Investigation of Tribological Performance of Ti:WS2/PFPE Composite Lubricating System Under Proton Radiation

Abstract

:1. Introduction

2. Experimental Details

2.1. Film Deposition and Construction of Ti:WS2/PFPE Composite Lubricating System

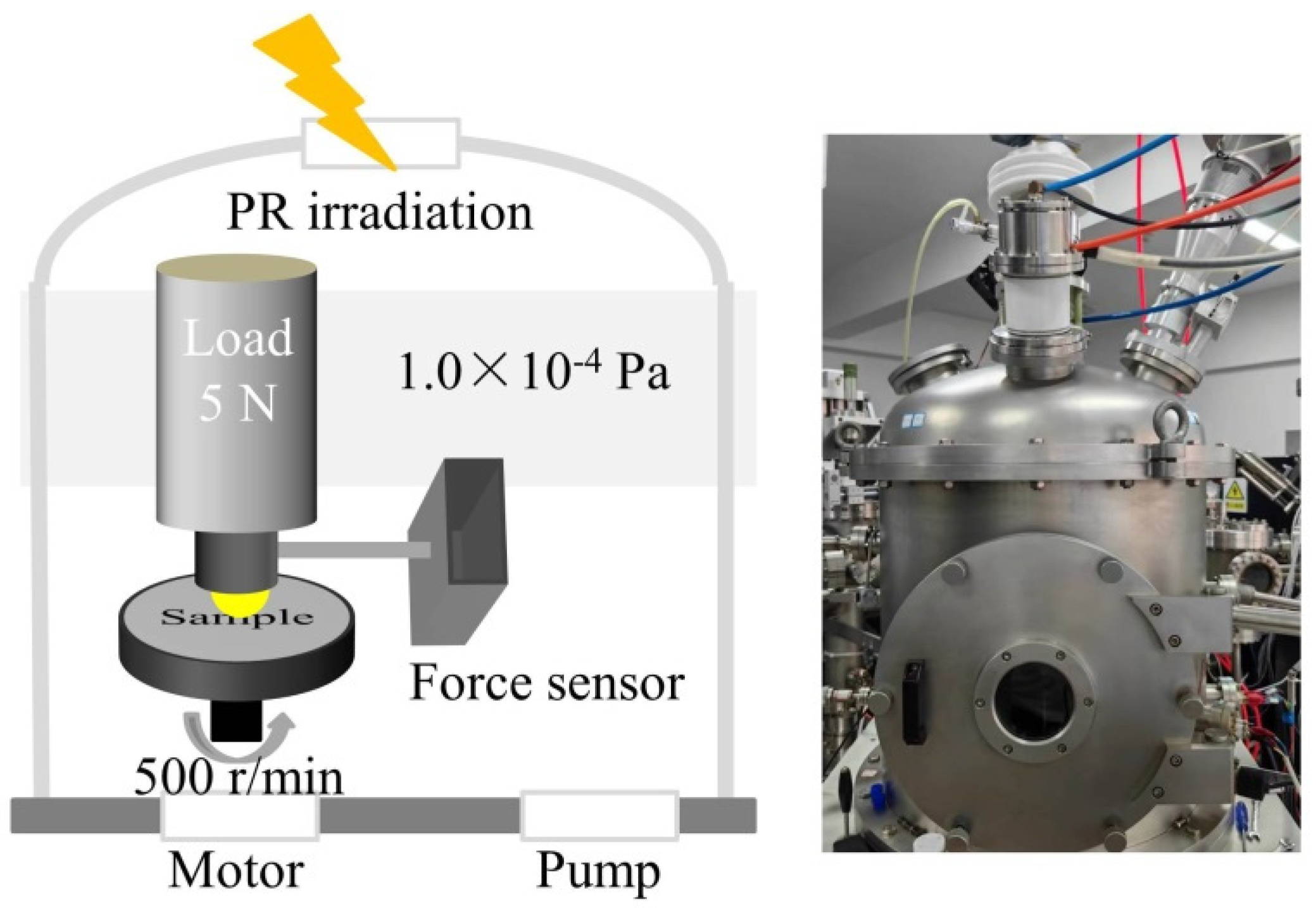

2.2. PR Irradiation and Tribological Test

2.3. Characterization

3. Results and Discussion

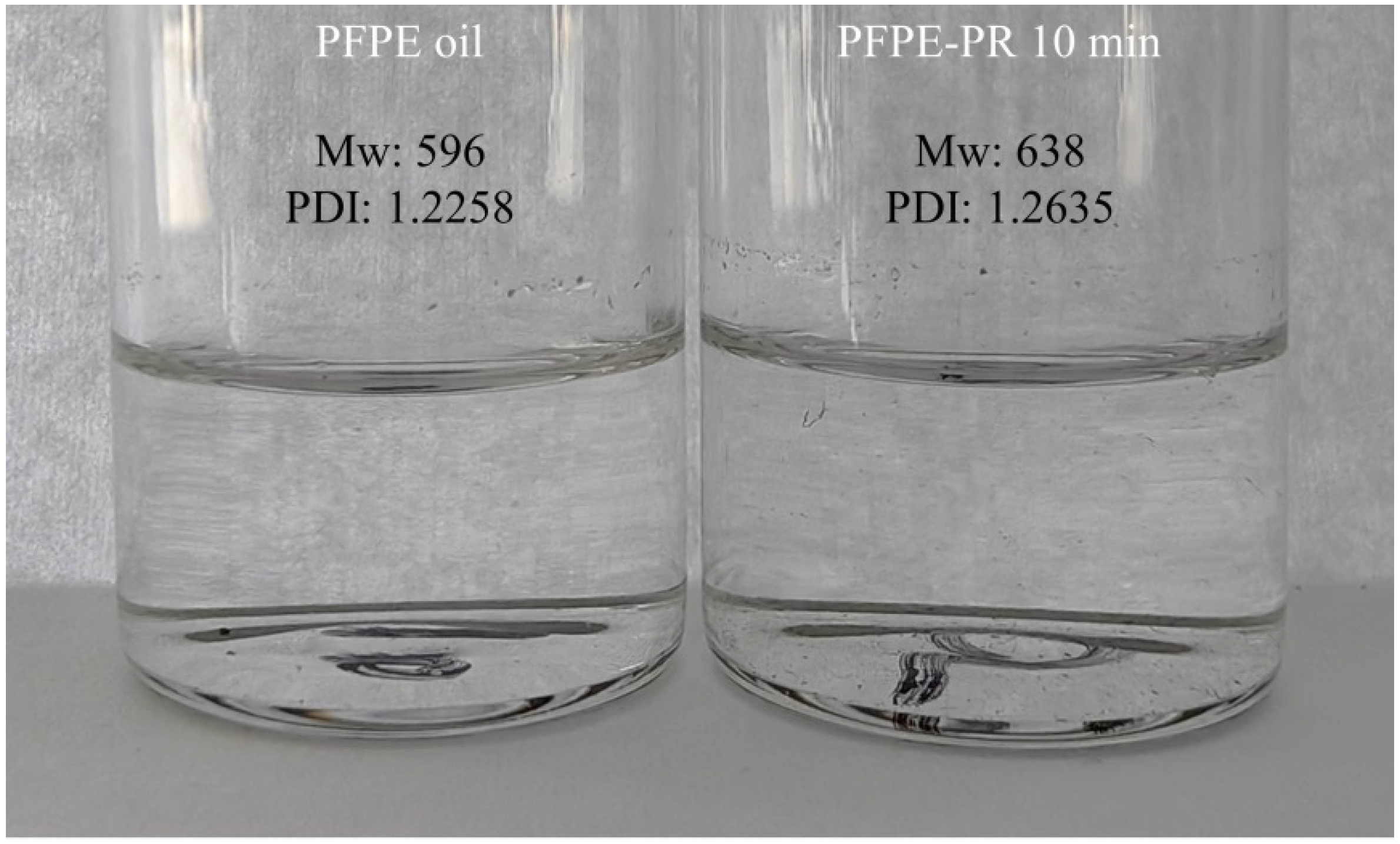

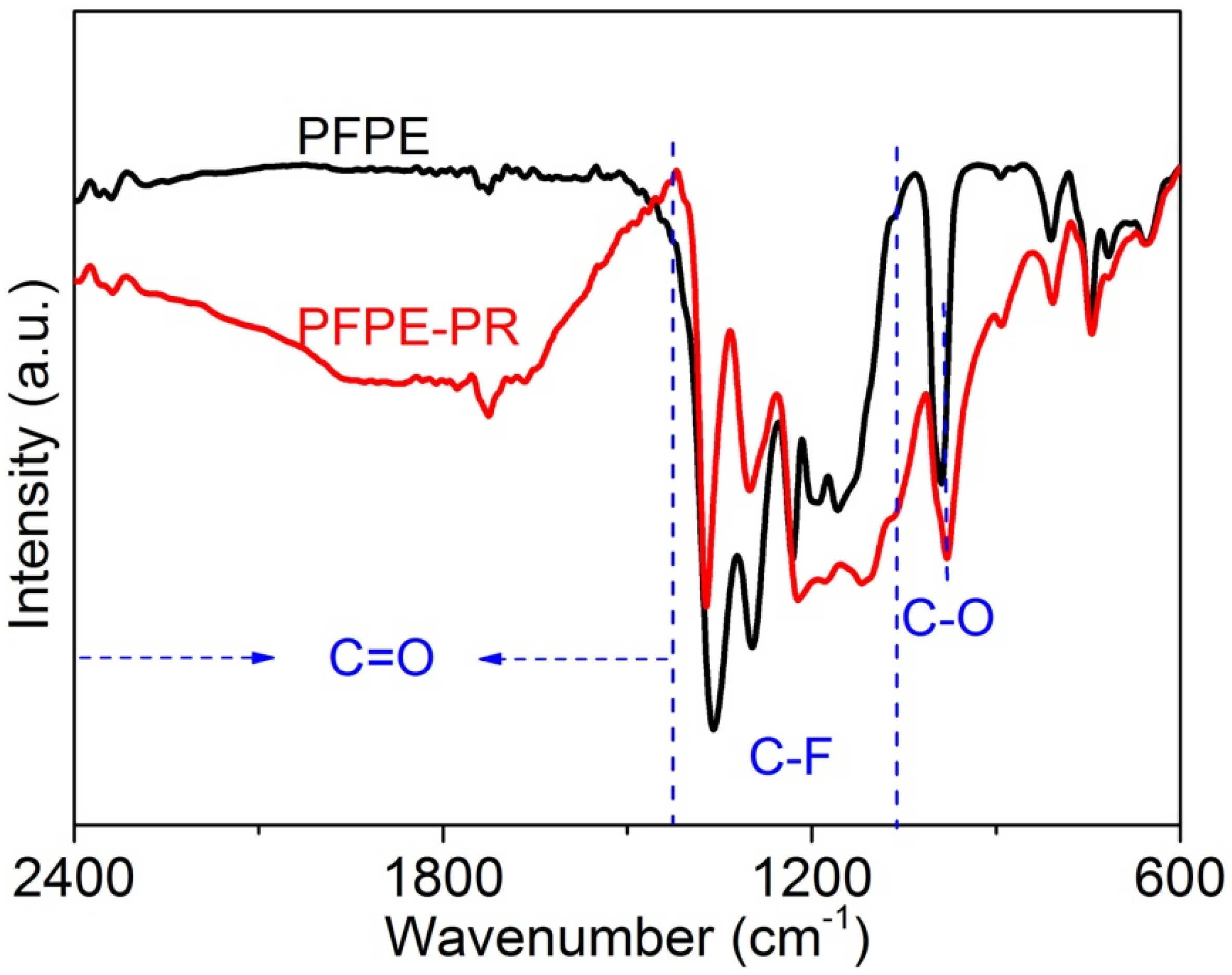

3.1. The Influence of PR Irradiation on the PFPE Oil

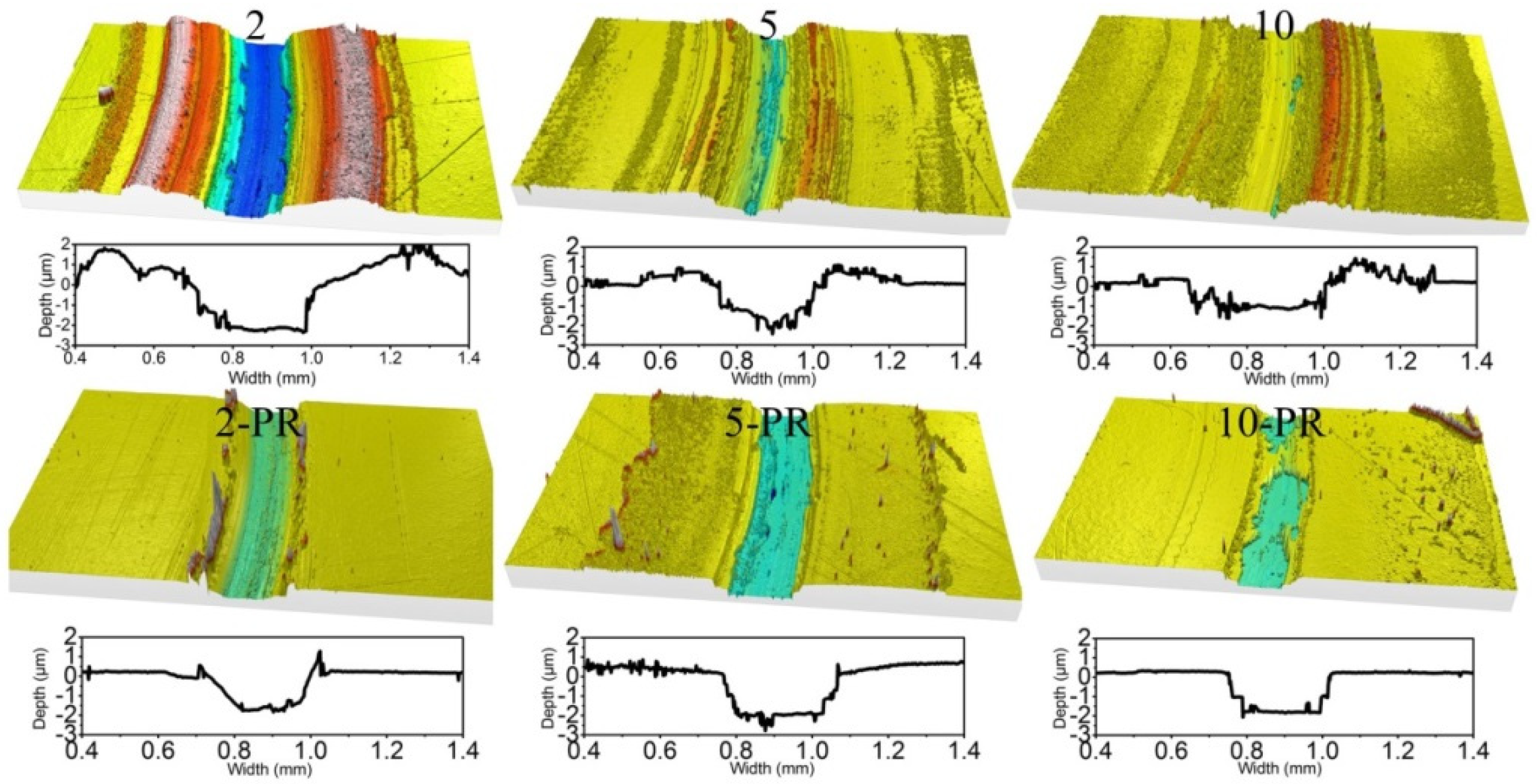

3.2. Tribological Properties of Ti:WS2/PFPE System

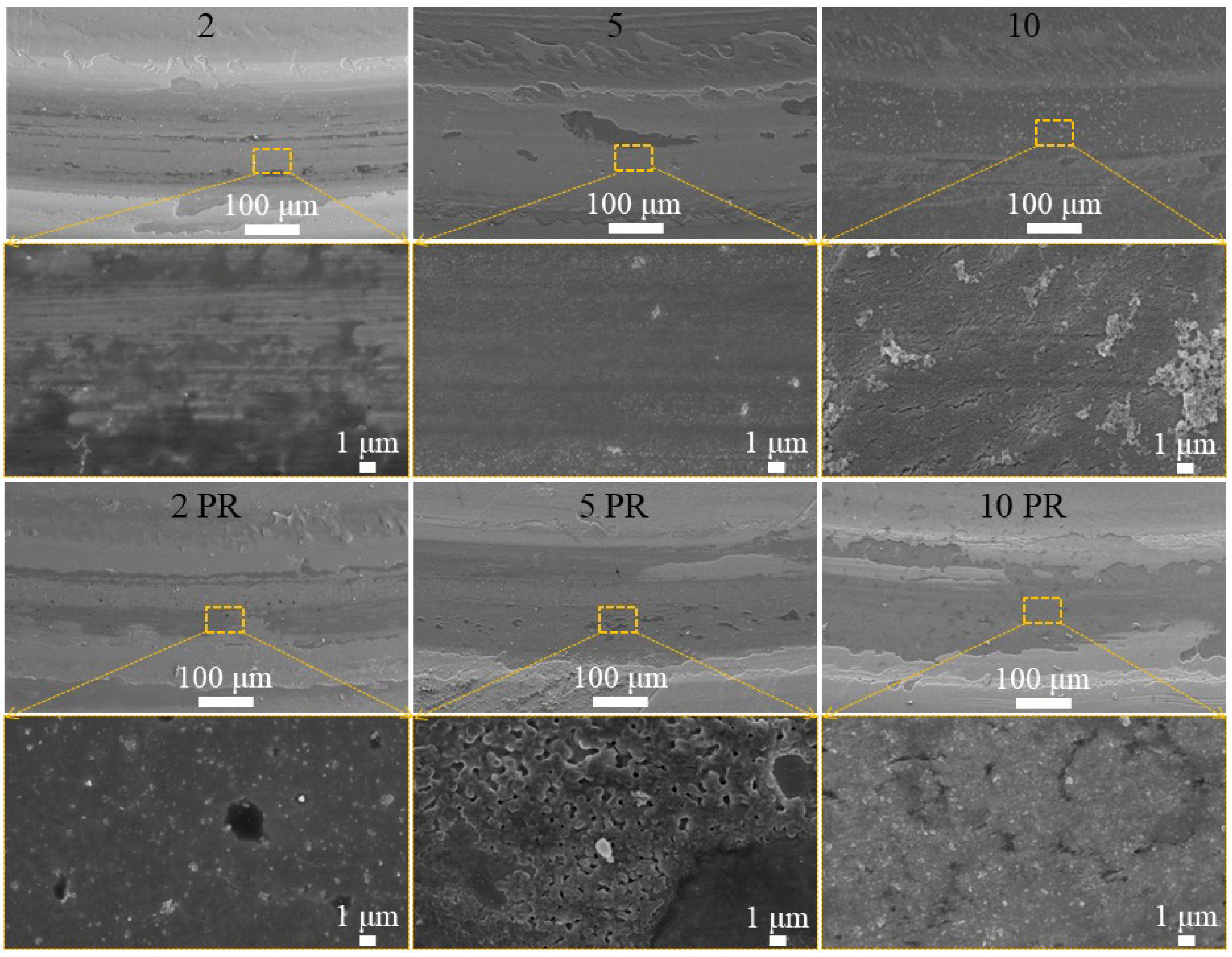

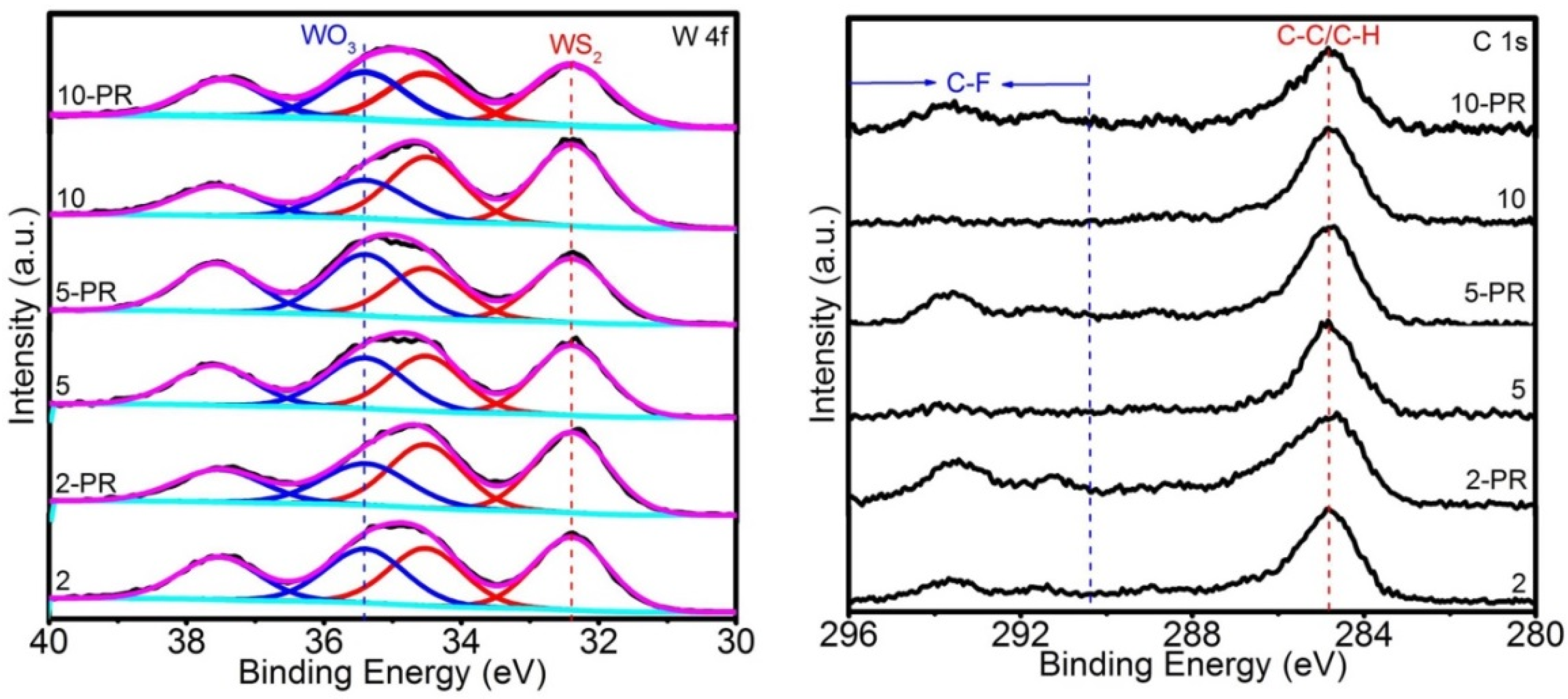

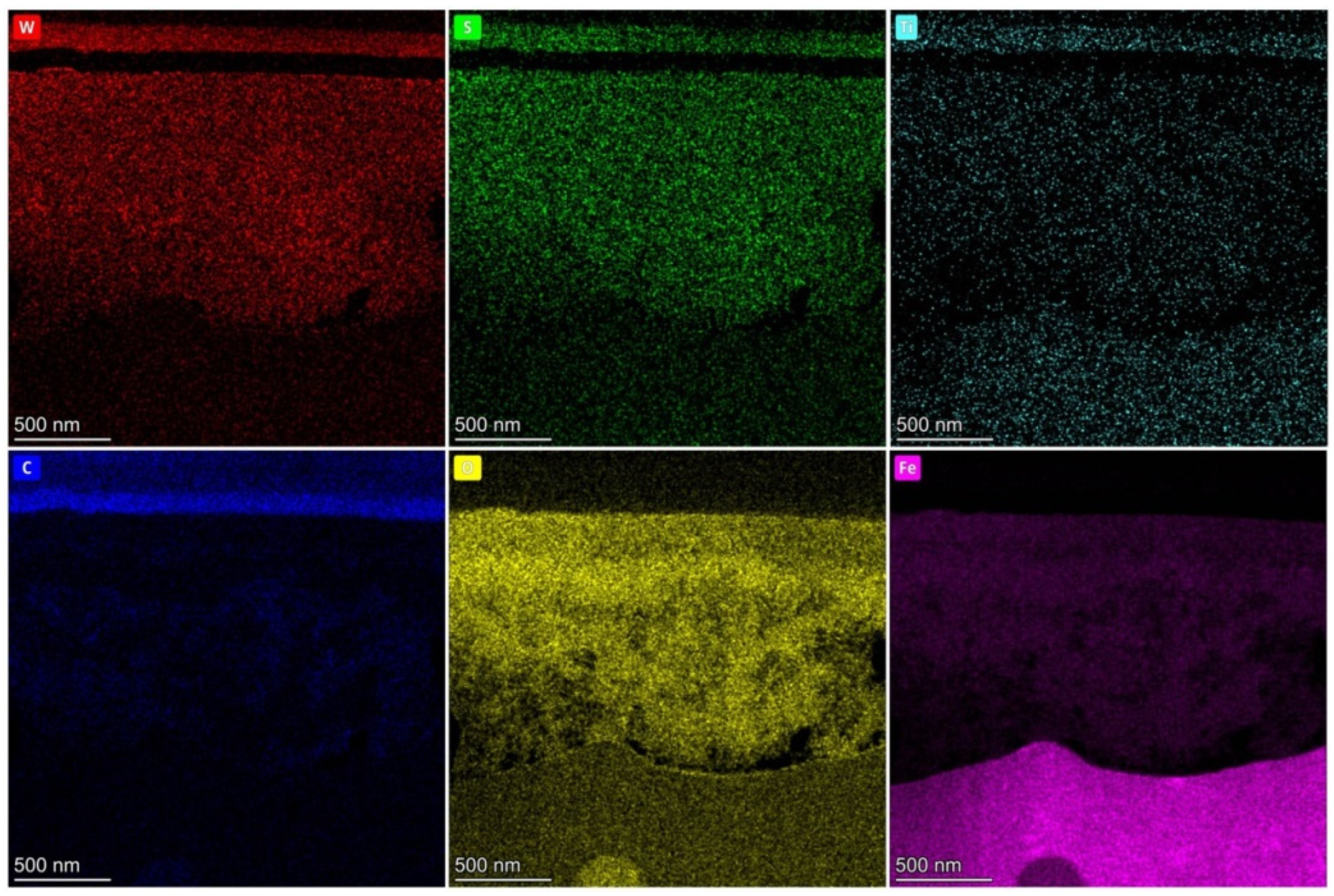

3.3. The Tribological Mechanisms

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Uzoma, P.C.; Hu, H.; Khadem, M.; Penkov, O.V. Tribology of 2D nanomaterials: A review. Coatings 2020, 10, 897. [Google Scholar] [CrossRef]

- Yang, J.F.; Parakash, B.; Hardell, J.; Fang, Q.F. Tribological properties of transition metal di-chalcogenide based lubricant coatings. Front Mater. Sci. 2012, 6, 116–127. [Google Scholar] [CrossRef]

- Marian, M.; Berman, D.; Rota, A.; Jackson, R.L.; Rosenkranz, A. Layered 2D nanomaterials to tailor friction and wear in machine elements—A review. Adv. Mater. Interfaces 2021, 9, 2101622. [Google Scholar] [CrossRef]

- Joseph, A.; Vijayan, A.S.; Shebeeb, C.M.; Akshay, K.S.; John Mathew, K.P.; Sajith, V. A review on tailoring the corrosion and oxidation properties of MoS2-based coatings. J. Mater. Chem. A 2023, 11, 3172–3209. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid lubrication with MoS2: A review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Tedstone, A.A.; Lewis, D.J.; O’Brien, P. Synthesis, properties, and applications of transition metal-doped layered transition metal dichalcogenides. Chem. Mater. 2016, 28, 1965–1974. [Google Scholar] [CrossRef]

- Ren, S.; Li, H.; Cui, M.; Wang, L.; Pu, J. Functional regulation of Pb-Ti/MoS2 composite coatings for environmentally adaptive solid lubrication. Appl. Surf. Sci. 2017, 401, 362–372. [Google Scholar] [CrossRef]

- Scharf, T.W.; Goeke, R.S.; Kotula, P.G.; Prasad, S.V. Synthesis of Au-MoS2 nanocomposites: Thermal and friction-induced changes to the structure. ACS Appl. Mater. Interfaces 2013, 5, 11762–11767. [Google Scholar] [CrossRef]

- Serles, P.; Nicholson, E.; Tam, J.; Barri, N.; Chemin, J.B.; Wang, G.; Michel, Y.; Veer Sigh, C.; Choquet, P.; Saulot, A.; et al. High performance space lubrication of MoS2 with tantalum. Adv. Funct. Mater. 2022, 32, 2110429. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D.; Wang, D.; Yu, Q.; Bai, Y.; Cai, M.; Weng, L.; Zhou, F.; Liu, W. MoS2 lubricating film meets supramolecular gel: A novel composite lubricating system for space applications. ACS Appl. Mater. Interfaces 2021, 13, 58036–58047. [Google Scholar] [CrossRef]

- Quan, X.; Hu, M.; Gao, X.; Fu, Y.; Weng, L.; Wang, D.; Jiang, D.; Sun, J. Friction and wear performance of dual lubrication systems combining WS2–MoS2 composite film and low volatility oils under vacuum condition. Tribol. Inter. 2016, 99, 57–66. [Google Scholar] [CrossRef]

- Zaretsky, E.V. Liquid lubrication in space. Tribol. Inter. 1990, 23, 75–93. [Google Scholar] [CrossRef]

- Fan, X.; Xue, Q.; Wang, L. Carbon-based solid-liquid lubricating coatings for space applications-a review. Friction 2015, 3, 191–207. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Xue, Q. DlC-based solid–liquid synergetic lubricating coatings for improving tribological behavior of boundary lubricated surfaces under high vacuum condition. Wear 2011, 271, 889–898. [Google Scholar] [CrossRef]

- Lv, M.; Yang, L.; Wang, Q.; Wang, T.; Liang, Y. Tribological performance and lubrication mechanism of solid–liquid lubricating materials in high-vacuum and irradiation environments. Tribol. Lett. 2015, 59, 20. [Google Scholar] [CrossRef]

- Quan, X.; Gao, X.; Weng, L.; Hu, M.; Jiang, D.; Wang, D.; Sun, J.; Liu, W. Tribological behavior of WS2-based solid/liquid lubricating systems dominated by the surface properties of WS2 crystallographic planes. RSC Adv. 2015, 5, 64892. [Google Scholar] [CrossRef]

- Lu, Z.; Lin, Q.; Cao, Z.; Li, W.; Gong, J.; Wang, Y.; Hu, K.; Hu, X. MoS2 nanomaterials as lubricant additives: A review. Lubricants 2023, 11, 527. [Google Scholar] [CrossRef]

- Cai, M.; Yu, Q.; Liu, W.; Zhou, F. Ionic liquid lubricants: When chemistry meets tribology. Chem. Soc. Rev. 2020, 49, 7753. [Google Scholar] [CrossRef]

- Quan, X.; Zhang, S.; Hu, M.; Gao, X.; Jiang, D.; Sun, J. Tribological properties of WS2 /MoS2-Ag composite films lubricated with ionic liquids under vacuum conditions. Tribol. Inter. 2017, 115, 389–396. [Google Scholar] [CrossRef]

- Zhuang, W.; Fan, X.; Li, W.; Li, H.; Zhang, L.; Peng, J.; Cai, Z.; Mo, J.; Zhang, G.; Zhu, M. Comparing space adaptability of diamond-like carbon and molybdenum disulfide films toward synergistic lubrication. Carbon 2018, 134, 163–173. [Google Scholar] [CrossRef]

- Nautiyal, H.; Singh, S.; Gautam, R.; Goswami, R.; Khatri, O.; Verma, P.; Tyagi, R. The state of art on lubrication methods in space environment. Phys. Scr. 2024, 99, 022003. [Google Scholar] [CrossRef]

- Nicholson, E.; Serles, P.; Wang, G.; Filleter, T.; Davis, J.W.; Singh, C.V. Low energy proton irradiation tolerance of molybdenum disulfide lubricants. Appl. Surf. Sci. 2021, 567, 150677. [Google Scholar] [CrossRef]

- Wei, R.; Wilbur, P.J.; Buchholz, B.W.; Kustas, S.M. In situ tribological evaluation of greases and solid lubricants in a simulated atomic oxygen environment. Tribol. Trans. 1995, 38, 950–958. [Google Scholar] [CrossRef]

- Fan, X.; Shi, Y.; Cui, M.; Ren, S.; Wang, H.; Pu, J. MoS2/WS2 nanosheet-based composite films irradiated by atomic oxygen: Implications for lubrication in space. ACS Appl. Nano Mater. 2021, 4, 10307–10320. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Y.; Li, H.; Chen, J.; Yu, S.; Zhou, B.; Tang, B. The effect of vacuum atomic oxygen and ultraviolet radiations on Ag/a-C:H nanocomposite film. Tribol. Inter. 2016, 101, 395–401. [Google Scholar] [CrossRef]

- Ren, J.; Gong, K.; Zhao, G.; Lou, W.; Wu, X.; Wang, X. Investigation of the tribological performances of graphene and WS2 nanosheets as additives for perfluoroalkylpolyethers under simulated space environment. Tribol. Lett. 2021, 69, 45. [Google Scholar] [CrossRef]

- Minn, M.; Sinha, S.K.; Lee, S.K.; Kondo, H. High-speed tribology of PFPEs with different functional groups and molecular weights coated on DLC. Tribol. Lett. 2006, 24, 67–76. [Google Scholar] [CrossRef]

- Cui, H.C.; Li, D.C.; Wang, C. Infrared spectrum analysis of perfluoro polyethers (PFPE) of fluorocarbon-based magnetic fluid’s base liquid. Adv. Mater. Res. 2011, 391–392, 1311–1314. [Google Scholar] [CrossRef]

- Yang, J.; Wang, D.; Fu, Y.; Wang, Q.; Hu, M.; Jiang, D.; Gao, X.; Sun, J.; Weng, J. Improving the tribological and anti-corrosion property of the WS2 film through Ta doping. Vacuum 2021, 192, 110485. [Google Scholar] [CrossRef]

- Takahashi, A.; Takeichi, Y.; Kimura, M.; Hashimoto, K. Low friction mechanism survey of tungsten disulfide by using XRD, XPS, and XAFS. Tribol. Lett. 2021, 69, 84. [Google Scholar] [CrossRef]

- Mignuzzi, S.; Pollard, A.J.; Bonini, N.; Brennan, B.; Gilmore, I.S.; Pimenta, M.A.; Pichards, D.; Roy, D. Effect of disorder on Raman scattering of single-layer MoS2. Phys. Rev. B 2015, 91, 195411. [Google Scholar] [CrossRef]

- Windom, B.C.; Sawyer, W.G.; Hahn, D.W. A Raman Spectroscopic study of MoS2 and MoO3: Applications to tribological systems. Tribol. Lett. 2011, 42, 301–310. [Google Scholar] [CrossRef]

- He, M.; Yeo, C.D. Micro-wear and friction of carbon film with molecularly thin PFPE lubricants. J. Mech. Sci. Technol. 2018, 32, 3291–3297. [Google Scholar] [CrossRef]

- Alov, N.V. XPS study of MoO3 and WO3 oxide surface modification by low-energy Ar+ ion bombardment. Phys. Status Solidi. C 2015, 12, 263–266. [Google Scholar] [CrossRef]

- Liu, J.; Yan, Z.; Hao, J.; Liu, W. Tribological performance and failure mechanism of Ti:WS2/P201 hybrid lubrication system under atomic oxygen irradiation. Vacuum 2023, 211, 111976. [Google Scholar] [CrossRef]

- Pan, F.M.; Lin, Y.L.; Horng, S.S. Decomposition of perfluoropolyethers during XPS measurements. Appl. Surf. Sci. 1991, 47, 9–16. [Google Scholar] [CrossRef]

- Pu, J.; Ren, S.; Lu, Z.; Wang, L. A feasible multilayer structure design for solid lubricant coatings in a lunar environment. RSC Adv. 2016, 6, 65504–65517. [Google Scholar] [CrossRef]

- Gustavsson, F.; Svahn, F.; Bexell, U.; Jacobson, S. Nanoparticle based and sputtered WS2 low-friction coatings—differences and similarities with respect to friction mechanisms and tribofilm formation. Surf. Coat. Technol. 2013, 232, 616–626. [Google Scholar] [CrossRef]

| Before Irradiation | After Irradiation | |||||

|---|---|---|---|---|---|---|

| PFPE oil content (μL) | 2 | 5 | 10 | 2 | 5 | 10 |

| WS2 (atom%) | 55.7 | 55.8 | 65.8 | 62.3 | 49.6 | 55.7 |

| WO3 (atom%) | 44.3 | 44.2 | 34.2 | 37.7 | 50.4 | 44.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Yan, Z.; Hao, J.; Liu, W. Investigation of Tribological Performance of Ti:WS2/PFPE Composite Lubricating System Under Proton Radiation. Lubricants 2024, 12, 403. https://doi.org/10.3390/lubricants12120403

Liu J, Yan Z, Hao J, Liu W. Investigation of Tribological Performance of Ti:WS2/PFPE Composite Lubricating System Under Proton Radiation. Lubricants. 2024; 12(12):403. https://doi.org/10.3390/lubricants12120403

Chicago/Turabian StyleLiu, Jian, Zhen Yan, Junying Hao, and Weimin Liu. 2024. "Investigation of Tribological Performance of Ti:WS2/PFPE Composite Lubricating System Under Proton Radiation" Lubricants 12, no. 12: 403. https://doi.org/10.3390/lubricants12120403

APA StyleLiu, J., Yan, Z., Hao, J., & Liu, W. (2024). Investigation of Tribological Performance of Ti:WS2/PFPE Composite Lubricating System Under Proton Radiation. Lubricants, 12(12), 403. https://doi.org/10.3390/lubricants12120403