High-Temperature and High-Pressure Tribological Properties of Siliconized Graphite for Water-Lubricated Thrust Bearing Application in Main Coolant Pump

Abstract

1. Introduction

2. Experimental

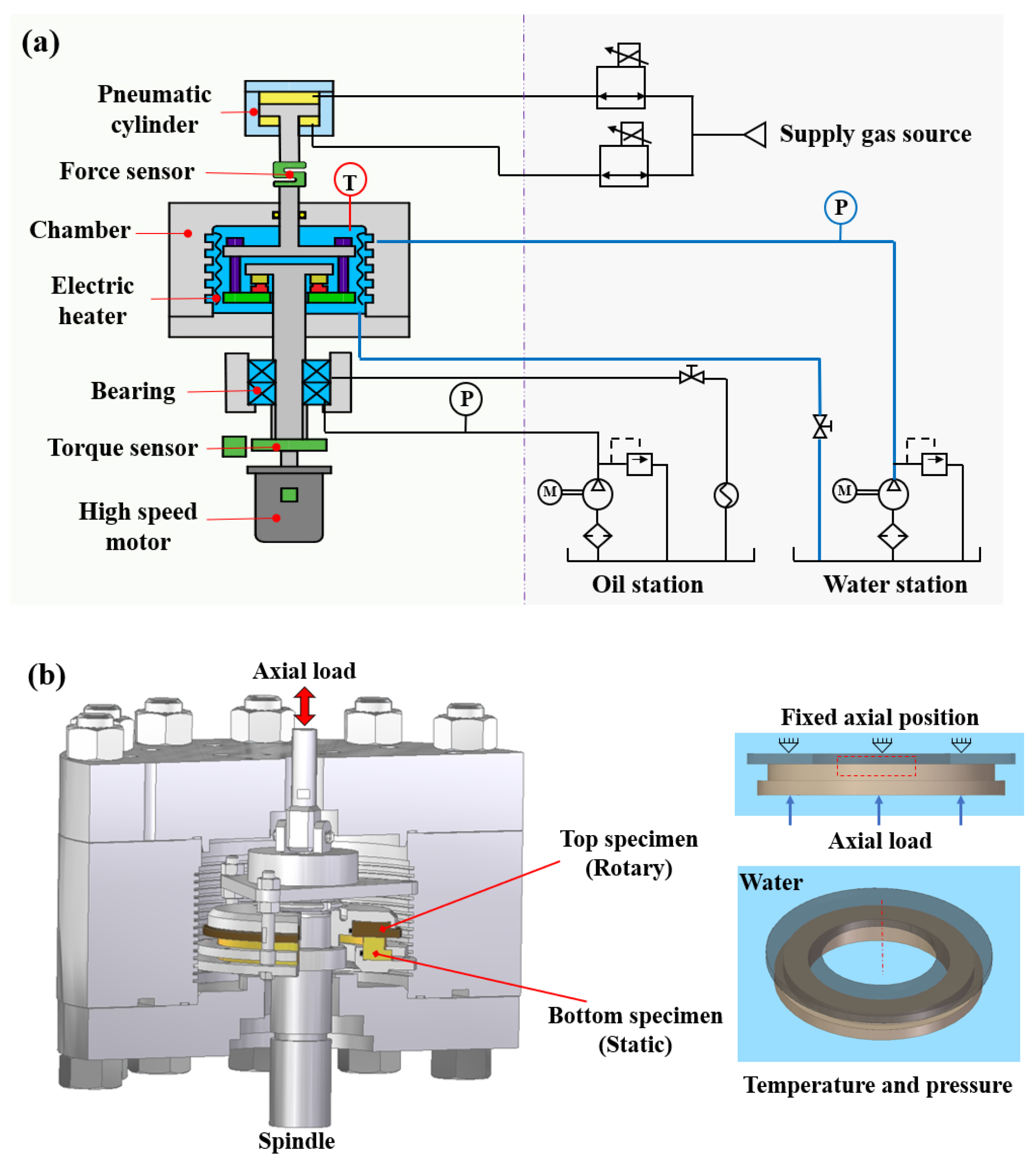

2.1. Tribological Experiment in High-Temperature and High-Pressure Water

2.2. Characterization of Worn Siliconized Graphite Rings

3. Results

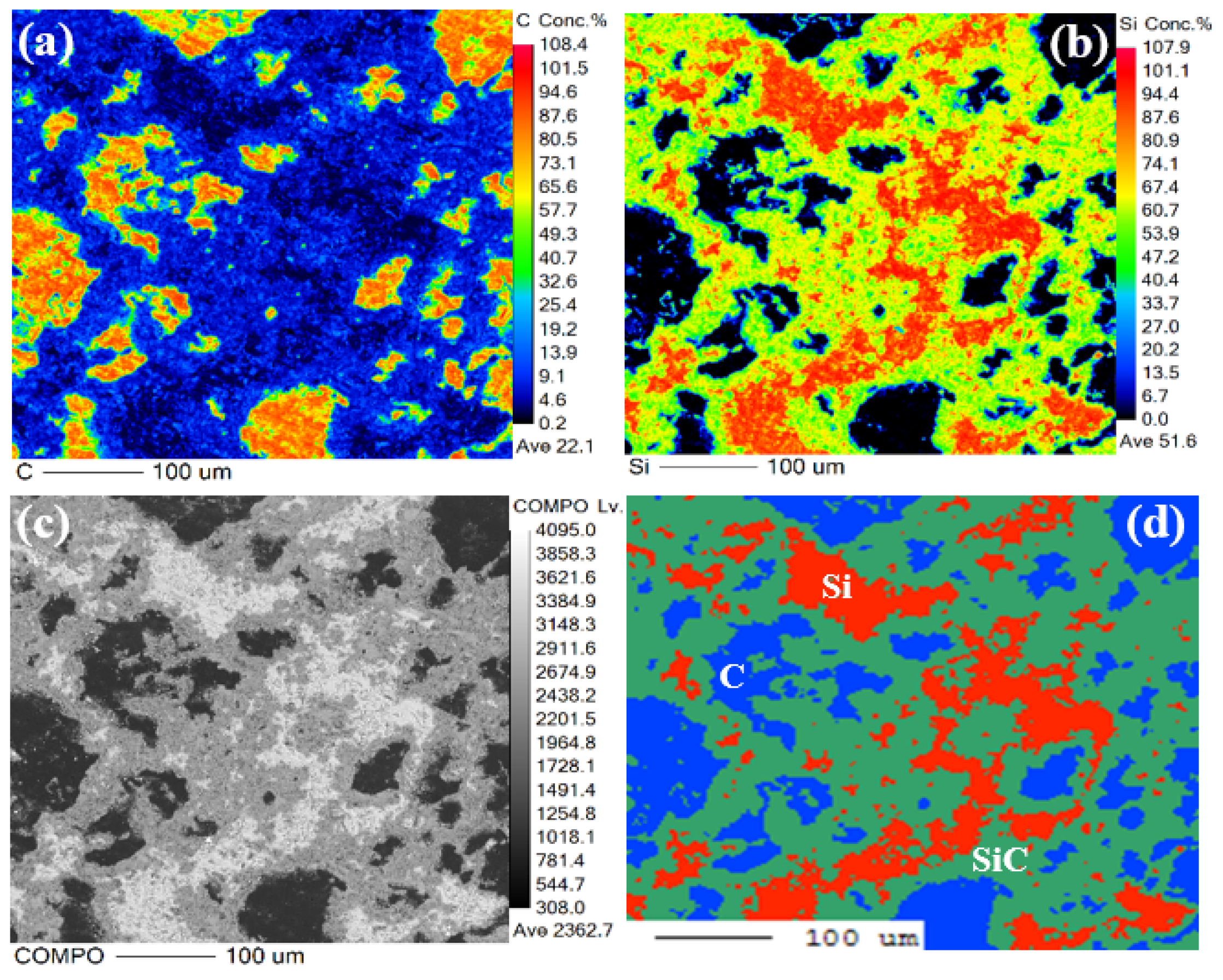

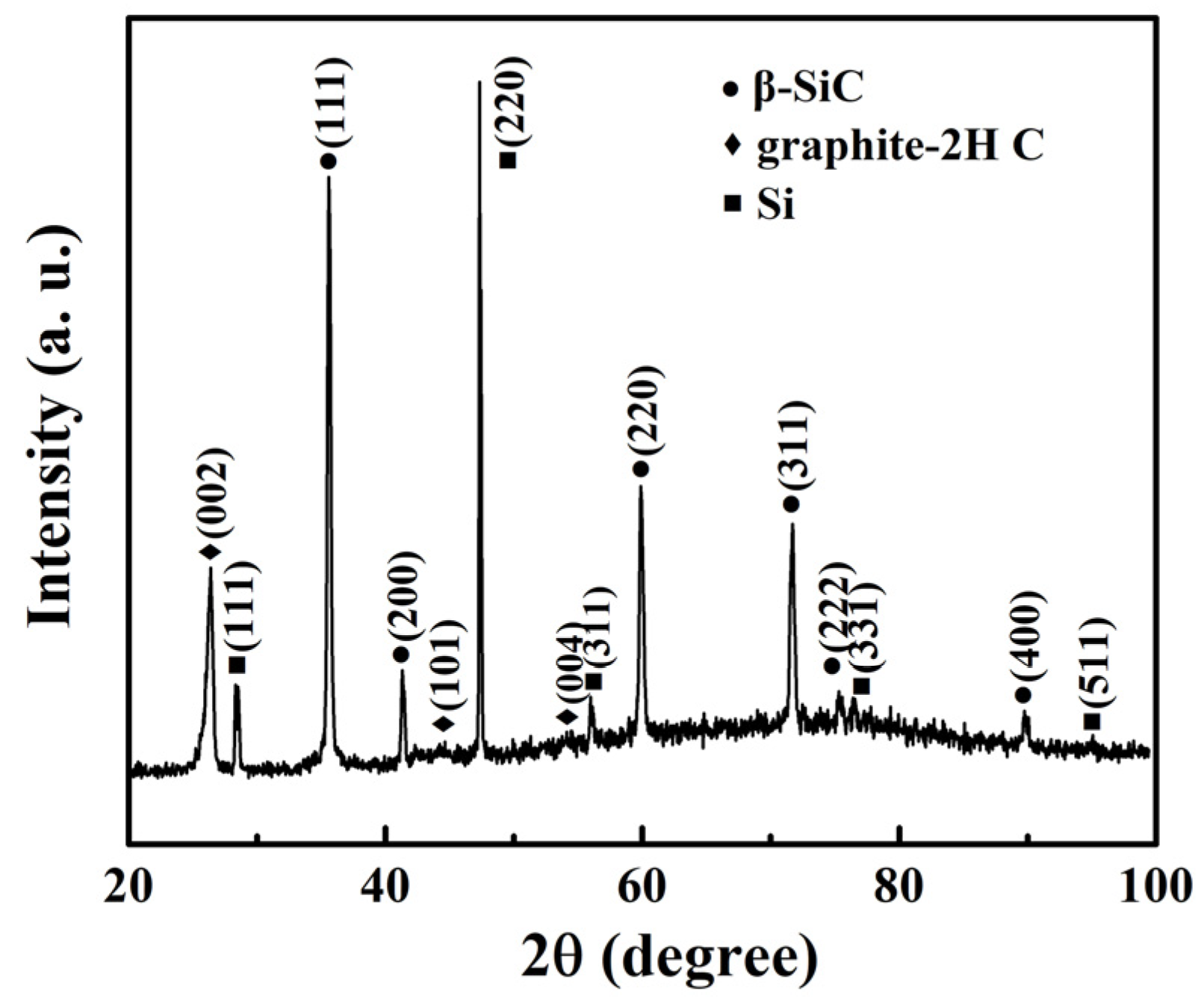

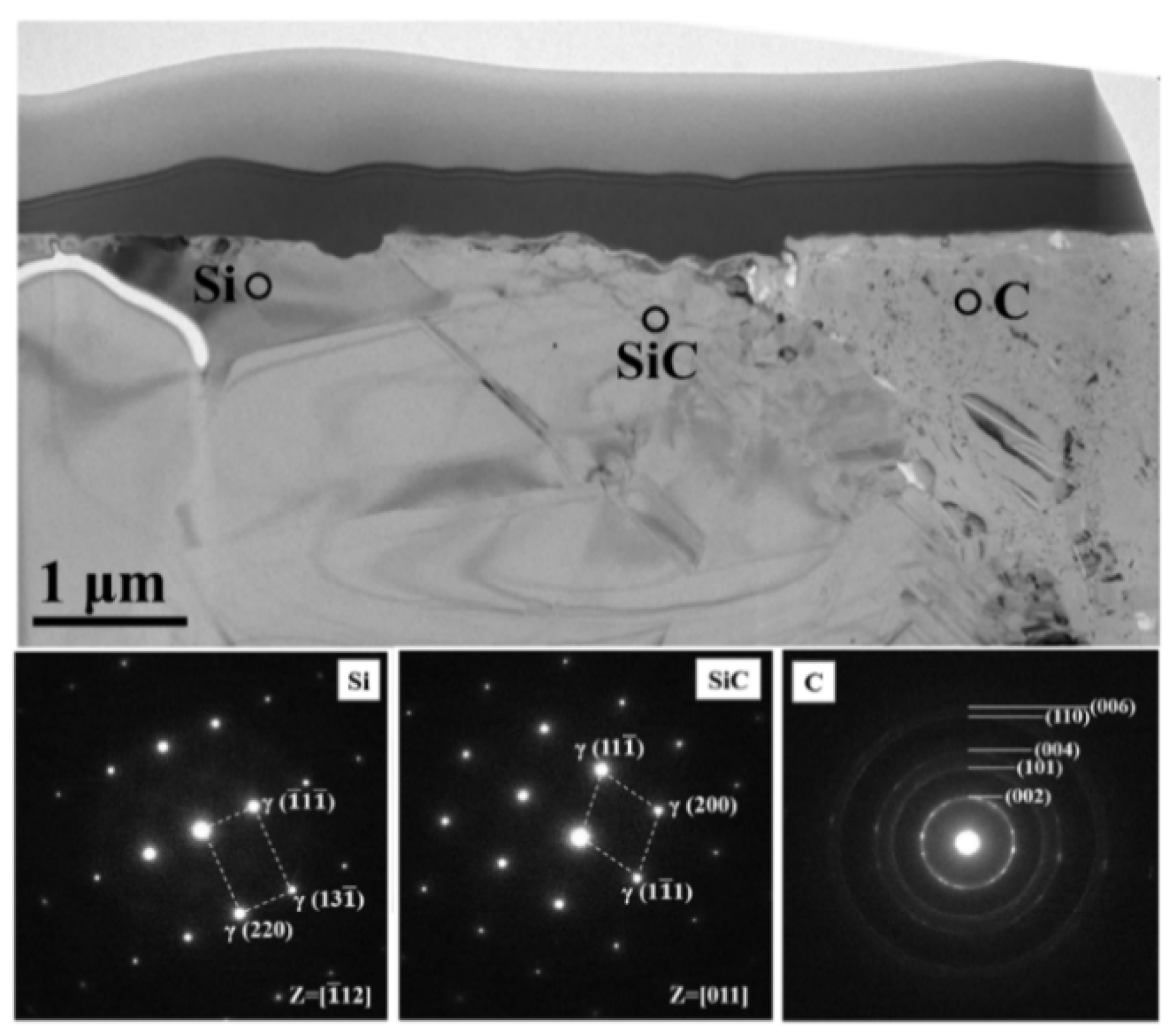

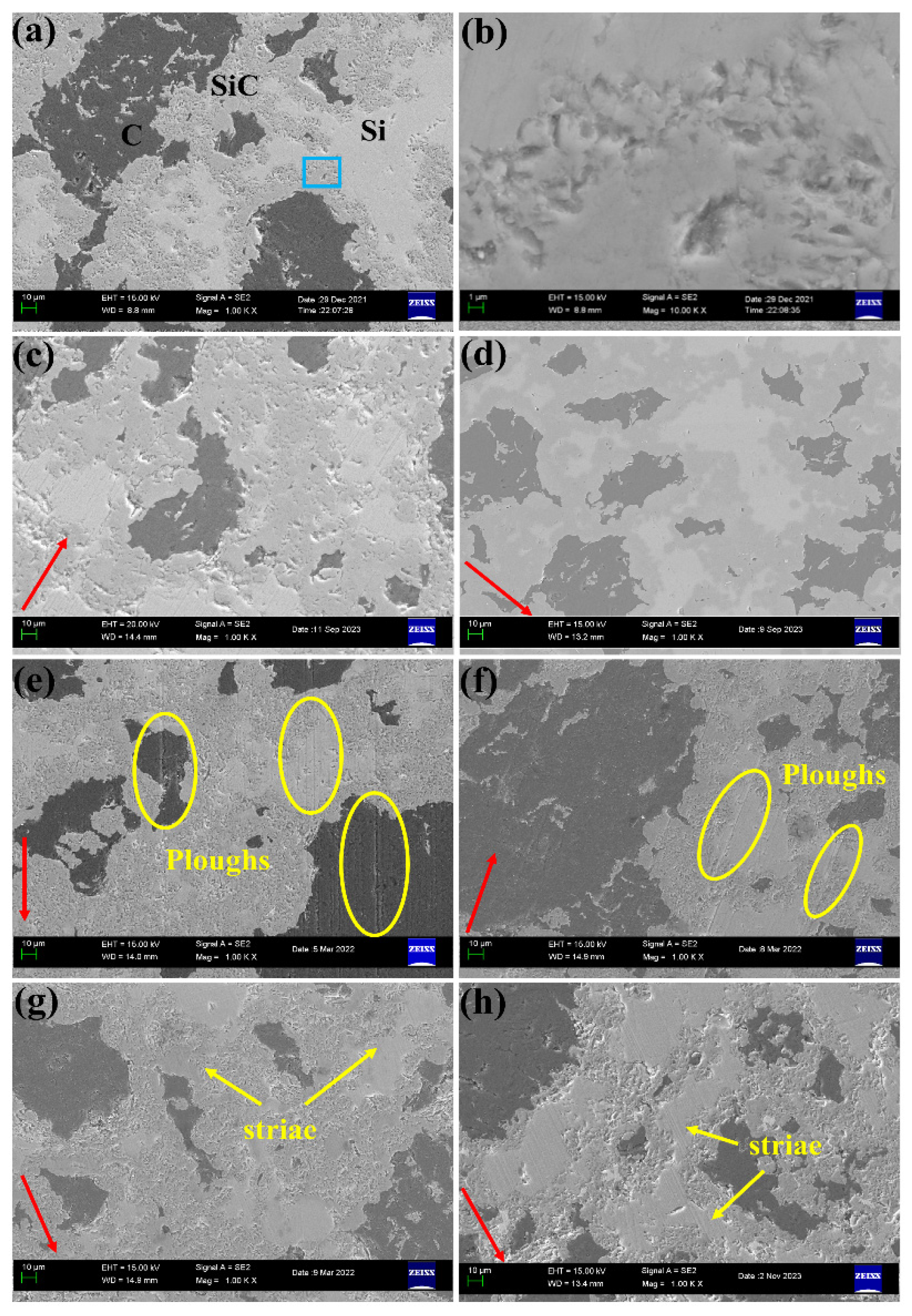

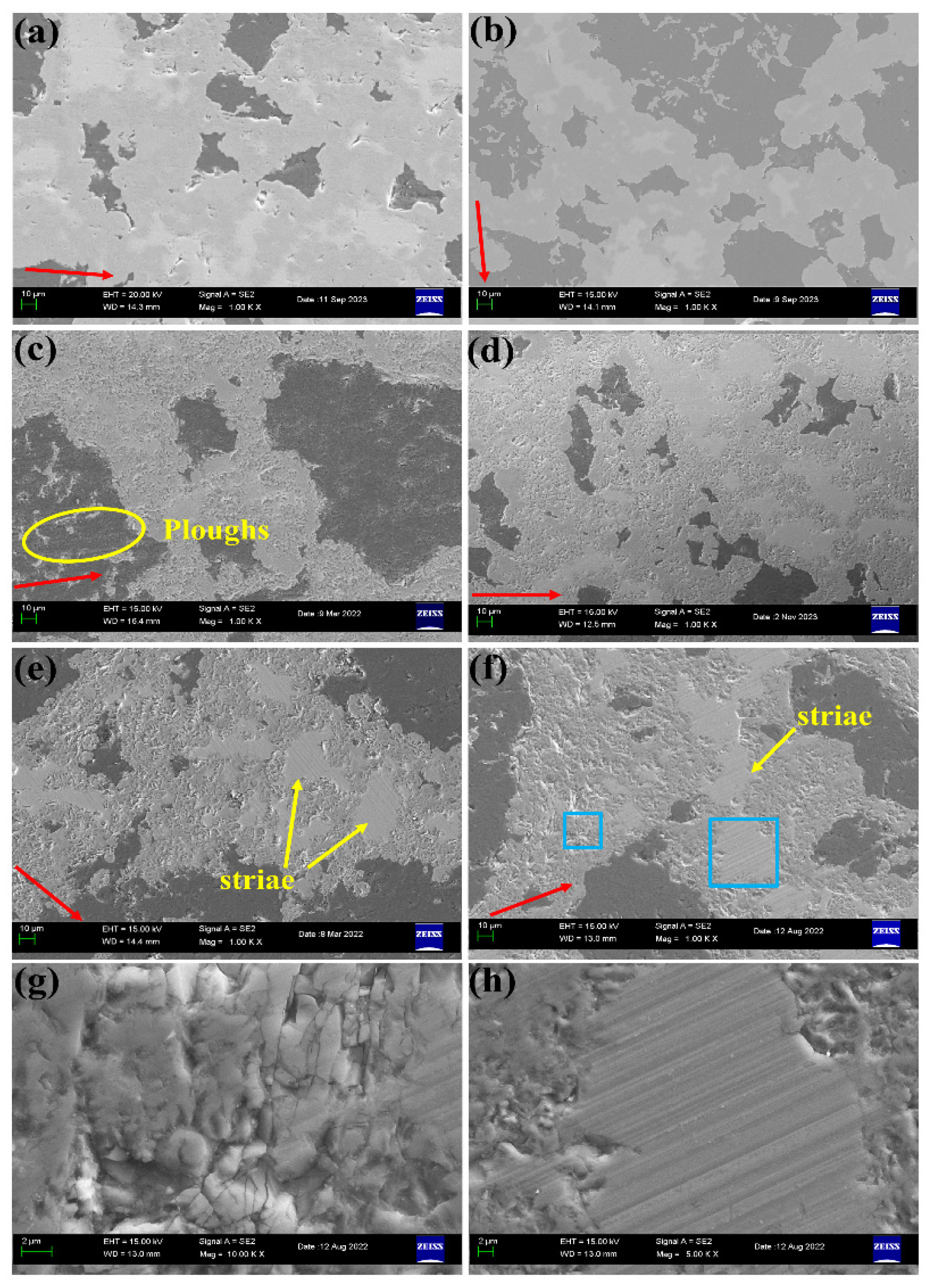

3.1. Microstructure of Siliconized Graphite

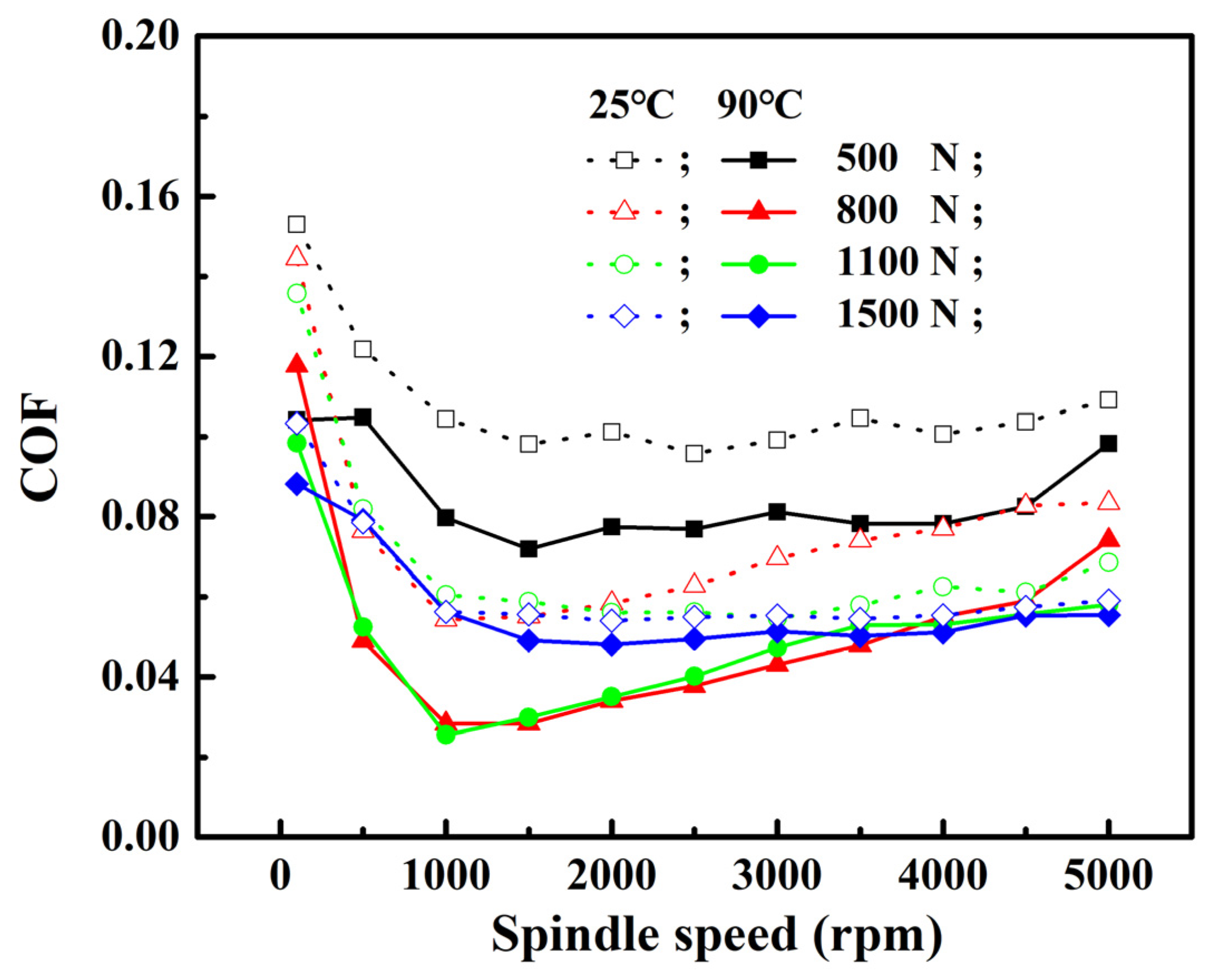

3.2. Stribeck Curve Measurements

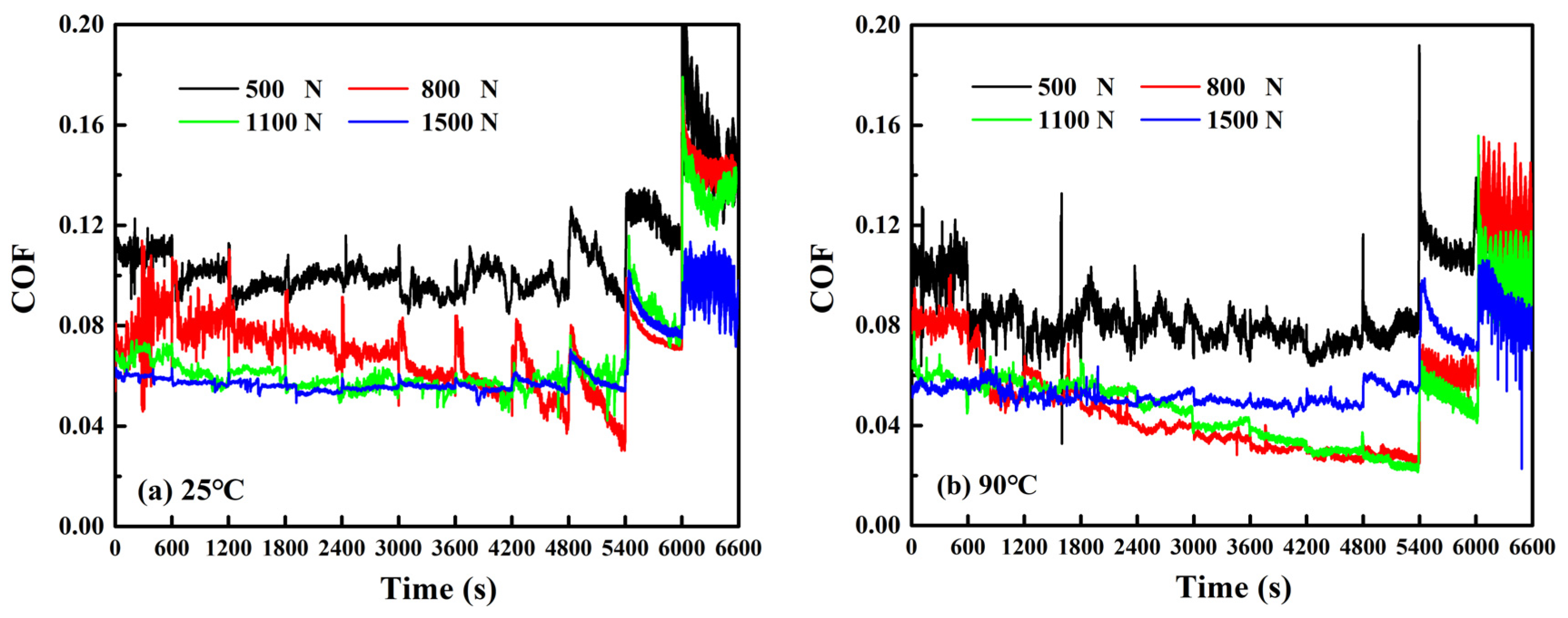

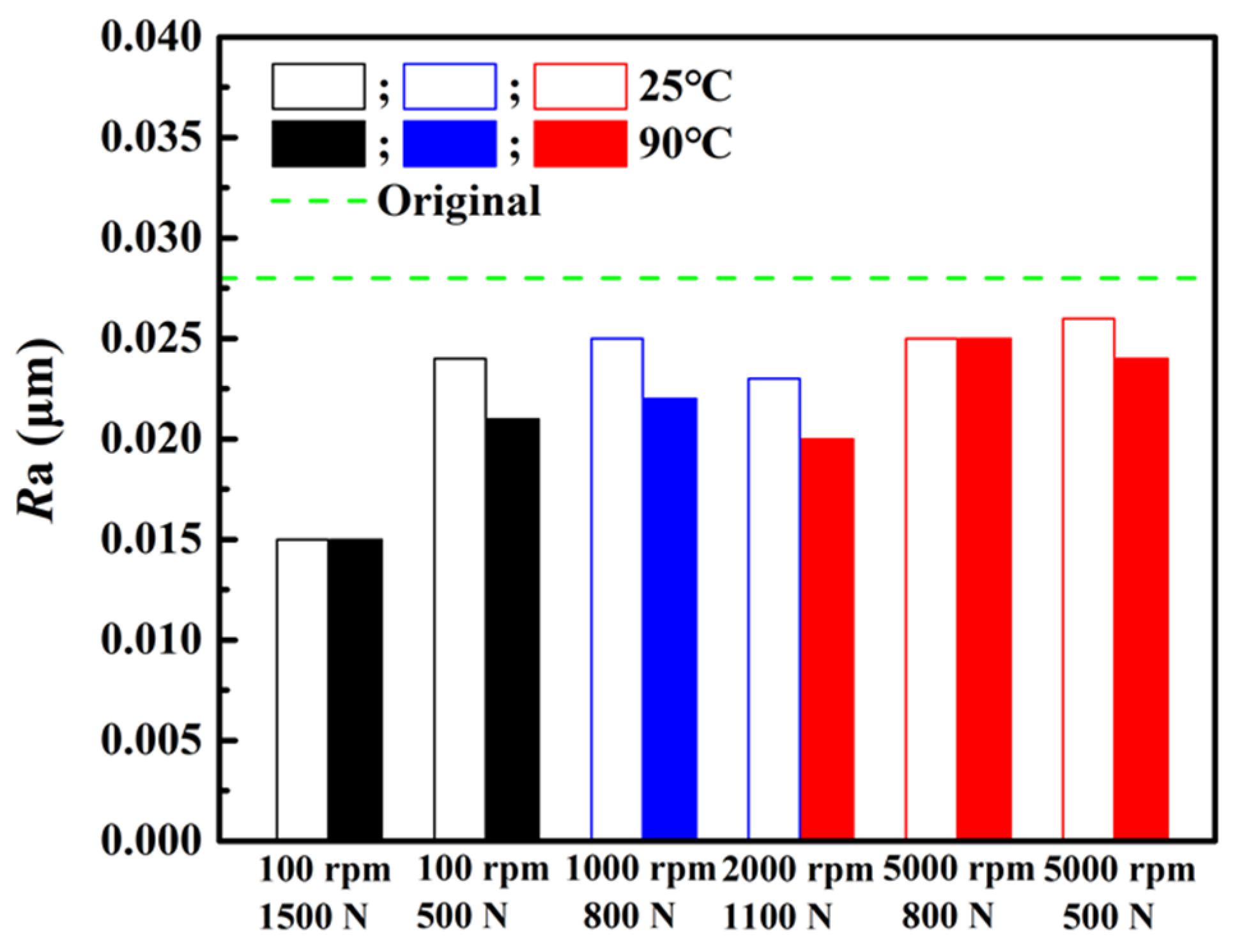

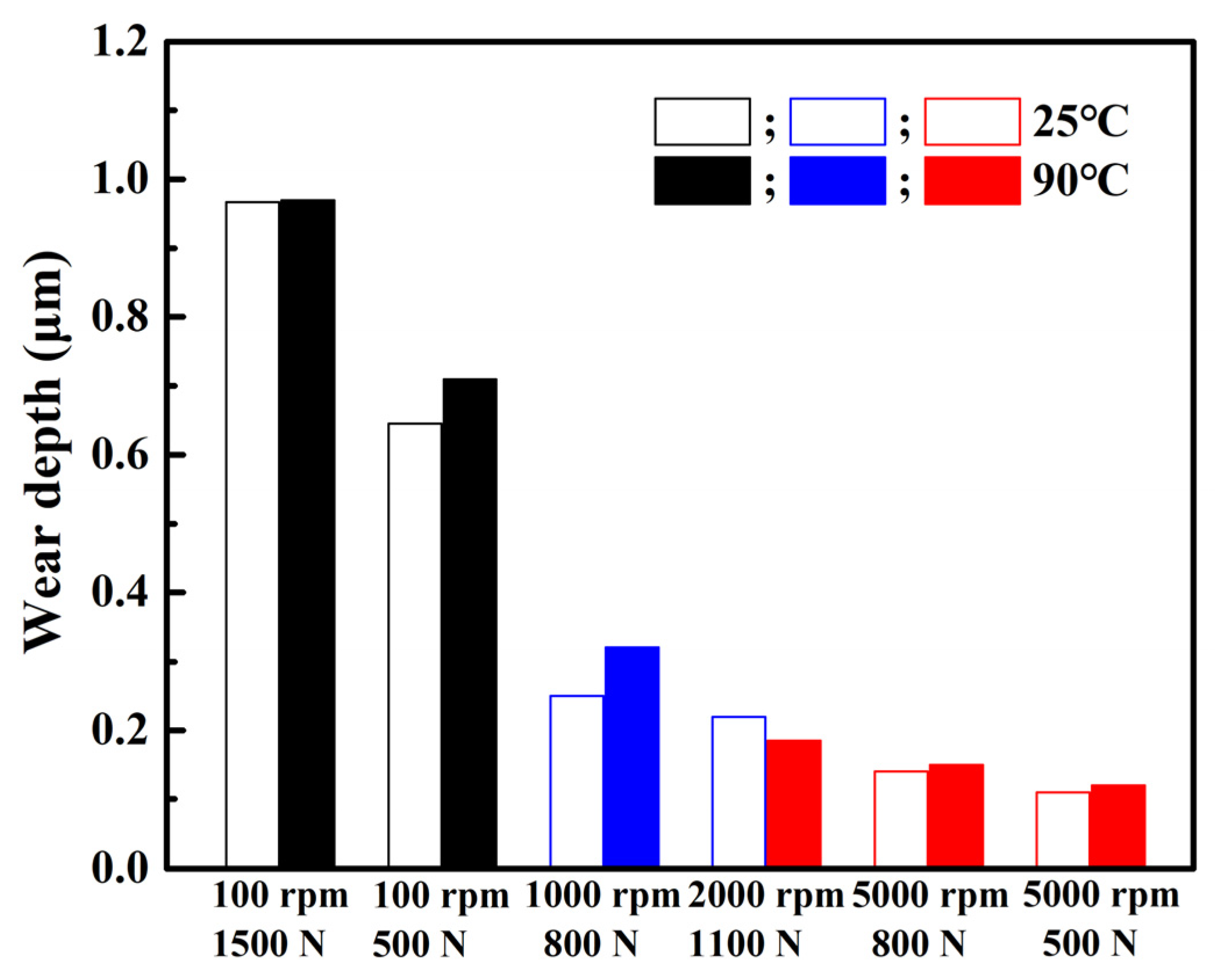

3.3. Wear Tests in 25 °C (1 MPa) and 90 °C (5 MPa) Water Environments

4. Discussion

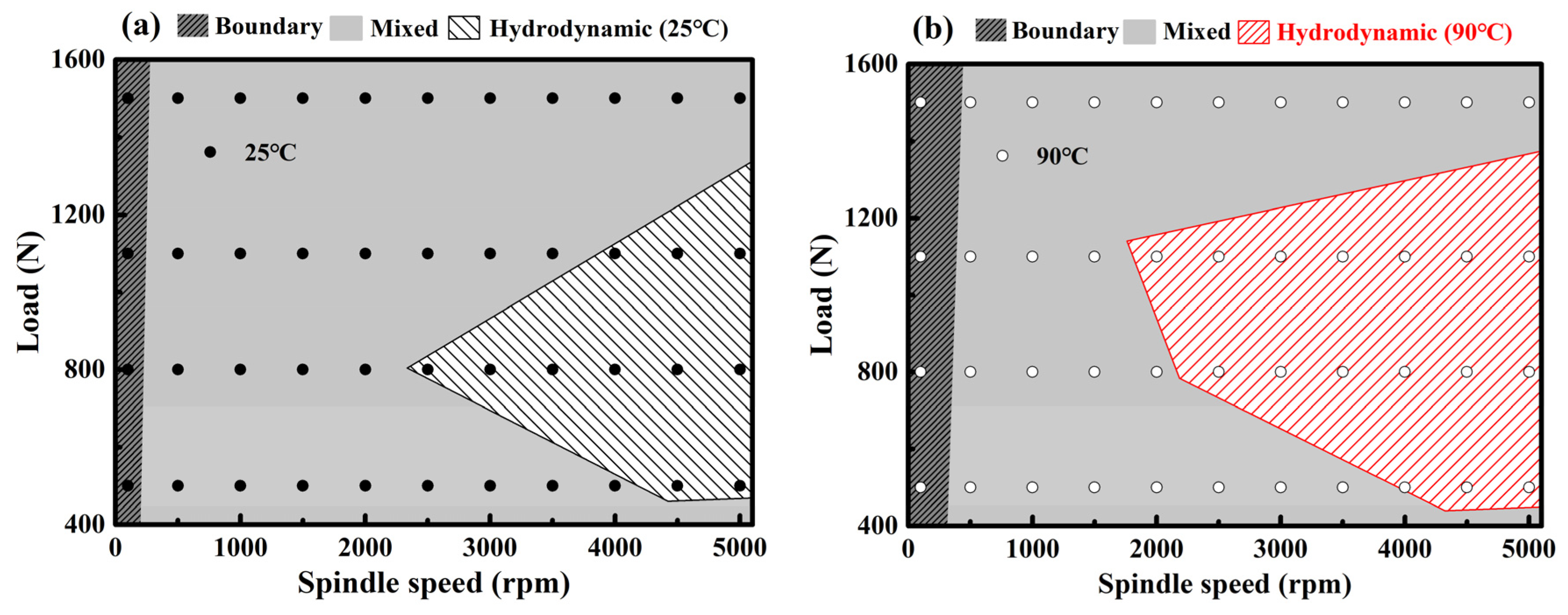

4.1. Lubrication Regimes in High-Temperature and High-Pressure Water

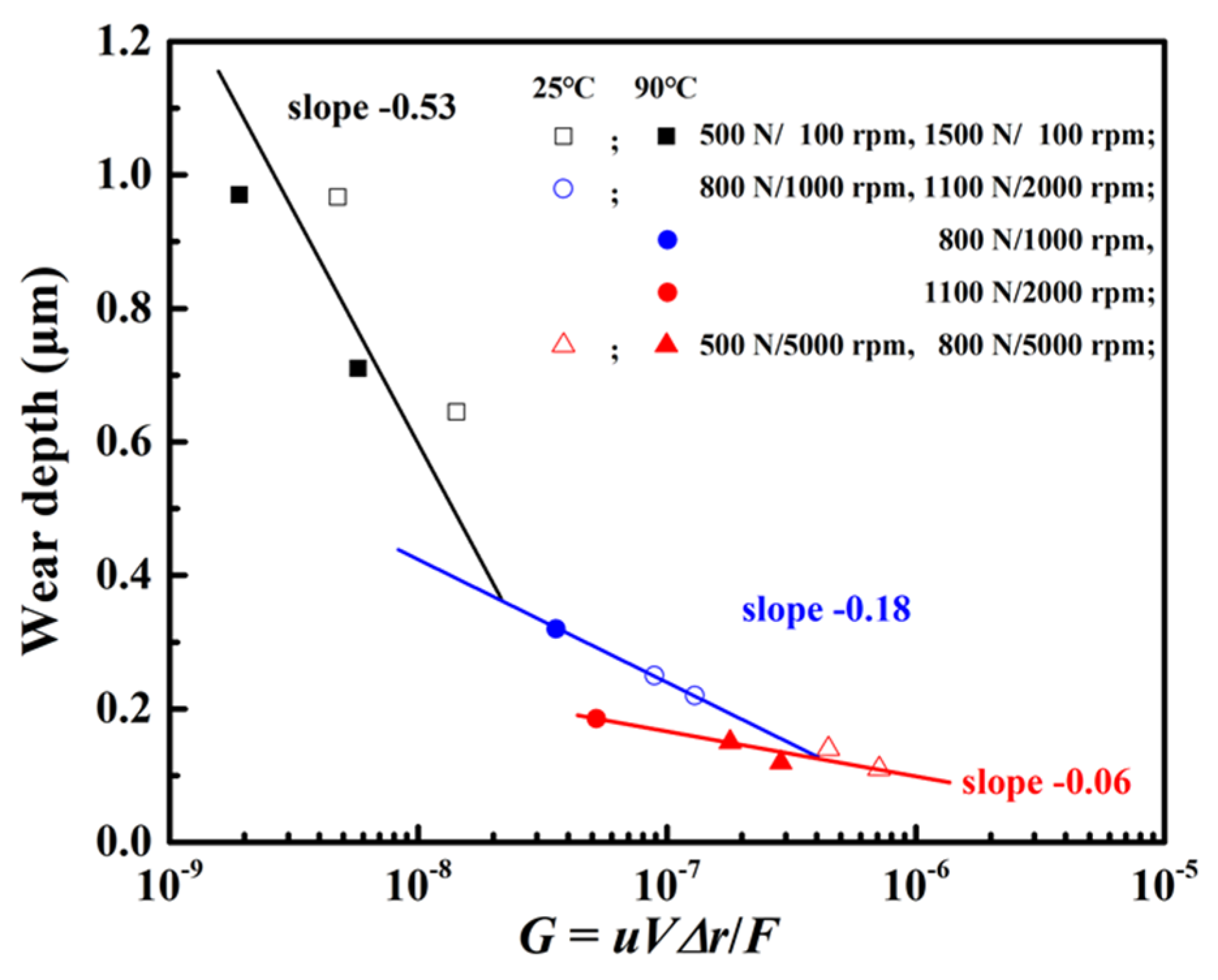

4.2. Integrated Evaluation by G Duty Parameters

5. Conclusions

- (1)

- The effect of the microstructure of siliconized graphite on the tribological properties is investigated by Stribeck curves and wear tests under an applied load of 500–1500 N with a spindle speed of 100–5000 rpm in both 25 °C (1 MPa) and 90 °C (5 MPa) water environments, respectively.

- (2)

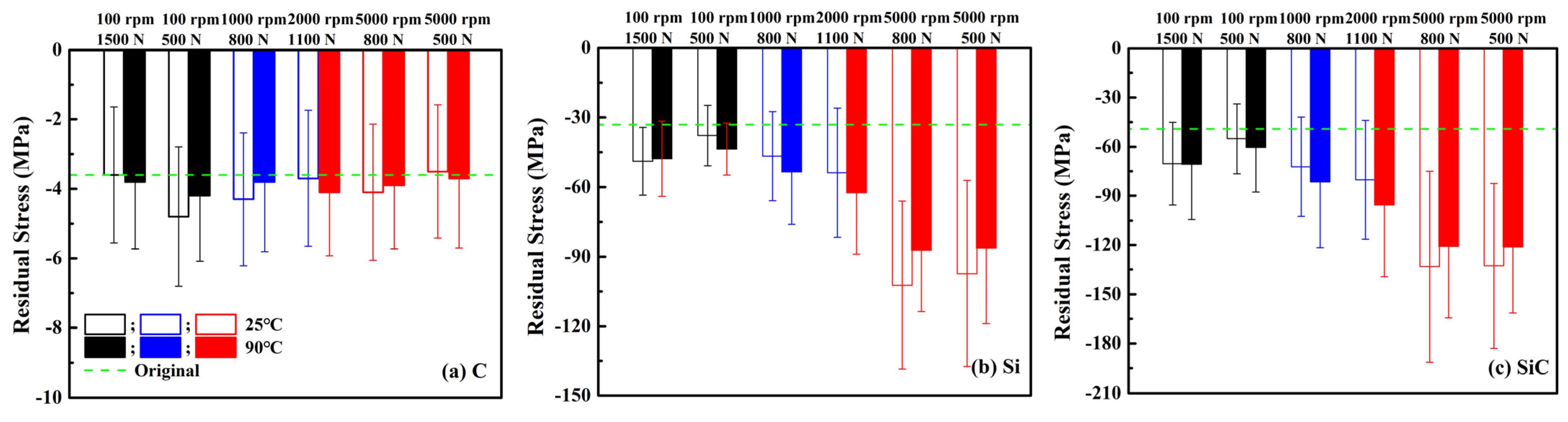

- The lubrication regimes of self-mated siliconized graphite on a ring-on-ring configuration are characterized by the coefficient of friction, wear depth, and worn morphology with surface roughness and residual stress, which are dependent not only on the applied load and spindle speed but also on the graphite, Si, and SiC phases of siliconized graphite.

- (3)

- The abrasive wear of SiC and Si asperities together with graphite solid lubrication is attributed to the boundary lubrication. The partially abrasive wear in the thin water film causes the mixed lubrication. The full water film scouring with the wavy feature of SiC and uniform flow-oriented striae of Si contributes to the hydrodynamic lubrication.

- (4)

- An integrated evaluation method of the G duty parameters as a function of the wear depths with the segment slopes is successfully used to identify the lubrication regimes from boundary, mixed, to hydrodynamic lubrications for the water-lubricated thrust bearings of the main coolant pump in a nuclear power plant.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baumgarten, S.; Brecht, B.; Bruhns, U.; Fehring, P. Reactor Coolant Pump Type RUV for Westinghouse Electric Company LLC Reactor AP1000TM. In Proceedings of the International Congress on Advances in Nuclear Power Plants, San Diego, CA, USA, 13–17 June 2010; pp. 177–185. [Google Scholar]

- Li, T.; Ma, L. Research and Development of Wet Winding Motor Reactor Coolant Pump for Generation 3 Nuclear Power Plant. In Proceedings of the ASME Proceedings of 29th International Conference on Nuclear Engineering, Online, 8–12 August 2022. [Google Scholar]

- Barbosa, J.; Cavallini, A.A., Jr.; Santos, I.; Steffen, V., Jr. Dynamic Behavior of A Tilting-Pad Thrust Bearing Operating under a Hybrid Lubrication Regime. ASME J. Tribol. 2023, 145, 114101. [Google Scholar] [CrossRef]

- Yu, X.; Tang, B.; Wang, S.; Han, Z.; Li, S.; Chen, M.; Zhang, R.; Wang, J.; Jiao, J.; Jiang, H. High-speed and heavy-load tribological properties of Hydrostatic Thrust Bearing with Double Rectangular Recess. Int. J. Hydrogen Energy 2022, 47, 21273–21286. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, X.; Wang, J.; Tang, X.; Kuang, F. Influence of Temperature on Friction of Polymeric Materials in Water. Wear 2019, 426, 868–876. [Google Scholar] [CrossRef]

- Kitaoka, S.; Tsuji, T.; Katoh, T.; Yamaguchi, Y.; Kashiwagi, K. Tribological Characteristics of SiC Ceramics in High-Temperature and High-Pressure Water. J. Am. Ceram. Soc. 1994, 77, 1851–1856. [Google Scholar] [CrossRef]

- Yin, T.; Wei, D.; Wang, T.; Xie, Z. Thermal Compression and Accumulation Effect on Lubrication Regime Transition Mechanism of Water Seal. Tribol. Int. 2023, 181, 108285. [Google Scholar] [CrossRef]

- Wolf, R. Boronized and Siliconized Graphites-Material Processing and Effects on Properties. J. Nucl. Mater. 1994, 212, 1174–1177. [Google Scholar] [CrossRef]

- Krasilnikov, A.; Ryaposov, A. Corrosion Resistance of Siliconized Graphite Based Structural Materials under Decontamination Conditions. At. Energy 2022, 132, 258–261. [Google Scholar] [CrossRef]

- Yu, P.; Li, G.; Zhang, L.; Zhao, F.; Chen, S.; Dmitriev, A.; Zhang, G. Regulating Microstructures of Interpenetrating Polyurethane-Epoxy Networks towards High-Performance Water-Lubricated Bearing Materials. Tribol. Int. 2019, 131, 454–464. [Google Scholar] [CrossRef]

- Liang, X.; Yang, Z. Experimental Study on the Influence of Friction Pair Material Hardness on the Tribological Behaviors of Water Lubricated Thrust Bearings. Ind. Lubr. Tribol. 2021, 73, 929–936. [Google Scholar] [CrossRef]

- Yu, H.; Zheng, W.; Zhang, C.; Chen, S.; Tian, G.; Wang, T. Dual Network Co-Crosslinked HNBR Composites with Enhanced Tribological Properties under Water Lubrication. Lubricants 2024, 11, 534. [Google Scholar] [CrossRef]

- Wodtke, M.; Wasilczuk, M. Evaluation of Apparent Young’s Modulus of the Composite Polymer Layers Used as Sliding Surfaces in Hydrodynamic Thrust Bearings. Tribol. Int. 2016, 97, 244–252. [Google Scholar] [CrossRef]

- Hyuga, H.; Yoshizawa, I.; Hirao, K.; Rani, D.; Jones, M. Tribological Behavior of Si3N4 and Si3N4/carbon Fiber Composites Against Stainless Steel under Water Lubrication for a Thrust-Bearing Application. Int. J. Appl. Ceram. Technol. 2008, 5, 111–118. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, W.; Zhang, Z.; Xing, H.; Wang, C.; Zhang, Z.; Gao, D. Effect of Material Selection and Surface Texture on Tribological Properties of Key Friction Pairs in Water Hydraulic Axial Piston Pumps: A Review. Lubricants 2023, 11, 324. [Google Scholar] [CrossRef]

- Xia, H.; Wang, J.; Shi, Z.; Qiao, G. Reciprocating Friction and Wear Properties of Mesocarbon Microbeads-Based Graphite and Siliconized Graphite. J. Nucl. Mater. 2013, 433, 341–344. [Google Scholar] [CrossRef]

- Xue, Z.; Xue, R.; Zhang, N.; Zhang, L.; Liu, X.; Hou, B.; Zhang, Y.; Wang, J. Water-lubricated Friction Properties of C/C-SiC Composites with Different SiC-phase Contents Fabricated by RMI. Tribol. Trans. 2021, 64, 468–476. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Z.; Yu, X.; Li, K.; Wang, Z.; Zhang, Z.; Wang, Y. Enhancement of Tribological Properties in Siliconized Graphite via Hierarchically Hybrid SiC/C Composite. Prog. Nat. Sci. Mater. Int. 2021, 31, 255–263. [Google Scholar] [CrossRef]

- Yuan, Z.; He, Y.; Cheng, K.; Duan, Z.; Wang, L. Effect of self-developed graphene lubricant on tribological behaviour of silicon carbide/silicon nitride interface. Ceram. Int. 2019, 45, 10211–10222. [Google Scholar] [CrossRef]

- Wan, F.; Pizada, T.; Liu, R.; Wang, Y.; Qi, G.; Zhang, C.; Marrow, T. Structure and Flexural Properties of 3D Needled Carbon Fiber Reinforced Carbon and Silicon Carbide (C/C-SiC) Composites Fabricated by Gaseous and Liquid Silicon Infiltration. Ceram. Int. 2019, 45, 17978–17986. [Google Scholar] [CrossRef]

- Chae, S.; Choi, S.-H.; Kim, N.; Sung, J.; Cho, J. Integration of Graphite and Silicon Anodes for the Commercialization of High-Energy Lithium-Ion Batteries. Angew. Chem. Int. Ed. 2020, 59, 110–135. [Google Scholar] [CrossRef]

- Tong, Y.; Wang, L.; Wang, B.; Hu, Y.; Cai, Z.; Ren, J.; Liu, J.; Li, S. Microstructure and Mechanical Behavior of Carbon Fiber Reinforced Carbon, Silicon Carbide, and Copper Alloy Hybrid Composite Fabricated by Cu-Si Alloy Melt Infiltration. Adv. Compos. Hybrid Mater. 2023, 6, 25. [Google Scholar] [CrossRef]

- März, B.; Jolley, K.; Smith, R.; Wu, H. Near-surface Structure and Residual Stress in As-Machined Synthetic Graphite. Mater. Des. 2018, 159, 103–116. [Google Scholar] [CrossRef]

- Fan, X.; Yin, X.; Cao, X.; Chen, L.; Cheng, L.; Zhang, L. Improvement of the Mechanical and Thermophysical Properties of C/SiC Composites Fabricated by Liquid Silicon Infiltration. Compos. Sci. Technol. 2015, 115, 21–27. [Google Scholar] [CrossRef]

- Tong, Y.; Bai, S.; Liang, X.; Qin, Q.; Zhai, J. Reactive Melt Infiltration Fabrication of C/C-SiC Composite: Wetting and infiltration. Ceram. Int. 2016, 42, 17174–17178. [Google Scholar] [CrossRef]

- Li, W.; Long, G.; Shi, F.; Zhou, S.; Yin, J.; Yang, J. Influence of the Fiber Orientation on 3D C/C-SiC Composite Material and its Formation Mechanism of the Machining Surface. Int. J. Adv. Manuf. Technol. 2022, 118, 2725–2743. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, Y. Boundary Lubrication by Adsorption Film. Friction 2015, 3, 115–147. [Google Scholar] [CrossRef]

- Ahmad, I.; Anwar, S.; Xu, F.; Zhu, Y. Tribological Investigation of Multilayer Graphene Reinforced Alumina Ceramic Nanocomposites. ASME J. Tribol. 2019, 141, 022002. [Google Scholar] [CrossRef]

- Calderon, N.; Martinez-Escandell, M.; Narciso, J.; Rodriguez-Reinoso, F. The Combined Effect of Porosity and Reactivity of the Carbon Preforms on the Properties of SiC Produced by Reactive Infiltration with Liquid Si. Carbon 2009, 47, 2200–2210. [Google Scholar] [CrossRef]

- Azam, A.; Ghanbarzadeh, A.; Neville, A.; Morina, A.; Wilson, M.C.T. Modelling Tribochemistry in the Mixed Lubrication Regime. Tribol. Int. 2019, 132, 265–274. [Google Scholar] [CrossRef]

- Hirani, H. Fundamentals of Engineering Tribology with Application; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic Lubrication of Textured Surfaces: A Review of Modeling Techniques and Key Findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Chen, M.; Kato, K.; Adachi, K. The Difference in Running-in Period and Friction Coefficient between Self-Mated Si3N4 and SiC under Water Lubrication. Tribol. Lett. 2001, 11, 23–28. [Google Scholar] [CrossRef]

- Chen, M.; Kato, K.; Adachi, K. Friction and Wear of Self-mated SiC and Si3N4 Sliding in Water. Wear 2001, 250, 246–255. [Google Scholar] [CrossRef]

- Zhang, W. Tribology of SiC Ceramics under Lubrication: Features, Developments, and Perspectives. Curr. Opin. Solid State Mater. Sci. 2022, 26, 101000. [Google Scholar] [CrossRef]

- Brunetiere, N.; Francisco, A. Lubrication Mechanisms between Parallel Rough Surfaces. Tribol. Lett. 2019, 67, 116. [Google Scholar] [CrossRef]

| Experiment Type | Water Environment | Applied Load (N) | Speed (rpm) | Time |

|---|---|---|---|---|

| (I) Stribeck curves in high-temperature and high-pressure water | 25 °C (1 MPa) | 500 | Step-down 5000–100 (25.0–0.5 m/s) | A stage duration of 600 s |

| 800 | ||||

| 1100 | ||||

| 1500 | ||||

| 90 °C (5 MPa) | 500 | |||

| 800 | ||||

| 1100 | ||||

| 1500 | ||||

| (II) Wear for high-temperature and high-pressure water-lubricated tribometer | 25 °C (1 MPa) | 500 | 100 | For 7200 s duration |

| 500 | 5000 | |||

| 800 | 1000 | |||

| 800 | 5000 | |||

| 1100 | 2000 | |||

| 1500 | 100 | |||

| 90 °C (5 MPa) | 500 | 100 | ||

| 500 | 5000 | |||

| 800 | 1000 | |||

| 800 | 5000 | |||

| 1100 | 2000 | |||

| 1500 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhang, B.; Cai, L.; Wang, W.; Liang, T.; Lei, M. High-Temperature and High-Pressure Tribological Properties of Siliconized Graphite for Water-Lubricated Thrust Bearing Application in Main Coolant Pump. Lubricants 2024, 12, 159. https://doi.org/10.3390/lubricants12050159

Liu S, Zhang B, Cai L, Wang W, Liang T, Lei M. High-Temperature and High-Pressure Tribological Properties of Siliconized Graphite for Water-Lubricated Thrust Bearing Application in Main Coolant Pump. Lubricants. 2024; 12(5):159. https://doi.org/10.3390/lubricants12050159

Chicago/Turabian StyleLiu, Sihang, Baojun Zhang, Long Cai, Weiguang Wang, Taihe Liang, and Mingkai Lei. 2024. "High-Temperature and High-Pressure Tribological Properties of Siliconized Graphite for Water-Lubricated Thrust Bearing Application in Main Coolant Pump" Lubricants 12, no. 5: 159. https://doi.org/10.3390/lubricants12050159

APA StyleLiu, S., Zhang, B., Cai, L., Wang, W., Liang, T., & Lei, M. (2024). High-Temperature and High-Pressure Tribological Properties of Siliconized Graphite for Water-Lubricated Thrust Bearing Application in Main Coolant Pump. Lubricants, 12(5), 159. https://doi.org/10.3390/lubricants12050159