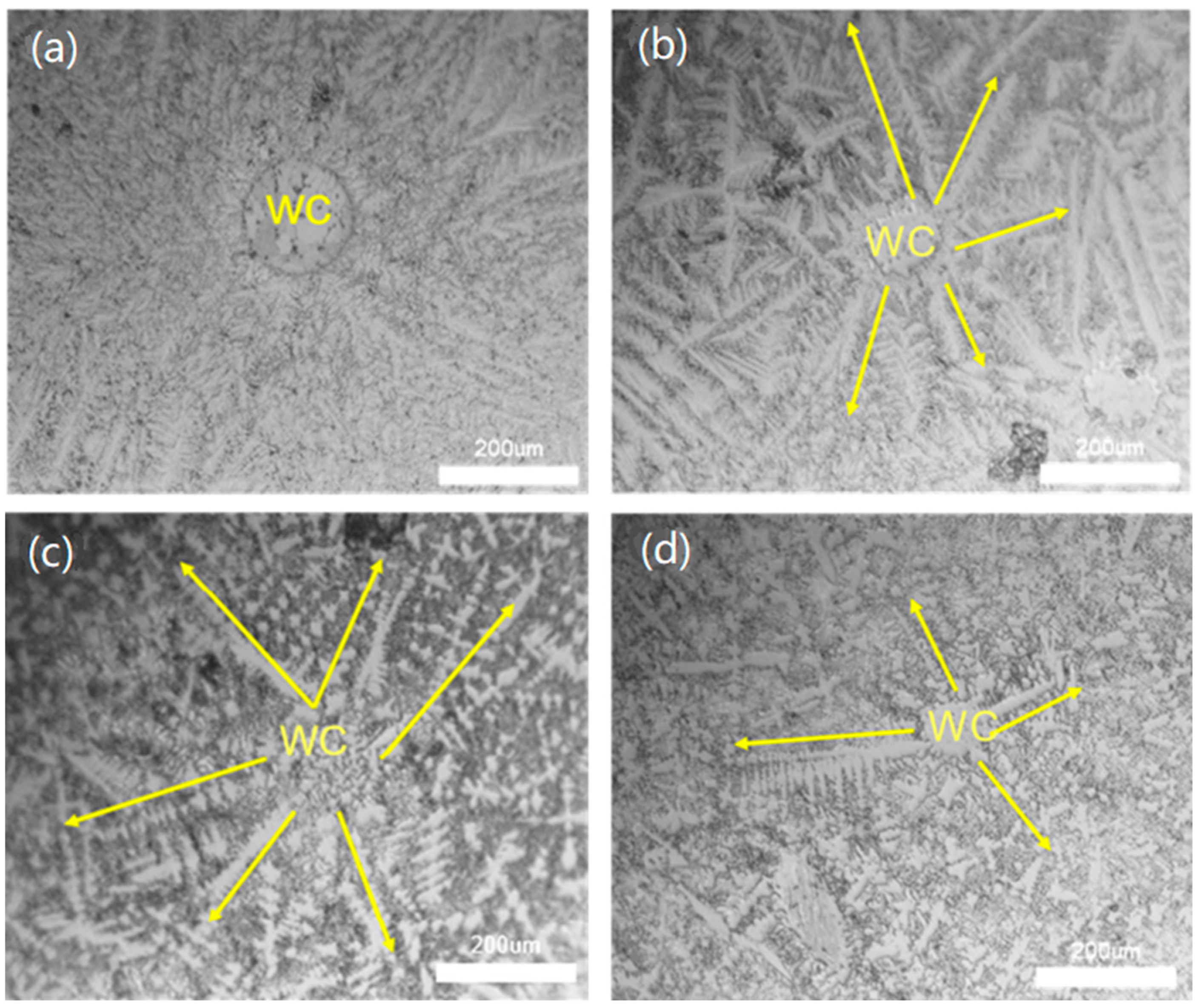

3.2. Microscopic Morphology

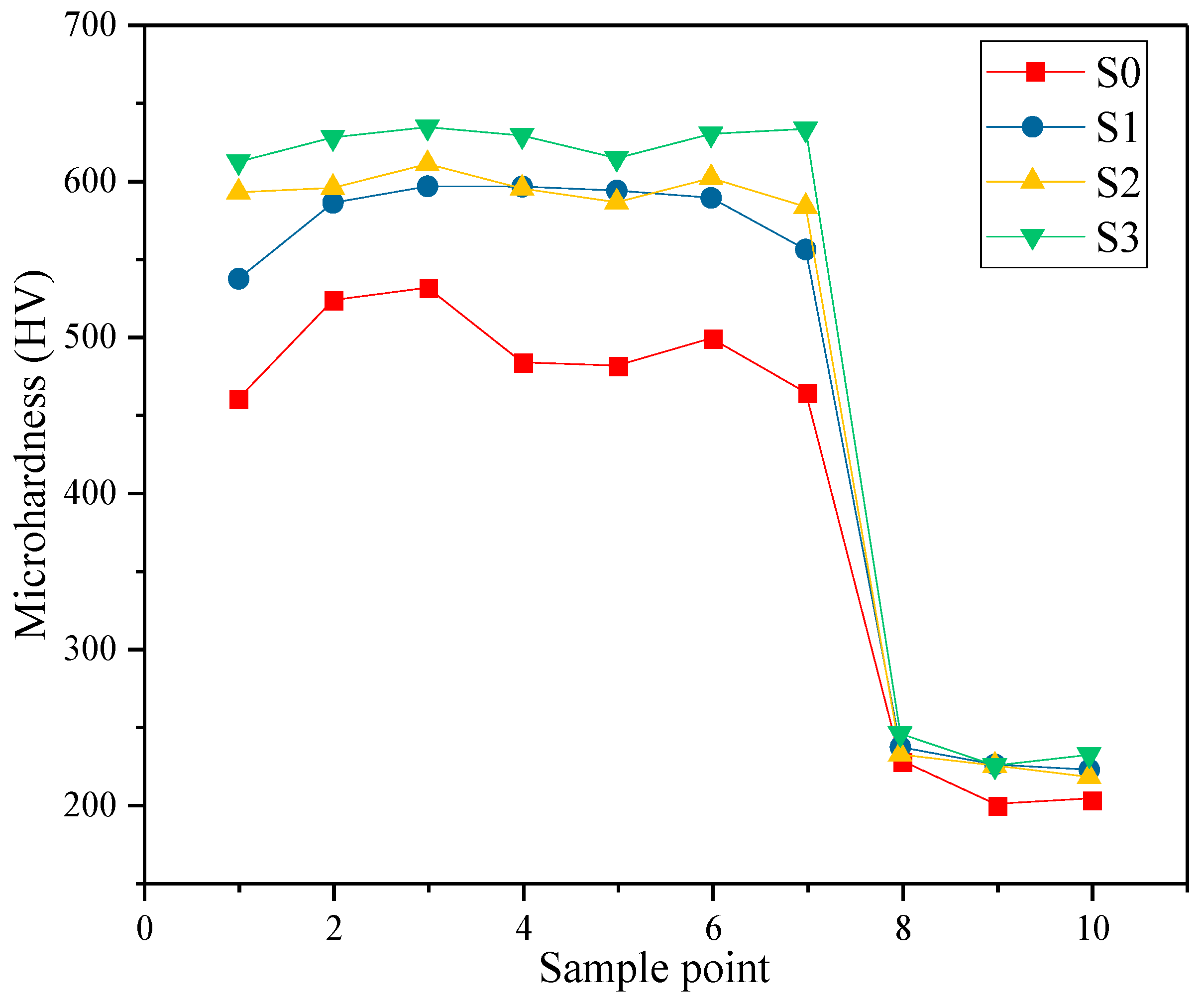

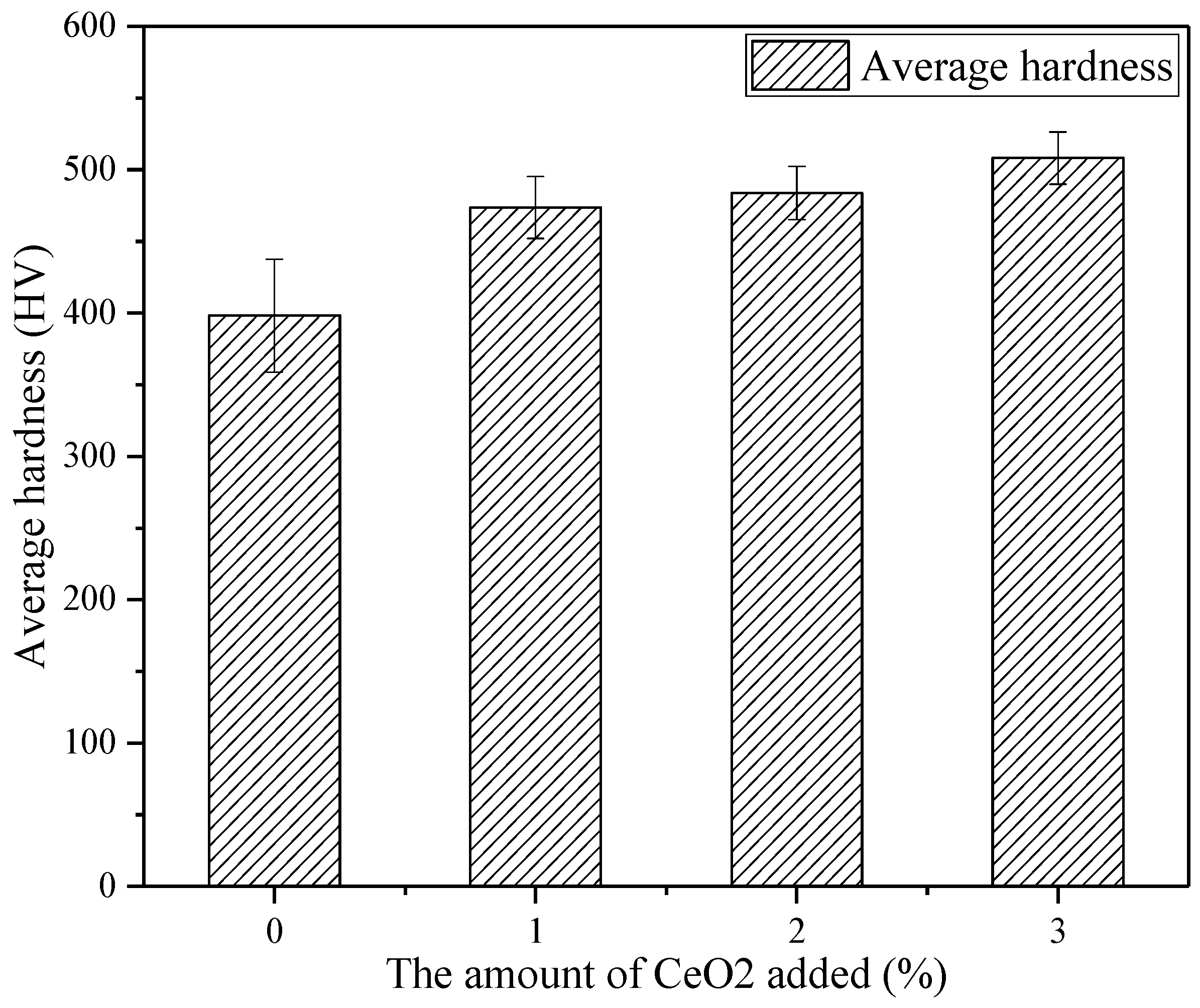

3.3. Hardness Analysis

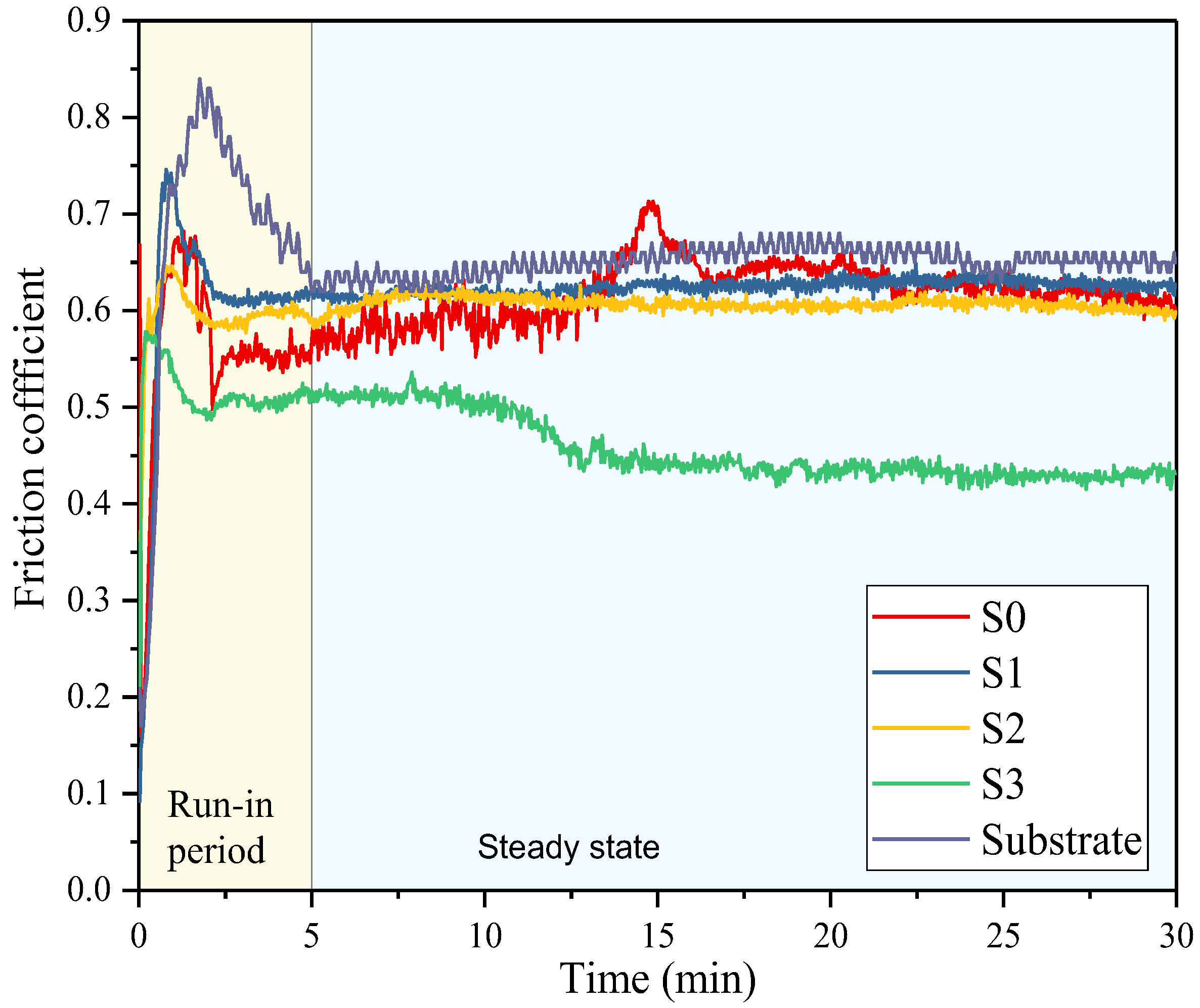

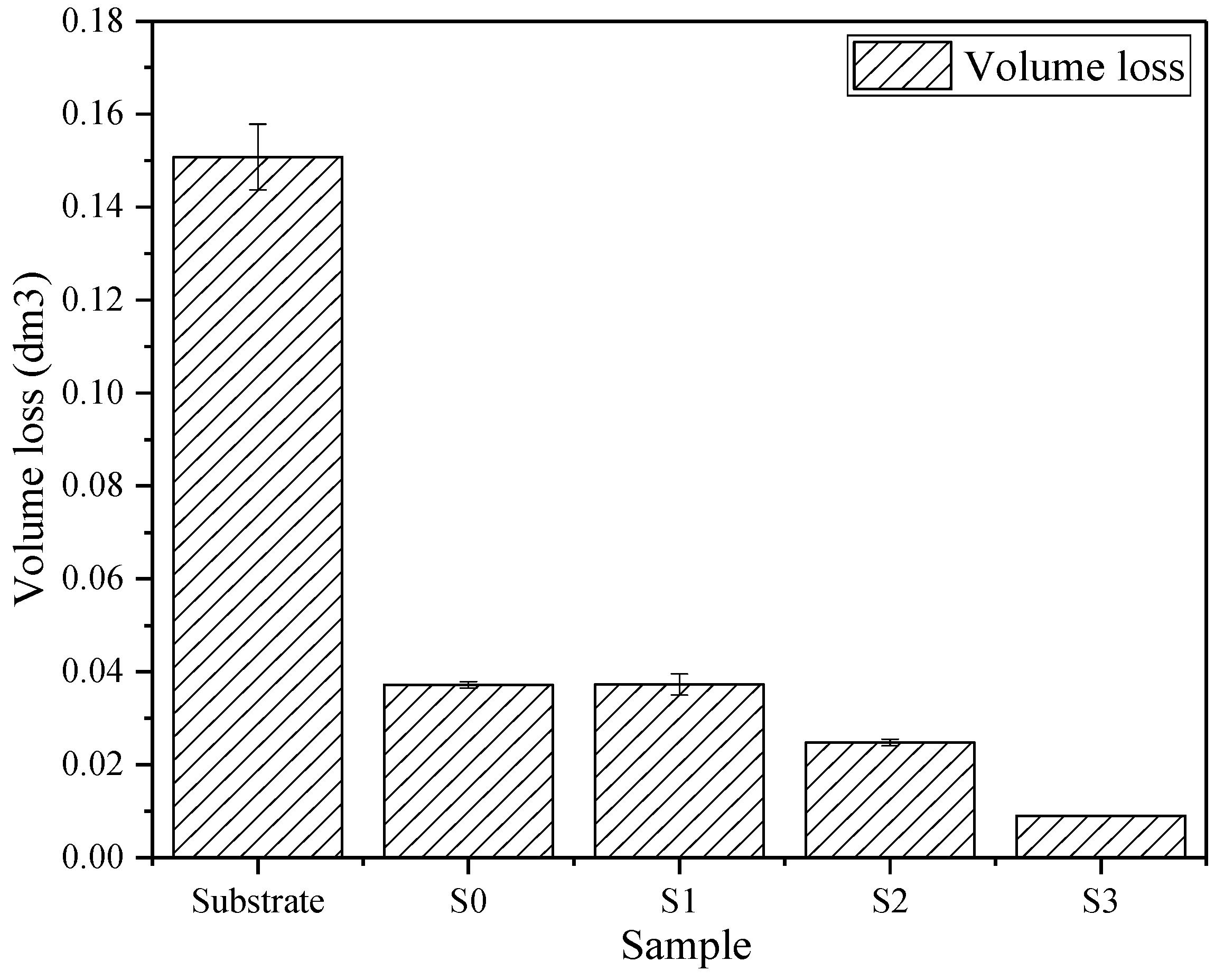

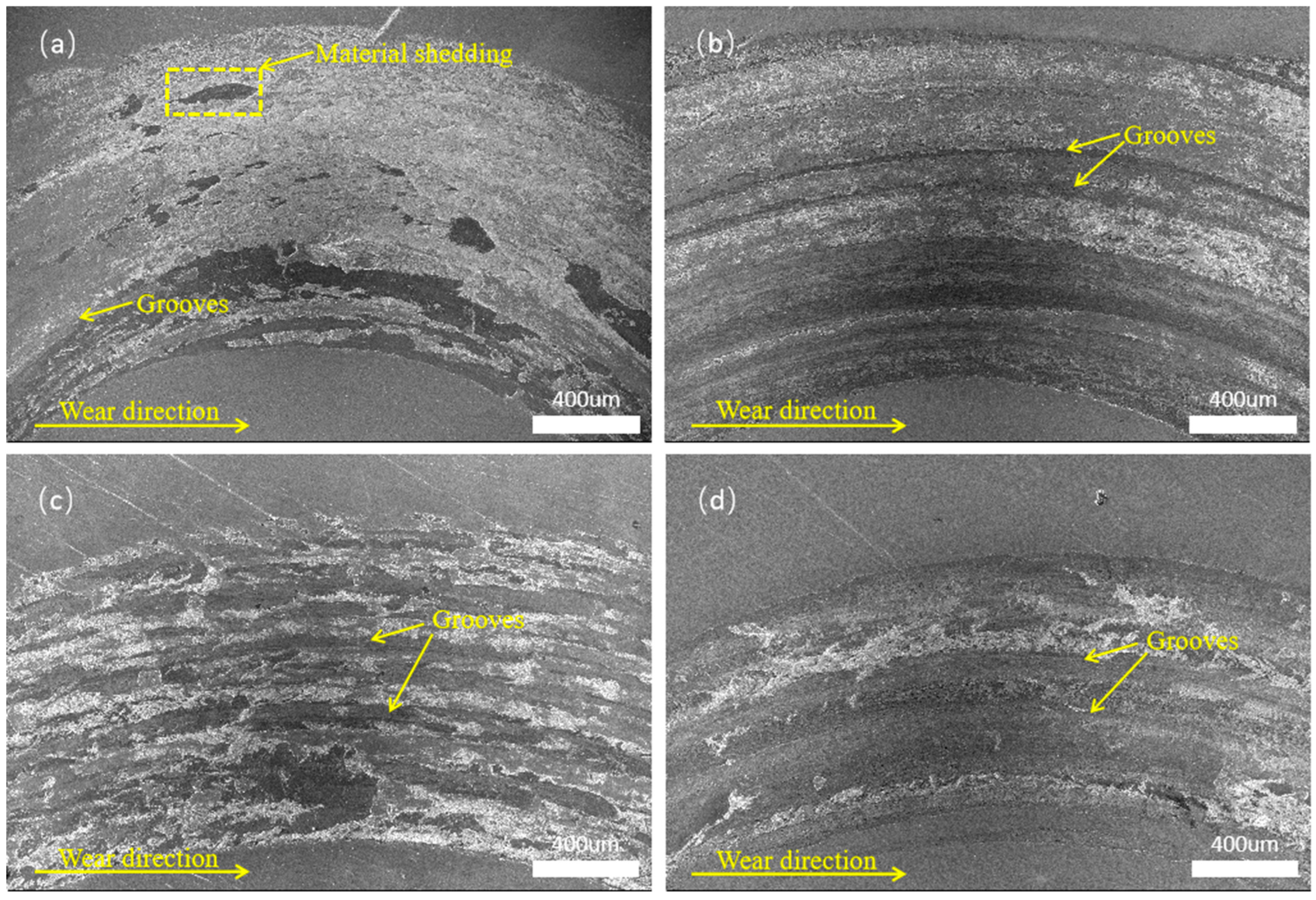

3.4. Wear Resistance Analysis

4. Conclusions

- The incorporation of CeO2 into the cladding powder demonstrated a capacity to mitigate surface cracks in nickel-based composite coatings, thereby enhancing the overall quality of the formed composite coating.

- An optimal quantity of CeO2 was shown to refine grain structures, promote uniformity in the microstructure of the cladding layer, and enhance solid solution strengthening within the cladding layer, thereby augmenting both the hardness and wear resistance properties of the coating.

- When the CeO2 addition reached 2%, notable enhancements in both the hardness and wear resistance of the composite coating were observed, resulting in optimized mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, B.X.; Fan, K.Y.; Yin, F.X.; Feng, J.H.; Ji, P.G. Effect of Caliber Rolling Reduction Ratios on the Microstructure and Mechanical Properties of 45 Medium Carbon Steel. Mater. Sci. Eng. A 2020, 774, 138954. [Google Scholar] [CrossRef]

- Liu, H.; Wei, J.; Dong, J.; Zhou, Y.; Chen, Y.; Wu, Y.; Babu, S.D.; Umoh, A.J.; Ke, W. The Synergy between Cementite Spheroidization and Cu Alloying on the Corrosion Resistance of Ferrite-Pearlite Steel in Acidic Chloride Solution. J. Mater. Sci. Technol. 2021, 84, 65–75. [Google Scholar] [CrossRef]

- Sun, L.; Yang, Q.; Zou, J.; Ni, L.; Song, X.; Zhang, R.; Liang, S. Effect of Hot-Dip Tin Coating Treatment on the Cusn10pb10/45 Steel Joint Fabricated by Diffusion Bonding. J. Mater. Res. Technol. 2022, 18, 1147–1154. [Google Scholar] [CrossRef]

- Sun, Y.-G.; Qi, Y.-S.; Li, J.; Du, Z.-M.; Chen, L.-L.; Chen, L.-H. Fabrication and Performance Analyses of 45# Steel Supports Using Liquid Forging. J. Zhejiang Univ.-Sci. A 2020, 21, 908–922. [Google Scholar] [CrossRef]

- Su, Z.; Li, J.; Shi, Y.; Ren, S.; Zhang, Z.; Wang, X. Effect of Process Parameters on Microstructure and Tribological Properties of Ni60a/Cr3C2 Laser Cladding on 60Si2Mn Steel. Surf. Coat. Technol. 2023, 473, 130005. [Google Scholar] [CrossRef]

- Deng, C.; Yi, Y.; Jiang, M.; Hu, L.; Zhou, S. Microstructure and High-Temperature Resistance of Al2O3/Conicraly Coatings by Laser Cladding. Ceram. Int. 2023, 49, 32885–32895. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Z.; Pang, M. Effect of Wc Content on Laser Cladding Ni-Based Coating on the Surface of Stainless Steel. Mater. Today Commun. 2022, 31, 103357. [Google Scholar] [CrossRef]

- Xia, Y.; Chen, H.; Liang, X.; Lei, J. Circular Oscillating Laser Melting Deposition of Nickel-Based Superalloy Reinforced by WC: Microstructure, Wear Resistance and Electrochemical Properties. J. Manuf. Process. 2021, 68, 1694–1704. [Google Scholar] [CrossRef]

- Zhou, S.; Xu, Y.; Liao, B.; Sun, Y.; Dai, X.; Yang, J.; Li, Z. Effect of Laser Remelting on Microstructure and Properties of WC Reinforced Fe-Based Amorphous Composite Coatings by Laser Cladding. Opt. Laser Technol. 2018, 103, 8–16. [Google Scholar] [CrossRef]

- Li, M.; Huang, K.; Yi, X. Crack Formation Mechanisms and Control Methods of Laser Cladding Coatings: A Review. Coatings 2023, 13, 1117. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research Status of Laser Cladding on Titanium and Its Alloys: A Review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. Effect of Rare Earth Elements and Their Oxides on Tribo-Mechanical Performance of Laser Claddings: A Review. J. Rare Earths 2016, 34, 549–564. [Google Scholar] [CrossRef]

- Ye, F.; Shao, W.; Ye, X.; Liu, M.; Xie, Y.; Bian, P.; Wang, X.; Liu, L.; Wu, H. Microstructure and Corrosion Behavior of Laser-Cladding CeO2-Doped Ni-Based Composite Coatings on TC4. J. Chem. 2020, 2020, 8690428. [Google Scholar] [CrossRef]

- Zhang, T.; Xiao, H.; Zhang, Z.; Yao, B.; Yang, F. Effect of Y2O3 Addition on Microstructural Characteristics and Microhardness of Laser-Cladded Ti-6Al-4V Alloy Coating. J. Mater. Eng. Perform. 2020, 29, 8221–8235. [Google Scholar] [CrossRef]

- Sun, S.; Fu, H.; Chen, S.; Ping, X.; Wang, K.; Guo, X.; Lin, J.; Lei, Y. A Numerical-Experimental Investigation of Heat Distribution, Stress Field and Crack Susceptibility in Ni60A Coatings. Opt. Laser Technol. 2019, 117, 175–185. [Google Scholar] [CrossRef]

- Li, W.; Yang, X.; Xiao, J.; Hou, Q. Effect of WC Mass Fraction on the Microstructure and Friction Properties of WC/Ni60 Laser Cladding Layer of Brake Discs. Ceram. Int. 2021, 47, 28754–28763. [Google Scholar] [CrossRef]

- Shu, D.; Dai, S.; Wang, G.; Si, W.; Xiao, P.; Cui, X.; Chen, X. Influence of CeO2 Content on Wc Morphology and Mechanical Properties of WC/Ni Matrix Composites Coating Prepared by Laser In-Situ Synthesis Method. J. Mater. Res. Technol. 2020, 9, 11111–11120. [Google Scholar] [CrossRef]

- Zhao, J.; Li, R.; Feng, A.; Feng, H. Effect of Rare Earth La2O3 Particles on Structure and Properties of Laser Cladding WC-Ni60 Composite Coatings. Surf. Coat. Technol. 2024, 479, 130569. [Google Scholar] [CrossRef]

- Chang, W. Study on the Fabrication of Laser Cladding Cermet Cutting Tools and Its Cutting Performance. Master’s Thesis, Qilu University of Technology, Jinan, China, 2023. [Google Scholar]

- Wang, C.; Gao, Y.; Wang, R.; Wei, D.; Cai, M.; Fu, Y. Microstructure of Laser-Clad Ni60 Cladding Layers Added with Different Amounts of Rare-Earth Oxides on 6063 Al Alloys. J. Alloys Compd. 2018, 740, 1099–1107. [Google Scholar] [CrossRef]

- Zheng, C.; Huang, K.; Mi, T.; Li, M.; Li, S.; Yi, X. Impact of Ceo2 Modification on the Quality and Wear Performance of Al2O3/SiC Reinforced Metal-Based Coatings. Mater. Charact. 2024, 208, 113641. [Google Scholar] [CrossRef]

- Lu, J.Z.; Cao, J.; Lu, H.F.; Zhang, L.Y.; Luo, K.Y. Wear Properties and Microstructural Analyses of Fe-Based Coatings with Various Wc Contents on H13 Die Steel by Laser Cladding. Surf. Coat. Technol. 2019, 369, 228–237. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, X.; Jiang, J.; Lian, G.; Chen, C. Study on the Effect of Rare Earth Oxide Addition on the Microstructure and Properties of Ni60/WC-Ni Coatings Prepared by Laser Cladding. Materials 2023, 16, 7263. [Google Scholar] [CrossRef]

- Shen, X.; Peng, H.; Xue, Y.; Wang, B.; Su, G.; Zhu, J.; Li, A. Microstructure and Properties of WC/Ni-Based Laser-Clad Coatings with Different WC Content Values. Materials 2022, 15, 6309. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Q.; Zhang, L.; Chen, D.X.; Jin, H.; Li, J.D.; Zhang, J.W.; Ban, C.Y. Microstructure and Properties of Ni-WC Gradient Composite Coating Prepared by Laser Cladding. Ceram. Int. 2022, 48, 7905–7917. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Q.; Yang, F.; Zhang, H.; Zhang, T.; Wang, H.; Ma, Q. Comparative Investigation on Wear Properties of Composite Coatings with Varying CeO2 Contents. Coatings 2022, 12, 906. [Google Scholar] [CrossRef]

- Liang, F.; Li, K.; Shi, W.; Zhu, Z. Effect of Y2O3 Content on Microstructure and Corrosion Properties of Laser Cladding Ni-Based/WC Composite Coated on 316L Substrate. Coatings 2023, 13, 1532. [Google Scholar] [CrossRef]

- Ren, M.; Li, R.; Zhang, X.; Gu, J.; Jiao, C. Effect of Wc Particles Preparation Method on Microstructure and Properties of Laser Cladded Ni60-WC Coatings. J. Mater. Res. Technol. 2023, 22, 605–616. [Google Scholar] [CrossRef]

- Rupert, T.J.; Schuh, C.A. Sliding Wear of Nanocrystalline Ni–W: Structural Evolution and the Apparent Breakdown of Archard Scaling. Acta Mater. 2010, 58, 4137–4148. [Google Scholar] [CrossRef]

- Li, S.; Liu, D.; Liu, G.; Xin, S.; Deng, Z.; Li, C.; Chen, T. Study on the Preparation of CeO2-Doped Alcocrfeniti High Entropy Alloy Bioinert Coatings by Laser Cladding: The Effect of CeO2 Particle Size on the Tribological Properties of the Coatings. Surf. Coat. Technol. 2023, 475, 130155. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.; He, R.; Gong, Y.; Miao, X. Effect of CeO2 Addition on Grain Refinement and Mechanical Properties of Stellite-6 Coating Fabricated by Laser Cladding. J. Therm. Spray Technol. 2022, 31, 2621–2634. [Google Scholar] [CrossRef]

- Li, W.; Di, R.; Yuan, R.; Song, H.; Lei, J. Microstructure, Wear Resistance and Electrochemical Properties of Spherical/Non-Spherical WC Reinforced Inconel 625 Superalloy by Laser Melting Deposition. J. Manuf. Process. 2022, 74, 413–422. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | Ni | Cu | Fe |

|---|---|---|---|---|---|---|

| Value | 0.42–0.05 | 0.17–0.37 | 0.5–0.8 | ≤0.30 | ≤0.25 | Bal |

| Sample | A | B | C | D |

|---|---|---|---|---|

| Ni60 | 7 | 6.3 | 5.6 | 4.9 |

| WC | 3 | 2.7 | 2.4 | 2.1 |

| CeO2 | 0 | 1 | 2 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Shi, W.; Lin, Y.; Jiang, L.; Wang, L.; He, K. Effect of CeO2 Content on Microstructure and Wear Resistance of Laser-Cladded Ni-Based Composite Coating. Lubricants 2024, 12, 227. https://doi.org/10.3390/lubricants12060227

Zhang B, Shi W, Lin Y, Jiang L, Wang L, He K. Effect of CeO2 Content on Microstructure and Wear Resistance of Laser-Cladded Ni-Based Composite Coating. Lubricants. 2024; 12(6):227. https://doi.org/10.3390/lubricants12060227

Chicago/Turabian StyleZhang, Bingqing, Wenqing Shi, Yiming Lin, Longwei Jiang, Lijun Wang, and Kuanfang He. 2024. "Effect of CeO2 Content on Microstructure and Wear Resistance of Laser-Cladded Ni-Based Composite Coating" Lubricants 12, no. 6: 227. https://doi.org/10.3390/lubricants12060227

APA StyleZhang, B., Shi, W., Lin, Y., Jiang, L., Wang, L., & He, K. (2024). Effect of CeO2 Content on Microstructure and Wear Resistance of Laser-Cladded Ni-Based Composite Coating. Lubricants, 12(6), 227. https://doi.org/10.3390/lubricants12060227