A Promising Conductive Lubricant for Space Sliding Electrical Contact: NbSe2-Ti Film

Abstract

1. Introduction

2. Experimental Details

2.1. Film Deposition

2.2. General Characterization

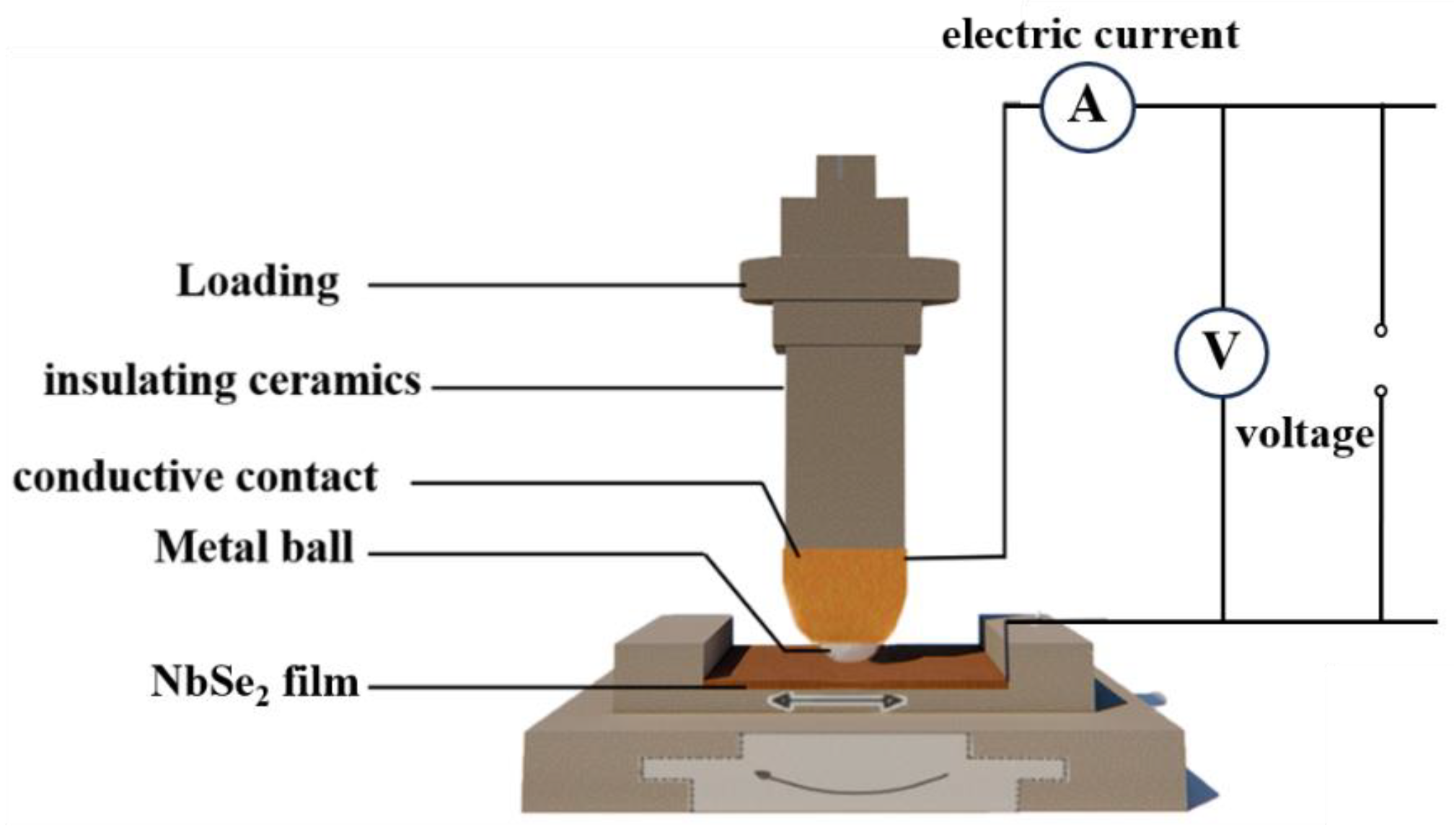

2.3. Tribological Test

3. Results and Discussion

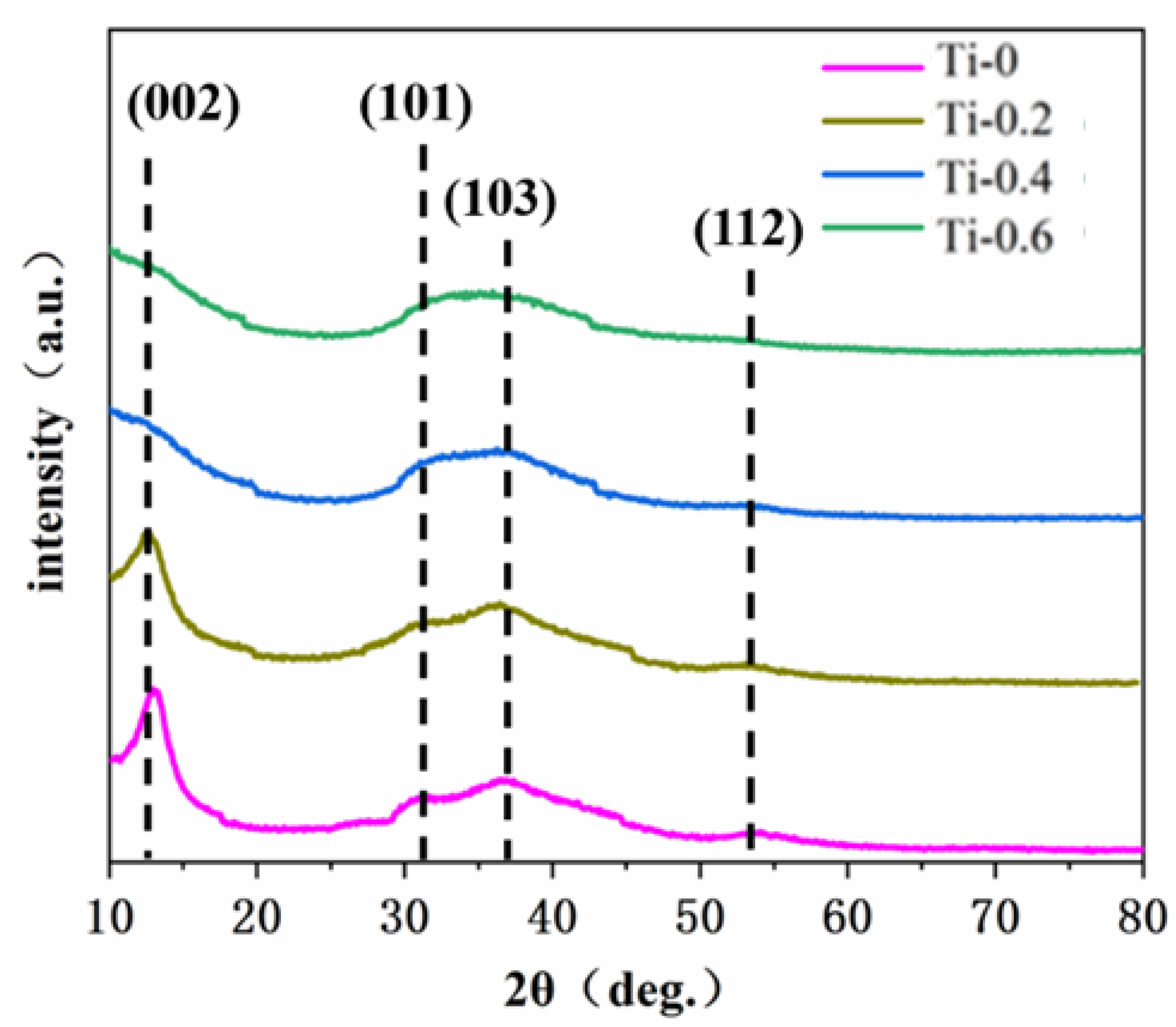

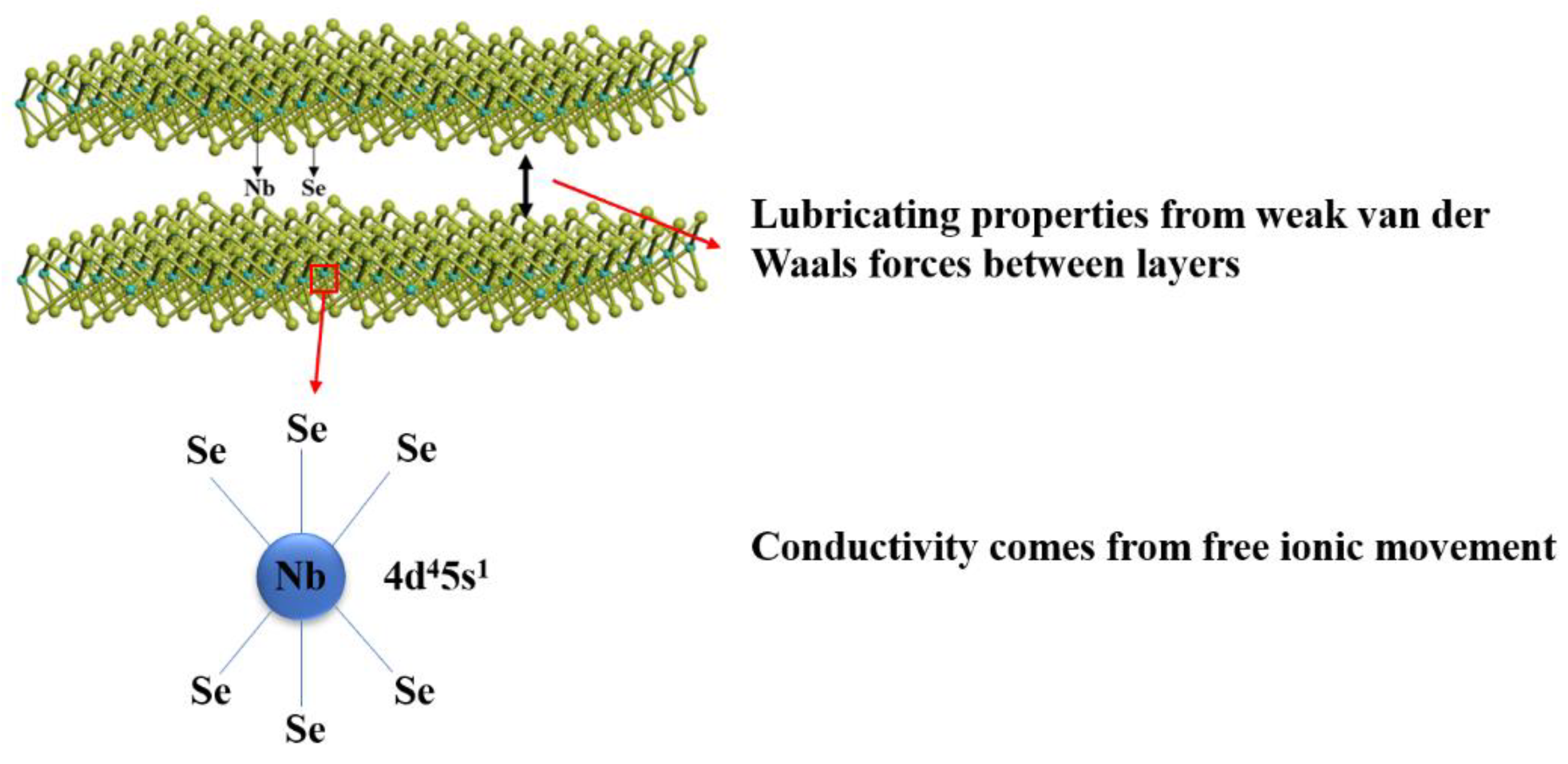

3.1. Composition and Structure of Films

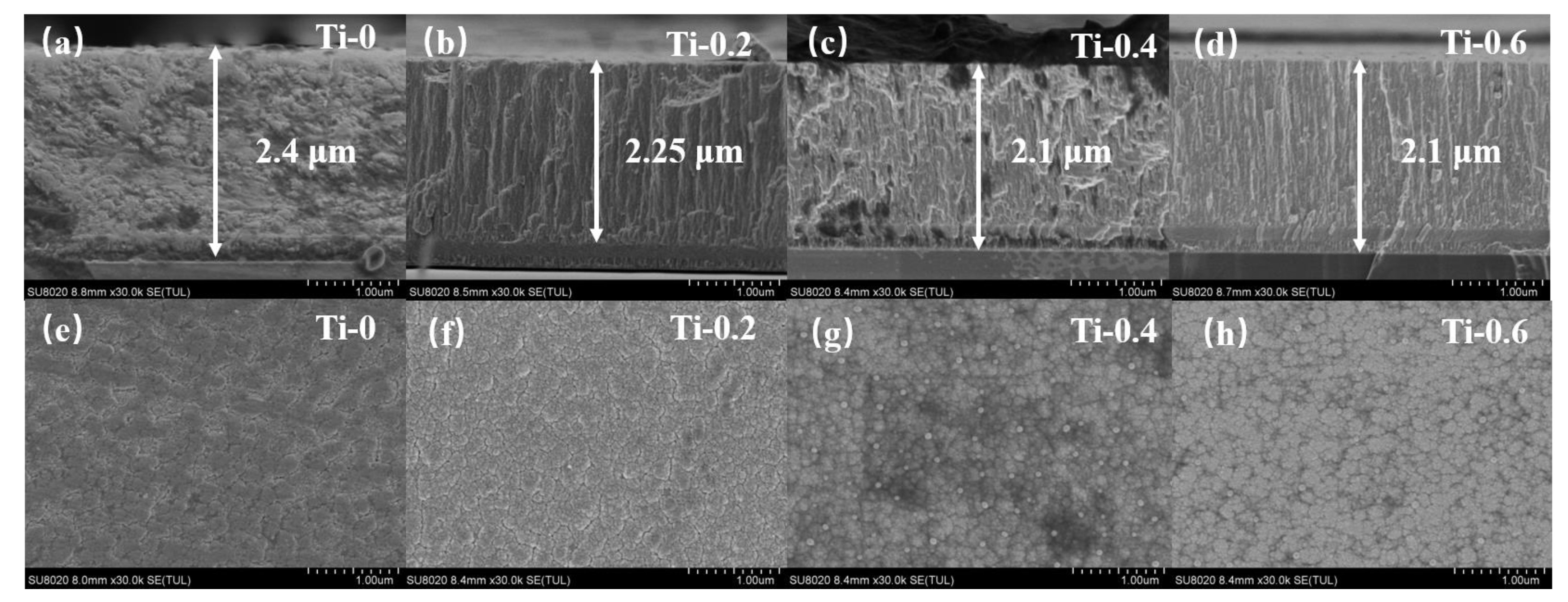

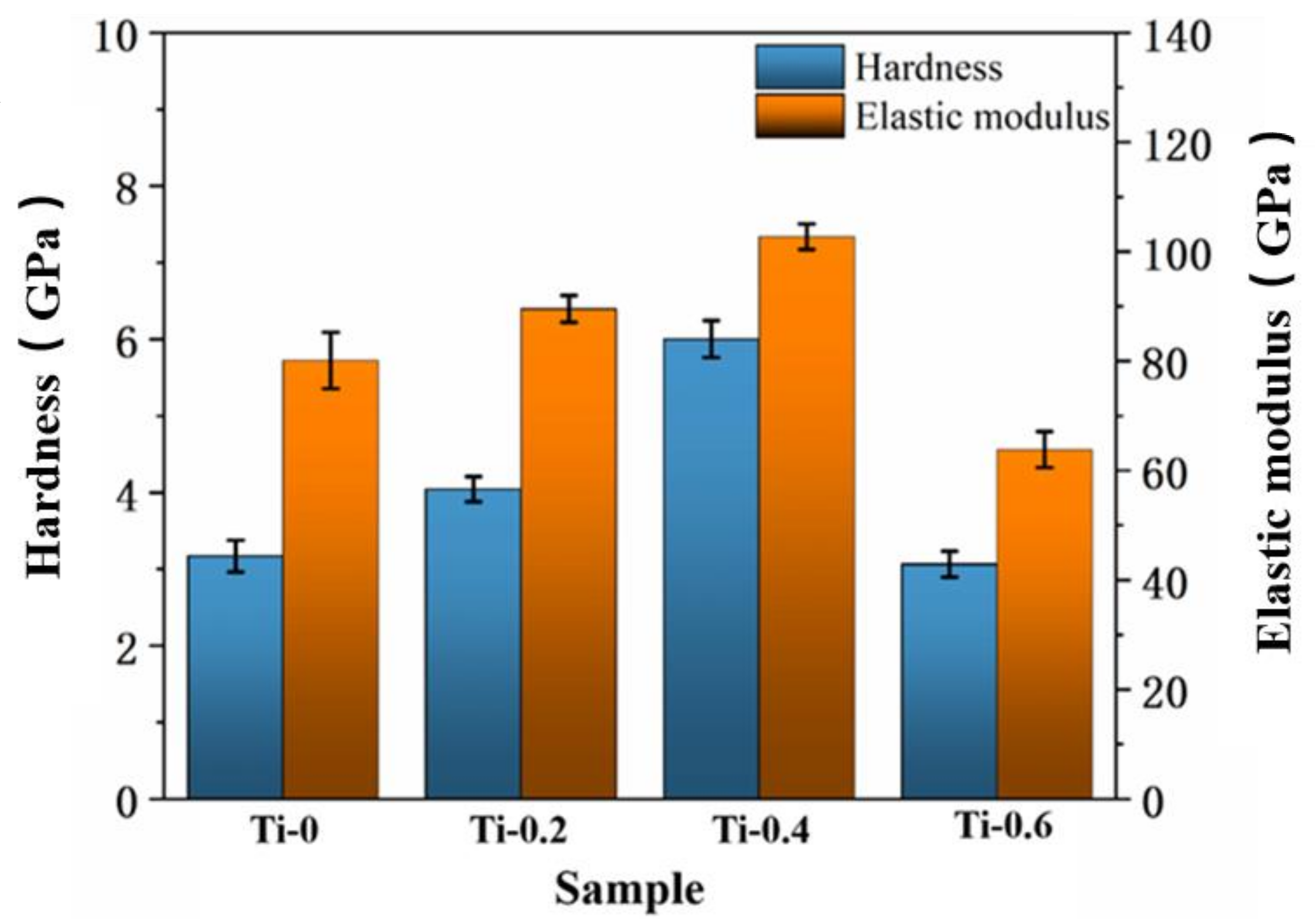

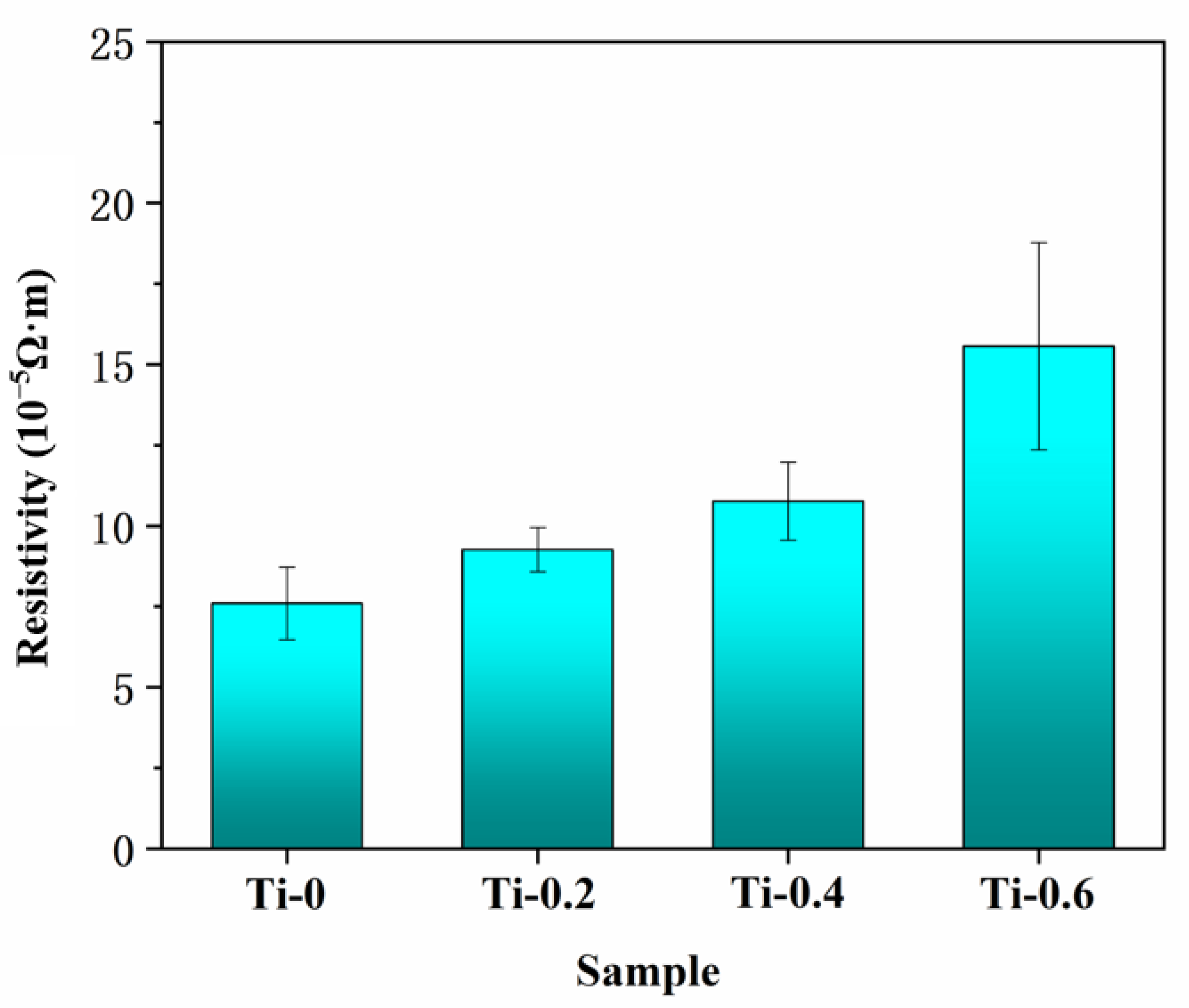

3.2. Physical Properties

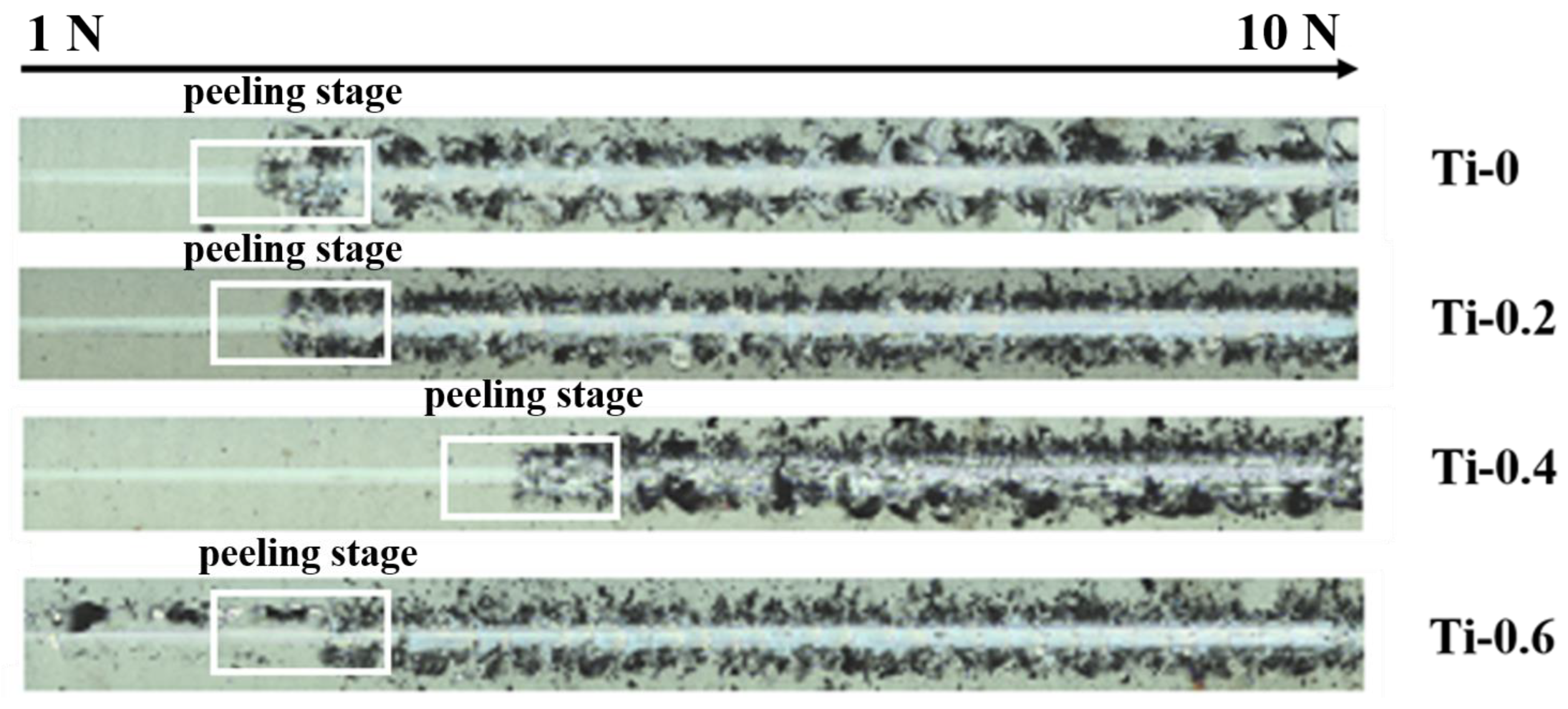

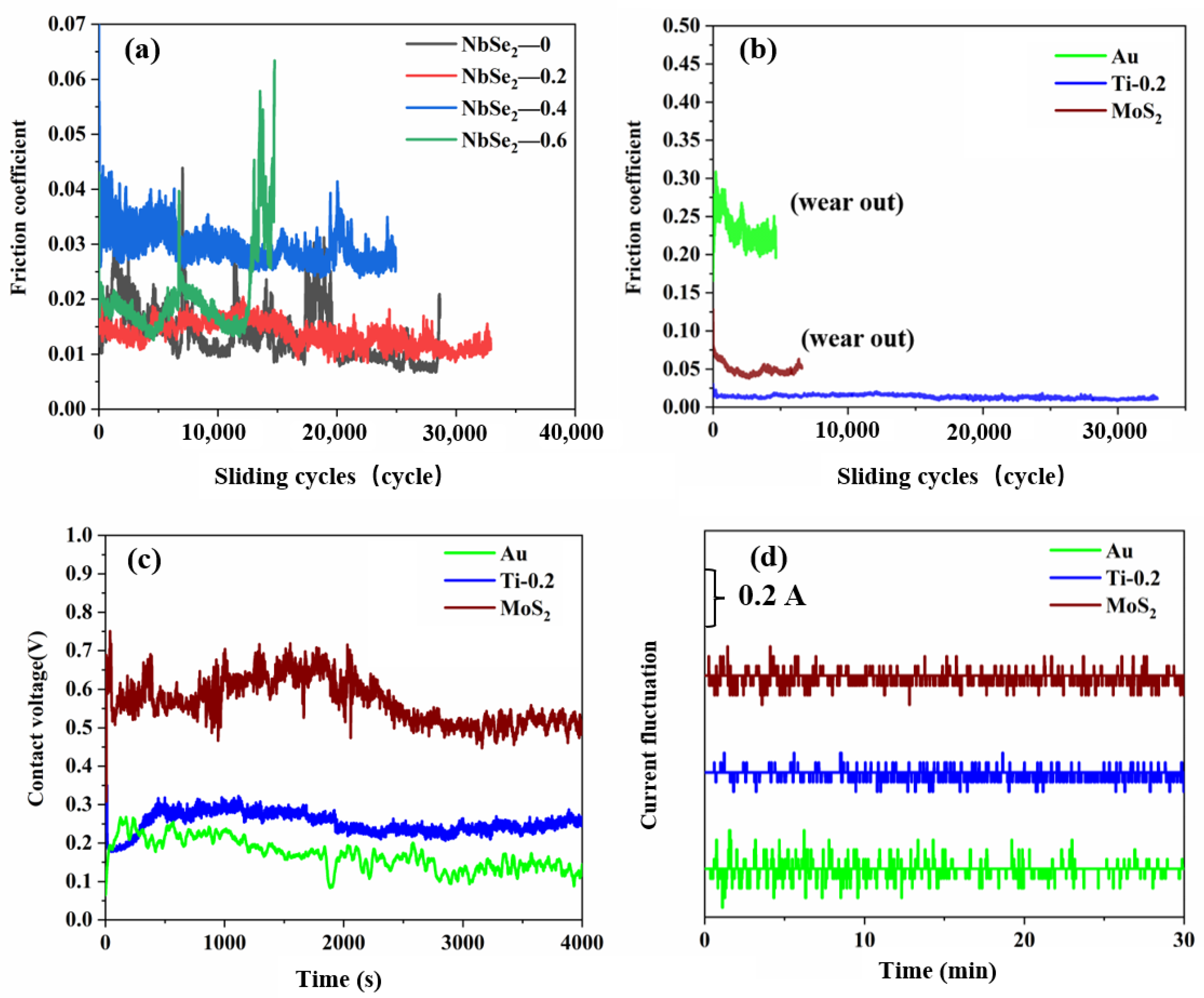

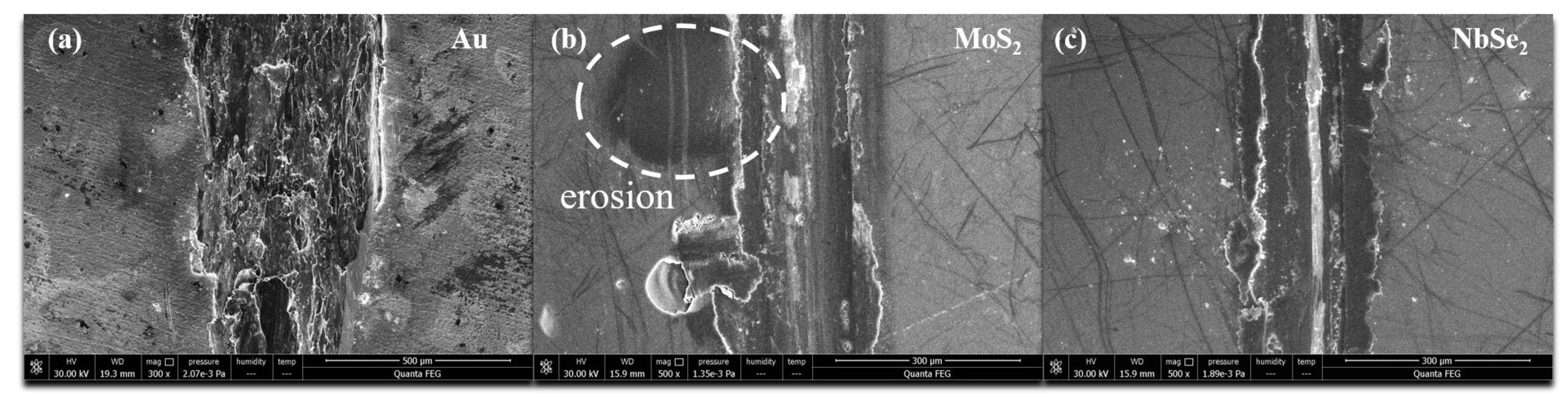

3.3. Tribological Property under the Combined Current-Carrying and Vacuum Conditions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, D.H.; Manory, R. A novel electrical contact material with improved self-lubrication for railway current collectors. Wear 2001, 249, 626–636. [Google Scholar] [CrossRef]

- Nedfors, N.; Primetzhofer, D.; Wang, L.; Lu, J.; Hultman, L.; Jansson, U. Characterization of magnetron sputtered Cr-B and Cr-B-C thin films for electrical contact applications. Surf. Coat. Technol. 2015, 266, 167–176. [Google Scholar] [CrossRef]

- Lewin, E.; Wilhelmsson, O.; Jansson, U. Nanocomposite nc-TiC∕aC thin films for electrical contact applications. J. Appl. Phys. 2006, 100, 054303. [Google Scholar] [CrossRef]

- Lu, C.T.; Bryant, M.D. Thermoelastic evolution of contact area and mound temperatures in carbon graphite electrical brushes. Wear 1994, 174, 137–146. [Google Scholar]

- Casstevens, J.; Rylander, H.; Eliezer, Z. Influence of high velocities and high current densities on the friction and wear behavior of copper-graphite brushes. Wear 1978, 48, 121–130. [Google Scholar] [CrossRef]

- Yang, X.; Li, X.; Wang, S. Study on simulation of multifield coupled wear in reciprocating electrical contact. Ind. Lubr. Tribol. 2023, 75, 98–109. [Google Scholar] [CrossRef]

- Huang, S.; Feng, Y.; Liu, H.; Ding, K.; Qian, G. Electrical sliding friction and wear properties of Cu–MoS2–graphite–WS2 nanotubes composites in air and vacuum conditions. Mater. Sci. Eng. A 2013, 560, 685–692. [Google Scholar] [CrossRef]

- Goodman, P. Current and future uses of gold in electronics. Gold Bull. 2002, 35, 21–26. [Google Scholar] [CrossRef]

- Mogonye, J.; Argibay, N.; Goeke, R.; Kotula, P.; Scharf, T.; Prasad, S. Tribology and sliding electrical contact resistance of e-beam hard Au: Effects of annealing. Wear 2017, 376-377, 1662–1672. [Google Scholar] [CrossRef]

- Quan, X.; Zhang, S.; Hu, M.; Gao, X.; Jiang, D.; Sun, J. Tribological properties of WS2/MoS2-Ag composite films lubricated with ionic liquids under vacuum conditions. Tribol. Int. 2017, 115, 389–396. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Marchetto, D.; Feser, T.; Dienwiebel, M. Microscale study of frictional properties of graphene in ultra high vacuum. Friction 2015, 3, 161–169. [Google Scholar] [CrossRef]

- Savage, R.H. Graphite Lubrication. J. Appl. Phys. 1948, 19, 1–10. [Google Scholar] [CrossRef]

- Soto, F.; Berger, H.; Cabo, L.; Carballeira, C.; Mosqueira, J.; Pavuna, D.; Toimil, P.; Vidal, F. Electric and magnetic characterization of NbSe2 single crystals: Anisotropic superconducting fluctuations above TC. Phys. C Supercond. 2007, 460-462, 789–790. [Google Scholar] [CrossRef]

- Zehetmayer, M.; Weber, H.W. Experimental evidence for a two-band superconducting state of NbSe2 single crystals. Phys. Rev. B 2010, 82, 014524. [Google Scholar] [CrossRef]

- Jian-Rong, S.; Chang-Sheng, L.; Hua, T.; Xi-Jun, H. Preparation and Tribological Behavior of Cu-based Electrical Contact Composite Containing NbSe2 in Vacuum. J. Inorg. Mater. 2014, 29, 936. [Google Scholar] [CrossRef]

- Chen, J.; Yang, J.; Chen, B.; Liu, S.; Dong, J.; Li, C. Large-scale synthesis of NbSe2 nanosheets and their use as nanofillers for improving the tribological properties of epoxy coatings. Surf. Coat. Technol. 2016, 305, 23–28. [Google Scholar] [CrossRef]

- Boscher, N.D.; Carmalt, C.J.; Parkin, I.P. Atmospheric Pressure Chemical Vapour Deposition of NbSe2 Thin Films on Glass. Eur. J. Inorg. Chem. 2006, 2006, 1255–1259. [Google Scholar] [CrossRef]

- Sun, S.; Wang, Y.; Lu, X.; Lu, X.; Mao, C.; Zeng, Z.; Xue, Q. Achieving excellent tribological performance of a-C: WC film by controlling sub-nano-structure. Tribol. Int. 2018, 128, 65–74. [Google Scholar] [CrossRef]

- Ren, S.; Li, H.; Cui, M.; Wang, L.; Pu, J. Functional regulation of Pb-Ti/MoS2 composite coatings for environmentally adaptive solid lubrication. Appl. Surf. Sci. 2017, 401, 362–372. [Google Scholar] [CrossRef]

- Fleischauer, P.D. Effects of Crystallite Orientation on Environmental Stability and Lubrication Properties of Sputtered MoS2 Thin Films. ASLE Trans. 1984, 27, 82–88. [Google Scholar] [CrossRef]

- Li-Na, Z.; Cheng-biao, W.; Hai-dou, W.; Bin-shi, X.; Da-ming, Z.; Jia-jun, L.; Guo-lu, L. Microstructure and tribological properties of WS2/MoS2 multilayer films. Appl. Surf. Sci. 2012, 258, 1944–1948. [Google Scholar] [CrossRef]

- Koo, K.F.; Schrader, G.L. Method for Preparing Basal Oriented Molybdenum Disulfide (MoS2) Thin Films. U.S. Patent 5370778A, 6 December 1994. [Google Scholar]

- Jakovidis, G.; Jamieson, I.M.; Singh, A. RF-Sputtered MoS2 Film Morphology and the Imperfection Nucleation Model. Surf. Rev. Lett. 2003, 10, 443–448. [Google Scholar] [CrossRef]

- Spalvins, T. Frictional and morphological properties of Au MoS2 films sputtered from a compact target. Thin Solid Film. 1984, 118, 375–384. [Google Scholar] [CrossRef]

- Ding, X.-Z.; Zeng, X.; He, X.; Chen, Z. Tribological properties of Cr- and Ti-doped MoS2 composite coatings under different humidity atmosphere. Surf. Coat. Technol. 2010, 205, 224–231. [Google Scholar] [CrossRef]

- Suszko, A.T.; Gulbiński, W.; Jagielski, J. Mo2N/Cu thin films—The structure, mechanical and tribological properties. Surf. Coat. Technol. 2006, 22–23, 6288–6292. [Google Scholar] [CrossRef]

- Deepthi, B.; Deepthi, B.; Srinivas, G.; Kumar, P.; Rao, D.V.; Barshilia, H.C. Sputter deposited nanostructured Au-WS2 solid lubricant coatings. Nanosci. Nanotechnol. Lett. 2012, 4, 53–60. [Google Scholar] [CrossRef]

- Wu, H.-W.; Yang, R.-Y.; Hsiung, C.-M.; Chu, C.-H. Characterization of aluminum-doped zinc oxide thin films by RF magnetron sputtering at different substrate temperature and sputtering power. J. Mater. Sci. Mater. Electron. 2012, 24, 166–171. [Google Scholar] [CrossRef]

- Cammarata, A.; Polcar, T. Overcoming nanoscale friction barriers in transition metal dichalcogenides. Phys. Rev. B 2017, 96, 085406. [Google Scholar] [CrossRef]

- Wang, P.; Yue, W.; Lu, Z.; Zhang, G.; Zhu, L. Friction and wear properties of MoS2-based coatings sliding against Cu and Al under electric current. Tribol. Int. 2018, 127, 379–388. [Google Scholar] [CrossRef]

- Sun, K.; Diao, D. Current density effect on current-carrying friction of amorphous carbon film. Carbon 2020, 157, 113–119. [Google Scholar] [CrossRef]

- Hounkponou, E.; Nery, H.; Paulmier, D.; Bouchoucha, A.; Zaidi, H. Tribological behaviour of graphite/graphite and graphite/copper couples in sliding electrical contact: Influence on the contact electric field on the surface passivation. Appl. Surf. Sci. 1993, 70–71, 176–179. [Google Scholar] [CrossRef]

- Liskiewicz, T.; Fouvry, S. Development of a friction energy capacity approach to predict the surface coating endurance under complex oscillating sliding conditions. Tribol. Int. 2005, 38, 69–79. [Google Scholar] [CrossRef]

- Tsuneta, T.; Toshima, T.; Inagaki, K.; Shibayama, T.; Tanda, S.; Uji, S.; Ahlskog, M.; Hakonen, P.; Paalanen, M. Formation of metallic NbSe2 nanotubes and nanofibers. Curr. Appl. Phys. 2003, 3, 473–476. [Google Scholar] [CrossRef]

| NbSe2 Target Current (A) | Ti Target Current (A) | Thickness (μm) | Ti (at. %) | |

|---|---|---|---|---|

| Ti-0 | 1.2 | 0 | 2.4 | 0 |

| Ti-0.2 | 1.2 | 0.2 | 2.25 | 6.6 |

| Ti-0.4 | 1.2 | 0.4 | 2.1 | 9.3 |

| Ti-0.6 | 1.2 | 0.6 | 2.1 | 12.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Wang, G.; Zhou, X.; Su, X.; Gu, L. A Promising Conductive Lubricant for Space Sliding Electrical Contact: NbSe2-Ti Film. Lubricants 2024, 12, 44. https://doi.org/10.3390/lubricants12020044

Yang Y, Wang G, Zhou X, Su X, Gu L. A Promising Conductive Lubricant for Space Sliding Electrical Contact: NbSe2-Ti Film. Lubricants. 2024; 12(2):44. https://doi.org/10.3390/lubricants12020044

Chicago/Turabian StyleYang, Yang, Guan Wang, Xingchen Zhou, Xingkang Su, and Long Gu. 2024. "A Promising Conductive Lubricant for Space Sliding Electrical Contact: NbSe2-Ti Film" Lubricants 12, no. 2: 44. https://doi.org/10.3390/lubricants12020044

APA StyleYang, Y., Wang, G., Zhou, X., Su, X., & Gu, L. (2024). A Promising Conductive Lubricant for Space Sliding Electrical Contact: NbSe2-Ti Film. Lubricants, 12(2), 44. https://doi.org/10.3390/lubricants12020044