1. Introduction

Cavitation is the main mechanism that causes performance degradation in most engineering applications. Regarding its impact in piston ring lubrication, it changes oil film thickness as it is being developed with reciprocating speed and changes the oil film pressure profile, which is generated due to the wedge geometry of the piston ring and liner interface. An area of the piston ring surface is void; this area corresponds to sub-atmospheric pressures that initiate the phenomenon, and thus impacting the load capacity of the piston ring. The viscosity of non-shear-thinning mineral lubricants would result in greater friction power loss when compared with shear-thinning fluids. The load-carrying capacity of the interface is the integral of the pressure distribution, the lubricant film thickness, the friction force and the lubricant flow rate [

1]. The viscosity of the lubricant at the piston ring cylinder liner interface varies during the cycle as the shear rate experienced by it changes [

2].

Previous studies have focused on providing a simplified version of the lubrication at the interface together with modelling of the equations describing lubricant flow [

3,

4,

5,

6,

7,

8,

9]. A single-ring simulating test rig is the basic tool with the necessary measurement sensors and modifications to support this research [

3,

4,

5,

7,

8]. On the engine side, tests in both motored and firing engines were utilised to assess the lubricant flow and compare the simplified test rig results to real engine ones [

6,

8,

9].

Polymer addition was found to increase the cavitation inhibition effect for the base oils. The effect of OFT on cavitation should be also considered in parallel to the evaluation of viscosity influence on cavitation [

2]. The different lubrication regimes during the stroke make their own contribution to friction profiles and total power losses. Extensive parametric study of different lubricants was carried out in [

10] where the effect of different lubricants, viscosity, high-temperature high-shear viscosity properties (HTHS viscosity) and piston ring geometry was parametrically studied. The influence of cavitation effects in OFT has been presented in the past, with higher temperatures leading to lower viscosity and affecting the signals. OFT and its load-carrying capacity decrease to a great degree as oil temperature increases [

5]. Test rig geometry and its dynamics play an important role as lubrication is affected. Along with friction, OFT measurements (both with laser-induced fluorescence (LIF) sensors and capacitance), oil film pressure measurements and visualisation, and various shapes of cavitation have been identified and classified, for the case of the simulating test rig, that have lubricant rheological effects [

4,

7].

Cavities’ development influences the oil film pressure in the thin lubricant film and its load capacity, the latter being subject to cavitation initiation points and the cavitation region, which was altered in size because of the piston rings’ geometry and lubricant properties [

4,

5,

10]. In the wedge geometry of the piston ring/cylinder liner interface, the load-carrying hydrodynamic pressures are built in the convergent wedge, and conversely, in the divergent side, cavitation reformation influences to a great degree the peak pressure in the full film region and the area of cavitation. This latter phenomenon is particularly evident when high oil film pressure appears on the divergent wedge of the piston ring specimen [

5].

In engine testing, friction results showed that the lubrication in the boundary region contributes significantly to the total friction power losses in the case of the twin-land oil control ring [

11]. Other researchers used LIF techniques to visualise the lubricant film, taking two-dimensional images in their specially modified IC engines and charge-coupled device cameras (CCD) [

12,

13,

14,

15,

16,

17].

A theoretical model to study the lubrication of twin-land oil control rings was developed considering the shear-thinning effects of multigrade oils, with both oil squeezing and asperity contact included for their interaction [

14]. Increasing oil temperature, a simultaneous effect of liner surface temperature, reduces the viscous film friction. Close to the dead-centres of the stroke, where the lubrication regime is boundary, increased friction is the main contributor to power losses, reducing at the same time the effect of liner surface temperature [

18].

Lubrication models have also included more parameters to achieve a better degree of validation when compared to experiments. The cavitation of compressible fluid was included in the mass flow equations, and this interpretation was further verified [

19]. Another group implemented a computational fluid dynamics (CFD) model along with limited experiments for a thin compression ring of a single-cylinder firing engine, regarding friction. For modelling purposes, they used a two-phase flow and a gas blow-by model in the mixed lubrication region [

20,

21,

22]. Another aspect that was studied was the effect of a piston ring profile after substantial hours of testing in a diesel engine. Deposits led to a worse sealing behaviour [

22].

Nouri et al. [

23] argued that the cavities’ initiation dynamics were demonstrated in images showing time-dependent initiation of cavitation, with shapes varying from fern cavities and bubbles, to fissure-shaped cavities and, when fully developed, to sheet and string cavities. These images were taken at a liner velocity of approx. 0.17 m/s. With increasing speed in the simulating single-ring test rig, the number and the length of string cavities increased, as the oil film is fully developed with higher speed and according to lubrication theory. Two different cameras were used to capture video images at high speed with high-intensity light sources, and these images were analysed; the images were introduced to a custom-built computer program so that further analysis of the cavitation images could be undertaken and cavitation statistics could be delivered. The temperature parametric effect was also studied at the engine test rig, which showed that cavitation was intensified. At higher temperatures, cavitation intensity increases but bubbles collapse, reducing its overall area on the piston ring. Speed parametric tests had a dramatic increase in the cavitating area, which was evident at even higher speeds, this time limited. After that engine speed threshold, there was a smaller increase in the cavitation area, with similar intensity and distribution across the ring [

9].

Modelling work extracts matrices with cavity length, cavity width, area of cavitation and number of cavities present under the piston ring and the cylinder liner [

8,

9]. This more-controlled experiment introducing a specially modified engine cylinder block, tried to extend and solidify the findings of a simulated single-ring test rig [

5,

7], and undertook partial imaging from the size-limited windows of a Lister–Petter engine [

5,

6].

According to Taylor [

24], the important and useful property of squeeze films is their ability to provide increased load capacity even if for a short period of time when the lubricating interface is suddenly under high loads. The squeeze effects have a significant impact on OFT, and also affect friction, as it differs depending on the sliding direction. Squeeze film acts as a saviour at low speeds as there is a substantial film capable of handling load, with its appearance changing in terms of crank angle (CA) according to lubricant properties and operating conditions [

25]. On the one hand, the squeeze film acts as a saviour in the mixed/boundary region and, on another hand, initiation of cavitation happens at similar CAs where friction force reaches its peak value. With the use of oils with different properties, the friction peaks varied as well. Various lubricants affect the squeeze film [

26]. There are differences at top dead centre (TDC) and bottom dead centre (BDC) at high temperatures and high loads, this time appearing in the signals as a slight shift towards dead centres. Squeeze film measurements are altered as a result of test rig dynamics and the rig’s geometrical characteristics. In the minimum oil film thickness (MOFT), measurements appear as an asymmetry [

26].

A focus on interpreting the results obtained from each lubricant under different operating conditions was achieved. Lubricant properties influenced MOFT measurements (capacitance sensor) and cavitation with the laser-induced fluorescence (LIF) method [

7]. Without considering lubricant degradation, different lubricants were measured in the test rig and it was established that, for the same testing conditions, cavitation and OFT varied according to their properties. Motored engine experiments [

5,

6,

8,

25] complemented the test rig findings. These modifications allowed for extensive research of oil transport, cavitation initiation and development, and the effect of varying temperature, in a detailed study on engine lubrication. Results were validated with findings taken from the parallel working test rigs.

A few previous works used optical engines to visualise the oil film flow, which will be analysed further.

Lubrication optimisation is the principal objective in this research. It includes optimising lubrication of the piston/liner interface, which always requires balancing between competing factors, such as the viscous losses and effective lubrication. The main focus is highlighting the parametric results and their combination in lubricant flow, towards suggesting an optimal piston ring/cylinder liner design that enhances the theoretical lubrication regimes at all engine operating modes and simultaneously minimises friction power losses. Various experimental test rigs contributed to this thorough study, which effectively turned into a comparison of results taken from these rigs, whether being simplified versions of the piston ring/cylinder liner interface or modified single-cylinder engines at different time intervals. An extensive visualisation process with computer-based image analysis followed the initial phase of results. A comprehensive analysis was conducted on the formation and development of cavitating lubricant flow between the piston ring and cylinder liner assembly, and gives the parameters needed to compare the degree of cavitation in the various experimental test rigs.

2. Experimental Set-Up and Methods

The importance of these investigations emerges when experimental results from investigations of cavitation initiation and its development after the dead centres of the stroke are combined. Lubricant formulation with the use of different additives plays an important role because at higher temperatures the additives have a different interaction with contacting surfaces, and in this manner the resulting effect of asperity contact is either increased or reduced. The challenging nature of achieving visualisation in engine set-ups is combined with serious manufacturing limitations of visualisation windows. Oil starvation causes further implications. Handling combustion pressures that accompany firing experiments is another particular challenge. Image acquisition is limited as extensive cleaning is a prerequisite.

In previous research, different lubricant properties affected MOFT measurements, applied either with the LIF technique or with a capacitance sensor. A specially designed liner was used for mounting an ultra-miniature pressure transducer, so that the identified cavitation results could be further quantified and verified [

27]. Blow-by phenomena were captured by the imaging process.

The effect of cavitation is quantified with results derived through image processing. As already pointed out and carried out in previous research, the operating conditions and lubricant properties influence cavitation [

4,

5,

6,

7,

8,

9,

10,

23,

25,

26,

27].

Three experimental test rigs were used: two optical engines, specially modified to capture lubricant film and transport imaging, and the simplified single-ring test rig.

2.1. Single-Ring Simulating Test Rig

The simulating test rig minimises operating uncertainties and is focused on studying the fundamental aspects and physics of piston ring lubrication. This simplified test rig consists of a steady piston ring section having a 5 mm width, fixed under a flat liner moving section, with its motion being inverted. It was initially developed by Arcoumanis et al. [

3]. Various sensors are used for oil film pressure, MOFT (optical—LIF and electrical—capacitance), and friction, and extensive liner modifications allow imaging and provide parametric data of speed, load, temperature and piston ring geometry, for various lubricant grades. As the liner reaches TDC or BDC, the lubrication at the interface is mixed; contact between the interacting surfaces is achieved through surface asperities while friction power losses increase up to the lubrication regime change to boundary. The squeeze film effect has its own beneficial support close to the dead centres [

6,

25,

26]. Squeeze films provide increased load capacity, although temporary. With liner movement away from TDC or BDC, oil film develops, decreasing asperity interaction and frictional losses at the same time, while the lubrication regime changes from boundary to elastohydrodynamic, and then hydrodynamic when the full fluid film has developed close to the liner’s highest speed.

A custom made LABVIEW program was used to process the results over degrees of CA. Repeatability issues required selecting a number of 50 cycles, and error analysis for MOFT, LIF, friction and pressure data was also provided. In

Figure 1a–d, the test rig schematic and sensors can be seen.

2.2. Optical Engines

This section presents relevant previous work on heavily modified single-cylinder engines, methods and findings on oil film visualisation before the research methods used in this project.

2.2.1. MIT Research on Oil Transport

MIT researchers [

11,

13,

14] used two engines to visualise the oil flow:

- (a)

A Kubota single-cylinder engine;

- (b)

A PSA single-cylinder engine.

(a) Kubota engine: A quartz window was installed in the removable liner of the Kubota engine. The window was designed with a trapezoidal section in both vertical and horizontal directions to better support the combustion pressure. The window was located in the anti-thrust side (

Figure 2).

Quartz provides:

Good optical quality (excellent transmittance of the visible wavelength);

Good mechanical properties (very scratch resistant);

Inexpensive raw material and low-cost machining.

The engine incorporated a relatively small window in a well-cooled cast iron cylinder liner. It was located below the mid-stroke position and therefore not exposed to the very high temperatures encountered during the combustion process.

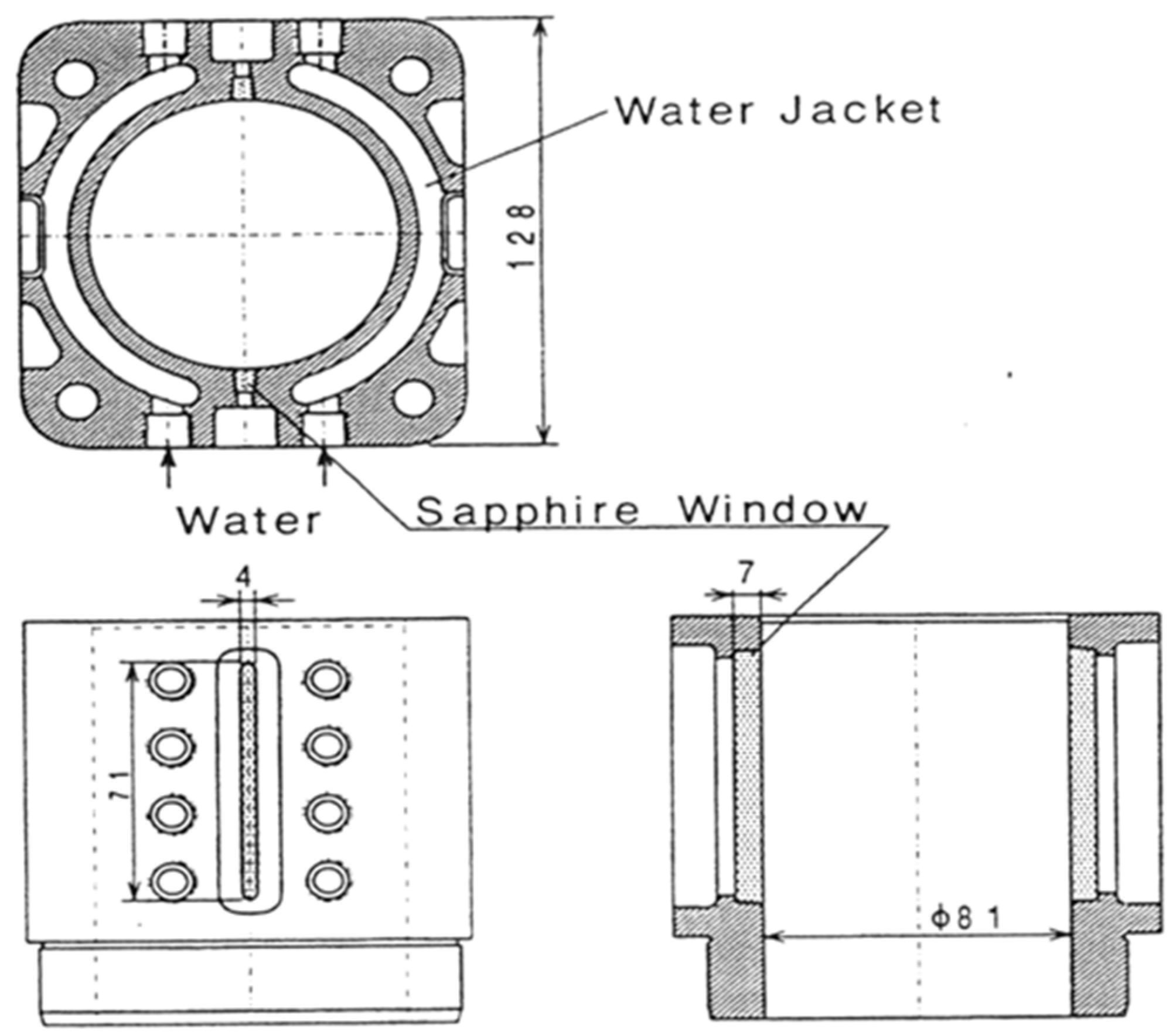

(b) PSA engine: To verify experimentally more aspects of piston ring oil transport, a spark ignition engine was equipped with extensive optical access in the form of a long window having 104.5 mm × 18 mm dimensions, as shown in

Figure 3. The window was made of sapphire, which has superior mechanical properties and is therefore more likely to resist the stresses induced by the combustion chamber pressure. Since sapphire and cast iron have very similar thermal expansion coefficients, it is expected that with a sapphire window, the gap between the window and the liner will not increase as temperature rises, minimising the risk of leakage. High-temperature-resistant and high-thermal-conductivity epoxy glue was used to fix the window in its place. Both windows were polished on the outside and honed on the inside.

A visualisation system using multiple-dye LIF was implemented to observe oil displacement among various regions of the piston ring pack in both engines. The two-dimensional oil distribution measuring system was developed using a pulsed laser. Special fluorescent dyes were used to minimise the sensitivity of the LIF signal to oil temperature. An intensified CCD camera was used. High resolution images and video recordings of the oil distribution were acquired over a range of running conditions representative of passenger car engine operation.

On the piston lands, oil was observed to move in both the axial and circumferential directions. The axial oil displacement was found to be driven by the inertia forces resulting from the piston alternating motion. The circumferential flow appeared to result from the dragging action of the blow-by gases. Inertia forces dictate the oil repartition along the axial direction of the piston lands. It forces oil to repeatedly accumulate against the rings and spread over the piston surface. The predictions were in good agreement with the oil distribution profile measured during engine operation, providing considerable help in simulating and developing oil transport models. Two major mechanisms were found to be responsible for oil flows from the piston lands to the ring grooves: the ring pumping, which was observed experimentally, and the lateral motion of the piston relative to the rings. By changing the second ring and third land geometry, it was experimentally proven that the amount of oil that accumulates in front of the lower clearance of the second ring groove greatly affects the oil flow rate through the back of the scraper ring.

2.2.2. Toyota Researchers

Inagaki et al. [

17] used a single-cylinder spark ignition engine and two types of cylinder liners. For the motoring test, a whole optical glass transparent cylinder was used. For the firing test, a cast iron liner having a pair of tapered slit holes in the axial direction at the thrust and anti-thrust side was used (

Figure 4). The researchers used a Xe-flash lamp (blue filter), a filtered CCD video camera, a PC-based signal analyser and fluorescent dye in the lubricating oil. A fluorescent dye was used and its emission had an intensity appropriate to the OFT through two-dimensional images. Under high speed (5000 rpm), oil spouts were observed from the first ring gap. The measured oil consumption rate agrees with the variation in the rate of spouted OFT, as very clear images of the OFT distribution on the piston skirt, piston lands and piston rings were obtained under both motoring and firing operating conditions.

2.2.3. Noticeable Optical Engine and Test Rig Simulations

Sanda et al. [

12] used LIF to capture two-dimensional images of the oil film. Kim et al. [

28] manufactured an experimental test rig that would be able to simulate the piston ring/liner lubrication, measure oil film pressure, visualise cavitation and categorise its shapes. The rig consisted of a reciprocating flat plate with a straight bar test piece loaded on top of it. The researchers tried to investigate cavitation with this optical technique. Another group of researchers inserted a 5 mm thick transparent quartz cylinder [

29]. A red dye was added to the lubricant and a video camera was used to record the characteristics of the oil flow through the ring pack. When the piston ring gaps were in line, greater oil flow was observed. In a later publication [

30], the oil flow was increased by a higher pressure difference, greater oil temperature and engine speed, and lower oil ring tension, and it was observed that the lubrication oil was flowing through the ring gaps. The main oil flow paths were observed to be through the ring gaps and along the lands. In 1999, the same researchers found that a triangular step joint in the top piston ring reduced the oil flow [

31]. Yoshida et al. [

32] investigated the oil flow to the combustion chamber through a V-shaped groove into the second land and stated that it was greatly reduced.

Schäffer et al. [

33] developed a measuring system for the visualisation of the oil film between the piston liner of a gasoline engine, reporting that the oil flow to the combustion chamber changes significantly with engine speed and load. For operating conditions with a closed throttle during high engine speed, a large amount of oil enters the combustion chamber. The transition from fired to motored engine operation is associated with increased oil consumption.

Azetsu et al. [

34] utilised an optical engine in an experimental design using photochromic dye dissolved in the oil, illuminated with ultraviolet light. The engine was a motored single-cylinder, 4-stroke engine. The quartz cylinder liner allowed full access to visualise the lubrication according to piston movement. An ester-based, 5W-30 oil was used. Low operating temperatures (30 °C) avoided the effect of the fading reaction, and low engine speed (600 r/min) enabled imaging at intervals of 1° CA. The researchers concluded that this new visualisation technique can be implemented successfully, and the next steps would be to utilise this technique over a wide variety of engine operating conditions to investigate oil flow and the basic route for oil consumption and dilution in the fuel [

34].

Regarding oil mist investigations, because the presence of oil droplets (mist) in the gas that flows through the piston assembly and crankcase of an ICE has important implications for performance, particularly lubricant supply to the upper piston assembly, oil consumption and lubricant degradation, an experimental test rig was developed to simulate the gas and lubricant film interaction at the top piston ring gap, where flow conditions are most severe (see

Figure 5) [

35]. Lubricant viscosity had a significant effect and the viscosity modifiers contributed to oil droplet formation. This triggered a detailed study of a set of viscosity modifiers, which tried to establish the fundamentals of lubricant chemistry on viscoelasticity and mist formation.

2.2.4. Leeds University Research on Optical Engines

Gamble [

15] dealt with the modelling of the piston ring pack and monitored the lubricant condition. An extensive description of the oil transport mechanisms in the piston ring assembly was given so that the lubricant degradation can be studied more effectively. Modelling work was divided into two sections: (a) piston ring pack and (b) piston.

2.3. Single-Ring Test Rig Sensor and Optical Engine Set-Up

In this project, two single-cylinder engines were used: a single-cylinder Lister–Petter PHW1 diesel engine and a single-cylinder Ricardo HYDRA engine. Ideally, the engines, after the motoring tests, would be used for evaluation of firing conditions [

25].

Optical access to the ring/liner interface along the stroke length can provide lubricant flow details for the proposed investigations and allow direct comparison with the respective operating conditions of mass-produced engines [

9]. In

Figure 6, the Lister–Petter modifications and optical set-up for visualisation experiments can be seen. Drawing details accompany this figure to provide a representation of the preparation work needed to proceed with the first phase of modifications, which include high precision window sections fitted after special machining on the cast iron liner body.

A large amount of important information on lubricant flow properties is gathered from the test rig, which, in turn, leads to understanding of the flow in a conventional engine assembly. Eventually, characterisation of the lubricant transport phenomena in the piston ring pack of production engines [

8,

9], along with a link, via a parametric study, to the effect of lubricant properties in oil film characteristics [

5,

7,

8,

10,

23,

27], was achieved. In

Figure 7, the piston ring details for the Lister–Petter PHW1 engine can be seen.

The nature of the simulating single-ring test rig interface with simplified assembly and reassembly processes enabled extensive parametric lubricant testing acquired from the installed measurement sensors. Engine in-cylinder uncertainties resulting from its inherent complexity (ring dynamics, thermal and elastic deformation of the rings, starved lubrication, circumferential ring variations, lubricant degradation and blow-by) were avoided [

6,

25].

The investigations of the oil flow characteristics and cavitation incipience in the idealised test rig are dependent on the implementation of numerous measurement techniques. Improvements and measurement method optimisation at the test rig were a prerequisite to ensure that the simulation at the piston ring and the liner interface was achieved in the best possible manner. OFT, through employing the capacitance method and friction force measurements by a piezoresistive force sensor, was successfully acquired. The optical liner was integrated into the test rig allowing the imaging of cavitation development through a still CCD camera. The integration of a high-speed video system allowed the acquisition of meticulous flow images. Furthermore, the measurement of oil film pressure with a miniature pressure transducer supported the cavitation findings and provided an insight into the flow behaviour at the piston ring and liner interface, with an emphasis on the change in pressure profiles due to operating conditions, combined with the area of cavitation at the diverging wedge of the piston ring.

The extensive investigation of the cavitating oil flow was captured with high-speed cameras and high frame rates that, in turn, were established as an essential tool in identifying the highly transient lubricant flow. The single-ring test rig acted as the medium that enhanced the confidence in interpreting the results. The transfer of knowledge acquired in measuring the oil film pressure in the test rig, to that of the engine, eventually allowed the direct assessment of engine imaging. At first, in the test rig, the parametric results enhanced the ability to quantitatively interpret the cavitation development at the ring/liner interface and, at a later stage, the two engine test rigs acted as the field of implementing the initial interpretations. The converging–diverging wedge of the moving liner relative to the steady piston ring section constructs a positive lubricant pressure at the converging wedge of the ring, and therefore, an adequate hydrodynamic film that, in turn, can withstand the load acting on the ring surface. In contrast, in the diverging wedge, negative pressures arise, and this relationship is combined with different boundary conditions when modelled [

25].

The modified single-cylinder Lister–Petter PHW1 engine used for visualisation imaging in motoring tests results could be directly compared to the respective ones from the test rig with a view to cavitation stage development [

5,

6]. As in the case of the simplified test rig, pressure and LIF measurement stations were prepared in the engine liner with their respective engine block fittings, but neither sensor was fitted due to failure during their machining process [

25].

The two modified engines tried to shed light on the lubrication occurring during the whole of the stroke. The Lister–Petter motoring tests were conducted for a direct comparison to the single-ring test rig results. In the next phase, Vasilakos [

8] modified the Ricardo engine and managed to obtain visualisation results that quantified the cavitation as recognised by the imaging process, and eventually led to the results that are going to be discussed in the following sections. The Ricardo HYDRA engine, with an extended viewing area, produced solid results, which were compared to the respective ones from the test rig and coupled to the images taken from the Lister–Petter engine [

25].

The modifications of the cylinder block can be seen in

Figure 8. The machining specifications were the same as for the original HYDRA block, with the extra use of special honing tools so that a very smooth inner cylinder surface could be achieved. This was an important process in terms of achieving the same surface roughness. A very important aspect of the machining was to make sure that the optical design can support firing operation forces, temperatures and pressures, without interfering in terms of tolerances with the cast iron fitting [

9].

4. Discussion

Oil transportation mechanisms have been evaluated and associated with different cavitation stages. Extensive parametric study helps in identifying squeeze film and cavitation initiation according to the measured friction peaks at the boundary lubrication region. These friction peaks are produced as a function of piston ring geometry operating characteristics, such as speed, load and temperature, and lubricant properties, namely the high-temperature high-shear (HTHS) viscosity of the lubricant [

10]. These results of the cavitation images, and the outcome of this processing, show how cavitation initiation, the squeeze film effect shift and the cavitation area on the piston surface can be put together in interpreting the observed rheological phenomena [

25]. Kinematic viscosity and friction in the test rig are linked to the cavitation images. Image processing extracts the geometrical values of the cavities and a correlation to lubricant properties is derived. Initiation, development and diminishing of cavitation is strongly influenced by lubricant formulation. As shown in cavitation figures, cavitation initiation and the area during fully developed hydrodynamic flow changes, regardless of evaluating images from the engine piston rings or the simulation test rig, as the produced images show. The lubricant without a viscous modifier shows longer cavities, and a smaller-sized cavitation area is linked to a greater kinematic viscosity value [

8].

The squeeze film effect takes place close to the stroke reversal points, where the lubrication is boundary and cavities start forming. Low frictional losses are combined with low-viscosity oils, increasing efficiency and emissions as the path towards the combustion chamber is easier to follow [

6]. Load increase shifts the flow reversal closer to stroke reversal, as the squeeze film appears. With an increase in speed for a constant load, friction force peaks develop a lower value while appearing at a greater distance from the dead centres [

26].

Cavitation damage is the outcome of fluid impact on the interacting surfaces as the cavities formed at low oil film pressure collapse. It is expected that the collapse velocity will be lower in a Newtonian lubricant than in a shear-thinning lubricant; the same applies for the cavitation zone, i.e., it is larger in the shear-thinning ones. Shear-thinning affects cavitation behaviour, its effect being OFT change [

2,

5,

6]. Shear-thinning multigrade lubricants, as well as thin monograde oils, tend to reduce friction power losses, while at the same time increasing cylinder wear [

6]. The effect of OFT on cavitation behaviour should be also considered while assessing the influence of viscosity and cavitation damage. At the same time, the load effect on starved surfaces should be assessed [

25]. Shear-thinning fluids having lower tensile strength influence cavitation behaviour [

2]. Initiation, development and disappearance of cavities are linked directly to the properties of the tested lubricant, with change in OFT being an indirect change [

6].

The forms of cavitation, such as string cavities, were verified. Friction force arising in the region of oil film breakage should be evaluated to assess the impact on wear; as shown, friction peaks shift closer to or further from the dead centre of the stroke, and their magnitude varies according to the lubricant properties [

10,

26]. Cavitation shortens the effective load piston ring area, deteriorating load capacity, even in the hydrodynamic lubrication region with substantial oil film pressures [

25]. Different lubricants, operating conditions and piston ring geometries should be considered and, at the same time, the effect of the squeeze film and its shift due to operating conditions and property changes should be included. Simultaneously, when collapsing at the stroke reversal points, the development of friction peaks prevails at the boundary lubrication region. This is evidence of wear development [

6].

Starvation, together with cavitation, significantly reduces the amount of load supported by the ring. An effective load region amounts to 15-40% of the nominal region of the ring [

34], which, following the results of Equation (3) for the top compression ring, is in good accordance with the lowest percentage. Additionally, the flatter ring is linked to extensive hydrodynamic lubrication, even if it is weakened in the middle of the stroke, as shown in the oil film pressure experiments (lower peak film pressure value). It generates a smaller cavitation area than the barrel-faced one, i.e., rings with a smaller radius of curvature. A curved profile will strengthen the hydrodynamic film lift, extending the cavitation area and deteriorating the load-carrying capacity of the piston ring. More effective load support comes with a flat-face ring rather than a curved one. The load capacity of the piston is a major mechanism contributing to engine wear [

37].

Both Thirouard [

13] and Gamble [

15] mention the contribution of oil mist to oil transport through the ring pack. The experimental visualisation data showed that oil could be transported out of the ring gap as oil mist. Other identified mechanisms that drive oil film from the lands to the ring groove clearance were identified as follows:

Inertia force generates a pressure gradient which, in turn, transports oil only in the oil control ring. The oil transport rate, resulting from the above mechanisms depends on the following:

Ring and piston dynamics, which consequently vary with engine speed and load;

The amount of available lubricant in the vicinity of the ring groove clearances.

The ideal situation of the single-ring test rig is confronted with the real-size engine test rig experiments, where more parameters affect the piston ring pack during reciprocation.

Higher MOFT can by itself explain why the string cavities might offer a smaller length or width, with the former being in favour of the lubricant with the viscous modifier [

9,

23].

Hydrodynamic oil film pressure measurements were taken within a range of 500 to ≈1200 kPa, and linked to operating conditions and piston ring geometry. This increased with higher speed and higher loads. In contrast, higher temperatures reduce the peak pressures and, in terms of piston ring geometry, a smaller piston ring radius clearly developed higher oil film pressures. Open-form cavitation significantly influences oil film peak pressures in the hydrodynamic region. Increasing speed, load and temperature showed that film pressure peaks are shifted to the diverging wedge of the piston ring [

27].

Considering that cavitation during the intake and exhaust strokes is not evident, the in-cylinder pressure stands out as the main mechanism behind the appearance and control of cavitation [

9]. Cavitation wear, along with shockwaves, can erode the piston ring/cylinder liner interface. The small volumes of liquid, when the cavitation bubbles collapse, result in many small high-pressure and high-temperature spots [

8]. Bubbles are formed as gas is released and has a near-zero or negative oil film pressure. When a bubble collapses against a solid surface, very high stresses reaching 0.5 GPa in some cases are generated, and this will cause wear [

38]. Eventually, load capacity is reduced when compared to the values calculated by hydrodynamic theory assuming no cavitation effects [

6]. According to Stachowiak and Batchelor [

38], if a significant quantity of bubbles is formed in the lubricant film, load capacity is reduced. A decrease in lubricant viscosity reduces friction power losses, but at the same time this increases the boundary friction in the case of the expansion stroke. The friction characteristics are affected by the shear-thinning effect when multigrade lubricants are used [

36]. The reduced viscosity of shear-thinning lubricants should lead to large-sized cavities. In [

35], it was found that the effect of lubricant viscosity was particularly important and viscosity modifiers were found to have the greatest effect on droplet formation. In particular, when additives were included in the base oil, the viscosity modifier was shown to be the major factor causing this reduction in misting tendency. This tendency should be explored further in future engine visualisation experiments.

On the piston lands, oil was observed to move in both axial directions and along the ring circumference. The axial oil displacement was found to be driven by the inertia forces. The circumferential flow appeared to result from the dragging action of the blow-by gases as the fluid speed is approx. 2 mm/s (second piston land). Oil can move with the gas as it is dragged by the shear stress forces. This process takes the lubricant out of the second land region through the ring gaps. Through experimental observation, it was established that the inertia forces dictate the oil repartition along the axial direction of the piston lands. This forces oil to repeatedly accumulate against the rings and spread over the piston surface [

36]. Oil loss from the ring pack into the combustion chamber is dominated by reverse blow-by [

15]. Furthermore, it was found from engine test results and analytical calculations that the actual gas flow resulting from ring fluttering has little effect on the land oil distribution. The experimental observation further suggested that the direction of the oil flows through the back of the rings was linked to the main oil supply location towards the ring groove. Typically, because more oil was supplied to the lower clearance of the ring grooves, oil flowed from the lower to the upper land. The ring/groove relative angle, which affects the squeezing process and the flutter-induced gas flow, appeared to affect the rate at which the oil was flowing through the ring grooves, but not the total transport value direction [

39]. By changing the geometry of the second ring and third land, it can be argued that the amount of oil that accumulates in front of the lower clearance of the second ring groove (

Figure 38) greatly affects the lubricant flow rate through the back of the scraper ring [

39].

The influence of geometrical parameters on the shaping of the lubrication wedge, taking into account liquid microflows on curved surfaces and coating micro-geometries in a friction loss analytical model, was assessed by Wróblewski and Kachel [

40]. It was also found that micro-irregularities influence the distribution of oil film thickness at peak cylinder pressure, which is critical for the piston ring sealing process [

40]. The same group of researchers studied the effect of lubricant chemistry on the oil film formation process through the coating of engine parts, affecting both load-carrying capacity and the ability to form a lubricating film. Physical and chemical parameters of the coatings of the parts at the lubricating interface were assessed, as the value of the contact angle of the liquid on the surface of the coating depends on the value of the intermolecular force of attraction [

41]. This research provides further evidence of the effect of geometrical considerations on oil film build-up and transport, as well as the influence of physical and chemical lubricant properties.

5. Conclusions

With the different experimental methods used, a picture of the parameters affecting lubrication and piston ring performance could be drawn. The parameters extend from the operating range and lubricant properties, to piston ring/liner interface geometry. All of these parameters, when measured with the different sensors and optical techniques, contribute, on their own part and in accordance between them, to supporting the visualisation findings. The aim was to shed light on the parametric effect of lubricant cavitation, its initiation and development, and on friction and wear in piston ring lubrication. The cavity measurements (size of the microscopic forms, area, length and width) taken from imaging can correlate with the lubricant formulation.

There is an agreement with the results presented by other research groups in the past. Images taken from the second compression ring, as well as images from the third ring, show a fully developed oil film on the surface of the rings.

The visualisation images show the string cavities with different magnification lenses. Oil mist can also be noticed with the higher magnification lenses, as well as oil droplets on top of the piston rings and at the ring side clearance. Oil droplets were also noticed when the piston was at BDC and in front of the second compression ring, the scraper ring and the top piston land. The oil droplets and their source of appearance was captured, though, and higher magnification provided good imaging quality of how these droplets emerge through the ring side clearances. The most probable explanation is that these droplets adhere to the inner surface of the window.

Cavitation striations were observed mainly on the surface of the top compression ring. There are images, however, that show oil film developed on the top compression ring surface, as well as the second compression and scraper ring, but no string cavities were visualised. A possible reason for the appearance of the film on one hand, and the strings on the other (for the same piston ring but in different strokes and distances from TDC), is ring fluttering, which causes oil to pump into the ring groove, thus affecting the oil availability at the converging wedge. So, as the piston ring changes position, oil is squeezed or enters the side clearances.

The outcome of the ring/window interaction is the development of a rough surface. Surface profilometry results showed a groove depth up to 8 μm after the visualisation testing. The inner surface of the window has long linear grooves/scratches that are formed across the circumference of the liner. With the piston reciprocating, oil can penetrate the groove, producing droplets depending on the local depth of the groove. So, the corresponding figures indicate how the lubricant inside these cracks is shaped as droplets. Images taken from a cracked region of a visualisation window (long and deep groove) showed that larger oil droplets were formed inside these crevices.

Two major mechanisms were found to be responsible for oil flows from the piston lands to the ring grooves: the ring pumping, which was observed experimentally, and the lateral motion of the piston relative to the rings. The amount of oil in the grooves depended on the amount of oil in front of the ring groove clearances during ring lift and/or the piston lateral movement. Accordingly, it can be concluded that the rate at which oil from the lands is supplied to the grooves of the top two rings is strongly dependent on the timing of the inertia-driven oil displacement and the piston/ring interface dynamics.

The oil flows from the ring grooves to the piston lands appeared to be governed by the ring squeezing action and the dragging effect of the gases flowing through the ring groove clearances; this latter mechanism combined with ring flutter. The experimental observations of the land oil distribution during top ring fluttering clearly showed that gas flows resulting from ring instability could remove most of the oil accumulated in the top ring groove, preventing oil from flowing to the crown land.

Cavitation is directly linked to lubricant viscosity. An increase in temperature results in an MOFT decrease, as well as an oil film pressure peak decrease. Parametric study of temperature in the simulating test rig advanced the initiation of the cavitation towards the dead centre of the stroke and enhanced its intensity. After 60 °C, the cavitation area decreased as bubbles collapsed at higher oil temperatures. Bubbles, in general, were found to diminish at high temperatures (greater than 60 °C).

Formulation significantly affects the initiation and development of the various cavitation shapes, this being an effect of various parameters. Observations related to the chemistry of the lubricants can promote novel techniques in additive design and future research composing, optimising and improving (new) lubricant properties, promoting piston ring load-carrying capacity, improving efficiency, and limiting wear over a wider operating range.

This constitutes an evolutionary point for evaluating the basic lubrication performance aspects via study using a large-scale simulation single-ring test rig fitted with the various sensors, and with the aid of a custom-made visualisation window that enables visualisation of cavitation and its properties through the reciprocating cycle. This parametric study, at a second stage, was implemented in the engine cylinder, where complexity and a vast number of interconnecting unknowns have a small or detrimental effect on the operating lubrication interface.