Moringa Oil and Carbon Phases of Different Shapes as Additives for Lubrication

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

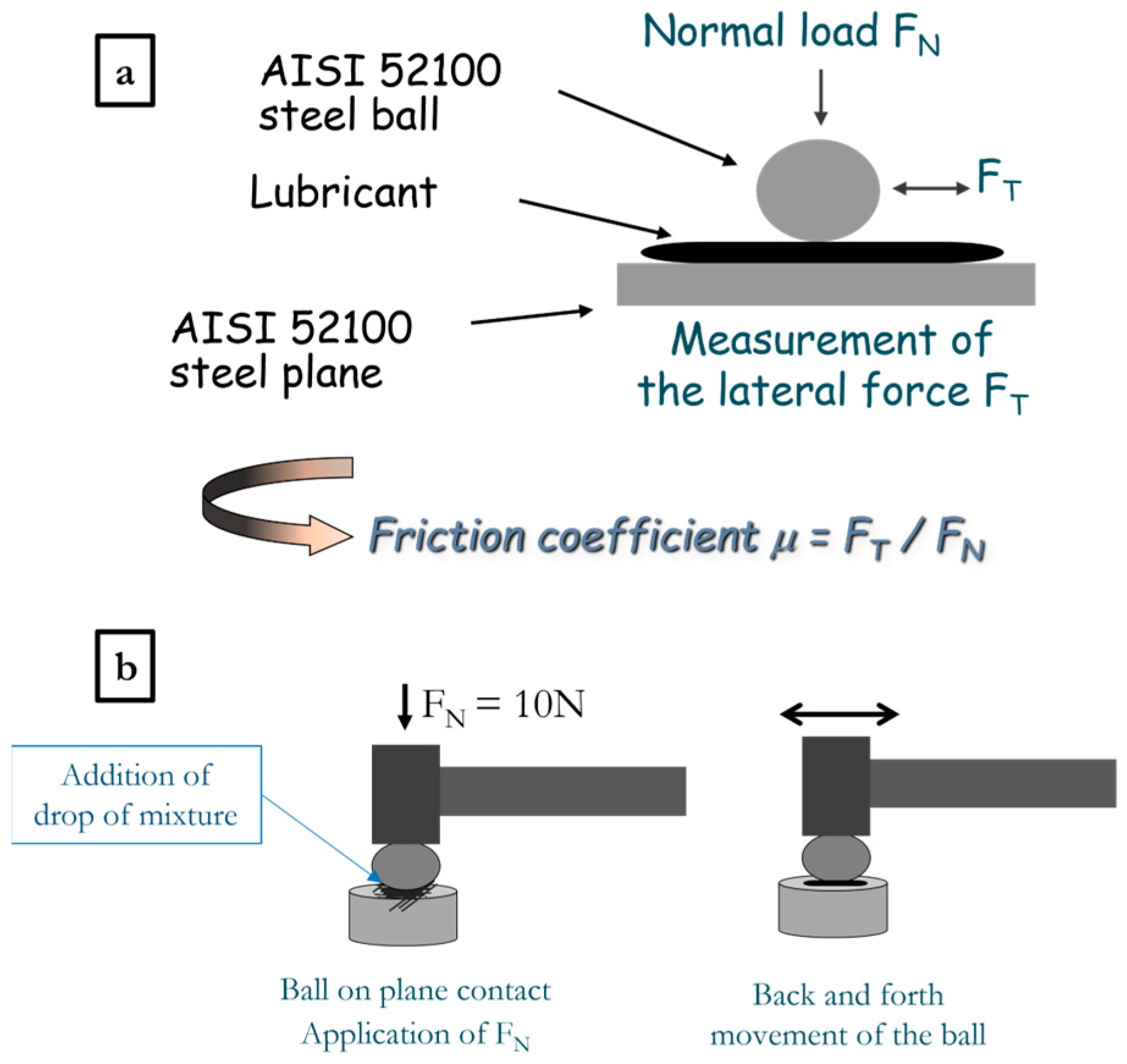

2.2. Tribological Tests

2.3. Physicochemical Characterizations

3. Results

3.1. Moringa Oil as Additive in Dodecane

3.2. Solid Particles as Additives

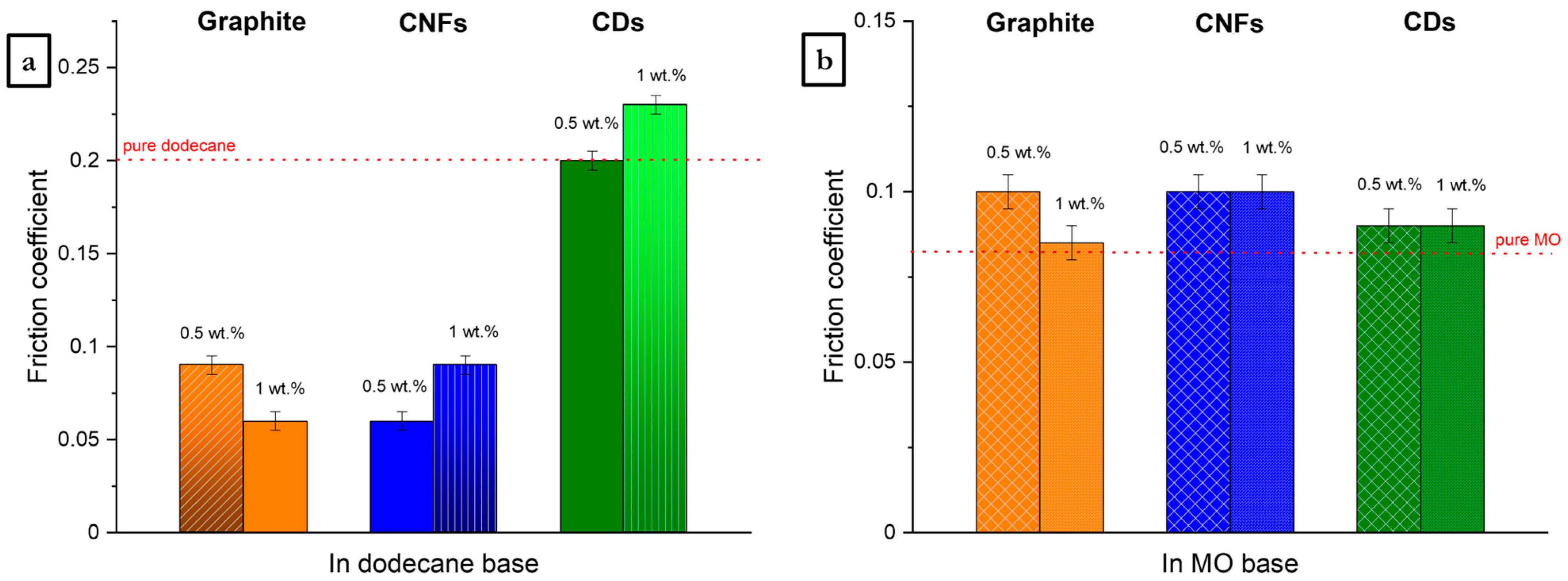

3.2.1. In Dodecane Base

3.2.2. In MO Base

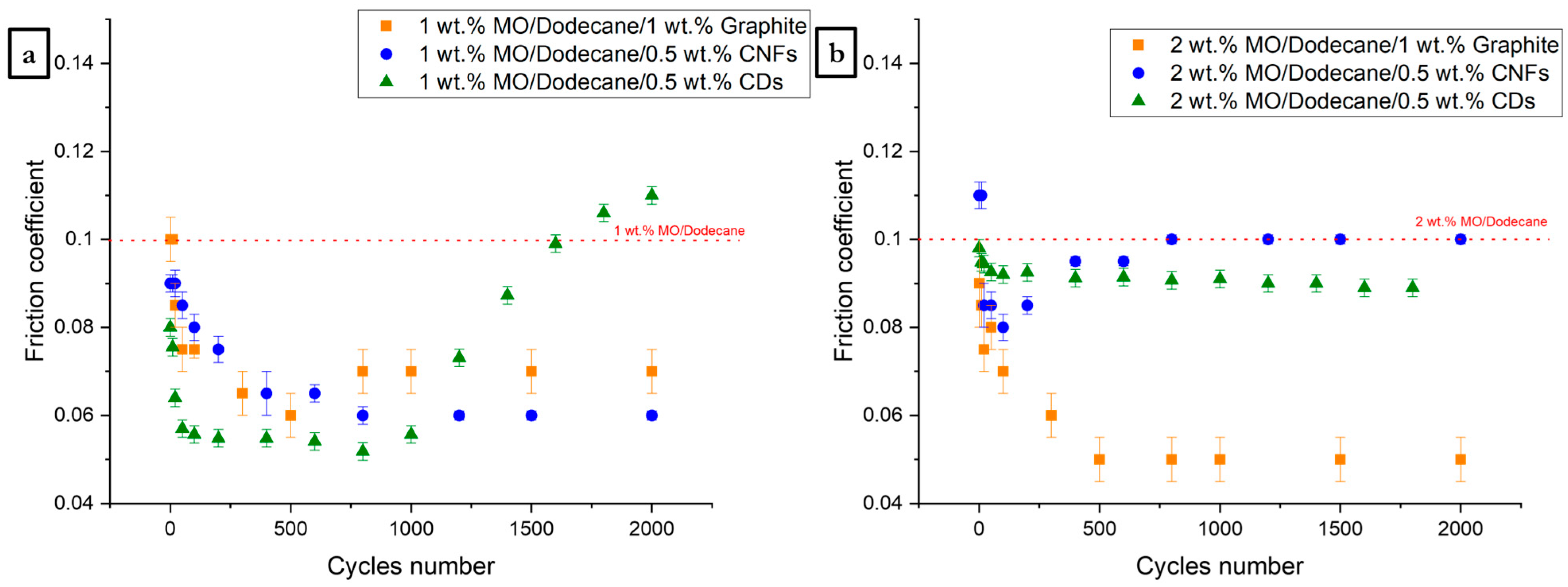

3.2.3. In 1 wt.% of MO/Dodecane Mixtures

3.2.4. In 2 wt.% of MO/Dodecane Mixtures

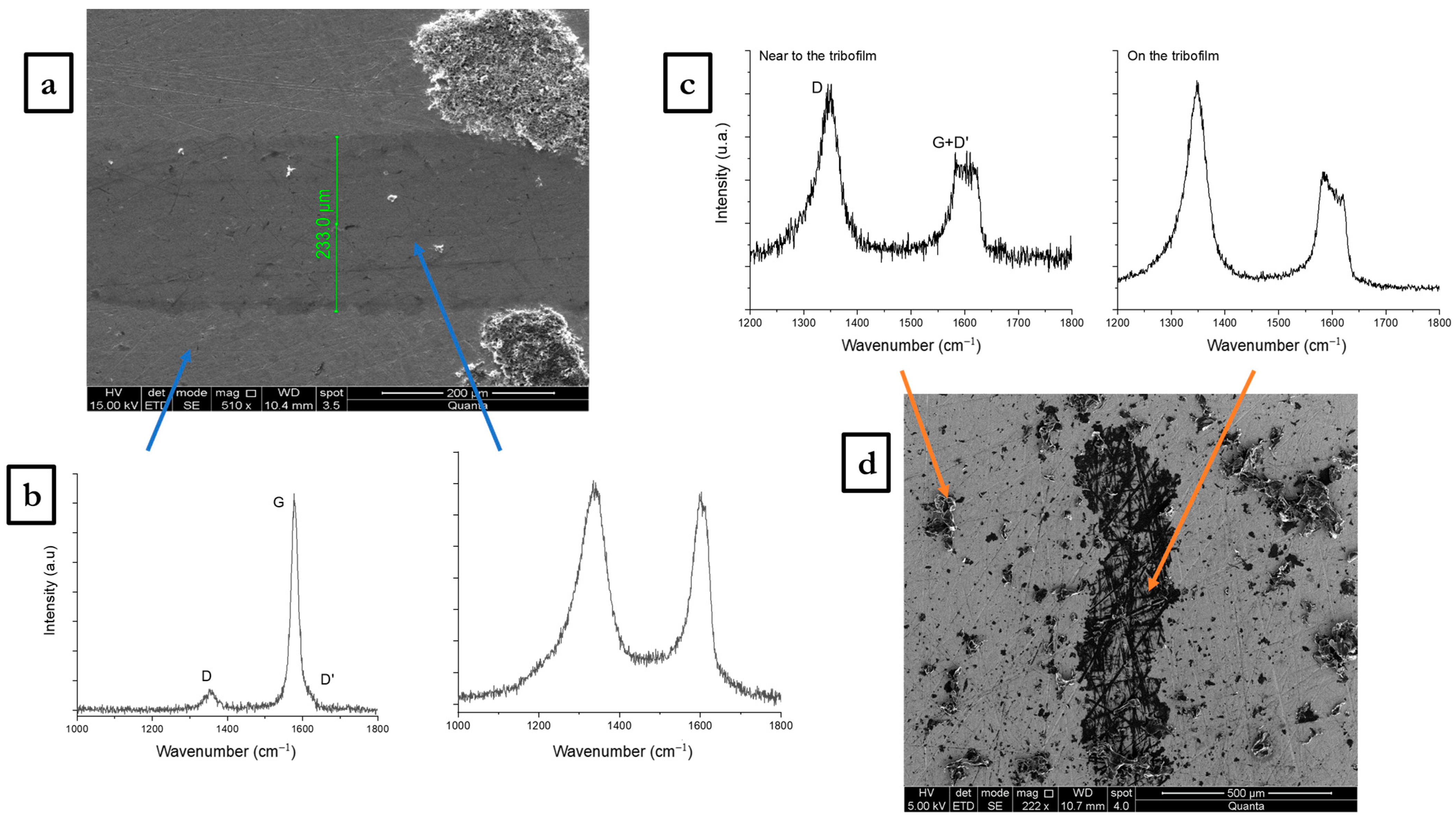

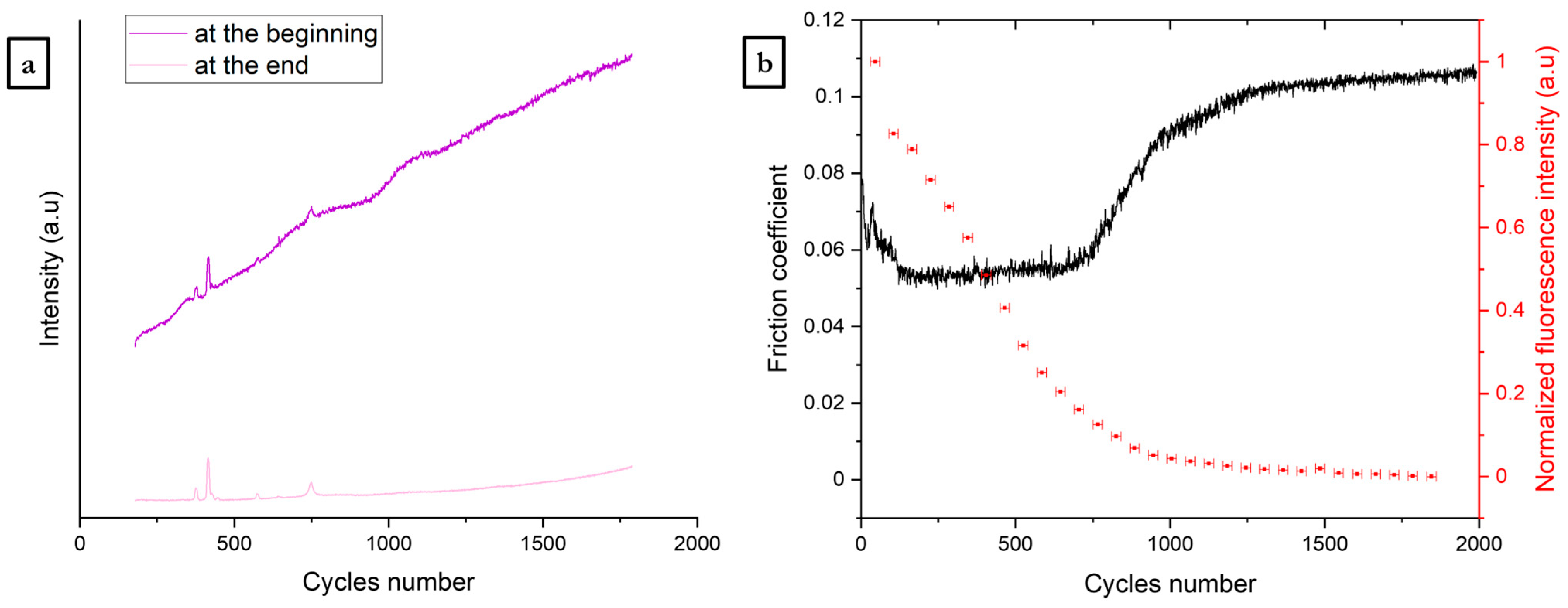

3.3. Physicochemical Characterization

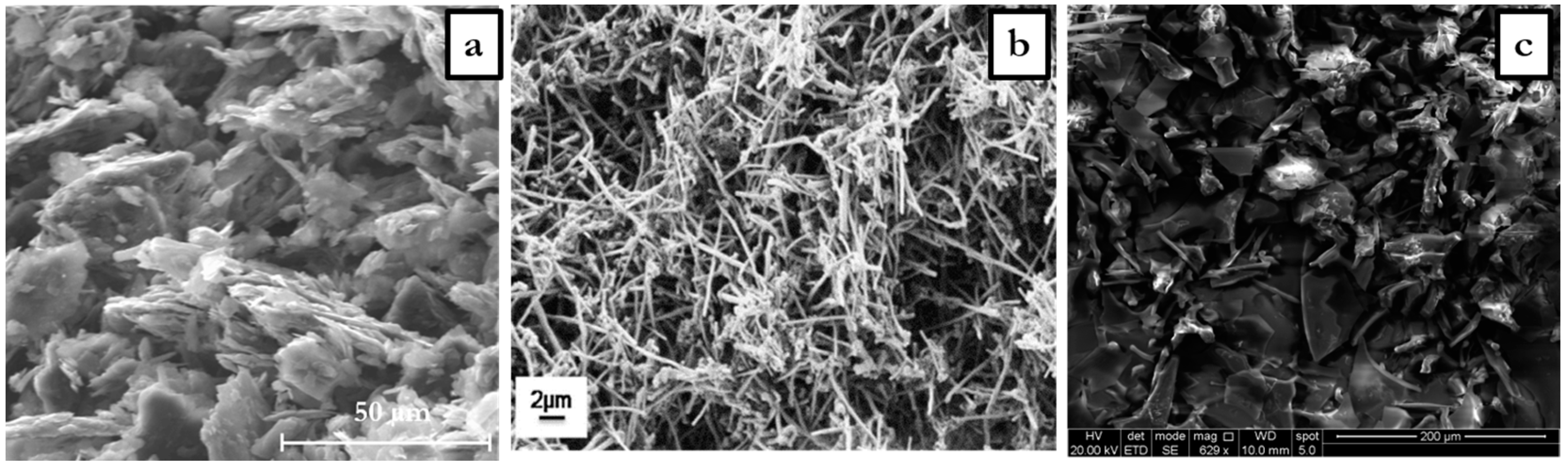

3.3.1. CNFs

3.3.2. Graphite

3.3.3. CDs

4. Discussion

5. Conclusions

- Moringa oil as a lubricant base is not efficient due to its high viscosity parameters. Indeed, with a similar composition, an important friction reduction is obtained for blends composed with a dodecane base, contrary to moringa base oil.

- Moringa oil used as a liquid additive for lubricants has a beneficial action on the friction of mineral base oil and on the tribological properties of blends according to the shape of the carbon-phase when used as additives.

- The 0D particles could be an excellent candidate for the biolubrication field, but more investigations will have to be realized to increase their stability during friction experiments. The CDs used are natural carbon phases, and present good results in the blends.

- The 1D particles are additives and are less interesting for lubricant blends due to the random movements in the nanofluid during the sliding.

- The 2D particles present the best stable friction properties. However, the additive composition of the lubricant blends composed of graphite is higher.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Crespo, A.; Morgado, N.; Mazuyer, D.; Cayer-Barrioz, J. Effect of Unsaturation on the Adsorption and the Mechanical Behavior of Fatty Acid Layers. Langmuir 2018, 34, 4560–4567. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8, 221–300. [Google Scholar] [CrossRef]

- Wood, M.H.; Casford, M.T.; Steitz, R.; Zarbakhsh, A.; Welbourn, R.J.L.; Clarke, S.M. Comparative Adsorption of Saturated and Unsaturated Fatty Acids at the Iron Oxide/Oil Interface. Langmuir 2016, 32, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Siniawski, M.T.; Saniei, N.; Adhikari, B.; Doezema, L.A. Influence of fatty acid composition on the tribological performance of two vegetable-based lubricants. J. Synth. Lubr. 2007, 24, 101–110. [Google Scholar] [CrossRef]

- Winfield, D.M.D.; Cermak, S.C.; Evangelista, R.L.; Moser, B.R.; McKinney, J.; Pantalone, V. Evaluation of a high oleic soybean oil variety in lubricant and biodiesel applications. J. Am. Oil Chem. Soc. 2024, 101, 493–499. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Jen, T.; Lovell, M.R. The influence of fatty acids on tribological and thermal properties of natural oils as sustainable biolubricants. Tribiol. Int. 2015, 90, 123–134. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Yang, S.; Yi, C.; Liu, T.; Zhang, R.; Jia, D.; Peng, S.; Yang, Q. Prediction of Lubrication Performances of Vegetable Oils by Genetic Functional Approximation Algorithm. Lubricants 2024, 12, 226. [Google Scholar] [CrossRef]

- Loehle, S.; Matta, C.; Minfray, C. Mixed Lubrication with C18 Fatty Acids: Effect of Unsaturation. Tribol. Lett. 2014, 53, 319–328. [Google Scholar] [CrossRef]

- Bahari, A.; Lewis, R.; Slatter, T. Friction and wear response of vegetable oils and their blends with mineral engine oil in a reciprocating sliding contact at severe contact conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 244–258. [Google Scholar] [CrossRef]

- Chan, C.H.; Tang, S.W.; Mohd, N.K.; Lim, W.H.; Yeong, S.K.; Idris, Z. Tribological behavior of biolubricant base stocks and additives. Renew. Sustain. Energy Rev. 2018, 93, 145–157. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Kong, H.; Li, Y.; Xin, X.; Wang, C.; Liang, Q.; Wang, Y. Lanthanide complexes functionalized carbon dot nanocomposites as lubricant additives for improving tribological performance. Mater. Lett. 2023, 333, 133697. [Google Scholar] [CrossRef]

- Tang, W.; Zhu, X.; Li, Y. Tribological performance of various metal-doped carbon dots as water-based lubricant additives and their potential application as additives of poly(ethylene glycol). Friction 2022, 10, 688–705. [Google Scholar] [CrossRef]

- Guo, J.; Peng, R.; Du, H.; Shen, Y.; Li, Y.; Li, J.; Dong, G. The Application of Nano-MoS2 Quantum Dots as Liquid Lubricant Additive for Tribological Behavior Improvement. Nanomaterials 2020, 10, 200. [Google Scholar] [CrossRef] [PubMed]

- Spikes, H. Friction modifier additives. Tribol. Lett. 2015, 60, 1–26. [Google Scholar] [CrossRef]

- Nomède-Martyr, N.; Disa, E.; Thomas, P.; Romana, L.; Mansot, J.L.; Dubois, M.; Guérin, K.; Zhang, W.; Hamwi, A. Tribological properties of fluorinated nanocarbons with different shape factors. J. Fluor. Chem. 2012, 144, 10–16. [Google Scholar] [CrossRef]

- Rahman, M.M.; Islam, M.; Roy, R.; Younis, H.; AlNahyan, M.; Younes, H. Carbon Nanomaterial-Based Lubricants: Review of Recent Developments. Lubricants 2022, 10, 281. [Google Scholar] [CrossRef]

- Lee, J.; Cho, S.; Hwang, Y.; Lee, C.; Kim, S.H. Enhancement of lubrication properties of nano-oil by controlling the amount of fullerene nanoparticle additives. Tribol. Lett. 2007, 28, 203–208. [Google Scholar] [CrossRef]

- Cornelio, J.A.C.; Cuervo, P.A.; Hoyos-Palacio, L.M.; Lara-Romero, J.; Toro, A. Tribological properties of carbon nanotubes as lubricant additive in oil and water for a wheel–rail system. J. Mater. Res. Technol. 2016, 5, 68–76. [Google Scholar] [CrossRef]

- Nassef, B.G.; Pape, F.; Poll, G. Enhancing the Performance of Rapeseed Oil Lubricant for Machinery Component Applications through Hybrid Blends of Nanoadditives. Lubricants 2023, 11, 479. [Google Scholar] [CrossRef]

- Nomède-Martyr, N.; Bilas, P.; Bercion, Y.; Thomas, P. Moringa and Graphite as Additives to Conventional Petroleum-Based Lubricants. Lubricants 2021, 9, 65. [Google Scholar] [CrossRef]

- Bilas, P.; Nomède-Martyr, N.; Mathieu, G.; Bercion, Y.; Césaire, T.; Thomas, P. Tribological properties of Sargassum carbon dots as additives in water-based lubricants. Mater. Lett. 2024, 354, 135411. [Google Scholar] [CrossRef]

- Nomède-Martyr, N.; Vitulin, M.; Joseph, H.; Thomas, P. Moringa oil with graphite and hexagonal boron nitride particles as additives for lubrication. Diam. Relat. Mater. 2022, 124, 108930. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed]

- Nomede-Martyr, N.; Philippe, B.; Philippe, T.; Georges, M.; Laurence, R. Tribological performances of graphite and hexagonal boron nitride particles in the presence of liquid. J. Tribol. 2021, 43, 071401. [Google Scholar] [CrossRef]

- Salih, N.; Salimon, J. A review on eco-friendly green biolubricants from renewable and sustainable plant oil sources. Biointerface Res. Appl. Chem. 2021, 11, 13303–13327. [Google Scholar] [CrossRef]

- Nasr, J.; Cursaru, D.L. The Performance of Carbon-Based Nanomaterials in Different Base Oils and an Oil Blend. Lubricants 2024, 12, 90. [Google Scholar] [CrossRef]

- Kamarapu, S.K.; Muniyappa, A.; Bheemappa, S.; Vardhaman, B.S.A.; Ramkumar, J.; Rangappa, D. Tribological and vibration characteristics of palm-mineral blend as a sustainable lubricant in steel-steel contacts. Biomass Convers. Biorefinery 2024, 14, 14107–14137. [Google Scholar] [CrossRef]

- Sahu, A.; Saha, N. Comparative investigation of lubricant properties of pongamia and castor oil bio lubricant blended with (SAE20W40) mineral oil. Tribol. Ind. 2024, 46, 535–547. [Google Scholar] [CrossRef]

- Basiron, J.; Abdollah, M.F.B.; Abdullah, M.I.C.; Amiruddin, H. Lubricant mechanisms of eco-friendly lubricant blended with mineral oil for steel-steel contact. Tribol. Int. 2023, 186, 108653. [Google Scholar] [CrossRef]

- Fry, B.M.; Moody, G.; Spikes, H.; Wong, J.S.S. Effect of Surface Cleaning on Performance of Organic Friction Modifiers. Tribol. Trans. 2020, 63, 305–313. [Google Scholar] [CrossRef]

- Campen, S.; Green, J.H.; Lamb, G.D.; Spikes, H.A. In Situ Study of Model Organic Friction Modifiers Using Liquid Cell AFM; Saturated and Mono-unsaturated Carboxylic Acids. Tribol. Lett. 2015, 57, 18. [Google Scholar] [CrossRef]

- Fry, B.M.; Moody, G.; Spikes, H.A.; Wong, J.S.S. Adsorption of Organic Friction Modifier Additives. Langmuir 2020, 36, 1147–1155. [Google Scholar] [CrossRef] [PubMed]

- Atchudan, R.; Edison, T.N.J.I.; Perumal, S.; Muthuchamy, N.; Lee, Y.R. Hydrophilic nitrogen-doped carbon dots from biowaste using dwarf banana peel for environmental and biological applications. Fuel 2020, 275, 117821. [Google Scholar] [CrossRef]

- Bhaumik, S.; Maggirwar, R.; Datta, S.; Pathak, S.D. Analyses of anti-wear and extreme pressure properties of castor oil with zinc oxide nano friction modifiers. Appl. Surf. Sci. 2018, 449, 277–286. [Google Scholar] [CrossRef]

| Fatty Acid Methyl Ester | % Mole Fraction | |

|---|---|---|

| Palmitic | C16:0 | 6.09 |

| Palmitoleic | C16:1 | 1.94 |

| Stearic | C18:0 | 3.77 |

| Oleic | C18:1 | 75.33 |

| linoleic | C18:2 | 0.90 |

| Linolenic | C18:3 | 0.29 |

| Arachidic | C20:0 | 2.47 |

| Behenic | C22:0 | 5.67 |

| Lignoceric | C24:0 | 1.01 |

| Lubricant Base | Solid Additives | Liquid Additive | Experimental Methods |

|---|---|---|---|

| Dodecane | 0.5 and 1 wt.% of graphite— 0.5 and 1 wt.% of carbon nanofibers— 0.5 and 1 wt.% of carbon nanodots | Ball-on-plane tribometer | |

| Moringa oil | 0.5 and 1 wt.% of graphite— 0.5 and 1 wt.% of carbon nanofibers— 0.5 and 1 wt.% of carbon nanodots | Ball-on-plane tribometer | |

| Dodecane | 0.5, 1, 1.5, 2, 3 wt.% of moringa oil | Ball-on-plane tribometer Viscometer FTIR | |

| Dodecane | 1 wt.% of graphite | 1 and 2 wt.% of MO | Ball-on-plane tribometer Raman spectrometer SEM |

| Dodecane | 0.5 wt.% of carbon nanofibers | 1 and 2 wt.% of MO | Ball-on-plane tribometer Raman spectrometer SEM |

| Dodecane | 0.5 wt.% of carbon nanodots | 1 and 2 wt.% of MO | Ball-on-plane tribometer Raman spectrometer SEM |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nomède-Martyr, N.; Bilas, P.; Mathieu, G.; Bercion, Y.; Joseph, H.; Thomas, P. Moringa Oil and Carbon Phases of Different Shapes as Additives for Lubrication. Lubricants 2024, 12, 358. https://doi.org/10.3390/lubricants12100358

Nomède-Martyr N, Bilas P, Mathieu G, Bercion Y, Joseph H, Thomas P. Moringa Oil and Carbon Phases of Different Shapes as Additives for Lubrication. Lubricants. 2024; 12(10):358. https://doi.org/10.3390/lubricants12100358

Chicago/Turabian StyleNomède-Martyr, Nadiège, Philippe Bilas, Grégory Mathieu, Yves Bercion, Henry Joseph, and Philippe Thomas. 2024. "Moringa Oil and Carbon Phases of Different Shapes as Additives for Lubrication" Lubricants 12, no. 10: 358. https://doi.org/10.3390/lubricants12100358

APA StyleNomède-Martyr, N., Bilas, P., Mathieu, G., Bercion, Y., Joseph, H., & Thomas, P. (2024). Moringa Oil and Carbon Phases of Different Shapes as Additives for Lubrication. Lubricants, 12(10), 358. https://doi.org/10.3390/lubricants12100358