Identification and Regulation of Cold Rolling Interface State Based on a Novel Modified Forward Slip Model

Abstract

1. Introduction

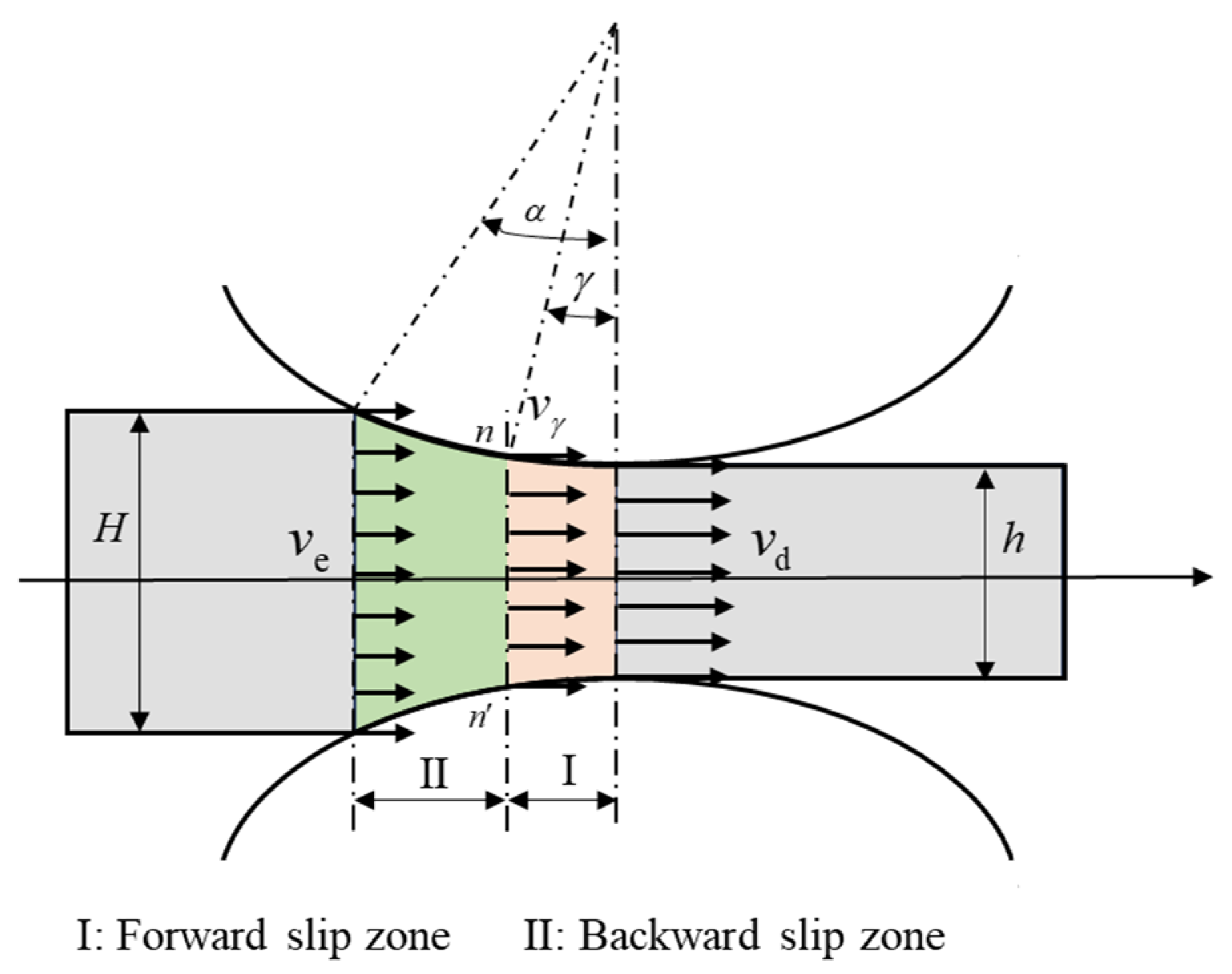

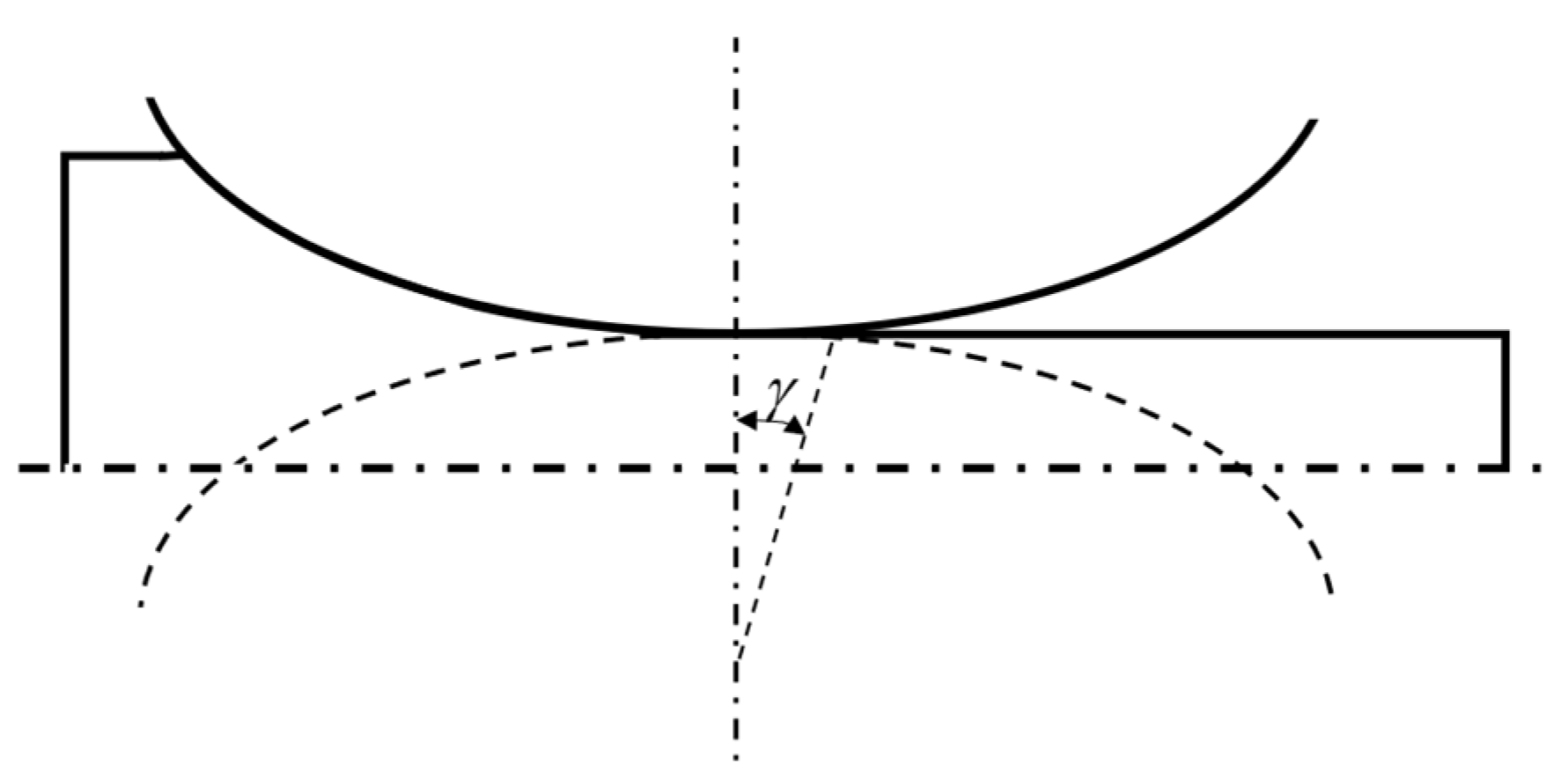

2. Modified Forward Slip Model

2.1. Modeling Based on Forward Slip Theory and Flatten Curve

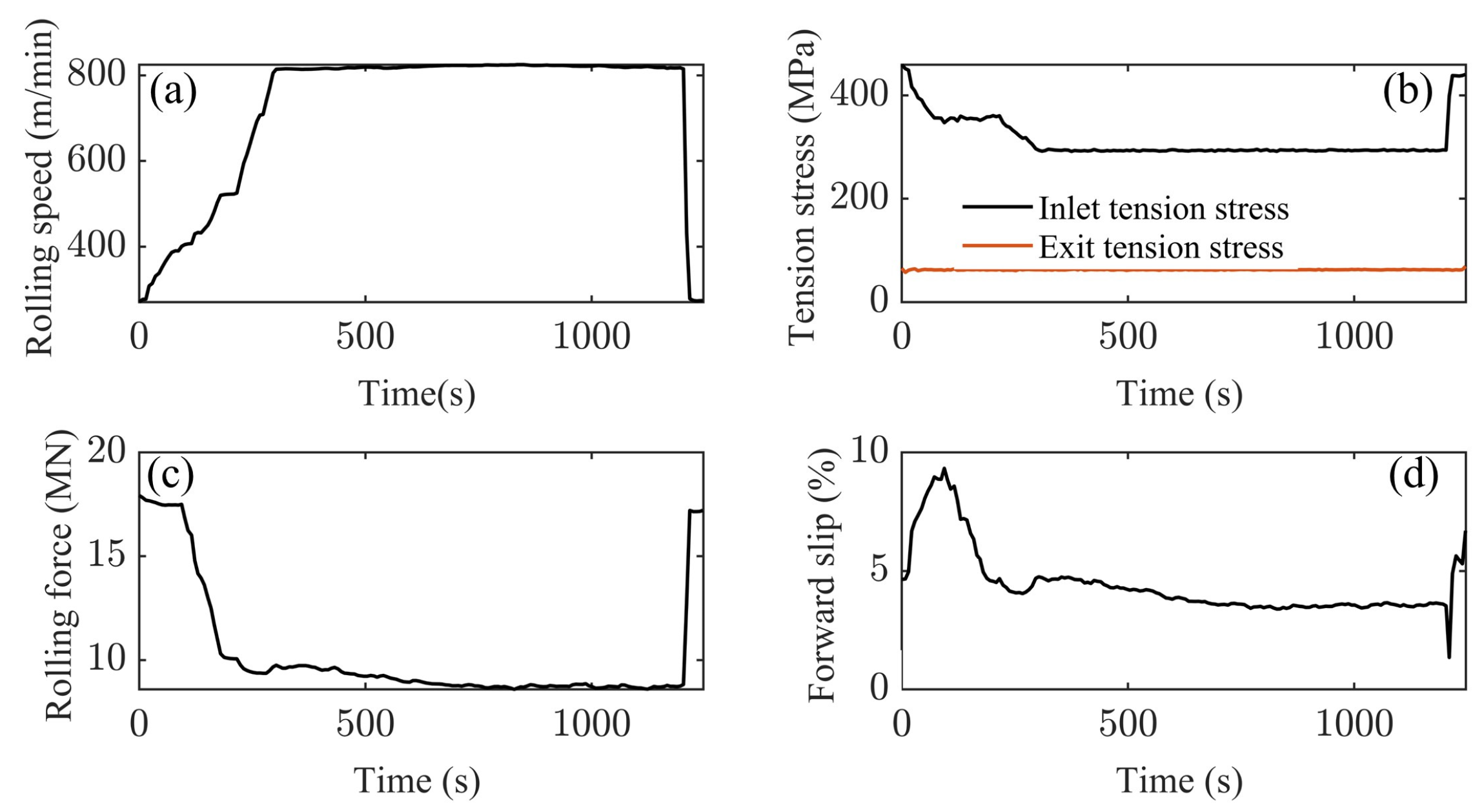

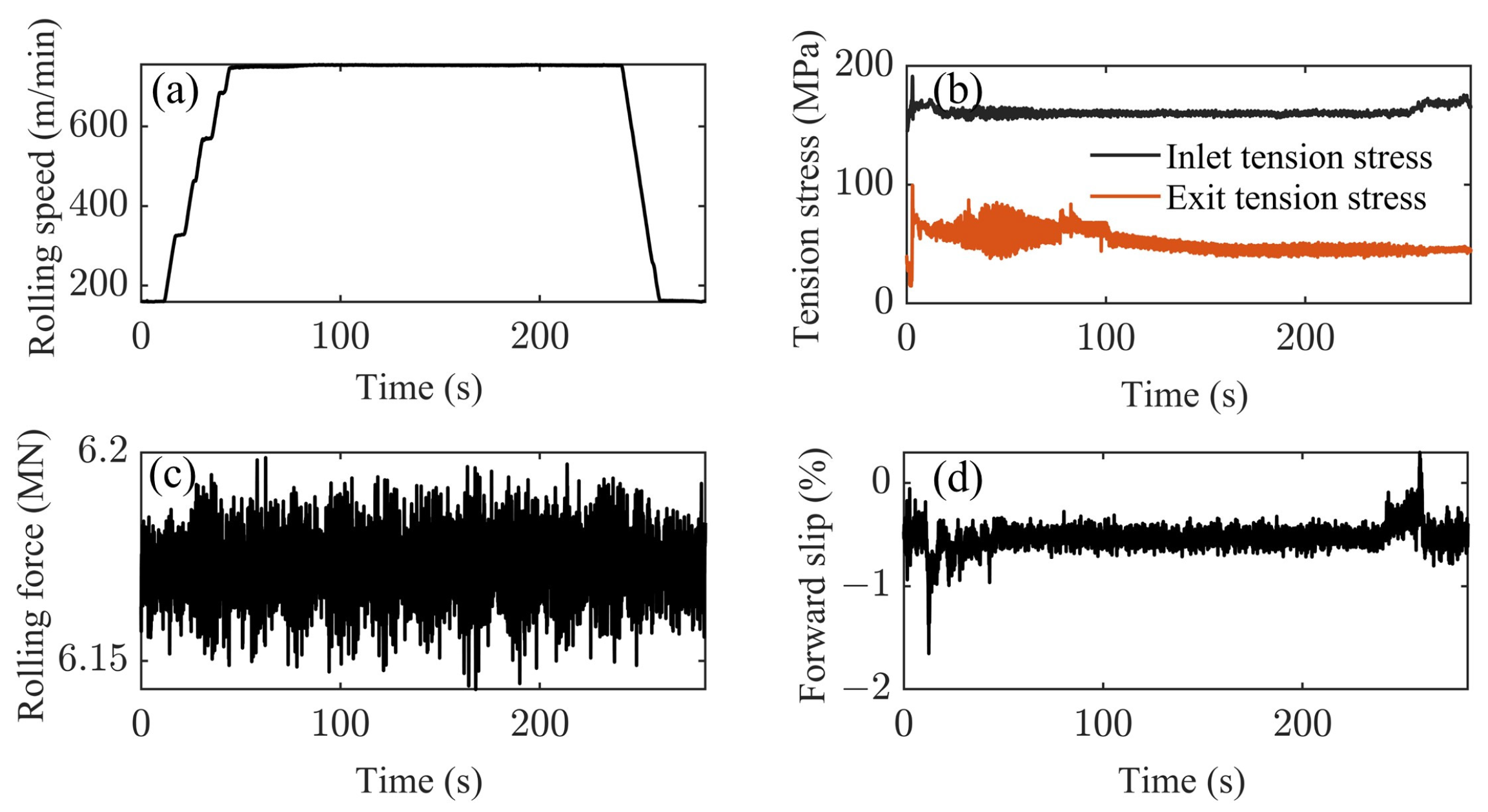

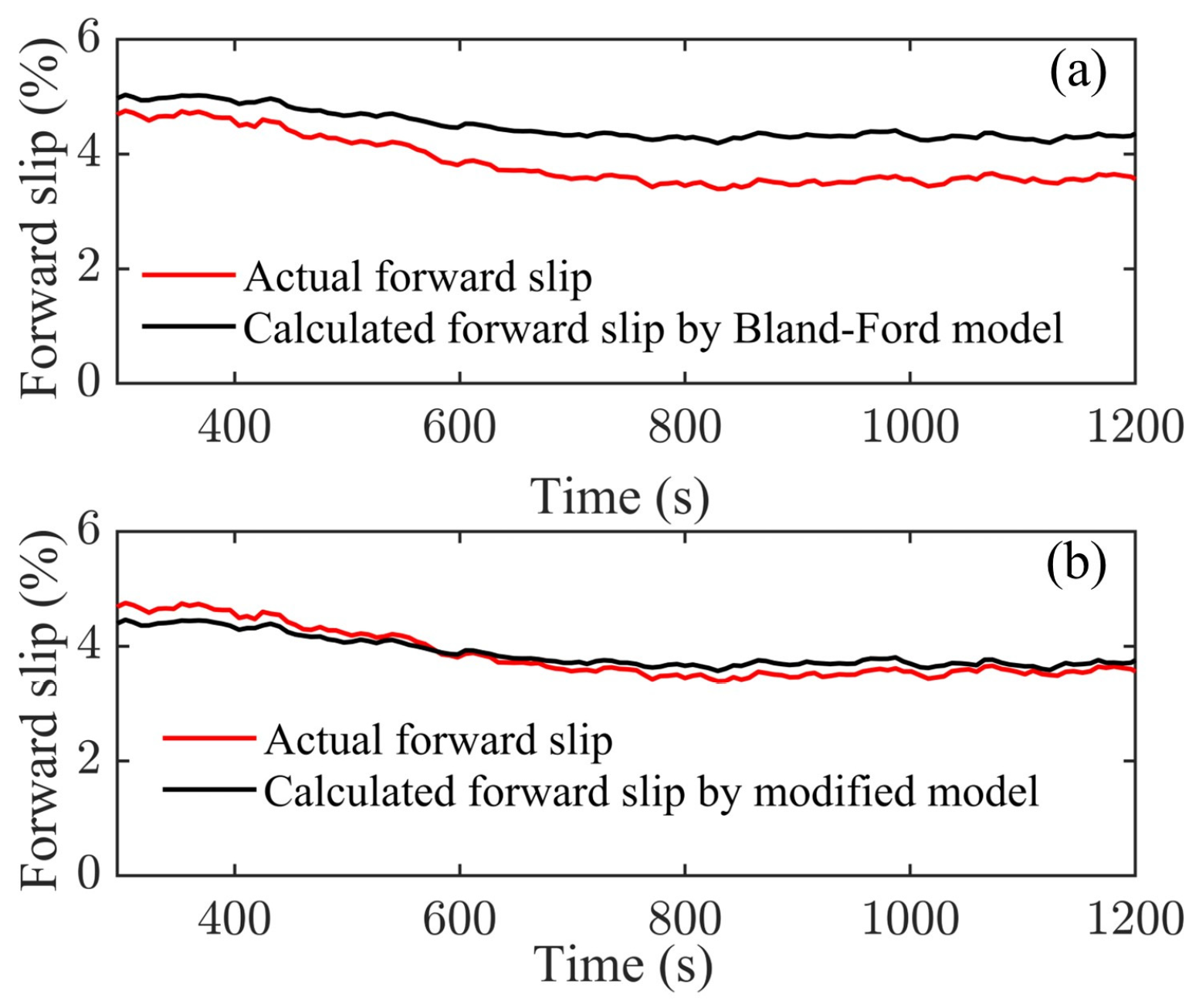

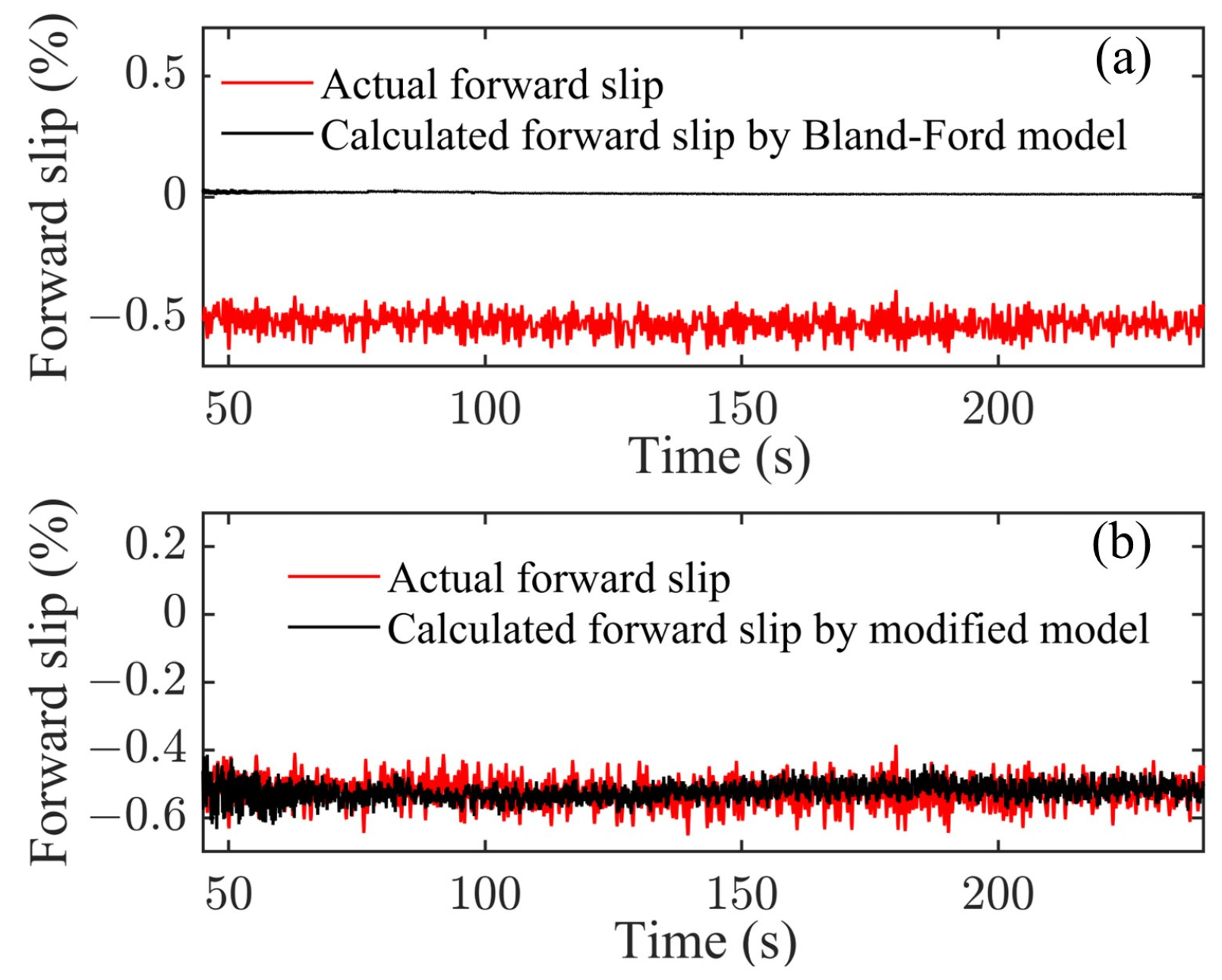

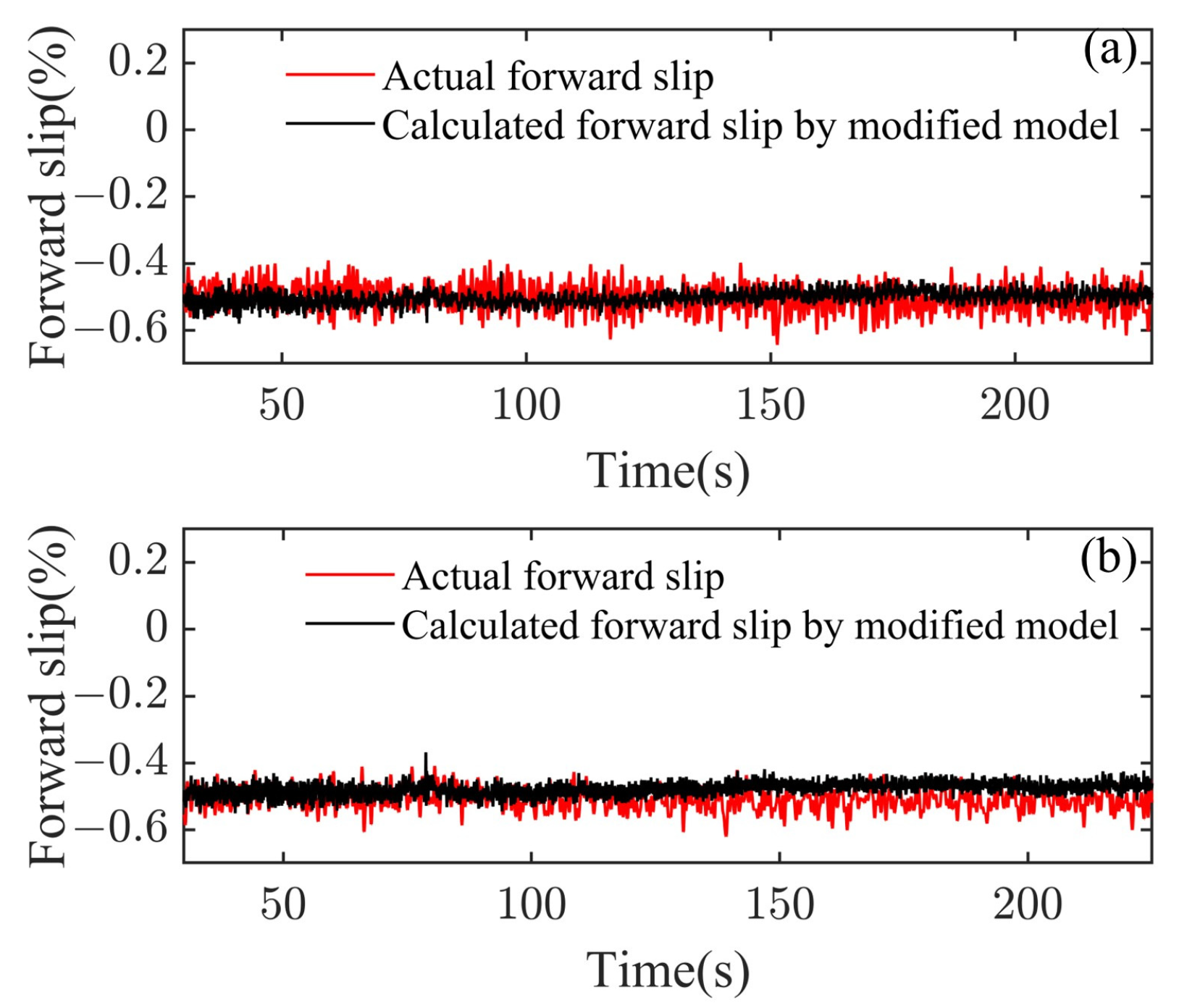

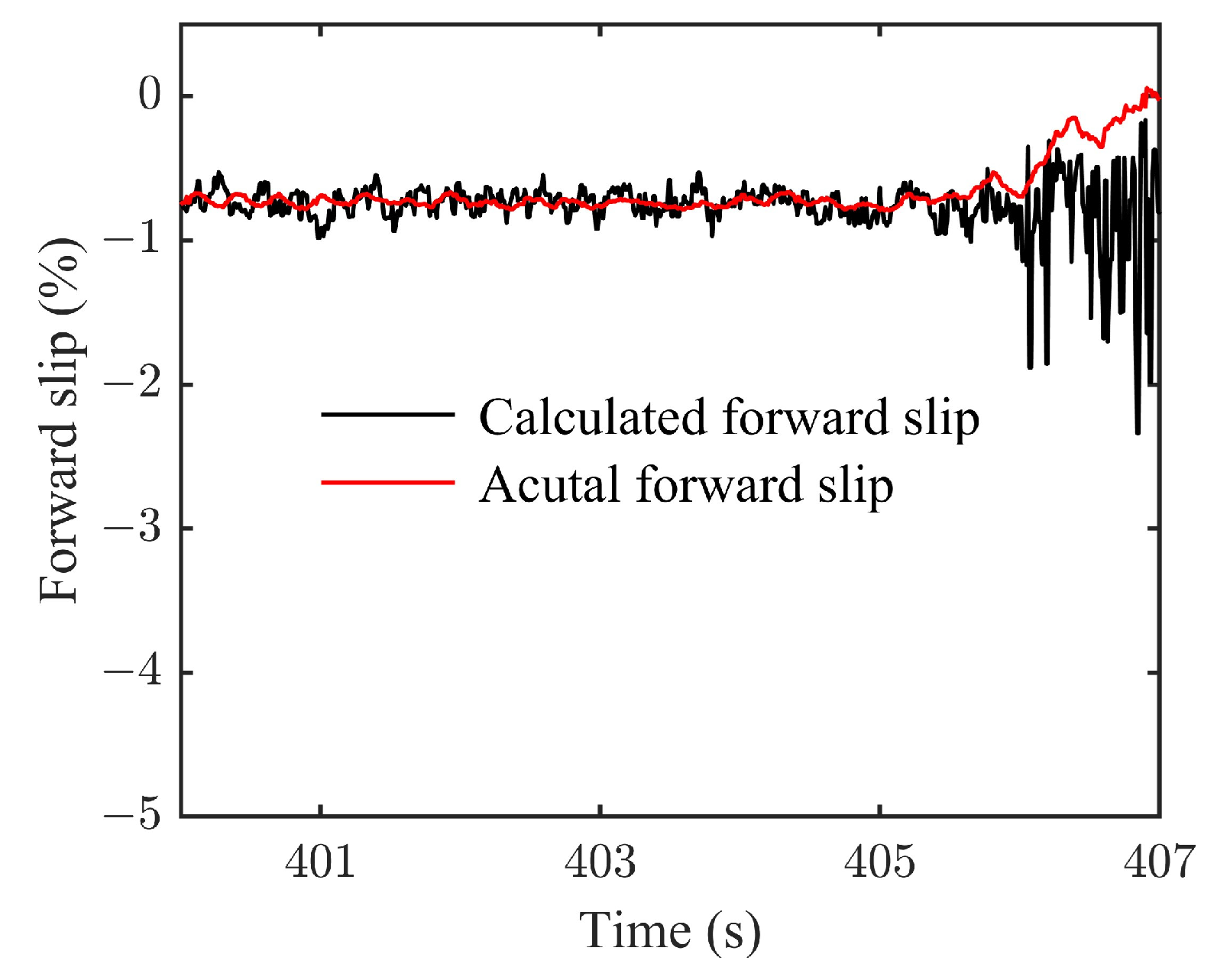

2.2. Application of Compensation Coefficient and Model Validation

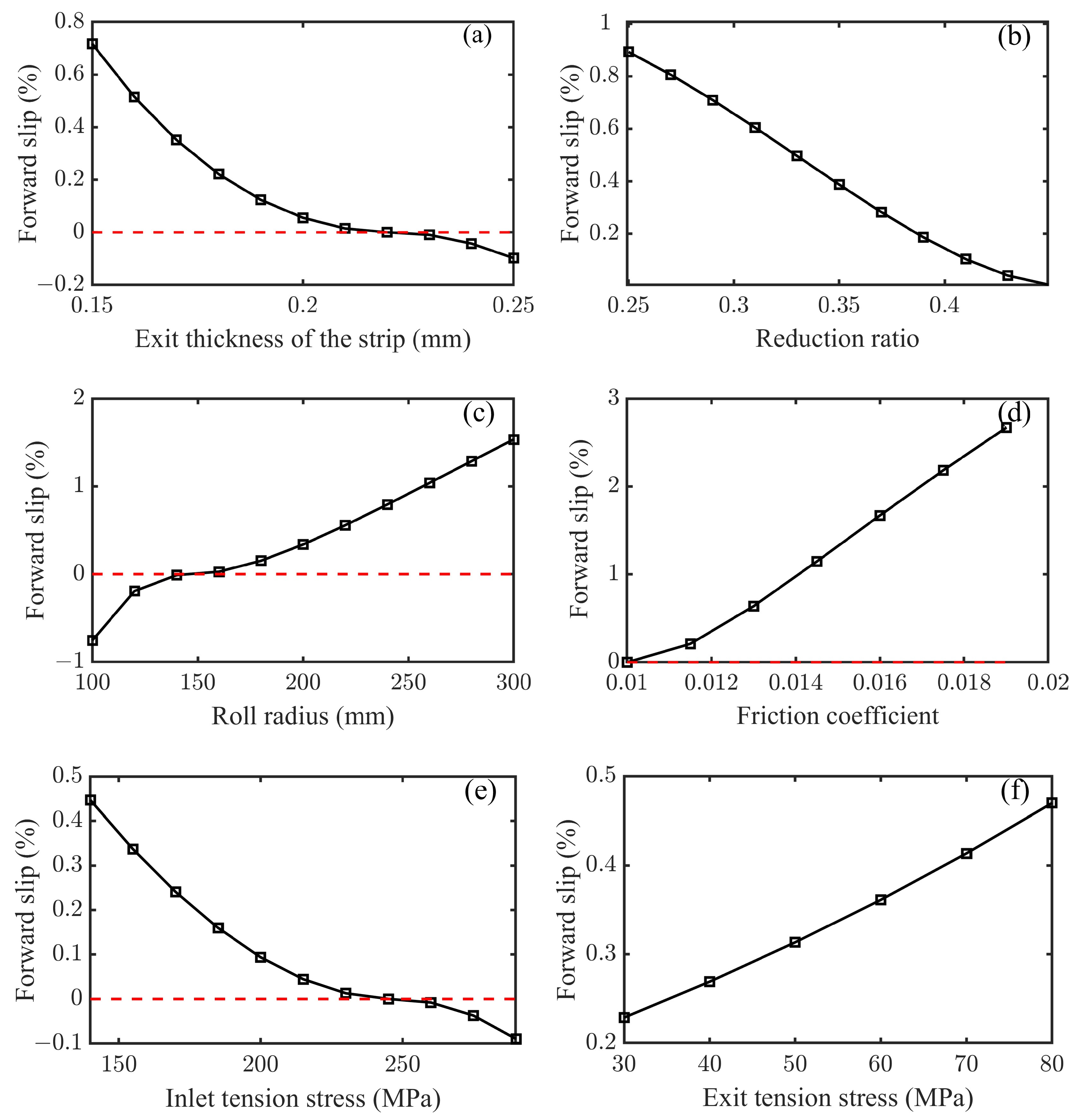

3. Influence of Parameters on Forward Slip

3.1. Variation of Forward Slip with Parameters

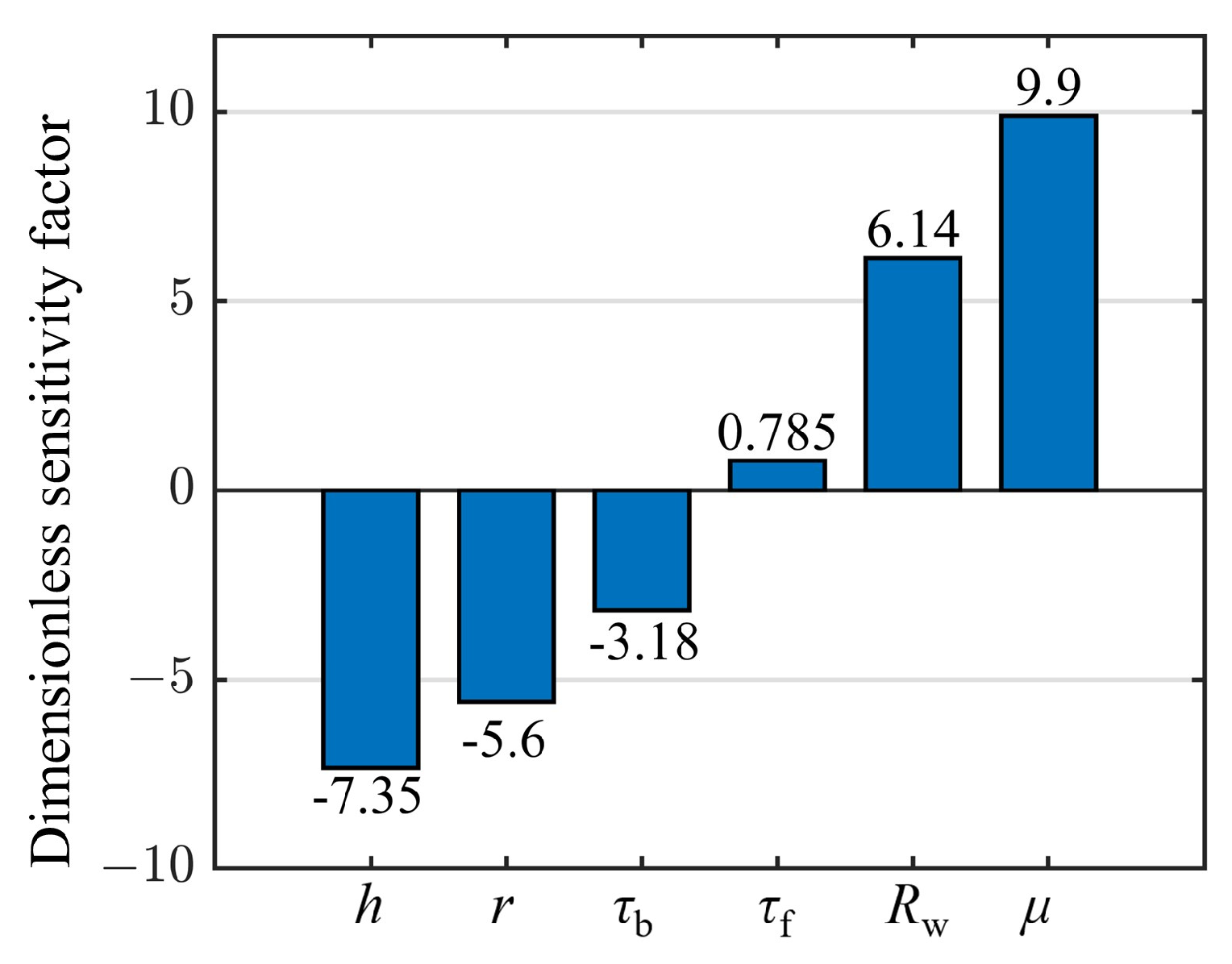

3.2. Comparison of Dimensionless Sensitivity Factor

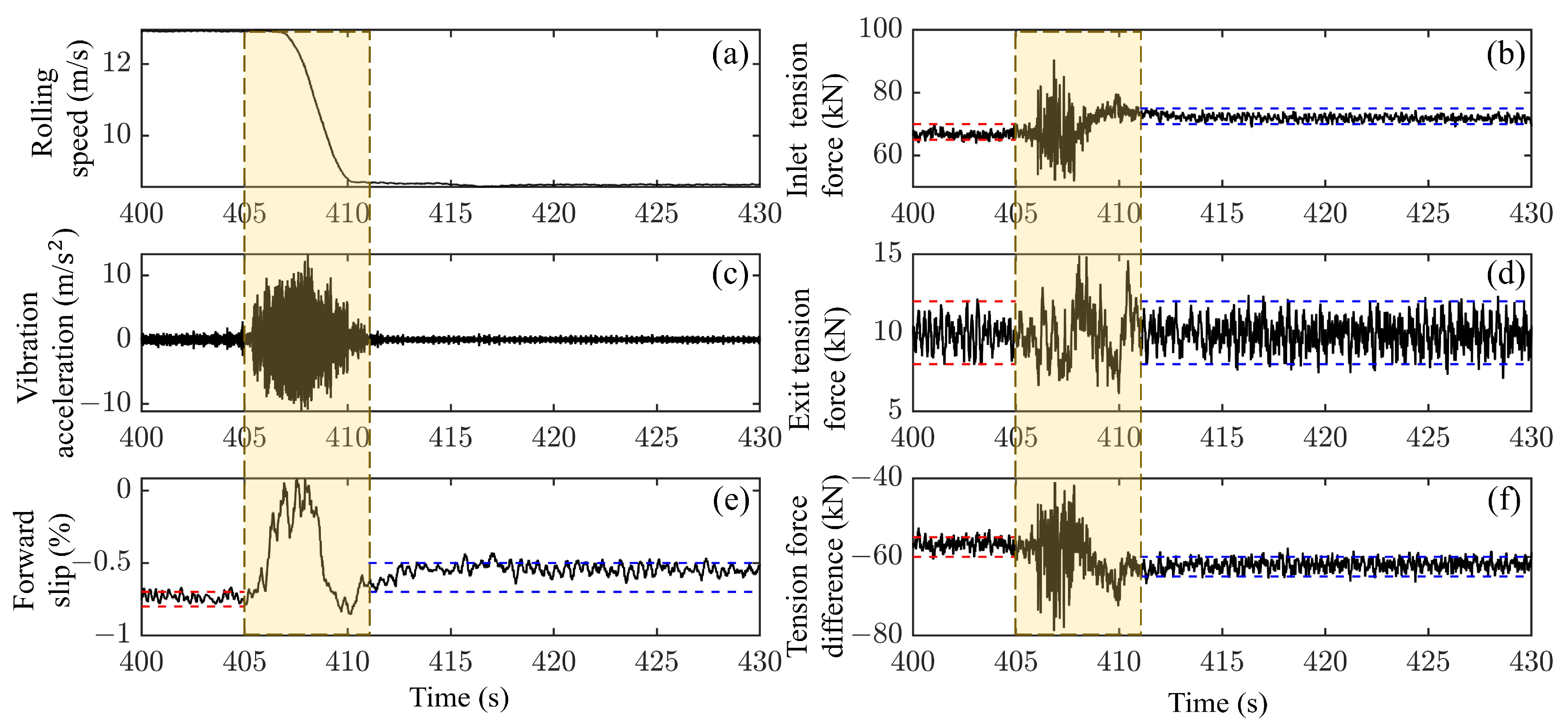

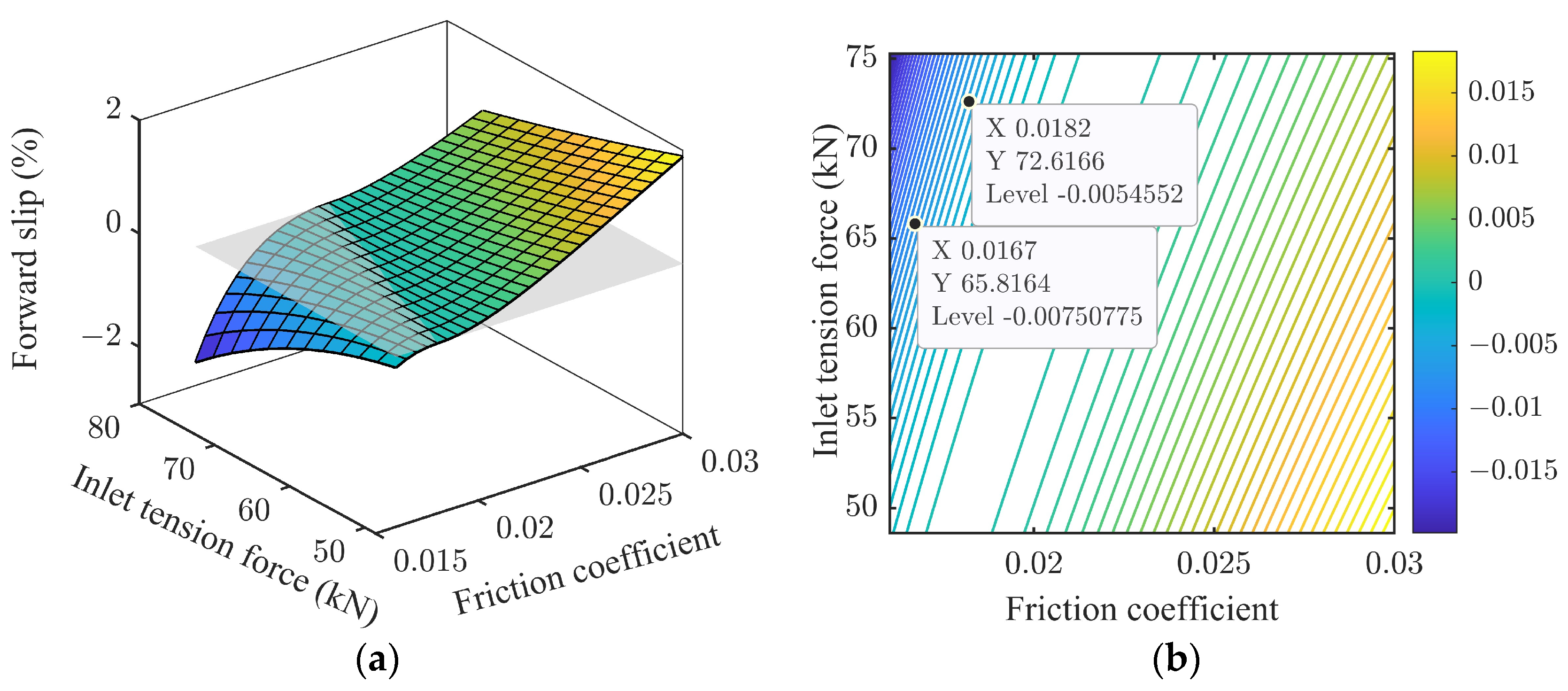

4. Dynamic Tension Regulation Based on Stable Forward Slip

5. Conclusions

- By characterizing the strip thickness corresponding to negative forward slip and combining it with the forward slip theory, the modified forward slip model is established. Moreover, after applying the compensation coefficient related to tension and coil number in the proposed model, the results shows that the modified model can calculate both positive and negative forward slips in different steel coils. The calculated results are in alignment with the actual outcomes, thereby verifying the effectiveness of the modified model. It should be noted that the modified forward slip model is universal, but the compensation coefficient needs to be obtained according to the specific specifications and materials.

- The influence of the parameters on forward slip is analyzed, including strip exit thickness, inlet tension stress, exit tension stress, friction coefficient and roll radius, and the dimensionless sensitivity factor is defined to quantify the degree of influence. Notably, the friction coefficient has the greatest positive influence on forward slip, whereas the exit thickness of the strip demonstrates the greatest negative influence.

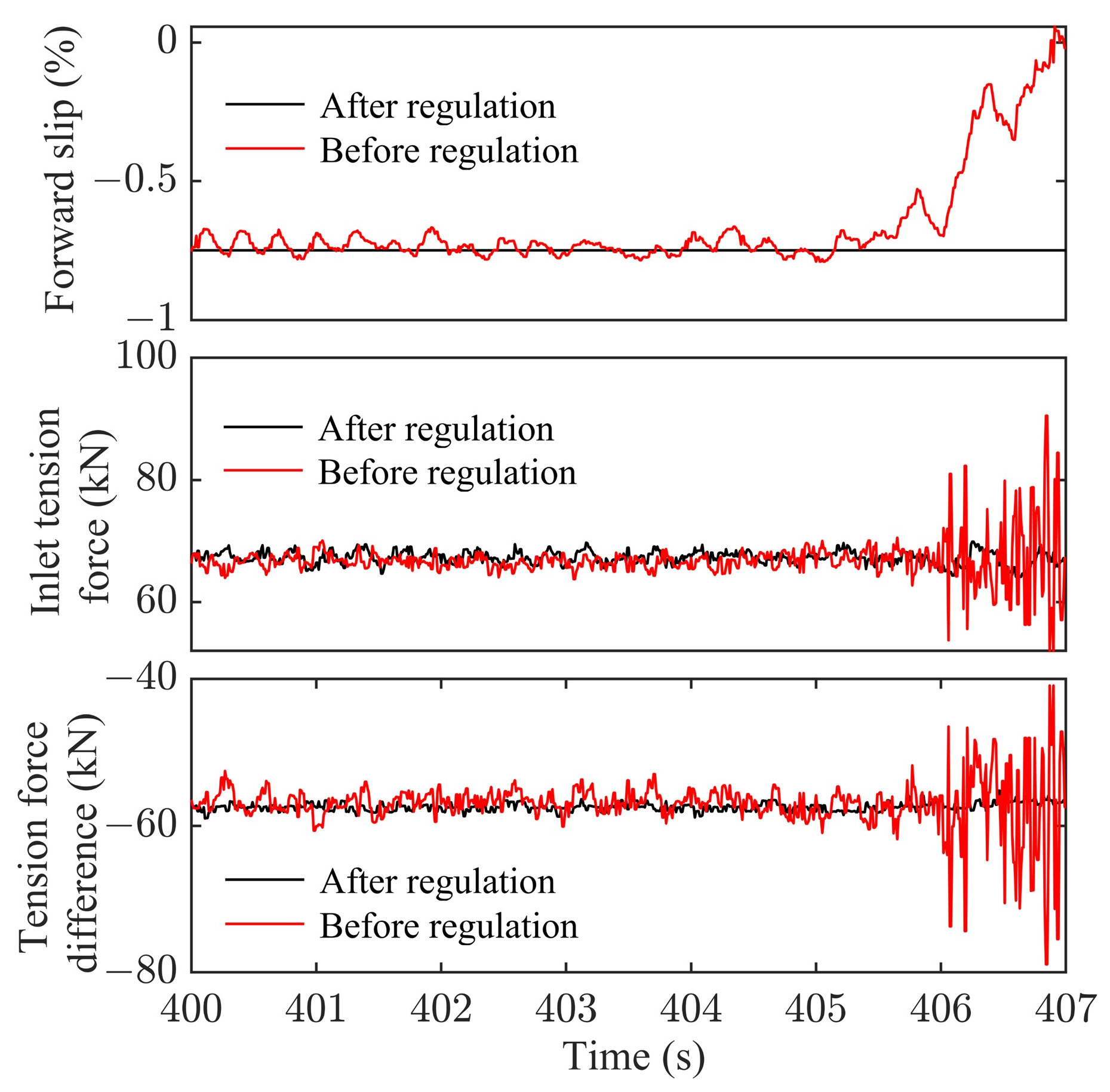

- Recognizing forward slip as an observable indicator of rolling process stability, the tension regulation strategy is proposed to maintain forward slip within a stable range. Analyzing the parameters of the chatter interval, forward slip is stabilized at approximately −0.75% by adjusting the inlet tension force, effectively avoiding the exacerbation of parameter fluctuations and rolling mill chatter.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.L. Influence factors of forward slip value and its application in cold rolling production. Shanxi Metall. 2023, 46, 156–158. [Google Scholar] [CrossRef]

- Moon, H.Y.; Jo, S.I.; Tyne, J.C. Control scheme using forward slip for a multi-stand hot strip rolling mill. KSME Int. J. 2004, 18, 972–978. [Google Scholar] [CrossRef]

- Bayoumi, L.S. A kinematic analytical approach to predict roll force, rolling torque and forward slip in thin hot strip continuous rolling. Ironmak. Steelmak. 2007, 34, 444–448. [Google Scholar] [CrossRef]

- Qu, F.J.; Xu, J.Z.; Jiang, Z.Y. Finite element analysis of forward slip in micro flexible rolling of thin aluminium strips. Metals 2019, 9, 1062. [Google Scholar] [CrossRef]

- Poursina, M.; Rahmatipour, M.; Mirmohammadi, H. A new method for prediction of forward slip in the tandem cold rolling mill. Int. J. Adv. Manuf. Technol. 2015, 78, 1827–1835. [Google Scholar] [CrossRef]

- Fujii, Y.; Maeda, Y.; Utsunomiya, H. Development of On-line model of forward slip on tandem cold strip mill. ISIJ Int. 2021, 107, 732–740. [Google Scholar] [CrossRef]

- Bu, H.N.; Yan, Z.W.; Zhang, D.H. A novel approach to improve the computing accuracy of rolling force and forward slip. Ironmak. Steelmak. 2019, 46, 269–276. [Google Scholar] [CrossRef]

- Zhao, H.P.; Pan, G. Application of Bland-Ford forward slip model in Baosteel cold rolling’s model system. Baosteel Technol. 2009, 4, 63–66+70. [Google Scholar]

- Cao, J.; Fan, Z.J.; Liu, Y.J.; Chen, W.; Liu, L. Study of forward slip model application and adjustment for tandem cold mill. In Proceedings of the 11th CSM Steel Congress, Beijing, China, 21 December 2017. [Google Scholar]

- Wang, Q.Y.; Zhu, Y.; Zhao, Y. Friction and forward slip in high-speed cold rolling process of aluminum alloys. Appl. Mech. Mater. 2012, 229–231, 361–364. [Google Scholar] [CrossRef]

- Lenard, J.G.; Zhang, S. A study of friction during the lubricated cold rolling of an aluminum alloy. J. Mater. Proc. Technol. 1997, 72, 293–301. [Google Scholar] [CrossRef]

- McConnell, C.; Lenard, J.G. Friction in cold rolling of a low carbon steel with lubricants. J. Mater. Process Technol. 2000, 99, 86–93. [Google Scholar] [CrossRef]

- Shirizly, A.; Lenard, J.G. Emulsions versus neat oils in the cold rolling of carbon steel strips. J. Tribol. 2000, 122, 550–556. [Google Scholar] [CrossRef]

- Lu, C.; Tieu, A.K. Measurement of the forward slip in cold strip rolling using a high speed digital camera. J. Mech. Sci. Technol. 2007, 21, 1528–1533. [Google Scholar] [CrossRef]

- Kiani, R.; Gali, O.A.; Hunter, J.A.; Riahi, A.R. An Evaluation of the influence of forward slip on the corrosion behavior of aluminum-manganese alloys. J. Mater. Eng. Perform. 2021, 30, 5811–5824. [Google Scholar] [CrossRef]

- Bai, Z.H.; Lian, J.C.; Wang, J.F. Screw-down schedule optimization for preventing slippage on cold tandem mill. Iron Steel 2003, 10, 35–38. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.S.; Jin, X.; Xiang, Y.G.; Li, X.G. Multi-objective optimization of rolling schedule for tandem cold strip rolling based on NSGA-II. J. Manuf. Process 2020, 60, 257–267. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Yin, C.; Zhao, Q. Multi-objective optimization of rolling schedule for five-stand tandem cold mill. IEEE Access 2020, 8, 80417–80426. [Google Scholar] [CrossRef]

- Kozhevnikov, A.V.; Kozhevnikova, I.A.; Bolobanova, N.L. Development of the model of cold rolling process in dynamic conditions. J. Chem. Technol. Metall. 2018, 53, 366–372. [Google Scholar]

- Cao, L.; Li, X.; Zhang, D. Research into the effect of flatness control actuators on vibration stability in cold rolling using the finite element method. Int. J. Adv. Manuf. Technol. 2023, 125, 245–266. [Google Scholar] [CrossRef]

- Wang, Y. Deformation Resistance and Forward Slip Model of High Strength Steel During Cold Rolling. Master’s Thesis, Northeastern University, Shenyang, China, 2017. [Google Scholar] [CrossRef]

- Reddy, V.N.; Suryanarayana, G. A set-up model for tandem cold rolling mills. J. Mater. Proc. Technol. 2001, 116, 269–272. [Google Scholar] [CrossRef]

- Bland, D.R.; Ford, H. The calculation of roll force and torque in cold strip rolling with tensions. Proc. I. Mech. Eng. 1948, 159, 144–153. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Strip width | 936 mm |

| Roll radius | 200 mm |

| Strip Inlet thickness | 0.267 mm |

| Strip Exit thickness | 0.171 mm |

| Friction coefficient | 0.02 |

| Reduction ration | 0.3596 |

| Inlet tension stress | 155 MPa |

| Exit tension stress | 55 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, Y.; Gao, Z.; Zang, Y.; Wang, X. Identification and Regulation of Cold Rolling Interface State Based on a Novel Modified Forward Slip Model. Lubricants 2024, 12, 404. https://doi.org/10.3390/lubricants12120404

Xin Y, Gao Z, Zang Y, Wang X. Identification and Regulation of Cold Rolling Interface State Based on a Novel Modified Forward Slip Model. Lubricants. 2024; 12(12):404. https://doi.org/10.3390/lubricants12120404

Chicago/Turabian StyleXin, Yanli, Zhiying Gao, Yong Zang, and Xiaoyong Wang. 2024. "Identification and Regulation of Cold Rolling Interface State Based on a Novel Modified Forward Slip Model" Lubricants 12, no. 12: 404. https://doi.org/10.3390/lubricants12120404

APA StyleXin, Y., Gao, Z., Zang, Y., & Wang, X. (2024). Identification and Regulation of Cold Rolling Interface State Based on a Novel Modified Forward Slip Model. Lubricants, 12(12), 404. https://doi.org/10.3390/lubricants12120404