Investigation of Tribological Properties of Inconel 601 under Environmentally Friendly MQL and Nano-Fluid MQL with Pack Boronizing

Abstract

1. Introduction

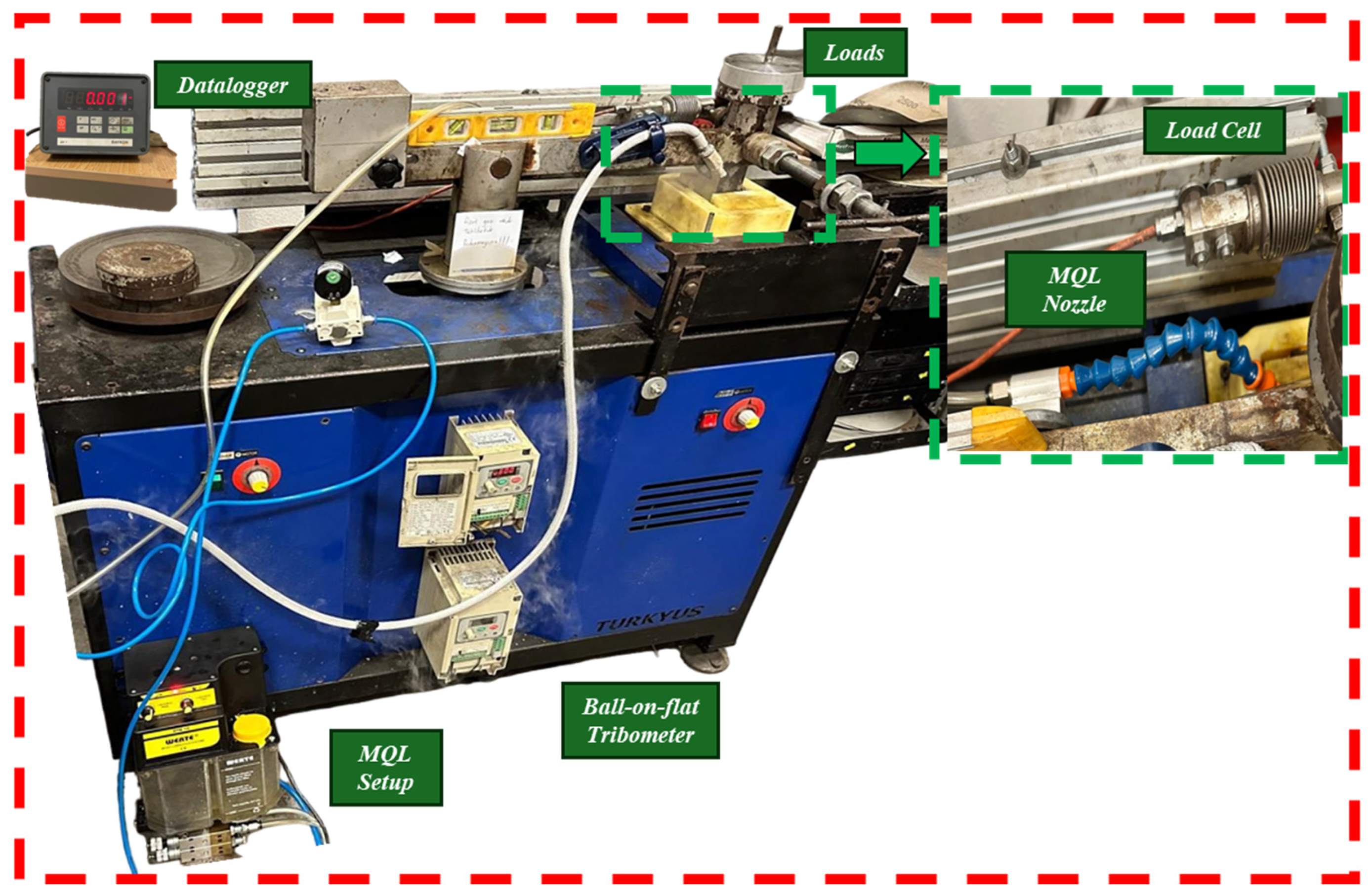

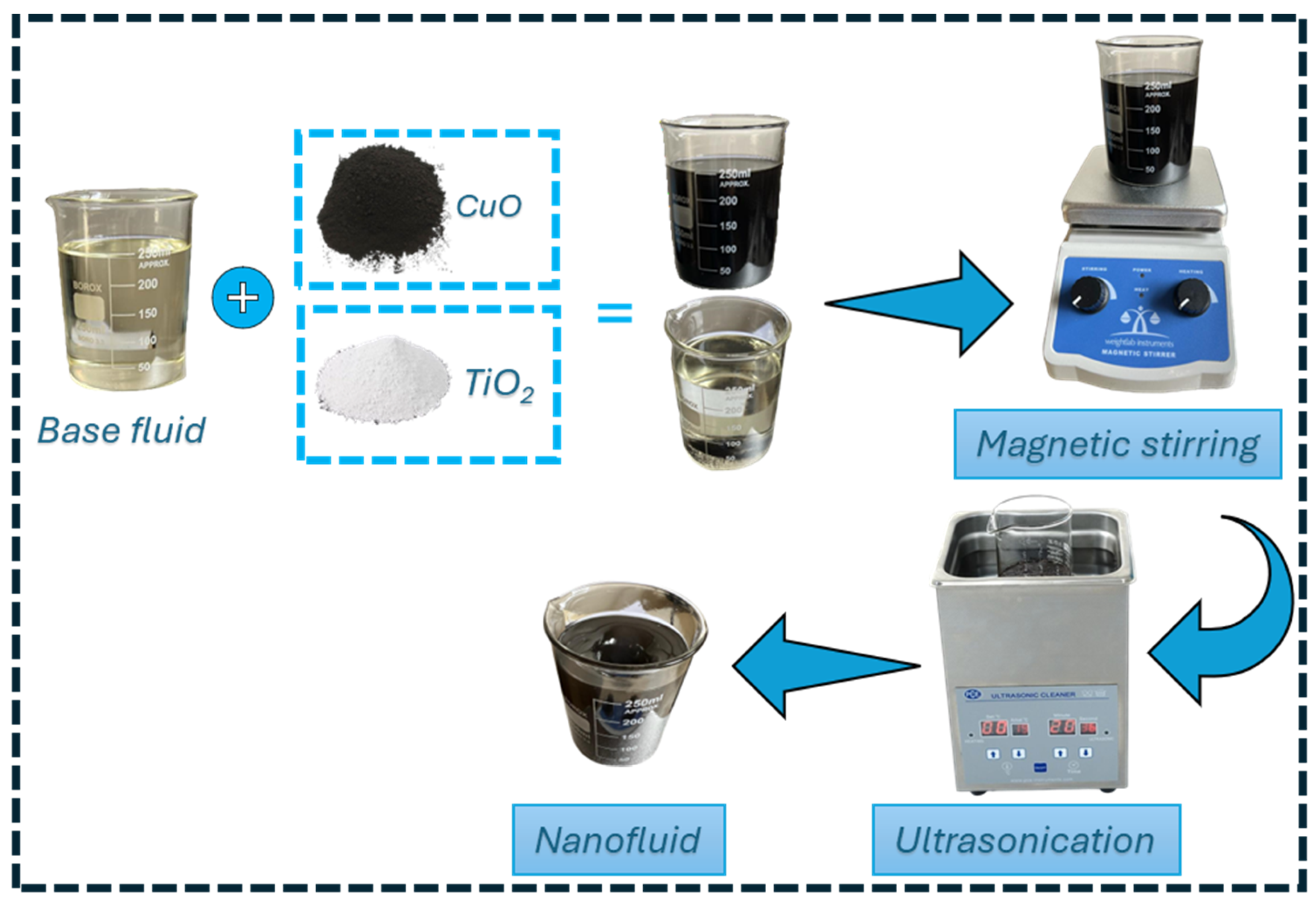

2. Materials and Methods

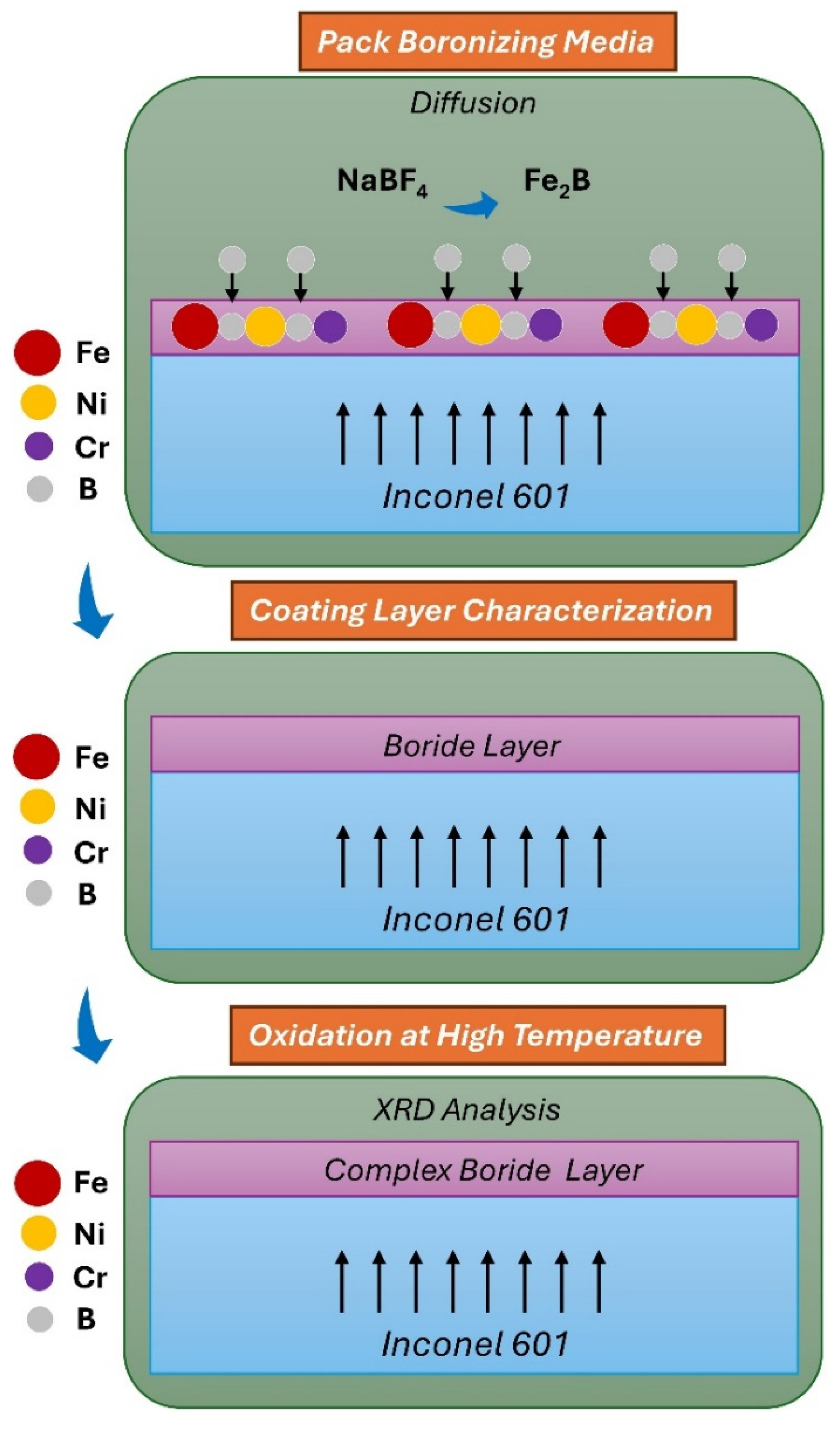

2.1. Boriding Process

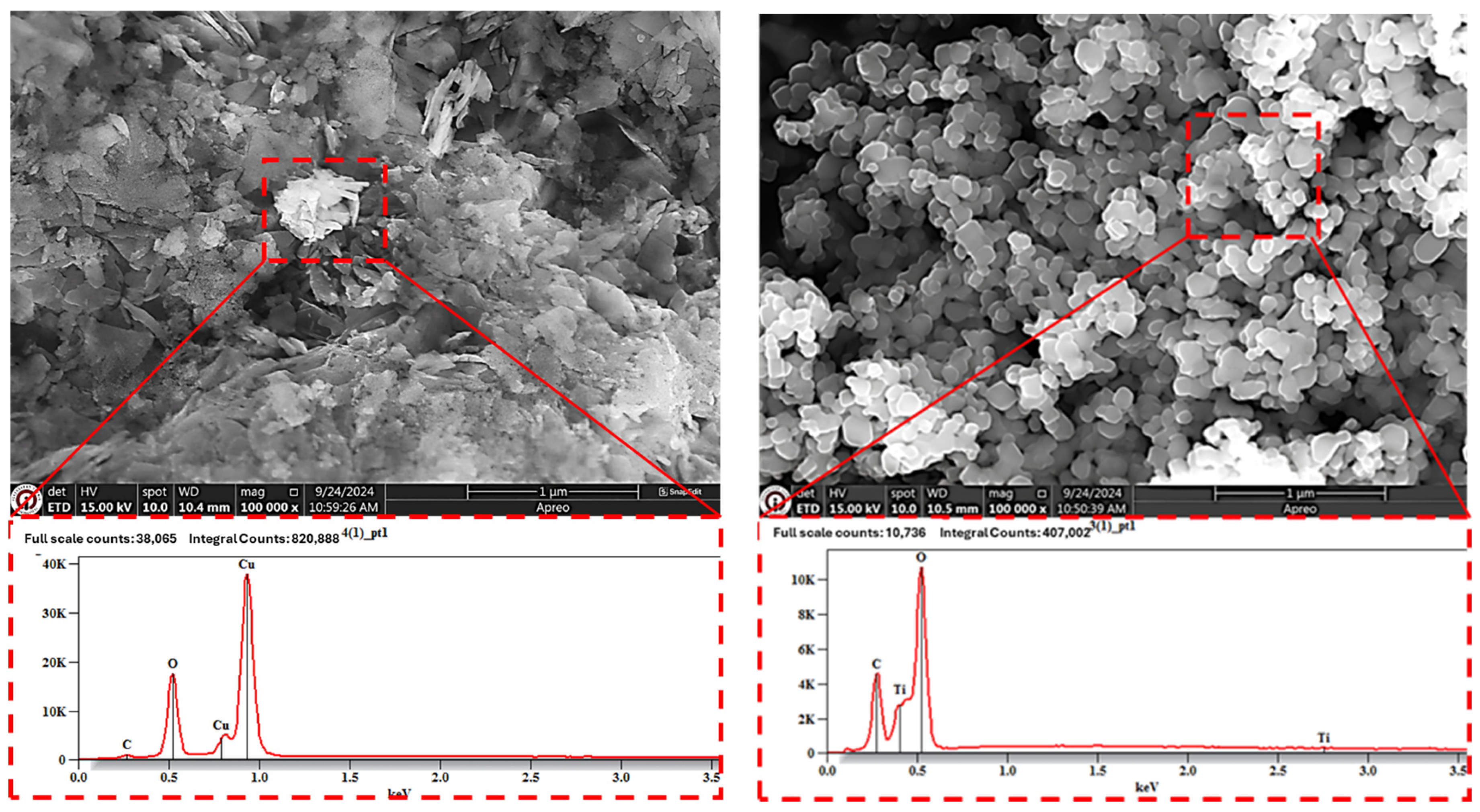

2.2. Material Characterization

3. Results and Discussion

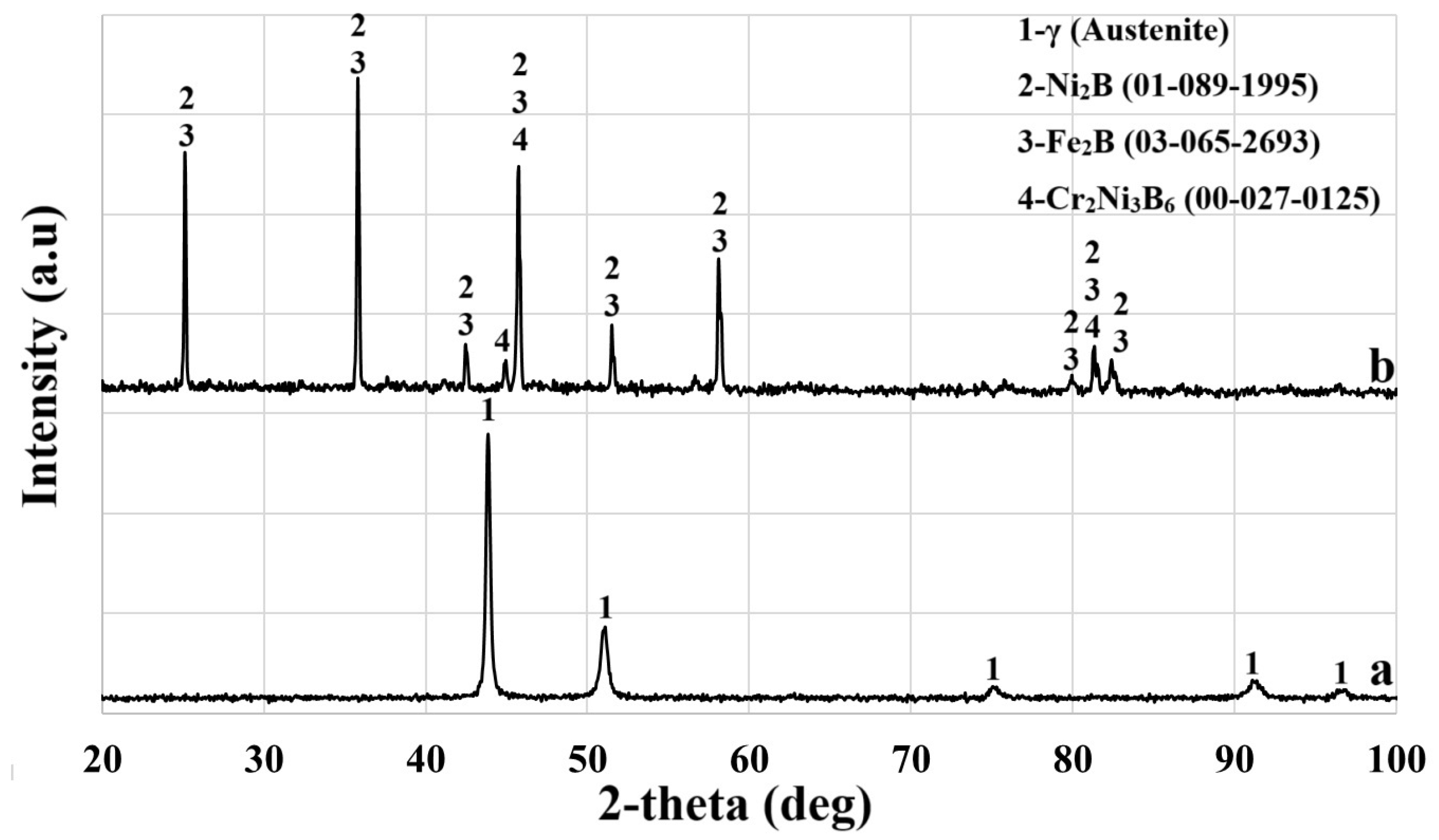

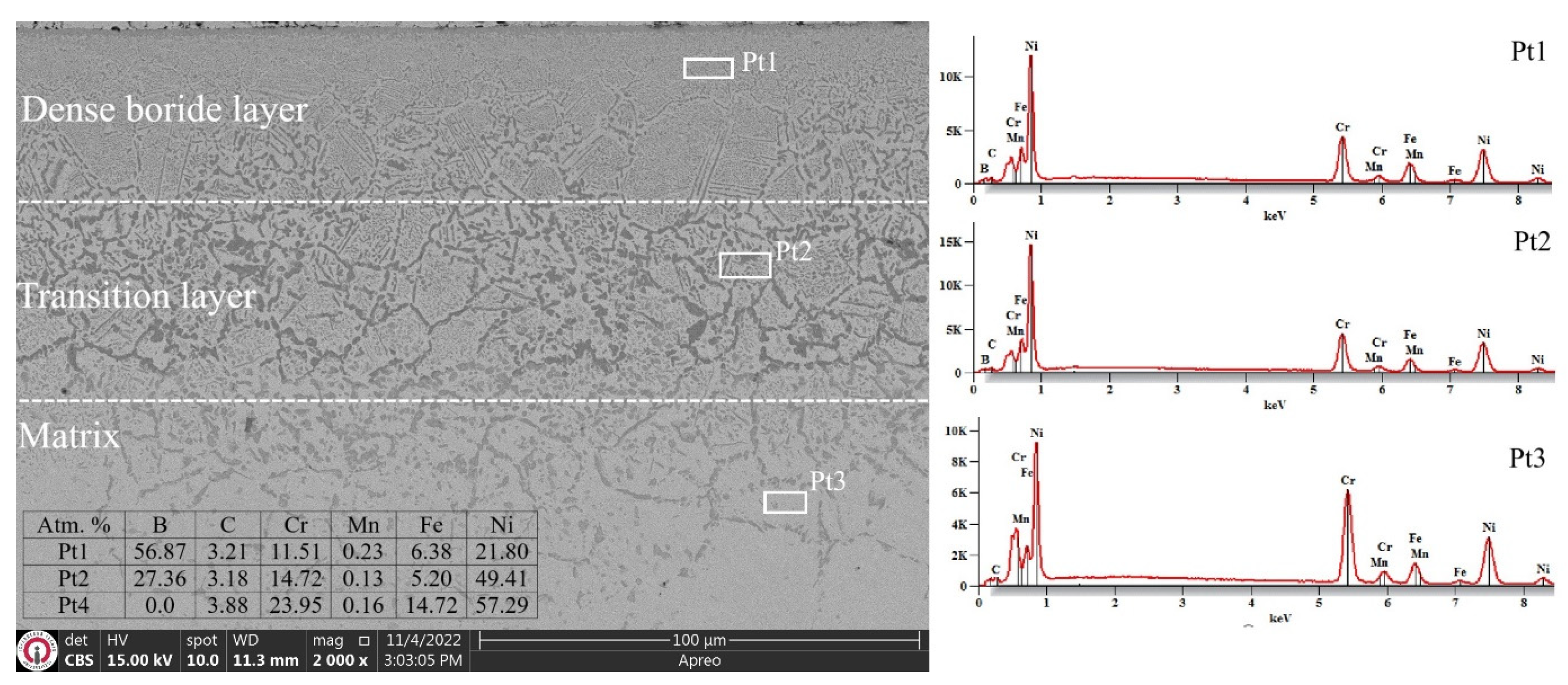

3.1. Characterization of Boride Layer

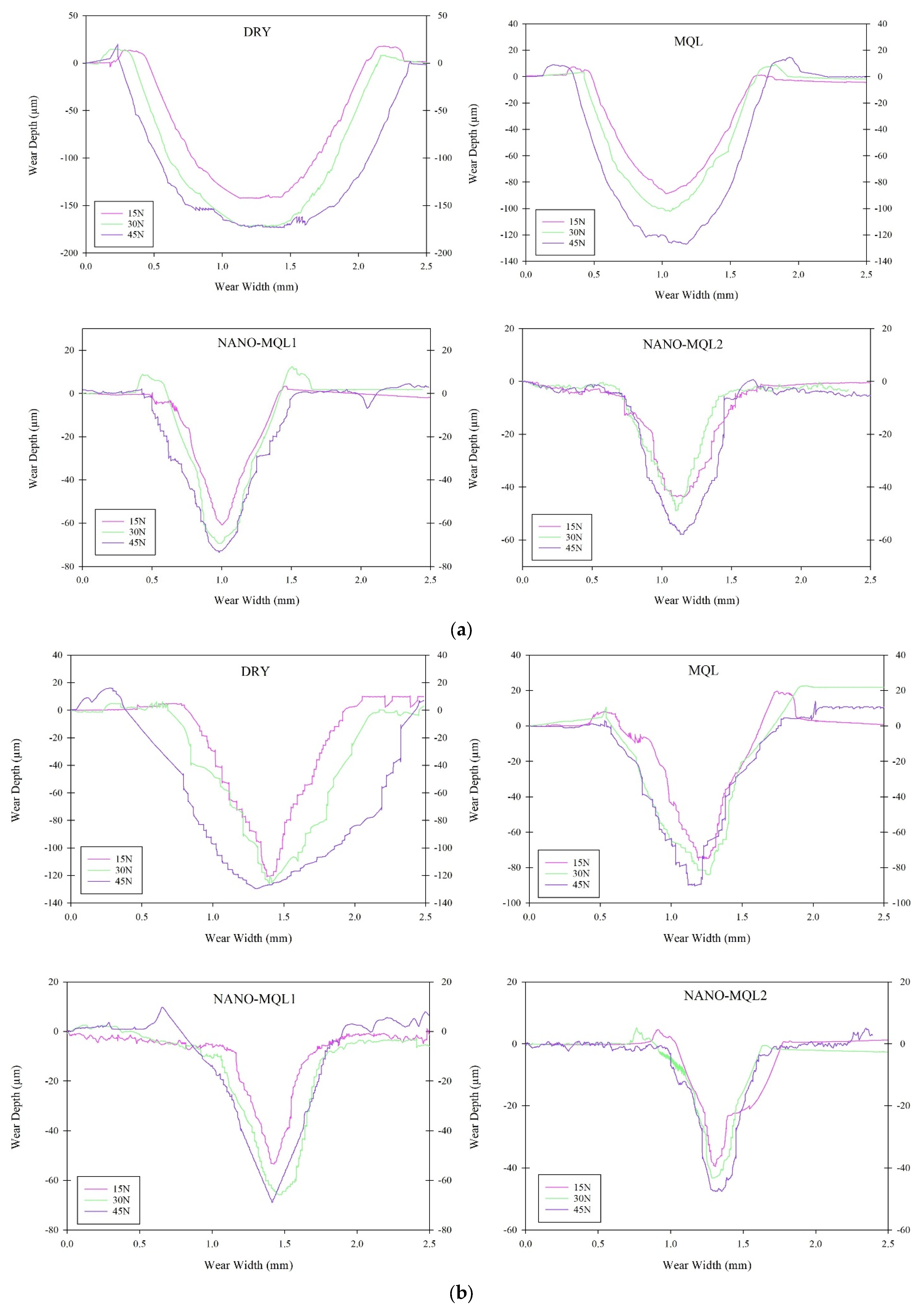

3.2. Assessment of Wear Rate

3.3. Assessment of Friction Force

3.4. Evaluation of CoF

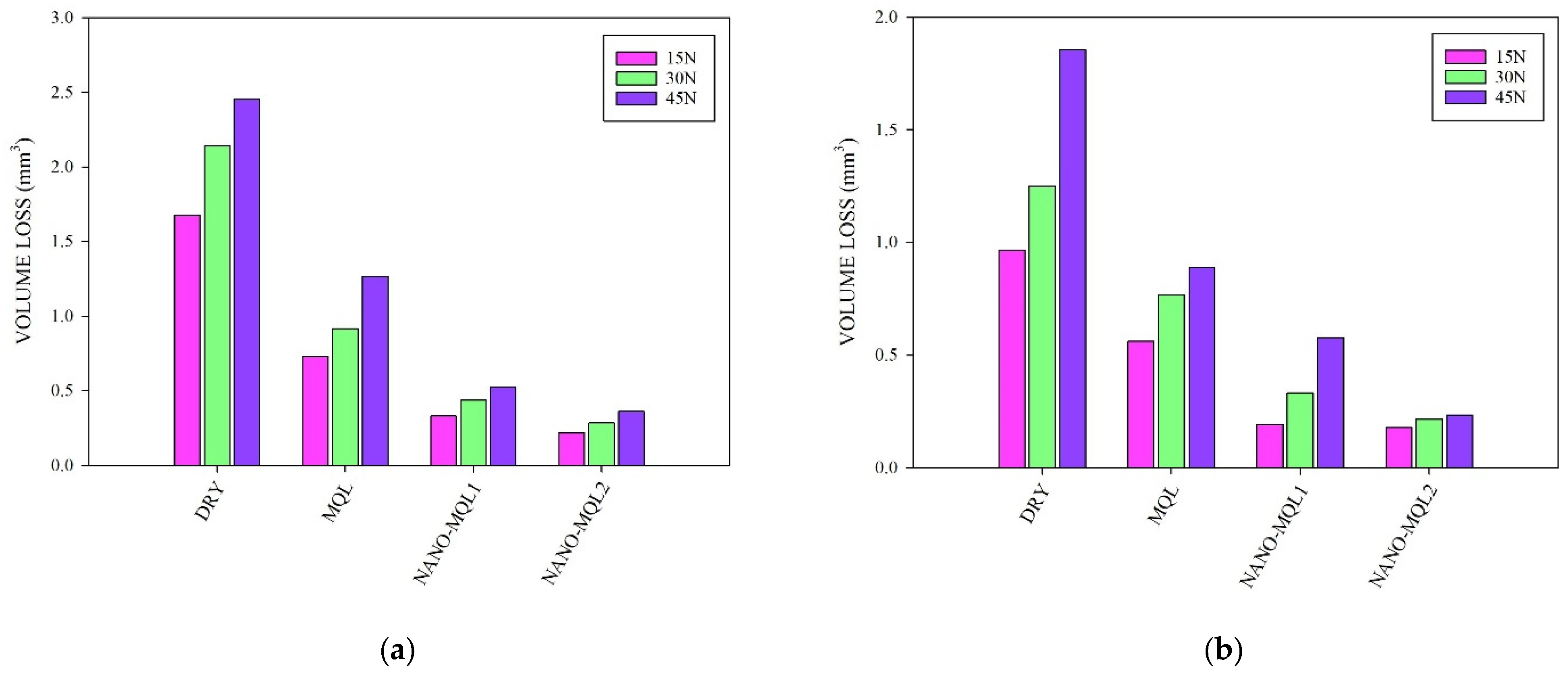

3.5. Evaluation of Volume Loss

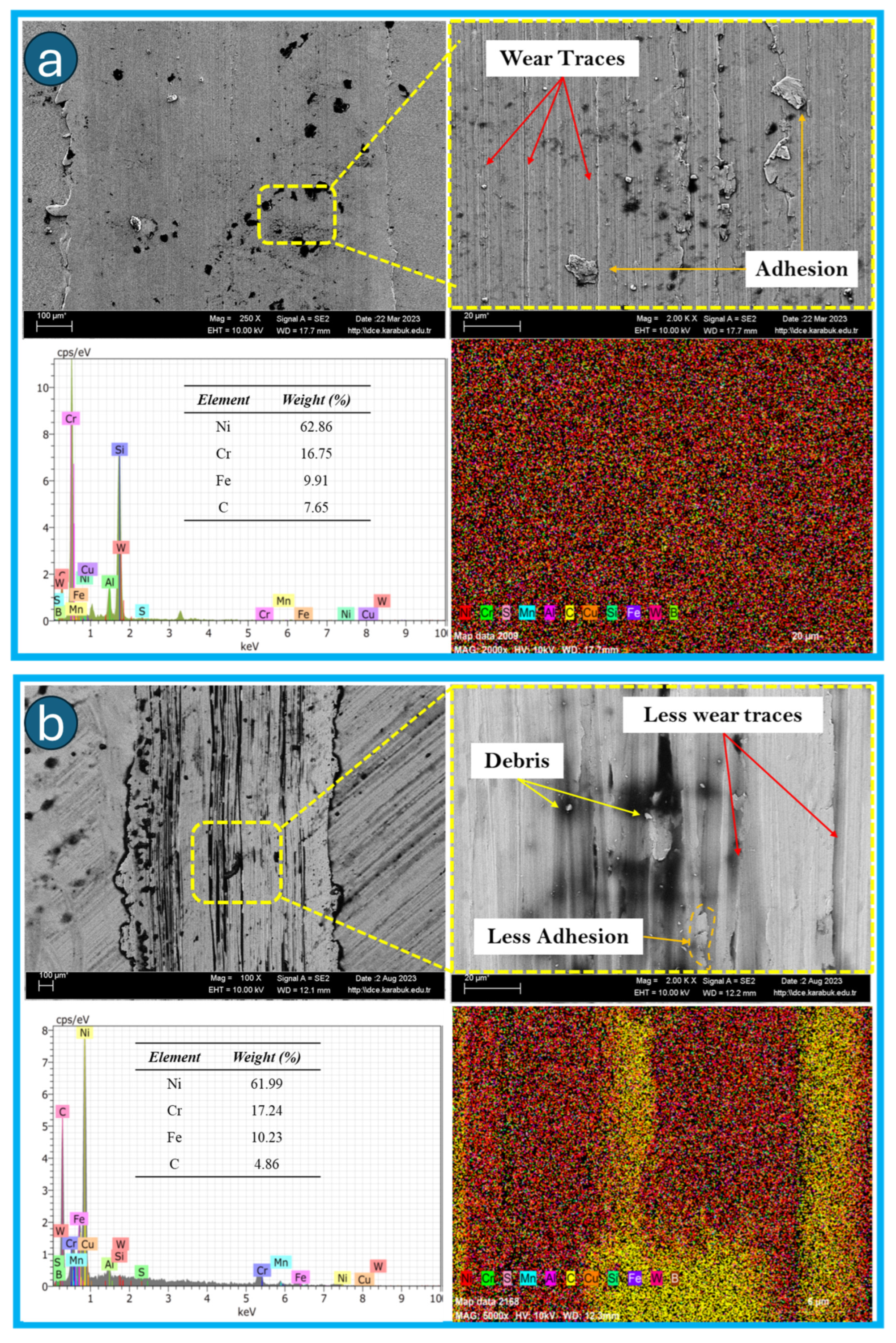

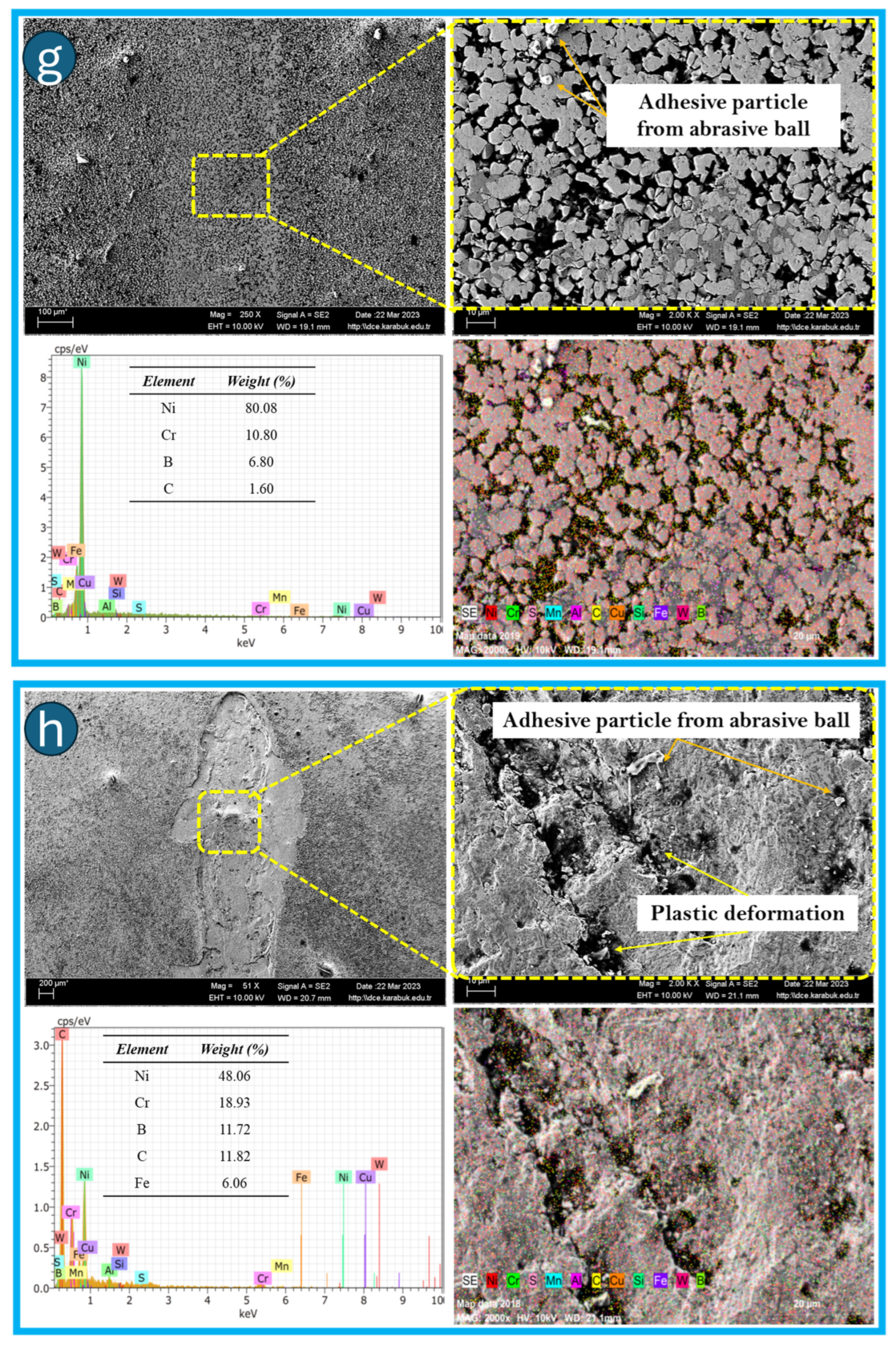

3.6. SEM Assessment of Worn Surfaces

4. Conclusions

- The research results revealed that MQL, nanoparticle reinforcement on MQL, and boron coating all are beneficial in reducing the wear depth. It turns out that the hard and flexible surfaces formed on the material surface by boriding provide resistance to abrasion, reducing the depth of wear. Under a 15 N load in a dry environment, the wear depth was determined as 141.554 µm for as-received Inconel 601, while it was determined as 120.518 µm for boron-coated Inconel 601 (14.86% reduction). In the nano-MQL2 environment, the wear depth value of boron-coated Inconel 601 was reduced by 9.96% (from 43.811 µm to 39.45 µm) at 15 N compared to as-received Inconel 601.

- With as-received Inconel 601, the average friction force in the MQL environment decreased by 30.87% compared to the dry environment. These reductions were 53.07% and 59.31% in nano-MQL1 and nano-MQL2 environments, respectively. In boron-coated Inconel 601, the average friction forces in MQL, nano-MQL1, and nano-MQL2 environments decreased by 30.23%, 41.60%, and 52.32%, respectively, compared to the dry environment. This situation is explained by the decrease in the heat between the workpiece and the work tool due to the cooling and lubricating effect of MQL and nanoparticles compared to the dry environment.

- The results showed that the maximum CoF value was 0.958 with as-received Inconel 601 in a dry environment at a 15 N load, while the lowest CoF value was 0.267 with boron-coated Inconel 601 in a nano-MQL2 environment at 45 N. It has been understood that the increase in surface hardness with boron coating and the formation of a lubricating film layer between the workpiece and the tool by nanoparticles support the reduction of CoF.

- In as-received Inconel 601, the volume loss in the dry environment and at a 45 N load was 2.46 mm3, while this value was 1.85 mm3 in boron-coated Inconel 601; thus, a 24.8% decrease was achieved. However, in the nano-MQL2 environment and at a 15 N load, the volume losses for as-received and boron-coated Inconel 601 were determined as 0.288 mm3 and 0.249 mm3, respectively (13.54% decrease). It can be claimed that the volume loss decreases as a result of the boron coating’s increased surface hardness and the MQL and nano-MQL application’s decreased wear environment friction.

- The higher frequency of cracks and wear indicators that show up under dry conditions is due to the increased removal of material from the surface. Cracks and the deposition of materials can be significantly decreased by changing the lubricating conditions. Furthermore, the application of nano-MQL lubrication reduces the build-up of material on the object’s surface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bölükbaşı, Ö.S.; Serindağ, T.; Gürol, U.; Günen, A.; Çam, G. Improving oxidation resistance of wire arc additive manufactured Inconel 625 Ni-based superalloy by pack aluminizing. CIRP J. Manuf. Sci. Technol. 2023, 46, 89–97. [Google Scholar] [CrossRef]

- Çavdar, F.; Günen, A.; Kanca, E.; Er, Y.; Gök, M.S.; Campos-Silva, I.; Olvares-Luna, M. An Experimental and Statistical Analysis on Dry Sliding Wear Failure Behavior of Incoloy 825 at Elevated Temperatures. J. Mater. Eng. Perform. 2023, 32, 4161–4184. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.; Zhang, P.; Cao, K.; Wang, Z.; Chen, F.; Liu, D.; Tang, B.; Kou, H.; Li, J. Influence of heat treatment on Inconel 625 superalloy sheet: Carbides, γ’’, δ phase precipitation and tensile deformation behavior. J. Alloys Compd. 2023, 930, 167522. [Google Scholar] [CrossRef]

- Kayalı, Y.; Kanca, E.; Günen, A. Effect of boronizing on microstructure, high-temperature wear and corrosion behavior of additive manufactured Inconel 718. Mater. Charact. 2022, 191, 112155. [Google Scholar] [CrossRef]

- Günen, A.; Keddam, M.; Alkan, S.; Erdoğan, A.; Çetin, M. Microstructural characterization, boriding kinetics and tribo-wear behavior of borided Fe-based A286 superalloy. Mater. Charact. 2022, 186, 111778. [Google Scholar] [CrossRef]

- Günen, A. Properties and High Temperature Dry Sliding Wear Behavior of Boronized Inconel 718. Metall. Mater. Trans. A 2020, 51, 927–939. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, C.; Yu, X.; Liu, B.; Quan, Y. Tool wear mechanism, monitoring and remaining useful life (RUL) technology based on big data: A review. SN Appl. Sci. 2022, 4, 232. [Google Scholar] [CrossRef]

- Shafiee Sabet, A.; Domitner, J.; Ristić, A.; Öksüz, K.I.; Rodríguez Ripoll, M.; Sommitsch, C. Effects of temperature on friction and degradation of dry film lubricants during sliding against aluminum alloy sheets. Tribol. Int. 2023, 180, 108205. [Google Scholar] [CrossRef]

- Wang, P.; Liang, H.; Jiang, L.; Qian, L. Effect of nanoscale surface roughness on sliding friction and wear in mixed lubrication. Wear 2023, 530–531, 204995. [Google Scholar] [CrossRef]

- Ijaz Malik, M.A.; Kalam, M.A.; Mujtaba, M.A.; Almomani, F. A review of recent advances in the synthesis of environmentally friendly, sustainable, and nontoxic bio-lubricants: Recommendations for the future implementations. Environ. Technol. Innov. 2023, 32, 103366. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Demirsöz, R. Understanding the lubrication regime phenomenon and its influence on tribological characteristics of additively manufactured 316 Steel under novel lubrication environment. Tribol. Int. 2022, 173, 107686. [Google Scholar] [CrossRef]

- Sinha, M.K.; Archana, K.K.; Kumar, R. Hybrid approach for modelling and optimizing MQL grinding of Inconel 625 with machine learning and MCDM techniques. Int. J. Interact. Des. Manuf. 2024, 18, 4697–4713. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, Z.; Pan, S.; Meng, X.; Liu, D.; Mu, K.; Zhu, Q.; Zhu, J.; Cai, C. High-performance liquid metal-based SiC/Graphene-Mo hybrid nanofluid for hydraulic transmission. Tribol. Int. 2024, 198, 109871. [Google Scholar] [CrossRef]

- Etri, H.E.; Singla, A.K.; Özdemir, M.T.; Korkmaz, M.E.; Demirsöz, R.; Gupta, M.K.; Krolczyk, J.B.; Ross, N.S. Wear performance of Ti-6Al-4 V titanium alloy through nano-doped lubricants. Arch. Civ. Mech. Eng. 2023, 23, 147. [Google Scholar] [CrossRef]

- Vardhaman, B.S.A.; Amarnath, M.; Ramkumar, J.; Mondal, K. Enhanced tribological performances of zinc oxide/MWCNTs hybrid nanomaterials as the effective lubricant additive in engine oil. Mater. Chem. Phys. 2020, 253, 123447. [Google Scholar] [CrossRef]

- Abdullah, M.I.; Abdollah, M.F.; Amiruddin, H.; Tamaldin, N.; Nuri, N.R. The potential of hBN nanoparticles as friction modifier and antiwear additive in engine oil. Mech. Ind. 2016, 17, 104. [Google Scholar] [CrossRef]

- Yilmaz, A.C. Tribological Enhancement Features of Various Nanoparticles as Engine Lubricant Additives: An Experimental Study. Arab. J. Sci. Eng. 2020, 45, 1125–1134. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R. Tribological characteristics of synthesized hybrid nanofluid composed of CuO and TiO2 nanoparticle additives. Wear 2023, 518–519, 204623. [Google Scholar] [CrossRef]

- Günen, A.; Kanca, E.; Çakir, H.; Karakaş, M.S.; Gök, M.S.; Küçük, Y.; Demir, M. Effect of borotitanizing on microstructure and wear behavior of Inconel 625. Surf. Coat. Technol. 2017, 311, 374–382. [Google Scholar] [CrossRef]

- Gunen, A.; Keddam, M.; Sunbul, S.E.; Icin, K.; Doleker, K.M.; Gok, M.S.; Dal, S.; Erdogan, A. Powder-pack boronizing of CoCrFeNiAl0.5Nb0.5 HEA: Modeling of kinetics, microstructural, mechanical, and tribological characterizations. J. Alloys Compd. 2022, 929, 167310. [Google Scholar] [CrossRef]

- Zhu, D.; Martini, A.; Wang, W.; Hu, Y.; Lisowsky, B.; Wang, Q.J. Simulation of Sliding Wear in Mixed Lubrication. J. Tribol. 2007, 129, 544–552. [Google Scholar] [CrossRef]

- Barai, R.; Kumar, D.; Wankhade, A. Heat transfer performance of nanofluids in heat exchanger: A review. J. Therm. Eng. 2023, 9, 86–106. [Google Scholar] [CrossRef]

- Ghaednia, H.; Babaei, H.; Jackson, R.L.; Bozack, M.J.; Khodadadi, J.M. The effect of nanoparticles on thin film elasto-hydrodynamic lubrication. Appl. Phys. Lett. 2013, 103, 263111. [Google Scholar] [CrossRef]

- Kanca, Y.; Gokcekaya, O.; Günen, A. Sliding Wear and Friction Performance of Pack-Borided Co–28Cr–6Mo Alloy in Physiological Lubricants. Met. Mater. Trans. A 2023, 54, 4634–4649. [Google Scholar] [CrossRef]

| Inconel 601 | Ni (%) | Cr (%) | Cu (%) | Si (%) | Fe (%) |

| ~58–63 | ~21–25 | ~1.00 | ~0.50 | Balance | |

| WC Ball | Tungsten Carbide (%) | Co (%) | |||

| 94 | 6 | ||||

| Property | CuO | TiO2 |

|---|---|---|

| Density (kg/m3) | 6000 | 4230 |

| Thermal conductivity (W/m-K) | 33 | 8.4 |

| Specific heat (J/kg-K) | 551 | 692 |

| Diameter of nanoparticles (nm) | 25–50 | 25–50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uslu, G.; Korkmaz, M.E.; Elkilani, R.H.R.; Gupta, M.K.; Vashishtha, G. Investigation of Tribological Properties of Inconel 601 under Environmentally Friendly MQL and Nano-Fluid MQL with Pack Boronizing. Lubricants 2024, 12, 353. https://doi.org/10.3390/lubricants12100353

Uslu G, Korkmaz ME, Elkilani RHR, Gupta MK, Vashishtha G. Investigation of Tribological Properties of Inconel 601 under Environmentally Friendly MQL and Nano-Fluid MQL with Pack Boronizing. Lubricants. 2024; 12(10):353. https://doi.org/10.3390/lubricants12100353

Chicago/Turabian StyleUslu, Gonca, Mehmet Erdi Korkmaz, Rajab Hussein Rajab Elkilani, Munish Kumar Gupta, and Govind Vashishtha. 2024. "Investigation of Tribological Properties of Inconel 601 under Environmentally Friendly MQL and Nano-Fluid MQL with Pack Boronizing" Lubricants 12, no. 10: 353. https://doi.org/10.3390/lubricants12100353

APA StyleUslu, G., Korkmaz, M. E., Elkilani, R. H. R., Gupta, M. K., & Vashishtha, G. (2024). Investigation of Tribological Properties of Inconel 601 under Environmentally Friendly MQL and Nano-Fluid MQL with Pack Boronizing. Lubricants, 12(10), 353. https://doi.org/10.3390/lubricants12100353