Examining Wear Mechanisms in Railway Wheel Steels: Experimental Insights and Predictive Mapping

Abstract

1. Introduction

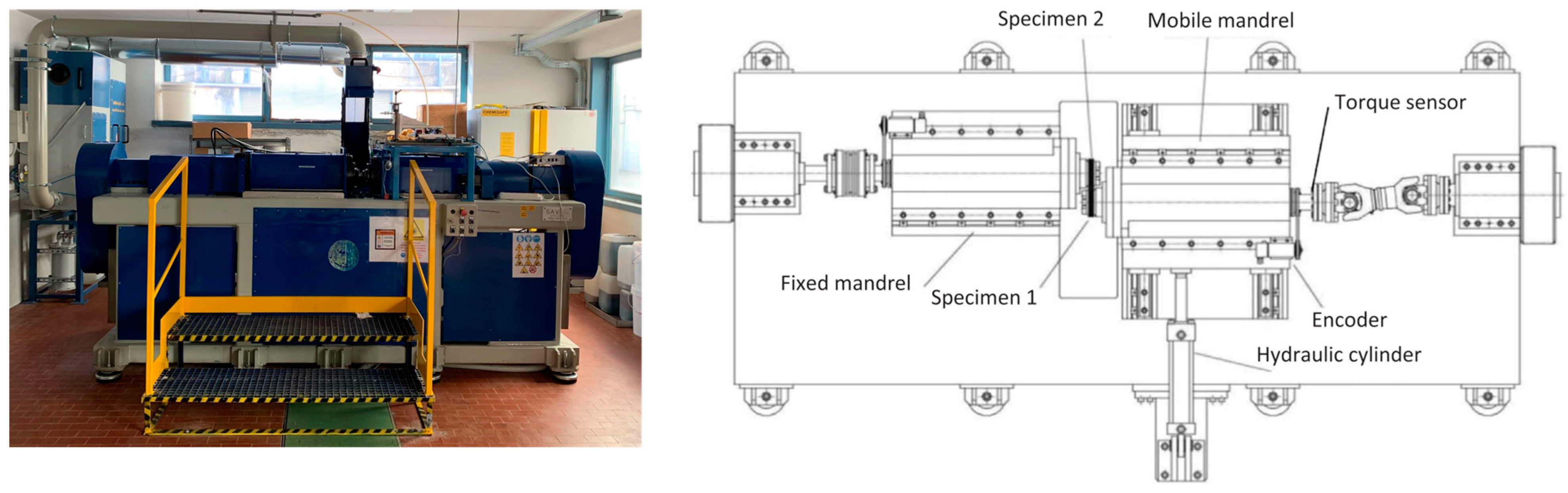

2. Experimental Details

3. Results and Discussion

4. Conclusions

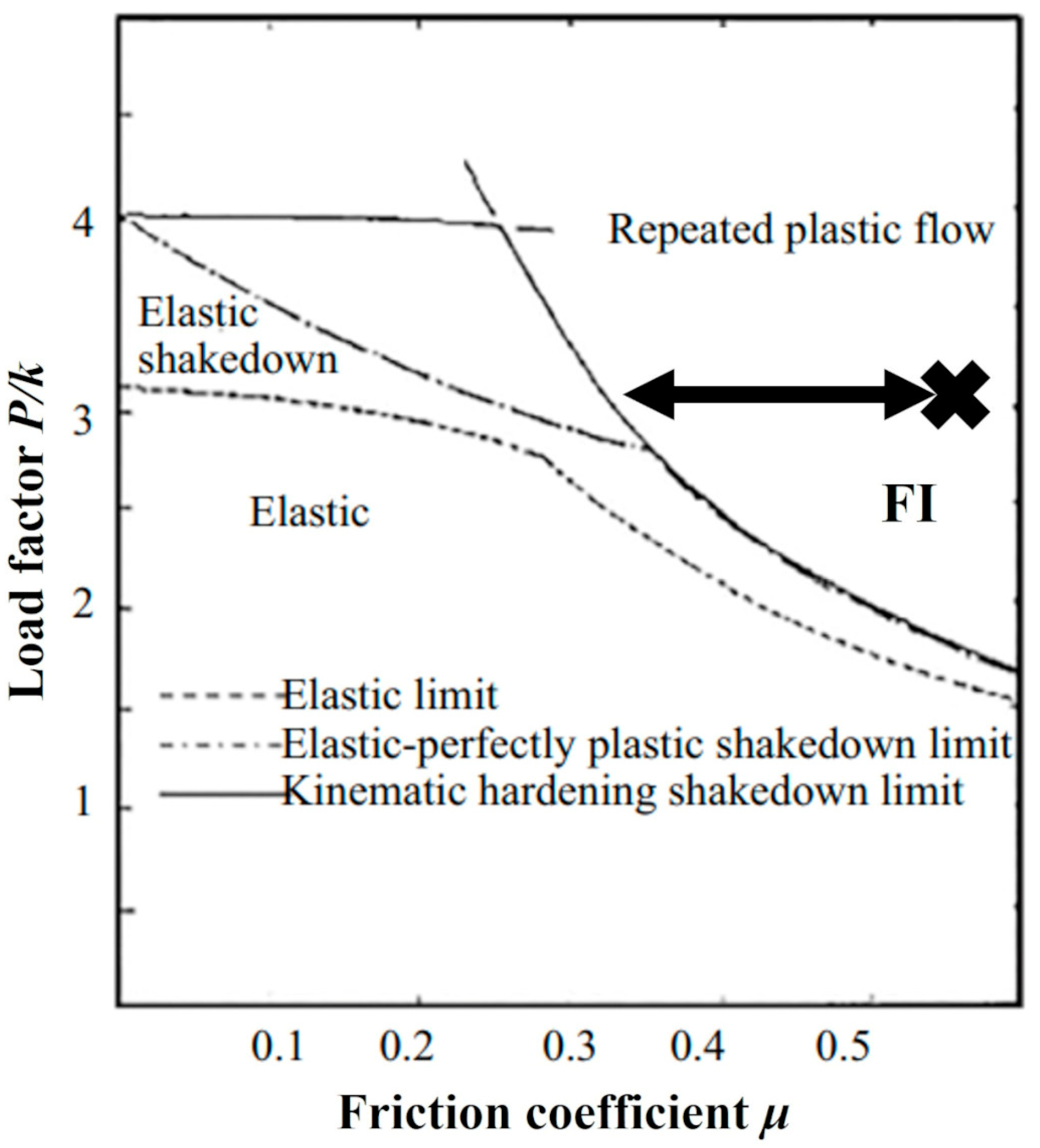

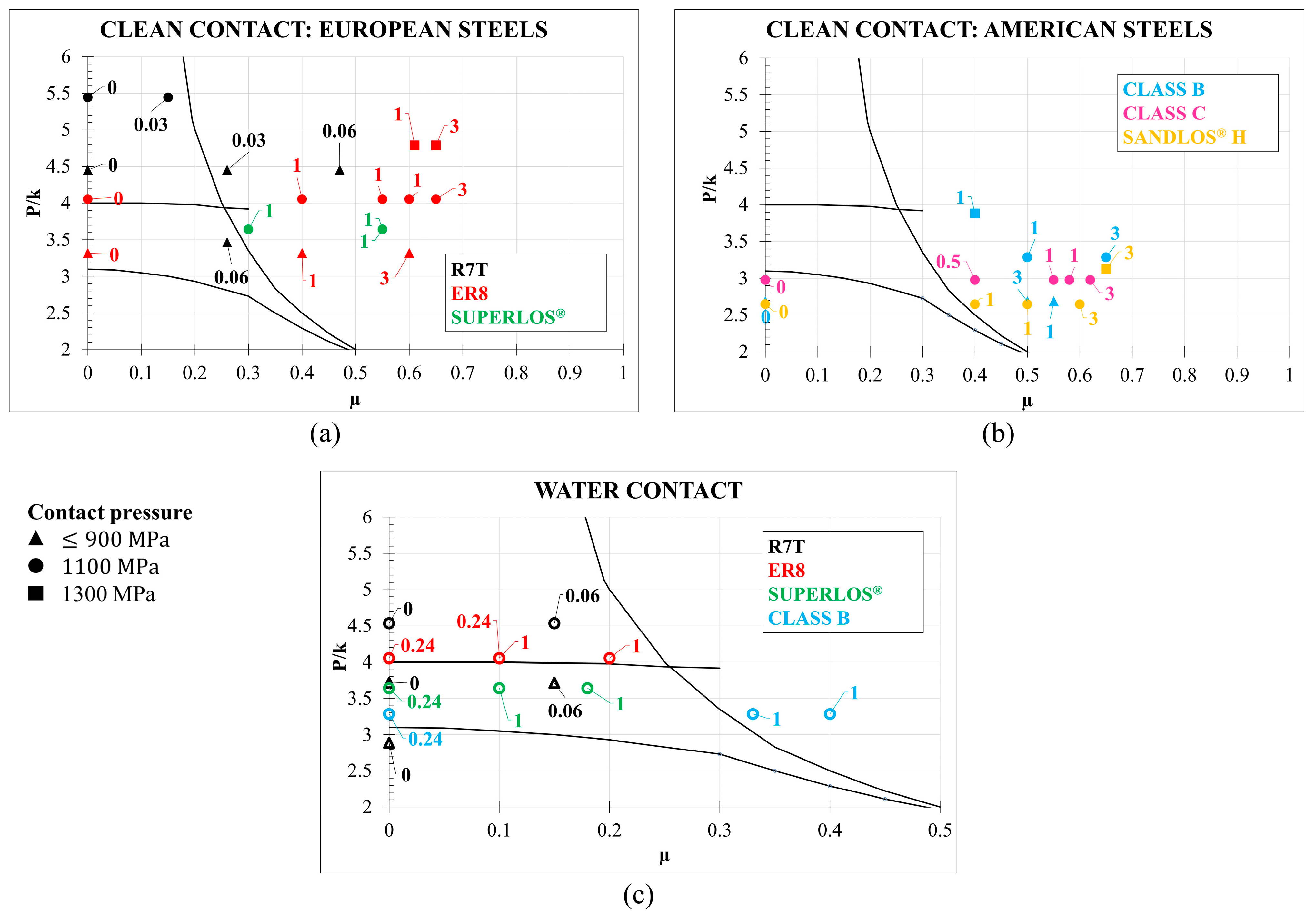

- Clean contact conditions resulted in higher coefficients of friction and maximum stress at the surface, while lubricated contact conditions showed lower coefficients of friction and maximum stress in the subsurface.

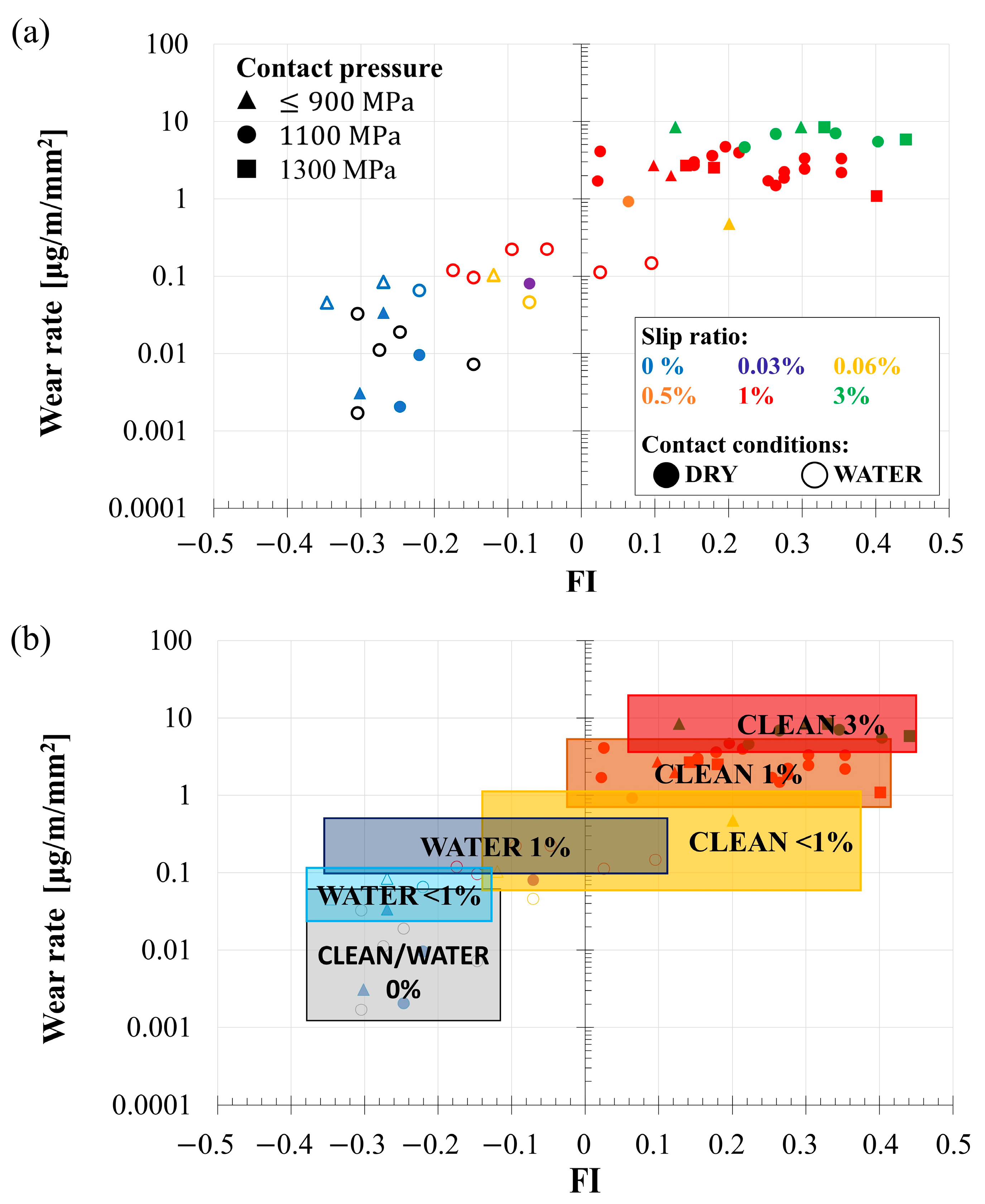

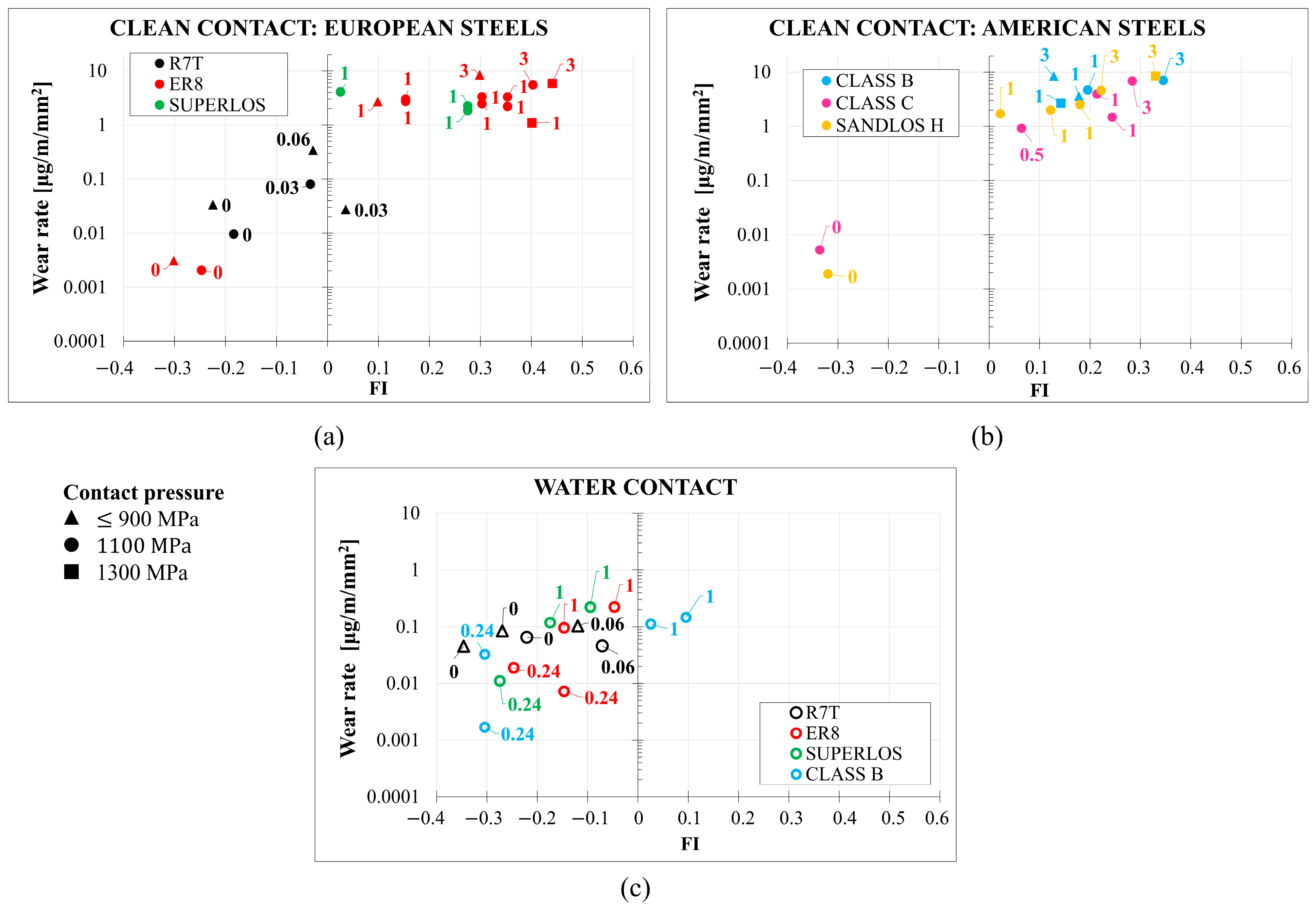

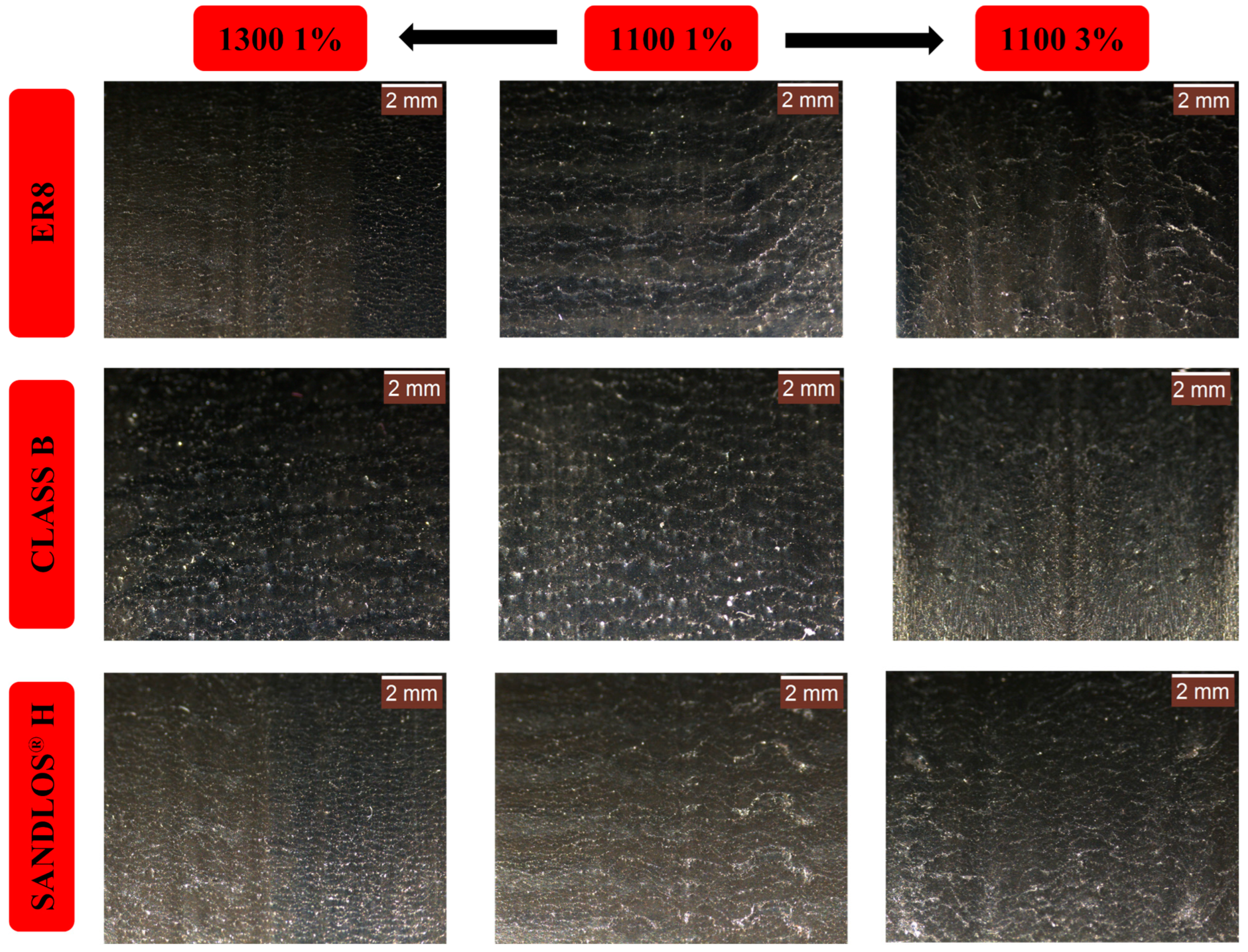

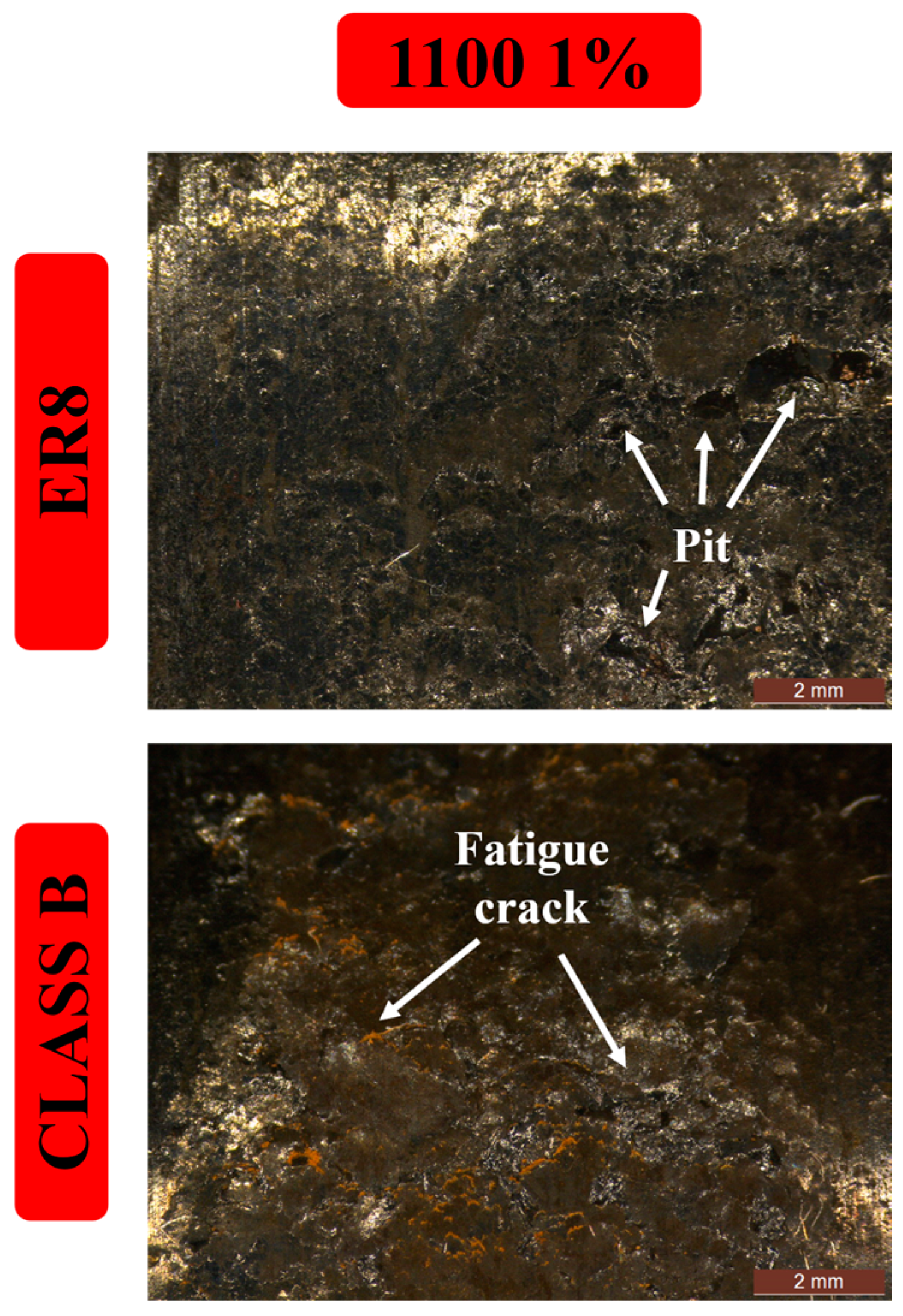

- Wear rates increased with increasing slip ratio, with a significant increase observed in clean contact conditions compared to lubricated conditions.

- Introducing new and improved materials led to lower wear rates, indicating the importance of material selection in minimising wear in wheel–rail systems.

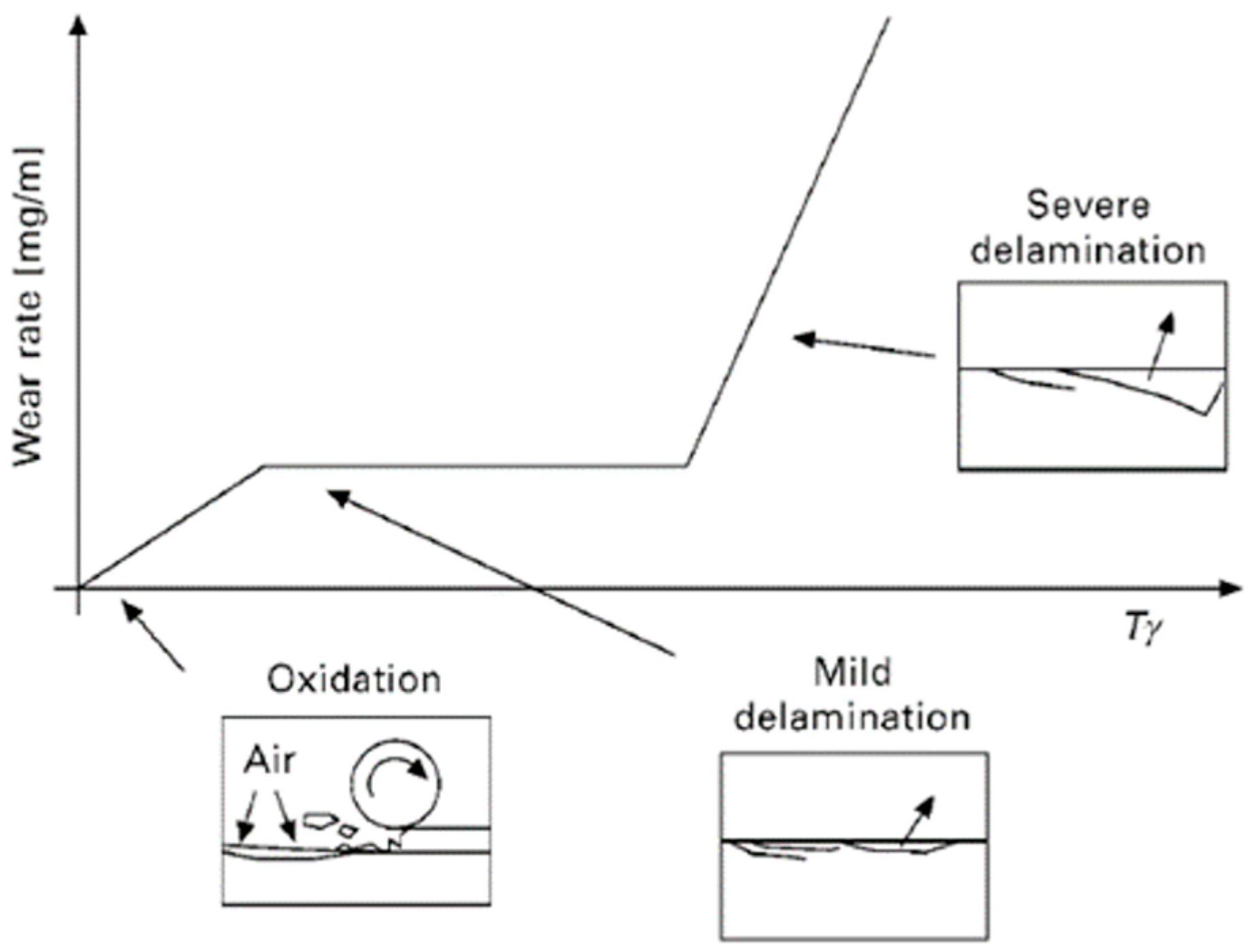

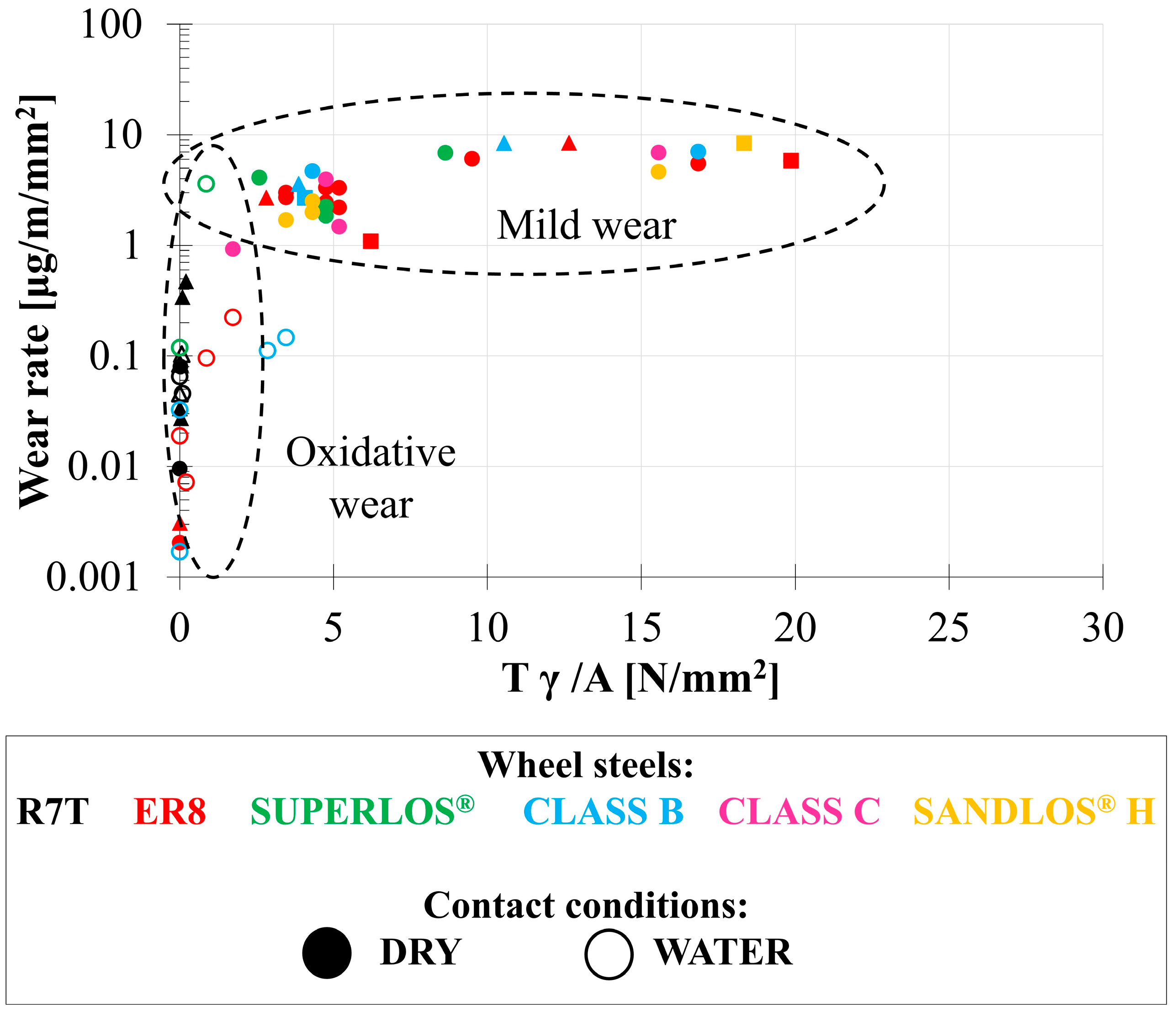

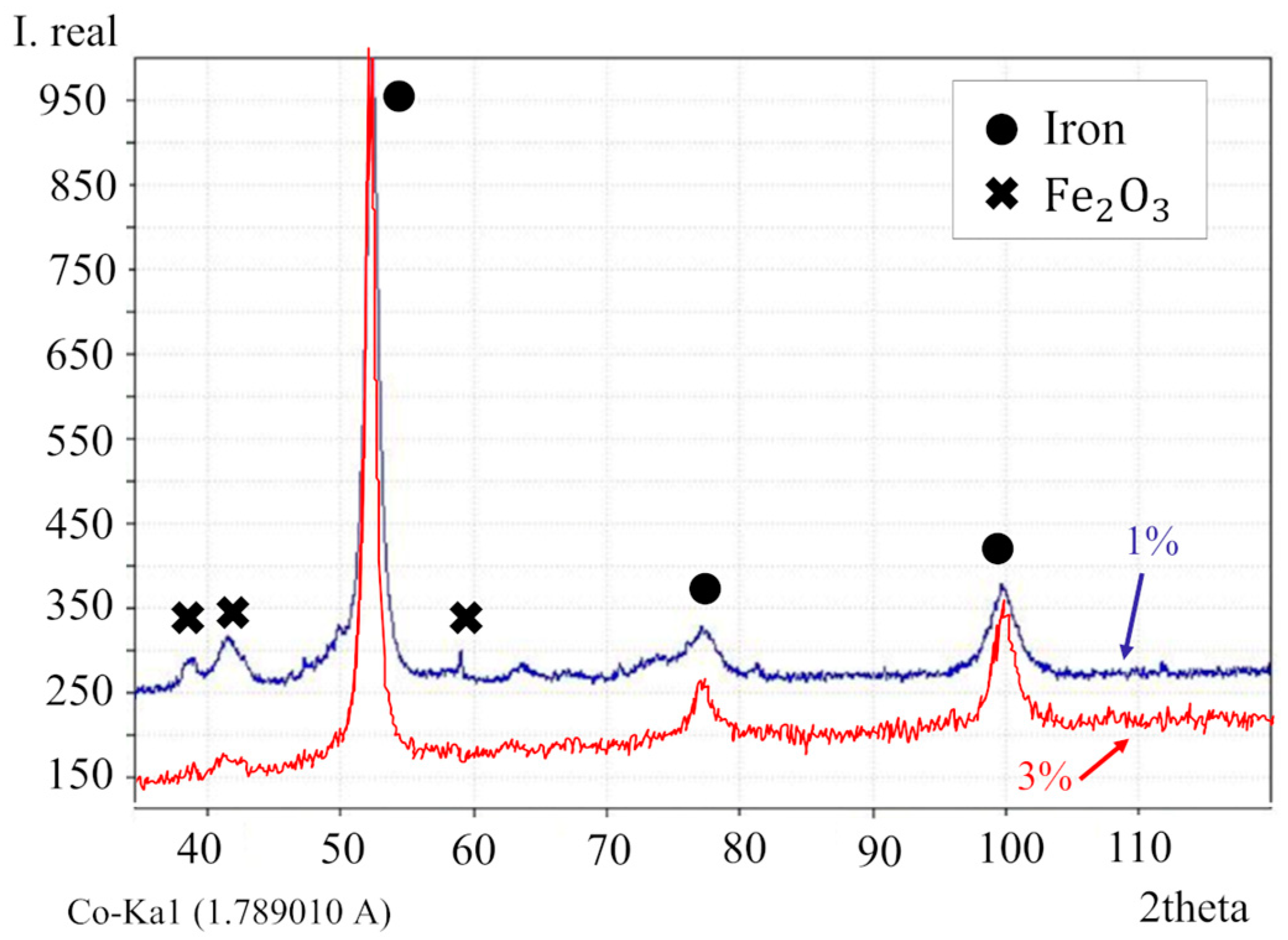

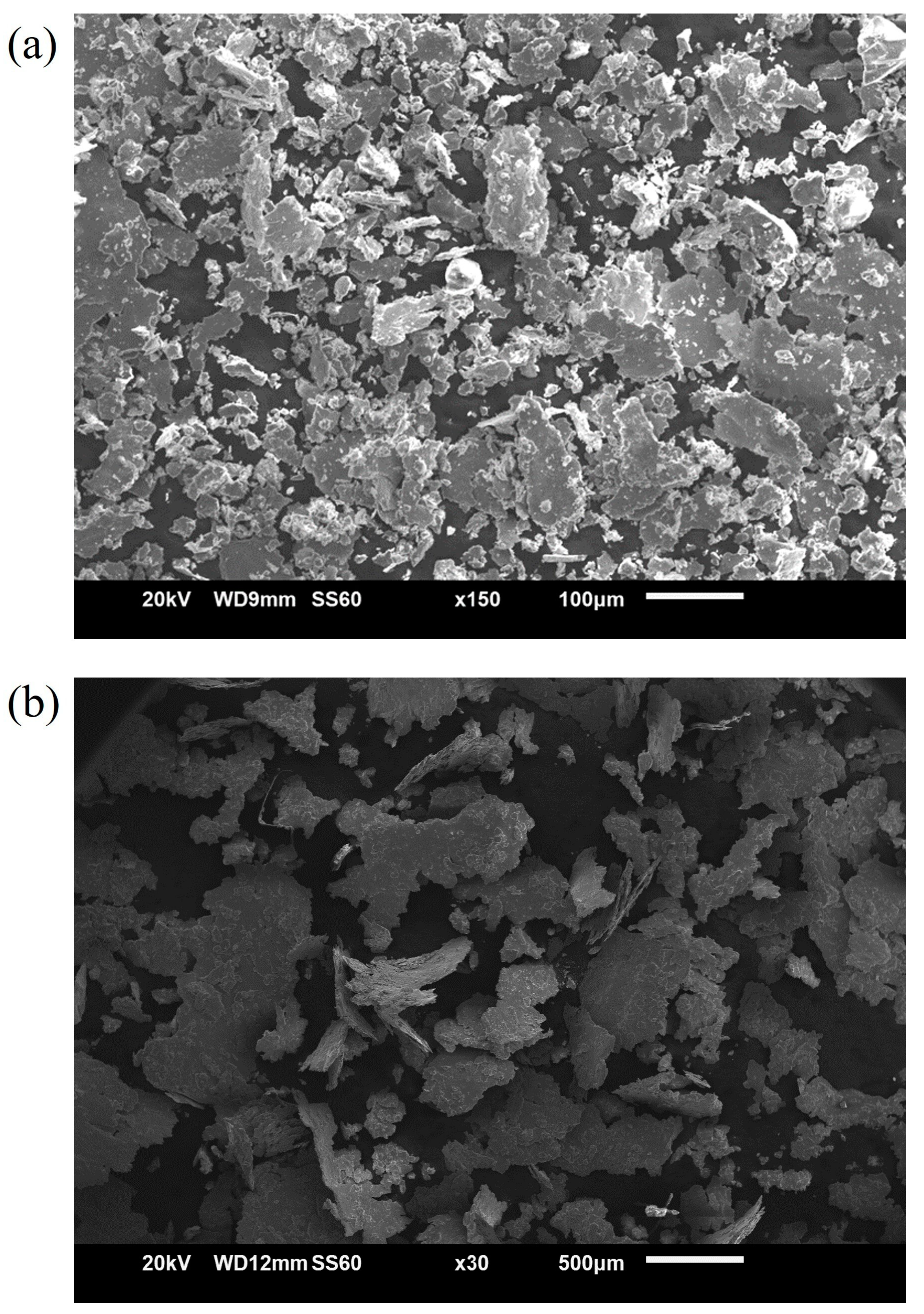

- Wear mechanisms were identified as oxidative and mild wear, with the presence of oxide and iron in wear debris in the former case and only the presence of iron in the latter, highlighting the role of lubrication and surface cleanliness in wear prevention.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Environment Agency. Transport and Environment Report 2020: Train or Plane? European Environment Agency: Copenhagen, Denmark, 2020; Volume 19.

- Šmach, J. Two Contributions to Rolling Contact Fatigue Testing Considering Different Diameters of Rail and Wheel Discs. Lubricants 2023, 11, 504. [Google Scholar] [CrossRef]

- Donzella, G.; Mazzù, A.; Petrogalli, C. Competition between wear and rolling contact fatigue at the wheel-rail interface: Some experimental evidence on rail steel. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2009, 223, 31–44. [Google Scholar] [CrossRef]

- Hardwick, C.; Lewis, R.; Eadie, D.T. Wheel and rail wear-Understanding the effects of water and grease. Wear 2014, 314, 198–204. [Google Scholar] [CrossRef]

- Leso, T.P.; Siyasiya, C.W.; Mostert, R.J.; Moema, J. Study of rolling contact fatigue, rolling and sliding wear of class B wheel steels against R350HT and R260 rail steels under dry contact conditions using the twin disc setup. Tribol. Int. 2022, 174, 107711. [Google Scholar] [CrossRef]

- Wang, W.J.; Jiang, W.J.; Wang, H.Y.; Liu, Q.Y.; Zhu, M.H.; Jin, X.S. Experimental Study on the Wear and Damage Behavior of Different Wheel/Rail Materials. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 3–14. [Google Scholar] [CrossRef]

- Ma, L.; He, C.G.; Zhao, X.J.; Guo, J.; Zhu, Y.; Wang, W.J.; Liu, Q.Y.; Jin, X.S. Study on Wear and Rolling Contact Fatigue Behaviors of Wheel/Rail Materials under Different Slip Ratio Conditions. Wear 2016, 366–367, 13–26. [Google Scholar] [CrossRef]

- Rocha, R.C.; Ewald, H.; Rezende, A.B.; Fonseca, S.T.; Mei, P.R. Using twin disc for applications in the railway: A systematic review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 191. [Google Scholar] [CrossRef]

- Jendel, T.; Berg, M. Prediction of Wheel Profile Wear: Methodology and Verification. Veh. Syst. Dyn. 2003, 37, 502–513. [Google Scholar] [CrossRef]

- Faccoli, M.; Zani, N.; Ghidini, A.; Petrogalli, C. Experimental and numerical investigation on the wear behavior of high performance railway wheel steels paired with various brake block materials under dry sliding conditions. Wear 2022, 506–507, 204456. [Google Scholar] [CrossRef]

- Provezza, L.; Bodini, I.; Petrogalli, C.; Lancini, M.; Solazzi, L.; Faccoli, M. Monitoring the Damage Evolution in Rolling Contact Fatigue Tests Using Machine Learning and Vibrations. Metals 2021, 11, 283. [Google Scholar] [CrossRef]

- Bruni, S.; Collina, A.; Diana, G.; Vanolo, P. Lateral dynamics of a railway vehicle in tangent track and curve: Tests and simulation. Veh. Syst. Dyn. 2000, 33, 464–477. [Google Scholar] [CrossRef]

- Braghin, F.; Bruni, S.; Resta, F. Wear of railway wheel profiles: A comparison between experimental results and a mathematical model. Veh. Syst. Dyn. 2003, 37, 478–489. [Google Scholar] [CrossRef]

- Iwnicki, S. Simulation of wheel—Rail contact forces. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 887–900. [Google Scholar] [CrossRef]

- Ye, Y.; Huang, C.; Zeng, J.; Wang, S.; Liu, C.; Li, F. Predicting Railway Wheel Wear by Calibrating Existing Wear Models: Principle and Application. Reliab. Eng. Syst. Saf. 2023, 238, 109462. [Google Scholar] [CrossRef]

- Kang, X.; Chen, G.; Chen, X.; Deng, C.; Ma, Y.; Zhao, Y.; Lu, S. Analysis of the Generation Mechanism and Evolution of the Wheel High-Order Polygonal Wear of Subway Trains. Eng. Fail. Anal. 2023, 151, 107375. [Google Scholar] [CrossRef]

- Ao, N.; Zhang, X.; Zhao, X.; Hu, F.; Jian, B.; Wu, S. Remaining Fatigue Life Assessment of High-Speed Railway Wheel Web under Measured Load Spectra. Eng. Fract. Mech. 2024, 295, 109813. [Google Scholar] [CrossRef]

- Sang, H.; Zeng, J.; Qi, Y.; Mu, J.; Gan, F. Study on Wheel Wear Mechanism of High-Speed Train in Accelerating Conditions. Wear 2023, 516–517, 204597. [Google Scholar] [CrossRef]

- de Paula Pacheco, P.A.; Endlich, C.S.; Vieira, K.L.S.; Reis, T.; dos Santos, G.F.M.; dos Santos Júnior, A.A. Optimization of Heavy Haul Railway Wheel Profile Based on Rolling Contact Fatigue and Wear Performance. Wear 2023, 522, 204704. [Google Scholar] [CrossRef]

- Kato, T.; Kato, H.; Makino, T. Effect of Elevated Temperature on Shelling Property of Railway Wheel Steel. Wear 2016, 366–367, 359–367. [Google Scholar] [CrossRef]

- Makino, T.; Kato, T.; Hirakawa, K. Review of the fatigue damage tolerance of high-speed railway axles in Japan. Eng. Fract. Mech. 2011, 78, 810–825. [Google Scholar] [CrossRef]

- Mazzù, A.; Petrogalli, C.; Lancini, M.; Ghidini, A.; Faccoli, M. Effect of Wear on Surface Crack Propagation in Rail–Wheel Wet Contact. J. Mater. Eng. Perform. 2018, 27, 630–639. [Google Scholar] [CrossRef]

- Faccoli, M.; Petrogalli, C.; Lancini, M.; Ghidini, A.; Mazzù, A. Rolling Contact Fatigue and Wear Behavior of High-Performance Railway Wheel Steels Under Various Rolling-Sliding Contact Conditions. J. Mater. Eng. Perform. 2017, 26, 3271–3284. [Google Scholar] [CrossRef]

- Gutsulyak, D.V.; Stanlake, L.J.E.; Qi, H. Twin Disc Evaluation of Third Body Materials in the Wheel/Rail Interface. Tribol.-Mater. Surf. Interfaces 2021, 15, 115–126. [Google Scholar] [CrossRef]

- Wang, W.J.; Zhang, H.F.; Wang, H.Y.; Liu, Q.Y.; Zhu, M.H. Study on the Adhesion Behavior of Wheel/Rail under Oil, Water and Sanding Conditions. Wear 2011, 271, 2693–2698. [Google Scholar] [CrossRef]

- Faccoli, M.; Petrogalli, C.; Lancini, M.; Ghidini, A.; Mazzù, A. Effect of desert sand on wear and rolling contact fatigue behaviour of various railway wheel steels. Wear 2018, 396–397, 146–161. [Google Scholar] [CrossRef]

- Grieve, D.G.; Dwyer-Joyce, R.S.; Beynon, J.H. Abrasive wear of railway track by solid contaminants. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2001, 215, 193–205. [Google Scholar] [CrossRef]

- Omasta, M.; Machatka, M.; Smejkal, D.; Hartl, M.; Křupka, I. Influence of sanding parameters on adhesion recovery in contaminated wheel–rail contact. Wear 2015, 322–323, 218–225. [Google Scholar] [CrossRef]

- Lewis, R.; Dwyer-Joyce, R.S. Wear at the wheel/rail interface when sanding is used to increase adhesion. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2006, 220, 29–41. [Google Scholar] [CrossRef]

- Skipper, W.A.; Chalisey, A.; Lewis, R. Particle characterisation of rail sand for understanding tribological behaviour. In Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems, Delft, The Netherlands, 27–28 September 2018; pp. 886–895. [Google Scholar]

- Mazzù, A.; Ghidini, A.; Zani, N.; Faccoli, M. A simplified numerical study of wheel/rail material coupling in presence of solid contaminants. Tribol.—Mater. Surf. Interfaces 2021, 15, 102–114. [Google Scholar] [CrossRef]

- Mazzù, A.; Ghidini, A.; Zani, N.; Faccoli, M. Study of wheel/rail material coupling in presence of solid contaminants. In Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems, Delft, The Netherlands, 27–28 September 2018; pp. 701–710. [Google Scholar]

- Suhr, B.; Skipper, W.A.; Lewis, R.; Six, K. Sanded Wheel–Rail Contacts: Experiments on Sand Crushing Behaviour. Lubricants 2023, 11, 38. [Google Scholar] [CrossRef]

- Shi, Z.; Nencioni, L.; Meli, E.; Ding, H.; Wang, W.; Andrea, R. Effect of Material Hardness Ratio on Wear and Rolling Contact Fatigue: Development and Validation of New Laws. Wear 2023, 514–515, 204561. [Google Scholar] [CrossRef]

- He, C.G.; Huang, Y.B.; Ma, L.; Guo, J.; Wang, W.J.; Liu, Q.Y.; Zhu, M.H. Experimental Investigation on the Effect of Tangential Force on Wear and Rolling Contact Fatigue Behaviors of Wheel Material. Tribol. Int. 2015, 92, 307–316. [Google Scholar] [CrossRef]

- Guo, L.C.; Zhu, W.T.; Shi, L.B.; Liu, Q.Y.; Cai, Z.B.; Wang, W.J. Study on Wear Transition Mechanism and Wear Map of CL60 Wheel Material under Dry and Wet Conditions. Wear 2019, 426–427, 1771–1780. [Google Scholar] [CrossRef]

- Qiu, C.; Cookson, J.; Mutton, P. The role of microstructure and its stability in performance of wheels in heavy haul service. J. Mod. Transp. 2017, 25, 261–267. [Google Scholar] [CrossRef]

- Stock, R.; Oldknow, K.; Magel, E. Addressing Perceptions Regarding the Influence of Relative Hardness on Wheel/Rail Performance. Wear 2024, 538–539, 205225. [Google Scholar] [CrossRef]

- Viáfara, C.C.; Castro, M.I.; Vélez, J.M.; Toro, A. Unlubricated sliding wear of pearlitic and bainitic steels. Wear 2005, 259, 405–411. [Google Scholar] [CrossRef]

- Zani, N.; Chaise, T.; Ghidini, A.; Faccoli, M.; Mazzù, A. Numerical study about the effect of bainitic traces on plasticity in ferritic-pearlitic railway wheels. Proc. Inst. Mech. Eng. Part. F J. Rail Rapid Transit 2020, 235, 726–740. [Google Scholar] [CrossRef]

- Faccoli, M.; Zani, N.; Ghidini, A.; Petrogalli, C. Tribological Behavior of Two High Performance Railway Wheel Steels Paired with a Brake Block Cast Iron. Tribol. Trans. 2021, 65, 296–307. [Google Scholar] [CrossRef]

- Miranda, R.S.; Rezende, A.B.; Fonseca, S.T.; Fernandes, F.M.; Sinatora, A.; Mei, P.R. Fatigue and Wear Behavior of Pearlitic and Bainitic Microstructures with the Same Chemical Composition and Hardness Using Twin-Disc Tests. Wear 2022, 494–495, 204253. [Google Scholar] [CrossRef]

- Ishikawa, N.; Yasuda, K.; Sueyoshi, H.; Endo, S.; Ikeda, H.; Morikawa, T.; Higashida, K. Microscopic Deformation and Strain Hardening Analysis of Ferrite-Bainite Dual-Phase Steels Using Micro-Grid Method. Acta Mater. 2015, 97, 257–268. [Google Scholar] [CrossRef]

- Seo, J.W.; Hur, H.M.; Kwon, S.J. Effect of Mechanical Properties of Rail and Wheel on Wear and Rolling Contact Fatigue. Metals 2022, 12, 630. [Google Scholar] [CrossRef]

- Seo, J.-W.; Kwon, S.-J.; Jun, H.-K.; Lee, C.-W. Effects of Wheel Materials on Wear and Fatigue Damage Behaviors of Wheels/Rails. Tribol. Trans. 2019, 62, 635–649. [Google Scholar] [CrossRef]

- Zeng, D.; Qiao, S.; Chen, X.; Gong, Y.; Jiang, B.; Zhao, H.; Zhang, J.; Lu, L. Rolling Contact Fatigue and Wear Behavior of a Vanadium Microalloyed Railway Wheel Steel under Dry Rolling / Sliding Condition. Int. J. Fatigue 2024, 182, 108207. [Google Scholar] [CrossRef]

- Cao, X.; Huang, W.L.; He, C.G.; Peng, J.F.; Guo, J.; Wang, W.J.; Liu, Q.Y.; Zhu, M.H. The effect of alumina particle on improving adhesion and wear damage of wheel/rail under wet conditions. Wear 2016, 348–349, 98–115. [Google Scholar] [CrossRef]

- Viesca, J.L.; González-Cachón, S.; García, A.; González, R.; Bernardo-Sánchez, A.; Hernández Battez, A. Influence of Environmental Conditions and Oxidation on the Coefficient of Friction Using Microalloyed Rail Steels. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 235, 353–360. [Google Scholar] [CrossRef]

- Chen, H. Review of Various Influencing Factors and Improvement Measures on Wheel-Rail Adhesion. Wear 2024, in press. [Google Scholar] [CrossRef]

- Shi, L.B.; Ma, L.; Guo, J.; Liu, Q.Y.; Zhou, Z.R.; Wang, W.J. Influence of Low Temperature Environment on the Adhesion Characteristics of Wheel-Rail Contact. Tribol. Int. 2018, 127, 59–68. [Google Scholar] [CrossRef]

- Liu, C.-P.; Liu, P.-T.; Pan, J.-Z.; Chen, C.-H.; Ren, R.-M. Effect of Original Microstructure on Wear Property of ER9 Wheel Steel. Ironmak. Steelmak. 2021, 48, 133–141. [Google Scholar] [CrossRef]

- Shen, M.X.; Qin, Y.F.; Ji, D.H.; Yu, M.; Li, S.X.; Huangfu, L.; Liu, S.P. Role of Ambient Temperature in the Adhesion and Damage Characteristics of Wheel/Rail Interface during Rolling-Sliding Contact. Wear 2022, 506–507, 204458. [Google Scholar] [CrossRef]

- Nakahara, T.; Baek, K.S.; Chen, H.; Ishida, M. Relationship between Surface Oxide Layer and Transient Traction Characteristics for Two Steel Rollers under Unlubricated and Water Lubricated Conditions. Wear 2011, 271, 25–31. [Google Scholar] [CrossRef]

- Rahaman, M.L.; Bernal, E.; Spiryagin, M.; Bosomworth, C.; Sneath, B.; Wu, Q.; Cole, C.; McSweeney, T. An Investigation into the Effect of Slip Rate on the Traction Coefficient Behaviour with a Laboratory Replication of a Locomotive Wheel Rolling/Sliding along a Railway Track. Tribol. Int. 2023, 187, 108773. [Google Scholar] [CrossRef]

- Chen, M.; Zhai, W.; Sun, Y. Investigation on effect of wheel polygonal wear on high-speed vehicle-track-subgrade interaction based on green function method. In Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems, Delft, The Netherlands, 27–28 September 2018; pp. 147–154. [Google Scholar]

- Shi, M.; Li, W.; Wu, M.; Shen, G. Analysis of Out-of-Round Wheels and the Effect of Wheel Polygonalization on Vehicle Vibration. In Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems, Delft, The Netherlands, 27–28 September 2018; pp. 856–861. [Google Scholar]

- Fu, B.; Bruni, S.; Luo, S. Numerical simulation for polygonal wear of railway wheels. In Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems, Delft, The Netherlands, 27–28 September 2018; pp. 271–280. [Google Scholar]

- Niu, Z.; Pang, F.; Zhang, X.; Du, T.; Su, J. Study on the Influence of Wheel Polygon on the Vibration Characteristics of Bogie System. Vib. Proced. 2022, 44, 47–53. [Google Scholar] [CrossRef]

- Ye, Y.; Zhu, B.; Huang, P.; Peng, B. OORNet: A Deep Learning Model for on-Board Condition Monitoring and Fault Diagnosis of out-of-Round Wheels of High-Speed Trains. Meas. J. Int. Meas. Confed. 2022, 199, 111268. [Google Scholar] [CrossRef]

- Ding, H.; Mu, X.; Zhu, Y.; Yang, W.; Xiao, Q.; Wang, W.; Liu, Q.; Guo, J.; Zhou, Z. Effect of Laser Claddings of Fe-Based Alloy Powder with Different Concentrations of WS2 on the Mechanical and Tribological Properties of Railway Wheel. Wear 2022, 488–489, 204174. [Google Scholar] [CrossRef]

- Lewis, S.R.; Lewis, R.; Fletcher, D.I. Assessment of Laser Cladding as an Option for Repairing/Enhancing Rails. Wear 2015, 330–331, 581–591. [Google Scholar] [CrossRef]

- Wang, X.; Lei, L.; Yu, H. A Review on Microstructural Features and Mechanical Properties of Wheels/Rails Cladded by Laser Cladding. Micromachines 2021, 12, 152. [Google Scholar] [CrossRef]

- Lu, P.; Lewis, S.R.; Fretwell-Smith, S.; Engelberg, D.L.; Fletcher, D.I.; Lewis, R. Laser Cladding of Rail; the Effects of Depositing Material on Lower Rail Grades. Wear 2019, 438–439, 203045. [Google Scholar] [CrossRef]

- Roy, T.; Lai, Q.; Abrahams, R.; Mutton, P.; Paradowska, A.; Soodi, M.; Yan, W. Effect of Deposition Material and Heat Treatment on Wear and Rolling Contact Fatigue of Laser Cladded Rails. Wear 2018, 412–413, 69–81. [Google Scholar] [CrossRef]

- Ekberg, A.; Åkesson, B.; Kabo, E. Wheel/rail rolling contact fatigue—Probe, predict, prevent. Wear 2014, 314, 2–12. [Google Scholar] [CrossRef]

- Ghidini, A.; Diener, M.; Mazzù, A.; Zani, N.; Petrogalli, C.; Faccoli, M. Considerations about Microstructure of Solid Wheels with Traces of Bainite Considerazioni Sulla Microstruttura Di Ruote Monoblocco Con Tracce Di Bainite. Ing. Ferrov. 2019, 75, 162–178. [Google Scholar]

- Akama, M.; Kimata, T. Numerical Simulation Model for the Competition between Short Crack Propagation and Wear in the Wheel Tread. Wear 2020, 448–449, 203205. [Google Scholar] [CrossRef]

- Wang, H.H.; Wang, W.J.; Han, Z.Y.; Wang, Y.; Ding, H.H.; Lewis, R.; Lin, Q.; Liu, Q.Y.; Zhou, Z.R. Wear and Rolling Contact Fatigue Competition Mechanism of Different Types of Rail Steels under Various Slip Ratios. Wear 2023, 522, 204721. [Google Scholar] [CrossRef]

- Magel, E.; Mutton, P.; Ekberg, A.; Kapoor, A. Rolling Contact Fatigue, Wear and Broken Rail Derailments. Wear 2016, 366–367, 249–257. [Google Scholar] [CrossRef]

- Bolton, P.J.; Clayton, P. Rolling-sliding wear damage in rail and tyre steels. Wear 1984, 93, 145–165. [Google Scholar] [CrossRef]

- Lewis, R.; Olofsson, U. Mapping rail wear regimes and transitions. Wear 2004, 257, 721–729. [Google Scholar] [CrossRef]

- Beagley, T.M. Severe wear of rolling/sliding contacts. Wear 1976, 36, 317–335. [Google Scholar] [CrossRef]

- Zakharov, S.; Komarovsky, I.; Zharov, I. Wheel flange/rail head wear simulation. Wear 1998, 215, 18–24. [Google Scholar] [CrossRef]

- Danks, D.; Clayton, P. Comparison of the wear process for eutectoid rail steels: Field and laboratory tests. Wear 1987, 120, 233–250. [Google Scholar] [CrossRef]

- Ding, H.H.; He, C.G.; Ma, L.; Guo, J.; Liu, Q.Y.; Wang, W.J. Wear Mapping and Transitions in Wheel and Rail Materials under Different Contact Pressure and Sliding Velocity Conditions. Wear 2016, 352–353, 1–8. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, W.; Guo, J.; An, B.; Chen, R.; Wu, Q.; Bernal, E.; Ding, H.; Spiryagin, M. Rail Rolling Contact Fatigue Response Diagram Construction and Shakedown Map Optimization. Wear 2023, 528–529, 204964. [Google Scholar] [CrossRef]

- Zhu, W.T.; Guo, L.C.; Shi, L.B.; Cai, Z.B.; Li, Q.L.; Liu, Q.Y.; Wang, W.J. Wear and Damage Transitions of Two Kinds of Wheel Materials in the Rolling-Sliding Contact. Wear 2018, 398–399, 79–89. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, W.J.; Hu, Y.; Marconi, S.; Meli, E.; Ding, H.H.; Liu, Q.Y.; Guo, J.; Rindi, A. Study on the Wear and Damage Behaviors of Hypereutectoid Rail Steel in Low Temperature Environment. Wear 2020, 456–457, 203365. [Google Scholar] [CrossRef]

- Zapata, D.; Jaramillo, J.; Toro, A. Rolling Contact and Adhesive Wear of Bainitic and Pearlitic Steels in Low Load Regime. Wear 2011, 271, 393–399. [Google Scholar] [CrossRef]

- Ashby, M.F.; Lim, S.C. Wear-mechanism maps. Scr. Metall. Mater. 1990, 24, 805–810. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Makino, T.; Kato, T.; Hirakawa, K. The effect of slip ratio on the rolling contact fatigue property of railway wheel steel. Int. J. Fatigue 2012, 36, 68–79. [Google Scholar] [CrossRef]

- Vakkalagadda, M.R.K.; Vineesh, K.P. Causes and Failure Forms of Railway Wheels. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Ancellotti, S.; Benedetti, M.; Dallago, M.; Fontanari, V. Fluid Pressurization and Entrapment Effects on the SIFs of Cracks Produced under Lubricated Rolling-Sliding Contact Fatigue. Procedia Struct. Integr. 2016, 2, 3098–3108. [Google Scholar] [CrossRef]

- Zani, N.; Ekh, M.; Ekberg, A.; Mazzù, A. Application of a semianalytical strain assessment and multiaxial fatigue analysis to compare rolling contact fatigue in twin-disk and full-scale wheel/rail contact conditions. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 222–238. [Google Scholar] [CrossRef]

- Beretta, S.; Donzella, G.; Roberti, R.; Ghidini, A. Contact fatigue propagation of deep defects in railway wheels. In Proceedings of the 13th European Conference on Fracture-ECF13, CD-ROM, San Sebastian, Spain, 6–9 September 2000; Elsevier: Oxford, UK, 2000; pp. 147–154. [Google Scholar]

- Kato, T.; Fujimura, T.; Yamamoto, Y.; Dedmon, S.; Hiramatsu, S.; Kato, H.; Kimura, Y.; Pilch, J. Critical Internal Defect Size for Subsurface Crack Initiation in Heavy Haul Car Wheels. Wear 2019, 438–439, 203038. [Google Scholar] [CrossRef]

- Zeng, D.; Lu, L.; Zhang, J.; Jin, X.; Zhu, M. Effect of Micro-Inclusions on Subsurface-Initiated Rolling Contact Fatigue of a Railway Wheel. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 544–553. [Google Scholar] [CrossRef]

- Zeng, D.; Xu, T.; Wang, J.; Lu, L.; Meng, W.; Jiang, B.; Zou, Q. Investigation of the Crack Initiation of Subsurface Rolling Contact Fatigue in Railway Wheels. Int. J. Fatigue 2020, 130, 105281. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Lewis, R.; Olofsson, U. Wheel-Rail Interface Handbook; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Foletti, S.; Desimone, H.J. Application of Shakedown Maps under Variable Loads. Eng. Fract. Mech. 2007, 74, 527–538. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Q.; Spiryagin, M.; Wu, Q.; Ding, H.; Wen, Z.; Wang, W. Gaps, Challenges and Possible Solution for Prediction of Wheel–Rail Rolling Contact Fatigue Crack Initiation. Railw. Eng. Sci. 2023, 31, 207–232. [Google Scholar] [CrossRef]

- Salas Vicente, F.; Pascual Guillamón, M. Use of the fatigue index to study rolling contact wear. Wear 2019, 436–437, 203036. [Google Scholar] [CrossRef]

- Zani, N.; Petrogalli, C. Predictive maps for the rolling contact fatigue and wear interaction in railway wheel steels. Wear 2022, 510–511, 204513. [Google Scholar] [CrossRef]

- M-107/208; AAR Manual of Standards and Recommended Practices Wheels and Axls. American Association of Railroads: Washington, DC, USA, 2011.

- Ghidini, A.; Faccoli, M.; Mazzù, A. SANDLOS® Wheels for Desert Environments; Lucchini RS: Lovere, BG, Italy, 2017. [Google Scholar]

- EN 13262; Railway Applications—Wheelsets and Bogies-Wheels-Product Requirements. European Committee for Standardization: Brussels, Belgium, 2011.

- Ghidini, A.; Diener, M.; Gianni, A.; Schneider, J. SUPERLOS® Innovative Steel by Lucchini RS for High-Speed Wheel Application; Lucchini RS: Lovere, BG, Italy, 2017. [Google Scholar]

- EN 13674-1; Railway Applications—Track—Rail—Part 1: Vignole Railway Rails 46 kg/m and above; Norm. CEN, European Committee for Standardization: Brussels, Belgium, 2011.

- UNI EN 13925-2; Non-Destructive Testing—X-Ray Diffraction from Polycrystalline and Amorphous Materials—Part 2: Procedures. Ente Nazionale Italiano di Normazione: Milan, Italy, 2006.

- Santa, J.F.; Cuervo, P.; Christoforou, P.; Harmon, M.; Beagles, A.; Toro, A.; Lewis, R. Twin Disc Assessment of Wear Regime Transitions and Rolling Contact Fatigue in R400HT—E8 Pairs. Wear 2019, 432–433, 102916. [Google Scholar] [CrossRef]

- Bodini, I.; Zani, N.; Petrogalli, C.; Mazzù, A.; Kato, T.; Makino, T. Damage Assessment in a Wheel Steel under Alternated Dry-Lubricated Contact by an Innovative Vision System. Wear 2023, 530–531, 205064. [Google Scholar] [CrossRef]

| Component | Specimen | Ref. | Monotonic Yield Stress [MPa] | Cyclic Yield Stress [MPa] | HB |

|---|---|---|---|---|---|

| Wheel | R7T | [3] | 420 | 350 | 247 |

| ER8 | [22,23,26] | 590–600 | 470 | 283 | |

| SUPERLOS® | [22,23] | 640 | 523 | 275 | |

| AAR CLASS B | [23] | 660 | 580 | 313 | |

| AAR CLASS C | [26] | 750 | 640 | 355 | |

| SANDLOS®H | [26] | 800 | 720 | 354 | |

| Rail | 350 HT | [26] | 470 | 390 | 300–350 |

| 900A | [3,22,23] |

| Wheel Specimen | Pressure [MPa] | Slip Ratio [%] |

|---|---|---|

| R7T | 700 | 0.06 (C), 0 (W) |

| 900 | 0 (C, W), 0.03 (C), 0.06 (C, W) | |

| 1100 | 0 (C, W), 0.03 (C), 0.06 (W) | |

| 1300 | 0.01 (C) | |

| ER8 | 900 | 0 (C), 1 (C), 3 (C) |

| 1100 | 0 (C), 0.24 (W), 1 (C, W), 3 (C) | |

| 1300 | 0 (C), 1 (C), 3 (C) | |

| SUPERLOS® | 1100 | 0.24 (W), 1 (C, W) |

| CLASS B | 900 | 0 (C), 1 (C), 3 (C) |

| 1100 | 0 (C), 0.24 (W), 1 (C, W) | |

| 1300 | 0 (C), 1 (C) | |

| CLASS C | 900 | 0.5 (C), 1 (C), 3 (C) |

| SANDLOS® H | 900 | 1 (C), 3 (C) |

| 1100 | 1 (C), 3 (C) | |

| 1300 | 0 (C), 1 (C), 3 (C) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zani, N.; Mazzù, A.; Solazzi, L.; Petrogalli, C. Examining Wear Mechanisms in Railway Wheel Steels: Experimental Insights and Predictive Mapping. Lubricants 2024, 12, 93. https://doi.org/10.3390/lubricants12030093

Zani N, Mazzù A, Solazzi L, Petrogalli C. Examining Wear Mechanisms in Railway Wheel Steels: Experimental Insights and Predictive Mapping. Lubricants. 2024; 12(3):93. https://doi.org/10.3390/lubricants12030093

Chicago/Turabian StyleZani, Nicola, Angelo Mazzù, Luigi Solazzi, and Candida Petrogalli. 2024. "Examining Wear Mechanisms in Railway Wheel Steels: Experimental Insights and Predictive Mapping" Lubricants 12, no. 3: 93. https://doi.org/10.3390/lubricants12030093

APA StyleZani, N., Mazzù, A., Solazzi, L., & Petrogalli, C. (2024). Examining Wear Mechanisms in Railway Wheel Steels: Experimental Insights and Predictive Mapping. Lubricants, 12(3), 93. https://doi.org/10.3390/lubricants12030093