Impact of Influence of Piston Design Parameters on the Hydrodynamic Characteristics of Internal Combustion Engines—A Numerical Study

Abstract

1. Introduction

2. Background

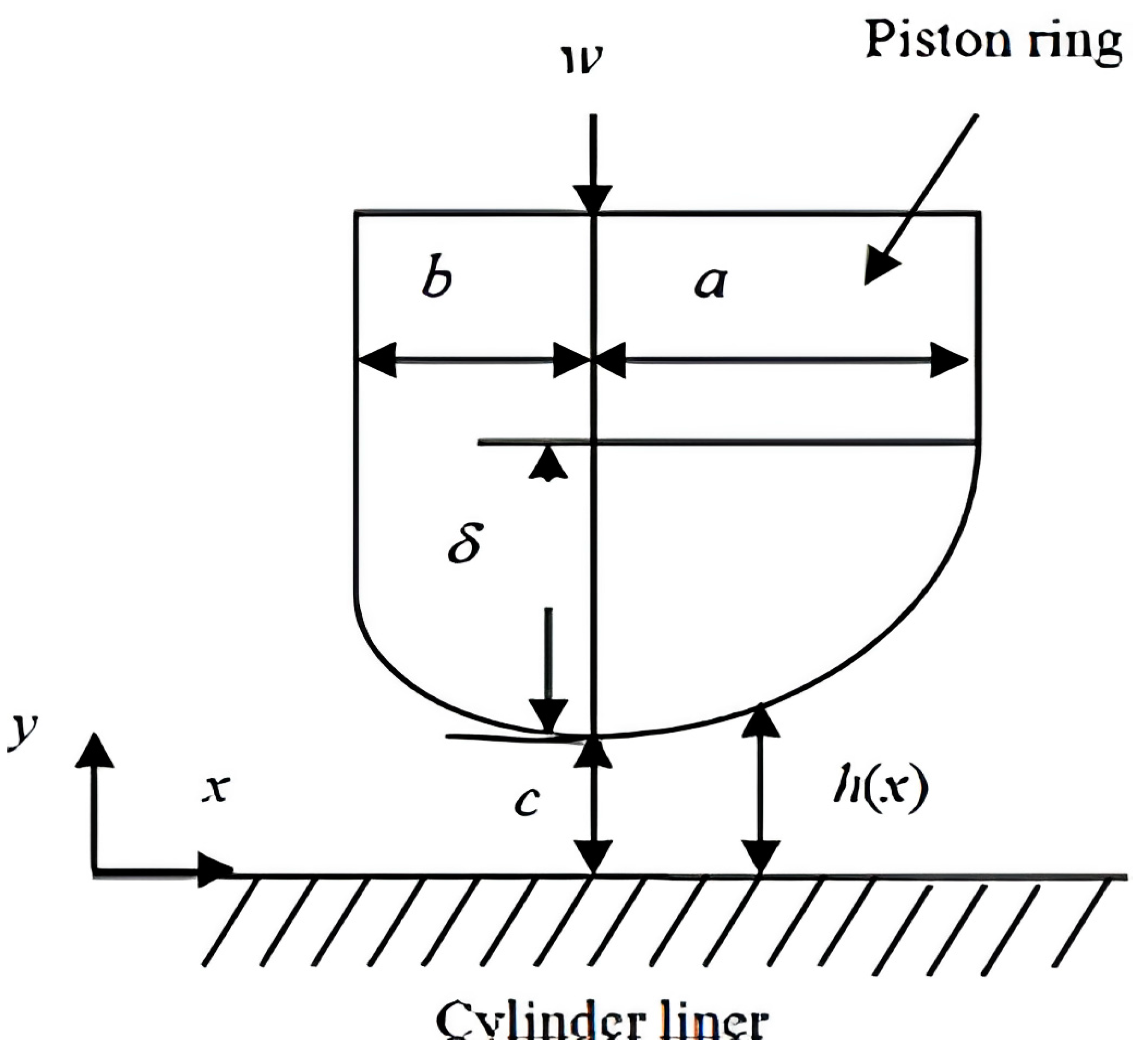

2.1. Piston Ring Geometry

2.2. Motion Formulation

- The force of friction between the rings and the liner included the fluid friction as well as contact friction given by the lubricant shear friction given as well as the friction due to the contact given by the Greenwood–Tripp model;

- The hydrodynamic oil film pressure developed was solved by using the Reynolds equation;

- The force of friction was maximum at mid-stroke when the speed of the piston was the maximum;

- Hydrodynamic lubrication was considered with the formation of full oil film thickness.

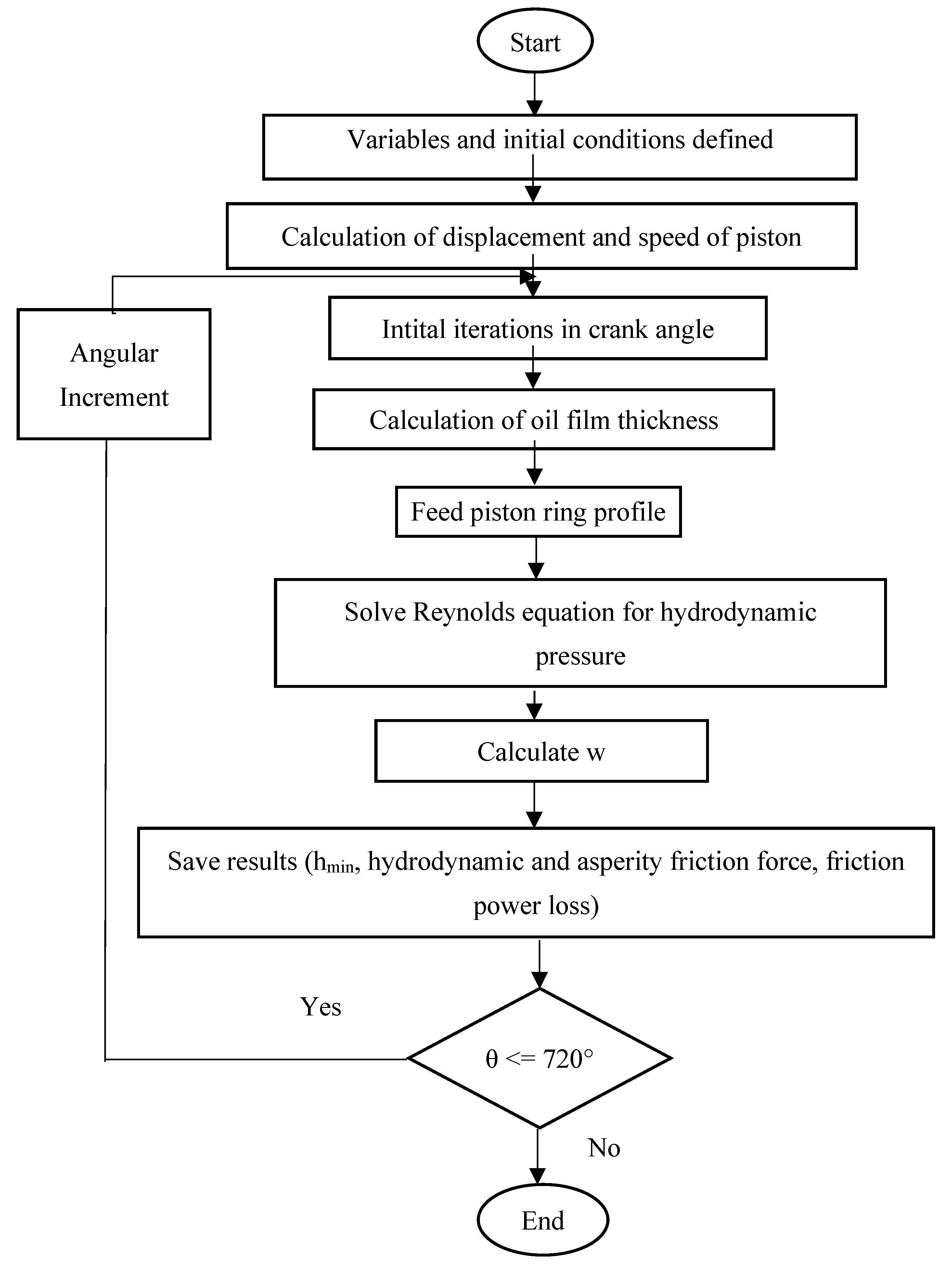

3. Materials and Methods

- Type: 1.5 L EFD diesel engine 4stroke, 4cylinder in line SOHC.

- Engine management: Sequential multi-point injection with PCM control unit.

- Displacement: 1497 cm3

- Bore: 76.0 mm

- Stroke: 82.5 mm

- Connecting Rod Length: 137 mm

- Compression Ratio: 16.5:1

- Max power/liter: 60 kW/lit

- Max torque: 256 N·m

3.1. Asperity Contact Model

3.2. Greenwood–Tripp Asperity Interaction Model

4. Results and Discussion

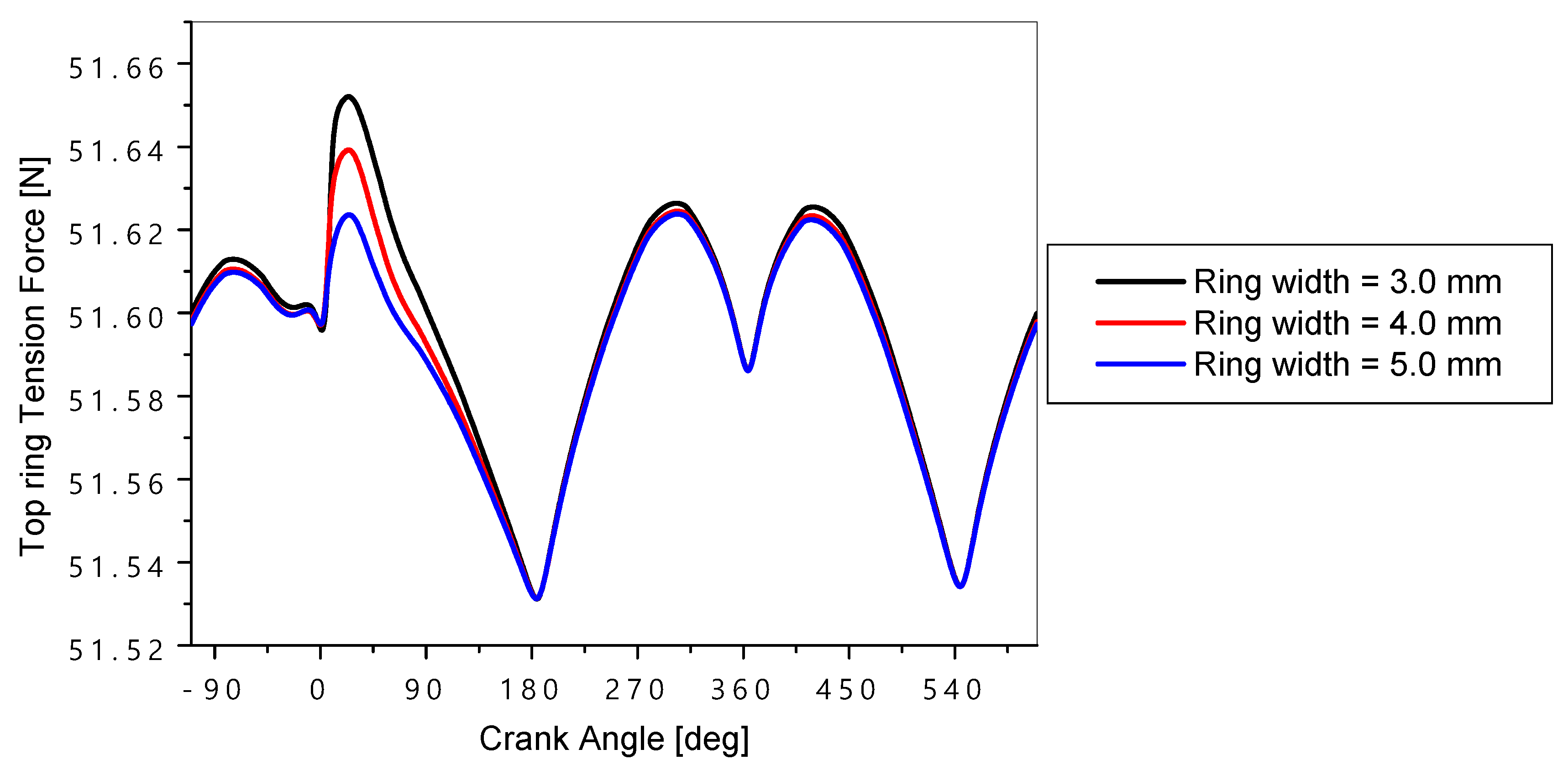

4.1. Effect of the Top Ring Width

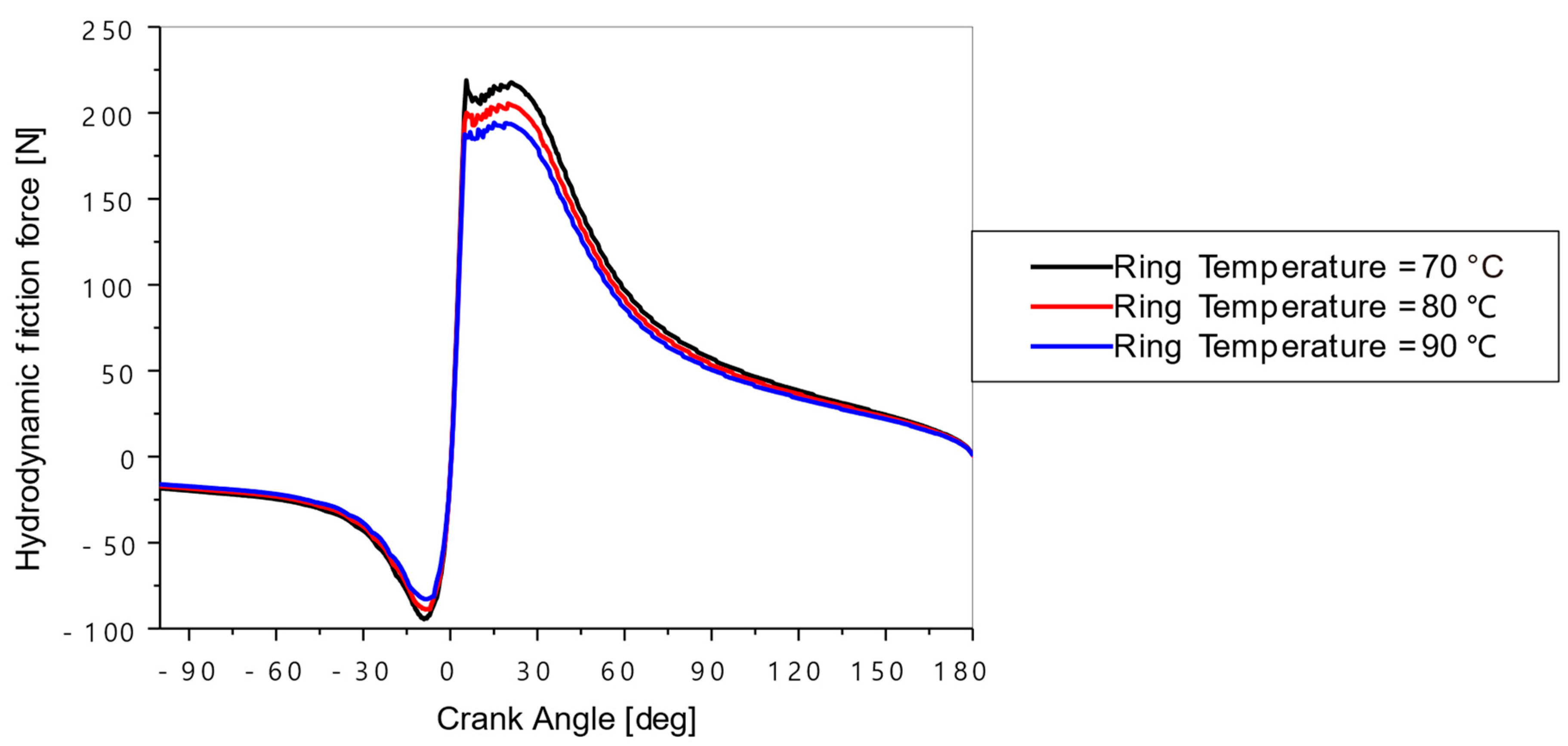

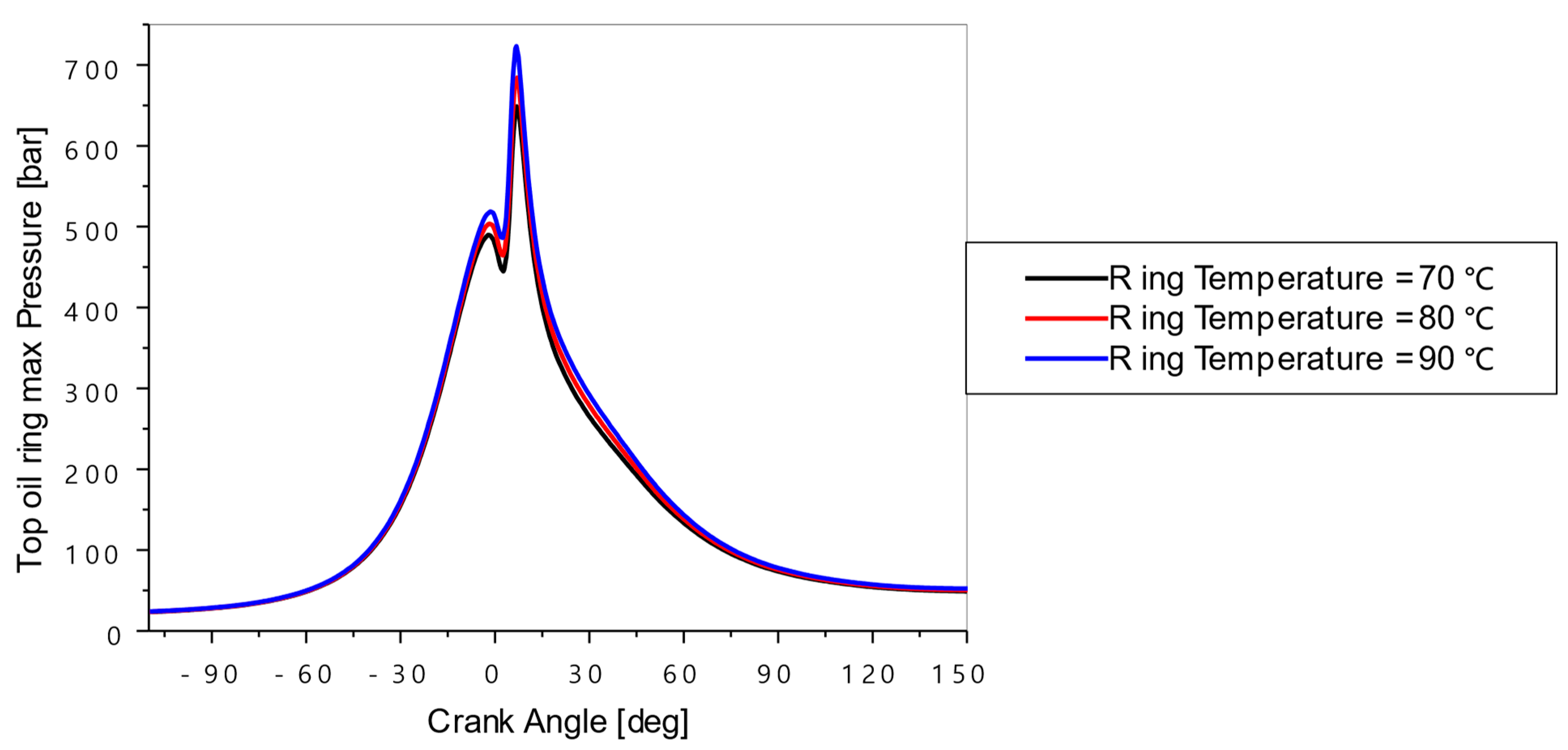

4.2. Effect of the Top Ring Temperature

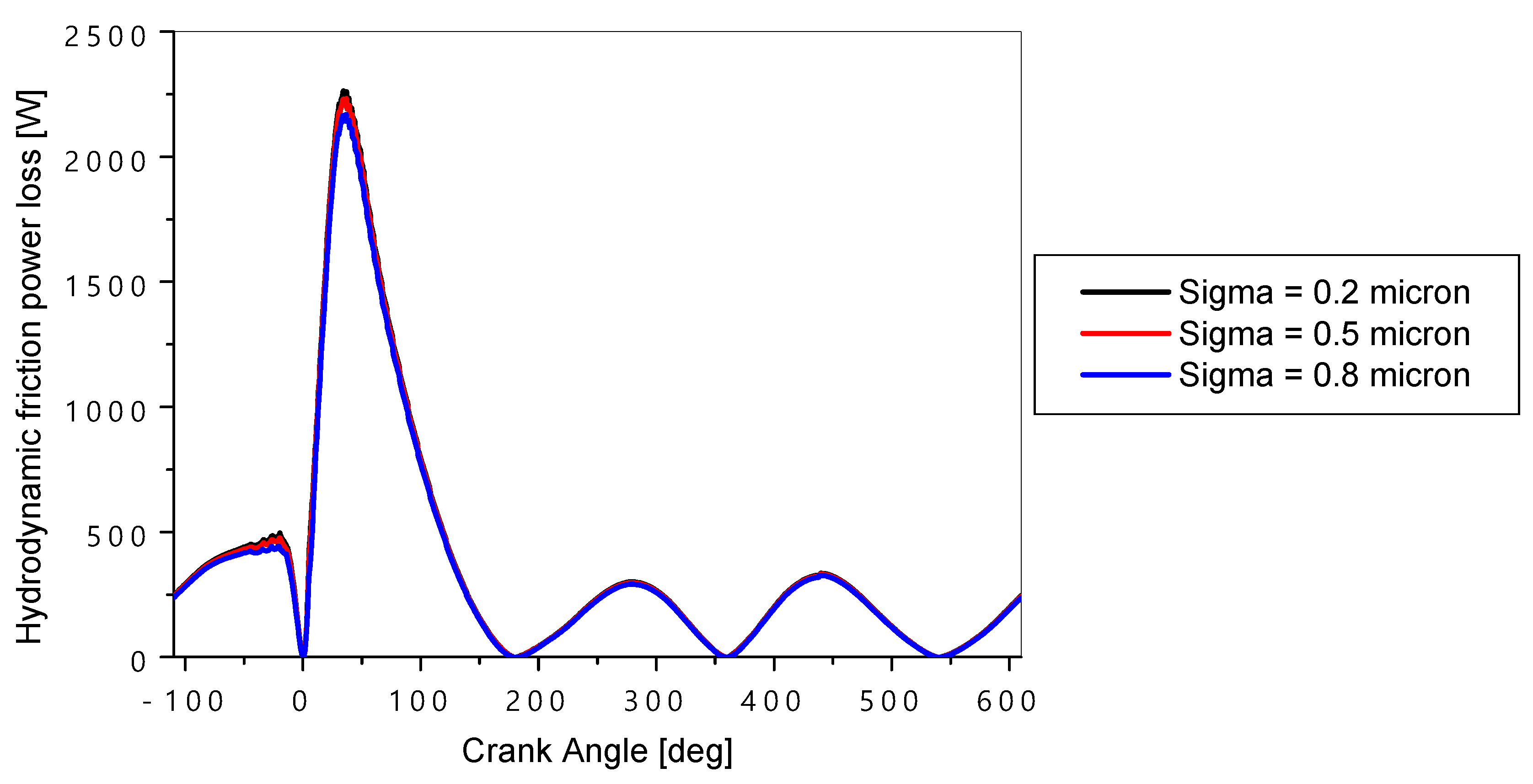

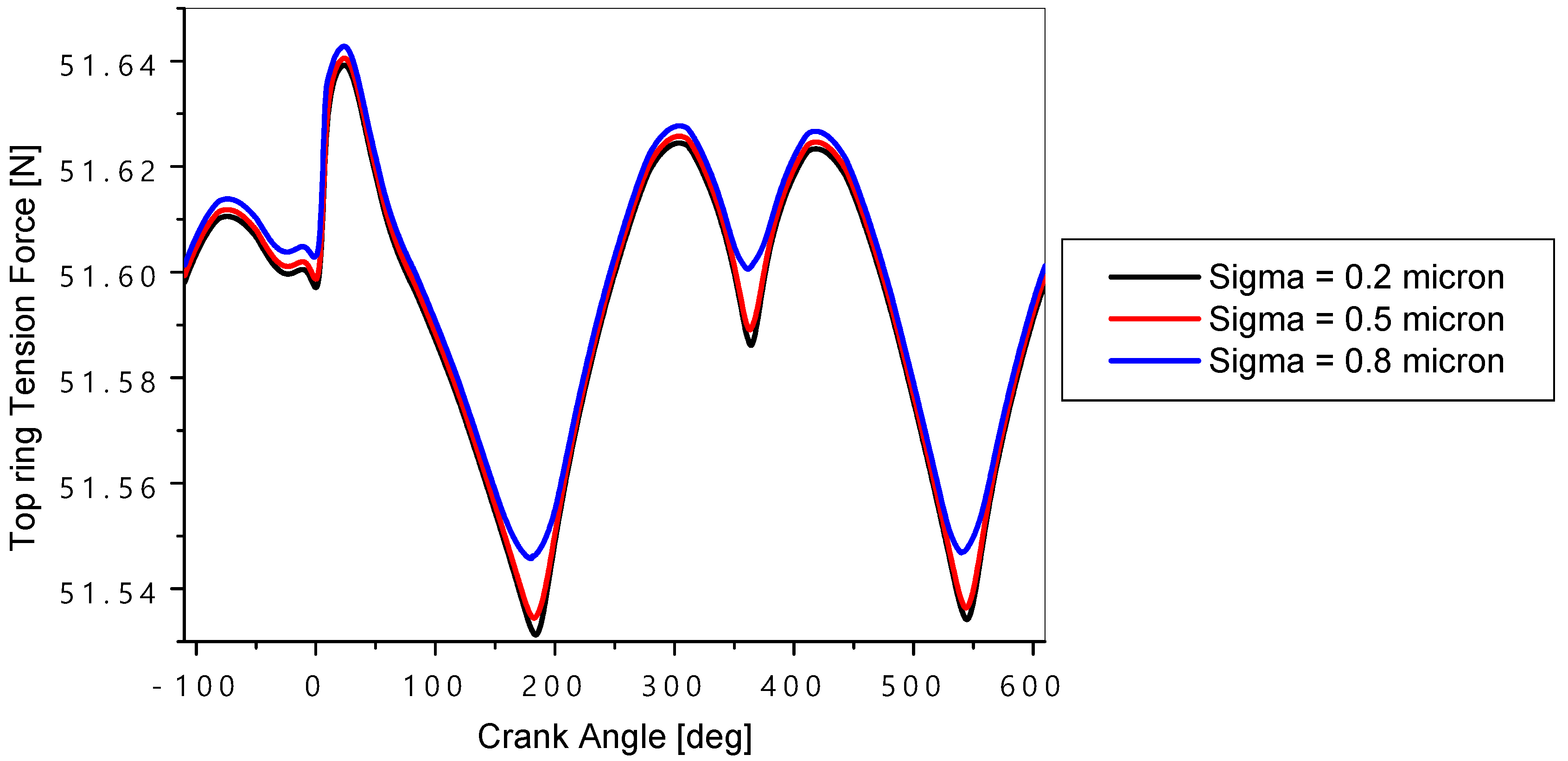

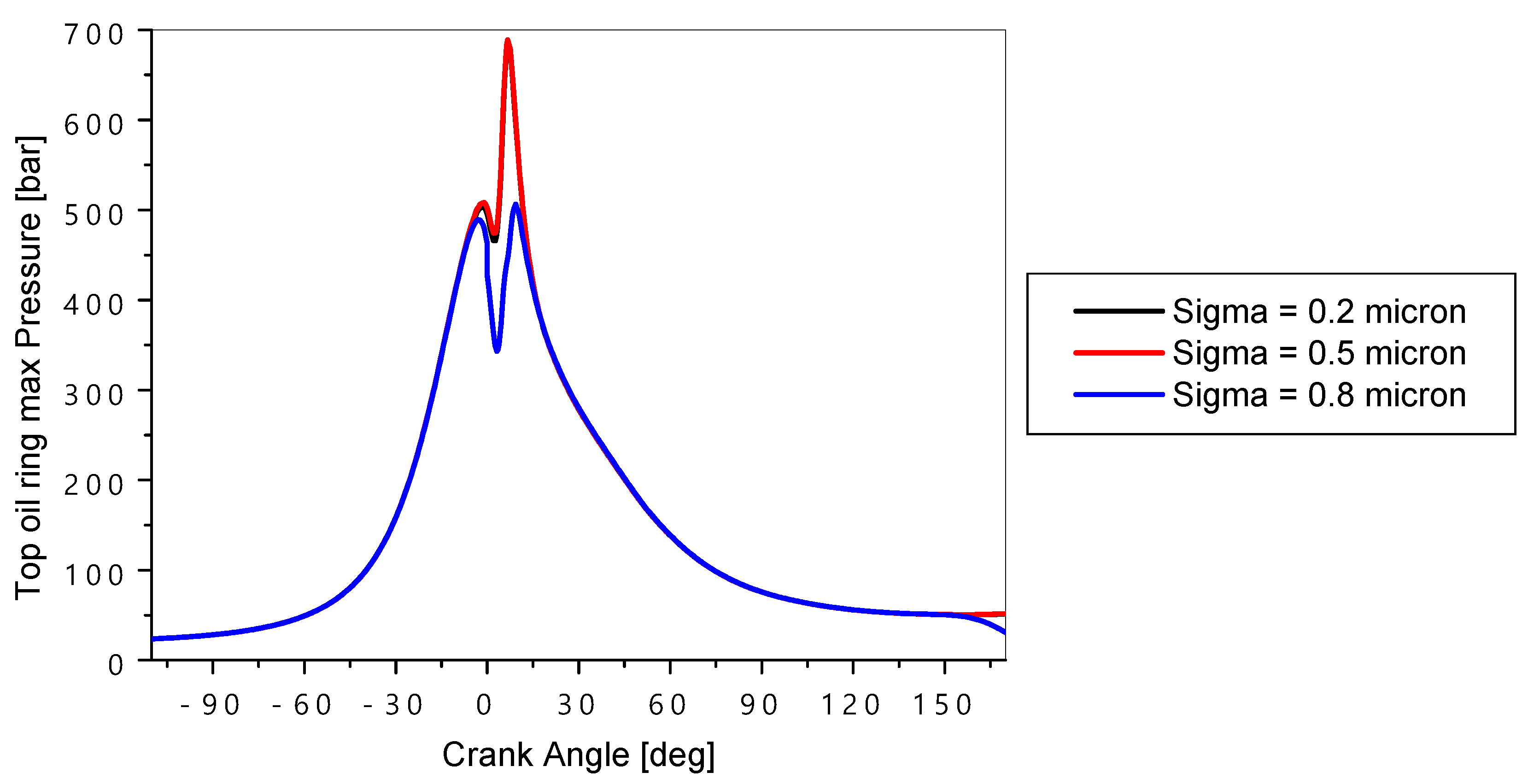

4.3. Effect of the Top Ring Surface Roughness

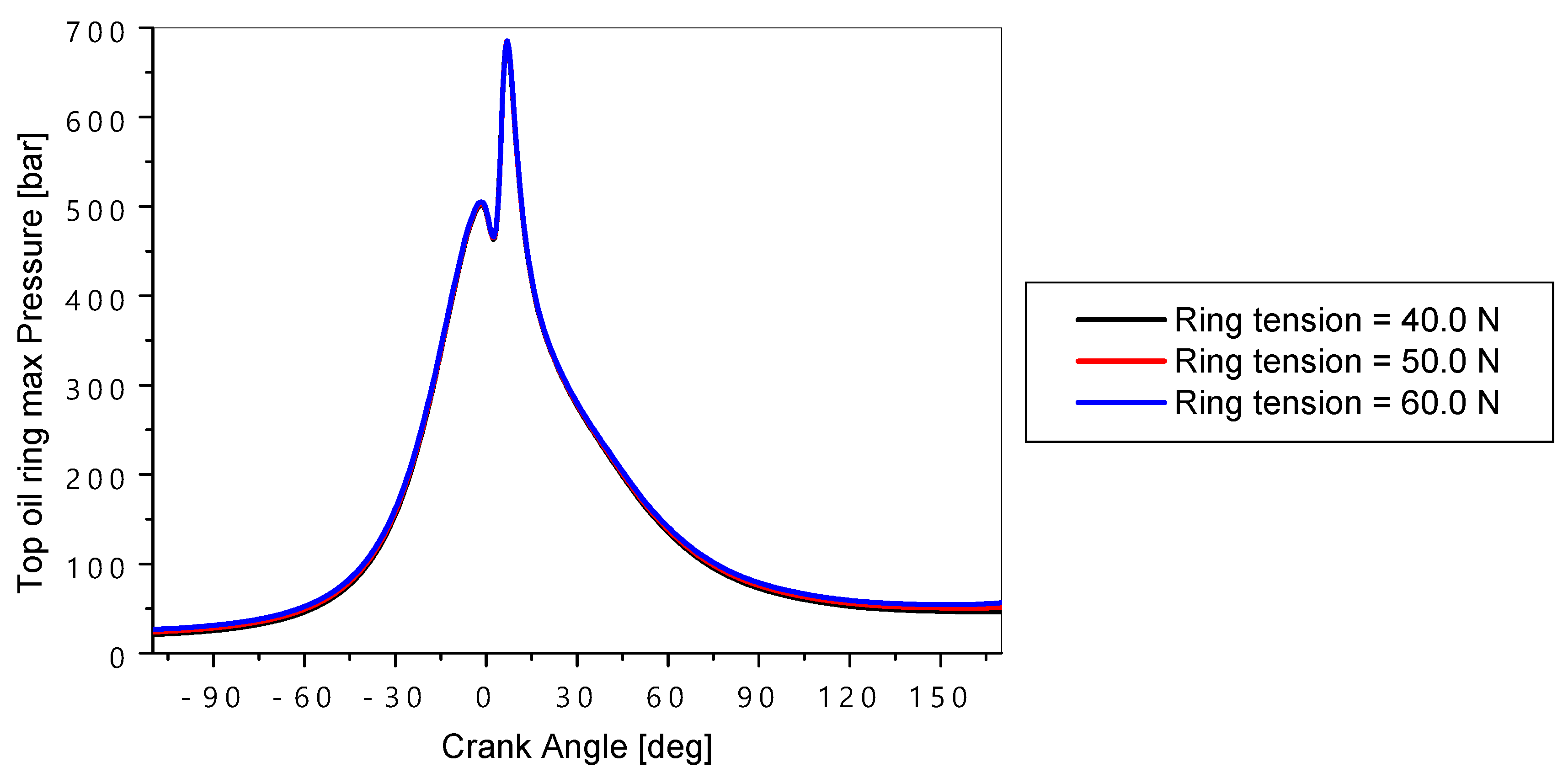

4.4. Effect of the Top Ring Tension

5. Conclusions

- ✓

- During the combustion relation period, an increase in the top ring thickness tends to reduce the minimum film thickness. This may even contribute to poor surface separation and increased metal-to-metal contact. However, this increase in the oil film may reduce the hydrodynamic friction force.

- ✓

- Higher temperatures tend to reduce the oil film thickness due to the reduction in the oil viscosity, hence increasing the risk of direct contact between surfaces. However, this increase in temperature also reduces the hydrodynamic friction force.

- ✓

- An increase in the roughness tends to disrupt the continuity in the oil film, which can lead to reduced lubrication efficiency. On the other hand, some roughness can also improve oil film adhesion, suggesting that optimizing the roughness could be a key parameter for the stability of lubrication film.

- ✓

- Higher tension in the top ring reduces the minimum oil film thickness, and can thus help to achieve a twist angle that favors the uniform distribution of the oil film.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Knauder, C.; Allmaier, H.; Sander, D.E.; Sams, T. Investigations of the Friction Losses of Different Engine Concepts: Part 3: Friction Reduction Potentials and Risk Assessment at the Sub-Assembly Level. Lubricants 2020, 8, 39. [Google Scholar] [CrossRef]

- Xiuyi, L.; Jiao, B.; Lu, X.; Zou, D.; Ma, X.; Neville, A. A statistical piston ring lubrication model considering the tribofilm and its effect of two-stroke marine engines. Tribol. Int. 2023, 177, 107996. [Google Scholar] [CrossRef]

- Forero, J.D.; Ochoa, G.V.; Rojas, J.P. Effect of the Geometric Profile of Top Ring on the Tribological Characteristics of a Low-Displacement Diesel Engine. Lubricants 2020, 8, 83. [Google Scholar] [CrossRef]

- Liu, L. Modeling the Performance of the Piston Ring-Pack with Consideration of Non-Axisymmetric Characteristics of the Power Cylinder System in Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2000. [Google Scholar]

- Dickinson, M.W. Dynamic Modelling of Compression Ring Conformability in High Performance Engines. Ph.D. Thesis, University of Central Lancashire, Preston, UK, 2016. [Google Scholar]

- Rao, X.; Sheng, C.; Guo, Z.; Zhang, X.; Yin, H.; Xu, C.; Yuan, C. Effects of textured cylinder liner piston ring on performances of diesel engine under hot engine tests. Renew. Sustain. Energy Rev. 2021, 146, 111193. [Google Scholar] [CrossRef]

- Gussmagg, J.; Maier, M.; Pusterhofer, M.; Grün, F. EHD simulation study on the influence of measured ICE compression piston ring profiles on the lubrication film formation. Tribol. Int. 2024, 199, 110015. [Google Scholar] [CrossRef]

- Wolff, A.; Koszalka, G. Influence of engine load on piston ring pack operation of an automotive IC engine. Combust. Engines 2022, 190, 88–94. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X.; Turkson, R.F.; Ezzat, M. An analytical study of tribological parameters between piston ring and cylinder liner in internal combustion engines. Proc. Inst. Mech. Eng. Part K-J. Multi-Body Dyn. 2016, 230, 329–349. [Google Scholar] [CrossRef]

- Liu, N.; Wang, C.; Xia, Q.; Gao, Y.; Liu, P. Simulation on the effect of cylinder liner and piston ring surface roughness on friction performance. Mech. Ind. 2022, 23, 8. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, S.; Xiong, P.; Li, Y.; Sun, W.; Deng, L. Effects of the Piston Skirt’s Surface Structure on Coating Quality and Friction Functions. Coatings 2024, 14, 1385. [Google Scholar] [CrossRef]

- Krakowski, R.; Marut, T. The Effect of Ecological Agents Added to Lubricating Oil on Selected Operating Parameters of an Internal Combustion Engine. Energies 2023, 16, 7510. [Google Scholar] [CrossRef]

- Edtmayer, J.; Lösch, S.; Hick, H.; Walch, S. Comparative study on the friction behaviour of piston/bore interface technologies. Automot. Engine Technol. 2019, 4, 101–109. [Google Scholar] [CrossRef]

- Kang, J.; Cho, J.; Park, S. Investigation of Friction Loss Characteristics of Engine Pistons for Different Engine Operating Conditions. Int. J. Automot. Technol. 2023, 24, 503–511. [Google Scholar] [CrossRef]

- Michelberger, B.; Jaitner, D.; Hagel, A.; Striemann, P.; Kröger, B.; Wetzel, F.-J.; Leson, A.; Lasagni, A.F. Friction Response of Piston Rings for Application-like Starvation and Benefit of Amorphous Carbon Coatings. Coatings 2022, 12, 738. [Google Scholar] [CrossRef]

- Dlugoš, J.; Novotný, P. Effective Implementation of Elastohydrodynamic Lubrication of Rough Surfaces into Multibody Dynamics Software. Appl. Sci. 2021, 11, 1488. [Google Scholar] [CrossRef]

- Ge, C.; Zhang, B.; Xu, X.; Lyu, X.; Ma, X.; Li, T.; Lu, X.; Liu, Z. Tribofilm distribution and tribological analysis of piston ring-cylinder liner interfaces under realistic engine conditions. Tribol. Int. 2025, 201, 110250. [Google Scholar] [CrossRef]

- Li, Z.; Han, X.; Shan, Y.; Shen, Y.; Xu, J. The effect of MoS2 concentration on the thickness and tribology performance of electro-codeposited Ni–Cr–MoS2 coatings. Wear 2024, 552–553, 205457. [Google Scholar] [CrossRef]

- Sanadhya, K.; Malkhede, D.N.; Nandgaonkar, M.R.; Aghav, Y.V.; Kumar, M.N. Effect of Piston Profile on Piston Motion and Liner Bore Polishing. Int. J. Automot. Technol. 2024, 25, 225–233. [Google Scholar] [CrossRef]

- Liu, S.; Gao, L.; Xing, M.; Cui, Y.; Meng, X. A new 3-D multi-physics coupling model for lubricated piston-liner systems. Int. J. Mech. Sci. 2024, 272, 109194. [Google Scholar] [CrossRef]

- Zhang, B.; Ma, X.; Liu, L.; Wang, Y.; Yu, H.; Morina, A.; Lu, X. Reciprocating sliding friction behavior and wear state transition mechanism of cylinder liner and piston ring. Wear 2024, 546-547, 205293. [Google Scholar] [CrossRef]

- Guo, P.; Yan, Z.; Xu, J.; Shen, Y.; Wang, J. Wear life prediction of piston ring and cylinder liner based on integration of experiment and bench test data. Eng. Fail. Anal. 2024, 161, 108259. [Google Scholar] [CrossRef]

- Kanemoto, K.; Ito, A. A study on the effect of factors of piston motion on the piston ring rotation of an engine. Tribol. Int. 2024, 194, 109483. [Google Scholar] [CrossRef]

- García-Rodiño, D.; Blanco-Rodríguez, J.; Cortada-García, M.; Fernández, S.; Porteiro, J. A numerical procedure for calculating roughness parameters for the Greenwood-Tripp model of asperity contact based on 3D measurements. Tribol. Int. 2024, 200, 110156. [Google Scholar] [CrossRef]

- Shah, A.S.; Bhatt, D.V. Experimental Study to Measure Piston Ring Assembly Friction of Multicylinder I.C. Engine (S.I.) on Motorized Engine Test Rig: A Case Study. In Proceedings of International Conference on Advances in Tribology and Engineering Systems. Lecture Notes in Mechanical Engineering; Patel, H., Deheri, G., Patel, H., Mehta, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Liu, C.; Lu, Y.-J.; Zhang, Y.-F.; Li, S.; Müller, N. Numerical study on the lubrication performance of compression ring-cylinder liner system with spherical dimples. PLOS ONE 2017, 12, e0181574. [Google Scholar] [CrossRef]

- Liu, C.; Lu, Y.; Zhang, Y.; Li, S.; Kang, J.; Müller, N. Numerical Study on the Tribological Performance of Ring/Liner System With Consideration of Oil Transport. J. Tribol. 2019, 141, 011701. [Google Scholar] [CrossRef]

- Hei, D.; Zheng, M.; Liu, C.; Jiang, L.; Zhang, Y.; Zhao, X. Study on the frictional properties of the top ring-liner conjunction for different-viscosity lubricant. Adv. Mech. Eng. 2023, 15. [Google Scholar] [CrossRef]

- Lining, G.; Yi, C.; Zhaohui, X.; Yan, F.; Shuo, L.; Yafen, L.; Xinrong, H. A fully coupled tribo-dynamic model for piston-ring-liner system. Tribol. Int. 2023, 178, 107998. [Google Scholar] [CrossRef]

- Li, G.; Gu, F.; Wang, T.; Yang, T.; Ball, A. Investigation into the dynamic response of cylinder liners in an IC engine based on a validated finite-element model. Syst. Sci. Control Eng. 2017, 5, 56–69. [Google Scholar] [CrossRef]

- Delprete, C.; Razavykia, A. Piston dynamics, lubrication and tribological performance evaluation: A review. Int. J. Engine Res. 2020, 21, 725–741. [Google Scholar] [CrossRef]

- Chowdhury, S. Cylinder Liner Velocity Calculation under Dynamic Condition in the Pursuit of Liner Cavitation Investigation of an Internal Combustion Engine. SAE Int. J. Engines 2024, 17, 309–320. [Google Scholar] [CrossRef]

- Totaro, P.P.; Westerfield, Z.; Tian, T. Introducing a New Piston Skirt Profile to Reduce Engine Friction; SAE Paper No. 2016-01-1046; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Mishra, P.; Ramkumar, P. Effect of additives on a surface textured piston ring–cylinder liner system. Tribol.-Mater. Surfaces Interfaces 2019, 13, 67–75. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Yuan, C. Influence of Surface Groove Width on Tribological Performance for Cylinder Liner–Piston Ring Components. Tribol. Trans. 2019, 62, 239–248. [Google Scholar] [CrossRef]

- Ma, Z.; Henein, N.A.; Bryzik, W. A Model for Wear and Friction in Cylinder Liners and Piston Rings. Tribol. Trans. 2006, 49, 315–327. [Google Scholar] [CrossRef]

- Xu, Y.F.; Yu, H.Q.; Wei, X.Y.; Cui, Z.; Hu, X.G.; Xue, T.; Zhang, D.Y. Friction and Wear Behaviors of a Cylinder Liner–Piston Ring with Emulsified Bio-Oil as Fuel. Tribol. Trans. 2013, 56, 359–365. [Google Scholar] [CrossRef]

- Vlădescu, S.-C.; Ciniero, A.; Tufail, K.; Gangopadhyay, A.; Reddyhoff, T. Optimization of Pocket Geometry for Friction Reduction in Piston–Liner Contacts. Tribol. Trans. 2017, 61, 522–531. [Google Scholar] [CrossRef]

- Yang, Q.; Keith, T.G. Two-Dimensional Piston Ring Lubrication—Part I: Rigid Ring and Liner Solution. Tribol. Trans. 1996, 39, 757–768. [Google Scholar] [CrossRef]

- Ananth, S.; Sivanesh, A.R.; Prakash, J.U.; Paul, P.J. Wear parameter optimisation of piston and cylinder liner material (GCI) using Taguchi technique. Int. J. Ambient. Energy 2019, 43, 783–787. [Google Scholar] [CrossRef]

- Kunt, M.A.; Calam, A.; Gunes, H. Analysis of the effects of lubricating oil viscosity and engine speed on piston-cylinder liner frictions in a single cylinder HCCI engine by GT-SUITE program. Proc. Inst. Mech. Eng. Part E: J. Process. Mech. Eng. 2022, 237, 399–409. [Google Scholar] [CrossRef]

- Menacer, B.; Bouchetara, M. The compression ring profile influence on hydrodynamic performance of the lubricant in diesel engine. Adv. Mech. Eng. 2014, 12, 1–13. [Google Scholar] [CrossRef]

- Assis, M.S.S.; de Castro, D.H.; Moreira, T.A.A.; Filho, F.A.R.; Malaquias, A.C.T.; Baêta, J.G.C. Numerical Study of Compression Ratio Influence on Specific Fuel Consumption of an Ethanol Fueled Engine Using GT POWER Code; SAE Technical Paper 2022-36-0075; SAE: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Kaushik, H.K.; Rani, A.; Sarna, N. Assessment of CNG & CBG Composition Variation on CO2 Emissions, Engine Performance and Durability for a Small Size PFI Engine; SAE Technical Paper 2022-28-0020; SAE: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Garcia, A.; Monsalve-Serrano, J.; Villalta, D.; Tripathi, S. Electric Vehicles vs e-Fuelled ICE Vehicles: Comparison of potentials for Life Cycle CO2 Emission Reduction; SAE Technical Paper 2022-01-0745; SAE: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Kumar, V.; Challa, K.; Banik, S.; Borado, P. Unified Thermal System Simulations of an Electric Truck. SAE Int. J. Adv. Curr. Pr. Mobil. 2023, 5, 1537–1543. [Google Scholar] [CrossRef]

- Ravikumar, A.; Bhatt, A.; Gainey, B.; Lawler, B. GT-Suite Modeling of Thermal Barrier Coatings in a Multi-Cylinder Turbocharged DISI Engine for Catalyst Light-Off Delay Improvement; SAE Technical Paper 2023-01-1602; SAE: Warrendale, PA, USA, 2023. [Google Scholar]

- Lesage, M.; Chalet, D.; Migaud, J.; Krautner, C. Optimization of air quality and energy consumption in the cabin of electric vehicles using system simulation. J. Environ. Manag. 2024, 358, 120861. [Google Scholar] [CrossRef]

- Narimani, M.; Emami, S.A.; Banazadeh, A.; Modarresi, A. A unified thermal management framework for electric vehicles: Design and test bench implementation. Appl. Therm. Eng. 2024, 248, 123057. [Google Scholar] [CrossRef]

- Nabi, N.; Ray, B.; Rashid, F.; Al Hussam, W.; Muyeen, S. Parametric analysis and prediction of energy consumption of electric vehicles using machine learning. J. Energy Storage 2023, 72, 108226. [Google Scholar] [CrossRef]

- Kalin, M.; Zugelj, B.; Lamut, M.; Hamouda, K. Elastic and plastic deformation of surface asperities and their load-carrying mechanisms during the formation of a real contact area. Tribol. Int. 2023, 178, 108067. [Google Scholar] [CrossRef]

- Esmaeil, T.; Kazerooni, R.B. Energy analysis and the comparison of gasoline direct injection engines performance parameters with port fuel injection engines. IOSR J. Mech. Civ. Eng. 2016, 13, 104–114. [Google Scholar] [CrossRef]

- Takiguchi, M.; Harigaya, Y.; Suzuki, M. Analysis of oil film thickness on a piston ring of diesel engine: Effect of oil film temperature. J. Eng. Gas Turbines Power 2003, 125, 596–603. [Google Scholar]

| Engine speed | 2000 | RPM |

| Ring surface roughness | 0.10 | μm |

| Bore surface roughness | 0.71 | μm |

| Oil density | 881.5 | Kg/m3 |

| Oil viscosity | 0.0087 | Pa-s |

| Oil density | 860 | kg/m3 |

| Oil viscosity | 064 | Centistoke |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menacer, B.; Narayan, S.; Tuninetti, V.; Khatir, T.; Oñate, A.; Osorio, L.; Abubakar, S.; Samuel, J.; Grujic, I.; Stojanovic, N.; et al. Impact of Influence of Piston Design Parameters on the Hydrodynamic Characteristics of Internal Combustion Engines—A Numerical Study. Lubricants 2024, 12, 427. https://doi.org/10.3390/lubricants12120427

Menacer B, Narayan S, Tuninetti V, Khatir T, Oñate A, Osorio L, Abubakar S, Samuel J, Grujic I, Stojanovic N, et al. Impact of Influence of Piston Design Parameters on the Hydrodynamic Characteristics of Internal Combustion Engines—A Numerical Study. Lubricants. 2024; 12(12):427. https://doi.org/10.3390/lubricants12120427

Chicago/Turabian StyleMenacer, Brahim, Sunny Narayan, Víctor Tuninetti, Tawfiq Khatir, Angelo Oñate, Liomnis Osorio, Shitu Abubakar, Joseph Samuel, Ivan Grujic, Nadica Stojanovic, and et al. 2024. "Impact of Influence of Piston Design Parameters on the Hydrodynamic Characteristics of Internal Combustion Engines—A Numerical Study" Lubricants 12, no. 12: 427. https://doi.org/10.3390/lubricants12120427

APA StyleMenacer, B., Narayan, S., Tuninetti, V., Khatir, T., Oñate, A., Osorio, L., Abubakar, S., Samuel, J., Grujic, I., Stojanovic, N., & Kaisan, M. U. (2024). Impact of Influence of Piston Design Parameters on the Hydrodynamic Characteristics of Internal Combustion Engines—A Numerical Study. Lubricants, 12(12), 427. https://doi.org/10.3390/lubricants12120427