Tribological Behavior and Cold-Rolling Lubrication Performance of Water-Based Nanolubricants with Varying Concentrations of Nano-TiO2 Additives

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

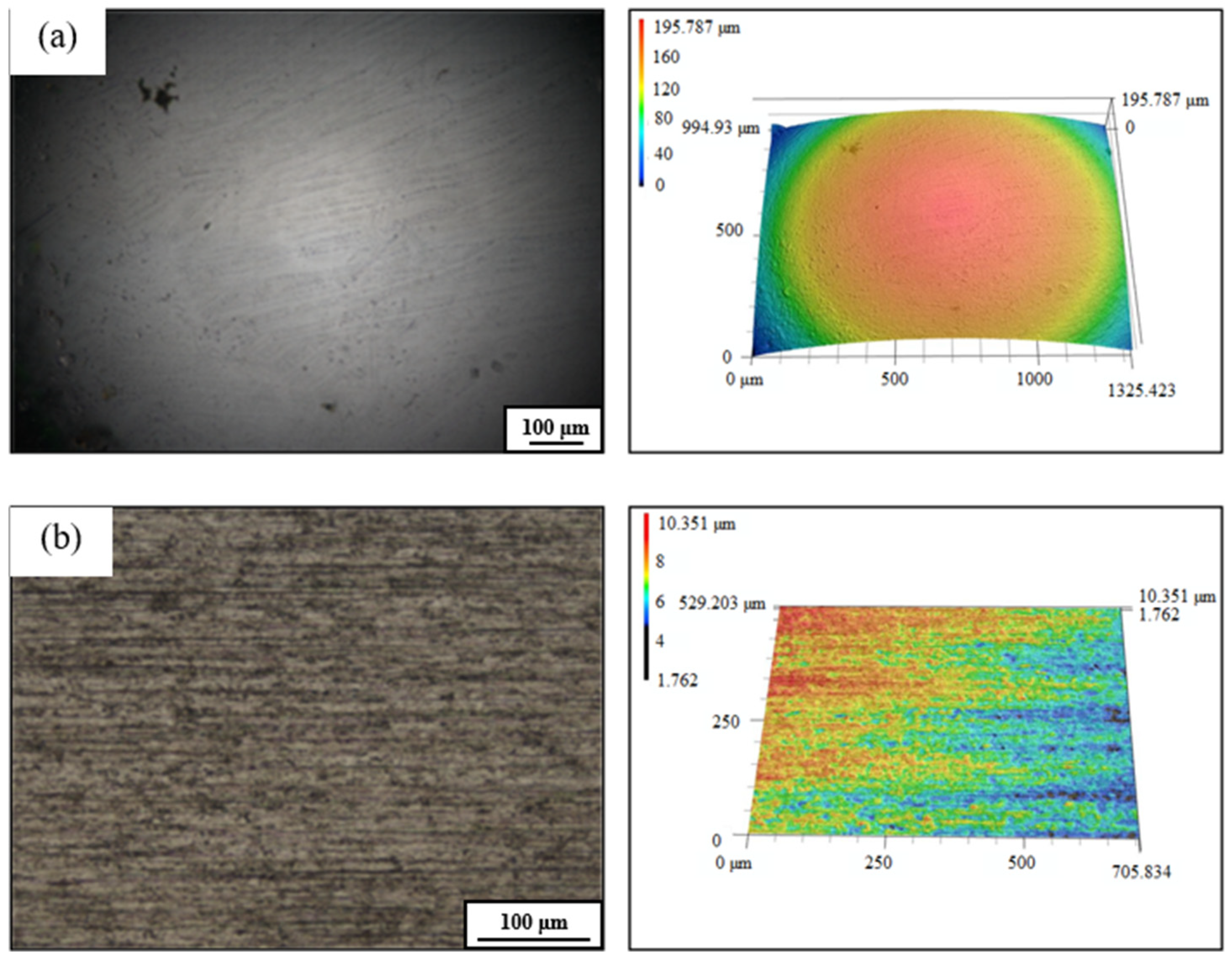

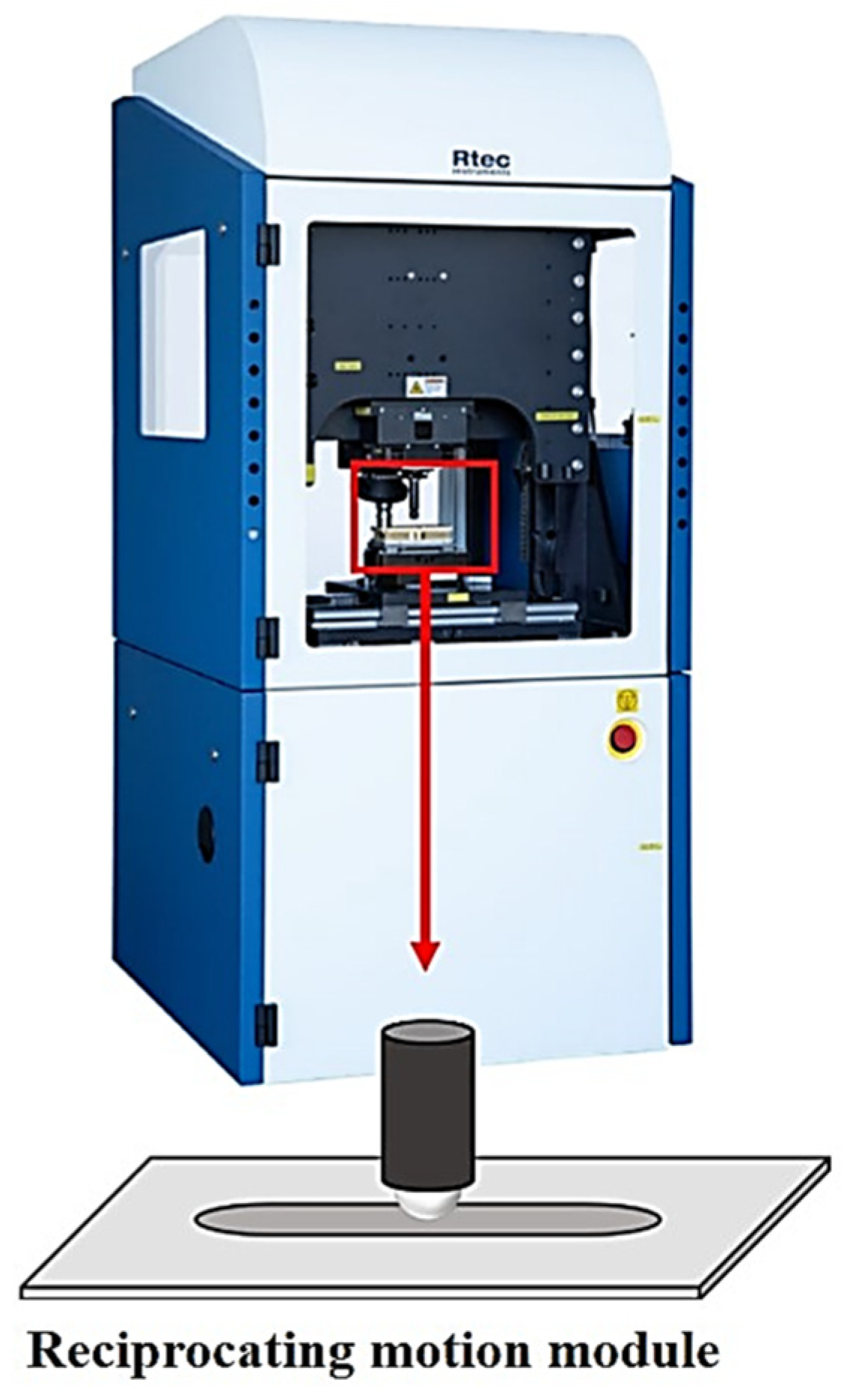

2.2. Tribological and Micro-Rolling Tests

2.3. Analytical Techniques

3. Results and Discussion

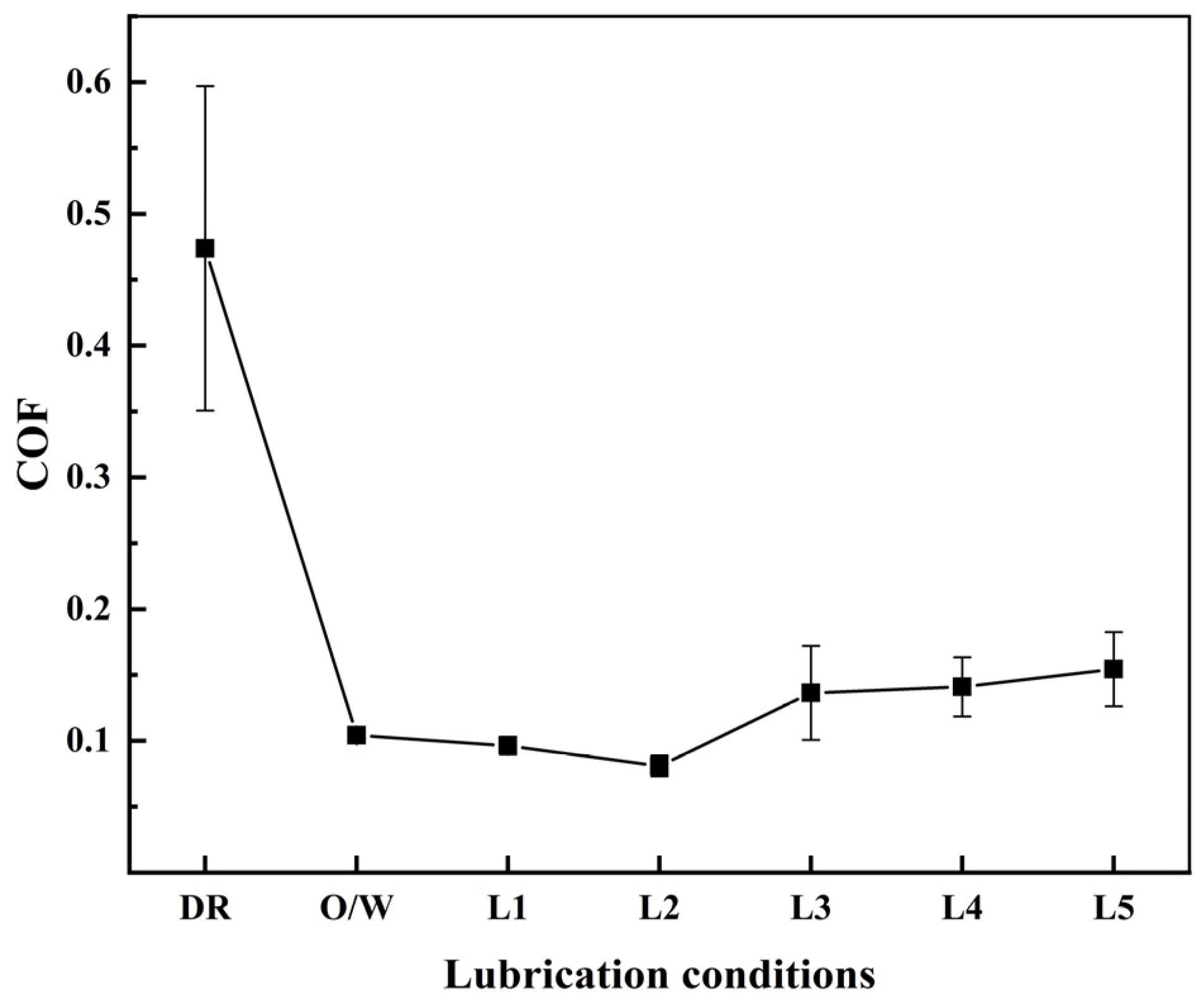

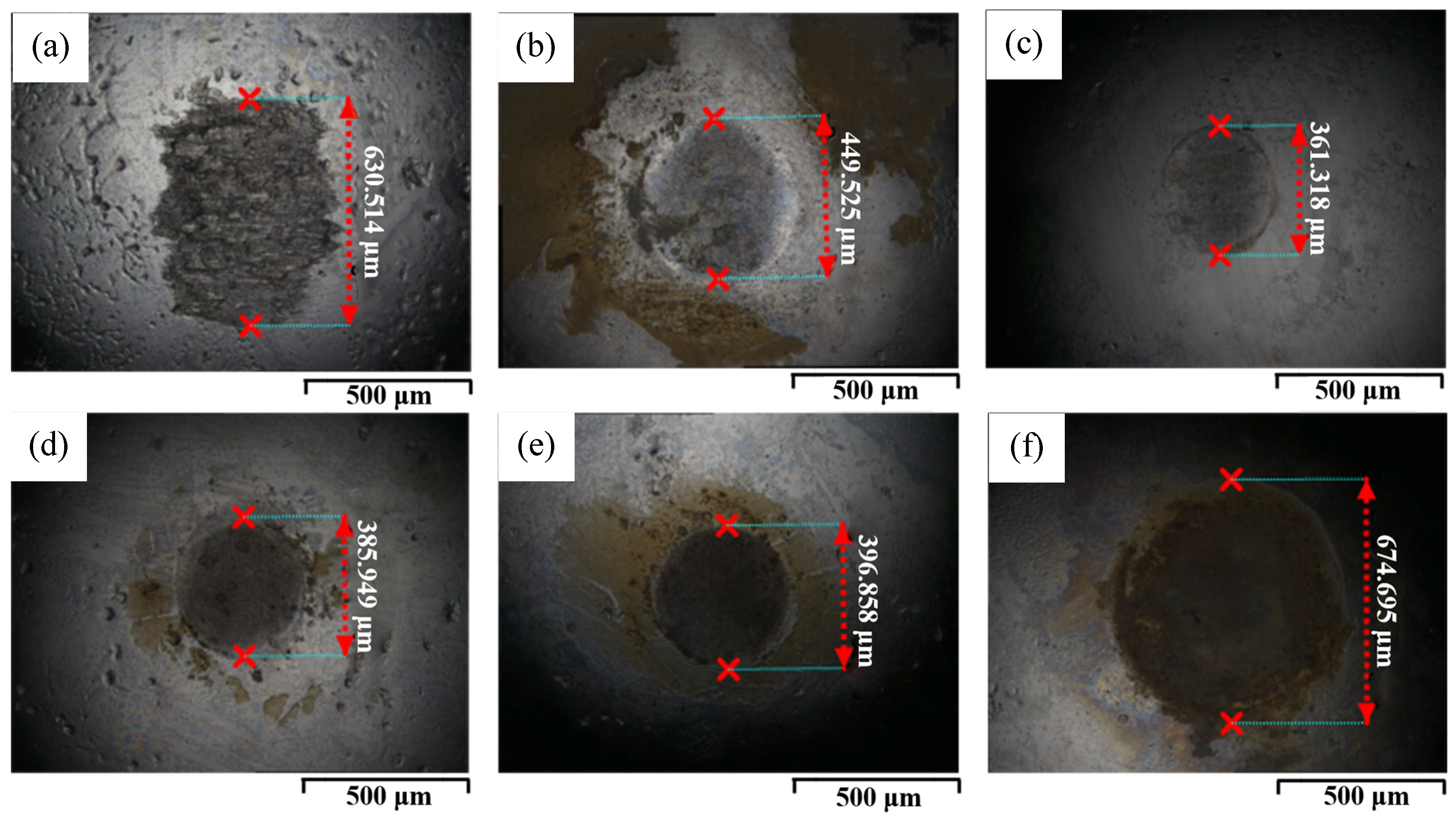

3.1. Tribological Behavior of Nanolubricants

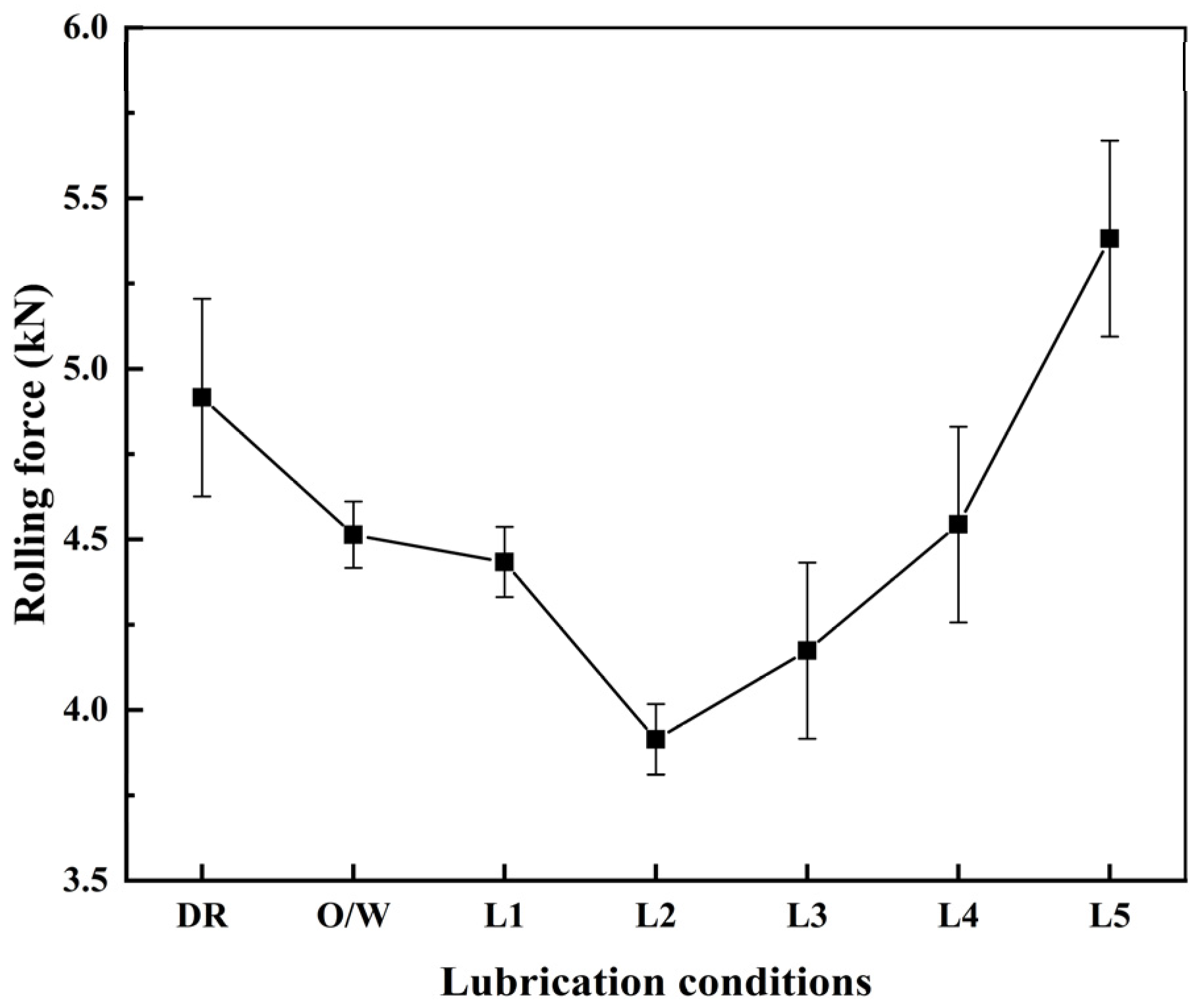

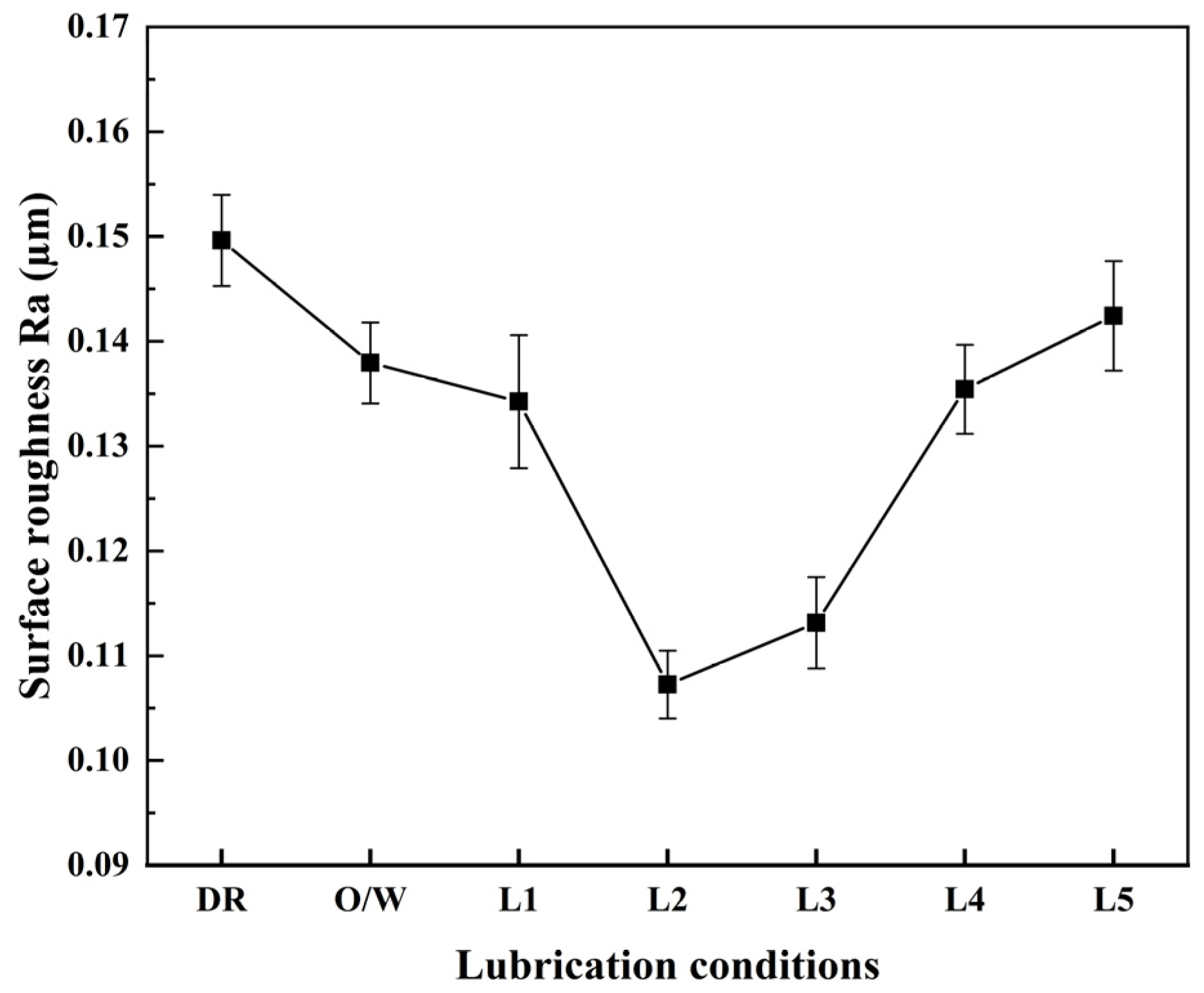

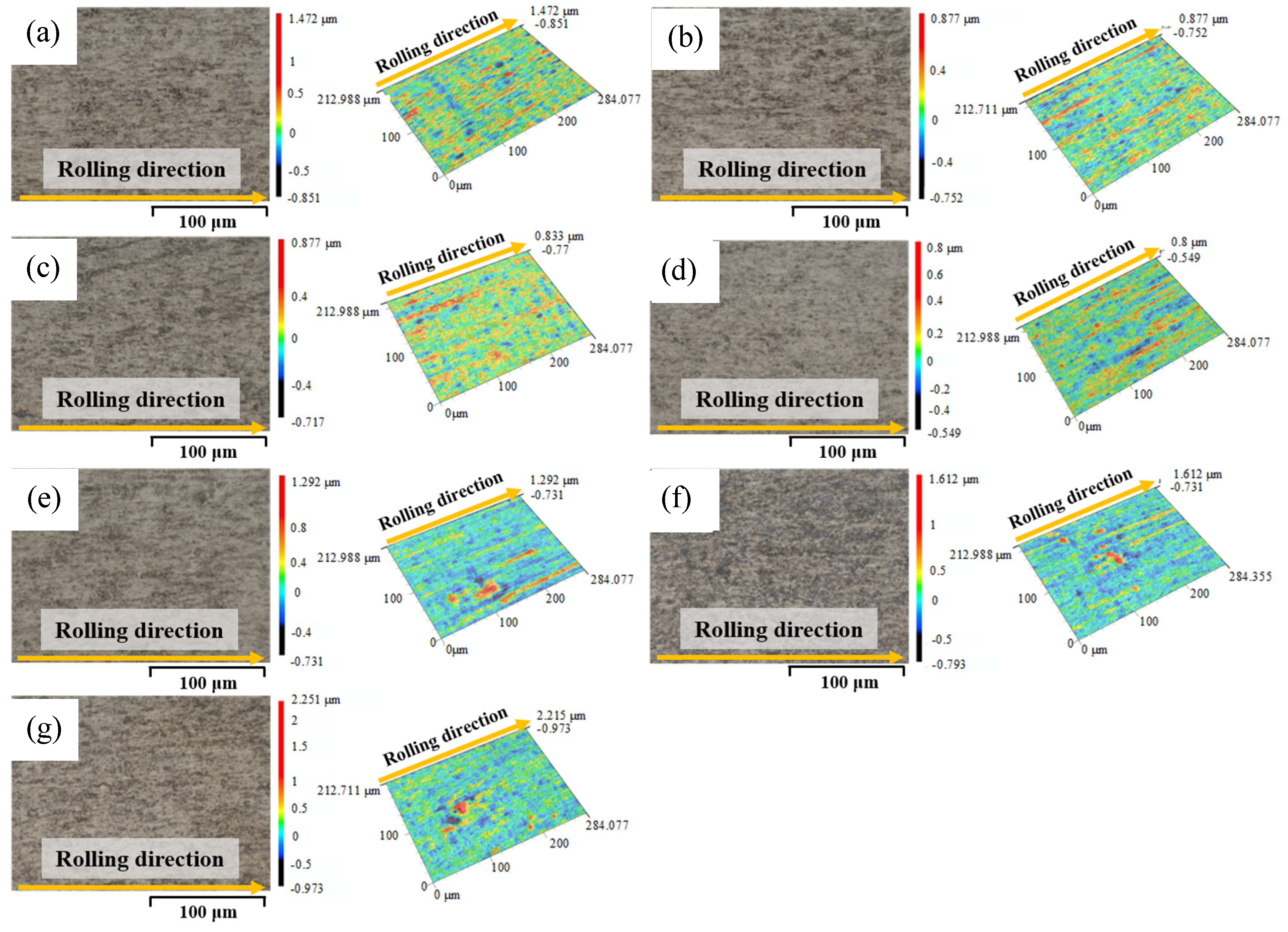

3.2. Tribological Performance of Nanolubricants in Micro Rolling

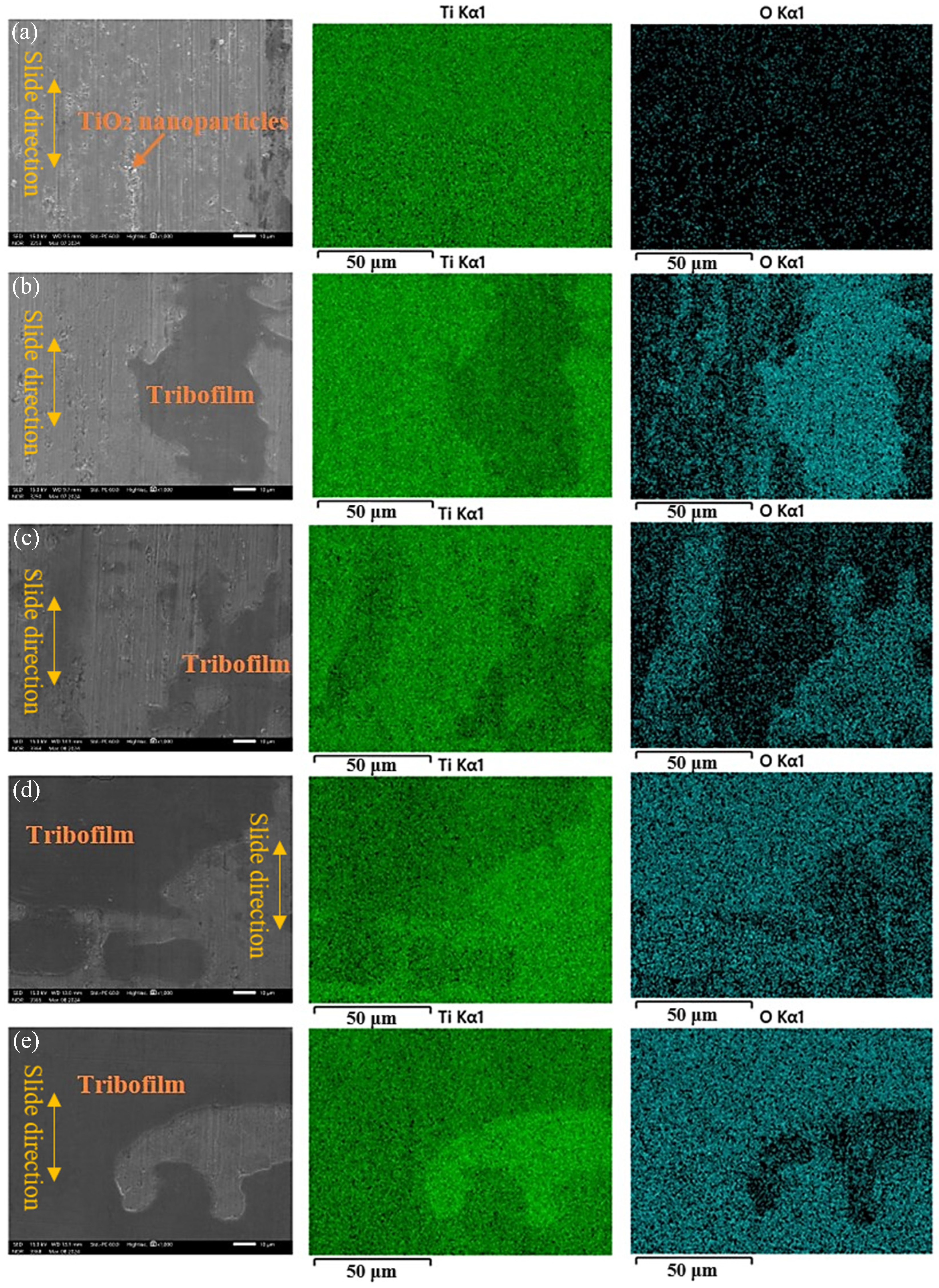

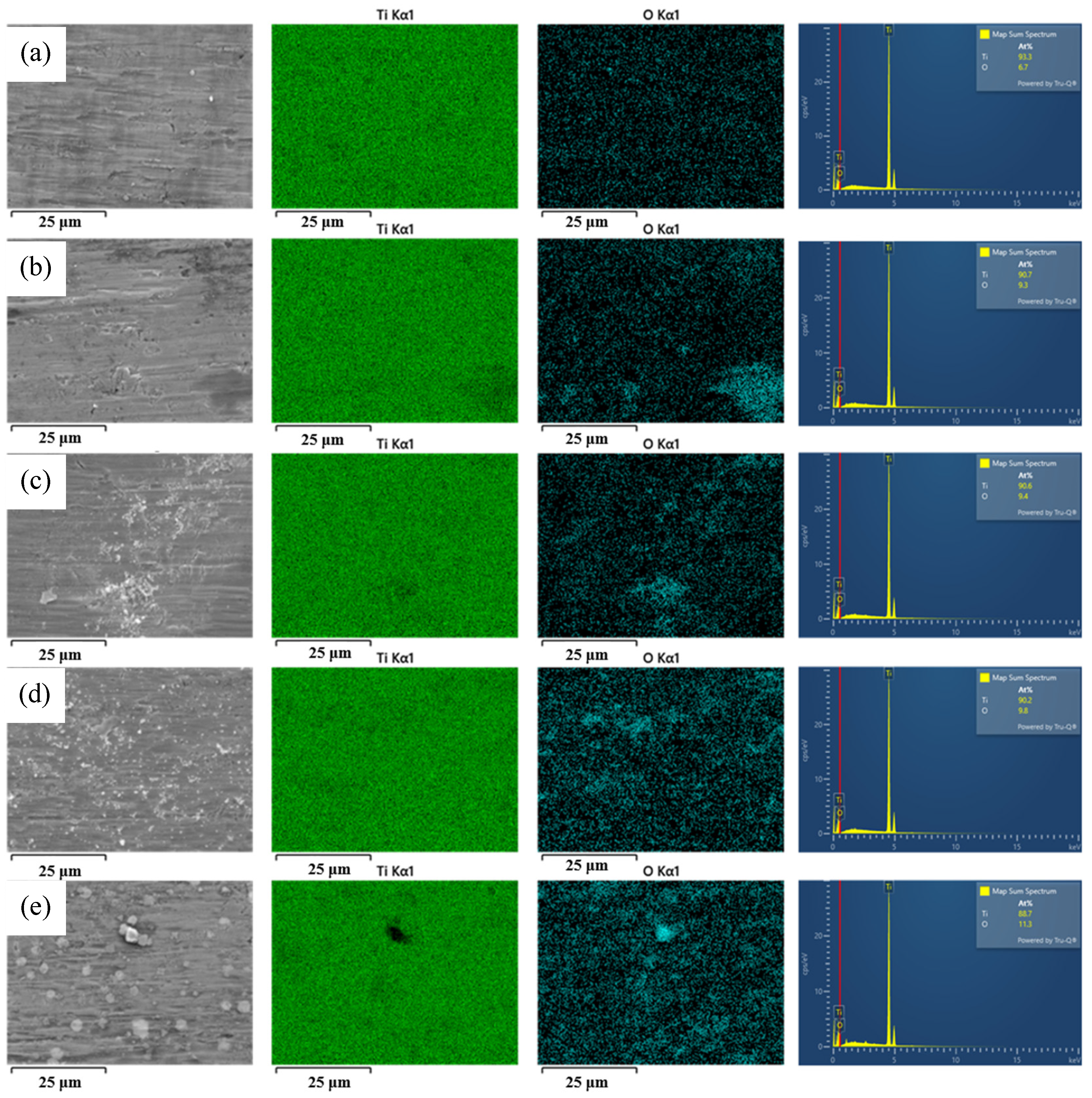

3.3. SEM–EDS Analysis

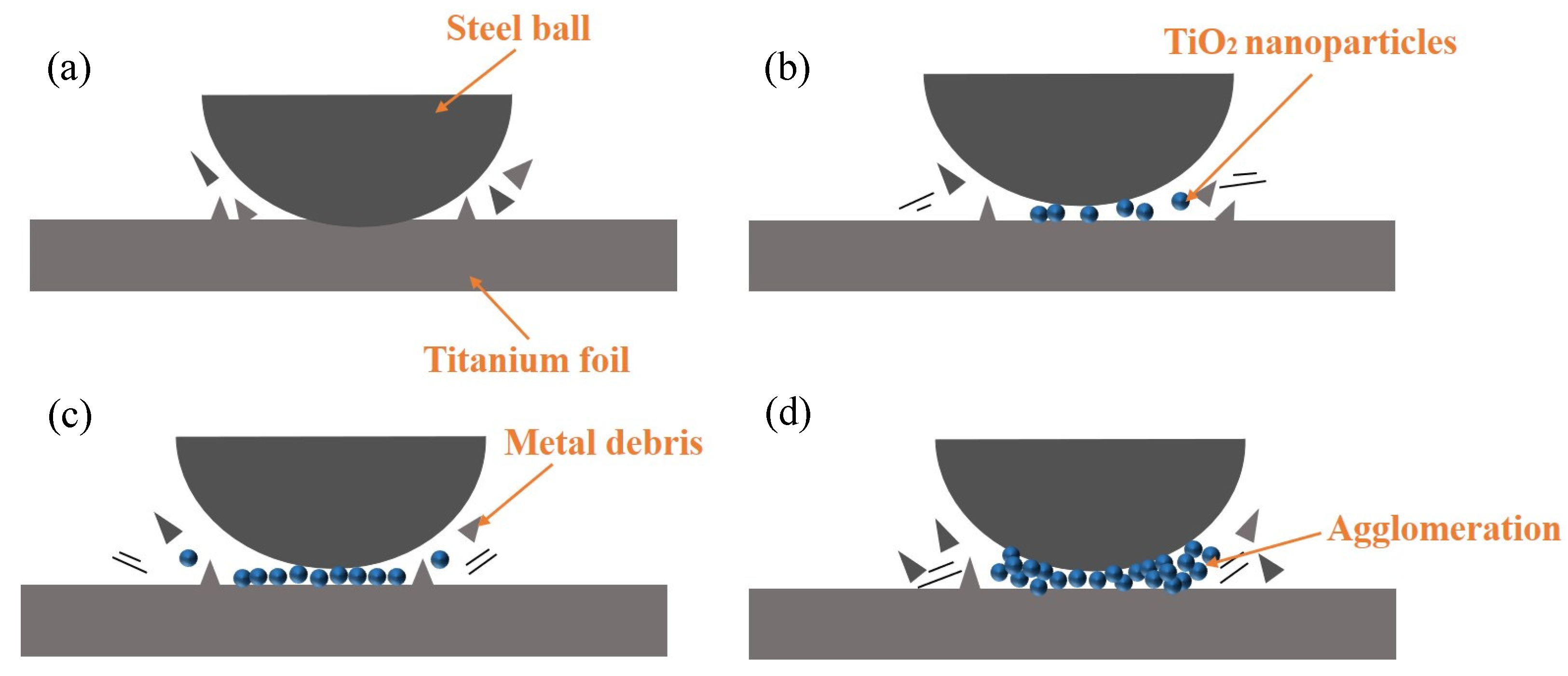

3.4. Lubrication Mechanisms

4. Conclusions

- Nanolubricants with an optimal concentration of TiO2 nanolubricant additives, which was 3.0 wt.%, exhibited excellent tribological performance, reducing the COF and ball wear by 82.9% and 42.7%, respectively, compared to the DR conditions. This phenomenon can be attributed to the formation of a nano-TiO2 friction film between the contact pairs.

- Compared with conventional O/W lubricants, the nanolubricants exhibited an improved lubrication performance during the micro-rolling processes, which confirms the superior lubricating effect of the nanolubricants.

- Applying nano-TiO2 nanolubricants at a concentration of 3.0 wt.% led to a decrease in the rolling force and an enhancement in the surface quality of the TFs, which is primarily ascribed to the combined effects of the rolling effect, repairing effect, polishing effect and tribo-film effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hiroyasu, K.; Yoshimasa, T.; Hideyuki, I.; Tatsushi, K.; Takayuki, Y. Application of titanium and titanium alloys to fixed dental prostheses. J. Prosthodont. Res. 2019, 63, 266–270. [Google Scholar]

- Zhao, J.; Lv, L.; Liu, G.; Wang, K. Analysis of deformation inhomogeneity and slip mode of TA15 titanium alloy sheets during the hot tensile process based on crystal plasticity model. Mater. Sci. Eng. A 2017, 707, 30–39. [Google Scholar] [CrossRef]

- Ghosh, A.; Singh, A.; Gurao, N.P. Effect of rolling mode and annealing temperature on microstructure and texture of commercially pure-titanium. Mater. Charact. 2017, 125, 83–93. [Google Scholar] [CrossRef]

- Nagendramma, P.; Kaul, S. Development of ecofriendly/biodegradable lubricants: An overview. Renew. Sustain. Energy Rev. 2012, 16, 764–774. [Google Scholar] [CrossRef]

- Huo, M.; Wu, H.; Xie, H.; Zhao, J.; Su, G.; Jia, F.; Li, Z.; Lin, F.; Li, S.; Zhang, H.; et al. Understanding the role of water-based nanolubricants in micro flexible rolling of aluminum. Tribol. Int. 2020, 151, 106378. [Google Scholar] [CrossRef]

- Zhao, J.; Huo, M.; Ma, X.; Jia, F.; Jiang, Z. Study on edge cracking of copper foils in micro rolling. Mater. Sci. Eng. A 2019, 747, 53–62. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, J.; Du, W.; Zhang, X.; Jiang, Z. Effects of rolling processes on ridging generation of ferritic stainless steel. Mater. Charact. 2018, 137, 201–211. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, H.; Li, N.; Jiang, Z. Friction and Wear Characteristics of Fe3O4 Nano-Additive Lubricant in Micro-Rolling. Lubricants 2023, 11, 434. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, Y.; He, Y.; Shi, Y. Nanolubricant additives: A review. Friction 2021, 9, 891–917. [Google Scholar] [CrossRef]

- Thapliyal, P.; Thakre, G.D. Influence of Cu nanofluids on the rolling contact fatigue life of bearing steel. Eng. Fail. Anal. 2017, 78, 110–121. [Google Scholar] [CrossRef]

- Bao, Y.; Sun, J.; Kong, L. Effects of nano-SiO2 as water-based lubricant additive on surface qualities of strips after hot rolling. Tribol. Int. 2017, 114, 257–263. [Google Scholar] [CrossRef]

- Kong, N.; Zhang, J.; Zhang, J.; Li, H.; Wei, B.; Li, D.; Zhu, H. Chemical- and Mechanical-Induced Lubrication Mechanisms during Hot Rolling of Titanium Alloys Using a Mixed Graphene-Incorporating Lubricant. Nanomaterials 2020, 10, 665. [Google Scholar] [CrossRef] [PubMed]

- Du, S.; Sun, J.; Wu, P. Preparation, characterization and lubrication performances of graphene oxide-TiO2 nanofluid in rolling strips. Carbon 2018, 140, 338–351. [Google Scholar] [CrossRef]

- Srivyas, P.D.; Charoo, M.S. Nano lubrication behaviour of Graphite, h-BN and Graphene Nano Platelets for reducing friction and wear. Mater. Today Proc. 2021, 44, 7–11. [Google Scholar] [CrossRef]

- Nassef MG, A.; Nassef, B.G.; Hassan, H.S.; Nassef, G.A.; Elkady, M.; Pape, F. Tribological and Chemical–Physical Behavior of a Novel Palm Grease Blended with Zinc Oxide and Reduced Graphene Oxide Nano-Additives. Lubricants 2024, 12, 191. [Google Scholar] [CrossRef]

- Singh, A.; Chauhan, P.; Mamatha, T.G. A review on tribological performance of lubricants with nanoparticles additives. Mater. Today Proc. 2020, 25, 586–591. [Google Scholar] [CrossRef]

- Jason YJ, J.; How, H.G.; Teoh, Y.H.; Chuah, H.G. A Study on the Tribological Performance of Nanolubricants. Processes 2020, 8, 1372. [Google Scholar] [CrossRef]

- del Río, J.M.L.; Mariño, F.; López, E.R.; Gonçalves, D.E.P.; Seabra, J.H.O.; Fernández, J. Tribological enhancement of potential electric vehicle lubricants using coated TiO2 nanoparticles as additives. J. Mol. Liq. 2023, 371, 121097. [Google Scholar] [CrossRef]

- Beel, A.; Gottschalk, M.; Huetten, A.; Toensing, K.; Anselmetti, D. Tribological Performance of TiO2-Nanostructured Particles as Oil-Lubricant Additives for Different Iron-Carbon Alloys. Mater. Today Proc. 2017, 4, S75–S80. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Cheng, X.; Xia, W.; He, A.; Yun, J.; Huang, S.; Wang, L.; Huang, H.; Jiao, S.; et al. Friction and wear characteristics of TiO2 nano-additive water-based lubricant on ferritic stainless steel. Tribol. Int. 2018, 117, 24–38. [Google Scholar] [CrossRef]

- Sharma, V.; Timmons, R.B.; Erdemir, A.; Aswath, P.B. Interaction of plasma functionalized TiO2 nanoparticles and ZDDP on friction and wear under boundary lubrication. Appl. Surf. Sci. 2019, 489, 372–383. [Google Scholar] [CrossRef]

- Wang, L.; Tieu, A.K.; Zhu, H.; Deng, G.; Cui, S.; Zhu, Q. A study of water-based lubricant with a mixture of polyphosphate and nano-TiO2 as additives for hot rolling process. Wear 2021, 477, 203895. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, J.; Wu, H.; Zhao, X.; Zhang, X.; Xu, J.; Hee, A.C.; Jiang, Z. Effects of Nano-TiO2 Additive in Oil-in-Water Lubricant on Contact Angle and Antiscratch Behavior. Tribol. Trans. 2017, 60, 362–372. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, D.; Yang, S. Investigation of pH and SDBS on enhancement of thermal conductivity in nanofluids. Chem. Phys. Lett. 2009, 470, 107–111. [Google Scholar] [CrossRef]

- Wang, B.X.; Zhao, Y.; Zhao, X.P. The wettability, size effect and electrorheological activity of modified titanium oxide nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2007, 295, 27–33. [Google Scholar] [CrossRef]

- Wang, C.; Yang, Y. Tunable volume memory poly(acrylic acid sodium) hydrogel by metal ionsd. Funct. Mater. Lett. 2022, 15, 2250010. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Lubr. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lvovsky, M.; Lapsker, I.; Volovik, Y.; Feldman, Y.; Popovitz-Biro, R.; Tenne, R. Superior tribological properties of powder materials with solid lubricant nanoparticles. Wear 2003, 255, 794–800. [Google Scholar] [CrossRef]

- Su, Y.; Gong, L.; Chen, D. An investigation on tribological properties and lubrication mechanism of graphite nanoparticles as vegetable based oil additive. J. Nanomater. 2015, 2015, 276753. [Google Scholar] [CrossRef]

- Jiao, D.; Zheng, S.; Wang, Y.; Guan, R.; Cao, B. The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Appl. Surf. Sci. 2011, 257, 5720–5725. [Google Scholar] [CrossRef]

- Li, X.; Cao, Z.; Zhang, Z.; Dang, H. Surface-modification in situ of nano-SiO2 and its structure and tribological properties. Appl. Surf. Sci. 2005, 252, 7856–7861. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, J.; Niu, T.; Liu, N. Experimental research on tribological performance of water-based rolling liquid containing nano-TiO2. Proc. Inst. Mech. Eng. Part N J. Nanoeng. Nanosyst. 2015, 229, 104–109. [Google Scholar] [CrossRef]

- Kim, H.J.; Shin, D.G.; Kim, D.E. Frictional behavior between silicon and steel coated with graphene oxide in dry sliding and water lubrication conditions. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 91–97. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | P | Cr | S | Ni |

|---|---|---|---|---|---|---|---|

| Content | 0.96 | 0.31 | 0.22 | 0.014 | 1.52 | 0.002 | 0.004 |

| Element | Ti | Fe | N | H | O | C |

|---|---|---|---|---|---|---|

| Content | ≥99.6 | ≤0.014 | ≤0.008 | ≤0.0013 | ≤0.046 | ≤0.010 |

| Lubricant Conditions | Description |

|---|---|

| DR | Dry |

| O/W | 1.0 wt.% oil + balance water |

| L1 | 1.0 wt.% TiO2 + 0.2 wt.% SDBS + 0.3 wt.% PAAS + balance water |

| L2 | 3.0 wt.% TiO2 + 0.6 wt.% SDBS + 0.3 wt.% PAAS + balance water |

| L3 | 5.0 wt.% TiO2 + 1.0 wt.% SDBS + 0.3 wt.% PAAS + balance water |

| L4 | 7.0 wt.% TiO2 + 1.4 wt.% SDBS + 0.3 wt.% PAAS + balance water |

| L5 | 9.0 wt.% TiO2 + 1.8 wt.% SDBS + 0.3 wt.% PAAS + balance water |

| Sliding Distance/mm | Load/N | Frequency/Hz | Time/s |

|---|---|---|---|

| 10 | 10 | 1 | 600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Ma, L.; Lian, J.; Wang, C.; Ma, X.; Zhao, J. Tribological Behavior and Cold-Rolling Lubrication Performance of Water-Based Nanolubricants with Varying Concentrations of Nano-TiO2 Additives. Lubricants 2024, 12, 361. https://doi.org/10.3390/lubricants12110361

Ma L, Ma L, Lian J, Wang C, Ma X, Zhao J. Tribological Behavior and Cold-Rolling Lubrication Performance of Water-Based Nanolubricants with Varying Concentrations of Nano-TiO2 Additives. Lubricants. 2024; 12(11):361. https://doi.org/10.3390/lubricants12110361

Chicago/Turabian StyleMa, Linan, Luhu Ma, Junjie Lian, Chen Wang, Xiaoguang Ma, and Jingwei Zhao. 2024. "Tribological Behavior and Cold-Rolling Lubrication Performance of Water-Based Nanolubricants with Varying Concentrations of Nano-TiO2 Additives" Lubricants 12, no. 11: 361. https://doi.org/10.3390/lubricants12110361

APA StyleMa, L., Ma, L., Lian, J., Wang, C., Ma, X., & Zhao, J. (2024). Tribological Behavior and Cold-Rolling Lubrication Performance of Water-Based Nanolubricants with Varying Concentrations of Nano-TiO2 Additives. Lubricants, 12(11), 361. https://doi.org/10.3390/lubricants12110361