Machine Learning-Based Predictive Model to Assess Rheological Dynamics of Eco-Friendly Oils as Biolubricants Enriched with SiO2 Nanoparticles

Abstract

1. Introduction

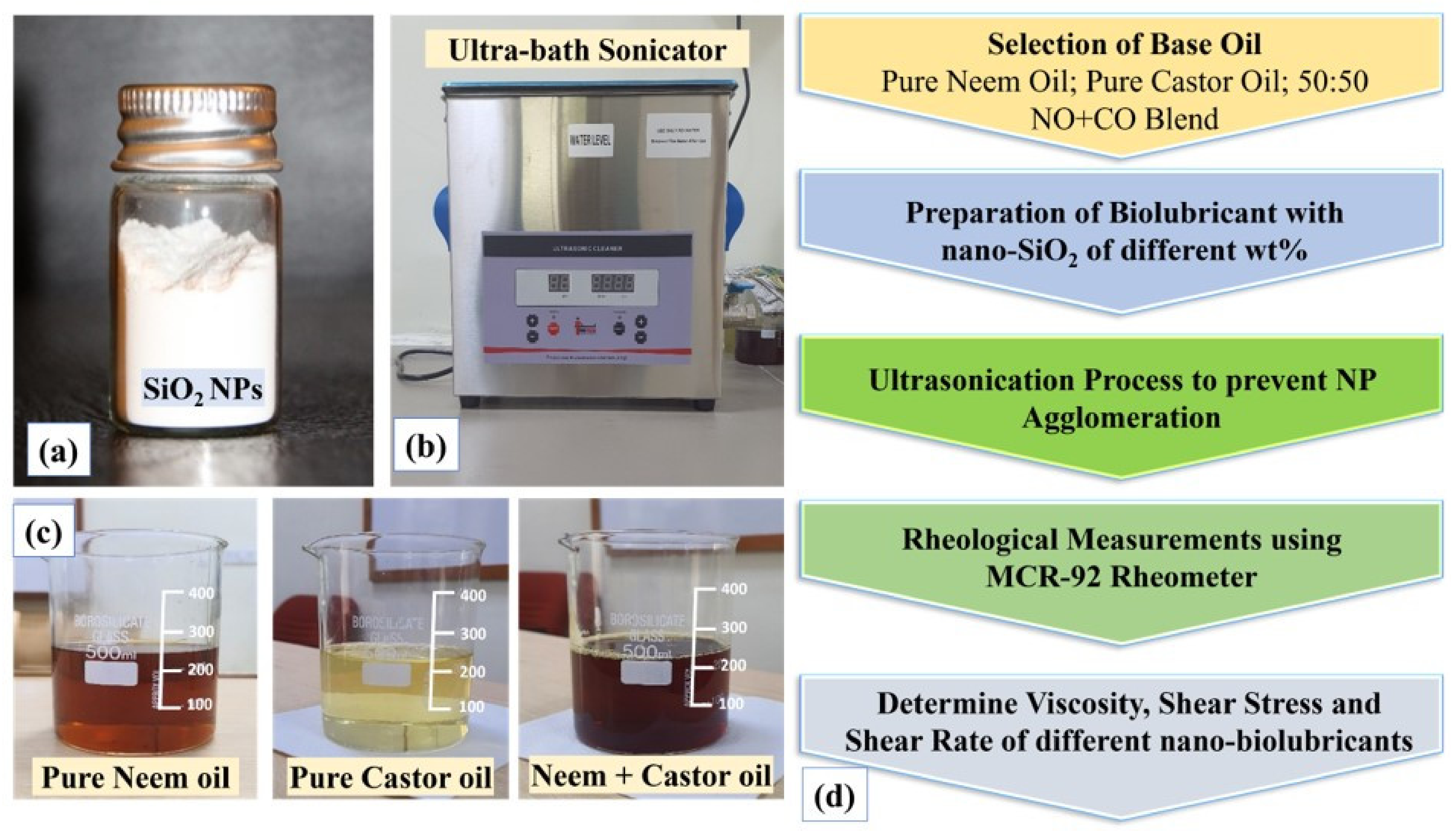

2. Materials and Methods

2.1. SiO2 Nanoparticles Selection

2.2. Selection of Biolubricants

2.3. Preparation of SiO2-Enriched Nanobiolubricants

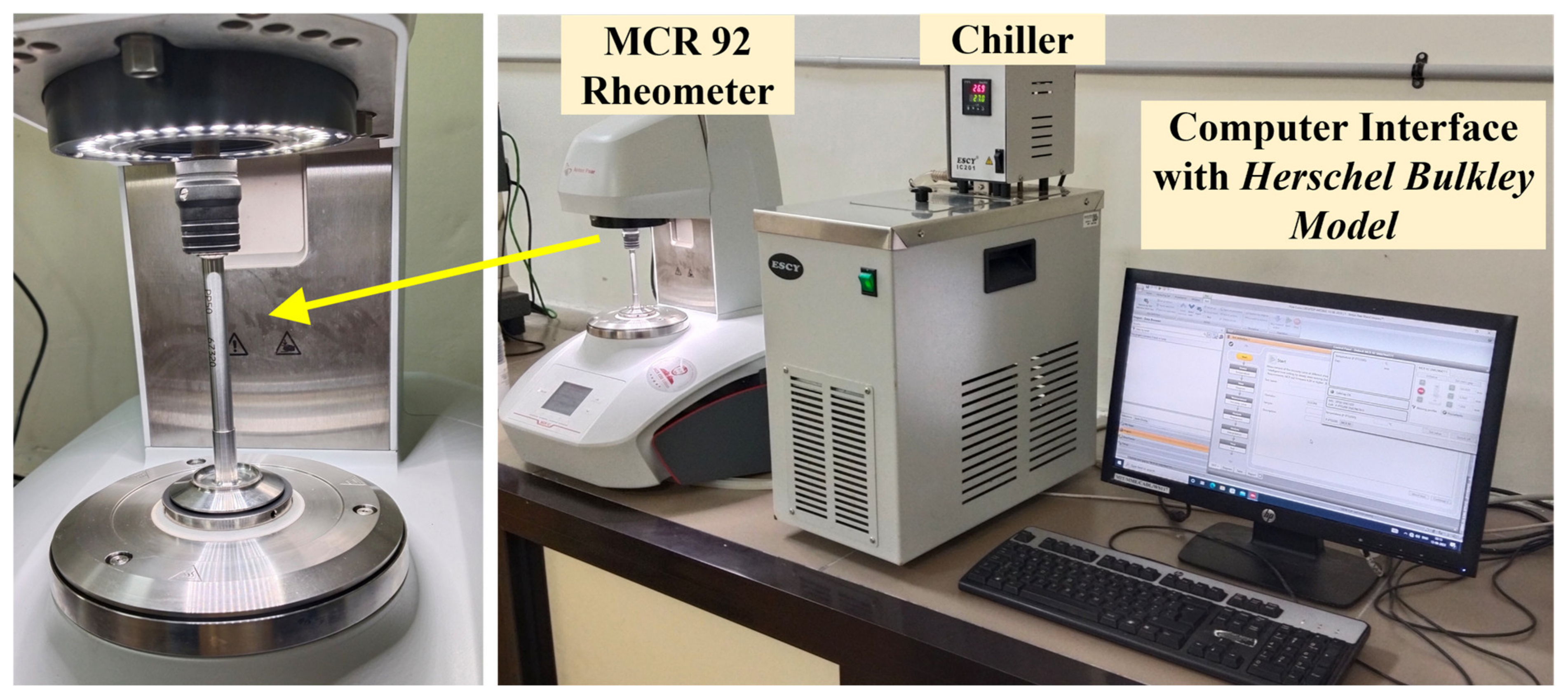

2.4. Rheological Measurements

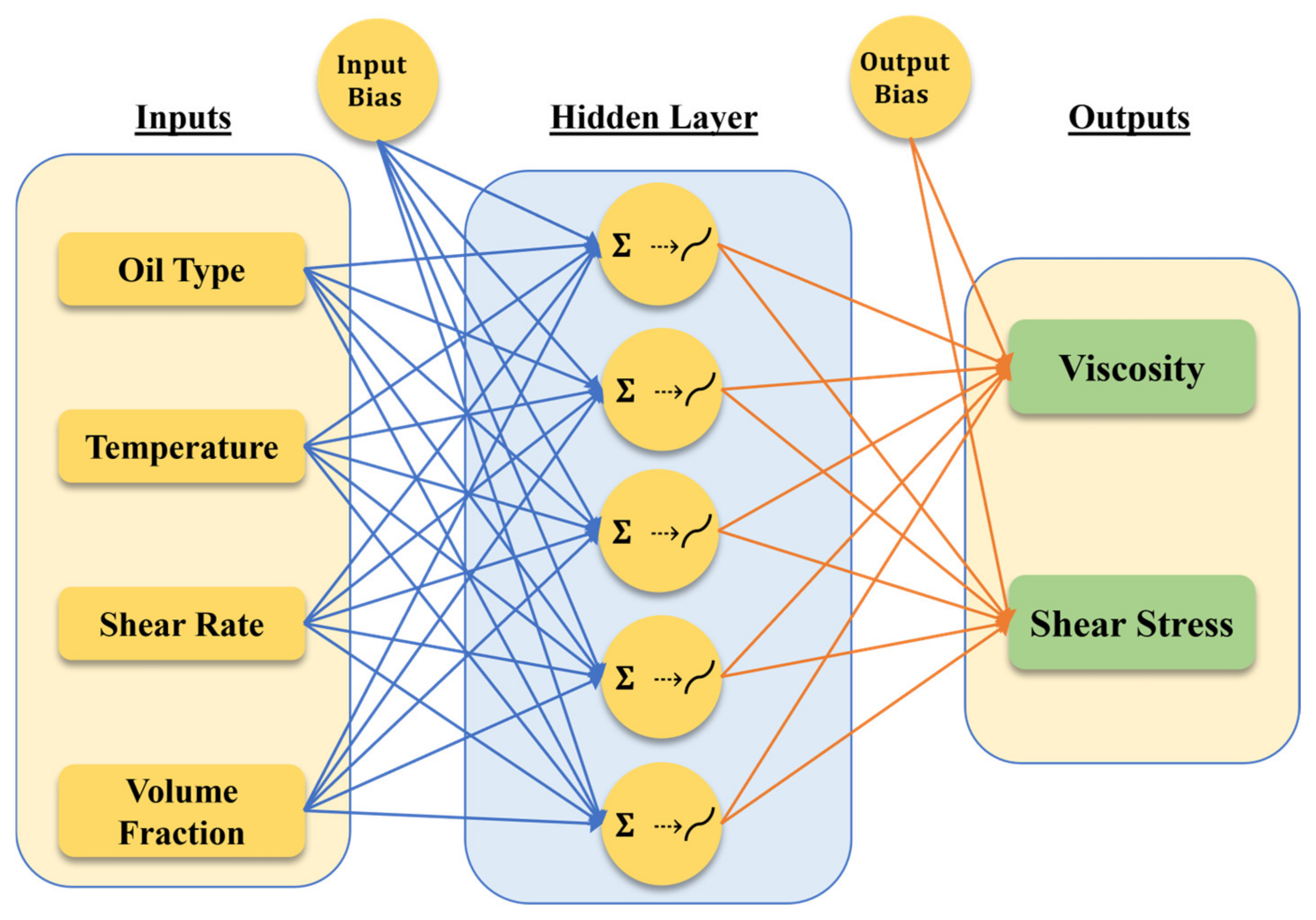

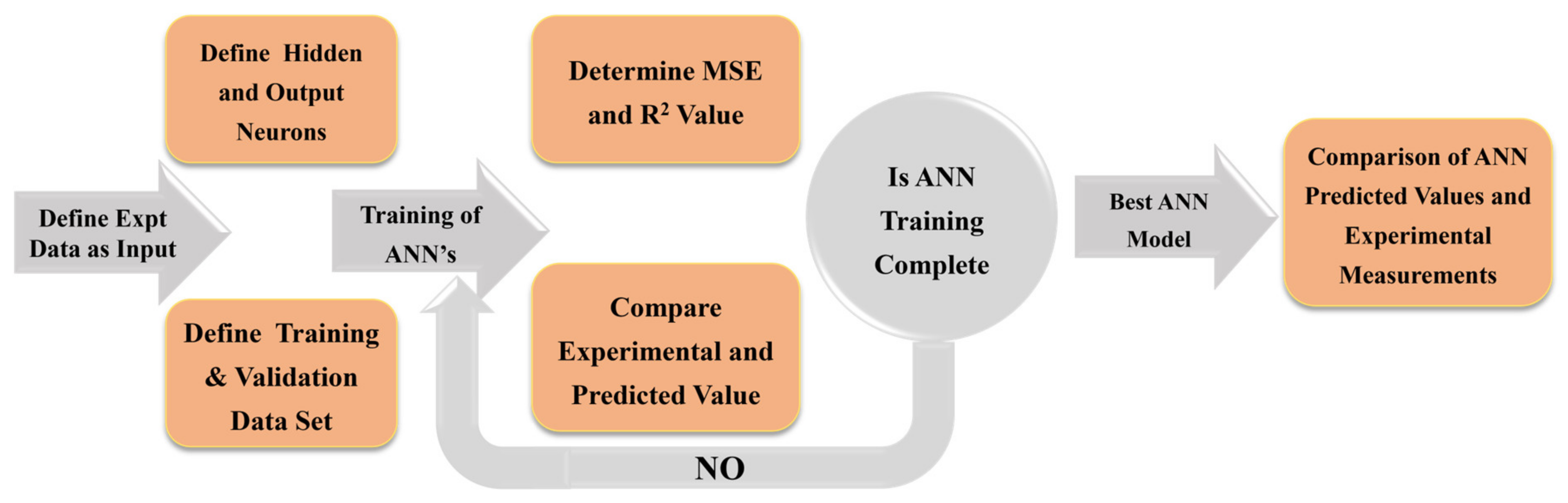

3. ANN Development and Optimization

Prediction Model Using ANN

4. Results

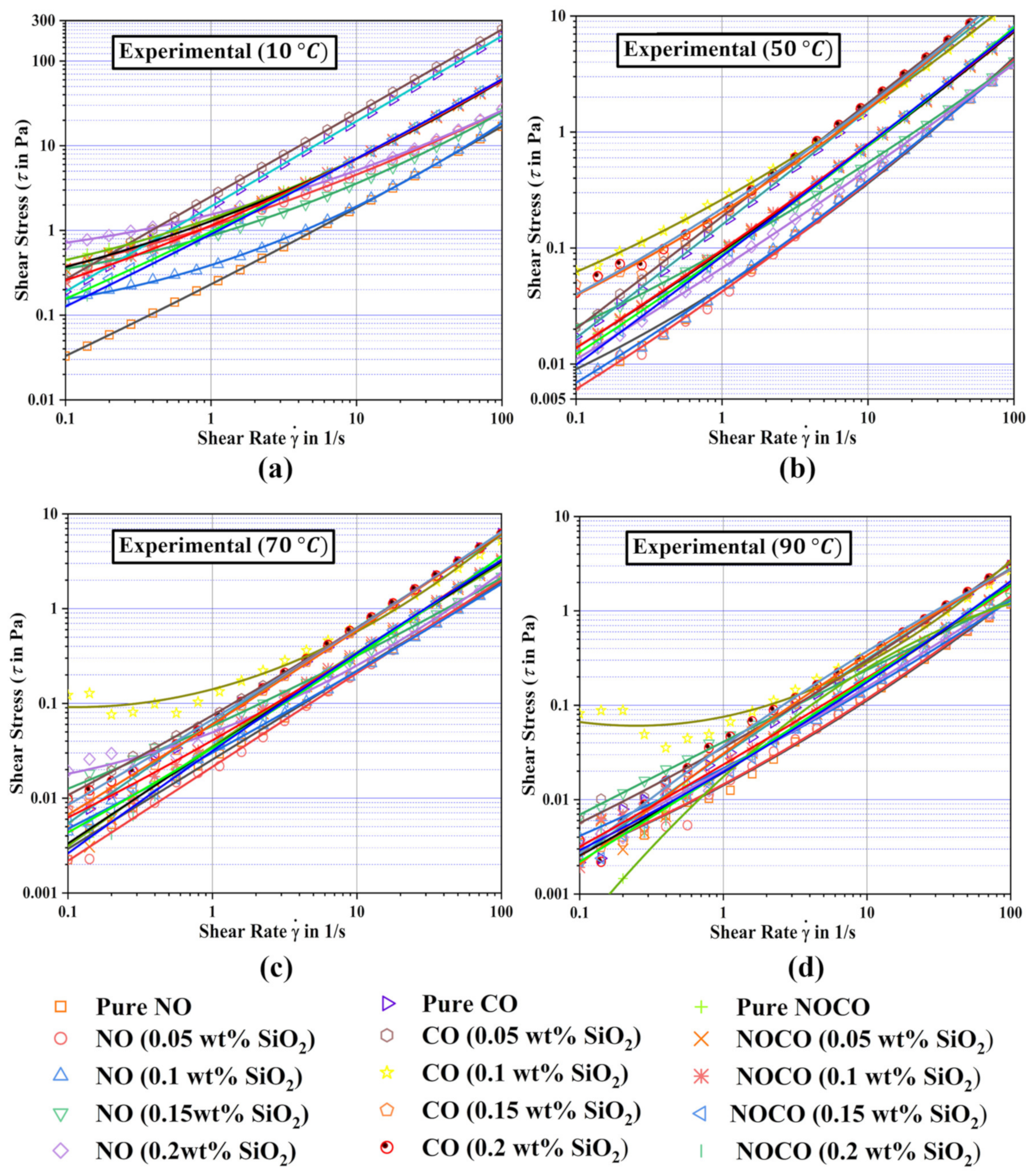

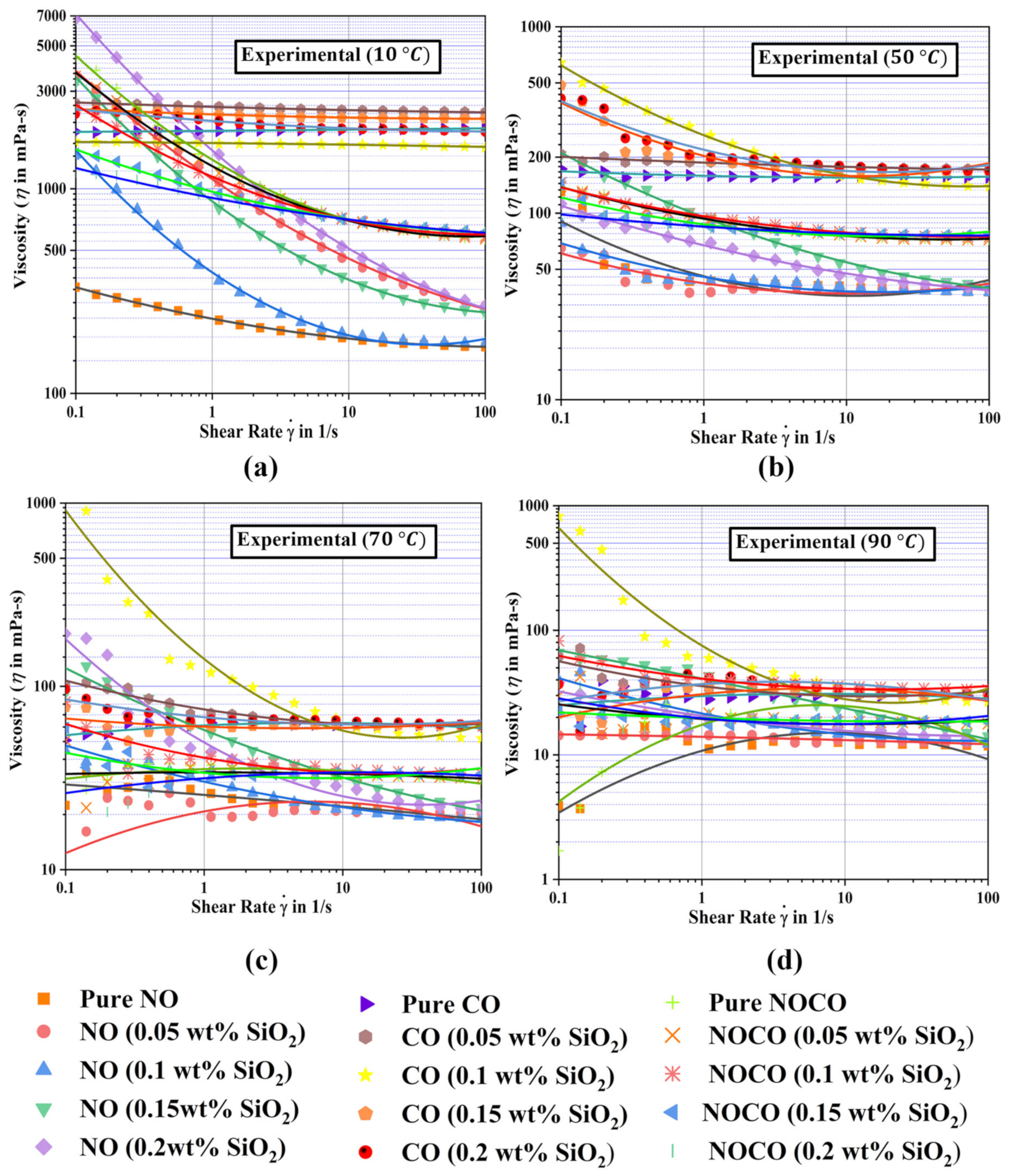

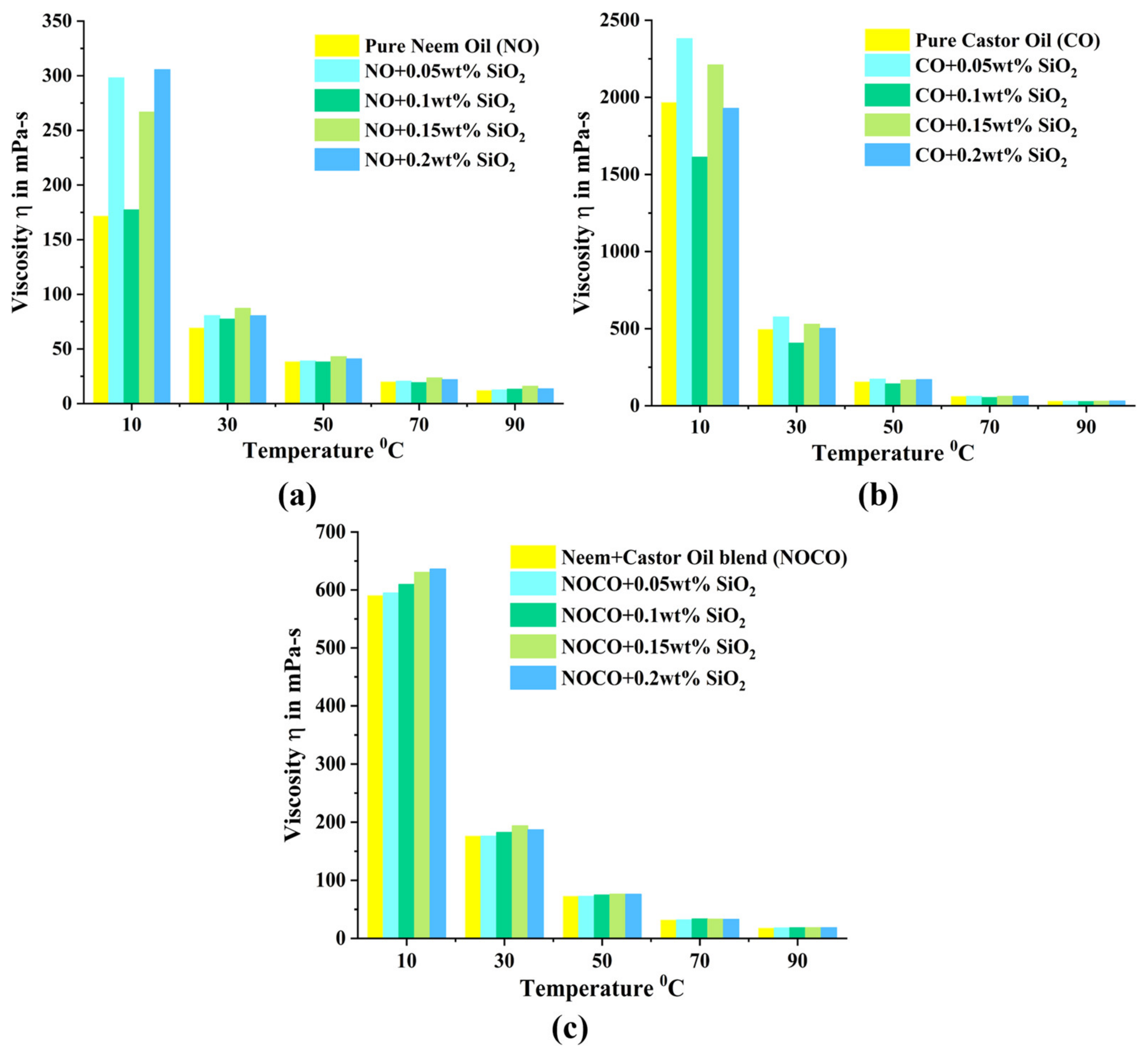

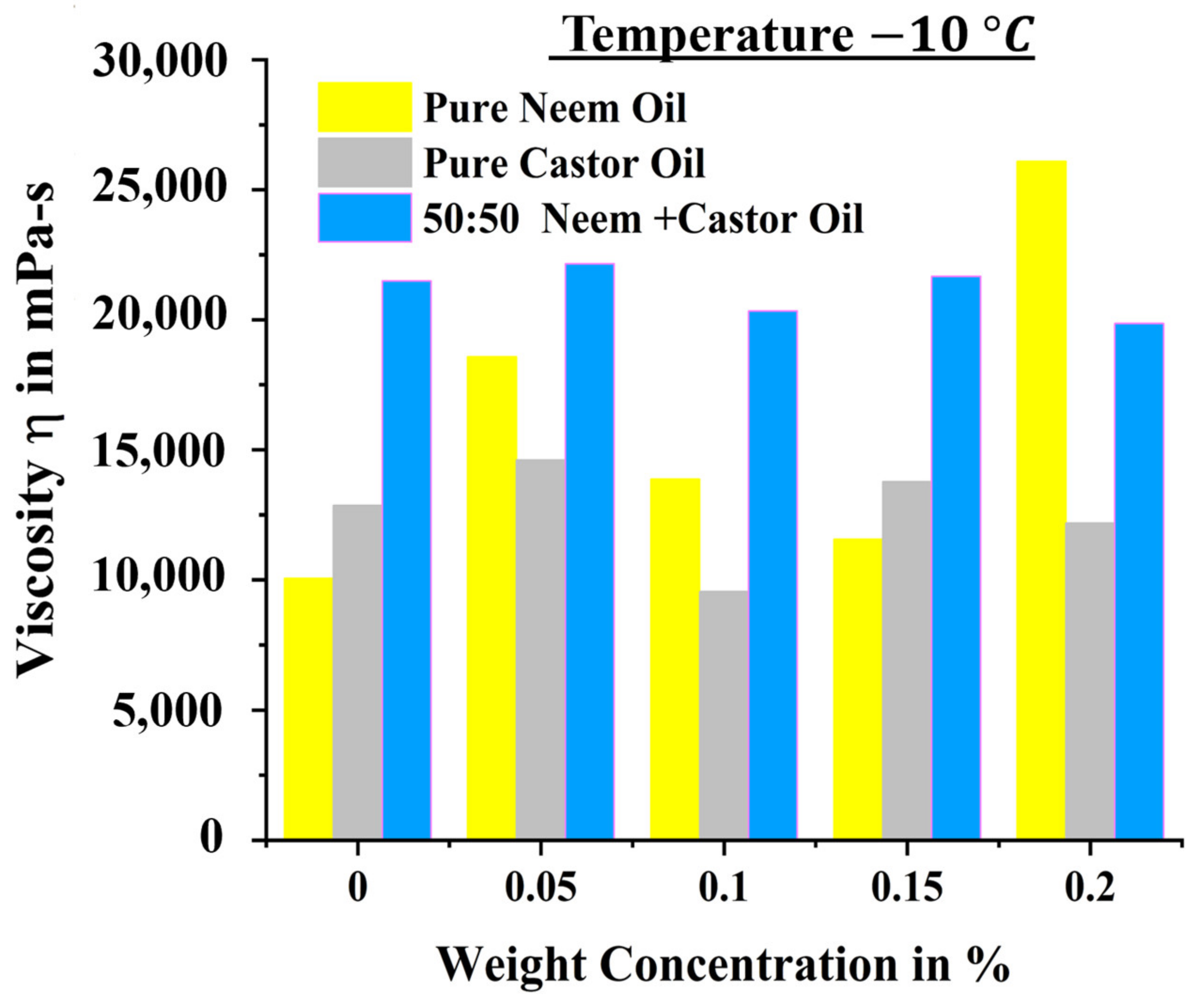

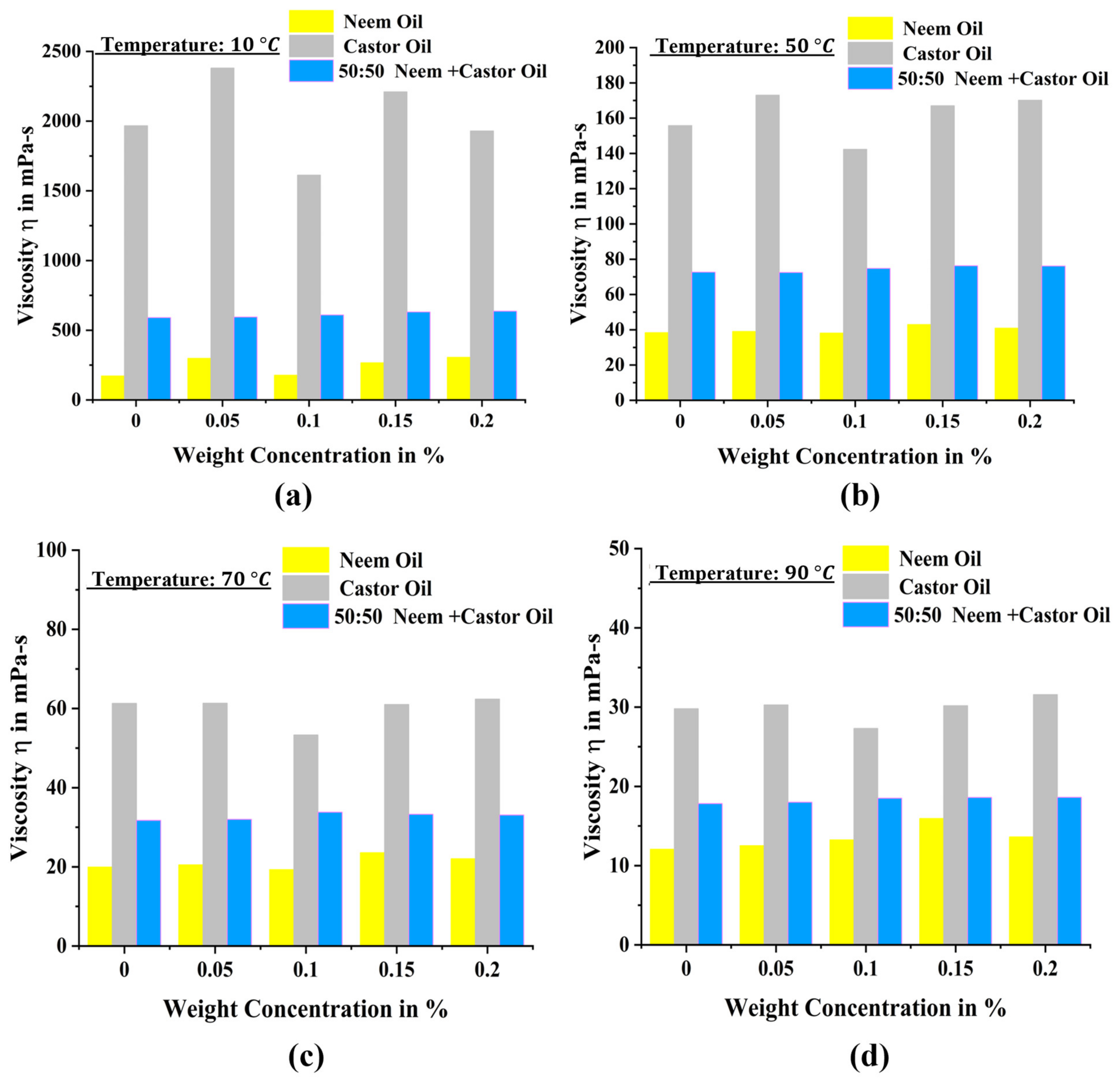

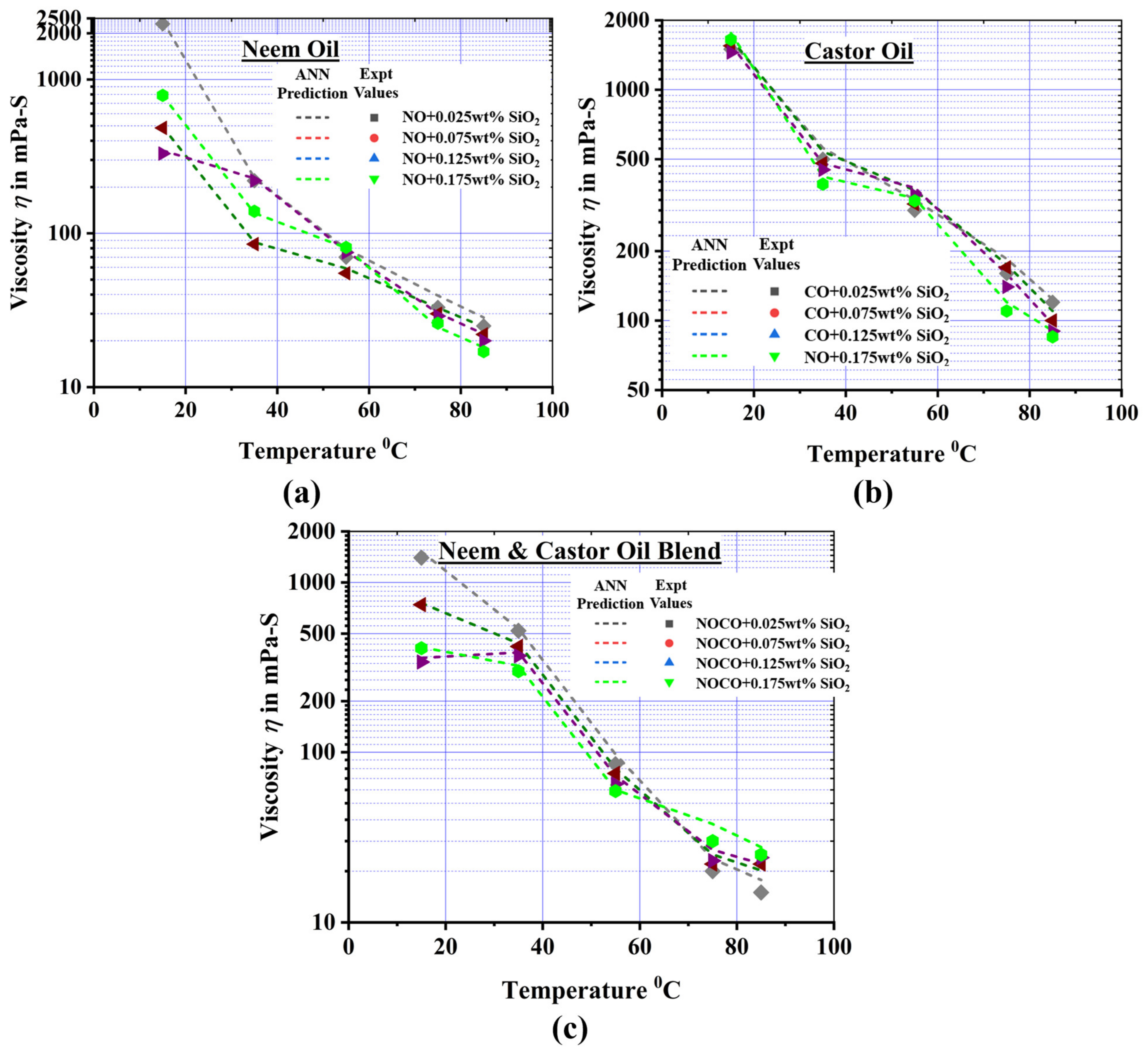

4.1. Rheological Analysis of Lubricant

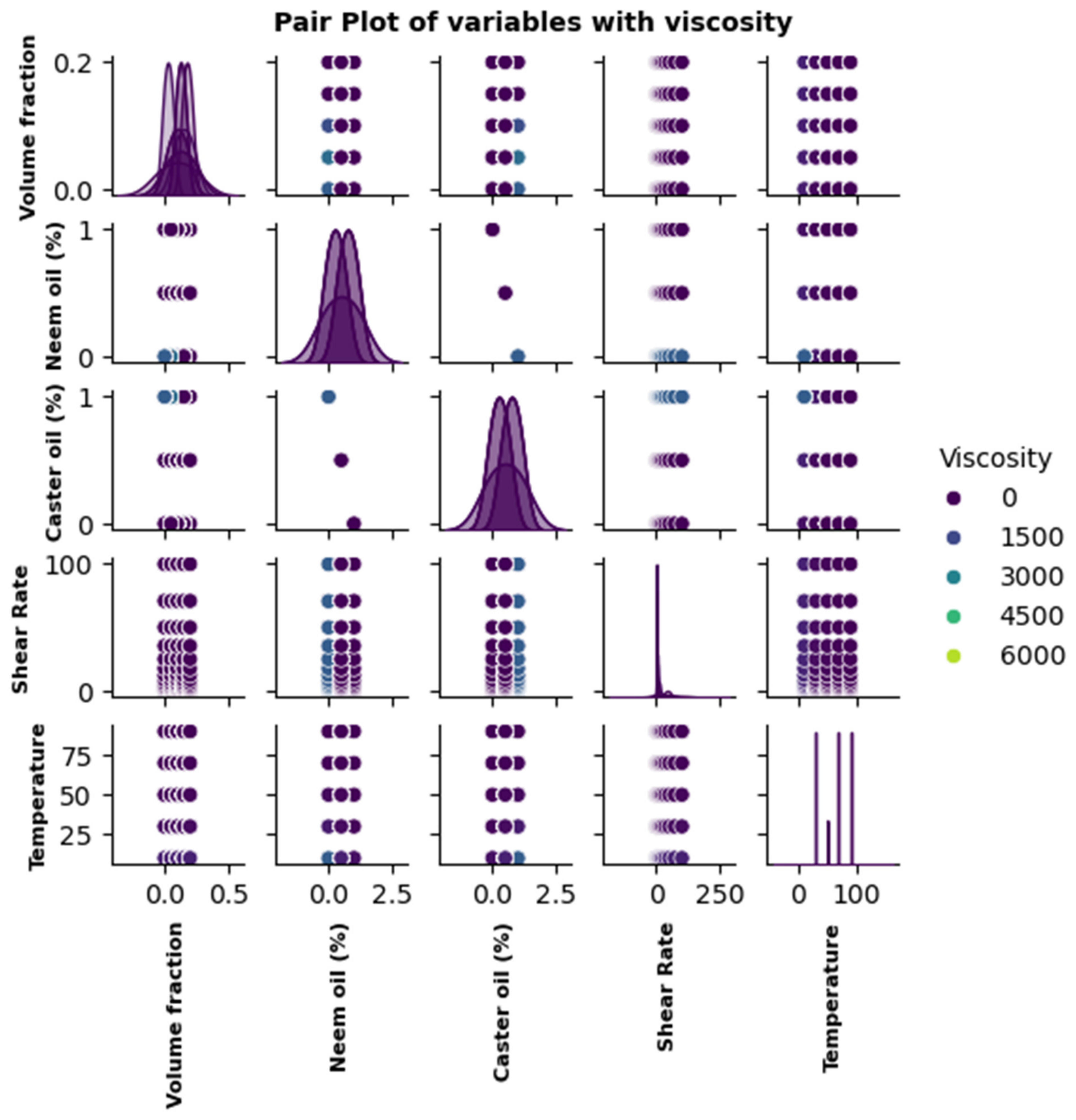

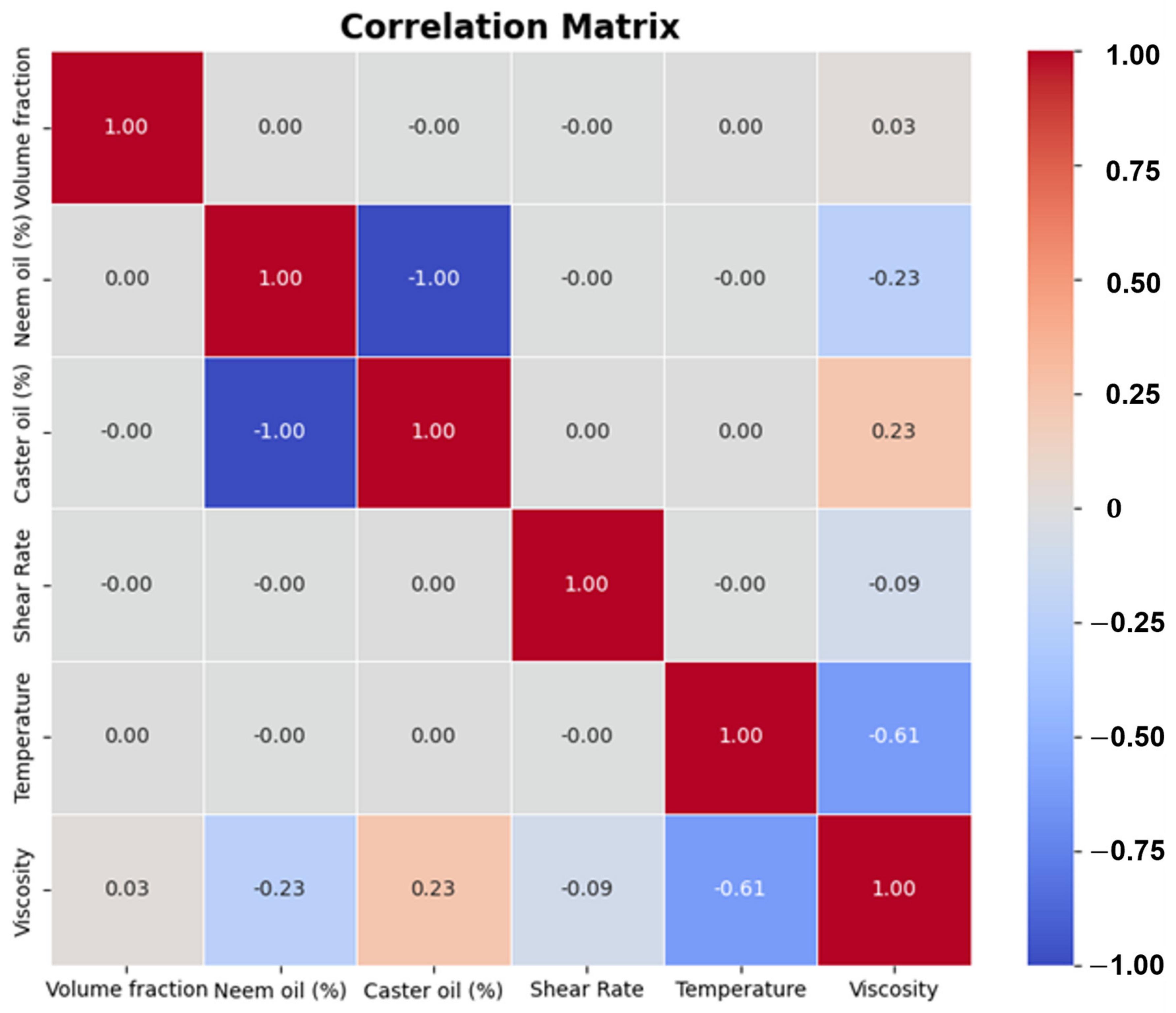

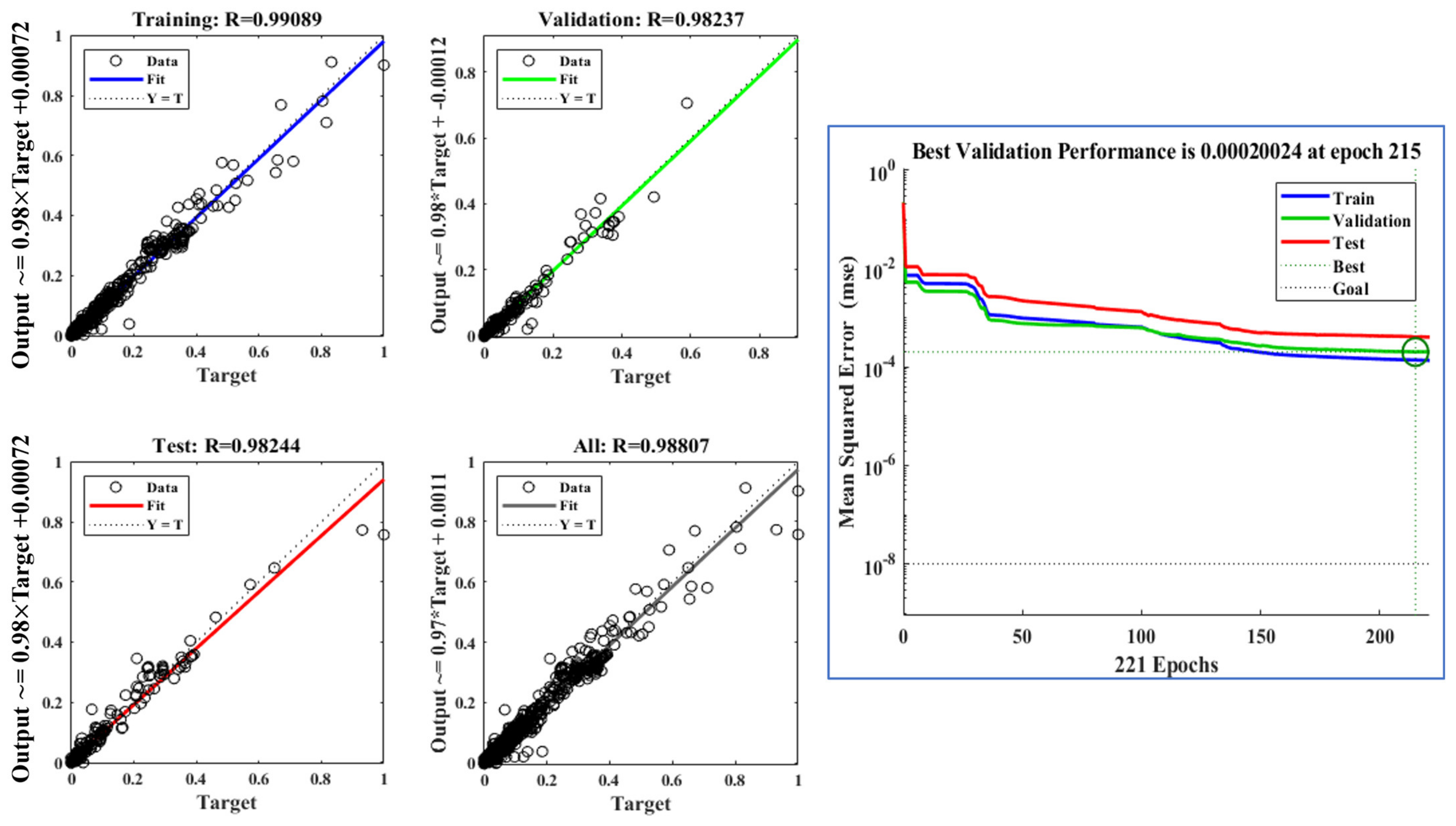

4.2. Performance Prediction Model and Output Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kreivaitis, R.; Gumbytė, M.; Kazancev, K.; Padgurskas, J.; Makarevičienė, V. A Comparison of Pure and Natural Antioxidant Modified Rapeseed Oil Storage Properties. Ind. Crops Prod. 2013, 43, 511–516. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, L.; Tian, M. Influence of Bio-Lubricants on the Tribological Properties of Ti6Al4V Alloy. J. Bionic Eng. 2013, 10, 84–89. [Google Scholar] [CrossRef]

- Ting, C.-C.; Chen, C.-C. Viscosity and Working Efficiency Analysis of Soybean Oil Based Bio-Lubricants. Measurement 2011, 44, 1337–1341. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Ren, T.; Zeng, X.; van der Heide, E. Hydrolytic Stability and Tribological Properties of N-Containing Heterocyclic Borate Esters as Lubricant Additives in Rapeseed Oil. Tribol. Int. 2014, 73, 101–107. [Google Scholar] [CrossRef]

- Cheenkachorn, K.; Fungtammasan, B. Development of Engine Oil Using Palm Oil as a Base Stock for Four-Stroke Engines. Energy 2010, 35, 2552–2556. [Google Scholar] [CrossRef]

- Dugmore, T.I.J.; Stark, M.S. Effect of Biodiesel on the Autoxidation of Lubricant Base Fluids. Fuel 2014, 124, 91–96. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of Soybean Biodiesel on a DI Diesel Engine Performance, Emission and Combustion Characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Franco, J.M.; Spikes, H.A.; Gallegos, C. Low-Temperature Flow Behaviour of Vegetable Oil-Based Lubricants. Ind. Crops Prod. 2012, 37, 383–388. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-Containing Nanomaterials as Lubricant Additives: State-of-the-Art and Future Development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Sankaranarayanan, V.; Ramaprabhu, S. Graphene-Based Engine Oil Nanofluids for Tribological Applications. ACS Appl. Mater. Interfaces 2011, 3, 4221–4227. [Google Scholar] [CrossRef]

- Yi, M.; Zhang, C. The Synthesis of MoS2 Particles with Different Morphologies for Tribological Applications. Tribol. Int. 2017, 116, 285–294. [Google Scholar] [CrossRef]

- Hu, K.H.; Hu, X.G.; Xu, Y.F.; Huang, F.; Liu, J.S. The Effect of Morphology on the Tribological Properties of MoS2 in Liquid Paraffin. Tribol. Lett. 2010, 40, 155–165. [Google Scholar] [CrossRef]

- Hu, K.H.; Hu, X.G.; Wang, J.; Xu, Y.F.; Han, C.L. Tribological Properties of MoS2 with Different Morphologies in High-Density Polyethylene. Tribol. Lett. 2012, 47, 79–90. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Liu, Y.; Gunsel, S.; Luo, J. Ultrathin MoS2 Nanosheets with Superior Extreme Pressure Property as Boundary Lubricants. Sci. Rep. 2015, 5, 12869. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, Y.; Chen, Z.; Wu, B.; Xu, S.; Luo, J. Layered Double Hydroxide Nanoplatelets with Excellent Tribological Properties under High Contact Pressure as Water-Based Lubricant Additives. Sci. Rep. 2016, 6, 22748. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, Y.; Guo, F.; Sheng, H.; Xia, K.; Liu, W.; Wen, J.; Shi, Y.; Erdemir, A.; Luo, J. Catalytically Active Oil-Based Lubricant Additives Enabled by Calcining Ni–Al Layered Double Hydroxides. J. Phys. Chem. Lett. 2020, 11, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Bai, Z.; Fu, Y.; Zhao, D.; Yan, C. Tribological Properties of Serpentine, La(OH)3 and Their Composite Particles as Lubricant Additives. Wear 2012, 288, 72–77. [Google Scholar] [CrossRef]

- Zulkifli, N.W.M.; Kalam, M.A.; Masjuki, H.H.; Shahabuddin, M.; Yunus, R. Wear Prevention Characteristics of a Palm Oil-Based TMP (Trimethylolpropane) Ester as an Engine Lubricant. Energy 2013, 54, 167–173. [Google Scholar] [CrossRef]

- Zulkifli, N.W.M.; Kalam, M.A.; Masjuki, H.H.; Yunus, R. Experimental Analysis of Tribological Properties of Biolubricant with Nanoparticle Additive. Procedia Eng. 2013, 68, 152–157. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Mufti, R.A.; Zulkifli, N.W.M.; Yunus, R.; Zahid, R. Improving the AW/EP Ability of Chemically Modified Palm Oil by Adding CuO and MoS2 Nanoparticles. Tribol. Int. 2015, 88, 271–279. [Google Scholar] [CrossRef]

- Katpatal, D.C.; Andhare, A.B.; Padole, P.M. Viscosity Behaviour and Thermal Conductivity Prediction of CuO-Blend Oil Based Nano-Blended Lubricant. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 233, 1154–1168. [Google Scholar] [CrossRef]

- Katpatal, D.C.; Andhare, A.B.; Padole, P.M.; Khedkar, R.S. Study of Dispersion Stability and Thermo-Physical Properties of CuO-Jatropha Oil-Based Nanolubricants. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3657–3668. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Ahmadi, H.; Rashidi, A.; Mohtasebi, S.S.; Alaei, M. Experimental Evaluation of Engine Oil Properties Containing Copper Oxide Nanoparticles as a Nanoadditive. Int. J. Ind. Chem. 2013, 4, 28. [Google Scholar] [CrossRef]

- Moghaddam, M.A.; Motahari, K. Experimental Investigation, Sensitivity Analysis and Modeling of Rheological Behavior of MWCNT-CuO (30–70)/SAE40 Hybrid Nano-Lubricant. Appl. Therm. Eng. 2017, 123, 1419–1433. [Google Scholar] [CrossRef]

- Dhanola, A.; Garg, H.C. Dispersion Stability and Rheology Study of Canola Oil Containing TiO2 Nanoadditives for Tribological Applications: An Experimental Approach. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 1765–1781. [Google Scholar] [CrossRef]

- Dhanola, A.; Garg, H.C. Influence of Different Surfactants on the Stability and Varying Concentrations of TiO2 Nanoparticles on the Rheological Properties of Canola Oil-Based Nanolubricants. Appl. Nanosci. 2020, 10, 3617–3637. [Google Scholar] [CrossRef]

- Cortes, V.; Ortega, J.A. Evaluating the Rheological and Tribological Behaviors of Coconut Oil Modified with Nanoparticles as Lubricant Additives. Lubricants 2019, 7, 76. [Google Scholar] [CrossRef]

- Singh, Y.; Rahim, E.A.; Singh, N.K.; Sharma, A.; Singla, A.; Palamanit, A. Friction and Wear Characteristics of Chemically Modified Mahua (Madhuca Indica) Oil Based Lubricant with SiO2 Nanoparticles as Additives. Wear 2022, 508–509, 204463. [Google Scholar] [CrossRef]

- Surana, A.R.; Singh, Y.; Rajubhai, V.H.; Suthar, K.; Sharma, A. Development of Mahua Oil as a Lubricant Additive and Its Tribological Characteristics. Mater. Today Proc. 2020, 25, 724–728. [Google Scholar] [CrossRef]

- Peng, D.; Chen, C.; Kang, Y.; Chang, Y.; Chang, S. Size Effects of SiO Nanoparticles as Oil Additives on Tribology of Lubricant. Ind. Lubr. Tribol. 2010, 62, 111–120. [Google Scholar] [CrossRef]

- Mahara, M.; Singh, Y. Tribological Analysis of the Neem Oil during the Addition of SiO2 Nanoparticles at Different Loads. Mater. Today Proc. 2020, 28, 1412–1415. [Google Scholar] [CrossRef]

- Sabarinath, S.; Rajendrakumar, P.K.; Prabhakaran Nair, K. Evaluation of Tribological Properties of Sesame Oil as Biolubricant with SiO2 Nanoparticles and Imidazolium-Based Ionic Liquid as Hybrid Additives. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 1306–1317. [Google Scholar] [CrossRef]

- Shafi, W.K.; Charoo, M.S. Rheological Properties of Hazelnut Oil Mixed with Zirconium-Dioxide Nanoparticles. Mater. Today Proc. 2020, 26, 745–749. [Google Scholar] [CrossRef]

- Singh, A.; Chauhan, P.; Mamatha, T.G. A Review on Tribological Performance of Lubricants with Nanoparticles Additives. Mater. Today Proc. 2020, 25, 586–591. [Google Scholar] [CrossRef]

- Silva, R.V.S.; Casilli, A.; Sampaio, A.L.; Ávila, B.M.F.; Veloso, M.C.C.; Azevedo, D.A.; Romeiro, G.A. The Analytical Characterization of Castor Seed Cake Pyrolysis Bio-Oils by Using Comprehensive GC Coupled to Time of Flight Mass Spectrometry. J. Anal. Appl. Pyrolysis 2014, 106, 152–159. [Google Scholar] [CrossRef]

- Ganesha, A.; Girish, H.; Shilpa, M.P.; Gurumurthy, S.C.; Pai, R.; Kumar, N. Viscosity Analysis of ZnO Enriched Neem Oil Biolubricant at Sub Zero Temperatures. In Proceedings of the 2021 International Conference on Maintenance and Intelligent Asset Management (ICMIAM), Ballarat, Australia, 12–15 December 2021; pp. 1–5. [Google Scholar]

- Patel, V.R.; Dumancas, G.G.; Kasi Viswanath, L.C.; Maples, R.; Subong, B.J.J. Castor Oil: Properties, Uses, and Optimization of Processing Parameters in Commercial Production. Lipid Insights 2016, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Sun, M.; Li, Z. A Novel Prediction Model of the Drag Coefficient of Shale Cuttings in Herschel–Bulkley Fluid. Energies 2022, 15, 4496. [Google Scholar] [CrossRef]

- Saasen, A.; Ytrehus, J.D. Viscosity Models for Drilling Fluids—Herschel-Bulkley Parameters and Their Use. Energies 2020, 13, 5271. [Google Scholar] [CrossRef]

- Panaseti, P.; Damianou, Y.; Georgiou, G.C.; Housiadas, K.D. Pressure-Driven Flow of a Herschel-Bulkley Fluid with Pressure-Dependent Rheological Parameters. Phys. Fluids 2018, 30, 030701. [Google Scholar] [CrossRef]

- Bird, R.B. Transport Phenomena. Appl. Mech. Rev. 2002, 55, R1–R4. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Cimbala, J.M. Fluid Mechanics: Fundamentals and Applications, 4th ed.; McGraw-Hill Education: Columbus, OH, USA, 2017. [Google Scholar]

- Sankarannair, S.; Nair, A.A.; Bijo, B.V.; Das, H.K.; Sureshkumar, H. Biolubricant from Pongamia Oil. In Tribology in Materials and Manufacturing-Wear, Friction and Lubrication; Patnaik, A., Singh, T., Kukshal, V., Eds.; IntechOpen: Rijeka, Croatia, 2020; Chapter 11; ISBN 978-1-83880-575-3. [Google Scholar]

| Nanoparticle | SiO2 |

|---|---|

| Purity | 99.5% |

| Average particle size | 15 nm |

| Specific surface area | 650 m2/g |

| Molecular weight | 60.08 g/mol |

| Shelf life | 60 months |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hariharan, G.; Navada, M.K.; Brahmavar, J.; Aroor, G. Machine Learning-Based Predictive Model to Assess Rheological Dynamics of Eco-Friendly Oils as Biolubricants Enriched with SiO2 Nanoparticles. Lubricants 2024, 12, 92. https://doi.org/10.3390/lubricants12030092

Hariharan G, Navada MK, Brahmavar J, Aroor G. Machine Learning-Based Predictive Model to Assess Rheological Dynamics of Eco-Friendly Oils as Biolubricants Enriched with SiO2 Nanoparticles. Lubricants. 2024; 12(3):92. https://doi.org/10.3390/lubricants12030092

Chicago/Turabian StyleHariharan, Girish, Meghana Kundala Navada, Jeevan Brahmavar, and Ganesha Aroor. 2024. "Machine Learning-Based Predictive Model to Assess Rheological Dynamics of Eco-Friendly Oils as Biolubricants Enriched with SiO2 Nanoparticles" Lubricants 12, no. 3: 92. https://doi.org/10.3390/lubricants12030092

APA StyleHariharan, G., Navada, M. K., Brahmavar, J., & Aroor, G. (2024). Machine Learning-Based Predictive Model to Assess Rheological Dynamics of Eco-Friendly Oils as Biolubricants Enriched with SiO2 Nanoparticles. Lubricants, 12(3), 92. https://doi.org/10.3390/lubricants12030092