Abstract

In this work, large-scale molecular dynamics (MD) computational simulations were performed in order to explore the sliding contact responses of rough surfaces with hexadecane lubricant and added nanoparticles. Simulation results revealed that the frictional state was dependent on the fluid, nanoparticle, and surface roughness. Three lubricating conditions were compared based on considerations of different amounts of fluid molecules. The lubricant was not able to separate the frictional contact surfaces if the quantity of lubricant molecules was insufficient. Particularly, there were no lubricating contributions when the amount of lubricant was too low, and the lubricant therefore only filled the pits in the surface roughness. Thus, the normal load was primarily supported by the contact between the two surfaces and nanoparticles, leading to significant surface morphology changes. In contrast, the frictional contact surfaces were able to be completely separated by the lubricant when there was a sufficient amount of fluid, and a very good lubricating effect could thus be achieved, resulting in a smaller friction force. In addition, the changes in surface morphology, contact area, and RMS are discussed in this paper, in order to reveal the dynamic frictional process.

1. Introduction

The development of high-performance lubricants is critical in improving manufacturing costs and increasing the service life of materials and mechanical parts [1]. In order to overcome the relatively poor tribological performance of conventional materials in mechanical contact systems, one strategy is to design and develop novel structures or new materials with superior friction and wear properties. These novel structures and materials include the widely reported gradient structures [2,3], nanostructures or nano-grained structures [4,5,6], hieratical or heterogeneous structures [7,8], and the recently proposed medium entropy alloys (MEAs) [9,10,11], high entropy alloys (HEAs) [12,13,14], high entropy ceramics (HECs) [15], and so on. In addition to improved mechanical properties, these novel structures and materials have been reported to possess excellent wear resistances under a wide range of environmental conditions. For example, compared with conventional coarse-grained structures, both the friction coefficient and wear rate were found to have decreased in Ti6Al4V when it instead consisted of bulk nano-grained structures [6]. With the help of nano/micro-wear testing, Chen et al. [3] revealed that a lower friction coefficient could be achieved in Cu and Cu–Ag alloys when they were composed of gradient nano-grained microstructures. Apart from advanced microstructure designs and fabrications, new alloys such as MEAs and HEAs have also been found to exhibit excellent friction and wear performances. Zhang et al. [9] found that the CrCoNi MEA has outstanding scratching properties, not only at room temperature, but also at cryogenic temperatures. According to Zhu et al. [14], the wear resistance of additively manufactured FeCoCrNi HEA can be affected by Cu-doping. Another promising strategy is to develop advanced lubricants, such as solid-self lubricants [16,17,18,19,20] and glass lubricants [21,22], for engineering applications under extreme conditions, like high temperature and pressure. Using HEAs as the solid matrix materials, Zhang et al. [17,20] developed several self-lubricating composites based on CoCrFeNi HEA. These HEA-based solid self-lubricating composites were found to perform very well in a wide temperature range, from RT up to 800 °C.

However, liquid-based lubricants are still very popular for use at relatively low temperatures, from the points of view of both lubricating and economic efficiency. For instance, nanoparticles, including metallic nanoparticles [23], their oxides [24,25,26,27,28], and non-metallic particles [29,30,31], have been widely added to lubricants as a strategy to reduce wear and friction during mechanical contacts in experiments. A comprehensive work by Dai et al. [32] discussed the role of nanoparticles in oil lubricants. They compared the influences of the physical and chemical properties of nanoparticles and discussed the effects of both size and morphology on their lubricating performance. They found that nanoparticle size demonstrates a significant effect on friction coefficient and wear volume, and that the optimum size is dependent on the working conditions, i.e., base lubricant, surface roughness, and chemical properties [33,34,35]. The sizes and shapes of particles have been studied widely, including spherical, sheet, granular, onion, and tubular particles. In addition to oils, the addition of nanoparticles or nanosheets has also been found to be able to greatly improve the tribological properties of water-based lubricants [36]. These nanoparticles contribute to low wear and friction in terms of rolling, sliding, and exfoliation, or a combination of these modes [30,32,35].

Unfortunately, it has been commonly accepted that the friction mechanisms of nanoparticles and lubricant are hardly observable by current experimental approaches. However, molecular dynamics (MD) simulation, which is based on Newton’s equations of motion for molecular systems, is considered to be one of the cheapest and most accurate approaches to explore tribological phenomena at the molecular or atomic level [37,38]. In recent research, numerous computations employing the MD approach have been carried out to explore the surface contacts and friction properties of diverse lubricants and nanoparticles. These models have encompassed surfaces with single asperities [38,39,40], and amorphous [41] or rough profiles [42,43]. Models with thin film, flat surfaces [13] and 3D rough surfaces [44,45] have also been studied. Most of the above simulation works were carried out with either dry contact or simple surface contact. Lv et al. [46] performed an MD simulation of Cu–Ar nanofluids between two solid surfaces. They revealed that the nanoparticles provided a supporting force on the plate, consequently diminishing the contacts between these solid surfaces. Hu et al. [30] compared the friction properties of fluids with and without nanoparticles under shearing. They found that liquid–solid transitions occurred in both the base and nanofluid cases when the normal load was increased. However, the nanofluids showed excellent friction-reducing properties when the load was high. They also examined frictional fluid with hard nanoparticles (diamond and silicon dioxide) and found that the nanoparticles could separate the two blocks. In their later work [31], it was observed that the hard nanoparticles contributed to polishing the frictional contact surfaces. Stephan et al. [38,39] explored the effects of lubricants on nanoparticle indentation. They found that trapped lubricant between tip-surface gaps led to a larger contact area when compared to the dry contact case. Zhang et al. [37] carried out multi-scale simulations of rough lubricated contact and found that the studied lubricant molecules could effectively separate aluminum surfaces and bear the external pressure. Ji et al. [47] conducted MD simulation of water and SiO2 mixed fluid confined between copper walls. They found that both rolling and sliding friction occurred during sliding. The simple rough surfaces with holes were partially filled by the nanoparticles, which helped to smooth the surfaces and decrease the friction coefficients. Moreover, when the normal pressure increased, nanoparticles underwent cutting and absorption into the solid surface, potentially influencing the filling of rough plates. However, most of the above MD models were based on simplifications with either flat or structured rough surfaces. The combined effects of fluids, nanoparticles, and surface roughness have not been well studied.

In the case of boundary friction, the frictional state is very complicated and can be affected by the lubricating fluid, the composition of particles, and the surface roughness condition. It is therefore very important to understand the effects of nanoparticles in a lubricant on the mechanical contacts between two rough surfaces. In our previous work [44], we examined the friction behavior of confined fluid between rough surfaces with dry, partially lubricated, and fully lubricated cases. More recently, the effects of lubricant and nanoparticles on sliding surfaces were discussed [48]. This modelling study is an extension of our prior MD simulations to explore the combined effects of fluid, particles, and surface roughness, which are hardly detectible by direct experimental observations. The findings in this study provide a fundamental and comprehensive understanding of nano-scale boundary lubrication and associated mechanisms from a MD simulation standpoint.

2. Simulation Models and Details

2.1. Simulation Model

MD simulation has been proven to be one of the most powerful numerical models for studying plastic deformation and tribology at the nano-scale [9,37]. It provides insights into non-equilibrium processes under diverse conditions, enabling exploration of surface contacts and boundary lubrication. In this paper, all the MD simulations were carried out using a larger-scale atomic or molecular massively parallel simulator (LAMMPS) [49].

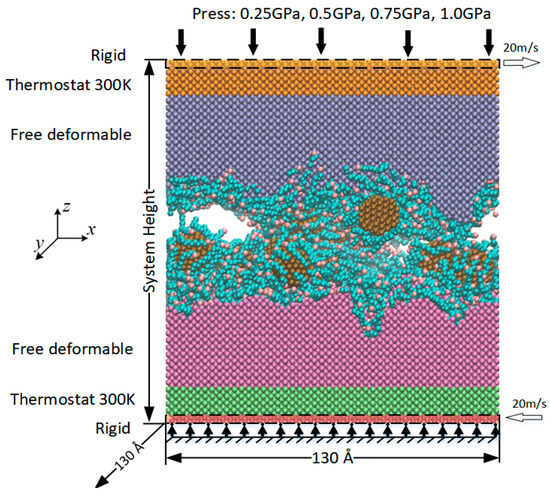

As displayed in Figure 1, the tribological model consisted of upper and lower <001> oriented BCC iron walls. Hexadecane was used as the lubricant, and 16 Fe rigid nanoparticles with a radius of 8 Å comprised the additive. The current research mainly focused on the combined effect from nanoparticles. Thus, the tribological system was simplified to only consider the rigid particles. The BCC iron wall was further divided into three parts: the rigid region, the thermostat region, and the deformable free region, as labelled in Figure 1. Periodic boundary conditions were applied to the lateral (x and y) directions. The y and z directions were allowed to move as the system height fluctuated during compression and sliding processes under four different normal forces, from 0.25 GPa to 1.0 GPa. The influences of the amount of lubricating fluid molecules (250, 500, 750, and 1000) were investigated to represent the different amounts of lubricant between the upper and lower contacting surfaces. However, the number of nanoparticles was kept the same for all cases, at 16. To ensure a reasonable duration of calculations and also enough surface area to accommodate multiple roughness peaks and valleys, 45 × 45 BCC lattice units were used to construct the surfaces both along the x and y directions, in total equaling approximately 130 × 130 Å. Figure 1 displays a schematic illustration of the atomic contact system. The surface roughness of both the upper and lower contact surfaces was about 0.8 nm in the current MD models.

Figure 1.

A snapshot of the simulation model with hexadecane confined between two BCC iron surfaces.

The MD simulation consisted of three steps: system relaxation (0.2 ns), then compression (0.8 ns), and finally sliding (3.0 ns). In the compression step, the lower rigid region was kept unchanged to support the whole system, while the upper fixed region was able to move in the y and z directions under normal loads. After compression, 20 m/s in the x direction was applied to both rigid regions but in opposite directions, which led to a shearing speed of 40 m/s. It has to be pointed out that the MD simulations in this study concentrated on very small spatial scales and high shear rates. A high shearing speed results in an increase in system temperature. In order to maintain the system temperature at 300 K during sliding, the Nosé–Hoover [50] thermostat with a damping constant of 100 fs was applied to the thermostat regions. The velocity Verlet algorithm was used for the numerical integration of the atomic classical equations of motion, with a time step of 2 fs.

Surface and interface roughness is crucial for boundary lubrication as it affects the contact status during surface sliding, particularly when the thin film thickness and particle size are close to its value. In our previous models [48], the roughness has been described using a self-affine fractal scaling with a Hurst exponent [51]. The random midpoint displacement (RMD) method with the Hurst exponent was used to generate rough surfaces, and the surface boundaries were periodic.

2.2. Molecular Dynamics

Due to the surface contact, severe plastic deformation was possible during sliding. Reasonable results intensively depended on the proper force field. Finnis–Sinclair (FS) EAM potentials [52] have been proven to correctly represent metal deformation. In this work, intensive surface contact occurred during sliding, and the EAM potential was used to model wall blocks. Real surfaces are usually covered by oxidized layers, which present relatively weak adhesion forces to their surroundings. To retain the model simplicity and focus on the influence of nanoparticles, the LJ potential (Equation (1)), with parameters = 0.02045 eV and = 0.321 nm [53], was used to simulate the contact between the surface contact and nanoparticles.

The hexadecane was modeled with the TraPPE-UA [54] force field, which simplified all of the CHx groups with pseudo carbon atoms. The parameters of unlike interactions were estimated using the mixing rules of the Lorentz–Berthelot theory (Equation (2)).

2.3. Atomic Scale Contact Conditions

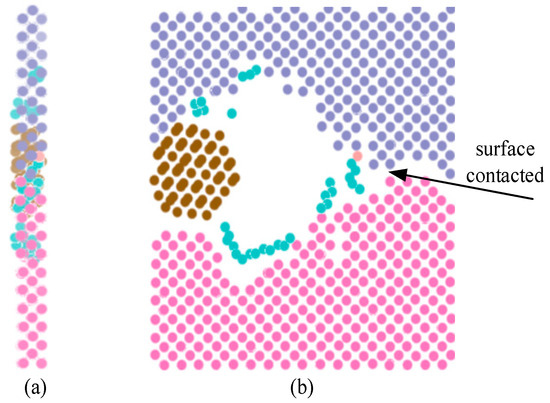

At the atomic scale, practical contact areas are crucial to heat conduction, friction, and adhesion. In this study, we focused on the effects of nanoparticles on lubricated surface contacts, so it was critical to study the contact areas during sliding. In continuum models, it is easy to obtain the contact area through the contact zone. However, in atomic models that contain discrete atoms, the atomic contacts are identified using the repulsive force or distance. For classical potentials like the LJ potential, the determination of whether two atoms are in contact or not is usually unclear. However, the attractive force of the LJ potential decays dramatically when two atoms are separated by several atomic diameters. For simplicity, contact between two atoms is established when their distance is less than or equal to the distance threshold. Namely, a contact is assumed to have occurred if two atoms are separated by a distance of less than 0.5 nm, as shown in Figure 2. The same calculation method and threshold distance has also been used by Spijer et al. [43] in an earlier report, in which they aimed to investigate the dry contact area at the atomic scale. Therefore, the practical contact areas were calculated by the projected cuboid of the surface atoms. Specifically, the x–y plane was divided into n × n grids, and the surface atoms were labeled with each individual cuboid based on the x coordinate and y coordinate. The grid size was equal to its BCC lattice size of 0.2855 × 0.2855 nm. Within each cuboid, the top surface atoms were checked to define whether they were within the contact threshold, thereby determining whether the grid was contacted or not.

Figure 2.

Slice of models at the y–z plane (a) and x–z plane (b) to define the surface contact. The arrow in (b) indicates the upper atom and lower atom distances within the contacting threshold.

3. Results and Discussion

3.1. Relaxation and Compression

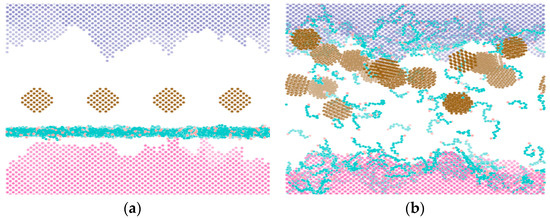

In order to construct the model, nanoparticles and fluid molecules were placed in an orderly formation first. The rigid layer was kept fixed before compression, which allowed lubricant molecules and nanoparticles to remain fully relaxed in the first 0.2 ns. Figure 3 shows a typical model in which 250 molecules and nanoparticles are relaxing.

Figure 3.

Initial models (a) and relaxing models (b) with 250 molecules.

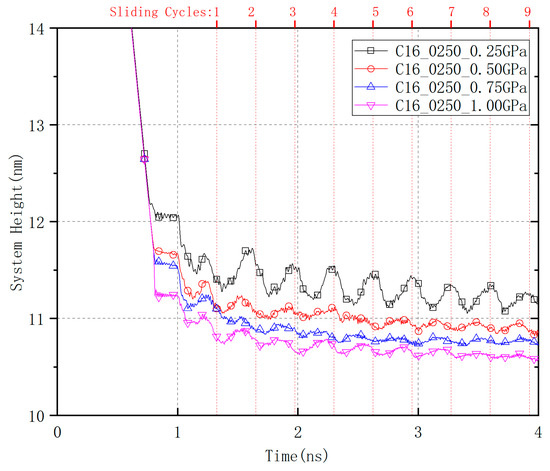

Following the relaxation phase, the upper rigid layer had the normal load. At the beginning, no supporting forces were supplied from the nanoparticles, the fluid, or the lower surface, causing the upper surface to descend rapidly. This situation was detrimental to surface contact, eliciting huge momentum just before the two surfaces made contact. Even when the normal load remained constant, this process was liable to lead to the deformation of large asperities, as the initial wall separation was different due to the number of lubricant molecules. Therefore, the descending speed of the upper surface in the z direction was limited by a maximum displacement value (around 0.125 m/s). Under this limitation, despite varying initial separation distances, the starting contact between the surfaces maintained a constant momentum. The total duration of the compression step was 0.8 ns, where the first 0.6 ns was under the constrained displacements. Figure 4 shows the system height of the model with 250 molecules under 0.25 GPa. The system reached a stable system height after the compression stem, as evident from the small curve platforms before 1 ns.

Figure 4.

System height of 250 molecules under different loads.

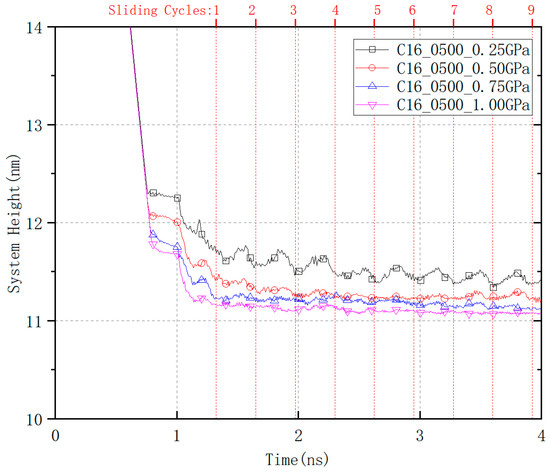

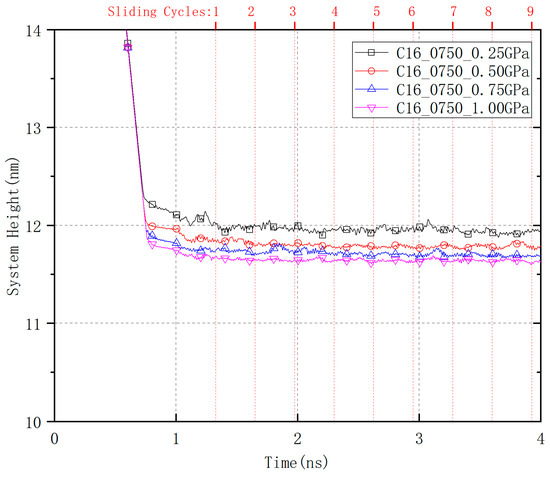

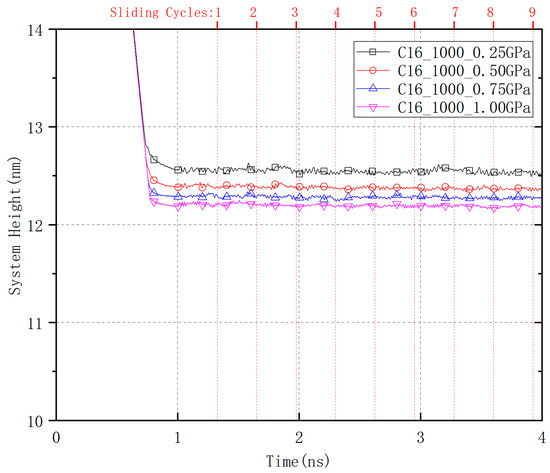

In studying lubrication states using MD simulations, periodic boundary conditions are typically employed along the flow direction of the lubricant, confining the lubricant within a restricted lubricating region. In such scenarios, the boundary lubrication state is determined by the quantity of lubricant present. In cases where the lubricant is scarce and the surface roughness is large, the friction state is determined either by direct contact between the surfaces, or by the presence of abrasive particles causing wear. Comparing the results in Figure 4, it can be observed that 250 and 500 lubricant molecules were insufficient to completely fill the contact spaces formed by surfaces and particles. Consequently, the pressure displayed inconsistent height changes after compression. However, with the presence of more lubricant molecules, it became evident that the changes in system height exhibited a corresponding increase with the growth of pressure. The details can be examined by referring to the variations in Figure 4, Figure 5, Figure 6 and Figure 7 between 0.8 ns and 1 ns.

Figure 5.

System height of 500 molecules under different loads.

Figure 6.

System height of 750 molecules under different loads.

Figure 7.

System height of 1000 molecules under different loads.

3.2. Sliding Contact Behavior

When lubricant, surface roughness, and nanoparticles are present on frictional surfaces, the ultimate frictional state is collectively determined by these factors, particularly when the mean lubricant thickness is similar to the surface roughness dimension and nanoparticle size. After the system reaches the stable compression state, the upper and lower surfaces start to slide against each other parallel to the x direction. Although the MD model in this study experienced high shear rates, the temperature of the fluid was maintained around 310 K due to the temperature control applied to both the upper and lower surfaces.

In this section, the sliding effect of the fluid and nanoparticles on contact surfaces are discussed. The sliding step for all models was set to 3.0 ns, which was a sufficient duration to ensure that the surface contact reached nine sliding cycles. Surface roughness, nanoparticles, and lubricant jointly determine the state of surface sliding contact, ultimately determining the surface wear, or in other words, changes in the surface morphology. We believe that maintaining a stable surface morphology, i.e., stable surface roughness, reflects an equilibrium in surface relative sliding. When analyzing the surface contact, some researchers have observed the emission of dislocations in FCC structured metals and alloys [13]. This results in a great rise in the number of atoms in the deformable layer. However, the research focus in this study is primarily on the influences of nanoparticles, rough surfaces, and fluids, and their interactions. The investigation aims to reveal how these three factors determine the friction and affect the surface contact. Therefore, it is reasonable to have a deformable layer with an atomic quantity that meets the requirements for surface plastic deformation. As can be seen in Figure 4, the model included only 250 molecules of the lubricating fluid. Under a pressure of 0.25 GPa, the system height exhibited noticeable periodic fluctuations during the sliding step. This obvious fluctuation was also observed by Spijker et al. [43] during MD simulation of dry sliding contact between rough surfaces at the atomistic scale. This indicates that in situations of insufficient lubrication, nanoparticles and surface roughness play a decisive role in determining the contact state of the system. When the pressure was increased to 0.5 GPa or higher, the fluctuation became smaller. Under a larger pressure, there was more plastic deformation at surface asperities, and the particles tended to fill the surface valleys, which seemed to smoothen the rough surface and help in surface sliding. More stable sliding conditions could be observed when the lubricant molecules were increased to 1000. The system height remained relatively stable during the sliding process, which indicates that the surfaces were totally separated by the molecules of lubricant.

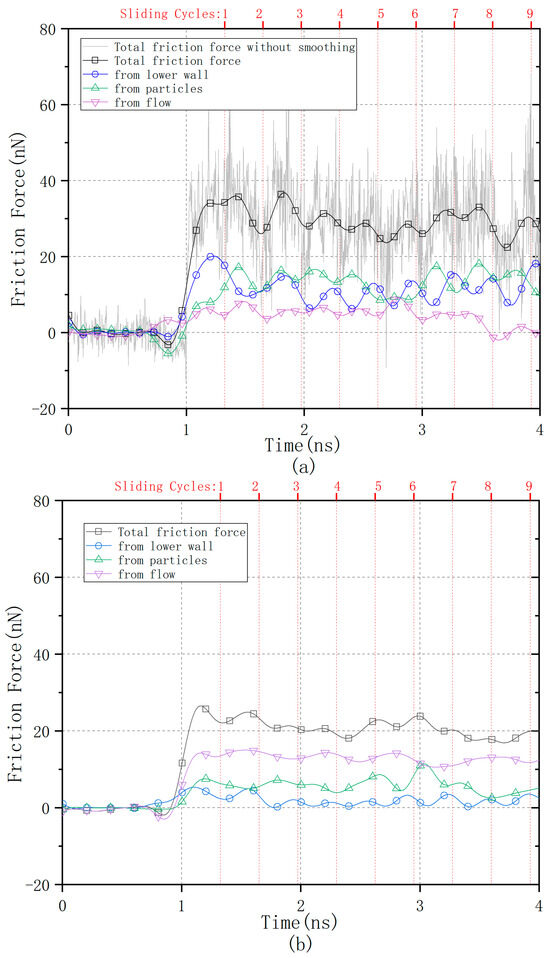

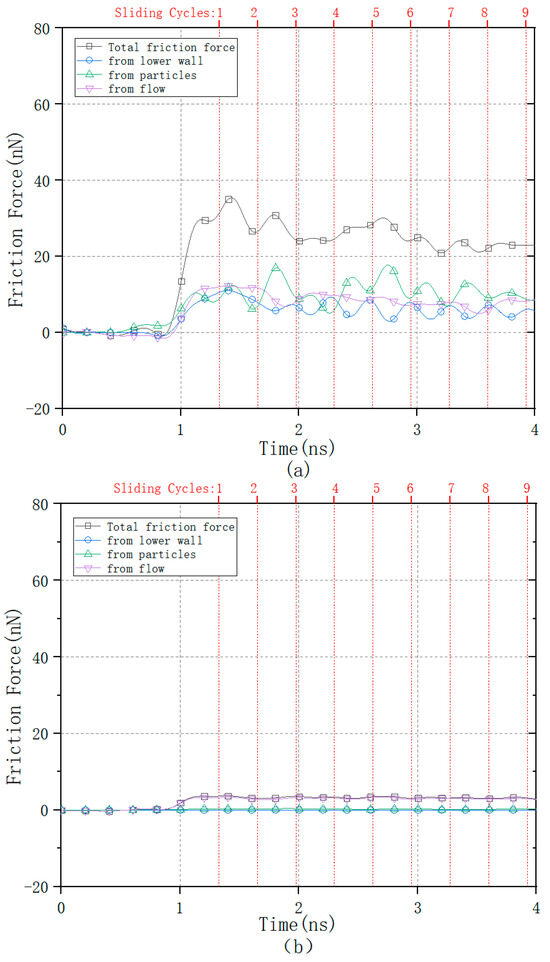

The contact state directly determines the frictional force and contact surface morphology. The calculation method of friction force from the MD simulations in this study is shown in the Supplementary Materials. From Figure 8a, it can be seen that the friction force fluctuated significantly as the sliding progressed. For the purpose of analysis, a window smoothing process with a size of 30 points was applied to the friction force and its components. For clarity, only the total friction force without smoothing was presented together. The total friction force was derived from three components: lower surface, nanoparticles, and lubricant. It can be observed that the contribution of lubricant to the friction force was smaller than the other two factors. Even in the later stages, its average contribution essentially diminished. This was possibly because the space formed by the surfaces and nanoparticles was relatively large. Simultaneously, the pits formed due to the surface roughness were filled by the fluid as sliding continued, ultimately leading to a reduction in interaction forces between the fluid and the surface. However, the friction forces induced by the nanoparticles and lower surface still remained at a certain level, although they fluctuated significantly. For comparison, the friction force of the flat surface model is also plotted in Figure 8b, which indicates that the friction force from flow was the dominant component during sliding contact.

Figure 8.

(a) Friction force of models with 250 molecules under 0.25 GPa, and (b) friction force of flat surface models with 250 molecules under 0.25 GPa.

When the number of lubricating fluid molecules was increased to 500, as illustrated in Figure 9a, the total friction forces were smaller than in the case of 250 molecules, particularly at the later stages of sliding, where the friction forces were close to 20 nN. At this increased number of fluid molecules, the friction contribution from the flow increased, but still did not play a dominant role. At the same time, the frictional force from the nanoparticles was slightly greater than that from the lower surface. This was because the surface asperities contacted their opposing counterparts at the beginning of sliding with this model setup. After several sliding cycles, the surface asperities experienced plastic deformation and their roughness became smaller; therefore, the space formed by the surfaces and nanoparticles grew smaller, which helped the lubricant to act with the sliding surfaces, i.e., the molecules filled the space and exerted a larger friction force on the sliding surfaces. Figure 9b shows that the friction force reduced significantly when the surfaces were flat, and there was only contribution from the flow. This was due to the fact that the flat surfaces were completely separated by the lubricant. In comparison with the results displayed in Figure 8b, it has also been found that friction forces decrease in flat surface models when the number of molecules is increased.

Figure 9.

(a) Friction force of models with 500 molecules under 0.25 GPa, and (b) friction force of flat surface models with 500 molecules under 0.25 GPa.

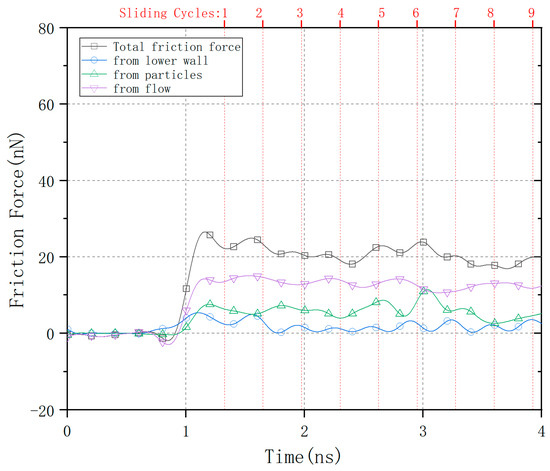

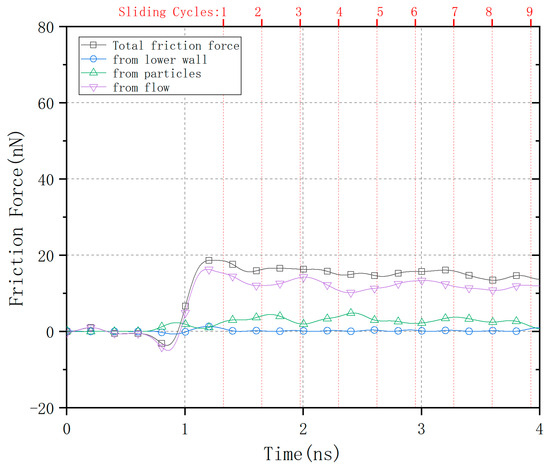

When the number of lubricating fluid molecules was further increased to 750 and 1000, as shown in Figure 10 and Figure 11, the total friction force not only experienced a small fluctuation, but its average value was also below 20 nN. It is worthwhile to note that each small fluctuation was represented a data point recorded in the simulation, and every 50th data point has been marked in the figure for a more clear visualization. This average value was lower compared to the values for 250 and 500 molecules. This result indicates that the primary frictional force came from the fluid, while the frictional force from the lower surface was nearly zero. This implies that the upper surface and lower surface were essentially separated because of the lubricating fluid. However, the nanoparticles still contacted the surfaces, but exerted a smaller friction force.

Figure 10.

Friction force of models with 750 molecules under 0.25 GPa.

Figure 11.

Friction force of models with 1000 molecules under 0.25 GPa.

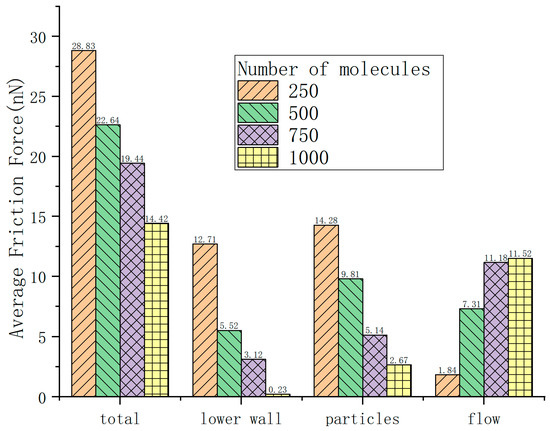

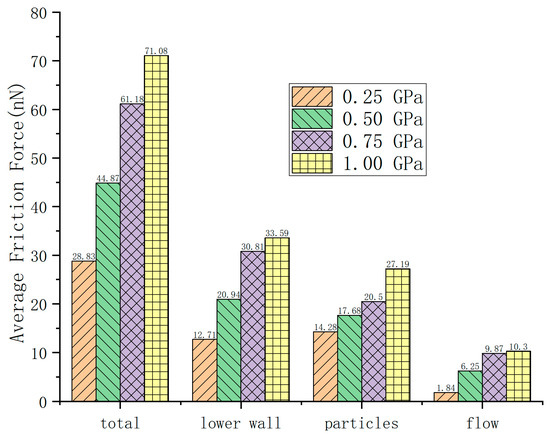

To sum up the influence of the lubricant and particles, the average friction force under 0.25 GPa within the last two cycles is plotted in Figure 12. Each of the contributions from the lower wall, the particles, and the flow are also plotted to show their influence. Generally, the total friction force decreased as the amount of lubricant increased. The same trend was also observed in the contribution from the lower wall and particles. Although the flow exerted a larger friction force when 1000 molecules existed, they actually helped to reduce the total friction force. In addition, the particles, which acted like abrasive debris, contributed an even larger friction force in the less lubricated cases (250 and 500 molecules). Figure 13 shows the average friction force for 250 molecules under different loads. Obviously, all of the friction forces increased with increasing pressure.

Figure 12.

Average friction force under 0.25 GPa within the last two sliding cycles and the contributions from the lower wall, particles, and flow.

Figure 13.

Average friction force of 250 molecules under 0.25 GPa, 0.50 GPa, 0.75 GPa, and 1.0 GPa within the last two sliding cycles, and its contribution from the lower wall, particles, and flow.

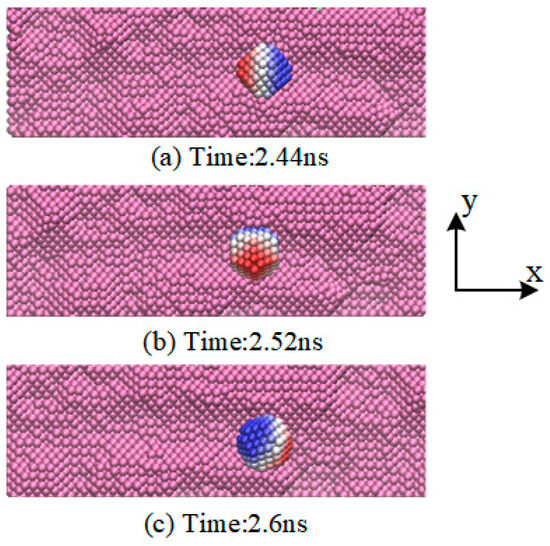

In our previous work [48], a flat BCC iron wall was used to construct the surfaces. When the surfaces were under dry contact, the nanoparticles showed a rolling effect during the sliding step, which helped to reduce the friction force. In this study, we also observed the rolling of certain particles between the upper and lower surfaces. Figure 14 shows a top view of a particle and a portion of the lower surface at different times, indicating the rolling effect of the nanoparticles during sliding contact. The color of the particle indicates its rolling posture.

Figure 14.

A top view of a particle and a portion of the lower surface at (a) 2.44 ns, (b) 2.52 ns, and (c) 2.6 ns. The color of the particle is merely for illustrating its rolling posture.

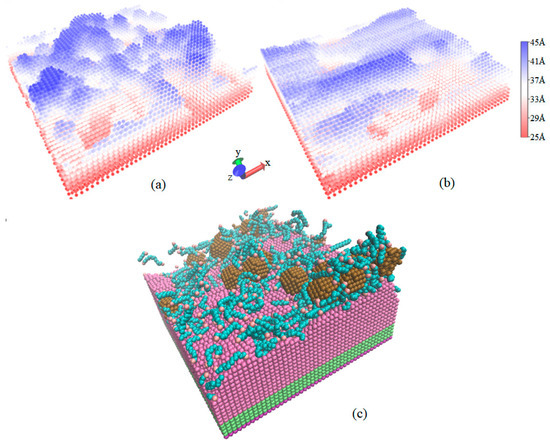

To further analyze the relationship among the three frictional factors, Figure 15 illustrates the changes in surface morphology when there were 250 lubricating fluid molecules. Only lower atoms having Z position > 25 Å have been plotted with color. It can be observed from the comparison between Figure 15a,b that as the sliding progressed, a groove was formed on the lower surface after 4.0 ns due to contact with the rigid particles and the upper surface, suggesting a cutting effect from the surface contact. In situations of insufficient lubrication, the presence of nanoparticles leads to a rapid wear of surface morphology. Figure 15c displays the lower surface with nanoparticles and fluid during sliding contact at 4.0 ns. Under a relatively low external pressure, the rolling of nanoparticles formed grooves in the sliding direction, aiding in stabilizing the sliding state. However, compared to the situations with higher external pressure, there was still considerable variation in the system height, as shown in Figure 4.

Figure 15.

Changes in lower surface morphology with 250 molecules under 0.25 GPa at (a) 1.0 ns and (b) 4.0 ns. Only the lower surface at Z > 25 Å has been plotted, and the color bar indicates the z position of atoms. (c) The snapshot of the lower surface with nanoparticles and fluid at the sliding contact time of 4.0 ns.

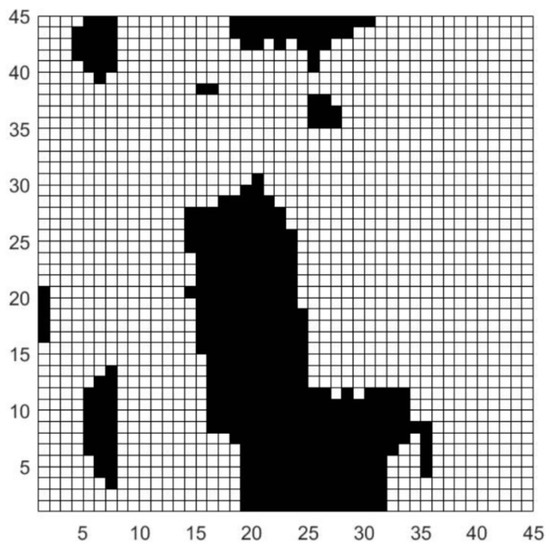

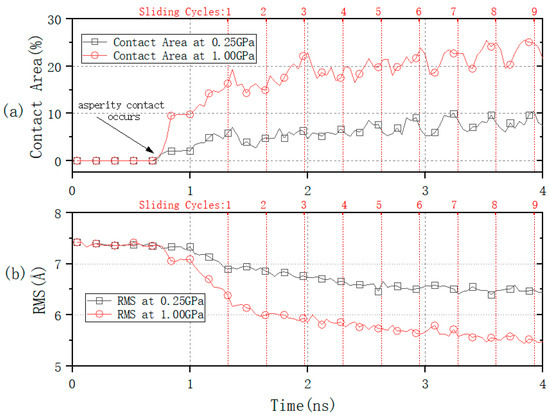

Sufficient lubricant helps to reduce the friction force. In other words, lubricant reduces the direct contact between the upper and lower surfaces. Therefore, it is crucial to monitor direct surface contact. As defined in Section 2.3, the contact area was calculated to show the contact condition. After 3 ns sliding, the contact area of the model with 250 molecules under 1.0 GPa is depicted in Figure 16, showing that up to 25% of the surface was contacted. Generally, the contact area increased with the pressure. Figure 17 shows the contact area during the simulation process. Under the less lubricated condition of 250 molecules, the surfaces were more easily contacted. There was less than 10% surface contact under 0.25 GPa after sliding. When the pressure increased to 1.0 GPa, a larger contact surface of up to 25 was observed, as shown in Figure 17a. During sliding, obvious periodic changes were also observed under 0.25 GPa and 1.0 GPa. This was due to the periodic boundary conditions applied to the x sliding direction. Similar changes can also be seen in system height in Figure 4. However, the contact area diminished to close to zero when there were 1000 lubricant molecules, as shown in Figure 18a.

Figure 16.

Contact area with 250 molecules at 1.0 GPa at 4 ns. Black squares indicate that surface atoms at these areas were contacted.

Figure 17.

Evolutions of (a) contact area and (b) RMS during the simulation process with 250 molecules at 0.25 and 1.0 GPa.

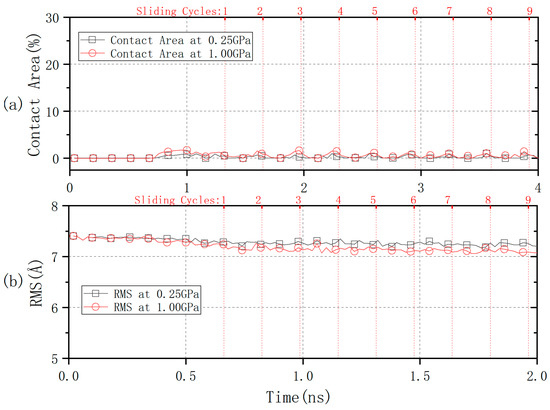

Figure 18.

Evolutions of (a) contact area and (b) RMS during the simulation process with 1000 molecules at 0.25 and 1.0 GPa.

The changes in surface morphology during sliding definitely altered the surface roughness. Figure 17b and Figure 18b show the change in RMS associated with the sliding process. Generally, the surface roughness RMS decreased with sliding, and a larger load resulted in a bigger change. After nine sliding cycles, it can be observed that the surface roughness remained at a relatively stable value. This indicates that a sliding time of 3 ns was sufficient for the currently simulated sliding contact system. Under the less lubricated condition of 250 molecules, RMS under 0.25 GPa and 1.0 GPa dropped to 6.5 Å and 5.5 Å, respectively. It should be pointed out that the initial RMS in these figures was about 7.5 Å. This was smaller than 8 Å due to the surface relaxation, i.e., we cut the initial surface with the ideal curve, but the EAM interaction among surface atoms could have changed the surface morphology, resulting in a smaller initial surface roughness. When the number of molecules reached 1000, the surface roughness reduced a little, as shown in Figure 18b, indicating that the lubricant supported the normal load, and there was no surface contact.

4. Conclusions

In this study, a molecular dynamics model with 3D rough surfaces, hexadecane, and nanoparticles was created to reveal the effects of fluid and nanoparticles on surface contacts and frictional behavior in the system of boundary friction. Simulations revealed the combined effect of fluid and nanoparticles during sliding contacts. It has been found that when the number of fluid molecules is insufficient, the friction force comes from the combined contributions of fluid, nanoparticles, and surface contact. This means that a smaller amount of fluid is unable to separate the contact surfaces, thus leading to surface plastic deformation from the rolling of nanoparticles and asperity contact. However, with a large increase in the number of molecules, the surfaces are fully separated by the lubricant fluid, and a smaller total friction force is observed. These findings provide a fundamental understanding of the features and mechanisms of boundary friction systems, and also a hint for the future design of powerful lubricants, considering the significance of the nanoparticle concentration.

The current model is for rigid particles. In future research, consideration of the deformation of nanoparticles during MD simulation of sliding contacts is recommended, which will contribute to a more comprehensive understanding of the effects of lubricants, surface roughness, and particle additions at the nanoscale.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/lubricants12050160/s1, Figure S1: A schematic view of original RMD process within first 8 iterations. The dark areas mean the surface point from previous iteration while the red areas present the surface profile in the current iteration.; Figure S2: The simulation domain is divided into 16 (4 × 4) sub-squares. In each sub-square, the RMD is carried out.

Author Contributions

Conceptualization, X.Z. and L.S.; software, X.Z., L.S. and G.D.; formal analysis, X.Z. and L.S.; investigation, X.Z., L.S. and G.D.; writing—original draft preparation, X.Z. and G.D.; writing—review and editing, L.S.; project administration, L.S. All authors have read and agreed to the published version of the manuscript.

Funding

L.S. is grateful to the Australian Research Council for awarding her the Discovery Early Career Researcher Award (DECRA) fellowship (DE180100124). G.D. is grateful to the University of Queensland (UQ) for awarding him the UQ Research Stimulus Allocation Fellowship. Simulations were conducted using the computing facilities from NCI National Facility of Australia.

Data Availability Statement

The data that supports the findings of this study are available in the Supplementary Material of this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Deng, G.; Zhu, H.; Tieu, A.K. Advances in Friction, Lubrication, Wear and Oxidation in Metals Manufacturing. Metals 2023, 13, 505. [Google Scholar] [CrossRef]

- Sun, J.; Mao, X.; Yang, Z.; Zhou, X.; Zhao, X. Effect of gradient microstructure on wear behavior of carbon steel. Mater. Res. Express 2019, 6, 126566. [Google Scholar] [CrossRef]

- Chen, X.; Han, Z. A low-to-high friction transition in gradient nano-grained Cu and Cu-Ag alloys. Friction 2021, 9, 1558–1567. [Google Scholar] [CrossRef]

- Su, L.; Deng, G.; Luzin, V.; Wang, H.; Wang, Z.; Yu, H.; Li, H.; Tieu, A.K. Effect of cryogenic temperature equal channel angular pressing on microstructure, bulk texture and tensile properties of AA1050. Mater. Sci. Eng. A 2020, 780, 139190. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Niu, H.Z.; Zhang, L.C.; Bai, X.F.; Zhang, X.M.; Zhang, P.X. Grain coarsening behavior in a nanocrystalline copper subjected to sliding friction. Mater. Lett. 2014, 123, 261–264. [Google Scholar] [CrossRef]

- Deng, G.; Chong, Y.; Su, L.; Zhan, L.; Wei, P.; Zhao, X.; Zhang, L.; Tian, Y.; Zhu, H.; Tsuji, N. Mechanisms of remarkable wear reduction and evolutions of subsurface microstructure and nano-mechanical properties during sliding of nano-grained Ti6Al4V alloy: A comparative study. Tribol. Int. 2022, 169, 107464. [Google Scholar] [CrossRef]

- Li, G.; Jiang, J.; Ma, H.; Zheng, R.; Gao, S.; Zhao, S.; Ma, C.; Ameyama, K.; Ding, B.; Li, X. Superior strength-ductility synergy in three-dimensional heterogeneous-nanostructured metals. Acta Mater. 2023, 256, 119143. [Google Scholar] [CrossRef]

- Zhou, G.; Ma, H.; Zhang, Z.; Sun, J.; Wang, X.; Zeng, P.; Zheng, R.; Chen, X.; Ameyama, K. Fatigue crack growth behavior in a harmonic structure designed austenitic stainless steel. Mater. Sci. Eng. A 2019, 758, 121–129. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, G.; Li, W.; Su, L.; Liu, X.; Ma, T.; Gao, L. Impacts of chemical short-range orders on nanotribological properties of CrCoNi medium-entropy alloy at room and cryogenic temperatures. Tribol. Int. 2024, 191, 109191. [Google Scholar] [CrossRef]

- Zhang, J.; Li, W.; Qin, R.; Chen, P.; Liu, Y.; Liu, X.; Gao, L. An atomic insight into the stoichiometry effect on the tribological behaviors of CrCoNi medium-entropy alloy. Appl. Surf. Sci. 2022, 593, 153391. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, D.; An, X.; Zhang, Y.; Zhou, Z.; Lu, S.; Munroe, P.; Zhang, S.; Liao, X.; Zhu, T.; et al. Unraveling dual phase transformations in a CrCoNi medium-entropy alloy. Acta Mater. 2021, 215, 117112. [Google Scholar] [CrossRef]

- Wu, J.; Chen, Y.; Zhu, H. A review on the tribological performances of high-entropy alloys. Adv. Eng. Mater. 2022, 24, 2101548. [Google Scholar] [CrossRef]

- Lei, G.; Zhang, Y.; Gao, H.T.; Cui, X.H.; Yu, H.L. Nano-tribological behavior of a CuCoCrFeNi high-entropy alloy at cryogenic temperature: A molecular dynamics study. J. Appl. Phys. 2023, 133, 155901. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Liu, X.B.; Liu, Y.F.; Zhang, S.Y.; Meng, Y.; Zhou, H.B.; Zhang, S.H. Effect of Cu-doping on tribological properties of laser-cladded FeCoCrNiCux high-entropy alloy coatings. Tribol. Int. 2023, 188, 108868. [Google Scholar]

- Sun, Q.; Tan, H.; Zhu, S.; Zhu, Z.; Wang, L.; Cheng, J.; Yang, J. Sing-phase (Hf-Mo-Nb-Ta-Ti)C high-entropy ceramic: A potential high temperature anti-wear material. Tribol. Int. 2021, 157, 106883. [Google Scholar] [CrossRef]

- Shi, P.Y.; Yu, Y.; Xiong, N.N.; Liu, M.Z.; Qiao, Z.H.; Yi, G.W.; Yao, Q.Q.; Zhao, G.P.; Xie, E.Q.; Wang, Q.H. Microstructure and tribological behavior of a novel atmospheric plasma sprayed AlCoCrFeNi high entropy alloy matrix self-lubricating composite coatings. Tribol. Int. 2020, 151, 106470. [Google Scholar] [CrossRef]

- Zhang, A.; Han, J.; Su, B.; Meng, J. A novel CoCrFeNi high entropy alloy matrix self-lubricating composite. J. Alloys Compd. 2017, 725, 700–710. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, J.; Li, J.S.; Kou, H.C.; Liu, W.M. Tribological behavior of AlCoCrFeNi(Ti0.5) high entropy alloys under oil and MACs lubrication. J. Mater. Sci. Technol. 2016, 32, 470. [Google Scholar] [CrossRef]

- Liu, Y.; Tao, C.; Liu, X.; Zhu, Y.; Wang, G.; Meng, Y.; Liang, J.; Xie, J. Research progress on tribological properties of high-entropy alloy coating. Surf. Technol. 2021, 50, 156–169. [Google Scholar]

- Zhang, A.; Han, J.; Su, B.; Meng, J. A promising new high temperature self-lubricating materials: CoCrFeNiS0.5 high entropy alloy. Mater. Sci. Eng. A 2018, 731, 36–43. [Google Scholar] [CrossRef]

- Tran, B.H.; Tieu, A.; Wan, S.; Zhu, H.; Cui, S.; Wang, L. Understanding the tribological impacts of alkali element on lubrication of binary borate melt. RSC Adv. 2018, 8, 28847–28860. [Google Scholar] [CrossRef] [PubMed]

- Ta, T.D.; Tieu, A.K.; Tran, B.H. Molecular dynamics simulations of nanolubricant films of alkali glasses under sliding asperity contacts. ACS Appl. Nano Mater. 2021, 10, 11210–11220. [Google Scholar] [CrossRef]

- Rodrigues, A.C.P.; Yonamine, T.; Albertin, E.; Sinatora, A.; Azevedo, C.R.F. Effect of Cu Particles as an Interfacial Media Addition on the Friction Coefficient and Interface Microstructure during (Steel/Steel) Pin on Disc Tribotest. Wear 2015, 330–331, 70–78. [Google Scholar] [CrossRef]

- Radice, S.; Mischler, S. Effect of Electrochemical and Mechanical Parameters on the Lubrication Behaviour of Al2O3 Nanoparticles in Aqueous Suspensions. Wear 2006, 261, 1032–1041. [Google Scholar] [CrossRef]

- Xie, H.; Jiang, B.; He, J.; Xia, X.; Pan, F. Lubrication Performance of MoS2 and SiO2 Nanoparticles as Lubricant Additives in Magnesium Alloy-Steel Contacts. Tribol. Int. 2016, 93, 63–70. [Google Scholar] [CrossRef]

- Sun, W.; Zhou, W.; Liu, J.; Fu, X.; Chen, G.; Yao, S. The Size Effect of SiO2 Particles on Friction Mechanisms of a Composite Friction Material. Tribol. Lett. 2018, 66, 35. [Google Scholar] [CrossRef]

- Rabaso, P.; Ville, F.; Dassenoy, F.; Diaby, M.; Afanasiev, P.; Cavoret, J.; Vacher, B.; Le Mogne, T. Boundary Lubrication: Influence of the Size and Structure of Inorganic Fullerene-like MoS2 Nanoparticles on Friction and Wear Reduction. Wear 2014, 320, 161–178. [Google Scholar] [CrossRef]

- Cizaire, L.; Vacher, B.; Le Mogne, T.; Martin, J.M.; Rapoport, L.; Margolin, A.; Tenne, R. Mechanisms of Ultra-Low Friction by Hollow Inorganic Fullerene-like MoS2 Nanoparticles. Surf. Coat. Technol. 2002, 160, 282–287. [Google Scholar] [CrossRef]

- Lahouij, I.; Dassenoy, F.; Vacher, B.; Martin, J.M. Real Time TEM Imaging of Compression and Shear of Single Fullerene-Like MoS2 Nanoparticle. Tribol. Lett. 2011, 45, 131–141. [Google Scholar] [CrossRef]

- Hu, C.; Bai, M.; Lv, J.; Kou, Z.; Li, X. Molecular Dynamics Simulation on the Tribology Properties of Two Hard Nanoparticles (Diamond and Silicon Dioxide) Confined by Two Iron Blocks. Tribol. Int. 2015, 90, 297–305. [Google Scholar] [CrossRef]

- Hu, C.; Bai, M.; Lv, J.; Wang, P.; Li, X. Molecular Dynamics Simulation on the Friction Properties of Nanofluids Confined by Idealized Surfaces. Tribol. Int. 2014, 78, 152–159. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of Nanoparticles in Oil Lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Moshkovith, A.; Perfiliev, V.; Lapsker, I.; Fleischer, N.; Tenne, R.; Rapoport, L. Friction of Fullerene-like WS2 Nanoparticles: Effect of Agglomeration. Tribol. Lett. 2006, 24, 225–228. [Google Scholar] [CrossRef]

- Tevet, O.; Von-Huth, P.; Popovitz-Biro, R.; Rosentsveig, R.; Wagner, H.D.; Tenne, R. Friction Mechanism of Individual Multilayered Nanoparticles. Proc. Natl. Acad. Sci. USA 2011, 108, 19901–19906. [Google Scholar] [CrossRef]

- Srivastava, I.; Kotia, A.; Ghosh, S.K.; Ali, M.K.A. Recent Advances of Molecular Dynamics Simulations in Nanotribology. J. Mol. Liq. 2021, 335, 116154. [Google Scholar] [CrossRef]

- Dong, S.; Wang, W.; Gao, Y.; Deng, G. Tribological properties of different-sized black phosphorus nanosheets as water-based lubrication additives for steel/titanium alloy wear. Metals 2022, 12, 288. [Google Scholar] [CrossRef]

- Zhang, J.; Su, L.; Wang, Z. Concurrent Multiscale Simulations of Rough Lubricated Contact of Aluminum Single Crystal. Metals 2020, 10, 965. [Google Scholar] [CrossRef]

- Stephan, S.; Lautenschlaeger, M.P.; Alhafez, I.A.; Horsch, M.T.; Urbassek, H.M.; Hasse, H. Molecular Dynamics Simulation Study of Mechanical Effects of Lubrication on a Nanoscale Contact Process. Tribol. Lett. 2018, 66, 126. [Google Scholar] [CrossRef]

- Stephan, S.; Schmitt, S.; Hasse, H. Molecular dynamics simulation of the Stribeck curve: Boundary lubrication, mixed lubrication, and hydrodynamic lubrication on the atomistic level. Friction 2023, 11, 2342–2366. [Google Scholar] [CrossRef]

- Zhang, C. Research on thin film lubrication: State of the art. Tribol. Int. 2005, 38, 443–448. [Google Scholar] [CrossRef]

- Jabbarzadeh, A.; Harrowell, P.; Tanner, R.I. Low Friction Lubrication between Amorphous Walls: Unraveling the Contributions of Surface Roughness and in-Plane Disorder. J. Chem. Phys. 2006, 125, 034703. [Google Scholar] [CrossRef] [PubMed]

- Jabbarzadeh, A.; Atkinson, J.D.; Tanner, R.I. Effect of the Wall Roughness on Slip and Rheological Properties of Hexadecane in Molecular Dynamics Simulation of Couette Shear Flow between Two Sinusoidal Walls. Phys. Rev. E 2000, 61, 690–699. [Google Scholar] [CrossRef] [PubMed]

- Spijker, P.; Anciaux, G.; Molinari, J.-F. Dry Sliding Contact Between Rough Surfaces at the Atomistic Scale. Tribol. Lett. 2011, 44, 279–285. [Google Scholar] [CrossRef]

- Zheng, X.; Zhu, H.; Tieu, A.K.; Kosasih, B. Roughness and Lubricant Effect on 3D Atomic Asperity Contact. Tribol. Lett. 2013, 53, 215–223. [Google Scholar] [CrossRef]

- Mackowiak, S.; Heyes, D.M.; Dini, D.; Branka, A.C. Non-equilibrium phase behavior and friction of confined molecular films under shear: A non-equilibrium molecular dynamics study. J. Chem. Phys. 2016, 145, 164704. [Google Scholar] [CrossRef]

- Lv, J.; Bai, M.; Cui, W.; Li, X. The Molecular Dynamic Simulation on Impact and Friction Characters of Nanofluids with Many Nanoparticles System. Nanoscale Res. Lett. 2011, 6, 200. [Google Scholar] [CrossRef] [PubMed]

- Ji, C.; Sun, S.; Wang, B.; Lin, B. Molecular Dynamic Simulations of the Roles of Nanoparticles in Sliding Friction Process. Chem. Phys. Lett. 2019, 728, 44–49. [Google Scholar] [CrossRef]

- Zheng, X.; Su, L.; Deng, G.; Zhang, J.; Zhu, H.; Tieu, A.K. Study on lubrication characteristics of C4-Alkane and nanoparticle during boundary friction by molecular dynamics simulation. Metals 2021, 11, 1464. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Evans, D.J.; Holian, B.L. The Nose–Hoover Thermostat. J. Chem. Phys. 1985, 83, 4069–4074. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Albohr, O.; Tartaglino, U.; Volokitin, A.I.; Tosatti, E. On the Nature of Surface Roughness with Application to Contact Mechanics, Sealing, Rubber Friction and Adhesion. J. Phys. Condens. Matter 2004, 17, R1. [Google Scholar] [CrossRef] [PubMed]

- Mendelev, M.I.; Han, S.; Srolovitz, D.J.; Ackland, G.J.; Sun, D.Y.; Asta, M. Development of New Interatomic Potentials Appropriate for Crystalline and Liquid Iron. Phil. Mag. 2003, 83, 3977–3994. [Google Scholar] [CrossRef]

- Savio, D.; Fillot, N.; Vergne, P.; Zaccheddu, M. A Model for Wall Slip Prediction of Confined N-Alkanes: Effect of Wall-Fluid Interaction Versus Fluid Resistance. Tribol. Lett. 2012, 46, 11–22. [Google Scholar] [CrossRef]

- Martin, M.G.; Siepmann, J.I. Transferable Potentials for Phase Equilibria. 1. United-Atom Description of n-Alkanes. J. Phys. Chem. B 1998, 102, 2569–2577. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).