Ceramic–Ceramic Hip Implants: Investigation of Various Factors Associated with Squeaking

Abstract

1. Introduction

- (1)

- Does a variation in inclination and anteversion lead to squeaking?

- (2)

- Does a variation in the protein concentration of the test fluid, or even dry test conditions, lead to squeaking?

- (3)

- Does an increased contact pressure lead to squeaking?

- (4)

- Does an increased surface roughness lead to squeaking?

2. Materials and Methods

2.1. Test Specimen

2.2. Test Setup

2.3. In Vitro Simulation

2.3.1. Parameters for Research Question 1

2.3.2. Parameters for Research Question 2

2.3.3. Parameters for Research Question 3

2.3.4. Parameters for Research Question 4

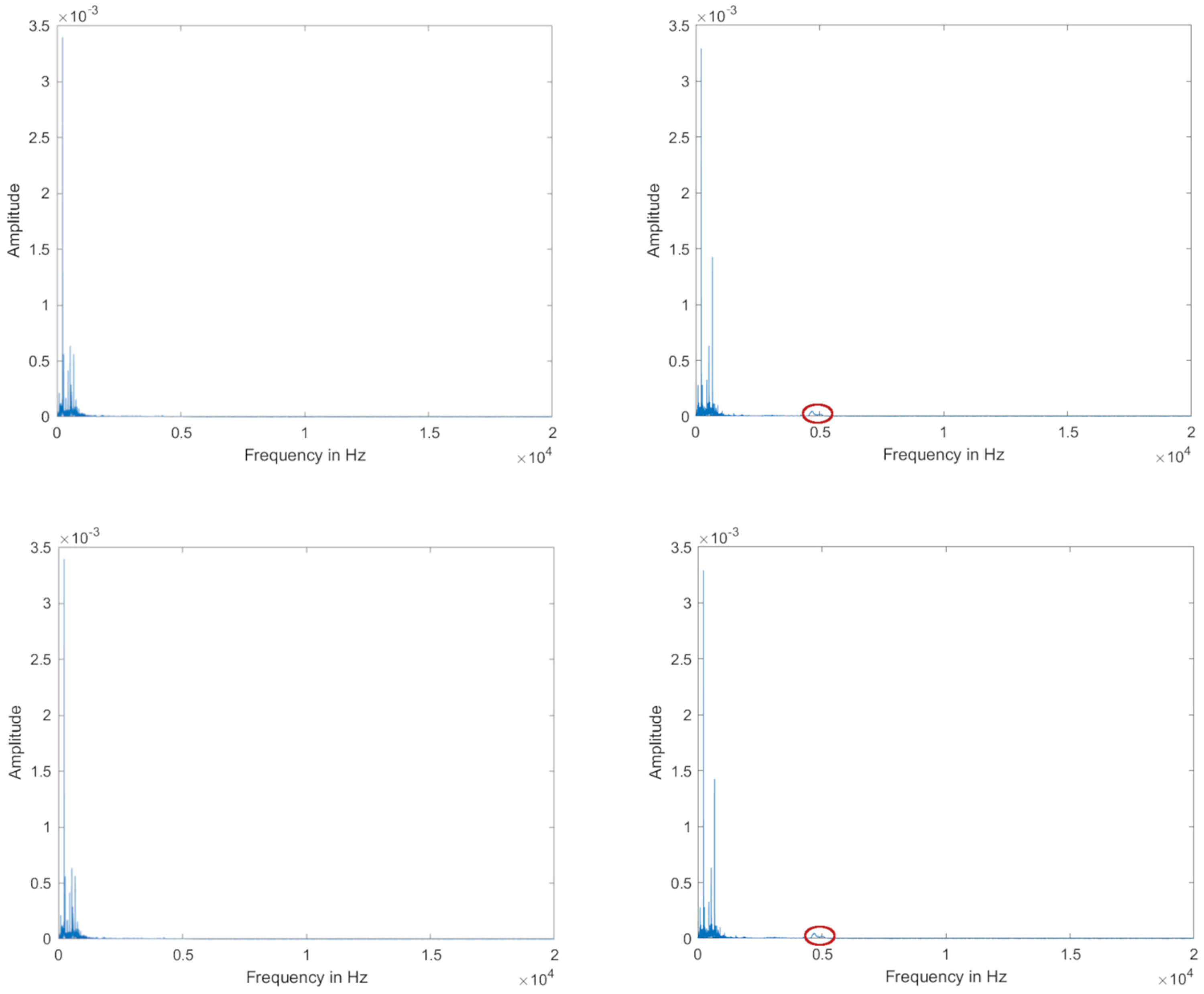

2.4. Data Collection

3. Results

3.1. Component Orientation

3.2. Test Fluids and Dry Conditions

3.3. Component Mismatch

3.4. Roughened Femoral Heads

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- van Loon, J.; Hoornenborg, D.; van der Vis, H.M.; Sierevelt, I.N.; Opdam, K.T.; Kerkhoffs, G.M.; Haverkamp, D. Ceramic-on-ceramic vs ceramic-on-polyethylene, a comparative study with 10-year follow-up. World J. Orthop. 2021, 12, 14–23. [Google Scholar] [CrossRef] [PubMed]

- Higuchi, Y.; Hasegawa, Y.; Seki, T.; Komatsu, D.; Ishiguro, N. Significantly Lower Wear of Ceramic-on-Ceramic Bearings Than Metal-on-Highly Cross-Linked Polyethylene Bearings: A 10- to 14-Year Follow-Up Study. J. Arthroplast. 2016, 31, 1246–1250. [Google Scholar] [CrossRef] [PubMed]

- National Joint Registry. 20th Annual Report 2023. Available online: https://reports.njrcentre.org.uk/Portals/0/PDFdownloads/NJR%2020th%20Annual%20Report%202023.pdf (accessed on 3 October 2024).

- The German Arthroplasty Registry. Annual Report 2023. Available online: https://www.eprd.de/fileadmin/user_upload/Dateien/Publikationen/Berichte/AnnualReport2023-Web_2024-03-26_F.pdf (accessed on 3 October 2024).

- American Joint Replacement Registry. Annual Report 2023. Available online: https://connect.registryapps.net/hubfs/PDFs%20and%20PPTs/AJRR%202023%20Annual%20Report.pdf?hsCtaTracking=cc9203b1-b118-49b8-b606-3a1a9530a657%7C189d3ddc-5ecd-4902-a9ba-3e68b2303c7a (accessed on 3 October 2024).

- Owen, D.H.; Russell, N.C.; Smith, P.N.; Walter, W.L. An estimation of the incidence of squeaking and revision surgery for squeaking in ceramic-on-ceramic total hip replacement: A meta-analysis and report from the Australian Orthopaedic Association National Joint Registry. Bone Jt. J. 2014, 96-B, 181–187. [Google Scholar] [CrossRef] [PubMed]

- Shang, Z.; Tanzer, M.; Al Badi, H.; Hart, A. Ceramic-on-Ceramic Total Hip Arthroplasty: I Can Hear You. Arthroplast. Today 2023, 23, 101203. [Google Scholar] [CrossRef]

- Inagaki, K.; Iida, S.; Miyamoto, S.; Suzuki, C.; Nakatani, T.; Shinada, Y.; Kawarai, Y.; Hagiwara, S.; Nakamura, J.; Orita, S.; et al. Natural history of noise and squeaking in cementless ceramic-on-ceramic total hip arthroplasty. J. Orthop. 2020, 21, 544–549. [Google Scholar] [CrossRef]

- Schroder, D.; Bornstein, L.; Bostrom, M.P.; Nestor, B.J.; Padgett, D.E.; Westrich, G.H. Ceramic-on-ceramic total hip arthroplasty: Incidence of instability and noise. Clin. Orthop. Relat. Res. 2011, 469, 437–442. [Google Scholar] [CrossRef]

- Kiyama, T.; Kinsey, T.L.; Mahoney, O.M. Can squeaking with ceramic-on-ceramic hip articulations in total hip arthroplasty be avoided? J. Arthroplast. 2013, 28, 1015–1020. [Google Scholar] [CrossRef]

- Chevillotte, C.; Trousdale, R.T.; Chen, Q.; Guyen, O.; An, K.N. The 2009 Frank Stinchfield Award: “Hip squeaking”: A biomechanical study of ceramic-on-ceramic bearing surfaces. Clin. Orthop. Relat. Res. 2010, 468, 345–350. [Google Scholar] [CrossRef]

- Brockett, C.L.; Williams, S.; Jin, Z.; Isaac, G.H.; Fisher, J. Squeaking hip arthroplasties: A tribological phenomenon. J. Arthroplast. 2013, 28, 90–97. [Google Scholar] [CrossRef]

- Walter, W.L.; O’Toole, G.C.; Walter, W.K.; Ellis, A.; Zicat, B.A. Squeaking in ceramic-on-ceramic hips: The importance of acetabular component orientation. J. Arthroplast. 2007, 22, 496–503. [Google Scholar] [CrossRef]

- Currier, J.H.; Anderson, D.E.; Van Citters, D.W. A proposed mechanism for squeaking of ceramic-on-ceramic hips. Wear Int. J. Sci. Technol. Frict. Lubr. Wear 2010, 269, 782–789. [Google Scholar] [CrossRef]

- Ouenzerfi, G.; Massi, F.; Renault, E.; Berthier, Y. Squeaking friction phenomena in ceramic hip endoprosthesis: Modeling and experimental validation. Mech. Syst. Signal Process. 2015, 58–59, 87–100. [Google Scholar] [CrossRef]

- Affatato, S.; Traina, F.; Mazzega-Fabbro, C.; Sergo, V.; Viceconti, M. Is ceramic-on-ceramic squeaking phenomenon reproducible in vitro? A long-term simulator study under severe conditions. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 91B, 264–271. [Google Scholar] [CrossRef] [PubMed]

- O’Dwyer Lancaster-Jones, O.; Reddiough, R. The occurrence of squeaking under wear testing standards for ceramic on ceramic total hip replacements. J. Mech. Behav. Biomed. Mater. 2023, 138, 105616. [Google Scholar] [CrossRef] [PubMed]

- ISO 14242-1:2014; Implants for Surgery-Wear of Total Hip-Joint Prostheses—Part 1: Loading and Displacement Parameters for Wear-Testing Machines and Corresponding Environmental Conditions for Test. International Organization for Standardization: Geneva, Switzerland, 2014.

- Murray, D.W. The definition and measurement of acetabular orientation. J. Bone Jt. Surgery. Br. Vol. 1993, 75, 228–232. [Google Scholar] [CrossRef]

- ISO 21920-2:2022-12; Geometrical Product Specifications (GPS)-Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters (ISO 21920-2:2021, Corrected Version 2022-06). International Organization for Standardization: Geneva, Switzerland, 2022.

- Tai, S.M.; Munir, S.; Walter, W.L.; Pearce, S.J.; Walter, W.K.; Zicat, B.A. Squeaking in large diameter ceramic-on-ceramic bearings in total hip arthroplasty. J. Arthroplast. 2015, 30, 282–285. [Google Scholar] [CrossRef]

- Restrepo, C.; Parvizi, J.; Kurtz, S.M.; Sharkey, P.F.; Hozack, W.J.; Rothman, R.H. The noisy ceramic hip: Is component malpositioning the cause? J. Arthroplast. 2008, 23, 643–649. [Google Scholar] [CrossRef]

- Bishop, N.E.; Hothan, A.; Morlock, M.M. High friction moments in large hard-on-hard hip replacement bearings in conditions of poor lubrication. J. Orthop. Res. Off. Publ. Orthop. Res. Soc. 2013, 31, 807–813. [Google Scholar] [CrossRef]

- Rodgers, G.W.; Welsh, R.; King, L.J.; FitzPatrick, A.J.; Woodfield, T.B.F.; Hooper, G.J. Signal processing and event detection of hip implant acoustic emissions. Control. Eng. Pract. 2017, 58, 287–297. [Google Scholar] [CrossRef]

- Brockett, C.L.; Harper, P.; Williams, S.; Isaac, G.H.; Dwyer-Joyce, R.S.; Jin, Z.; Fisher, J. The influence of clearance on friction, lubrication and squeaking in large diameter metal-on-metal hip replacements. J. Mater. Sci. Mater. Med. 2008, 19, 1575–1579. [Google Scholar] [CrossRef]

- Hothan, A.; Huber, G.; Weiss, C.; Hoffmann, N.; Morlock, M. The influence of component design, bearing clearance and axial load on the squeaking characteristics of ceramic hip articulations. J. Biomech. 2011, 44, 837–841. [Google Scholar] [CrossRef] [PubMed]

- Chevillotte, C.; Trousdale, R.T.; An, K.N.; Padgett, D.; Wright, T. Retrieval analysis of squeaking ceramic implants: Are there related specific features? Orthop. Traumatol. Surg. Res. OTSR 2012, 98, 281–287. [Google Scholar] [CrossRef] [PubMed]

- Sariali, E.; Stewart, T.; Jin, Z.; Fisher, J. In vitro investigation of friction under edge-loading conditions for ceramic-on-ceramic total hip prosthesis. J. Orthop. Res. Off. Publ. Orthop. Res. Soc. 2010, 28, 979–985. [Google Scholar] [CrossRef] [PubMed]

| Research Question | Femoral Head Number | Femoral Head Size | Rough or Polished Femoral Head | Insert Number | Insert Size |

|---|---|---|---|---|---|

| 1 | #1 | 36 mm | polished | #1 | 36 mm |

| 2 | #2 | 36 mm | polished | #1 | 36 mm |

| 3 | #4 and #5 | 28 and 34 mm | polished | #2 | 36 mm |

| 4 | #3 | 36 mm | roughened | #2 | 36 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schroeder, S.; Gaedeke, L.; Hariri, M.; Bormann, T.; Weiss, M.; Kretzer, J.P.; Uhler, M. Ceramic–Ceramic Hip Implants: Investigation of Various Factors Associated with Squeaking. Lubricants 2024, 12, 438. https://doi.org/10.3390/lubricants12120438

Schroeder S, Gaedeke L, Hariri M, Bormann T, Weiss M, Kretzer JP, Uhler M. Ceramic–Ceramic Hip Implants: Investigation of Various Factors Associated with Squeaking. Lubricants. 2024; 12(12):438. https://doi.org/10.3390/lubricants12120438

Chicago/Turabian StyleSchroeder, Stefan, Luisa Gaedeke, Mustafa Hariri, Therese Bormann, Maurice Weiss, Jan Philippe Kretzer, and Maximilian Uhler. 2024. "Ceramic–Ceramic Hip Implants: Investigation of Various Factors Associated with Squeaking" Lubricants 12, no. 12: 438. https://doi.org/10.3390/lubricants12120438

APA StyleSchroeder, S., Gaedeke, L., Hariri, M., Bormann, T., Weiss, M., Kretzer, J. P., & Uhler, M. (2024). Ceramic–Ceramic Hip Implants: Investigation of Various Factors Associated with Squeaking. Lubricants, 12(12), 438. https://doi.org/10.3390/lubricants12120438