Mechanical Properties and Tribological Study of Bottom Pouring Stir-Cast A356 Alloy Reinforced with Graphite Solid Lubricant Extracted from Corn Stover

Abstract

1. Introduction

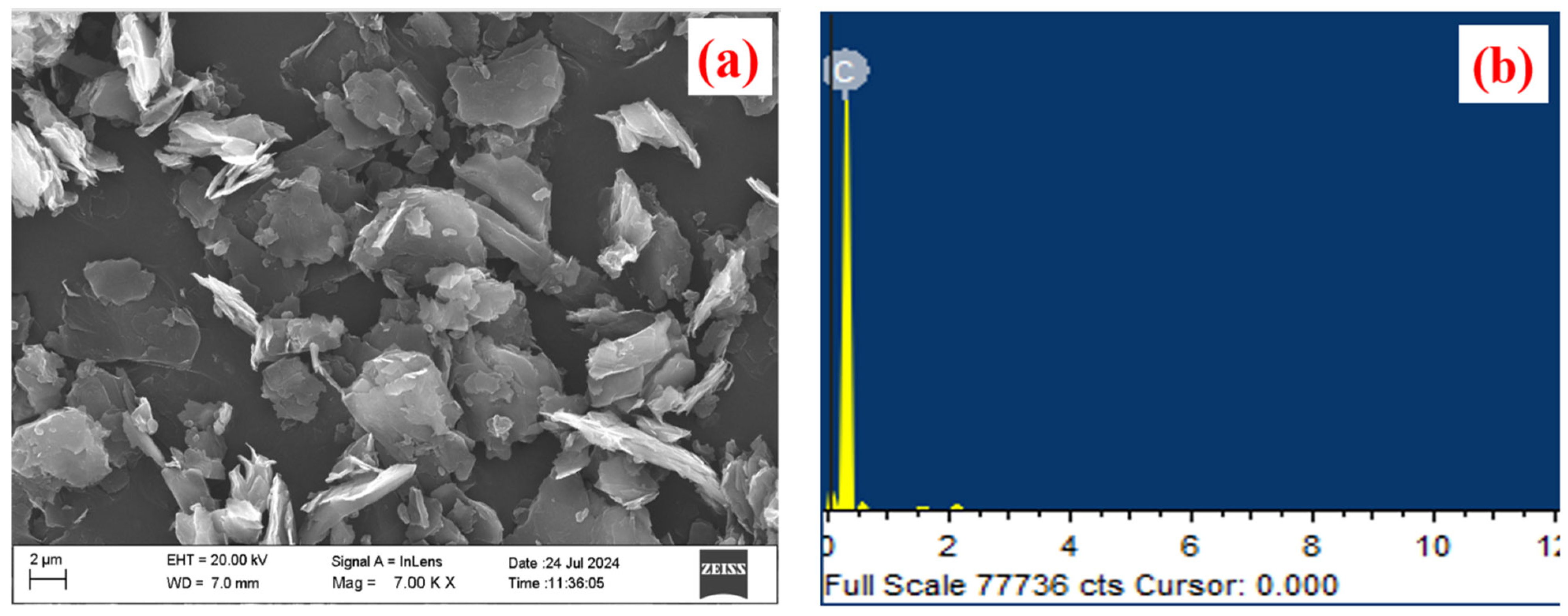

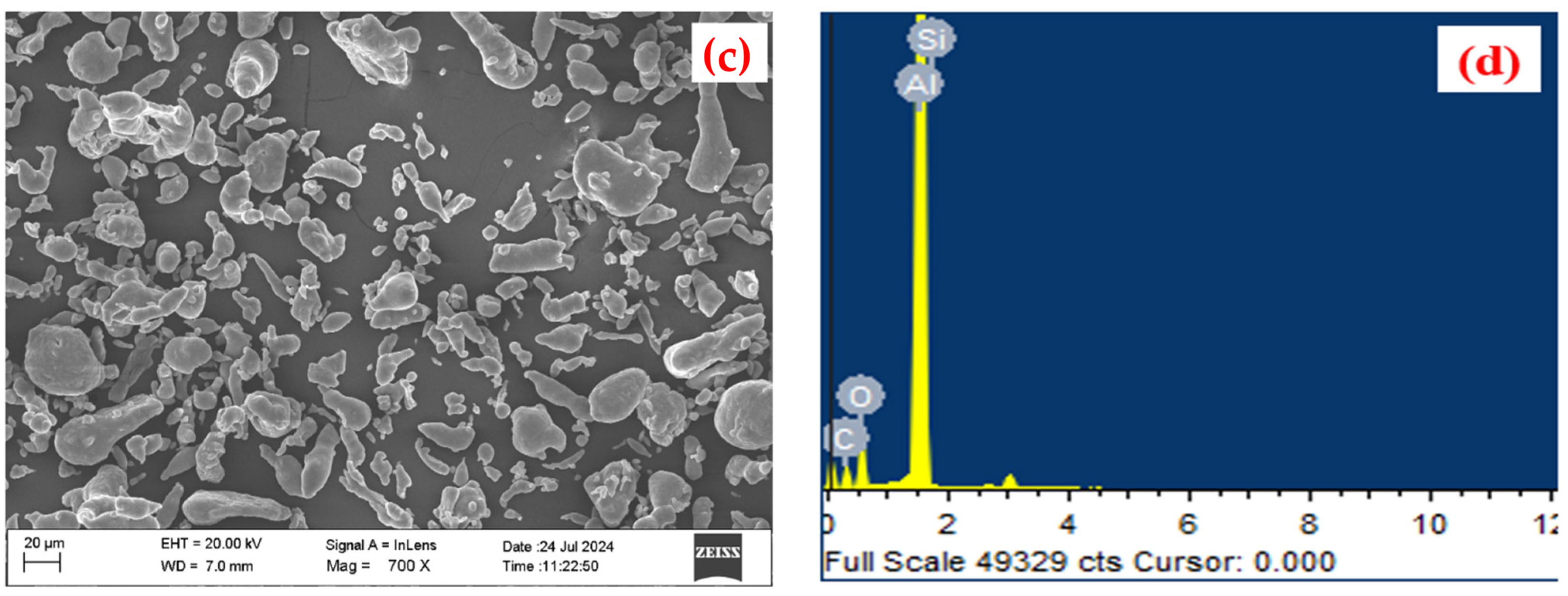

2. Materials and Composite Synthesis

3. Results and Discussion

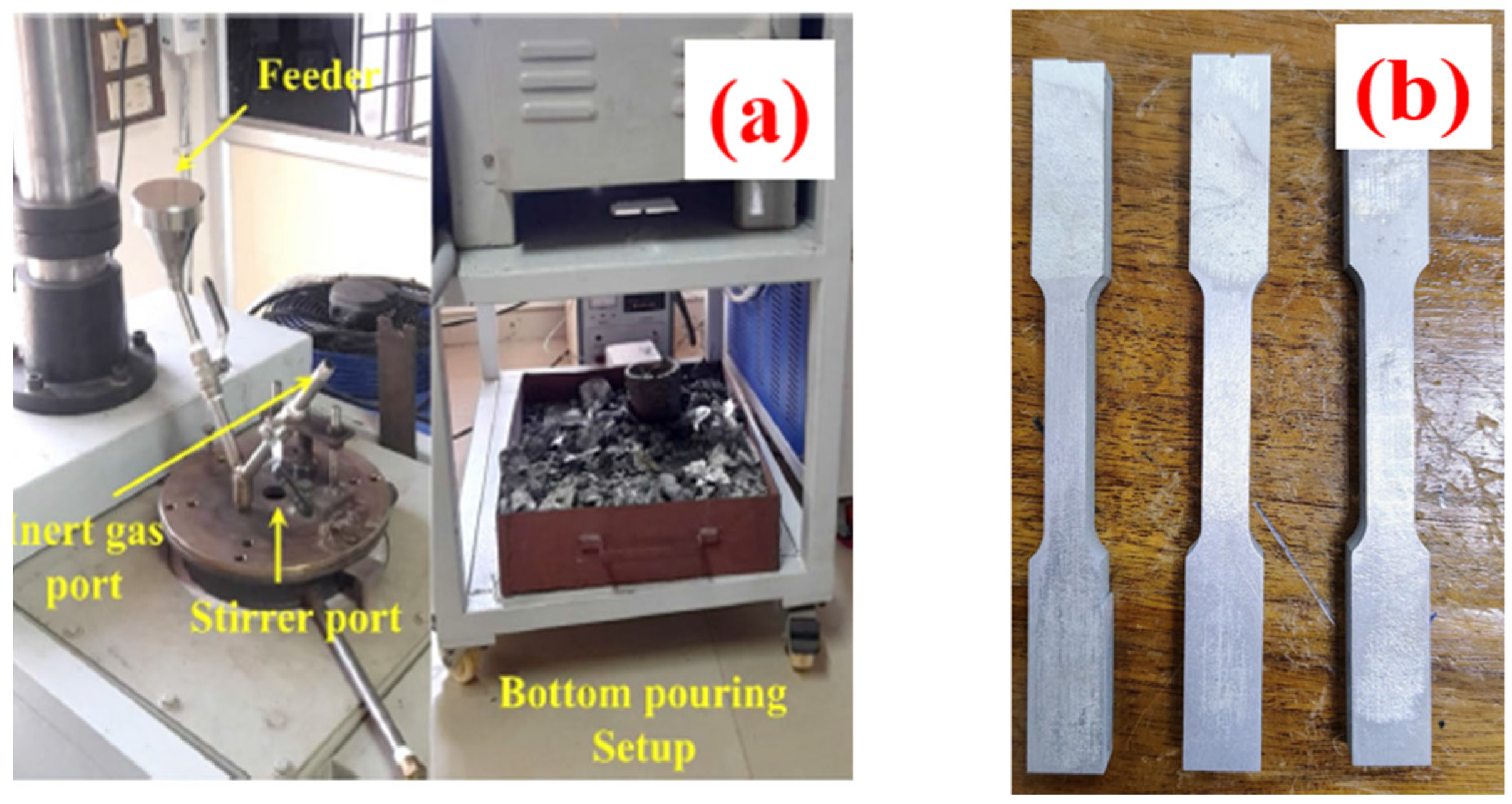

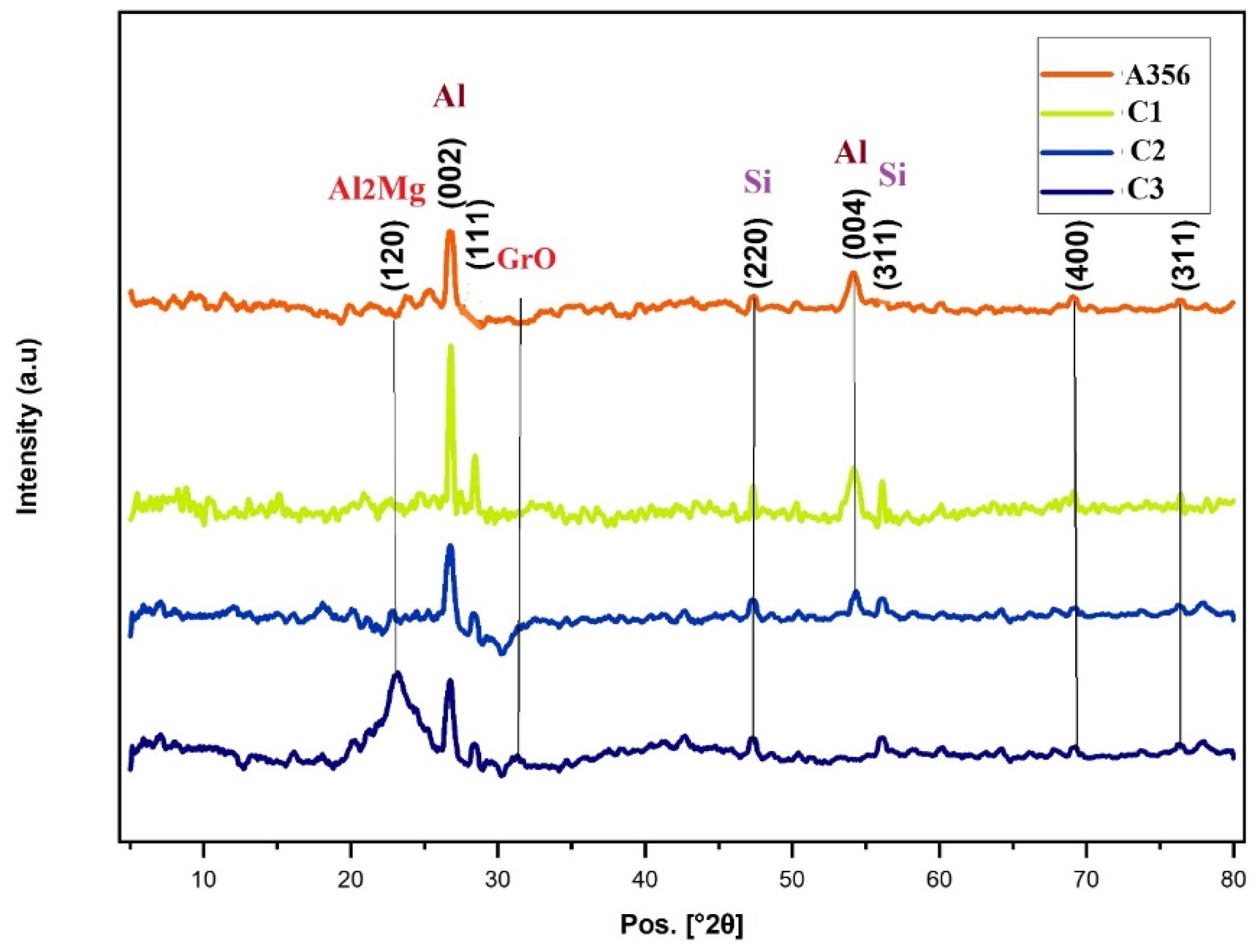

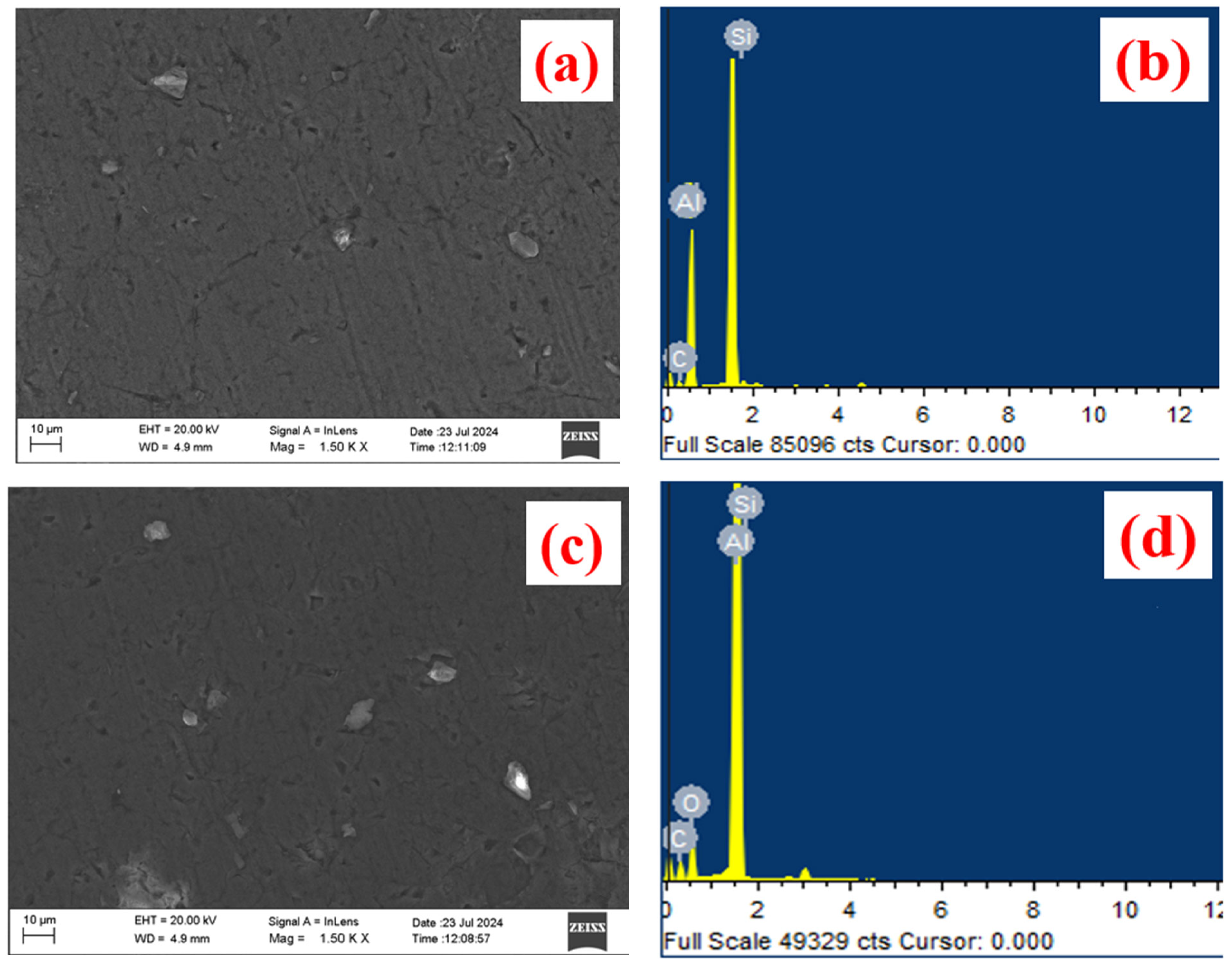

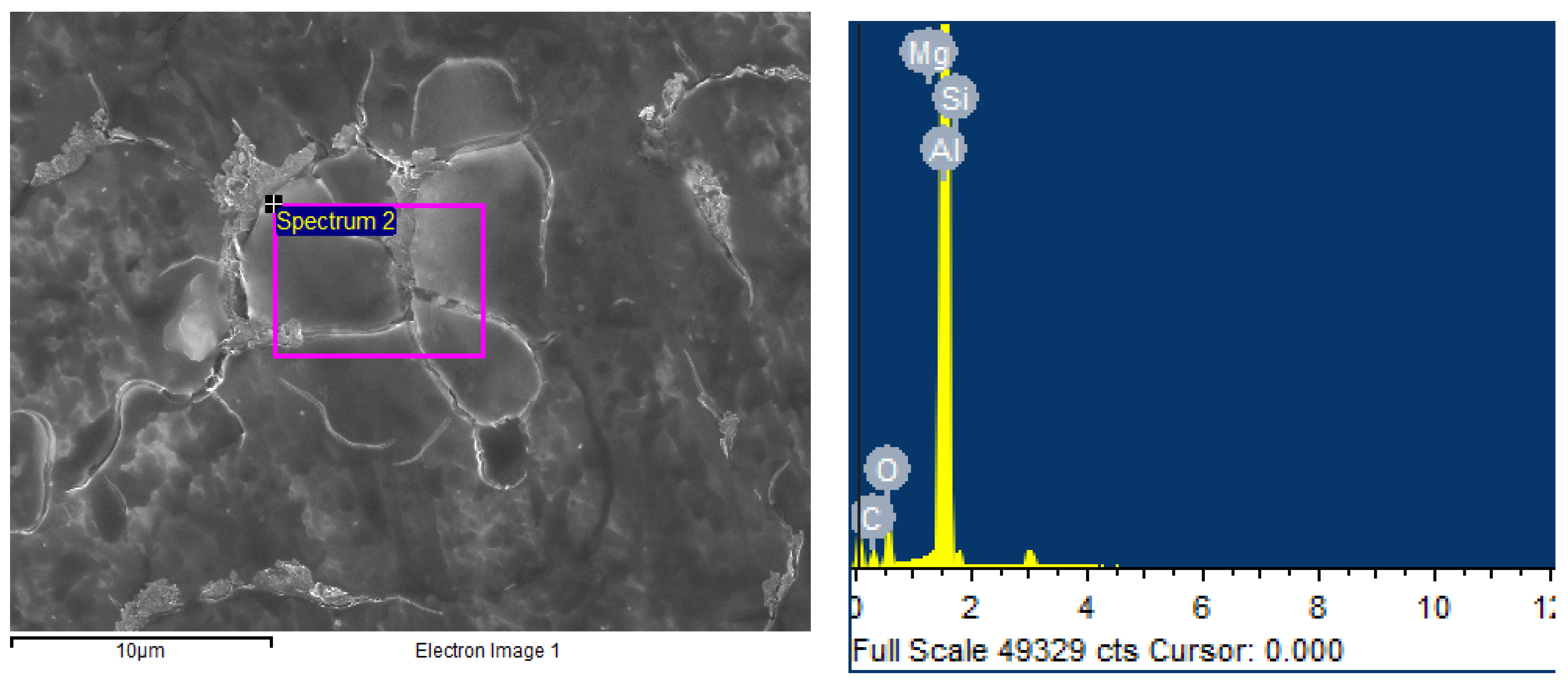

3.1. XRD Analysis and Microstructural Study

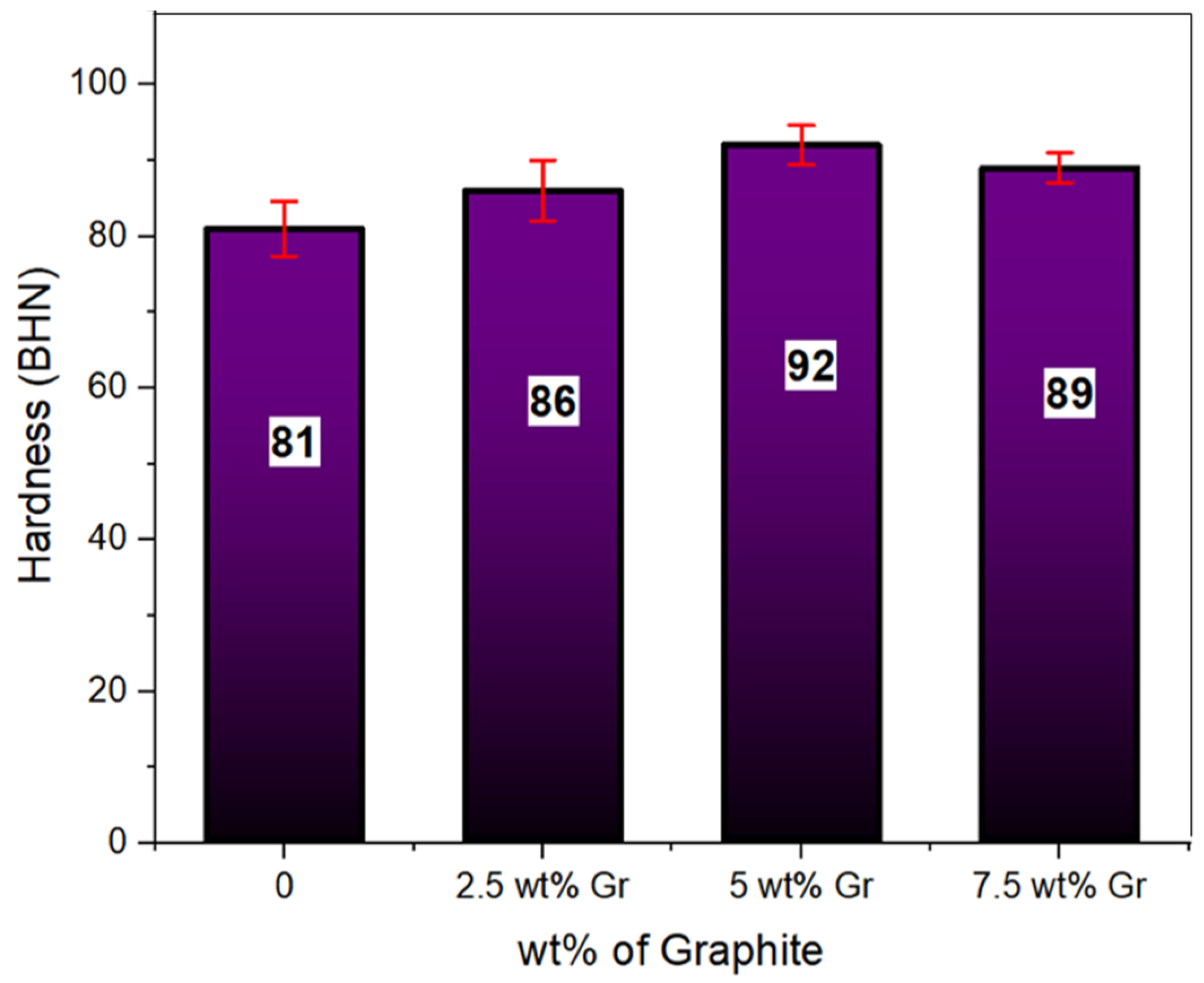

3.2. Hardness of the A356-Gr Composite

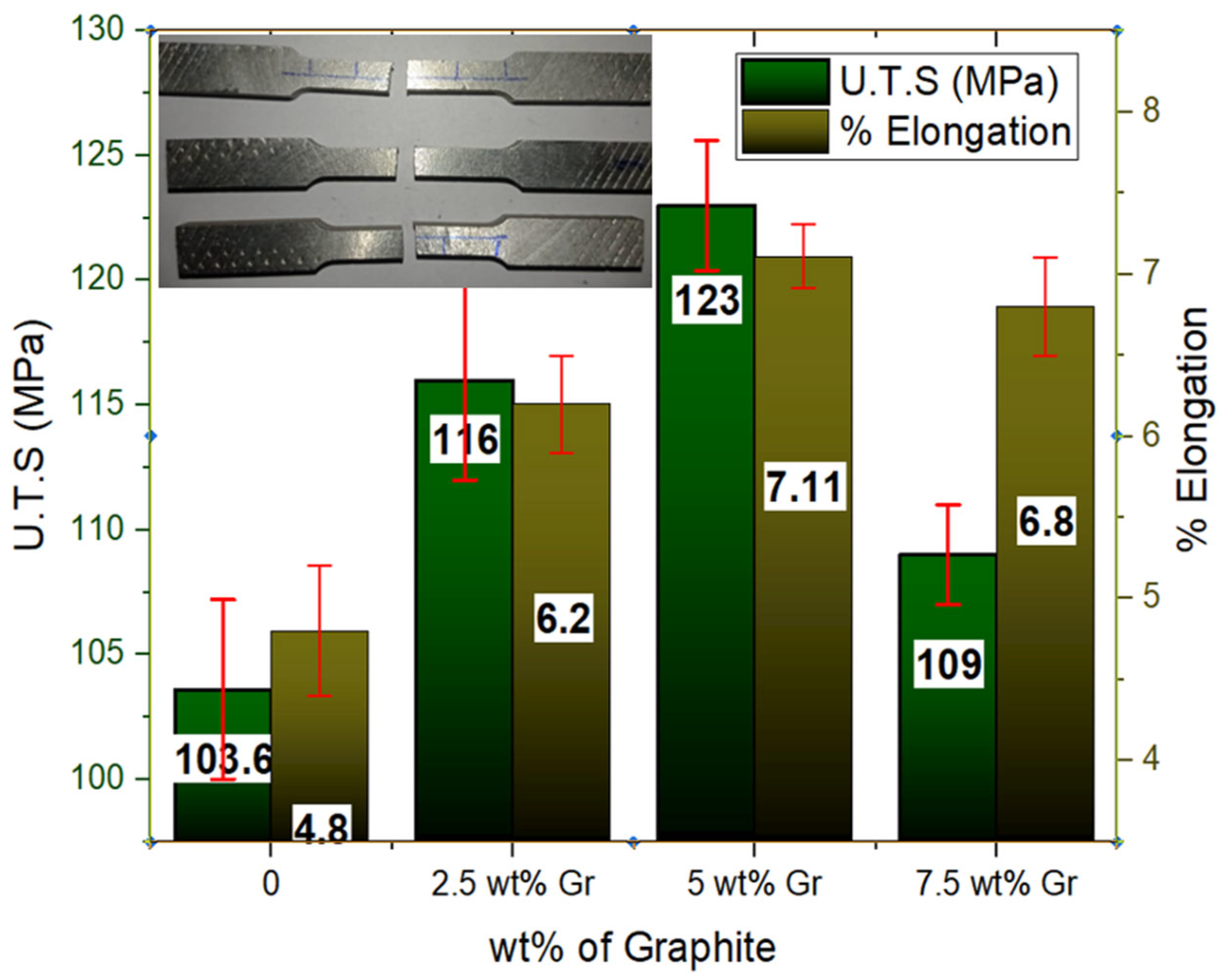

3.3. Tensile Strength and % Elongation of A356—Gr Composite

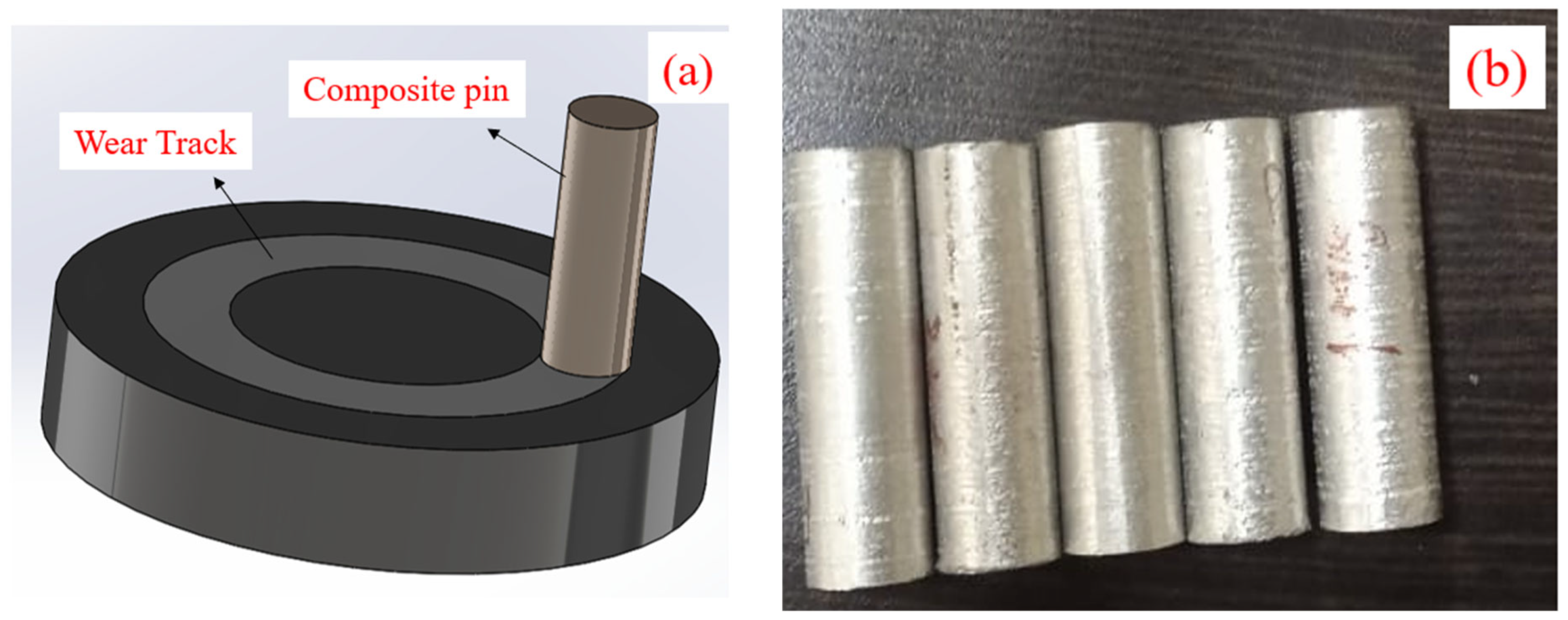

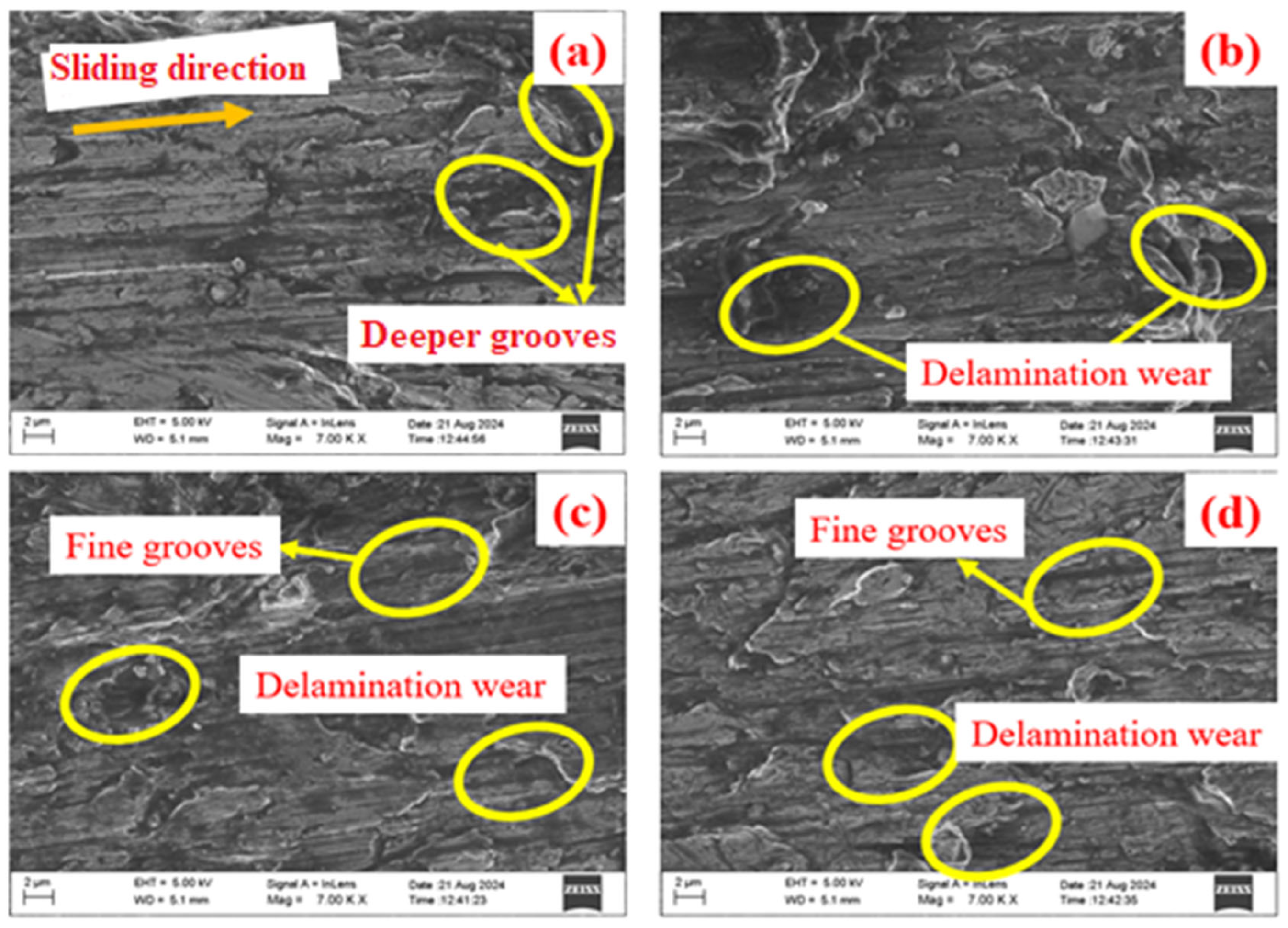

3.4. Tribological Behaviour of the A356-Gr Composite

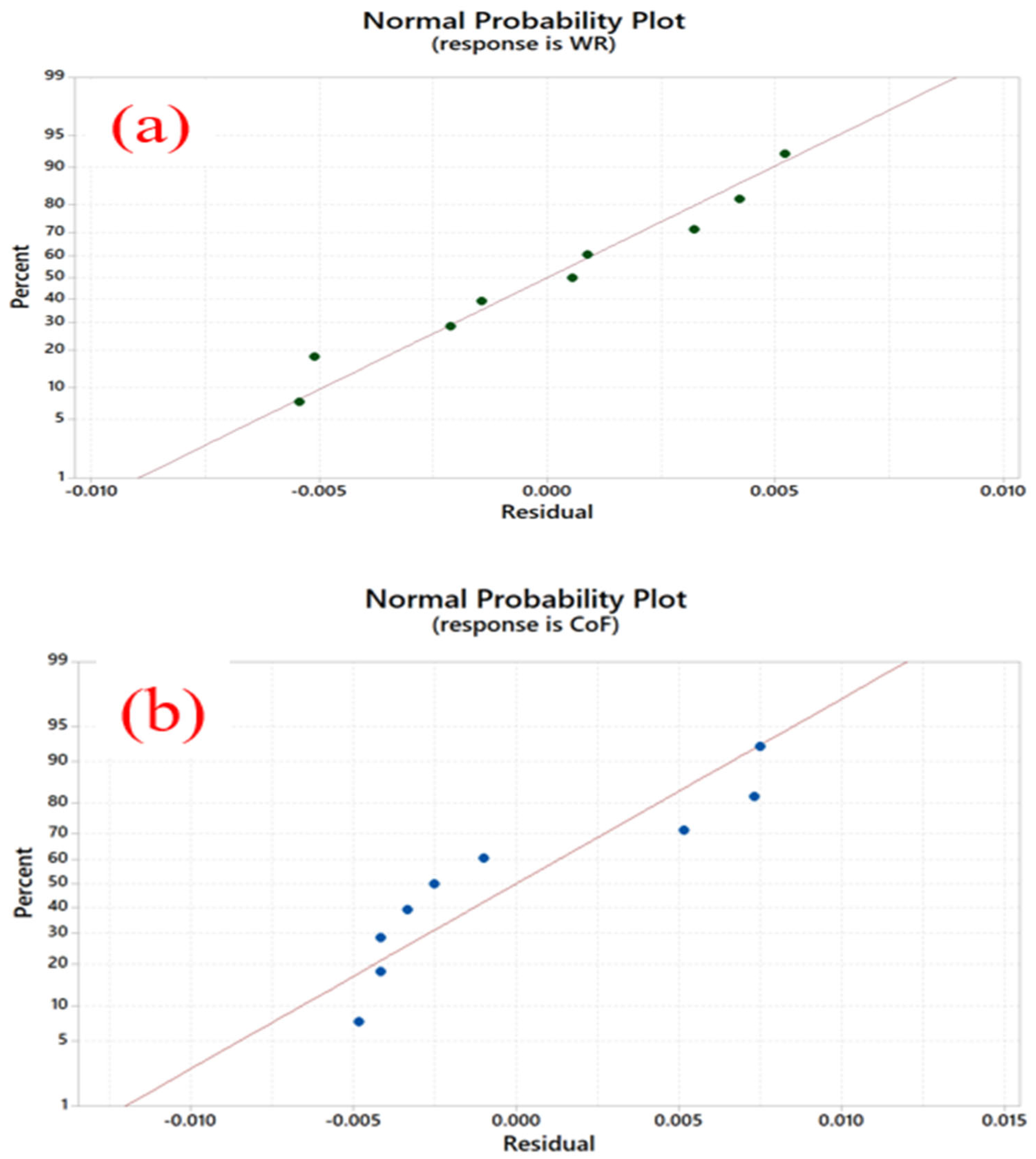

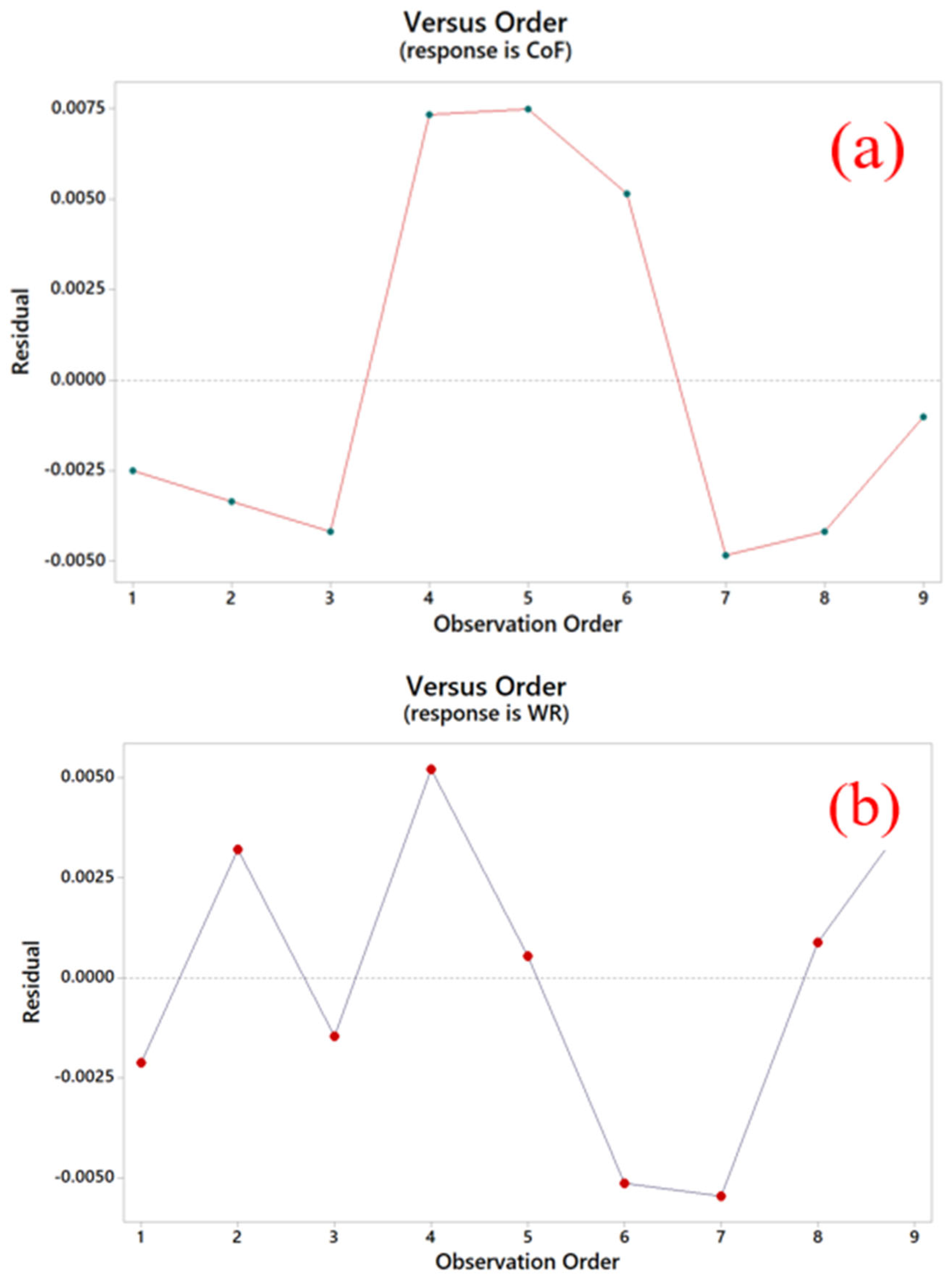

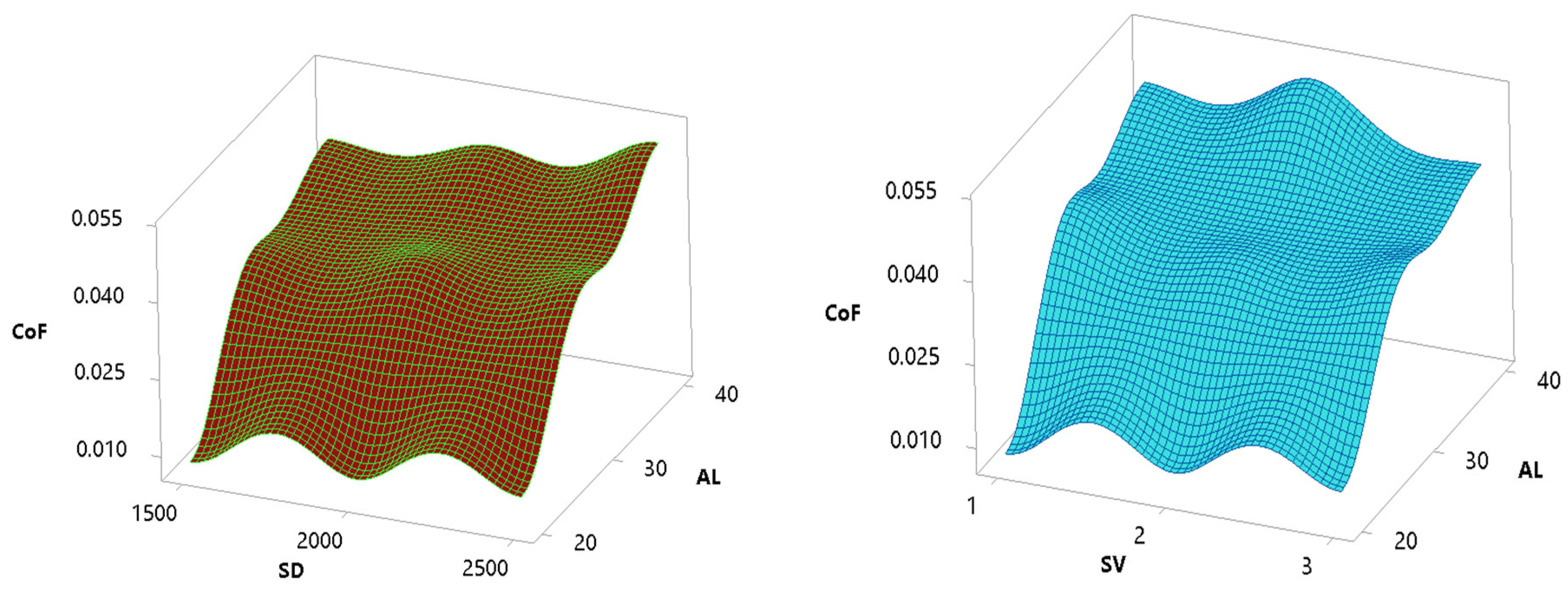

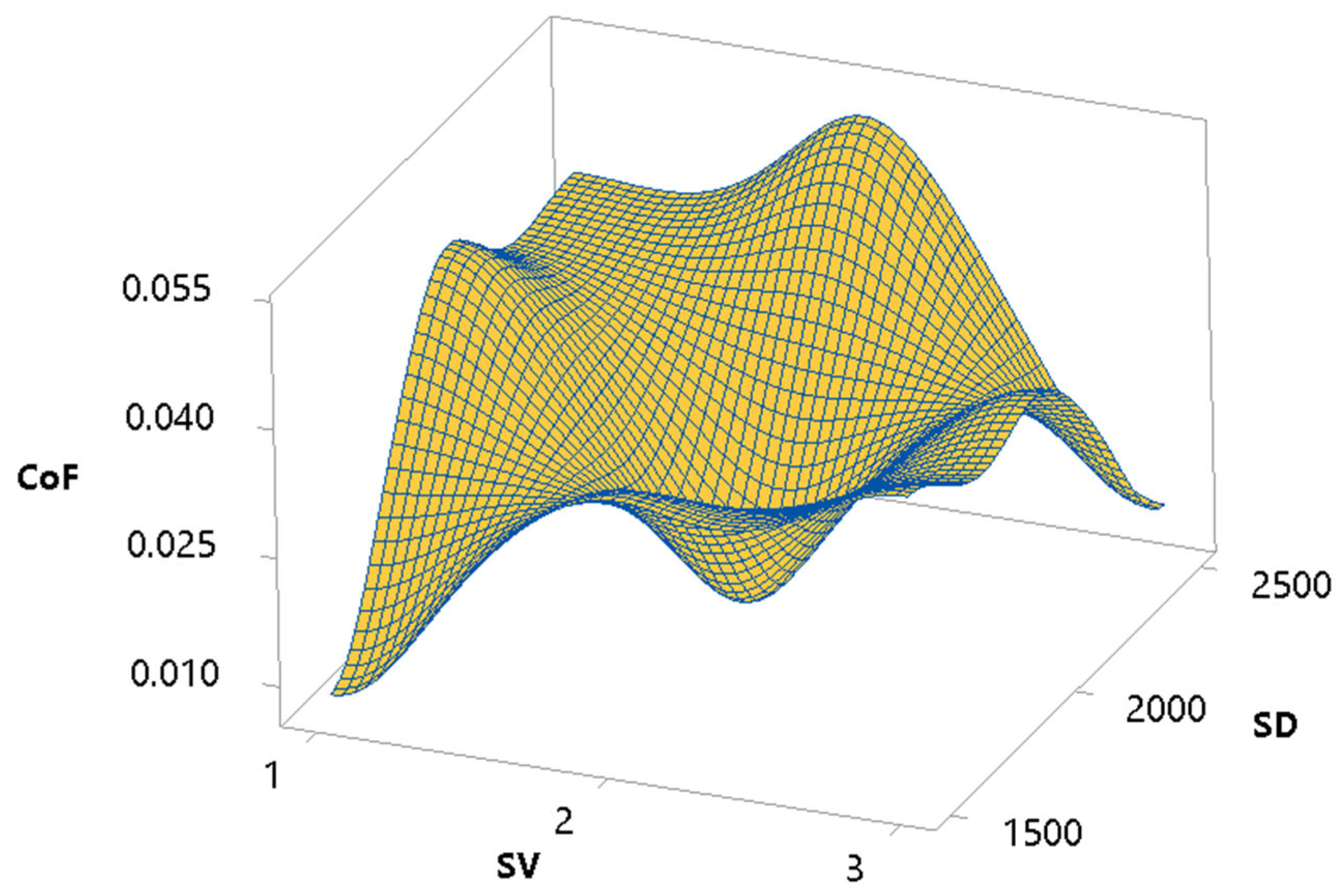

3.5. ANOVA Design of Experiments for Tribological Analysis

4. Conclusions

- 1.

- The U.T.S and % elongation for the A356-Gr were found to be increased up to the 5 wt% Gr addition, and the maximum U.T.S of 123 MPa and 7.11% elongation were attained due to strong interface bonding between Gr and the A356 alloy.

- 1.

- The presence of an Al2Mg cluster at 7.5 wt% Gr reinforcement led to a decrement in mechanical properties due to the uneven thermal expansions of the cluster and adjacent particles.

- 2.

- The obtained micro Brinell hardness at 5 wt% Gr reinforcement was 13.5%, 6.97%, and 3.37% higher than the A356 alloy, A356—2.5 wt% Gr, and A356—7.5 wt% composite.

- 2.

- The uniform dispersion of reinforcements was identified in the FESEM analysis of the A356—2.5 wt% Gr and A356—5 wt% Gr composite. However, Al2Mg clusters were confirmed in the A356—7.5 wt% Gr composite due to the non-uniform sintering, and the corresponding Al2Mg agglomeration was shown in the XRD pattern.

- 3.

- The wear rate and COF values were found to be decreased with an increase in % Gr addition due to the formation of the self-lubricated MML at the tribo interfaces. The minimum wear rate of 0.00563 g/km and COF of 0.3763 were found at 7.5 wt% Gr reinforcement with an applied load of 40 N.

- 4.

- The ANOVA results confirmed that the optimal process parameters for the minimum wear rate of 0.0052386 g/Km and 0.364 COF were 1 m/s sliding velocity, 1000 m sliding distance, and 20 N applied load conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.Q.; Afsar, A.M.; Jang, J.H.; Han, K.S.; Song, J.I. Room temperature dry and lubricant wear behaviors of Al2O3f/SiCp/Al hybrid metal matrix composites. Wear 2010, 268, 863–870. [Google Scholar] [CrossRef]

- Yadav, A.K.; Pandey, K.M.; Dey, A. Aluminium Metal Matrix Composite with Rice Husk as Reinforcement: A Review. Mater. Today Proc. 2018, 5, 20130–20137. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Deoghare, A.B. Microstructural Characterization and Mechanical Behaviour of SiC and Kaoline Reinforced Aluminium Metal Matrix Composites Fabricated Through Powder Metallurgy Technique. Silicon 2021, 14, 3723–3737. [Google Scholar] [CrossRef]

- Aydin, F.; Durgut, R.; Mustu, M.; Demir, B. Prediction of wear performance of ZK60/CeO2 composites using machine learning models. Tribol. Int. 2023, 177, 107945. [Google Scholar] [CrossRef]

- Reddy, A.P.; Krishna, P.V.; Rao, R.N. Tribological Behaviour of Al6061–2SiC-xGr Hybrid Metal Matrix Nanocomposites Fabricated through Ultrasonically Assisted Stir Casting Technique. Silicon 2019, 11, 2853–2871. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Muthuramalingam, T.; Anbuchezhiyan, G. Effect of B4C and MOS2 reinforcement on micro structure and wear properties of aluminum hybrid composite for automotive applications. Compos. Part B Eng. 2019, 176, 107329. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Deoghare, A.B. Effect of Particulate Type Reinforcements on Mechanical and Tribological Behavior of Aluminium Metal Matrix Composites: A Review. In Recent Advances in Mechanical Engineering; Pandey, K.M., Misra, R.D., Patowari, P.K., Dixit, U.S., Eds.; Springer: Singapore, 2021; pp. 295–303. [Google Scholar]

- Liu, J.; Li, Y.; Cheng, C.; Li, W.; Qin, X. Effect of temperature on the structure and mechanical properties of SiC–TiB2 composite ceramics by solid-phase spark plasma sintering. Ceram. Int. 2022, 48, 23151–23158. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Mahadevan, A.; Thangavelu, M.; Subramanian, R.; Gopalakrishnan, P. Influence of sliding speed on the dry sliding wear behaviour and the subsurface deformation on hybrid metal matrix composite. Wear 2007, 262, 1007–1012. [Google Scholar] [CrossRef]

- Singh, J. Fabrication characteristics and tribological behavior of Al/SiC/Gr hybrid aluminum matrix composites: A review. Friction 2016, 4, 191–207. [Google Scholar] [CrossRef]

- Chou, S.-N.; Huang, J.-L.; Lii, D.-F.; Lu, H.-H. The mechanical properties of Al2O3/aluminum alloy A356 composite manufactured by squeeze casting. J. Alloys Compd. 2006, 419, 98–102. [Google Scholar] [CrossRef]

- Maleki, K.; Alizadeh, A.; Hajizamani, M. Compressive strength and wear properties of SiC/Al6061 composites reinforced with high contents of SiC fabricated by pressure-assisted infiltration. Ceram. Int. 2021, 47, 2406–2413. [Google Scholar] [CrossRef]

- Ajay, C.V.; Mohammed, K.T.; Hariharasakthisudhan, P.; Kumar, V.N.; Vishnu, R. Characteristics Study of Mechanical and Tribological Behaviour of Gr/Sn Dispersed Al-7Si Alloy Matrix Composite Processed Through Bottom Pouring Stir Casting Technique. Silicon 2023, 15, 5089–5104. [Google Scholar] [CrossRef]

- Santhosh, N.; Praveena, B.A.; Jain, R.; Hasan, M.A.; Islam, S.; Khan, M.A.; Razak, A.; Daniyal, M. Analysis of friction and wear of aluminium AA 5083/WC composites for building applications using advanced machine learning models. Ain Shams Eng. J. 2023, 14, 102090. [Google Scholar] [CrossRef]

- Huang, W.; Lin, Q.; Zhang, X. Investigation of Tribological Properties of Magnesium Alloys under Dry Sliding and Lubrication Condition. Proc. Inst. Mech. Eng. Part J. 2011, 225, 35–42. [Google Scholar] [CrossRef]

- Manohar, G.; Pandey, K.M.; Maity, S.R. Effect of microwave sintering on the microstructure and mechanical properties of AA7075/B4C/ZrC hybrid nano composite fabricated by powder metallurgy techniques. Ceram. Int. 2021, 47, 32610–32618. [Google Scholar] [CrossRef]

- Manohar, G.; Pandey, K.M.; Maity, S.R. Effect of compaction pressure on mechanical properties of AA7075/B4C/graphite hybrid composite fabricated by powder metallurgy techniques. Mater. Today Proc. 2020, 38, 2157–2161. [Google Scholar] [CrossRef]

- Ramadoss, N.; Pazhanivel, K.; Anbuchezhiyan, G. Synthesis of B4C and BN reinforced Al7075 hybrid composites using stir casting method. J. Mater. Res. Technol. 2020, 9, 6297–6304. [Google Scholar] [CrossRef]

- Han, N.L.; Wang, Z.G.; Wang, W.L.; Zhang, G.D.; Shi, C.X. Low-cycle fatigue behavior of a particulate SiC/2024Al composite at ambient and elevated temperature. Compos. Sci. Technol. 1999, 59, 147–155. [Google Scholar] [CrossRef]

- Pazhouhanfar, Y.; Eghbali, B. Microstructural characterization and mechanical properties of TiB2 reinforced Al6061 matrix composites produced using stir casting process. Mater. Sci. Eng. A 2018, 710, 172–180. [Google Scholar] [CrossRef]

- Hasan, M.S.; Kordijazi, A.; Rohatgi, P.K.; Nosonovsky, M. Triboinformatics Approach for Friction and Wear Prediction of Al-Graphite Composites Using Machine Learning Methods. J. Tribol. 2022, 144, 011701. [Google Scholar] [CrossRef]

- Radhika, N.; Karthik, R.; Gowtham, S.; Ramkumar, S. Synthesis of Cu-10Sn/SiC Metal Matrix Composites and Experimental Investigation of its Adhesive Wear Behaviour. Silicon 2019, 11, 345–354. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Perumal, A.E. Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites. Compos. Part B Eng. 2013, 54, 146–152. [Google Scholar] [CrossRef]

- Kumar, H.G.P.; Xavior, M.A. Assessment of Mechanical and Tribological Properties of Al 2024-SiC-Graphene Hybrid Composites. Procedia Eng. 2017, 174, 992–999. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Deoghare, A.B. Modelling and Optimisation of Wear Parameters for Spark Plasma Sintered Al-SiC-Kaoline Hybrid Composite. Adv. Mater. Process. Technol. 2022, 8, 1286–1304. [Google Scholar] [CrossRef]

- Han, T.; Zhang, S.; Zhang, C. Unlocking the secrets behind liquid superlubricity: A state-of-the-art review on phenomena and mechanisms. Friction 2022, 10, 1137–1165. [Google Scholar] [CrossRef]

- Han, T.; Zhang, C.; Luo, J. Macroscale Superlubricity Enabled by Hydrated Alkali Metal Ions. Langmuir 2018, 34, 11281–11291. [Google Scholar] [CrossRef]

| Element | Si | Ti | Mg | C | Fe | Remaining |

|---|---|---|---|---|---|---|

| Wt% | 6.56 | 0.06 | 0.36 | 1.65 | 0.08 | Aluminium |

| Composite Code | wt% of A356 | wt% of Graphite Reinforcement |

|---|---|---|

| A356 | 100 | 0 |

| C1 | 97.5 | 2.5 |

| C2 | 95 | 5 |

| C3 | 92.5 | 7.5 |

| Applied Load (AL in Newtons) | Sliding Distance (SL in Meters) | Sliding Velocity (SL in m/s) |

|---|---|---|

| 20 | 1500 | 1 |

| 30 | 2000 | 2 |

| 30 | 2500 | 3 |

| Run Number | Applied Load (N) | Sliding Distance (m) | Sliding Velocity (m/s) | COF | Wear Rate (g/km) |

|---|---|---|---|---|---|

| 1 | 20 | 1500 | 1 | 0.008 | 0.26 |

| 2 | 20 | 2000 | 2 | 0010 | 0.28 |

| 3 | 20 | 2500 | 3 | 0.012 | 0.29 |

| 4 | 30 | 1500 | 2 | 0.036 | 0.3 |

| 5 | 30 | 2000 | 3 | 0.039 | 0.31 |

| 6 | 30 | 2500 | 1 | 0.04 | 0.318 |

| 7 | 40 | 1500 | 3 | 0.042 | 0.322 |

| 8 | 40 | 2000 | 1 | 0.046 | 0.342 |

| 9 | 40 | 2500 | 2 | 0.052 | 0.36 |

| Source | DOF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Applied Load (AL) | 2 | 0.006273 | 0.003136 | 227.65 | 0.004 |

| Sliding Distance (SD) | 2 | 0.001244 | 0.000622 | 45.13 | 0.022 |

| Sliding Velocity (SV) | 2 | 0.000081 | 0.000040 | 2.94 | 0.254 |

| Error | 2 | 0.000028 | 0.000014 | ||

| Total | 8 | 0.007625 |

| Source | DOF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Applied Load (AL) | 2 | 0.002217 | 0.001108 | 255.77 | 0.004 |

| Sliding Distance (SD) | 2 | 0.000054 | 0.000027 | 6.23 | 0.038 |

| Sliding Velocity (SV) | 2 | 0.000005 | 0.000002 | 0.54 | 0.650 |

| Error | 2 | 0.000009 | 0.000004 | ||

| Total | 8 | 0.002284 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venkatesh, V.S.S.; Vundavilli, P.R. Mechanical Properties and Tribological Study of Bottom Pouring Stir-Cast A356 Alloy Reinforced with Graphite Solid Lubricant Extracted from Corn Stover. Lubricants 2024, 12, 341. https://doi.org/10.3390/lubricants12100341

Venkatesh VSS, Vundavilli PR. Mechanical Properties and Tribological Study of Bottom Pouring Stir-Cast A356 Alloy Reinforced with Graphite Solid Lubricant Extracted from Corn Stover. Lubricants. 2024; 12(10):341. https://doi.org/10.3390/lubricants12100341

Chicago/Turabian StyleVenkatesh, Vavilada Satya Swamy, and Pandu Ranga Vundavilli. 2024. "Mechanical Properties and Tribological Study of Bottom Pouring Stir-Cast A356 Alloy Reinforced with Graphite Solid Lubricant Extracted from Corn Stover" Lubricants 12, no. 10: 341. https://doi.org/10.3390/lubricants12100341

APA StyleVenkatesh, V. S. S., & Vundavilli, P. R. (2024). Mechanical Properties and Tribological Study of Bottom Pouring Stir-Cast A356 Alloy Reinforced with Graphite Solid Lubricant Extracted from Corn Stover. Lubricants, 12(10), 341. https://doi.org/10.3390/lubricants12100341