Thermal–Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair of Balanced Double-Row Axial Piston Pumps

Abstract

1. Introduction

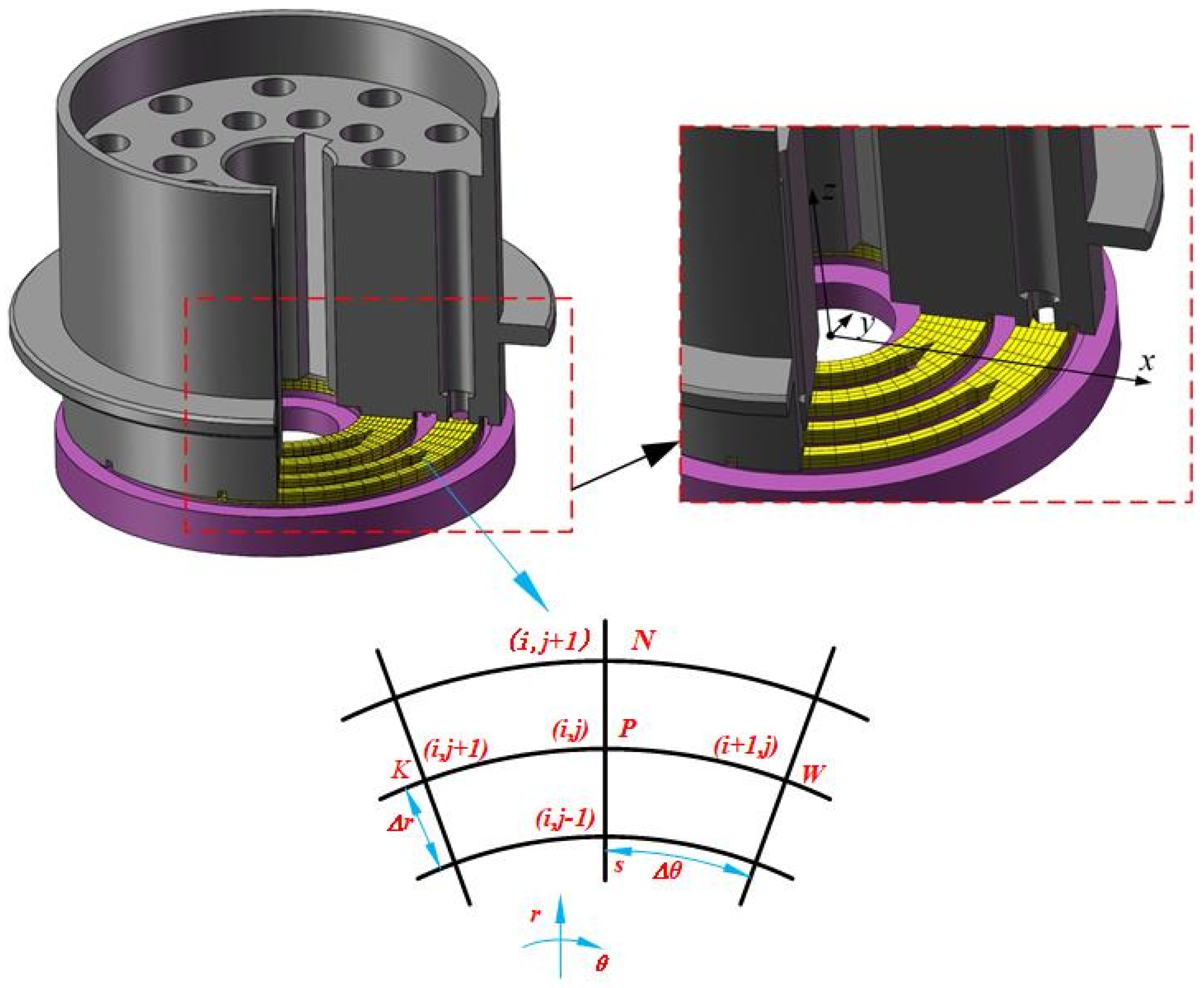

2. Thermal EHL Model of Flow Distribution Pair

2.1. Oil Film Pressure Governing Equations

2.2. Energy Equation

2.3. Thermal Conduction Equation

2.4. Model Discretization and Numerical Solution

2.5. Boundary Conditions of Port Pair of Balanced Double-Row Axial Piston Pump

2.5.1. Pressure Boundary Conditions

- (1)

- Forced boundary conditions

- (2)

- Natural boundary conditions

2.5.2. Thermal Boundary Conditions

- (1) fluid boundary

- (2) solid boundaryThe solid thermal boundary condition of the oil film is

3. Influence of Flow Distribution Pair on Thermal Elastohydrodynamic Lubrication Characteristics

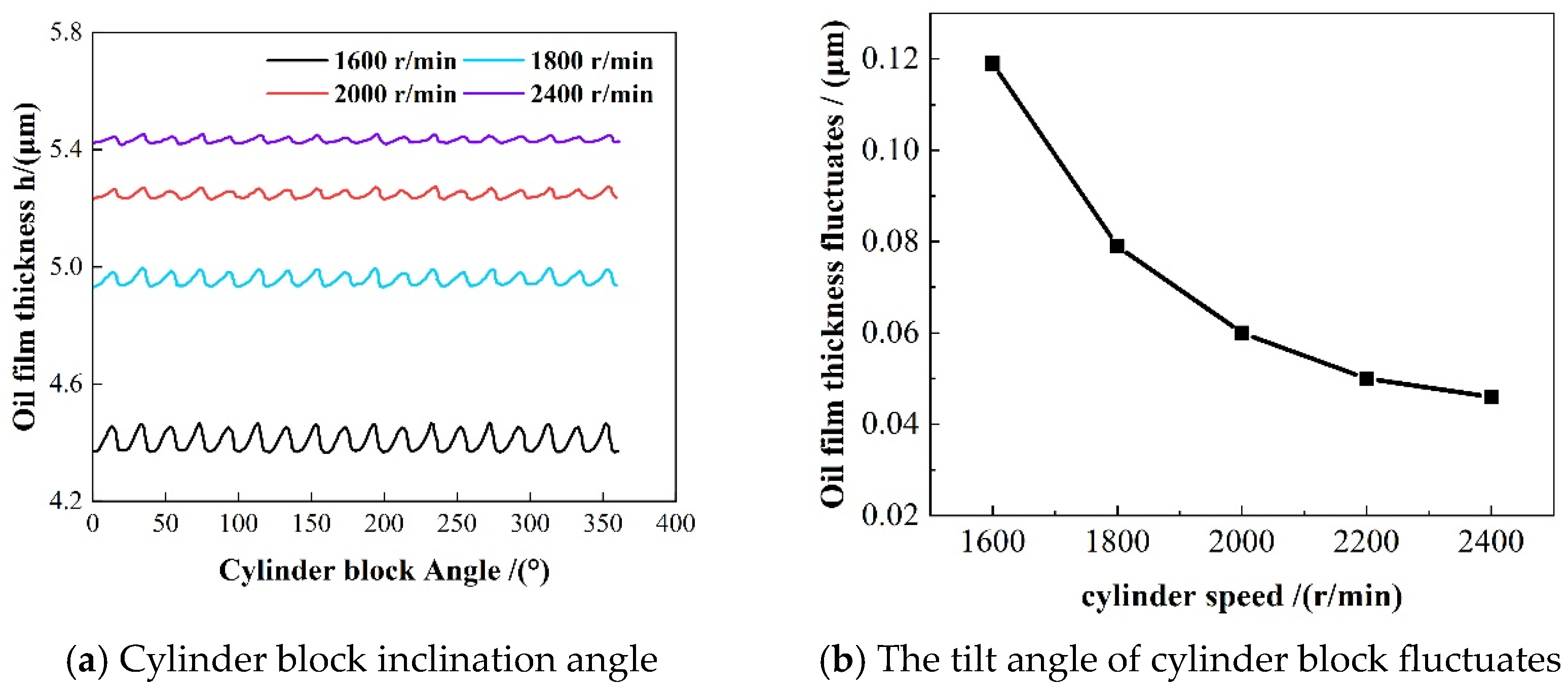

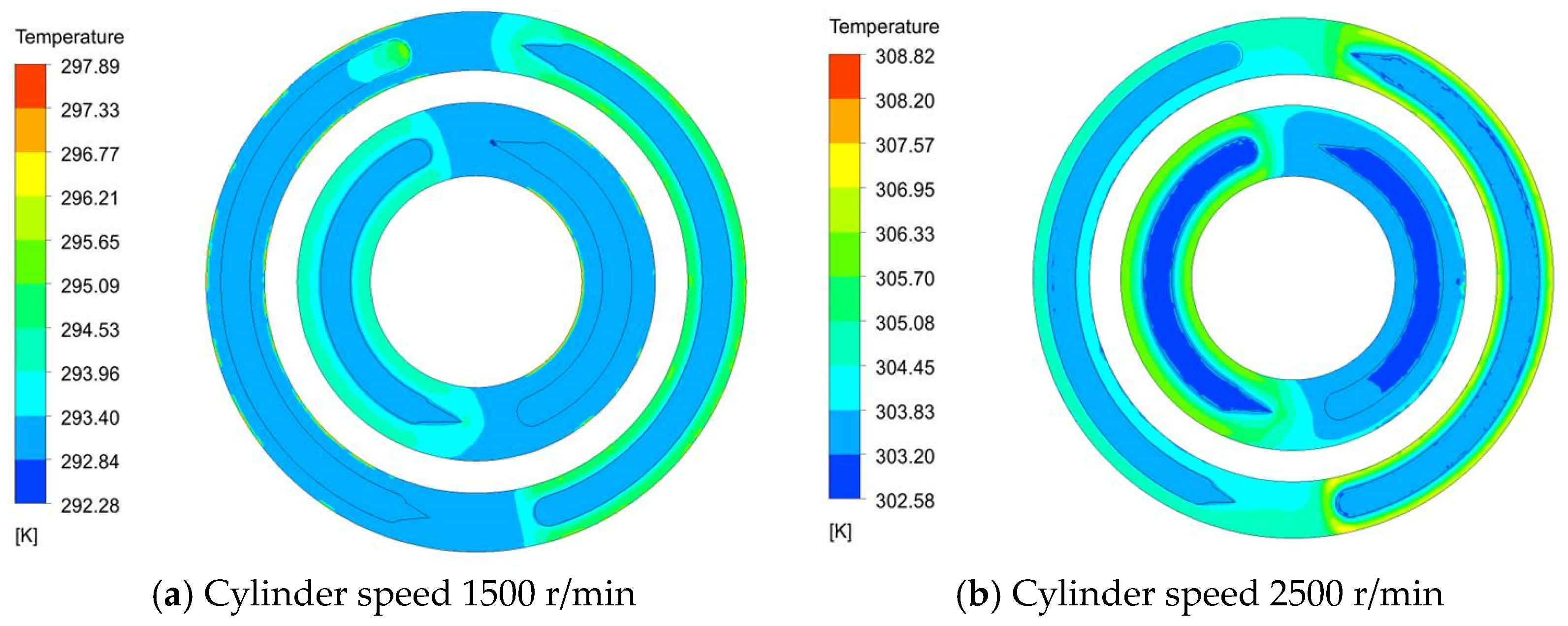

3.1. Influence of Cylinder Speed on Thermal Elastohydrodynamic Lubrication Characteristics of Flow Distribution Pair

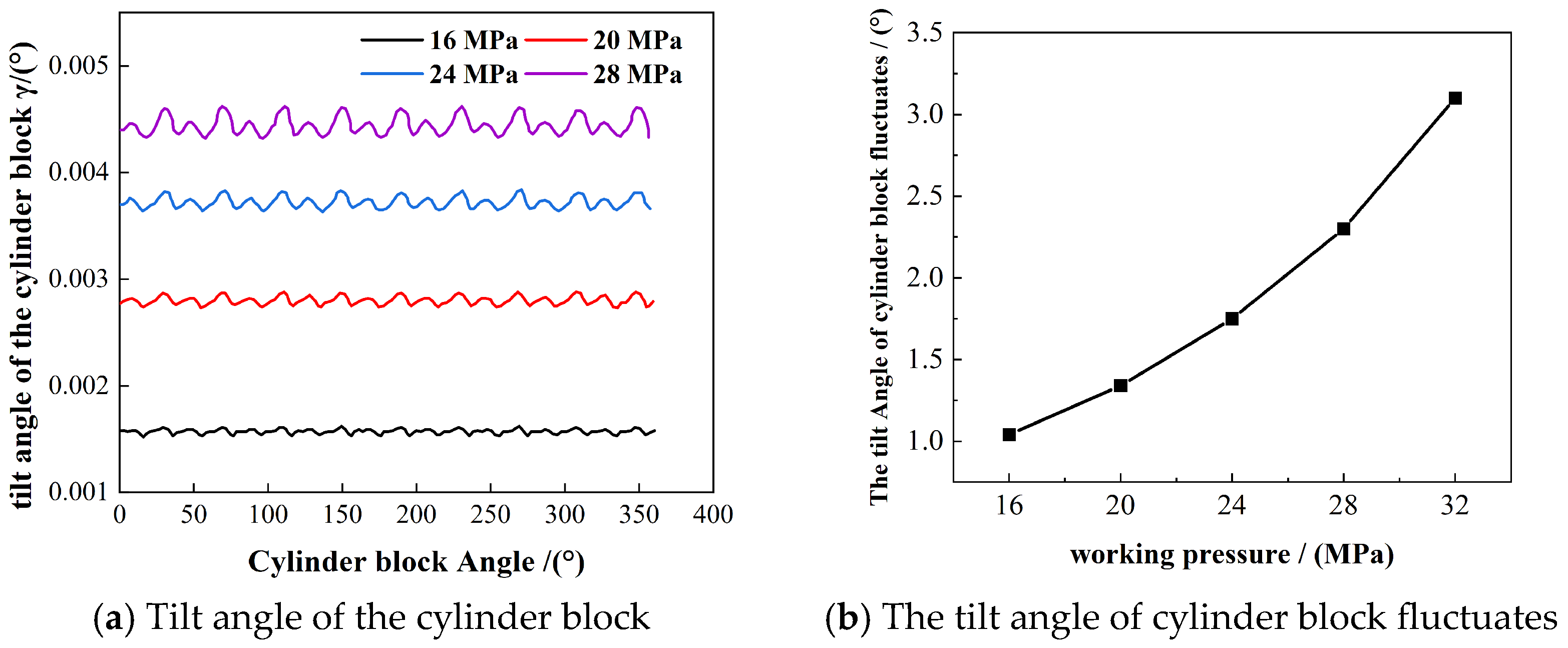

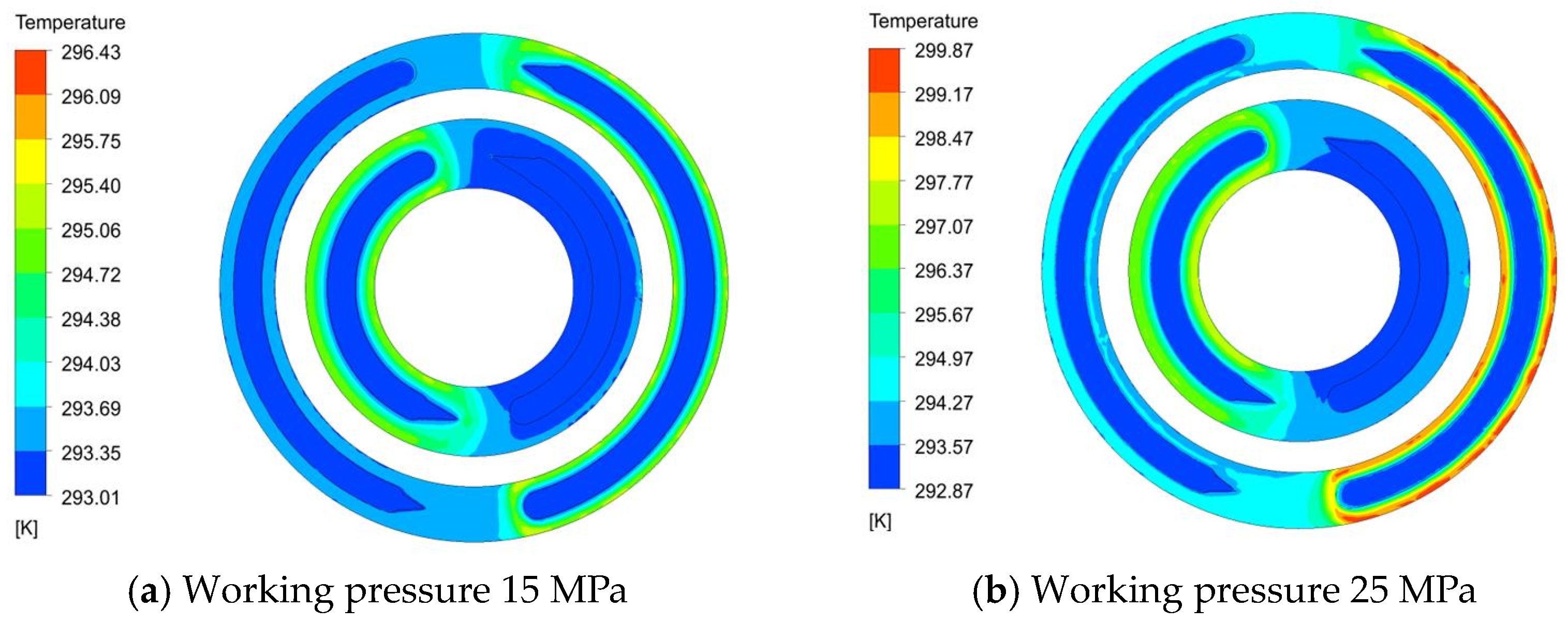

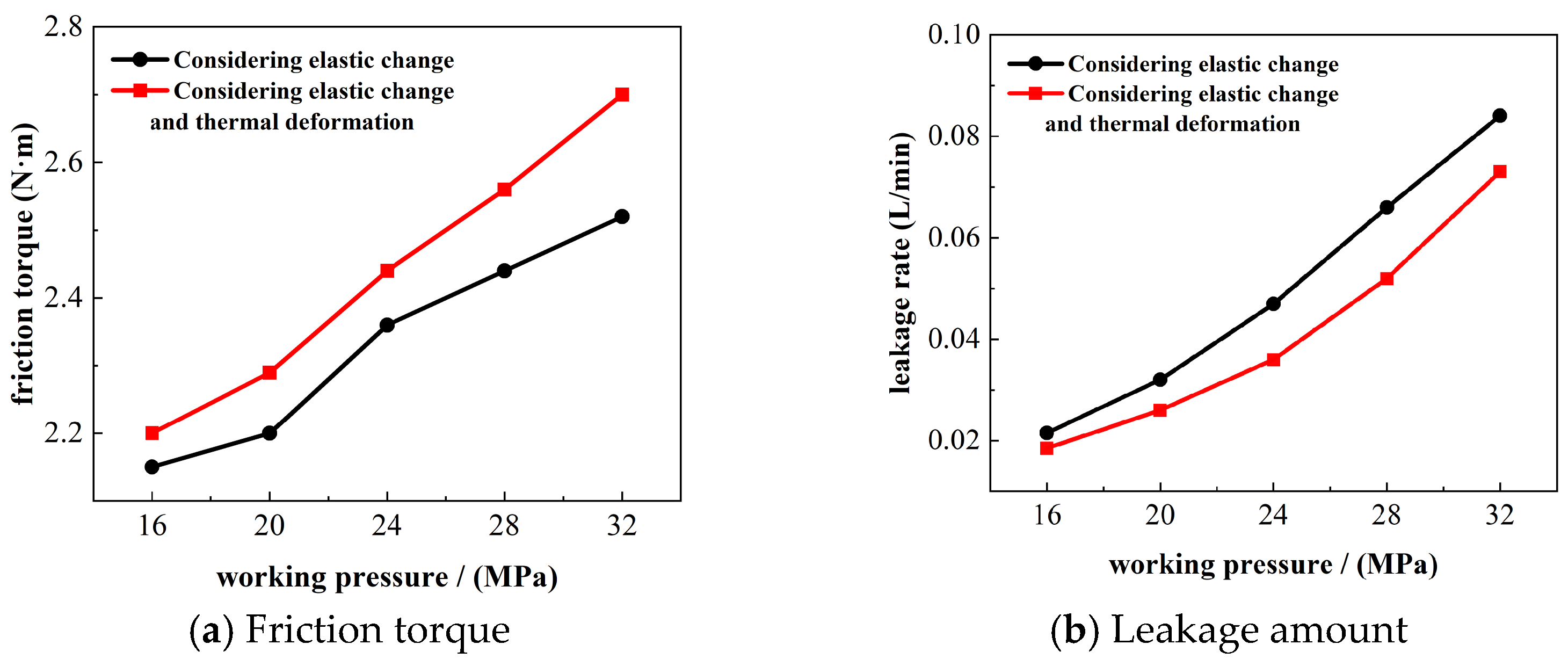

3.2. Influence of Working Pressure on Thermal Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair

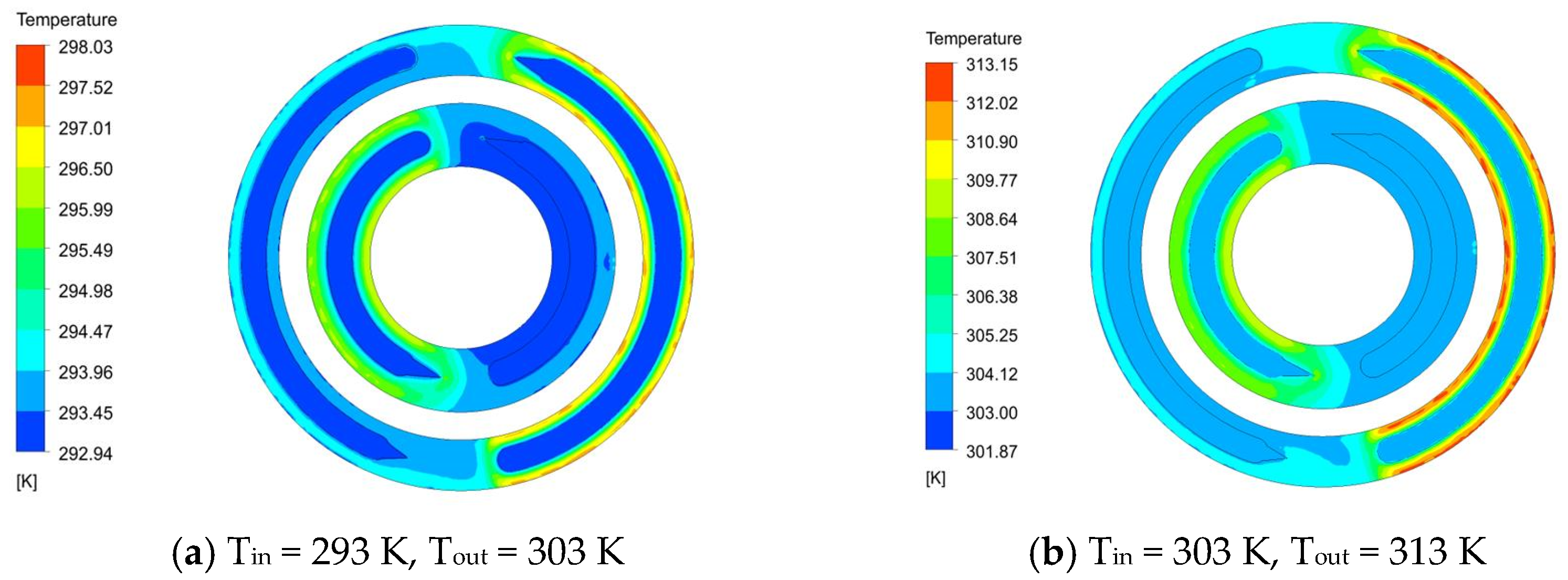

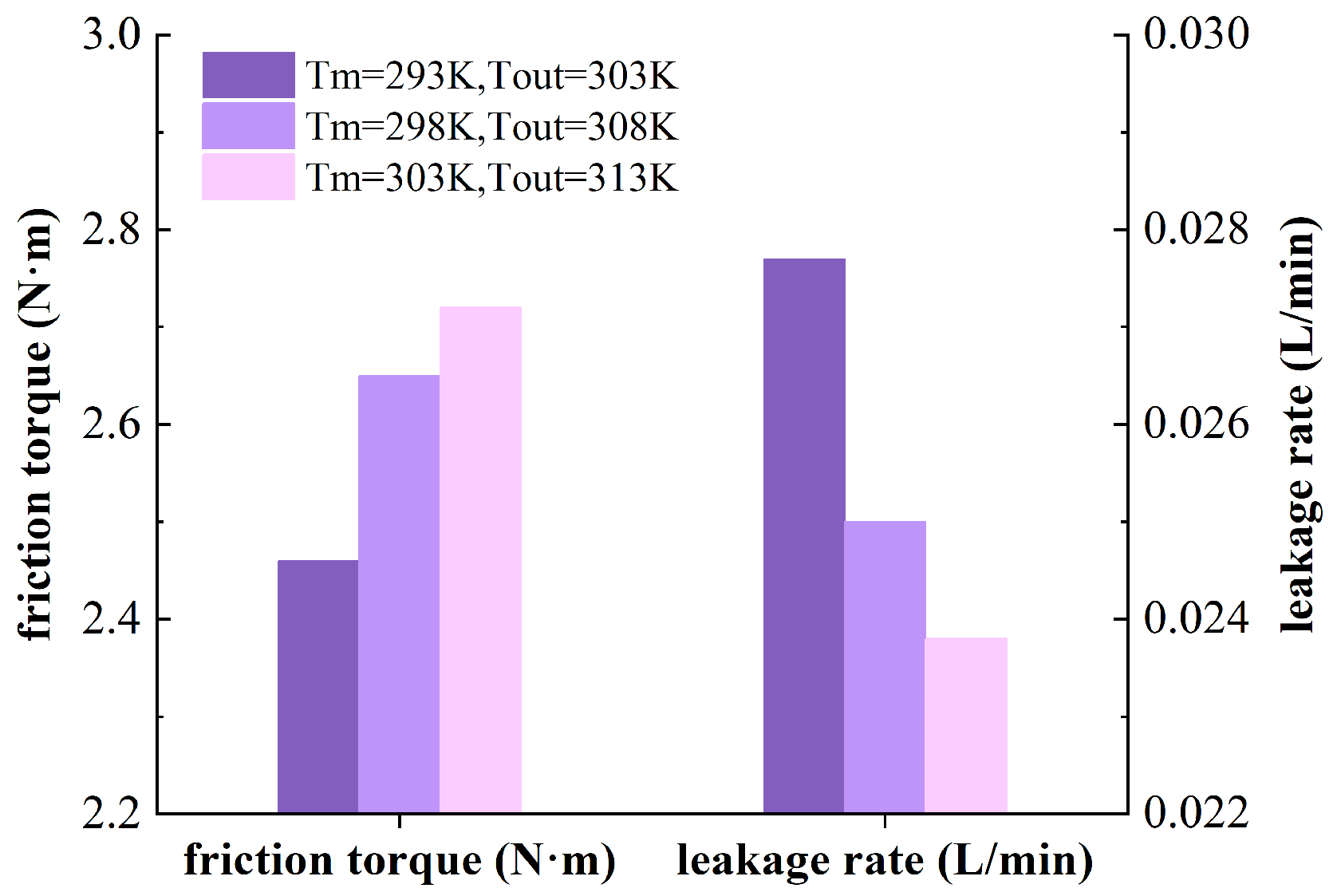

3.3. Influence of Temperature on Thermal Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair

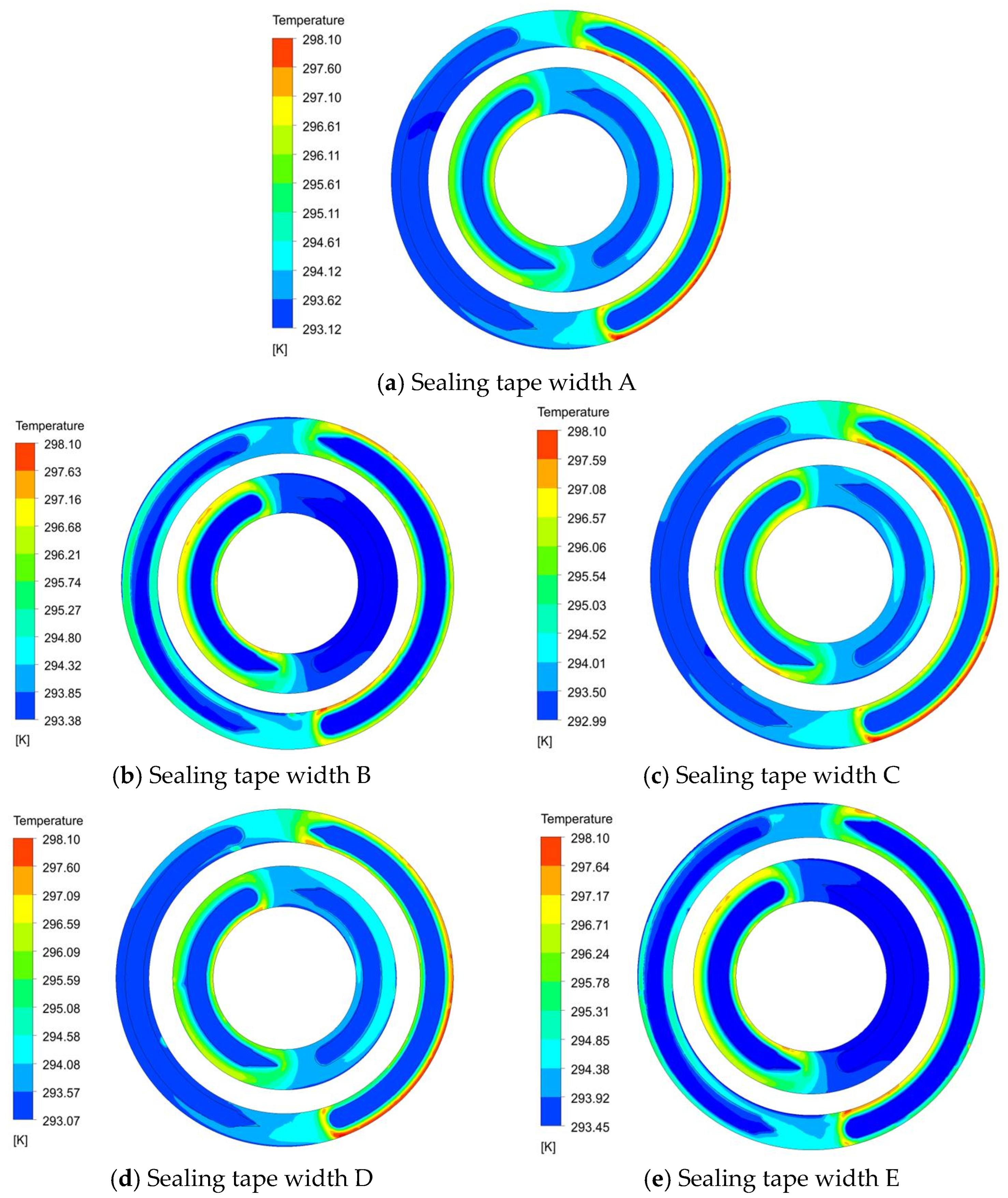

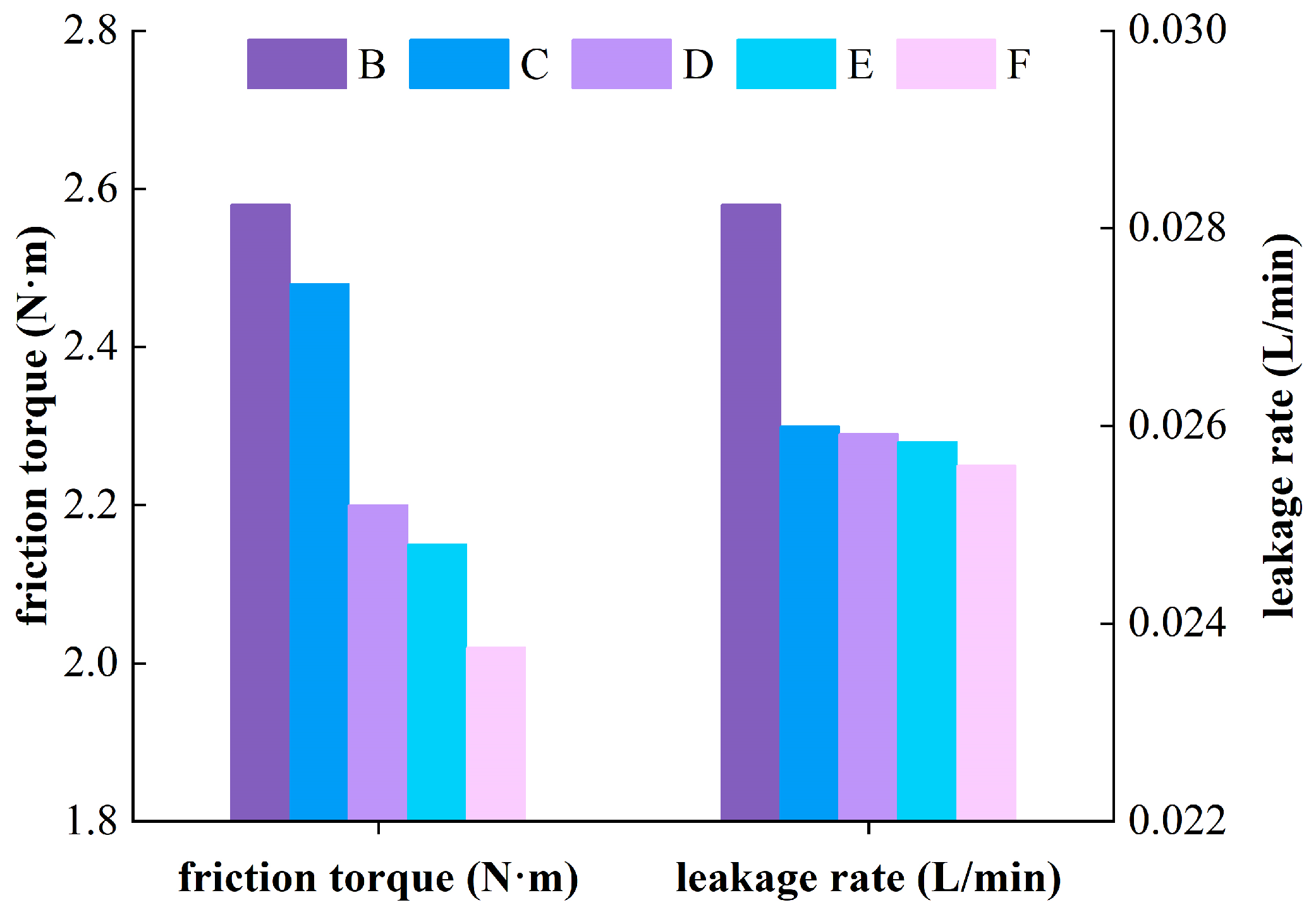

3.4. Influence of Sealing Belt Width on Thermal Elastohydrodynamic Lubrication Characteristics of Flow Distribution Pair

4. Discussion

5. Conclusions

- (1)

- The oil film thickness of the flow distribution pair and the tilt angle of the cylinder block change periodically with 40° in a working cycle. The average oil film thickness of the flow distribution pair increases with the increase in the cylinder speed, and its fluctuation decreases. The tilt angle of the cylinder block and its fluctuation amplitude decrease with the increase in rotational speed. As the working pressure increases, the average oil film thickness decreases, while the variation in oil film thickness increases. The tilt angle of the cylinder block and its fluctuation amplitude increase with the increase in working pressure.

- (2)

- The increase in the cylinder speed will increase the friction torque of the flow distribution pair, increase the viscous friction dissipation, increase the heat production, and cause the oil film temperature to increase. An increase in rotational speed results in a thicker oil film, which enhances the radial velocity of the oil film and subsequently leads to increased leakage. The increase in working pressure will cause the decrease in oil film thickness, increase the shear stress of oil film, increase the friction force of oil film, increase the dissipation of viscous friction, and cause the increase in oil film temperature. The increase in pressure will cause the increase in radial pressure difference velocity of oil film and the increase in leakage.

- (3)

- Temperature is a crucial factor that influences the oil film lubrication performance of the flow distribution pair. When the working temperature of the piston pump increases, the oil film thickness decreases, the friction torque increases, and the oil film temperature increases. In addition, the oil film thickness decreases, the effect of the oil film pressure difference decreases, the radial flow rate decreases, and the leakage decreases.

- (4)

- The appropriate width of the sealing belt significantly impacts the lubrication performance of the flow distribution pair. Reducing the width of the sealing belt will cause the total contact area of the oil film to decrease, resulting in a decrease in the friction torque of the flow distribution pair and a decrease in the oil film temperature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, X. Lubrication Characteristics Analysis of Four Valve Valve Axial Piston Pump Valve Pair. Master’s Thesis, Taiyuan University of Science and Technology, Tai Yuan Shi, China, 2021. Available online: https://link.cnki.net/doi/10.27721/d.cnki.gyzjc.2021.000227doi:10.27721/d.cnki.gyzjc.2021.00022 (accessed on 3 September 2024). [CrossRef]

- Tang, H.; Yin, Y.; Zhang, Y.; Li, J. Parametric analysis of thermal effect on hydrostatic slipper bearing capacity of axial piston pump. J. Cent. South Univ. 2016, 23, 333–343. [Google Scholar] [CrossRef]

- Ye, S.; Zhang, J.; Xu, B. Noise reduction of anaxial piston pump by valve plate optimization. Chin. J. Mech. Eng. 2018, 31, 1–16. [Google Scholar] [CrossRef]

- Zhang, S. Cavitation Research and Structural Transformation of Valve Plate of Axial Piston Pump. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2021. [Google Scholar]

- Yan, W. Study on Anti-Overturning Stability and Oil Film Lubrication Characteristics of Axial Piston Pump. Ph.D. Thesis, Harbin University of Technology, Harbin, China, 2020. [Google Scholar]

- Wang, Y.; Wang, Z.; Zhang, J. The influence of flow distribution pair parameters on friction performance of piston pump under thermal-fluid-solid coupling. Lubr. Seal. 2021, 46, 65–71. [Google Scholar]

- Baker, J.; Ivantysynova, M. Power loss in the lubricating gap between cylinders block and valve plate of swash plate type axial piston machines. Int. J. Fluid Power 2009, 10, 29–43. [Google Scholar]

- Li, W.; Liu, X.; Long, T.; Guo, F. Numerical Analysis of Non-Newtonian Elliptic Contact Thermoelastohydrodynamic Lubrication under Spinning and Sliding Conditions. Lubrication and Sealing, 1–10 [2024-10-01]. Available online: https://kns.cnki.net/kcms2/article/abstract?v=KzQCREa95bEa-KEgBmdHHReop7o9MRx-bnEauMQyMT6s7Bf13QvH7pInfebJry4jufamNN3Js8W59PpjP2xSOtYGPpzCJG3ug9x3Itfntu2XhHKNyeeUmRyDpyzoTaTneAUF_N2IqNoKyZkzimEGse_ydh8GH2pRMF0TEDp_j1a92Wt6Gxh1XwYgPewOiyWK&uniplatform=NZKPT&language=CHS (accessed on 3 September 2024).

- Chacon, R.; Ivantysynova, M. An Investigation of the Impact of Micro Surface on the Cylinder Block/Valve Plate Interface Performance. In Proceedings of the 8th FPNI Ph.D Symposium on Fluid Power, Lappeenranta, Finland, 11–13 June 2014; ASME: NEW York, NY, USA, 2014; p. V001T02A006. [Google Scholar] [CrossRef]

- Hu, S.; Wang, Z.; Ji, H.; Yang, J.; Zhang, H. Thermal-fluid-solid coupling lubrication characteristics of micro-textured port plate. Hydraul. Pneum. 2019, 12, 38–45. [Google Scholar]

- Ki Kim, J.; Jung, J.Y. Measurement of Fluid Thickness on the Valve Plate in Oil Hydraulic Axial Piston Pumps (Ⅱ): Spherical Design Effects. J. Mech. Sci. Technol. 2005, 19, 655–663. [Google Scholar] [CrossRef]

- Han, L.; Wang, S.; Zhang, C. A partial lubrication model between valve plate and cylinder block in axial piston pumps. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 3201–3217. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, S.; Ji, H.; Wang, Z.; Liu, X. Analysis of lubricating characteristics of valve plate pair of a piston pump. Tribol. Int. 2018, 126, 49–64. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Han, B.; Sun, L.; Gao, W. Lubrication characteristics of piston pump/motor port plate pair based on fractal theory. Lubr. Seal. 2023, 48, 68–74. [Google Scholar]

- Hou, L.; Lai, W.; Cui, K.; Ye, S.; Guo, Z.; Bu, X. Modeling and analysis of oil film lubrication characteristics of plane port plate pair of axial piston motor. J. South China Univ. Technol. (Nat. Sci. Ed.) 2021, 49, 99–109. [Google Scholar]

- Hu, J.; Zou, Y.; Li, X.; Lin, S. Effect of elastic deformation on lubrication characteristics of port plate pair in axial piston pump. Agric. Eng. J. 2009, 25, 114–118. [Google Scholar]

- Lu, R.; Tang, W.; Huang, Q.; Xie, J. An Improved Load Distribution Model for Gear Transmission in Thermal Elastohydrodynamic Lubrication. Lubricants 2023, 11, 177. [Google Scholar] [CrossRef]

- Xu, Y.; Deng, X.; Wang, S.; Ren, J.; Yang, H. Thermal elastohydrodynamic lubrication analysis of the roller enveloping hourglass worm drives considering the roller self-rotation behavior. Tribol. Int. 2024, 200, 110142. [Google Scholar] [CrossRef]

- Bergada, J.M.; Kumar, S.; Davies, D.L.; Watton, J. A complete analysis of axial piston pump leakage and output flow ripples. Appl. Math. Model. 2012, 36, 1731–1751. [Google Scholar] [CrossRef]

- Tang, H.; Ren, Y.; Xiang, J. A novel model for predicting thermoelastohydrodynamic lubrication characteristics of slipper pair in axial piston pump. Int. J. Mech. Sci. 2017, 124–125, 109–121. [Google Scholar] [CrossRef]

- Deng, H.; Wang, C.; Zhang, L. Study on flow pulsation of balanced two-row axial piston pump. J. Agric. Mach. 2014, 45, 305–309. [Google Scholar]

- Wang, Y.; Tang, W.; Chen, Y.; Wang, T.; Li, G.; Ball, A.D. Investigation into the meshing friction heat generation and transient thermal characteristics of spiral bevel gears. Appl. Therm. Eng. 2017, 119, 245–253. [Google Scholar] [CrossRef]

- Chen, J.; Liu, X.; Pei, X.; Wang, H. Effect of Viscous and Compressive Properties of Ionic Liquid Additives on Thermoelastohydrodynamic Lubrication. Lubrication and Sealing, 1–15 [2024-10-01]. Available online: https://kns.cnki.net/kcms2/article/abstract?v=KzQCREa95bFlYpN4H4fsaTBTtRFhR4xneXRN3G4balP1QVqQVAwgT10W4y37EoPkUzFnmdcSIkmoOOklsBhTIR4MSizuQHiqgZnDIDX98u0SK3P0WHucgHxmtSv79cpHnekAjXGI4aUzRSNnhVOJa6kPJLc2w_fbMxzypSRjnF3WJ_th2-nswW_IRARMcBPn&uniplatform=NZKPT&language=CHS (accessed on 3 September 2024).

- Li, C.; Jiang, T.; Liu, C.; Xu, H.; Shi, G. Investigation of the leakage in the flow distribution pair of radial piston hydraulic motors through CFD analysis and experiments. Flow Meas. Instrum. 2024, 96, 102555. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, C.; He, T.; Luo, G.; Qin, Y.; Fang, S. Theoretical and experimental study on lubrication and friction of slipper pair of valve distribution piston pump based on FVM-TRD coupling method. Tribol. Int. 2024, 194, 109456. [Google Scholar] [CrossRef]

- Pan, Y.; Chen, A.; Wang, Z. Fluid Dynamic Characteristics and Flow Distribution Structure Optimization of Axial Piston Pump Considering Cavitation Bubble Evolution. J. Appl. Fluid Mech. 2021, 14, 1603–1616. [Google Scholar]

- Ghiaasiaan, S. Convective Heat and Mass Transfer; Cambridge University Press: Cambridge, UK, 2011; p. 477. [Google Scholar]

- Gan, L.; Xiao, K.; Wang, J.; Cao, W.; Wang, J. A numerical method to investigate the temperature behavior of spiral bevel gears under mixed lubrication condition. Appl. Therm. Eng. 2019, 147, 866–875. [Google Scholar] [CrossRef]

- Ivantysyn, J.; Ivantysynova, M. Hydrostatic Pumps and Motors: Principle, Design, Performance, Modeling, Analysis, Control and Testing; Tech Books International: New Delhi, India, 2002. [Google Scholar]

- Ye, S.; Lai, W.; Hou, L.; Bu, X. Modeling and experimental verification of lubrication characteristics of conical cylinder block spherical port pair. China Mech. Eng. 2022, 33, 2420–2428+2436. [Google Scholar]

- Hamrock, B.; Schmid, S.; Jacobson, B. Fundamentals of Fluid Film Lubrication; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Richardson, D.; Sadeghi, F.; Rateick, R.G., Jr.; Rowan, S. Experimental and Analytical Investigation of Floating Valve Plate Motion in an Axial Piston Pump. Tribol. Trans. 2017, 60, 537–547. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, J.; Jing, C.; Wei, C. Dynamic pressure support characteristics of slotted port pair of axial piston pump. J. Harbin Inst. Technol. 2018, 50, 169–174. [Google Scholar]

| Parameter | Numerical Value |

|---|---|

| Viscous draining pressure ph | 20 MPa |

| Fuel inlet pressure pt | 0.2 MPa |

| Block rotation speed n | 2000 r/min |

| Oil inlet temperature Tin | 293 K |

| Oil outlet temperature Tout | 303 K |

| Specific heat capacity of lubricating oil cp | 1885 J·kg−1·K−1 |

| Thermal conductivity of lubricating oil | 0.14 W·m−1·K−1 |

| Viscosity-pressure coefficient of lubricating oil | 2.2 × 108 Pa−1 |

| Viscosity-temperature coefficient of lubricating oil | 0.047 K−1 |

| Part | Cylinder Block | Plate Type Rheostat Valve |

|---|---|---|

| Material | 42CrMo steel | HMn58-2 |

| Elastic modulus (Pa) | 2.12 × 1011 | 1.05 × 1011 |

| Poisson ratio | 0.280 | 0.350 |

| Density ρ (kg/m3) | 7850 | 8410 |

| Thermal expansion coefficient (K−1) | 1.10 × 10−5 | 1.90 × 10−5 |

| Specific heat (J·kg−1·K−1) | 460 | 394 |

| Thermal conductivity (W·m−1·K−1) | 42.0 | 92.8 |

| A | B | C | D | E | |

|---|---|---|---|---|---|

| Inner sealing bands of the inner rows/(mm) | 3.5 | 2.5 | 3.5 | 3.5 | 3.5 |

| Outer sealing bands of the inner rows/(mm) | 3.5 | 3.5 | 2.5 | 3.5 | 3.5 |

| Inner sealing bands of the outer rows/(mm) | 2.5 | 2.5 | 2.5 | 1.5 | 2.5 |

| Outer sealing bands of the outer rows/(mm) | 2.5 | 2.5 | 2.5 | 2.5 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, H.; Guo, B.; Huang, Z.; Xu, P.; Zhu, P. Thermal–Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair of Balanced Double-Row Axial Piston Pumps. Lubricants 2024, 12, 342. https://doi.org/10.3390/lubricants12100342

Deng H, Guo B, Huang Z, Xu P, Zhu P. Thermal–Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair of Balanced Double-Row Axial Piston Pumps. Lubricants. 2024; 12(10):342. https://doi.org/10.3390/lubricants12100342

Chicago/Turabian StyleDeng, Haishun, Binbin Guo, Zhixiang Huang, Pan Xu, and Pengkun Zhu. 2024. "Thermal–Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair of Balanced Double-Row Axial Piston Pumps" Lubricants 12, no. 10: 342. https://doi.org/10.3390/lubricants12100342

APA StyleDeng, H., Guo, B., Huang, Z., Xu, P., & Zhu, P. (2024). Thermal–Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair of Balanced Double-Row Axial Piston Pumps. Lubricants, 12(10), 342. https://doi.org/10.3390/lubricants12100342