1. Introduction

As one of the most critical components of rotating machinery, rolling bearings are called “industrial joints” because of their low price, strong interchangeability and mass production [

1,

2,

3,

4]. The overall performance and work efficiency of mechanical equipment are closely related to the operating state of rolling bearings, but rolling bearings are prone to faults due to the long-term operation of the mechanical equipment and the harsh working environment. Once a rolling bearing fails, it will threaten the normal operation of the entire equipment, potentially causing minor economic losses or, in severe cases, casualties [

5]. If rolling bearing faults can be identified promptly and accurately, economic losses and casualties can be effectively reduced or avoided [

6]. Therefore, conducting research on rolling bearing fault diagnosis is extremely necessary and significant.

At present, the fault diagnosis methods of rolling bearings based on vibration signal are mainly divided into two categories: fault diagnosis method based on signal processing and fault diagnosis method based on deep learning [

7,

8,

9].

The fault diagnosis method based on signal processing primarily includes fast Fourier transform (FFT), wavelet transform (WT), empirical mode decomposition (EMD) and variational mode decomposition (VMD) [

10,

11]. N. Sikder et al. [

12] proposed a bearing fault diagnosis method based on stochastic forest integrated learning, which adopts FFT to preprocess and extract characteristics from the bearing vibration signal and can effectively identify bearing fault types. B. Chen et al. [

13] combined WT with resonance-based sparse signal decomposition, utilizing the multi-resolution and locally optimized characteristics of WT to fully extract the fault characteristics of rolling bearing vibration signals, thereby achieving an effective diagnosis of rolling bearing faults in a strong noise environment. Q. Chen et al. [

14] proposed a rolling bearing fault diagnosis method combining EMD and fractional displacement entropy and proved the effectiveness of the method through experiments. W. Liu et al. [

15] proposed a bearing fault diagnosis method based on an improved program for optimal frequency band selection and conducted preliminary experimental validation. X. Li et al. [

16] proposed an improved fast kurtogram method to determine the bandwidth and center frequency of an optimal signal filter and applied it to fault diagnosis in rolling bearings. VMD can solve the mode mixing problem that cannot be solved by EMD and ensemble empirical mode decomposition (EEMD) to a certain extent, and it has fast convergence speed, strong robustness, and high decomposition accuracy. Therefore, VMD is highly suitable for processing rolling bearing vibration signals. However, if the parameters of VMD are not properly selected, the decomposition effect of VMD is not ideal, so it is necessary to optimize VMD to ensure the optimal parameters are obtained. H. Liu et al. [

17] used the multi-threshold center frequency method to determine the optimal number of modal components

K of VMD but did not consider the impact of penalty factor

α, another key parameter of VMD, on its decomposition results, thus restricting the fault diagnosis accuracy to a certain extent. P. Shi et al. [

18] proposed an improved VMD method that optimizes the number of modal components

K and the penalty factor

α separately, but this method ignores the interaction between

K and

α and thus cannot guarantee that the searched

K and

α are globally optimal, further failing to ensure that the decomposition effect of VMD reaches its optimal state. The fault diagnosis method based on signal processing requires less data and can directly analyze and process the original signal without complicated pre-processing steps. However, because the fault diagnosis method based on signal processing relies more on expert experience and prior knowledge, and more and more vibration signals of rolling bearings show coupling, uncertainty and incompleteness, it can no longer meet the requirements in terms of efficiency and accuracy of rolling bearing fault diagnosis.

The fault diagnosis method based on deep learning mainly realizes the automatic characteristic extraction and fault diagnosis of input data through the model, which has a high degree of automation and a low degree of dependence on expert knowledge so that the diagnosis process in practical application is greatly simplified. The fault diagnosis method based on deep learning mainly includes recurrent neural network (RNN), multi-layer perceptron (MLP) and convolutional neural network (CNN) [

19]. CNN has strong spatial characteristic extraction ability due to its unique local perception field of view, sparse link and weight sharing, which is suitable for extracting the spatial characteristics of rolling bearing vibration signals. C. Chen et al. [

20] used a one-dimensional convolutional neural network (1D-CNN) to diagnose rolling bearing faults, which overcame the shortcomings of traditional methods to a certain extent and effectively improved diagnostic accuracy. W. Huang et al. [

21] proposed the multiscale convolution kernel to obtain different fault characteristics by using convolution kernels of different sizes. J. He et al. [

22] constructed a fault diagnosis model based on 1D-CNN and optimized the model by using cross-entropy loss function and Adam optimizer, thus realizing bearing fault identification. However, the rolling bearing vibration signal is a kind of time series data, and the fault diagnosis methods based on CNN only consider the spatial characteristics of the rolling bearing vibration signal while ignoring its temporal characteristics during characteristic extraction, so they cannot fully and comprehensively extract the fault characteristics of rolling bearings. Long short-term memory (LSTM) is a special structure of RNN, which can capture long-term dependencies in time series data and thus has a powerful ability to extract temporal characteristics [

23]. Therefore, it is suitable for extracting the temporal characteristics of rolling bearing vibration signals. Considering the timing of bearing vibration signals, L. Cao et al. [

24] proposed a bearing fault diagnosis method based on LSTM, which can effectively use the original time signal to classify bearing faults. C. Zhong et al. [

25] proposed a rolling bearing fault diagnosis method that combines bi-directional long short-term memory (BiLSTM) with segmented intercepted autoregressive spectrum analysis. The effectiveness of this method in fault diagnosis of rolling bearings is verified by experiments. The above fault diagnosis methods based on LSTM can effectively extract the temporal characteristics of the rolling bearing vibration signal, but there are limitations in the spatial characteristic extraction, so it can not fully and comprehensively extract the rolling bearing fault characteristics. Most of the existing fault diagnosis methods based on deep learning adopt a single CNN or a single LSTM for fault diagnosis of rolling bearings, which can only analyze the characteristics of fault data in a single dimension (spatial dimension or temporal dimension). There is a lack of interaction and synergy in utilizing the information related to spatial characteristics and temporal characteristics, making it impossible to extract and analyze multi-dimensional characteristic information from rolling bearing fault data. It leads to a mismatch between the characteristics of the rolling bearing vibration signal and the fault diagnosis model, which hinders effective fault diagnosis of rolling bearings. Although the fault diagnosis method based on deep learning has obvious advantages in rolling bearing fault diagnosis, it also has some disadvantages [

26]: Deep learning models require a large amount of high-quality data for training and optimization, but it is difficult to obtain sufficient quantity and quality rolling bearing fault data in practical applications; In order to obtain high fault diagnosis accuracy, it is necessary to build a complex network structure, which leads to complex operations, difficult rule establishment, long learning time, poor real-time performance and poor generalization ability of deep learning models; The interpretability and transparency of deep learning models are poor; The stability and reliability of deep learning models still need to be further verified in practical applications.

In order to solve the above problems, a rolling bearing fault diagnosis model combining MSSSA-VMD (VMD optimized by the improved salp swarm algorithm based on mixed strategy (MSSSA) [

27]) with the parallel network of GASF-CNN (CNN based on Gramian angular summation field (GASF)) and BiLSTM is proposed in this paper. Aiming at the problem that the decomposition effect of VMD is not ideal due to improper parameter selection and the optimal parameter combination [

K,

α] cannot be obtained by traditional methods, the proposed MSSSA is used to search for the optimal parameter combination [

K,

α] of VMD; Aiming at the problem that CNN is effective in extracting spatial characteristics but not efficient in extracting temporal characteristics, while BiLSTM excels in temporal characteristic extraction but has limitations in spatial characteristic extraction, CNN and BiLSTM are combined into a parallel network. The advantages of the two are utilized to extract the fault characteristics of rolling bearings fully and comprehensively, Aiming at the problem that one-dimensional signals lack the ability to characterize fault information of rolling bearings and that directly intercepting one-dimensional signals in segments and arranging them in sequence to form two-dimensional signals is easy to cause sample information fragmentation, GASF is utilized to convert one-dimensional signals into two-dimensional signals; In view of the respective advantages and limitations of fault diagnosis methods based on signal processing and deep learning, the two types of methods are integrated. Firstly, the signal processing method (MSSSA-VMD) is employed to preprocess and extract characteristics from the vibration signal of the rolling bearing. Based on the optimal parameter combination, VMD decomposition of the rolling bearing vibration signal is carried out, and the 9 time-domain characteristics (mean, variance, peak value, kurtosis, effective value, peak factor, impulse factor, waveform factor and clearance factor) of the optimal intrinsic mode function (IMF) component of each fault type are extracted to construct characteristic vectors. Secondly, the extracted characteristics are input into the deep learning model (the parallel network of GASF-CNN and BiLSTM) for further analysis and diagnosis. In one channel of the parallel network, GASF is used to convert the characteristic vector extracted by MSSSA-VMD into a two-dimensional image, which is then fed into the CNN for spatial characteristic extraction. In the other channel of the parallel network, the characteristic vector extracted by MSSSA-VMD is directly input into the BiLSTM for temporal characteristic extraction. The extracted spatial and temporal characteristics are fused and then fed into the Softmax classifier for classification.

The contributions of the proposed rolling bearing fault diagnosis model are summarized as follows. Firstly, the proposed MSSSA-VMD can adaptively determine the optimal parameter combination of VMD and then extract the fault characteristics of rolling bearings efficiently. Secondly, the proposed parallel network of GASF-CNN and BiLSTM can make full use of the powerful spatial characteristic extraction capability of CNN and the excellent time series processing performance of BiLSTM, effectively solving the problem of insufficient representation capability of one-dimensional signal for fault information, and use dual-channel parallel training strategy to improve diagnosis efficiency. Thirdly, combining the signal processing method (MSSSA-VMD) with the deep learning method (the parallel network of GASF-CNN and BiLSTM) for rolling bearing fault diagnosis can maximize the advantages of both, thereby effectively enhancing the fault diagnosis performance of the model.

The upcoming sections of this paper are organized as follows: In

Section 2, the principles of MSSSA-VMD, CNN, BiLSTM and GASF are explained. A rolling bearing fault diagnosis model combining MSSSA-VMD with the parallel network of GASF-CNN and BiLSTM is proposed in

Section 3. In

Section 4, experimental verification and result analysis are conducted. Lastly, the conclusions are drawn in

Section 5.

3. A Rolling Bearing Fault Diagnosis Model Combining MSSSA-VMD with the Parallel Network of GASF-CNN and BiLSTM

A rolling bearing fault diagnosis model combining MSSSA-VMD with the parallel network of GASF-CNN and BiLSTM is proposed in this paper. The overall structure and fault diagnosis process of the proposed model are shown in

Figure 4.

The proposed model consists of two parts:

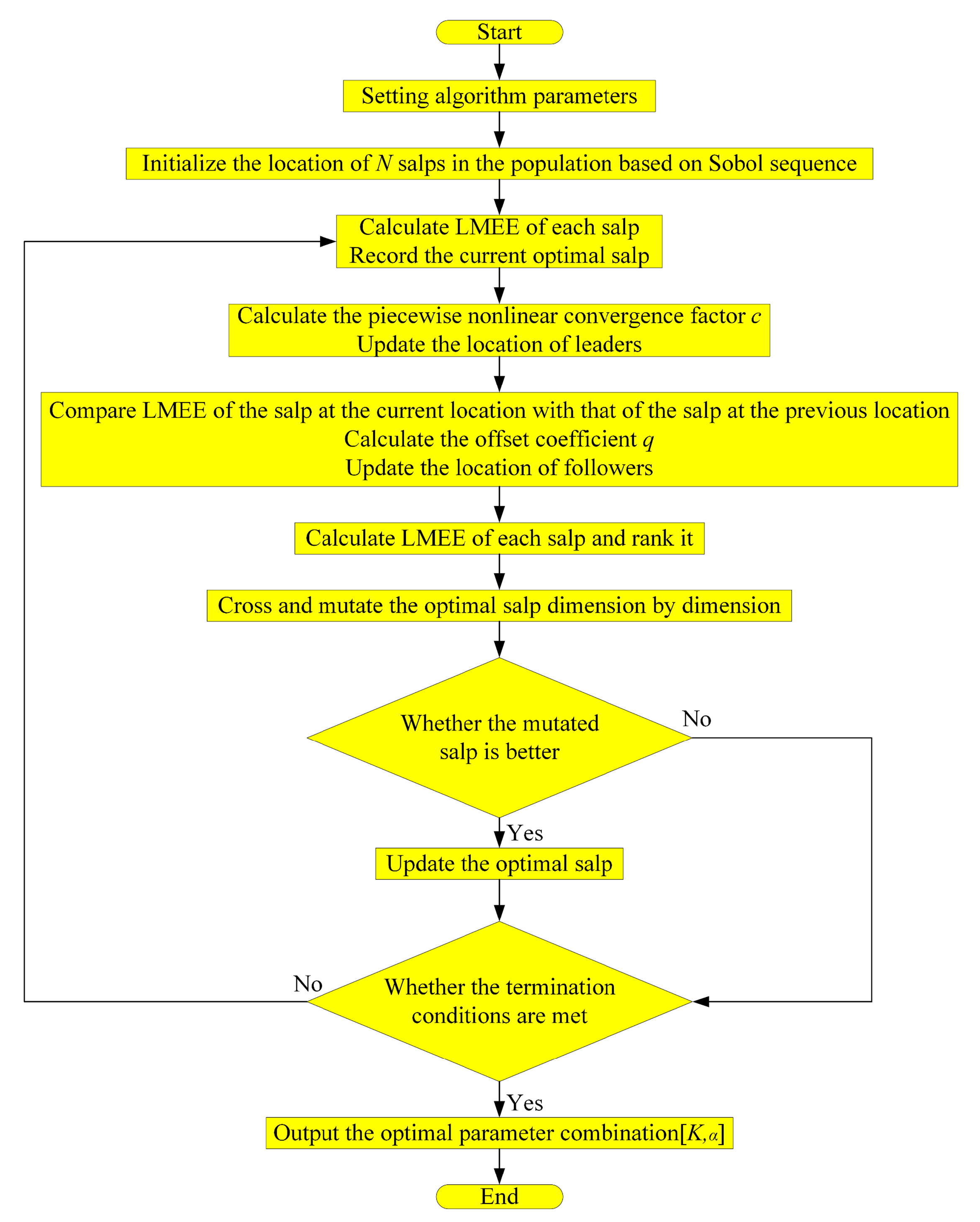

Part 1: Preprocessing and characteristic extraction based on MSSSA-VMD. According to the process shown in

Figure 1, MSSSA is used to optimize VMD to obtain the optimal parameter combination of VMD. Based on the optimal parameter combination, VMD decomposition is performed on the rolling bearing vibration signal, and then the 9 time-domain characteristics (mean, variance, peak value, kurtosis, effective value, peak factor, impulse factor, waveform factor and clearance factor) of the optimal IMF component of each fault type are extracted to construct vectors.

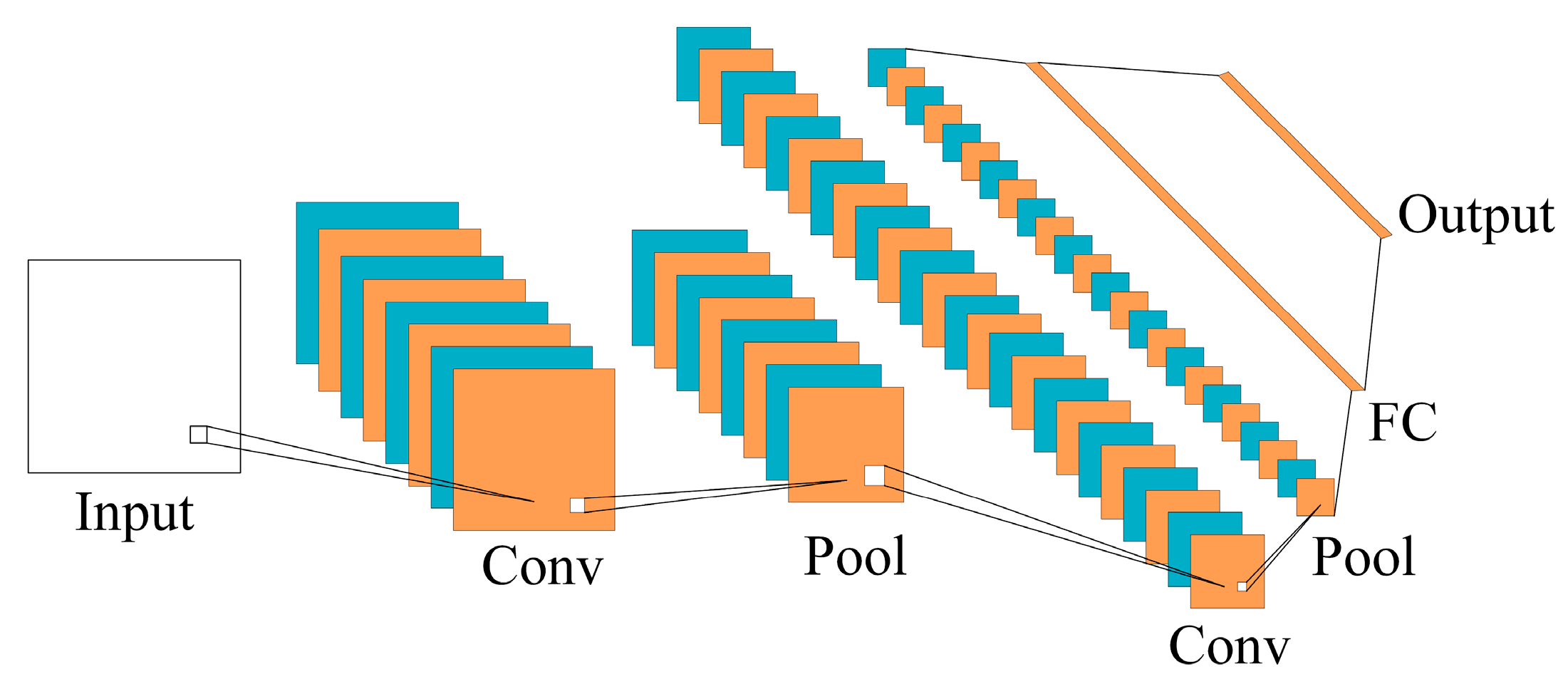

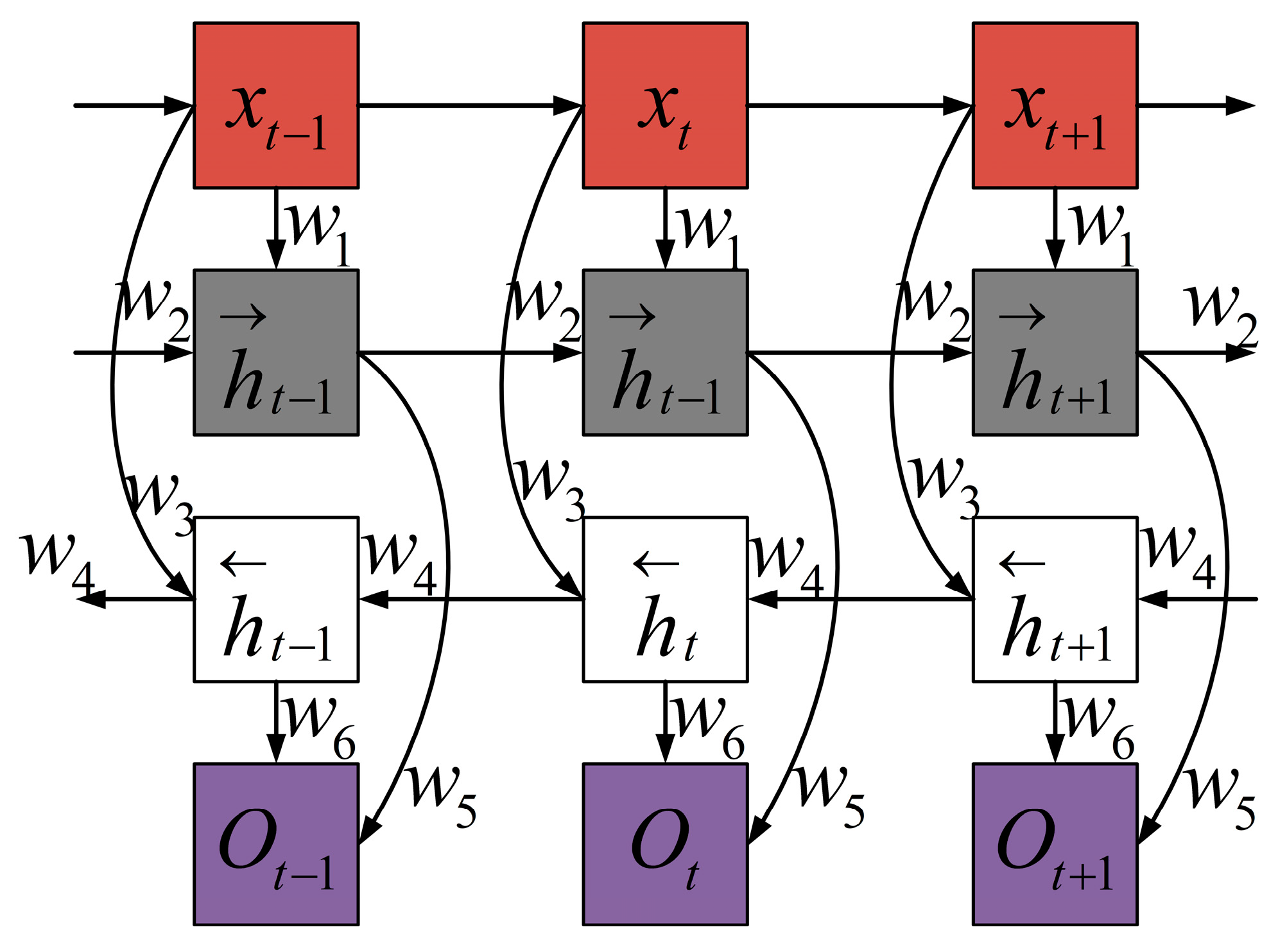

Part 2: Fault diagnosis based on the parallel network of GASF-CNN and BiLSTM. In one channel, the characteristic vectors are converted into a two-dimensional image by GASF and fed into CNN. Then, the spatial characteristics of the two-dimensional image are extracted by CNN through convolution and pooling, and a set of one-dimensional vectors is outputted through the fully connected layer. In the other channel, the characteristic vectors are directly fed into BiLSTM, where their temporal characteristics are extracted. Then, a set of one-dimensional vectors is outputted through the fully connected layer. Afterward, the two sets of one-dimensional vectors are fused. Finally, the fused characteristics are sent to the Softmax classifier for classification.

5. Conclusions

To solve the problem of poor diagnostic performance for rolling bearing faults caused by the respective limitations of existing fault diagnosis methods based on signal processing and deep learning, this paper proposes a rolling bearing fault diagnosis model combining MSSSA-VMD with the parallel network of GASF-CNN and BiLSTM. In the first stage, MSSSA-VMD is proposed for preprocessing and characteristic extraction. VMD is optimized by MSSSA to obtain the optimal parameter combination, then VMD decomposition of the rolling bearing vibration signal is carried out based on the optimal parameter combination. Subsequently, nine time-domain characteristics of the optimal IMF component corresponding to each fault type obtained by decomposition are extracted to construct the characteristic vectors. In the second stage, the parallel network of GASF-CNN and BiLSTM is constructed to diagnose rolling bearing faults. In one channel of the parallel network, the obtained characteristic vectors are converted into the two-dimensional image by GASF and sent to CNN for spatial characteristic extraction. In the other channel of the parallel network, the obtained characteristic vectors are directly sent to BiLSTM for temporal characteristic extraction. Subsequently, the two sets of one-dimensional vectors output by the two parallel channels are spliced and fused. Finally, the fusion characteristics are fed into the Softmax classifier for classification so as to realize the fault diagnosis of rolling bearings. The performance of the proposed rolling bearing fault diagnosis model is experimentally validated based on the CWRU bearing dataset and the JNU bearing dataset used in this research. Through comparisons with other rolling bearing fault diagnosis models in terms of fault diagnosis performance under constant operating conditions, generalization ability under variable operating conditions and noise resistance, it can be observed that the proposed model exhibits superior performance compared to other rolling bearing fault diagnosis models. The experimental results show that the proposed model can effectively solve the problem of poor diagnostic performance for rolling bearing faults caused by the respective limitations of existing fault diagnosis methods based on signal processing and deep learning.

Through in-depth analysis of the experimental results, it can be seen that the proposed model has certain limitations. In order to achieve higher diagnostic accuracy, the proposed model sacrifices some inference time, resulting in a slightly longer computation time compared to models with simpler structures. This undoubtedly poses a constraint on its real-time performance. Furthermore, although the generalization capability of the proposed model is acceptable, it still needs further enhancement. Therefore, in future research, we will take measures to improve the proposed model, focusing specifically on the above two limitations. We will compress the proposed model through techniques such as pruning, quantization, and distillation to reduce its size and computational requirements, thereby significantly decreasing its inference time without sacrificing its performance. At the same time, we will optimize the training process by adjusting the hyperparameters of the proposed model to reduce its computation time. To enhance the generalization ability of the proposed model, we will strive to diversify the training dataset by incorporating a broader range of samples that represent various scenarios and conditions. Additionally, we will explore ensemble learning methods, where multiple models are trained, and their predictions are combined to improve the overall generalization ability.