Effect of Counterbody Material on the Boundary Lubrication Behavior of Commercially Pure Titanium in a Motor Oil

Abstract

:1. Introduction

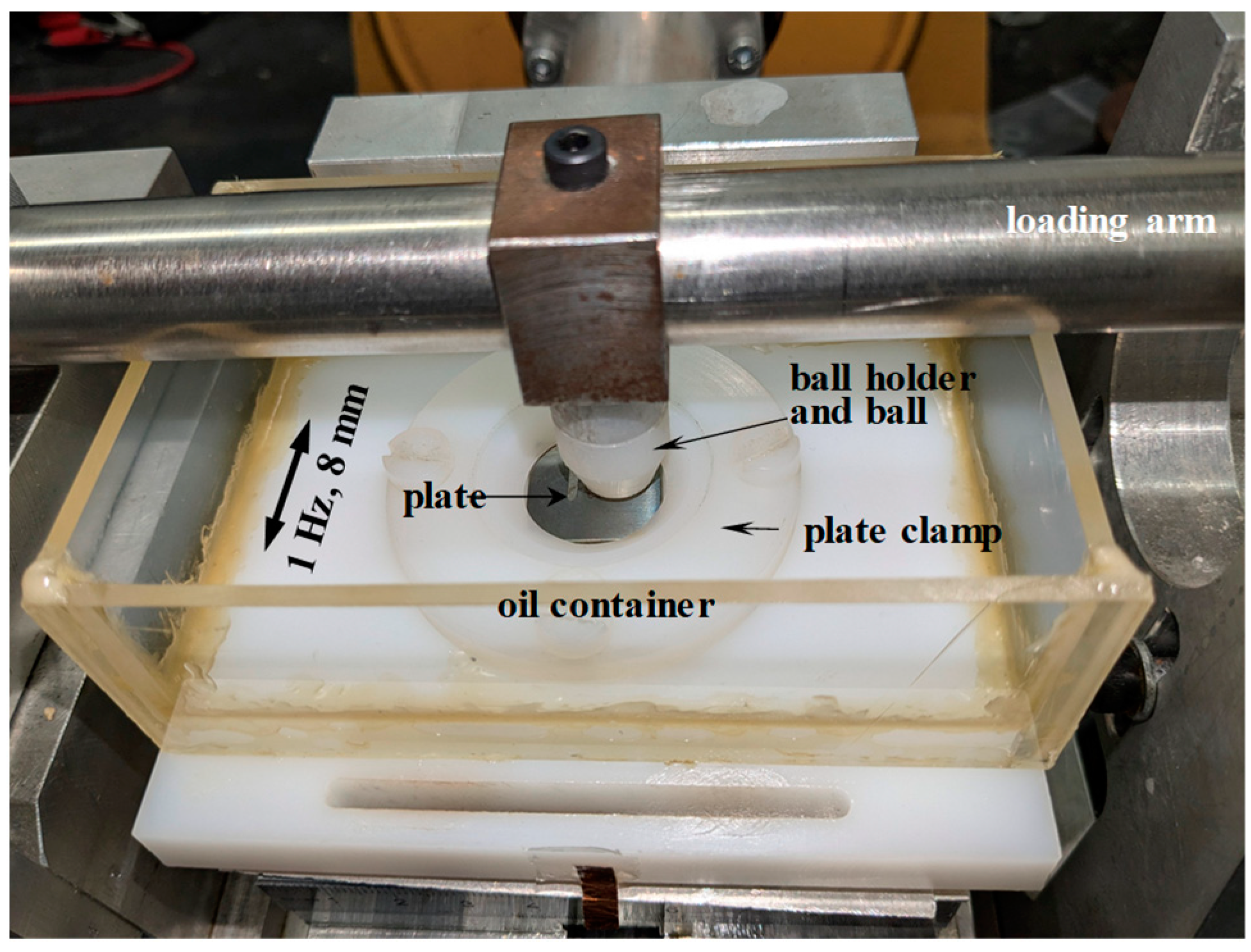

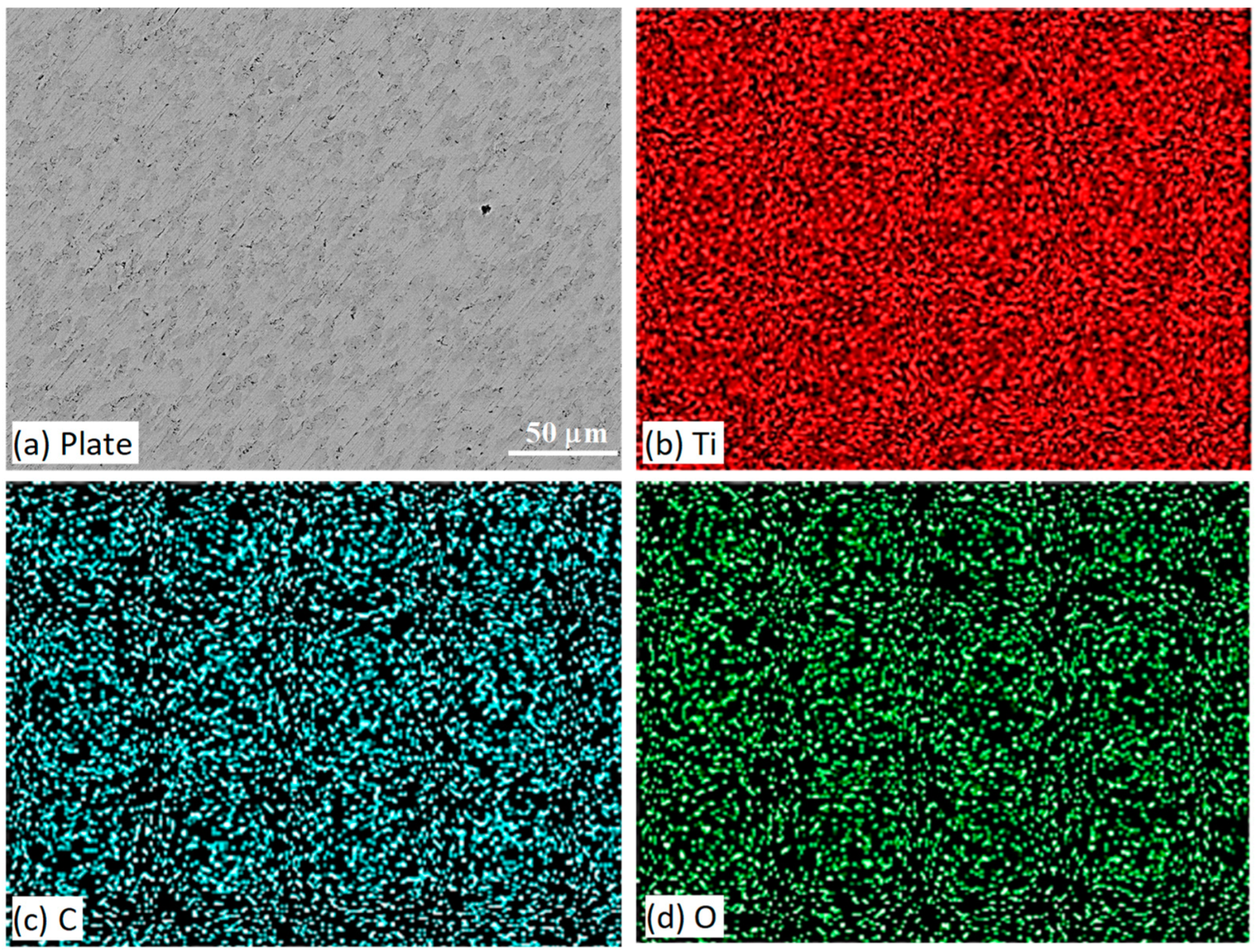

2. Materials and Methods

3. Results and Discussion

3.1. Friction

- (1)

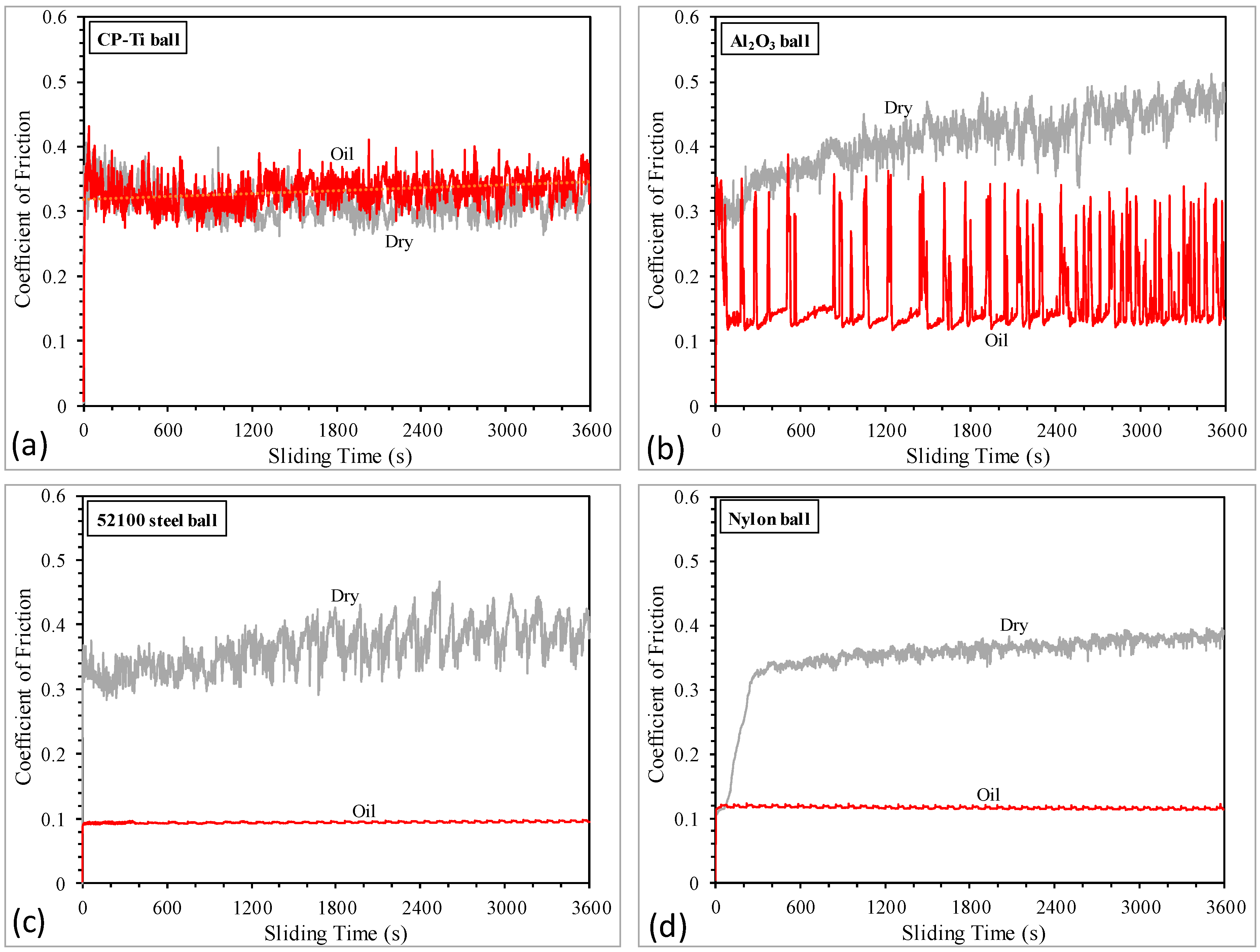

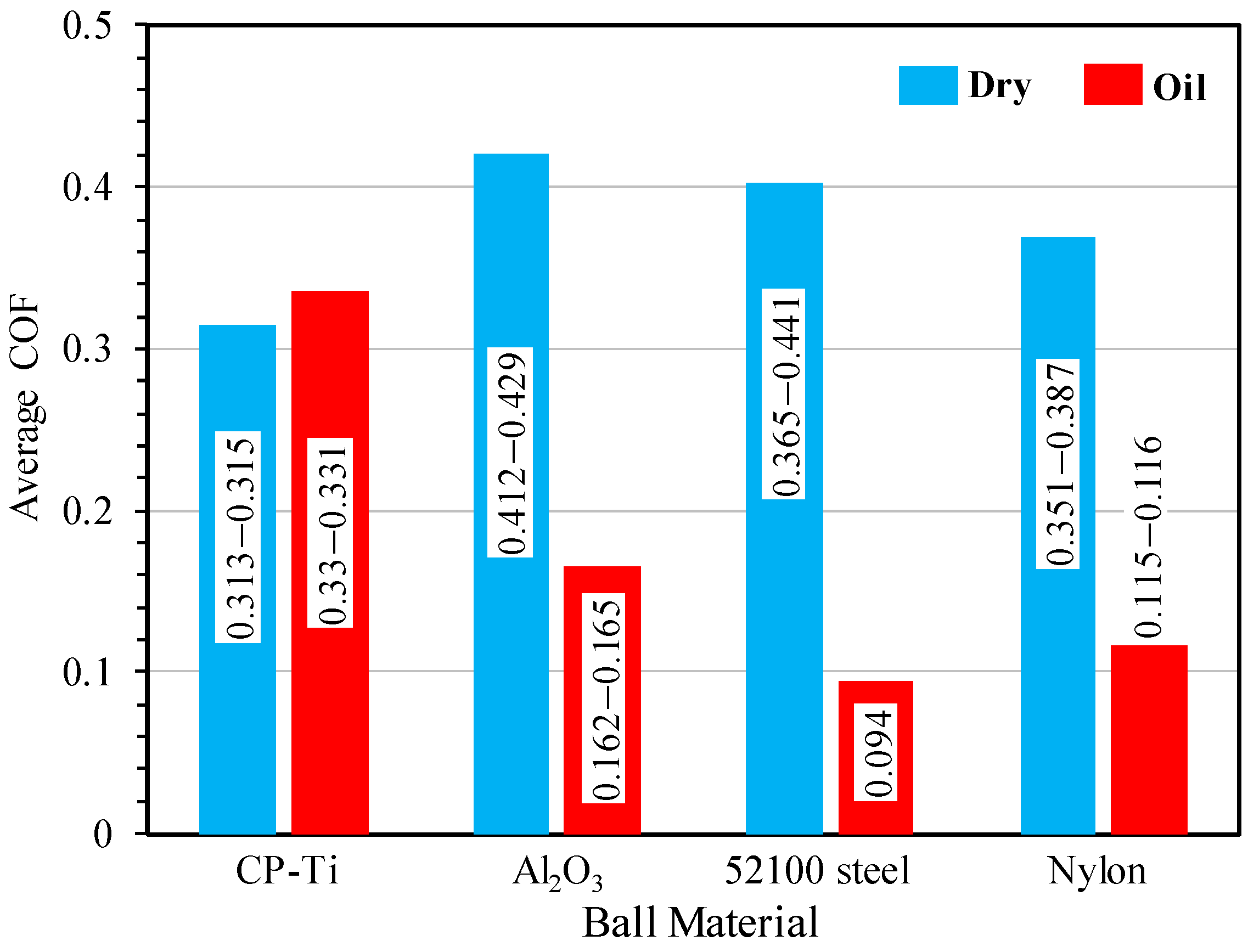

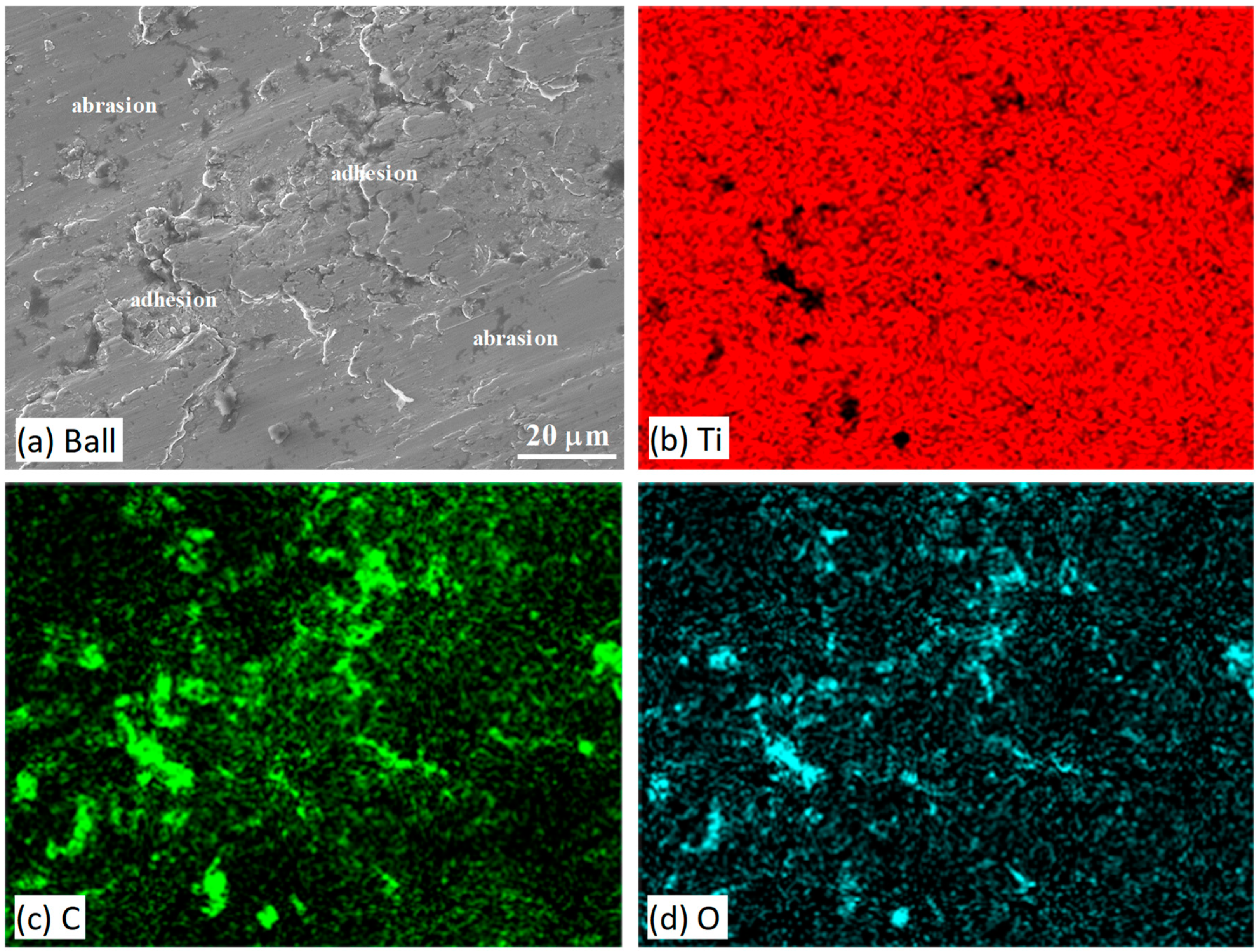

- Lubrication failure. The 0W-30 motor oil fails to lubricate the Ti-Ti pair (Figure 2a), such that the friction curve measured under oil lubrication is similar to that measured under dry sliding conditions. Both friction curves show large variations during sliding, with average COF values larger than 0.3 (Figure 3). Similar results have been reported by several investigators for such a sliding pair [6,16,31]. Clearly, the motor oil fails to prevent adhesion between the two contacting titanium surfaces. The average COF is actually slightly higher under oil-lubricated conditions than under dry sliding conditions (Figure 3). This could be explained by the oxidation of the titanium surfaces during dry sliding, which helps to slightly reduce friction [35,36].

- (2)

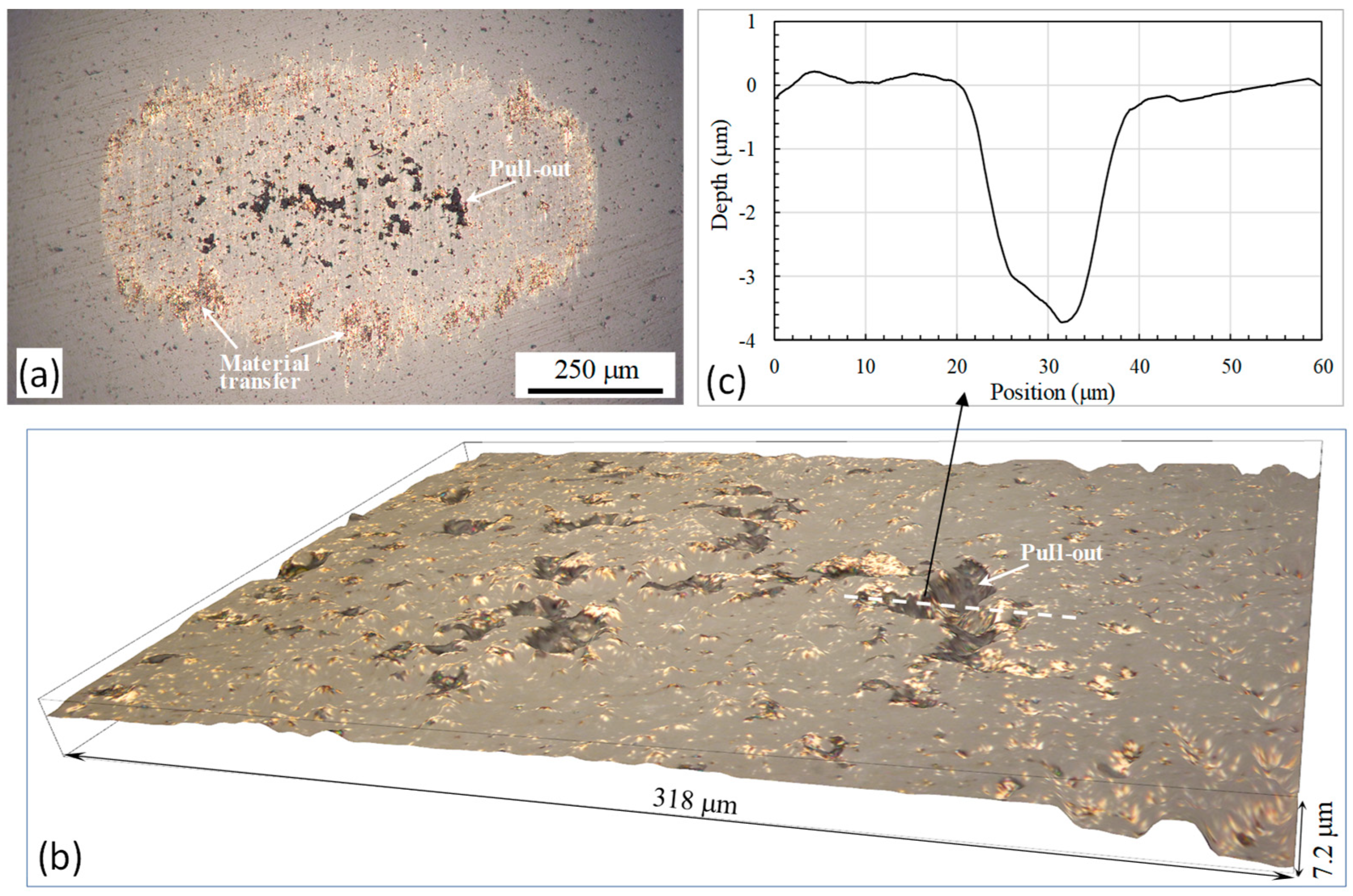

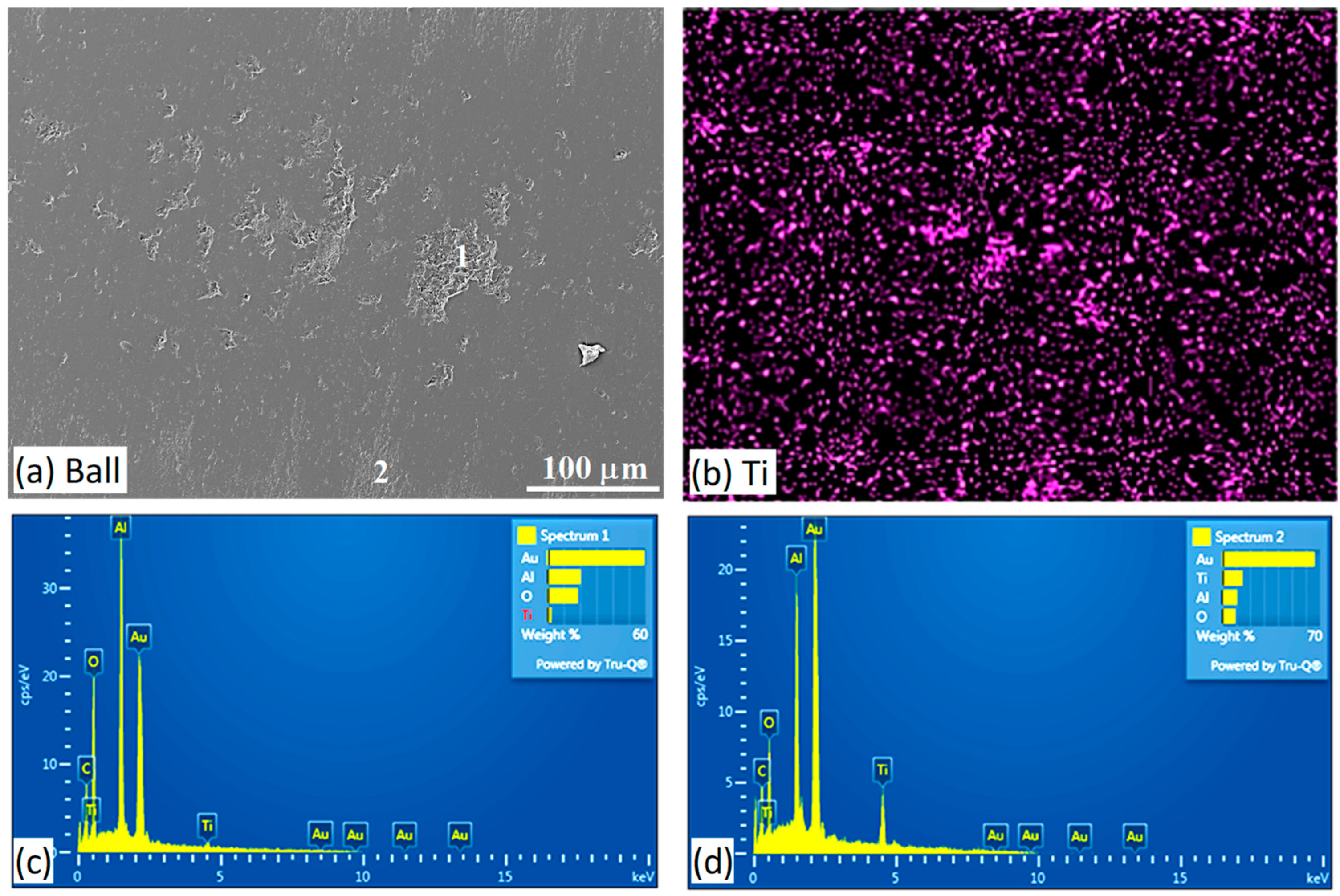

- Improved lubrication but with friction instability. This is observed for the Ti-Al2O3 pair (Figure 2b), where the COF is reduced from around 0.4 under dry sliding conditions to a base level around 0.14 under oil-lubricated conditions but friction under oil-lubricated conditions is instable, indicated by the many friction spikes. Many of these spikes have COF values larger than 0.3 and occur frequently during sliding. This suggests that an oil film is formed at the contact interface, which is responsible for the reduced base COF values, but the oil film is disrupted frequently during sliding, resulting in the friction spikes. As discussed later, the friction spikes are caused by the transfer of material from the Ti plate to the ball and the subsequent pull-out of grains from the Al2O3 ball, which results in third body plowing and destruction of the oil film. Such a phenomenon has not been reported previously.

- (3)

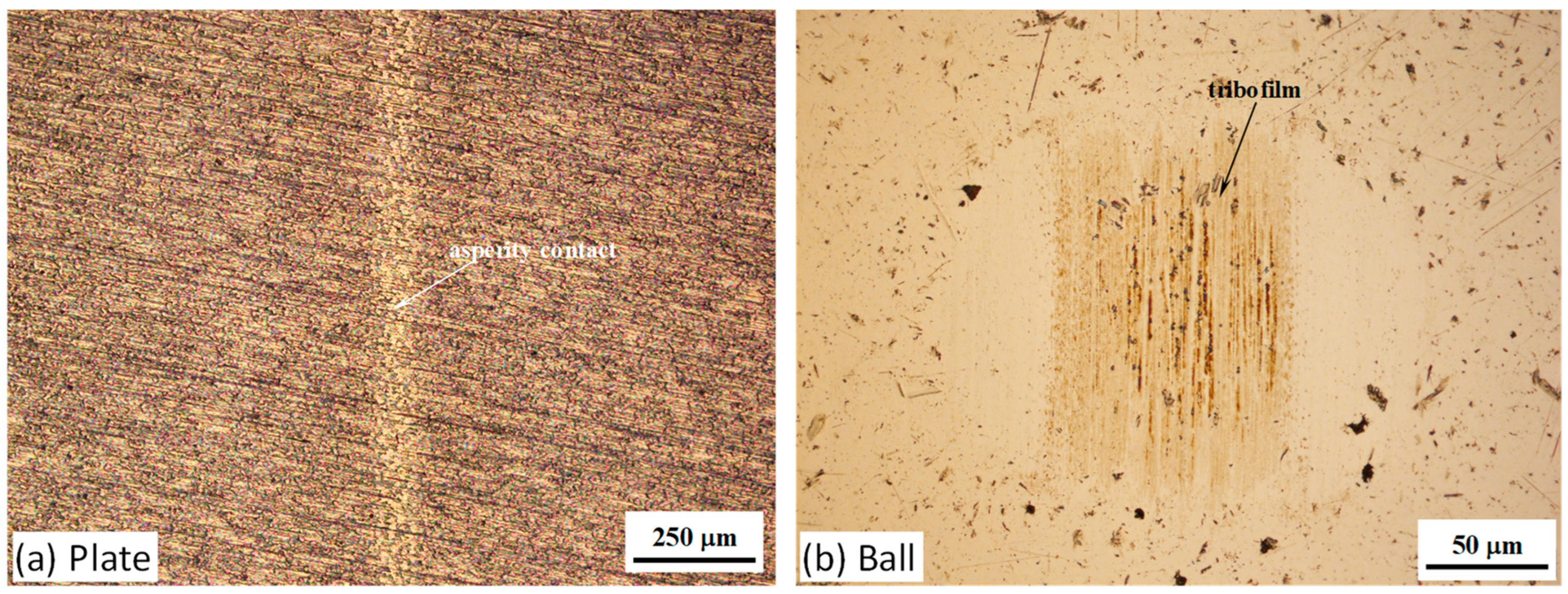

- Effective lubrication. This is observed for the Ti–52100 steel and Ti–nylon pairs (Figure 2c,d), where the friction curves recorded under oil-lubricated conditions are low and smooth, as compared to the high and fluctuating curves recorded during dry sliding. The effective lubrication of the Ti–steel pair with an average COF of 0.094 was found with some surprise (Figure 3), considering the reported poor lubrication of a Ti–steel pair in other work [9,12,37,38]. Thus, replicate tests were conducted many times in this work which confirmed the results shown in Figure 2c and Figure 3. Further experiments were also conducted to determine the load dependence of this Ti–steel pair under oil-lubricated conditions, as reported in Section 3.4. For the Ti–nylon pair (Figure 2d), although relatively high friction with an average COF of around 0.36 is observed under the dry sliding condition (Figure 3), the dry friction curve is relatively smooth and does not fluctuate as much as the Ti–Ti and Ti–steel pairs. Since nylon is a self-lubricating material [39,40], lubrication by oil is effective when sliding against Ti, with average COF values of around 0.12. There have been few reports on oil lubrication of Ti sliding against nylon in the literature.

3.2. Wear

- (1)

- Lubrication failure. In the Ti-Ti pair, the wear rate of the Ti plate under oil-lubricated conditions is similar to that under dry sliding conditions (Figure 4a), which confirms the results of previous studies [13,16,41,42]. Furthermore, the wear rate of the Ti ball under oil-lubricated conditions is slightly larger than that under dry sliding conditions (Figure 4b). This, again, could be explained by the reduced oxidation of the titanium surfaces under oil-lubricated conditions. Oxidation during dry sliding may help to reduce wear [36]. Clearly, the lubricant fails to lubricate the Ti-Ti pair, resulting in high and unstable friction and severe wear to both the plate and ball.

- (2)

- Improved lubrication but with friction instability. The improved lubrication effectiveness of the Ti-Al2O3 pair results in reduced wear rates of the Ti plate and the Al2O3 ball by 2.4 times and 7 times, respectively (Figure 4). However, wear rates in the order of 10−4–10−3 mm3/Nm are still very high, within the regime of severe wear [43]. The high wear rates are obviously related to the friction instability, with many spikes (Figure 2b), which originates from material transfer from the plate to the ball and pull-out Al2O3 grains from the alumina ball, as discussed later.

- (3)

- Effective lubrication. Under oil-lubricated conditions, the low and smooth friction of the Ti–52100 steel pair (Figure 2c) is accompanied with a significant reduction in the wear rates of both the Ti plate and the steel ball (Figure 4). The wear rate of the Ti plate is reduced from the order of 10−3 mm3/Nm under dry sliding to the order of 10−7 mm3/Nm under oil-lubricated conditions, a reduction of four orders of magnitude (Figure 4a). The wear rate of the 52100 steel ball is also reduced significantly by three orders of magnitude under oil-lubricated conditions, as compared to that under dry sliding conditions (Figure 4b). Effective lubrication has successfully changed the wear regime of the tribopair from severe wear to mild wear. In the Ti–nylon pair, wear from the Ti plate is unmeasurable under both dry sliding and oil-lubricated conditions, which could be due to the fact that nylon is much softer than CP-Ti (see Table 1) and thus it cannot cause any measurable wear to Ti. However, under both dry sliding and oil-lubricated conditions, the nylon balls suffer from severe wear, with similar wear rates in the order of 10−3 mm3/Nm. Thus, the improved frictional behavior of the Ti–nylon pair by oil lubrication does not prevent severe wear of the soft nylon ball.

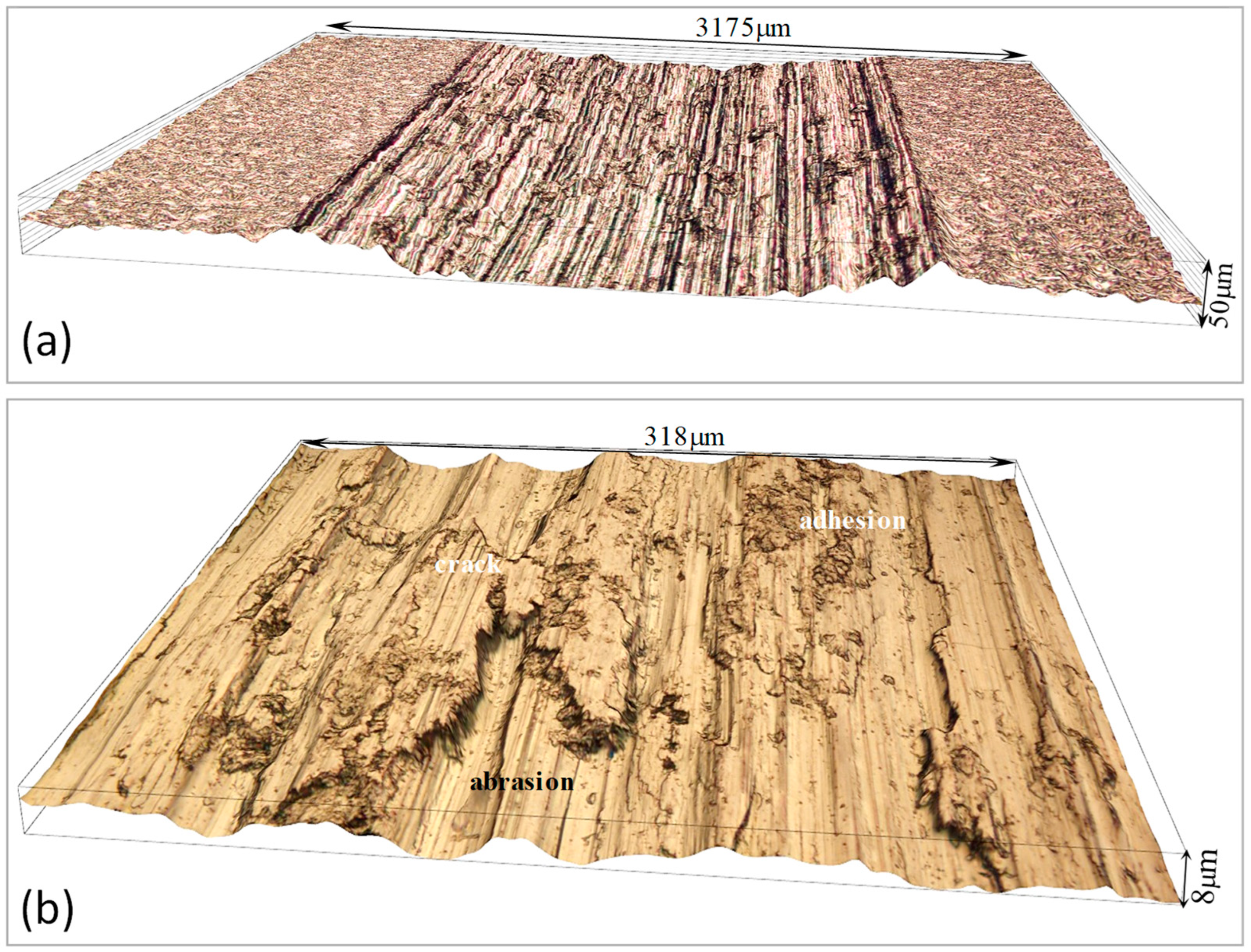

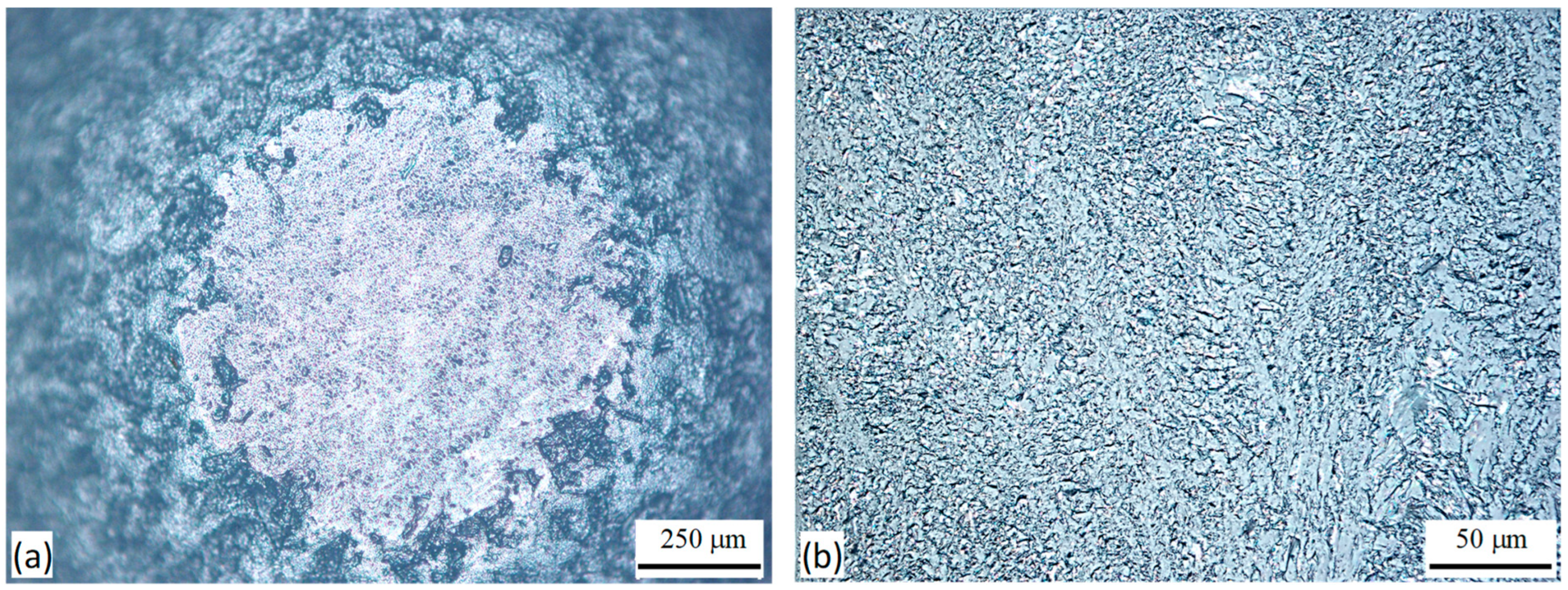

3.3. Friction and Wear Mechanisms

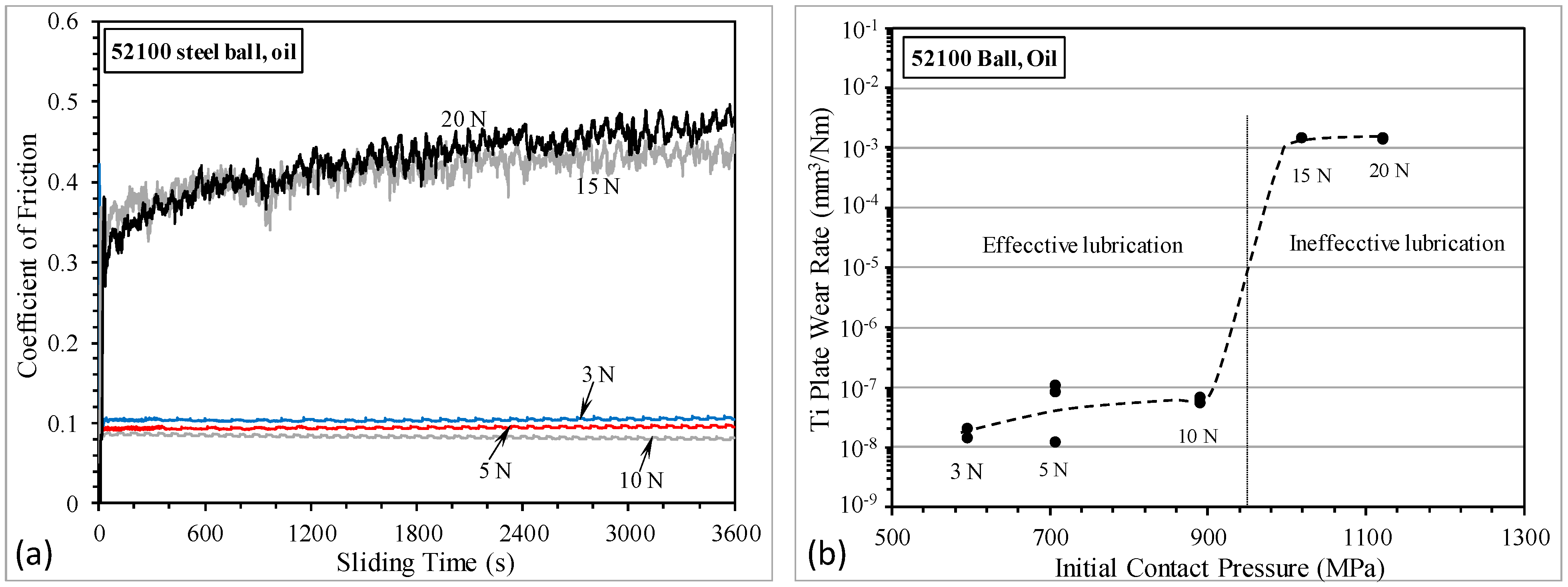

3.4. Effect of Load on the Ti–52100 Steel Pair

4. Conclusions

- (1)

- Three categories of lubrication behavior are identified, including lubrication failure (Ti-Ti pair), improved lubrication with friction instability (Ti-Al2O3 pair), and effective lubrication (Ti–steel and Ti–nylon pairs).

- (2)

- Lubrication failure of the Ti-Ti pair leads to high and unstable friction and severe wear from both the plate and ball. The lubricant fails to prevent adhesion between the contacting Ti surfaces and a tribofilm fails to form on the sliding surfaces, such that severe adhesive wear and abrasive wear are dominant during sliding.

- (3)

- The Ti-Al2O3 tribopair experiences reduced baseline friction compared to the Ti-Ti pair. However, friction is unstable, characterized by frequent spikes. The lubricant could not completely prevent material transfer from the Ti plate to the Al2O3 ball. These spikes are attributed to the removal of transferred material and grain pull-out from the ceramic ball, which disrupts the sliding process.

- (4)

- The effective lubrication of the Ti–52100 steel pair results in low and smooth friction and much-reduced wear rates of the Ti plate and the steel ball by three to four orders of magnitude, as compared to the wear rates measured under dry sliding conditions. This is due to the formation of a tribofilm, based on the additives in the oil (Zn and S), on the steel ball surface. The tribofilm prevents the adhesion of Ti to steel; thus, severe wear is avoided.

- (5)

- The Ti–nylon pair is effectively lubricated in terms of much-reduced friction. However, although wear from the Ti plate is unmeasurable, the nylon ball suffers from severe wear.

- (6)

- There is a limit in the load-bearing capacity of the Ti–52100 steel pair lubricated by the oil. Under heavy loading conditions, the lubricant fails to prevent the adhesion of Ti to the steel surface, such that a tribofilm fails to form on the steel ball surface, leading to high and unstable friction and severe wear.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Holmburg, K.; Erdemir, A. The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars. Tribol. Int. 2019, 135, 389–396. [Google Scholar] [CrossRef]

- Holmburg, L.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Li, Z. Application of titanium and titanium alloys in automotive fields. Chin. J. Nonferrous Met. 2010, 1, 1034–1038. [Google Scholar]

- Cao, L.; Sun, H.; Wan, Y.; Yang, S.; Xu, T. Tribological behavior of thermally oxidized TC4 titanium alloy under lubrication of a fully formulated engine oil. Tribology 2019, 39, 17–25. [Google Scholar]

- Rensselar, J.V. Lubricating titanium. Tribol. Lubr. Technol. 2012, 11, 20–28. [Google Scholar]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Molinari, A.; Straffelini, G.; Tesi, B.; Bacci, T. Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear 1997, 208, 105–112. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Watkins, T.R.; Cavin, O.B.; Kulkarni, N.S. Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 2005, 258, 1348–1356. [Google Scholar] [CrossRef]

- Roberts, R.W.; Owens, R.S. Boundary lubrication of titanium-titanium and titanium-steel. Wear 1963, 6, 444–456. [Google Scholar] [CrossRef]

- Bowen, F.P.; Leben, L. The friction of lubricated metals. Phil. Trans. R. Soc. Lond. 1940, 239, 1–27. [Google Scholar]

- Quan, X.; Xie, H.; Tang, J. Study on the enhanced tribological performance of titanium alloys by PEG oil/Zn-nanoparticles. Mater. Res. Express 2020, 7, 126502. [Google Scholar] [CrossRef]

- Senol, S.; Sitki, A.; Munish, K.G.; Turgay, K.; Navneet, K. A tribological performance of vegetable-based oil combined with GNPs and hBN nanoparticles on the friction-wear tests of titanium grade 2. Tribol. Int. 2023, 181, 108314. [Google Scholar]

- Cheng, J.; Yang, J.; Ma, J.; Bi, Q.; Zhang, X.; Fu, L.; Li, F.; Zhu, S.; Liu, W. The tribological behavior of a Ti-46Al-2Cr-2Nb alloy under liquid paraffine lubrication. Tribol. Int. 2012, 46, 233–241. [Google Scholar] [CrossRef]

- Li, H.; Xu, F.; Cui, K.; Tian, B.; Dong, R.; Fan, M. Interfacial adsorption and tribological response of various functional groups on titanium surface: In-depth research conducted on the lubricating mechanism of liquid lubricants. Tribol. Int. 2023, 189, 108885. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Dai, Y.; Luo, J. Tribological properties of titanium alloys under lubrication of SEE oil and aqueous solution. Tribol. Int. 2017, 109, 40–47. [Google Scholar] [CrossRef]

- Hsu, S.M. Boundary lubrication of materials. MRS Bull. 1991, 10, 54–58. [Google Scholar] [CrossRef]

- Mould, R.W.; Silver, H.B.; Syrett, R.J. Investigations of the activity of cutting oil additives II. Organochloride containing compounds. Wear 1972, 22, 269–286. [Google Scholar] [CrossRef]

- Shirani, A.; Nunn, N.; Shenderova, O.; Osawa, E.; Berman, D. Nanodiamonds for improving lubrication of titanium surfaces in simulated body fluids. Carbon 2019, 143, 890–896. [Google Scholar] [CrossRef]

- Etri, H.E.L.; Singla, A.K.K.; Ozdemir, M.T.; Korkmaz, M.E.; Demirsoz, R.; Gupta, M.K.; Krolczyk, J.B.; Ross, N.S. Wear performance of Ti-6Al-4V titanium alloy through nano-doped lubricants. Arch. Civ. Mech. Eng. 2023, 23, 147. [Google Scholar] [CrossRef]

- Davis, B.; Schueller, J.K.; Huang, Y. Study of ionic liquid as effective additive for minimum quantity lubrication during titanium machining. Manuf. Lett. 2015, 5, 1–6. [Google Scholar] [CrossRef]

- Jimenez, A.E.; Bermudez, M.D. Ionic liquids as lubricants of titanium-steel contact. Tribol. Let. 2009, 33, 111–126. [Google Scholar] [CrossRef]

- Li, H.; Ma, L.; Wen, P.; Han, Y.; Dong, R.; Fan, M. Molecular structure insight into the tribological behavior of sulfonate ionic liquids as lubricants for titanium alloys. J. Mol. Liq. 2022, 357, 119082. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, Z.; Zhao, N.; Liu, G.; Zhou, F.; Li, W. Exploration of aqueous lubrication of polymeric microgels between titanium alloy surfaces. ACS Omega 2021, 6, 32178–32185. [Google Scholar] [CrossRef] [PubMed]

- Erdemir, A. Review of engineered tribological interfaces for improved boundary lubrication. Tribol. Int. 2005, 38, 249–259. [Google Scholar] [CrossRef]

- Neville, A.; Morina, A.; Haque, T.; Voong, M. Compatibility between tribological surfaces and lubricant additives—How friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 2007, 40, 1680–1695. [Google Scholar] [CrossRef]

- Bansal, D.G.; Eryilmaz, O.L.; Blau, P.J. Surface engineering to improve the durability and lubricity of Ti-6Al-4V alloy. Wear 2011, 271, 2006–2015. [Google Scholar] [CrossRef]

- Klint, R.V.; Owens, R.S. Lubrication of diffusion-beryllided titanium. ASLE Trans. 1962, 5, 32–38. [Google Scholar] [CrossRef]

- Shapiro, A.; Gisser, H. Lubrication of titanium surfaces modified by metallic diffusion. ASLE Trans. 1963, 6, 40–48. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Howe, J.Y.; Meyer, H.M. Oxygen diffusion enables anti-wear boundary film formation on titanium surfaces in zinc-diakkyl-dithiophosphate (ZDDP)-containing lubricants. Scr. Mater. 2009, 60, 886–889. [Google Scholar] [CrossRef]

- Straffelini, G.; Molinari, A. Dry sliding wear of Ti-6Al-4V alloy as influenced by the counterface and sliding conditions. Wear 1999, 236, 328–338. [Google Scholar] [CrossRef]

- Sun, Y.; Bailey, R.; Zhang, J.; Liang, Y.; Ji, X. Effect of thermal oxidation on the dry sliding friction and wear behavior of CP-Ti on CP-Ti tribopairs. Surf. Sci. Tech. 2023, 1, 15. [Google Scholar] [CrossRef]

- Faure, L.; Bolle, B.; Philippon, S.; Schuman, C.; Chevrier, P.; Tidu, A. Friction experiments for titanium alloy tribopairs sliding in dry conditions: Sub-surface and surface analysis. Tribol. Int. 2012, 54, 17–25. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts Part III—Fully flooded results. J. Lubr. Technol. 1977, 99, 264–275. [Google Scholar] [CrossRef]

- Fatehallah, H.S.; Hammoudi, Z.S.; Zidane, L.Y. Effect of oil temperature on load capacity and friction power loss in point contact elasto-hydrodynamic lubrication. Al-Nahrain Eng. Sci. NJES 2019, 22, 180–186. [Google Scholar] [CrossRef]

- Maytorena-Sanchez, A.; Hernandez-Torres, J.; Zamora-Peredo, L.; Lopez-Hiuerta, F.; Baez-Rodriguez, A.; Garcia-Gonzalez, L. Study and optimization of the wear resistance of titanium Grade 2 through a thermal oxidation process with shot oxidation time. Tribol. Let. 2022, 70, 75. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Q.Y.; Li, X.X.; Cui, X.H.; Wang, S.Q. Severe-to-mild wear transition of titanium alloys as a function of temperature. Tribol. Let. 2014, 53, 511–520. [Google Scholar] [CrossRef]

- Tian, H.; Saka, N.; Suh, N.P. Boundary lubrication studies on undulated titanium surfaces. Tribol. Trans. 1989, 32, 289–296. [Google Scholar] [CrossRef]

- Amanov, A.; Sasaki, S. A study on the tribological characteristics of duplex-treated Ti6Al4V alloy under oil-lubricated sliding condition. Tribol. Int. 2013, 64, 155–163. [Google Scholar] [CrossRef]

- Watanabe, M.; Yamaguchi, H. The friction and wear properties of nylon. Wear 1986, 110, 379–388. [Google Scholar] [CrossRef]

- Adams, N. Friction and deformation of nylon. I. Experimental. J. Appl. Poly. Sci. 1963, 7, 2075–2103. [Google Scholar] [CrossRef]

- Roberts, R.W.; Owens, R.S. Titanium lubrication. Nature 1963, 200, 357–358. [Google Scholar] [CrossRef]

- Miller, P.D.; Halladay, J.W. Friction and wear properties of titanium. Wear 1958, 2, 133–140. [Google Scholar] [CrossRef]

- Lim, S.C.; Ashby, M.F. Wear-Mechanism maps. Acta. Metall. 1987, 35, 1–24. [Google Scholar] [CrossRef]

- Komvopoulos, K.; Saka, N.; Suh, N.P. The mechanism of friction in boundary lubrication. Trans. ASME 1985, 107, 452–462. [Google Scholar] [CrossRef]

- Suh, N.P.; Sin, H.C. The genesis of friction. Wear 1981, 69, 91–114. [Google Scholar] [CrossRef]

- Martin, J.M.; Crossiord, C.; Mogne, T.L.; Bec, S.; Tonck, A. The two-layer structure of Zndtp tribofilms Part I: AES, XPS and XANES analysis. Tribol. Int. 2001, 34, 523–530. [Google Scholar] [CrossRef]

| Material | Composition (wt%, or Chemical Formula) | Hardness (HV0.1) |

|---|---|---|

| CP-Ti | 0.08C, 0.024Fe, 0.03N, 0.21O, 0.014H, Ti (balance) | 207 ± 14 |

| Alumina | Al2O3 | 2116 ± 260 |

| AISI 52100 | 1.01C, 1.48Cr, 0.33Mn, 0.23Si, 0.25Ni, 0.10 Mo, Fe (balance) | 801 ± 19 |

| Nylon | (C12H22N2O2)n | 4 ± 0.5 |

| Contact Pair | Pmax (MPa) | hmin (μm) |

|---|---|---|

| Ti–Ti | 594 | 0.012 |

| Ti–Al2O3 | 792 | 0.011 |

| Ti–52100 steel | 706 | 0.011 |

| Ti–Nylon | 53 | 0.105 |

| Density @ 15 °C | Viscosity (Kinematic 40 °C) | Viscosity (Kinematic 100 °C) | Viscosity Index | Flash Temperature |

|---|---|---|---|---|

| 0.842 g/mL | 72 cSt | 12.3 cSt | 169 | 200 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Al-Shan, M.; Bailey, R.; Sun, Y. Effect of Counterbody Material on the Boundary Lubrication Behavior of Commercially Pure Titanium in a Motor Oil. Lubricants 2024, 12, 439. https://doi.org/10.3390/lubricants12120439

Liu Y, Al-Shan M, Bailey R, Sun Y. Effect of Counterbody Material on the Boundary Lubrication Behavior of Commercially Pure Titanium in a Motor Oil. Lubricants. 2024; 12(12):439. https://doi.org/10.3390/lubricants12120439

Chicago/Turabian StyleLiu, Yizhao, Mohammed Al-Shan, Richard Bailey, and Yong Sun. 2024. "Effect of Counterbody Material on the Boundary Lubrication Behavior of Commercially Pure Titanium in a Motor Oil" Lubricants 12, no. 12: 439. https://doi.org/10.3390/lubricants12120439

APA StyleLiu, Y., Al-Shan, M., Bailey, R., & Sun, Y. (2024). Effect of Counterbody Material on the Boundary Lubrication Behavior of Commercially Pure Titanium in a Motor Oil. Lubricants, 12(12), 439. https://doi.org/10.3390/lubricants12120439