Abstract

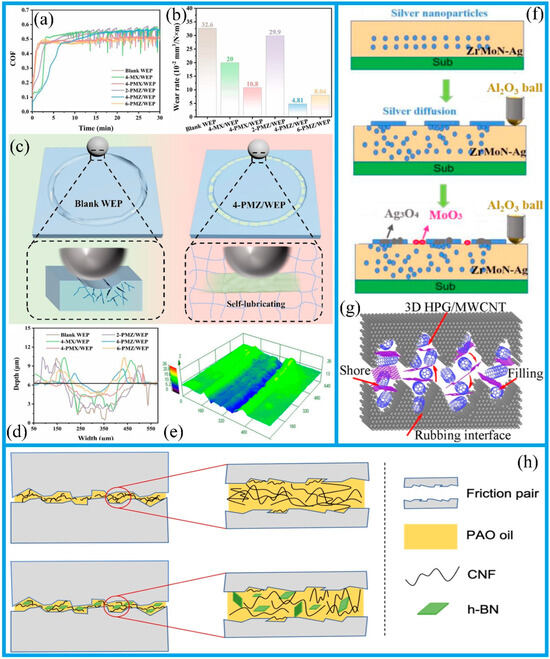

An investigation of the interaction between multidimensional nano-additives and tribofilms is crucial for enhancing mechanical efficiency, extending equipment lifespan, and reducing environmental impacts. Improved tribofilm performance is obtained via several mechanisms: filling surface defects with 0D nano-additives, directional lubrication for 1D nano-additives, interlayer slippage for 2D nano-additives, and improved film durability for 3D nano-additives. Under dry lubrication, the formation of tribofilms via mechanical mixing is influenced by material hardness, surface roughness, and frictional conditions, with their thicknesses increasing by 20–30% under high loading. Conversely, liquid-lubricated films result from the physical adsorption and chemical reactions of the lubricants, with extremely high pressure additives reducing the friction coefficient by 30–50% at high pressure. A greater understanding of these mechanisms is beneficial for optimizing industrial technologies and developing efficient, eco-friendly lubrication systems.

1. Introduction

Amidst the ongoing developments in engineering technologies, and with the continuous extension of their application fields, the demand for materials with properties of wear-resistance is increasing [1,2,3,4,5]. The performances of wear-resistant materials not only directly affect the service life and reliability of mechanical equipment but also relates to engineering costs and resource utilization efficiency [6,7]. To satisfy the needs of different fields, a variety of new wear-resistant materials and design strategies continue to emerge. In the design of wear-resistant materials, nanomaterials, as important functional materials, have shown great potential in increasing the wear resistance of materials due to their unique structures and properties [8,9,10].

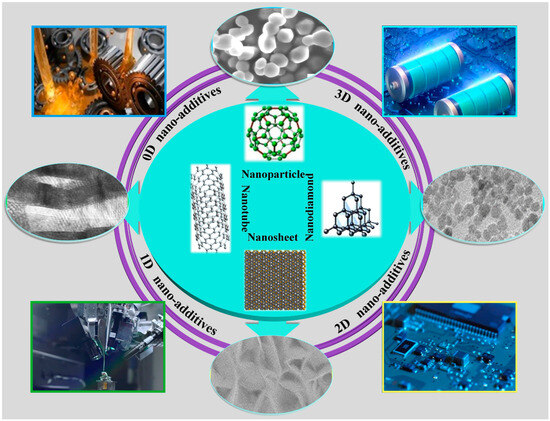

Research into the performance of nanomaterials under dry/liquid wear aims to enhance mechanical system efficiencies and reduce friction, thereby decreasing energy consumption and boosting equipment performance, particularly in energy-intensive industries such as automotive manufacturing and aerospace [11,12]. Furthermore, an understanding of how nano-additives affect the structure and properties of tribofilms under dry/liquid conditions contributes to the optimization of lubricant formulations, thus enhancing energy transfer efficiency and yielding significant economic and environmental benefits [13,14]. According to the dimensional characteristics of nano-additives, they can be placed into the following categories: zero-dimensional (0D), one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D) nano-additives [15,16,17]. As an important type of nanomaterial, 0D nano-additives have the characteristics of being nanoscale in size and they often exist in the form of particles; they have a high specific surface area, excellent mechanical properties and surface activity, and form a stable friction film on the friction surfaces of materials, effectively developing wear resistance for these materials [18,19]. One-dimensional nano-additives, usually in the form of nanofibers or nanotubes, have a high aspect ratio, which can enhance the chemical stability of friction films, extend the service life of the material, and reduce maintenance costs [20,21]. Additionally, 2D nano-additives are principally made up of various nanosheets and their corresponding multilayer structures; examples of these structures are graphene, two-dimensional transition metal sulfide, and two-dimensional oxides, whose thicknesses range from a few nanometers to tens of nanometers, with pre-eminent mechanical performances and chemical stability [22,23,24,25,26]. Unlike the above-mentioned nano-additives, 3D nano-additives are nanohybrids, comprising one or more zero-dimensional, one-dimensional, or two-dimensional structural units, and usually including porous or highly porous structures [27,28]. Figure 1 presents a molecular structure diagram of multidimensional nano-additives (including nanoparticles, nanotubes, nanosheets, and nanodiamonds), along with the representative morphologies of the corresponding materials (such as A12O3 nanoparticles, MoS2 nanotubes, ZnO nanosheets, and BP/TiO2 nanohybrids) that are widely used in various applications under dry/liquid wear conditions. Among them, 0D nano-additives enhance industrial lubricants, 1D nano-additives improve electronics and energy, 2D nano-additives enable transistor fabrication, and 3D nano-additives optimize battery electrodes for an extended service life. In particular, they can be added to the friction interface as a lubricant, thus leading to the formation of a stable friction film and a reduction in the coefficients of friction and wear.

Figure 1.

Representative patterns displaying the molecular nanostructures, micro-morphologies, and applications in various fields for multidimensional nano-additives. Reproduced with permission from the authors of [1,24,29,30,31,32,33].

The broad applications of nano-additives in dry wear and liquid wear scenarios provides significant options and possibilities for designing effective friction interface optimization strategies [34,35]. Through the rational selection and design of nano-additives, the performance of the friction interface can be effectively improved, and the goals of friction reduction, wear reduction, and interface lubrication can be achieved. In different dimensions, the contribution of nano-additives to the friction film is different. Zero-dimensional nano-additives, in the form of nanoparticles, can usually fill surface micro-pits, leading to an improvement of the friction film in terms of mechanical strength and smoothness [8,36]. The unparalleled “nano-rolling effect” in 1D nano-additives enables them to be mutative in the friction state, from sliding to rolling, and can form a stable friction film structure and improve the toughness and stability of the friction film [37,38,39,40,41]. Two-dimensional nano-additives, usually in the form of nanosheets, can form a continuous friction film on the friction surface, reducing the friction coefficient and wear rate [42,43,44]. Three-dimensional nano-additives have a larger specific surface area and surface activity, and they can form a porous friction film on the friction surface, improving the adsorption and lubrication properties of the friction film [5,45,46]. Therefore, in-depth research on the contribution of nano-additives of different dimensions under dry/liquid wear conditions is of great significance in guiding the design and preparation of new wear-resistant materials.

This review will provide a systematic overview of three important areas of nano-additives in tribology research (nano-additives’ effects and wear mechanisms under dry/liquid conditions). Firstly, the effects of various nano-additives in dry/liquid wear processes are examined. Due to their unique sizes, shapes, and chemical properties, dense and wear-resistant tribofilms are formed on the frictional interface, thus effectively reducing friction and wear while enhancing the thermal and chemical stability of tribofilms. Secondly, the mechanisms and factors by which nano-additives enhance wear-resistant materials are analyzed. The existence of nano-additives improves the friction interface’s load-bearing capacity and significantly extend the material lifespan under high loading; additionally, they have a role in the optimization of surface morphologies and in the regulation of environmental conditions, further enhancing integral material properties. Finally, the research results and future trends of multidimensional nano-additives in tribology are explored. Future studies should focus on their performance in complex environments and explore their compatibilities with new materials.

2. Zero-Dimensional Nano-Additives in Tribology

To explore efficient strategies in tribological optimization, 0D nano-additives like Al2O3, Fe3O4, and CuO nanoparticles have been widely applied in diverse dry/liquid friction applications for the purposes of controlling friction and wear [47,48]. The unique near-spherical structures of 0D nano-additives confer excellent tribological potential upon material systems, which manifests as a contribution towards the formation of lubricating films [49,50,51]. Lubricating films formed under 0D nanomaterials can consist of all of the known forms of nanoparticles and have easy shear, providing the tribological properties of friction reduction and anti-wear protection. In the subsequent sections, the tribological behavior relating to the wear-resistant and friction-reduction properties of 0D nano-additives under dry and liquid friction is investigated; the wear mechanisms of 0D-enhanced systems are analyzed. Table 1 shows the detail values of the tribological properties for 0D nano-additives under dry/liquid friction, respectively.

Table 1.

Tribological performance of 0D nano-additives under dry/liquid friction.

2.1. Contributions of 0D Nano-Additives on Lubrication Films under Dry Wear

Many nanomaterials can serve as functional additives in optimizing the properties of solid matrices (metal matrices, ceramic matrices, polymer matrices); this fact has attracted tremendous research interest [57,58,59]. This close research attention on nanomaterials has led to the acceleration of incentives for the application of 0D nano-additives in solid materials. Zero-dimensional nano-additives, including various nanoparticles and nanospheres measuring 1–100 nm, have been proved to be widely used in tribology.

Metal matrices have excellent ductility, which is advantageous for the compression of nanoparticles, enabling them to fill tiny defects on the surfaces that are a result of wear, thus producing a continuous friction layer. The good dispersion of 0D nano-additives plays a crucial role in determining the structure and properties of a composite. Additionally, the dispersion indirectly affects the formatting of a given tribofilm [60,61]. An essential prerequisite for the uniform dispersion of nano-additives is that the concentration must reach a certain range. The prevention of particle agglomeration is necessary if one is to avoid the creation of conditions that favor the formation of friction films through abrasive wear. The scattering of particles on a given surface is not uniform, and in some areas, particles are aggregated [52]. The specific parameters of such tribological behaviors have been presented in Table 1. It was noteworthy that, even when using nano-reinforced systems with appropriate concentrations, one cannot completely guarantee the formation of a high-performance tribofilm. The formation of a tribofilm is closely related to the contents of the elements on a given substrate, the tribological reaction on the surface in question, and the operating environment used [62,63]. For example, reducing the sodium content of used lubricants would limit the formation of a tribofilm; this would significantly reduce the friction and anti-wear properties of the lubricants. In contrast, the Fe3O4 surface was most favorable for tribofilm formation because it produces the most species and molecules [64,65].

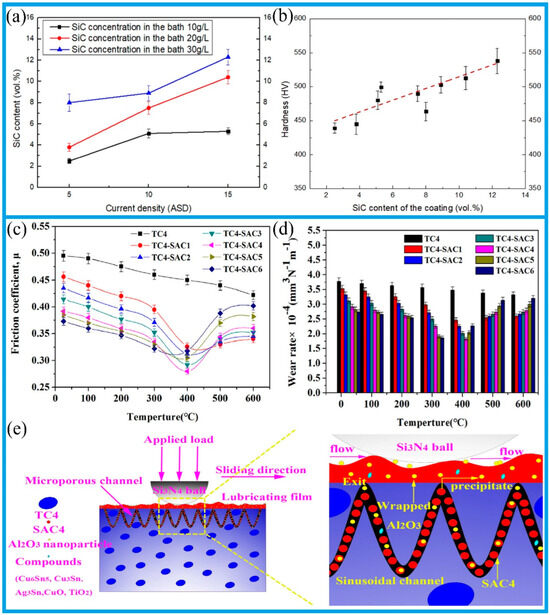

The current density has a noticeable effect on coatings with a high particle content [53]. As shown in Figure 2a, the SiC content in the coating increases depending on the increase in the current density. Figure 2b shows the microhardness curves for different SiC contents. With the increase in the SiC content in the coating, the hardness of the coating also increased; this was due to the dispersion and strengthening effect of the ceramic particles in the coating. The specific parameters in such tribological behaviors are presented in Table 1. Under dry conditions, polytetrafluoroethylene (PTFE)-combined wear chips produced a fluoro-based tribological film under the sliding surface; this changed the wear process into a sliding process between the smooth tribofilms. In turn, the component was crushed into worn fragments, which improved the quality of the formation of the tribofilm, while compacting the transfer film so that it reached a thin and uniform consistency. In addition, the tribo–chemical reaction of SiC nanoparticles promoted the formation of a strong tribofilm with a complex structure; this had protective and shielding effects [66,67].

Figure 2.

(a) Relation between current density with SiC content for coating; (b) relation between SiC content of coatings and hardness; reproduced with permission from the authors of [53]. (c) Average friction coefficient and (d) wear rate of TC4 and TC4−SAC; (e) schematic diagram of self-lubricating mechanism of sample. Reproduced with permission from the authors of [30].

The production of a PTFE nanocomposite filled with Al2O3 nanoparticles was carried out in dry conditions using a freshly created dual-pins-on-disk tribometer [68]. The results revealed that a concurrent effect between the two polymer components appeared, thereby improving the tribology performance of the hybrid system. The formation of a tribofilm and its different characteristics were elucidated via a surface analysis of the different run-in stages. For rough surfaces, the loosely adhered transfer film was formed at the beginning of the sliding process in order to form a durable transfer film. Inversely, for smooth anti-surfaces, durable transfer films were formed from the outset. A tribofilm with a thickness measuring microns was observed on the surface of the PTFE composite after the run-in; the film had an excellent low-friction performance [69,70]. Particularly, the tribological effect also plays an important function in the tribological behaviors of nanocomposites. Because of the insufficient strength of polymers, it was easy to conduct the removal and transferal of materials for polymer nanomaterials under friction, resulting in the formation of transfer-film-embracing additives. The mechanical performances and the bonding strengths of these films exerted a crucial influence on the tribological behaviors of the polymers.

After being exposed to the friction surface, the wrapped Al2O3 nanoparticles not only play a role in enhancing the load-carrying capacities of lubricating films, they also act as “micro-bearings” between the friction pairs [30]. Obviously, as shown in Figure 2c,d, in comparison to TC4 in all tested temperatures, TC4-Sn-Ag-Cu (TC4-SAC) achieved smaller coefficients for the friction and wear rates; these may be attributed to the outstanding lubricating characteristic of Sn-Ag-Cu. The detailed parameters of such tribological behaviors are displayed in Table 1. Further, Figure 2e shows the self-lubricating mechanism reaction. Under the action of low mechanical stress, a small amount of coated Al2O3 nanoparticles microporous channels were precipitated; only a local lubrication film was formed on the worn surface. When the load continued to increase, the coated Al2O3 nanoparticles exposed to the frictional surface could not only enhance the bearing capacity of the lubrication films but could also play a role of “micro-bearing” for the inner parts of the friction pairs. In addition, the wear surface was covered with a relatively smooth and uniform lubrication film during the frictional process, which can mainly be attributed to the addition of Al2O3 nanoparticles [71,72]. The decrease in the wear coefficient was mainly controlled by the formation of a tribofilm on the friction surface, which improved the friction and wear behaviors of the composites [73]. Structurally, these tribofilms were quite complex and may consist of all known forms of nanoparticles. For tribology, they were easy to shear and provided ultralow friction and anti-wear protection [74,75].

By introducing antifriction materials into ceramic matrices, the friction force which ceramics are subjected to can be reduced; synchronously, the tribological properties of ceramics can be improved [76]. A prediction model that could reflect the friction performance of antifriction materials on ceramics was established to predict the wear rate of friction films under dry friction conditions; this model provided theoretical guidance for ceramic designers [77]. Based on a process of calculating the wear rate through a mathematical model formula, with increase in normal force, the friction coefficients of a ceramic matrix began to decrease and then enter a state of stable fluctuation. Correspondingly, during the friction process, the extrusion of antifriction nanomaterials from the substrate can be carried out, forming a large area of lubrication-film-containing nano-additives, thus optimizing the friction coefficient. The presence of low-friction-coefficient films impede the direct contact of the friction pair and thus reduce friction.

The improvement in the tribology properties of lightweight alloys that is achieved through an increase in the presence of additive-surface chemical interactions is sufficiently noteworthy. In addition to the remarkable contribution of experimental results to our understanding of the formation mechanism of tribofilm, chemical interactions at the atomic level can be effectively explained by computer simulation, which also provides valuable viewpoint for its formation on metal substrates. Based on density functional theory simulations, the interaction of zinc dialkyldithiophosphates (ZDDP) with lightweight metallic substrates has been investigated [78]. The results of the study demonstrated that, compared to aluminum (Al) and magnesium (Mg), the molecular fragments from ZDDP were adsorbed more strongly on the intermetallic Mg17Al12 phase, owing to the higher surface energy of the mixed substrate. The tribofilm formed by ZDDP was insufficient in preventing the wear of the aluminum alloy. In this situation, the tribological activity of the nano-additives on the inner worn interface led to the formation of a tribofilm, to a certain extent. In summary, near-spherical 0D nanomaterials have a roller bearing function that is preponderant to the bearing capacity of tribofilms; this is easy to oxidize. Thus, it is suitable for the photoelectric properties of the material. However, nanoparticles are easy to agglomerate, which affects catalytic performances. The tribological effect of 0D nano-additives on a worn surface significantly influences the establishment of a tribofilm.

2.2. Enhancements of 0D Nano-Additives on Lubrication Films under Liquid Wear

The use of solid reinforcing agents remains the preferred choice in complex and harsh space environments; however, liquid lubricants are increasingly emerging as a potent means for a reducing in friction and wear within mechanical contact areas [79]. Under liquid wear, the wear mechanisms involve the formation of a lubricating film on the tribology surface, thereby preventing direct contact among the frictional pairs [80].

The synergistic effect between multicomponent nanoparticles performs an important role in the formation of high-performance tribofilms [81,82]. The introduction of nano-hexagonal boron nitride (nano-hBN) (0.75 wt%) and nano-Al2O3 (0.25 wt%) into calcium sulfonate complex grease (CSCG) results in optimal tribology performances: a 11.3% reduction in the mean friction coefficient, a 6.1% decrease in the wear scar diameter, and a significant improvement in worn surface morphology were observed in comparison with CSCG [83]. This can be explained through the synergistic effect: on the one hand, nano-hBN could promote the formation of a protective layer that is mainly composed of calcium carbonate; on the other hand, nano-Al2O3 could inhibit the agglomeration of hBN and strengthen the antifriction effect of calcium carbonate.

The modification of lubricants using nanoparticle additives to enhance the tribological performance of lubricants has become a promising approach in this technology [84]. The excellent lubrication ability of such materials has been found to lead to increased working efficiency, application accuracy, and service life for numerous moving contact parts. This ability is closely related to the mechanical characteristics of 0D nano-additives, like hardness and shear modulus. Nanoparticles have many advantages, such as high hardness, good thermal stability, and low cost. Nanoparticles can roll or slide between surfaces, repair surface defects, and form tribofilms via physical embedding or chemisorption.

On the basis of the intensity of friction chemical reactions, the process of the formation of tribofilms can be divided into two stages [85]. In the initial stage, particles gather in front of the contact area, and particle accumulation begins to move back and forth with the surface of the plate. Van der Waals forces combine with the electrostatic interaction of the nano-additives on the friction surface, making it easy for the films to adsorb onto the substrate surface; thus, they form physical protective films in an adsorptive manner, preventing any chemical reaction from occurring. The presence of adsorption films improves the lubrication conditions of the two contact surfaces, making it easier for the lubricating oil to enter the contact area, thus increasing the thickness of the oil film [86]. At this point, the lubrication film primarily plays a significant function in preventing direct contact with the frictional surface and reducing wear. Meanwhile, as the friction time continues, the deposited physical adsorption films begin to disintegrate. Because of the high load, friction heat, and mechanical energy produced by friction, tribo–chemical reactions occur on the sliding surface; this signifies that a formation of tribofilms have entered the subsequent stage. In the process of tribological chemical reactions, new tribofilms are formed; these mingle and become progressively displaced by the physical film, which significantly enhances the tribological properties of the friction system.

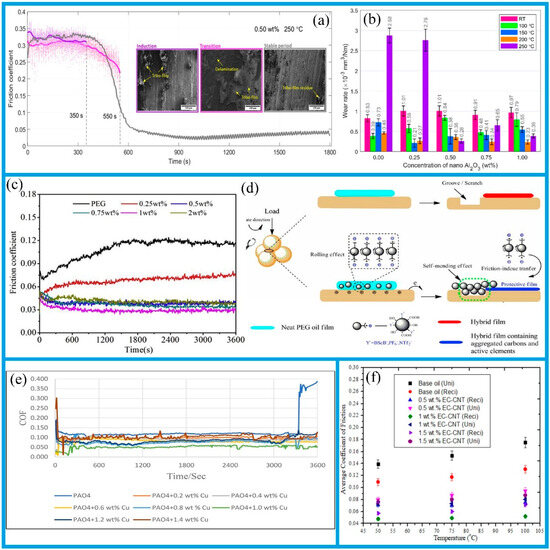

The tribological properties of magnesium silicate hydroxide (MSH) nanoparticles were explored using a four-ball test [87]. The results indicated that MSH could effectively increase the thickness of oil films, thus achieving a reduction in wear; this was ascribed to the formation of a tribofilm containing Mg, Si, and O on the worn surface. Figure 3a presents the change curve for the friction coefficients; additionally, one can see the corresponding scanning electron microscope (SEM)-captured surface morphologies in different periods [88]. During the stable period, the area that was left exposed after stripping following the stabilization period was rich in Mg and Al elements. In addition, the newly formed surface had higher tensile strength and yield strength, which could reduce cracks caused by fatigue wear. These potential tribological behaviors have led to extensive research being conducted. Under temperature conditions of 250 °C, the wear rate of the sample disc was the highest when using a 0.25 wt% nano-Al2O3 lubricant, as shown in Figure 3b.

Figure 3.

(a) Friction coefficient in different periods and the corresponding SEM surface morphologies; (b) wear rate as function of concentration and temperature; reproduced with permission from the authors of [88]. (c) Friction coefficient curves of CDs−PF6 in PEG; (d) schematic diagram of lubricating mechanism for CDs−IL nanoparticles; reproduced with permission from the authors of [54]. (e) Relation between friction coefficient and test period for various lubricating oil samples; reproduced with permission from the authors of [55]. (f) Average friction coefficient on the lubricated surfaces for various lubricating oil samples; reproduced with permission from the authors of [89].

CDs-PF6 was obtained via a method seeking to modify carbon nanodot–ionic liquid (CDs-IL) hybrids with hexafluorophosphate (PF6). CDs-PF6 nanoparticles, as polyethylene glycol-based (PEG) additives, possess outstanding antifriction and wear-resistant properties [54]. Figure 3c shows the curves of the friction coefficients for CDs-PF6 in PEG with various concentrations under loads of 392 N. CDs-PF6 could markedly enhance the anti-wear and friction-reduction characteristics of PEG at low concentrations (0.25–1 wt.%). CDs-PF6 achieved a remarkable concurrent improvement in anti-wear (96.5%) and friction-reduction (72.7%) characteristics; this is a result of the formation of a protective carbon-based layer at the contact regions. Table 1 shows the definite values of the friction coefficients and wear rates. However, the CDs-PF6/PEG were weakened at a concentration of 2 wt.%. This might be attributed to the competitive adsorption of CDs-PF6 and PEG at the friction interface, in addition to the fact that CDs-PF6 are more prone to agglomeration at high concentrations. The excellent tribological properties of PEG were mainly attributed to the formation of physical adsorption films, where nanoparticles can interact with the frictional surface. As shown in Figure 3d, the combination of the negatively charged anions of the CDs-IL and the positively charged sites of the grooves promoted the aggregation of CDs-IL on the rubbing surface during the friction process. With the continuation of the friction condition, the deposited physical adsorption films began to decompose and tribo–chemical reactions occurred because of the high pressure, the frictional heat, and the mechanical energy; this formed a protective transfer film on the metal surfaces and exhibited a “self-mending effect” by filling the deep scratches. This process grants it an outstanding anti-wear and friction-reduction property.

To enhance the tribological characteristics of the base oil, the use of nanoparticles as lubricant additives has attracted more and more attention. As shown in Figure 3e, the tribological properties of the PAO4 base oil were affected by the presence of Cu nanoparticles at certain concentrations [55]. This phenomenon was attributed to the dissemination and infiltration of nano-Cu on the friction interface when the nanoparticles were mixed with the base lubricants, forming a protective layer on the friction interface, and thus achieving the best tribological performances under optimal concentration conditions. The details of the values of the PAO4 base oil, containing 1.0 wt % nano-Cu, and how they influenced the tribological performance, are listed in Table 1. Furthermore, the friction coefficients increased due to the fracture of the synovial film or the surface layer, which was caused by increasing concentration; this provides a practicable solution for the separation of friction pairs and the related tribological optimization. The effect of the addition of eichhornia crassipes nanotube (EC-CNT) particles on the tribological property of the lubricants was examined [89]. When compared to the base oil, the tribological effects of the EC-CNT additive at different concentrations (0.5 wt%, 1 wt%, and 1.5 wt%) were studied at different temperatures and with a steady load of 100 N, as shown in Figure 3f. When the temperature increased from 50 °C to 100 °C, the average friction coefficients decreased more strongly, relative to the base lubricants. However, the reduction in the friction coefficient and in the unidirectional mode was small compared to those of the reciprocating orientation. A 49% reduction in friction was achieved using a 1 wt% EC-CNT nanoparticle under the unidirectional testing mode; meanwhile, a 58.1% reduction was obtained in the reciprocating mode compared to the base lubricant [90].

Nanoparticles can be used as additives to enhance the lubrication properties of films. However, due to their tendency to aggregate and settle, introducing 0D nano-additives into lubrication oil is a complicated issue. The homogeneous and stable diffusion of nano-additives has a significant sway in promoting the creation of high-performance tribofilms. The wear resistance of carbon-based nanoparticles was due to the protective layer that formed on the contact surface, minimizing friction and wear [91]. Overall, 0D nano-additives markedly enhance the wear resistance of friction systems. In mechanical systems, the addition of nanoparticles to base lubricants could improve the efficiency of systems by reducing the friction coefficient. With an increase in the concentration, the mean values of the friction coefficient decreased, reaching a low value when the nanoparticle concentration was 1.0 wt %, and then rose. A protective layer formed on the surfaces of the mechanical mating components when the nanoparticles were mixed with the base lubricants, resulting in the highest tribological performance, which reached the optimal concentration of lubrication. Furthermore, there was an increase in the friction coefficient because of the rupture in the lubricating films or the formed surface layers. Compared with pure PAO4 oil, the mean friction coefficient of the PAO4 oil containing the 1.0 wt% Cu nanoparticle was decreased by 51.85. This can be explained by the fact that the effective dispersion led to the formation of a protective tribofilm between the frictional pairs. The tribofilm prevented direct contact between the friction interfaces, thus improving the wear resistance.

In addition to oil-based lubricating materials, water-based lubricating materials can perform an important role in tribology. Adding an ionic liquid additive (IL-16) to water-based lubricants achieves low-friction and -wear characteristics [92]. Water-based lubricants with IL-16 (1.6 wt.%) exhibit excellent antifriction, anti-wear, and anti-corrosion properties at a load current of 1.5 A; this was mainly ascribed to the formation of stable physical adsorption films on the surfaces of the friction pairs, thus reducing friction and wear. It can be seen that the addition of an ionic liquid additive enables the creation of high-performance tribofilms. Furthermore, the leading product of frictional chemical reaction between nano-additives and ILs was found to be of great significance for the antifriction and anti-wear properties of tribofilms.

In conclusion, the formation of tribofilm plays an important role in the tribological behaviors of liquid lubrication systems. During the period of physical adsorption, 0D nanoparticles within a lubrication film also provide a function similar to that of ball bearings; the exceedingly small size of the particles facilitates the repair of defects on worn surfaces. These characteristics directly ensure that a lubricant has a low friction coefficient and outstanding anti-wear capacities. However, the high surface area of nanoparticles can result in their self-aggregation, which can lead to high performance among the lubrication films with a short service life. Consequently, improving the dispersion stability of nanomaterial contributes to increasing their applicability and facilitates their development in new fields. It is noteworthy that surface modification is essential for the effective dispersion of nanoparticles in lubricating oil. In order to effectively suspend nanoparticles, the compatibility between nanoparticles and biological lubricants must be considered. Meanwhile, surfactants as well as dispersants can be utilized to reduce agglomeration. The excellent dispersion capability also provides sufficient conditions for the formation of tribofilms.

2.3. Wear Mechanisms of 0D Nano-Additives

The wear mechanical and tribological properties of nanocomposites can be effectively improved due to the size effect of nanoparticles and the matrix’s bonding strength. Due to their unique structure, near-spherical 0D materials are beneficial in reducing friction resistance and providing a workable approach for enhancing the bearing capacity and lubrication property of the tribofilm. Moreover, in the context of fluid lubrication, 0D materials, i.e., particles with relatively small particle sizes, are applicable in repairing surface flaws of friction pairs, producing a “self-healing” effect in lubrication systems; this leads directly to exceptional lubrication performances. Meanwhile, due to their high specific surface area and high energy, 0D nano-additives typically have a strong tendency to self-aggregate.

Solid lubricating films have great advantages in extreme operating conditions. It is noteworthy that combining nanomaterials with a plastic deformation matrix contributes to the formation of high-performance solid lubricating films. In liquid lubrication, the friction interface undergoes two stages: physical adsorption film and tribo–chemical film. Among them, in the formation mechanism of tribofilms in solid–liquid composite systems, material phenomena such as deformation, damage, and reaction play crucial roles [93,94]. Furthermore, the physical characteristics of a lubricant, its molecular composition, and its potential reactions with various other wear byproducts are all pivotal factors in the mechanisms involved in generating tribofilms [95].

In the physical adsorption stage, there is no “stress assist” or “thermal effect” in the film-formation process; a tribofilm can be generated by surface electrostatic potential attraction. The adsorption film begins to decompose and a tribo–chemical reaction occurs under conditions of high pressure, friction heat, and mechanical energy. Subsequently, the formation of tribofilms enters into the next stage. It should be emphasized that, in this stage, fatigue wear caused by alternating stresses in the reciprocating sliding process induces three-body wear and accelerates the wear of the amorphous carbon film (a-C film) between friction interfaces, as shown in the nanofriction mechanism [96]. When an a-C film is scratched, it becomes difficult to form a transfer film under low shear stress. Owing to the elastic deformation and passivation of the a-C suspended bond, a-C films require higher stress and longer sliding distance to form transfer films. During the sliding process of an a-C film, the energy stored in the attached phase dissipates by increasing the contact area until the stable stage is reached.

The formation of tribo–chemical film goes through the initial phase of fast growth at a high reaction temperature; then, it progressively decelerates and reaches its final thickness. Nevertheless, high shear stress results in the elimination of the protective layer, thus leading to the surface being clean during wear. On the contrary, under light lubrication (low or moderate load), the interfacial shear stress is inadequate in effectively eliminating tribofilms. Friction stress is accountable for the good bond that forms between a tribo–chemical film and a worn surface, thereby resulting in a clean and smooth surface [97].

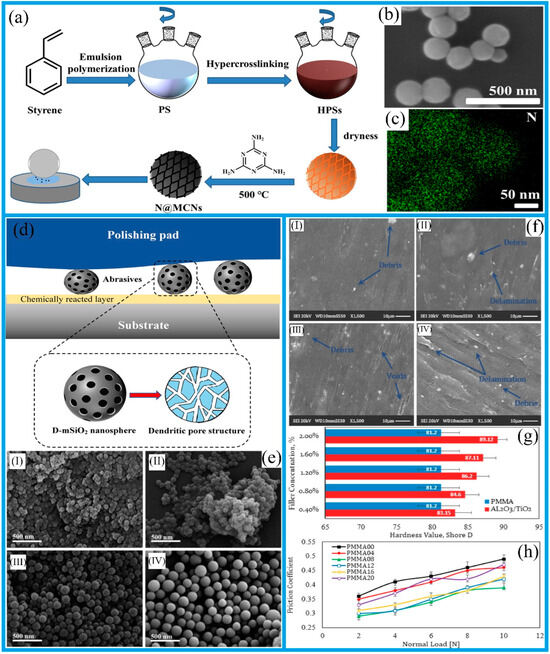

As shown in Figure 4a, Wang et al. obtained novel porous carbon nanospheres doped with nitrogen (N@MCNs) via melamine-assisted carbonization [56]. A ball-on-disc test was conducted on a 500 SN base oil containing 0.06 wt% N@MCNs; the results showed that the friction coefficients and wear volume were reduced to 0.11 and 6.05 × 104 μm3, respectively. The related values of the tribological performances are presented in detail in Table 1. Meanwhile, the friction and wear mechanisms of N@MCNs have been investigated through SEM and X-ray photoelectron spectroscopy (XPS) analyses of worn surfaces, as shown in Figure 4b,c. The images demonstrate that, during the friction process, protective tribofilms, including nitrides and metal oxides, form on contact interfaces as a result of tribo–chemical reactions between N@MCNs nanoparticles and an iron atom/iron oxide. The formation of tribofilms contributes to the prevention of friction during direct contact; thus, lower friction is achieved, improving the anti-wear and friction-reduction properties of the base oil. It is worth noting that an enlarged pore size on porous clusters leads to a decreased surface damage, which could be ascribed to a broadened contact area and a reduced penetration depth.

Figure 4.

(a) Preparation process of nitrogen-doped microporous carbon nanospheres; (b) SEM image of N@MCNs−4; (c) Image for N elemental mapping of N@MCNs−4; reprinted with permission from the authors of [56]. (d) Schematics for the interfacial contact behavior between D-mSiO2 with substrate; (e) FESEM images of different samples: (I) D−mSiO2−45, (II) D−mSiO2−60, (III) D−mSiO2−75, (IV) D−mSiO2−90. Reproduced with permission from the authors of [98]. (f) SEM images for worn surfaces of PMMA/Al2O3/TiO2 composite: (I) PMMA08, (II) PMMA12, (III) PMMA16, (IV) and PMMA20. (g) Hardness values of nanocomposite samples. (h) Friction coefficient for PMMA nanocomposite samples. Reproduced with permission from the authors of [99].

In a study by Chen et al., dendritic mesoporous silica (D-mSiO2) nanospheres featuring tunable structures were prepared, having particle sizes of 30–140 nm, pore diameters of 3–9 nm, surface areas of approximately 780 m2/g, and pore volumes of ~1.5 cm3/g. Figure 4d shows schematic diagrams for the interfacial contact behavior that was observed between D-mSiO2 and the substrate surface [98]. Low-modulus D-mSiO2 nanospheres might deform elastically when a load is applied, thus resulting in a reduction in the contact pressure at the contact interface and a decrease in the indentation depth of the particle on the surface. Excellent uniformity and dispersity of D-mSiO2 nanospheres could prevent the surface scratches that are caused by particle agglomerations. In addition, with increased reaction temperatures in the wear process, spherical topographies and uniform nanospheres are still well maintained, and the specific particle size enlarges from 45 nm to 90 nm, as shown in Figure 4e(I–IV).

Related research has evaluated the tribological features of the nanocomposites reinforced with aluminum nano-oxides (Al2O3) and titanium nano-oxides (TiO2) [99]. To study their wear mechanisms, SEM images of the worn surfaces of poly methyl methacrylate (PMMA)/Al2O3/TiO2 composites are presented in Figure 4f(I–IV). The morphologies of the rubbed surfaces changed in correspondence with the Al2O3/TiO2 filler amount used. Pure PMMA presented with numerous delamination layers, many voids, and lots of wear debris because of the ploughing of its rubbed surface, which in turn led to a reduction in weight. Moreover, the eliminated weak layers could enhance the shear resistance. Furthermore, the brittle failure of the rubbed surfaces resulted in an increase in the surface roughness, which in turn led to a reduction in toughness. The delamination wear mechanism, which typically elevates the friction coefficients and wear rate, was the predominant phenomenon observed in the case of pure PMMA. The surface morphology of other PMMA/Al2O3/TiO2 nanocomposites, instead, appeared relatively smooth, which could be attributed to the observed enhancement in the nanocomposite strength and hardness, resulting from the increase in the amount of Al2O3/TiO2 filler used.

The sample with a filler content of 2.0 wt% was demonstrated to have the most substantial enhancement in hardness, reaching a 9.75% increase compared to pure PMMA, as illustrated in Figure 4g. The improvement in PMMA in the mechanical properties indicated that the hardness of the TiO2 and Al2O3 nanoparticles was significantly greater than that of pure PMMA, thereby enhancing the load-bearing capacity. Furthermore, the incorporation of the filler into the microstructure of the matrix embedded the dislocation movement during loading, thereby enhancing the strength and modulus of the composites. As shown in Figure 4h, nanocomposites with 0.8 wt% filler content presented a remarkable performance among various filler amounts. To sum up, the 0D nano-additive not only transforms the friction condition from sliding to rolling, but also forms a protective tribofilm between the surfaces through physical adsorption or chemical reaction under the boundary lubrication condition, thus improving the friction performance. Furthermore, the elucidation of the relationship between macroscopic tribological behavior of material and nano/micro-scale properties of tribofilm is of great importance for understanding the mechanisms of friction and wear. Nevertheless, the characterization of the mechanical properties of tribofilms is a challenging task due to its low thickness and the inhomogeneous distribution it has on metallic surfaces.

3. One-Dimensional Nano-Additives in Tribology

Similar to 0D nano-additives, well-dispersed 1D nano-additives at higher contact pressures and shear run-in processes also contribute to the formation of high-performance lubrication films [100,101]. Many studies have been carried out to enhance the outstanding tribological characteristics of composites strengthened by 1D nano-additives [102,103]. This section primarily addresses the tribological behaviors and wear mechanisms of 1D nano-additives under dry and liquid friction conditions. Table 2 summarizes the improvements made in the frictional performances of 1D nano-additive materials under dry/liquid friction.

Table 2.

Tribological performance of 1D nano-additives under dry/liquid friction.

3.1. Contributions of 1D Nano-Additives to Lubrication Films under Dry Wear

One-dimensional nanomaterials are increasingly being recognized as appealing solid lubricants for a broad spectrum of tribological applications [110]. Their superb tribological potential presents a reasonable and effective way to protect the friction and wear of the surfaces of frictional pairs. One-dimensional nanomaterials, used as additives, exhibit ultralow interfacial shear strength and excellent tribological properties; these are similar to those of 0D nano-additives and contribute to the generation of high-performance tribofilms [111].

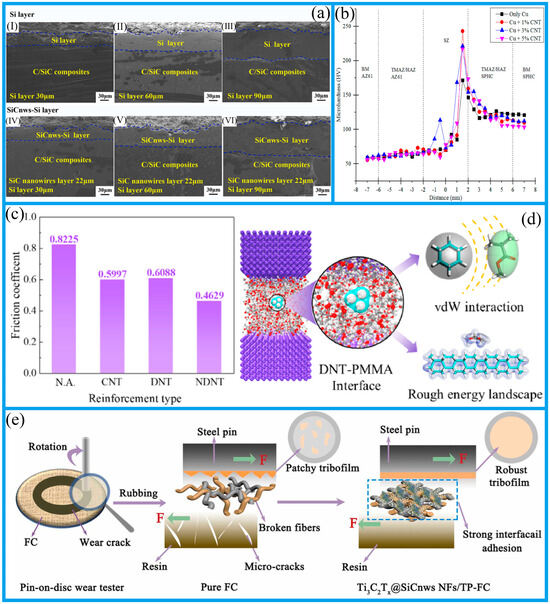

It is very important to repair crack growth and failure modes in ceramic materials. The load strengths of these materials are considered, in addition to the effects of mechanical fatigue owing to the periodic load applications, as they have the potential to produce defects and affect structural behaviors [112]. In this case, one-dimensional nano-additives could increasingly play a toughening role [113]. The ameliorative roughness brought by SiC nanowire deposition contributes to the enhanced bonding strength between matrices and composites [114]. As shown in Figure 5a(I–VI), compared with the Si layers (Si30, Si60, and Si90), the SiCnws-Si layers (SiCnws-Si30, SiCnws-Si60, and SiCnws-Si90) possessed compact structures, which increased the bonding strength between the matrix and the SiC nanowire layer. Meanwhile, the addition of carbon nanotubes effectively improves the microhardness of the composites, which is due to the grain refinement and enhancement of the carbon nanotubes in the matrix [115]. As shown in Figure 5b, the hardness values of the Mg/steel joints increases significantly when Cu and carbon nanotubes (CNTs) are added at the same time, compared to copper powder alone.

Figure 5.

(a) The cross-sections of the morphologies of Si layers and SiCnws−Si layers: (I) Si30; (II) Si60; (III) Si90; (IV) SiCnws−Si30; (V) SiCnws−Si60; (VI) SiCnws−Si90. Reproduced with permission from the authors of [114]. (b) Comparison of microhardness values at different additives. Reproduced with permission from the authors of [115]. (c) Effect of different reinforcements on surface sliding behaviors of polymer composites. (d) Schematic representation of the reinforcing mechanisms. Reproduced with permission from the authors of [116]. (e) Schematic diagram of tribological mechanism for Ti3C2Tx @SiCnws NFs/TP-FC. Reproduced with permission from the authors of [117].

The generation of a transfer film plays a vital role in the tribological behaviors of polymers. Consequently, researchers are increasingly interested in developing productive strategies to enhance the tribological properties of transfer films. Unlike ceramic matrices, polymer matrices in friction systems are prone to material transfer, owing to their relatively low strength. Yin et al. [116] explored the tribological properties of PMMA nanocomposites reinforced with diamond nanothreads (DNTs) using atomistic simulations and density functional theory calculations. The results indicated that the friction coefficients of PMMA nanocomposites decreased by 25.98% after DNT addition, which can be attributed to the excellent interfacial interactions such as Van Der Waals interaction and mechanical interlocking, as shown in Figure 5c,d. Furthermore, due to the rougher topography of molecular electronic potential and the presence of a higher binding energy, a better antifriction performance can be accomplished using nitrogen-doped DNTs.

By comparing the materials before and after modification, the variation trend of the friction coefficient for different composites with time was obtained [117]. Figure 5e shows the friction mechanism of Ti3C2Tx@SiCnws/TP-FC, including tannic acid–polyethyleneimine (TP) and fabric liner composites (FCs). It is worth noting that the modified FC maintained a minimum, stable friction coefficient. Meanwhile, the wear resistance of the composite was improved due to the synergistic enhancement between Ti3C2Tx@SiCnws, leading to enhanced interface adhesion and the dispersion of the filler. Meanwhile, after friction, a large number of microcracks and fiber fractures appear on the surface of the FC, transfering to the corresponding surface, forming a solid tribofilm. The formation of a tribofilm here led to it playing the role of a buffer layer in the process of friction.

During the run-in process, the high contact pressure and shear can lead to the generation of a composite tribofilm that has low shear strength, thus resulting in a state of super-lubrication. A higher concentration of copper nanowires could accelerate the run-in time and improve the formation of a tribofilm. However, a thicker film is more prone to flaking, which hinders its ability to meet the required friction and wear properties [118].

CNTs, as one-dimensional nano-additives, are widely used in diverse solid substrates such as metals, ceramics, and polymers, mainly on account of their remarkable tribological optimization mechanisms [119,120]. Studies on CNTs as additives into polymer materials to improve composites’ mechanical properties have been conducted. The dispersion and adhesion properties of carbon-nanotube-reinforced epoxy composites have been investigated using various means of analysis. Experimental outcomes have indicated that CNTs with bigger particle sizes (50–100 nm) had a more uniform dispersion, thus obtaining better adhesion properties and forming nanostructured tribofilms [121]. For such films, the orientation of the CNTs is important for the tribological characteristics. More accurately, when CNTs are aligned perpendicularly to the friction direction, this tends to lead to a slide/roll motion occurring between the paired friction surfaces, thereby leading to decreased friction and wear for the composites [122]. It is worth noting that the rolling effect of 1D nano-additives is an effective approach in improving the lubrication properties and load-bearing capacities of tribofilms.

Tailoring interface nanostructures to reduce friction and wear provides a feasible tactic for creating high-performing polymer-on-metal sliding pairs. Hu et al. [104] obtained polyimide (PI) composites through the in-situ addition of multiwalled CNTs. A ball-on-disc test was conducted on PI composites reinforced with CNTs; the results demonstrated that the friction coefficients and wear rates for PI composites with 1.0 wt% CNTs decreased by 90.7% and 82.0% in comparison to those of pure PI, respectively. The specific parameters of this study are listed in Table 2. The proposed explanation for this phenomenon is that the continuous introduction of CNTs into sliding interfaces could turn into carbon nanospheres and graphene nanosheets, which promotes the formation of robust and lubricated tribofilms, thus achieving low friction. Uniform CuO nanowires on carbon fiber cloths (CFCs) might be able to improve interfacial bonding with PI matrices [105]. Meanwhile, CuO nanowires could introduce a lubricating phase into PI/CuO@CFC composites to boost their mechanical and tribological performances. PI/CuO@CFC composites have been shown to have excellent tribological properties. The specific relevant parameters of this study are listed in Table 2. The enhancement mechanism was put forward through an analysis for the composite interface and worn surface. In general, 1D nano-additives with a high aspect ratio have a high specific surface area, a high length–diameter ratio, high mechanical strength, high thermal conductivity, and other characteristics. It also provides an outstanding stress-transfer mechanism, as well as exhibiting a nano-rolling effect, which is essential in minimizing frictional resistance. Nevertheless, in applications of photocatalytic devices, one-dimensional nanorods have a low photocatalytic performance owing to their difficult morphologies. Customizing the interface nanostructures to reduce the friction and wear offers a feasible strategy for developing high-performance sliding pairs.

3.2. Enhancements of 1D Nano-Additives on Lubrication Films under Liquid Wear

Similar to 0D-nano-additive-enhanced lubricants, the uniform dispersion of 1D nano-additives in a mixture is vital in ensuring that their full tribological potential is reached. The dispersion stability of nano-additives in the lubricant medium is one of the most important factors affecting tribological properties; dispersion also plays an important role in the formation of lubrication films [123]. The enhanced tribological performances of lubricants incorporating 1D nano-additives is becoming increasingly acknowledged. Nevertheless, this beneficial lubrication is a short-term achievement due to the self-induced reaggregation of the additives in the mixture. Consequently, the first problem to be solved is the dispersion stability of additives in the base lubricating oil. The homogeneous and stably dispersed one-dimensional nano-additives can stick to the friction surface and progressively gather and densify under the applied load to form a lubrication film with a thicker boundary, which is very important in ensuring wear resistance.

The synergistic antagonism between MoS2 nanotubes and the representative oil additives also performs a significant role in the production and tribological properties of lubrication films [124]. The use of MoS2 nanotubes as an additive into oil exhibited excellent properties, including load-bearing capacities, resistance to wear, and friction reduction between moving mechanical parts. Optical micrographs for wear scars showed that wear was evident in tests using only a base oil, with unique plastic deformation occurring. Furthermore, the wear of the nanotube-lubricated mixture was greatly reduced, which showed evidence of tribofilms’ presence after the test, with the blend of pure base oil (PAO) containing MoS2 nanotubes (PAO+NTs). In addition, the friction coefficient was closely related to the sliding distance. The typical variation of friction coefficient and sliding distances between PAO and oil containing 5 wt% MoS2 nanotubes was investigated. It could be seen that the friction coefficient was stable and the run-in conditions were smoother and faster. The difference was even greater as the duration of the test increased. The specific tribological behaviors and test conditions for this are recorded in Table 2.

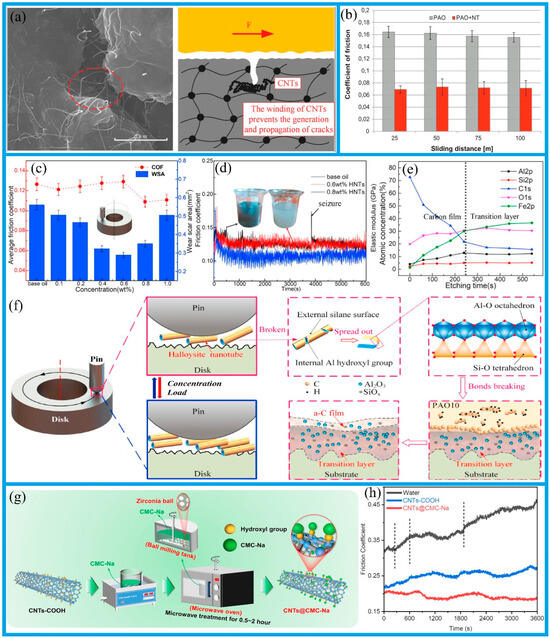

The addition of CNTs provides a feasible strategy for improve the wear resistance of nitrile butadiene rubber (NBR) [107]. As shown in Figure 6a, CNTs can be intertwined with the NBR molecular chain to prevent the rubber surface from being torn, thus improving the wear resistance of the rubber. However, when the physical adsorption caused by the Van der Waals force was difficult to resist, and the external force on the matrix materials increased, internal cracks appear in the parts where the interaction between the nanoparticles and the matrix material was weak; thus, carbon nanotubes are extruded from the nitrile rubber matrix during the wear process, which provides a possible route for the formation of excellent tribofilms.

Figure 6.

(a) Mechanistic diagrams of CNT-enhanced NBR wear performance. Reproduced with permission from the authors of [107]. (b) Tribological performance for using lubricating PAO and PAO+NTs. Reproduced with permission from the authors of [29]. Friction coefficient versus concentration (c) and sliding time (d); (e) variation of tribofilm elemental content with etching time; (f) schematic diagram of tribological behavior of modified HNTs (M-HNTs); reproduced with permission from the authors of [108]. (g) Schematic diagram of the preparation process of CNTs@CMC-Na; (h) friction coefficient curves of different samples in routine conditions. Reproduced with permission from the authors of [125].

The potential tribological performance of MoS2 multi-wall nanotubes (MWNTs) as additives in lubricating oil is dependent on the formation of the tribofilms [29]. A ball-on-disc test was conducted under 1 GPa contact pressure and 0.005 m/s sliding velocity; the results indicated that the addition of MWNTs to a base PAO oil significantly reduced the friction coefficient in comparison to that of a pure base PAO oil, as shown in Figure 6b. The specific values of these friction coefficients are shown in Table 2. These results are ascribed to the wear-resistant and low-shear films that formed on the surface; these formed through the attachment of MoS2 nanosheets to the surface.

Halloysite nanotubes (HNTs) have gradually become the focus of research owing to their excellent biocompatibility and potential film-forming properties with respect to tribology; the tribological properties of Span 80-modified HNTs into PAO10 oil were investigated using a pin-on-disk tribometer by the group of Qin et al. [108]. The results revealed that HNTs at low concentrations (0.1–0.6 wt%) exhibited excellent anti-wear performances, which were ascribed to the formation of a composite tribofilm on the surface, consisting of an exterior layer of soft amorphous carbon film and an interior hard layer containing Al2O3, SiOx, and iron oxide. Specifically, the friction coefficients and the wear scar size were determined and calculated, as shown in Figure 6c,e. As a result, designing the special double-layer film structure with a soft inside and a hard outside provided a feasible strategy for attaining excellent tribological properties. It is worth noting that the crucial factor in the generation of the composite tribofilms was the crushing of HNTs that occurred when loading was applied. Specific nanotube structures may act as rolling bearings to reduce the friction coefficient; this is possible because the nanotubes can only act as rolling bearings in specific directions. Spherical and quasi-spherical nanoparticles can roll when in contact with a surface, and they can change the sliding friction type into a mixture of sliding and rolling friction.

As shown in Figure 6g, sodium carboxymethylcellulose (CMC-Na)-functionalized CNTs (CNTs@CMC-Na) were obtained via a grafting technique using a microwave-assisted ball-milling apparatus [125]. A four-ball tribometer test was conducted following the addition of CNTs@CMC-Na (0.2 wt%) to water; the results indicated that tribological functions of the nano-additives in reducing friction (50.13%) and wear (58.3%) were superior to those of the pure water–CNTs-COOH condition, as illustrated in Figure 6h. These excellent tribological properties were attributed to the formation of high-quality lubricating films in the friction interface; they acted as a separation layer to prevent the concavity of the contact surface’s friction interface, enabling repairs and protection. Furthermore, it provided lubrication and protection during the friction process; this significantly decreased the generation of oxidation and metal–oxide particles at the frictional interface.

In a study by Jiang et al. [126], the tribological and lubricating properties of poly alpha olefin oil reinforced with MoS2/h-BN hybrid nanoparticles were investigated in conditions both with and without oleic acid (OA) modification. Exceptional tribological characteristics were identified in the hybrid lubricants; these were attributed to the generation of a tribofilm on the surface of the tribo-pair. It is noteworthy that, in the lubrication process with friction pairs under the same working conditions, the friction reduction and wear resistance performances of mixed nano-lubricants were more prominent than those of single nano-lubricants, because two or more nano-additives can compensate for the performance defects of individual nano-additives; there is often a synergistic effect between two nanomaterials. In conclusion, unlike 0D materials, the 1D nano-additives with an aspect ratio cannot provide a repair function; the particular structure resulted in one-way rolling only. Therefore, the orientation of one-dimensional materials in the adsorption film determines lubrication performance. Nevertheless, as the friction time extends, the deposited physical adsorption film starts to disintegrate, and the high reactivity of 1D materials is beneficial in increasing the occurrence of tribological chemical reactions. A one-dimensional friction chemical reaction film can be strongly attached to a worn surface and this contributes to the long-term effectiveness of the lubricant.

3.3. Wear Mechanisms of 1D Nano-Additives

The success of liquid lubrication is closely related to the generation of protective tribofilms and their characteristics [127,128,129]. It has been proven that adding multidimensional nano-additives can effectively improve the bearing capacity, adhesion strength, and lubrication performances of tribofilms [130,131,132]. However, nanomaterials with different structural parameters have different effects on the formation and tribological properties of tribofilms. Similar to 0D-nano-additive-enhanced lubricants, the dispersiveness and stability of 1D nano-additives also play important roles in the formation of lubrication films.

Surface modification technology is used to lower the surface tension and alter the surface polarity of nano-additive materials, thus improving the stability and lubrication performances of lubrication systems. Polyacrylamide (PAM)-grafted multiwalled carbon nanotubes (MWCNT-g-PAM) serving as additives for water lubrication were examined [109]. The results showed a 32% reduction in the friction coefficient and a 26% reduction in the wear rate when compared to pure PAM, as shown in Table 2. In a comparison between two-body wear and three-body wear conditions, CNTs can act as tiny bearings in the friction process, thus turning sliding friction into rolling friction. In addition, the changes of the hollow tubular structure for CNTs also plays an important role in the wear process [133]. As the load was increased, the axial structure of the CNTs undergoes a gradual destruction, resulting in the transformation of the cylindrical hollow structure into a lamellar structure. This process ultimately leads to the formation of a lamellar structure that is similar to that observed for graphene. The lamellar structures can be seen in sliding or rolling contact with the friction pairs. CNTs can be subjected to high contact pressure, resulting in their flattening or crushing. This process generates abrasive wear on the friction subsurface, which serves two functions: firstly, it forms effective protective films on the frictional surface; secondly, it contributes to a reduction in the friction coefficient for lubricating oils. The hollow tubular structure of CNTs allows them to roll in the wear process. This can be attributed to the good dispersal of functionalized MWCNTs in the base lubricant, with an increase in the presence of a grafted PAM. The reduction in the frictional coefficient implies that the MWCNTs-g-PAM composites can serve as spacers, preventing rough contact from occurring between counterparts, and thereby considerably improving the tribological properties of the base lubricant.

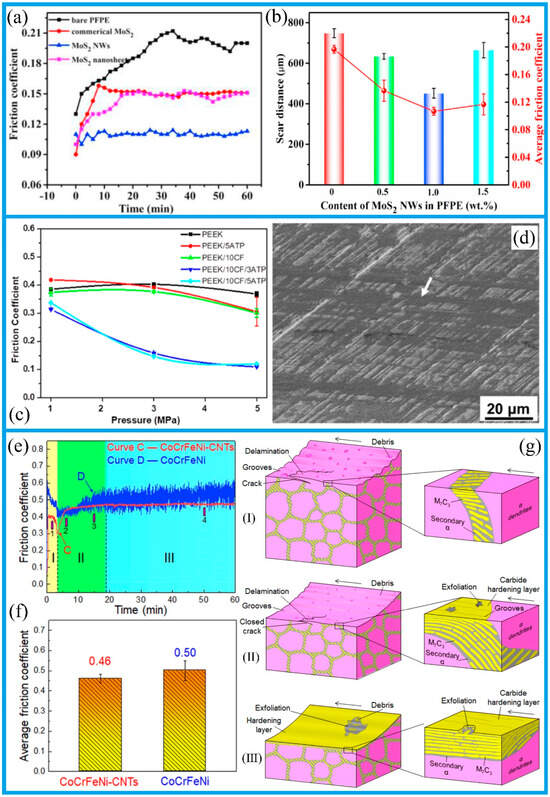

The content and dispersal state of 1D additives in lubricants performs a crucial role in improving the antifriction and anti-wear performances of lubricants. MoS2 nanowires were prepared by Zhang et al. via the electrospinning method as additives for perfluoropolyether (PFPE) base oil [134]. After the four-ball test, it was found that PFPE oil containing 1.0 wt% MoS2 exhibited excellent friction reduction and anti-wear properties; more specifically, these properties achieves a minimal value for the friction coefficient (0.11) and the wear scar diameter (452 μm), as shown in Figure 7a,b. This significant improvement for lubricant oil was mainly attributed to the distinctive nanowire morphology and the favorable dispersion of MoS2 nanowires in PFPE. It is worth noting that, when a concentration is less than optimal, the complete lubricating protective film cannot form on a friction surface, and antifriction and anti-wear properties become limited; in contrast, large particles that gather on a frictional surface occur as a result of the addition of excessive additives, thereby adversely affecting the whole friction system.

Figure 7.

(a) Frictional coefficient curves; (b) wear scar diameter and friction coefficient for different lubricating specimens. Reproduced with permission from the authors of [134]. (c,d) Average friction coefficients of PEEK−based materials. Reproduced with permission from the authors of [106]. (e,f) Variation curve of frictional coefficient and average frictional coefficients of CoCrFeNi−CNTs and CoCrFeNi coatings. (g) Schematic diagrams of microstructure evolution on worn surface for CoCrFeNi−CNTs coating; (I) a initial stage of wear; (II) partial formation stage; (III) complete formation stage for the carbide hardening layer. Reproduced with permission from the authors of [135].

Wang et al. [106] obtained hybrid nanocomposites made from mixed exfoliated attapulgite (ATP) nanofibers with polyetheretherketone (PEEK); these were reinforced with short carbon fiber (CF). The authors explored the function of attapulgite in the tribological properties of polyether-based materials through a pin-on-disc test. The findings revealed that, in comparison to pure PEEK, the friction coefficients of the PEEK-based materials reinforced with 10 CF/5 ATP at 5 Mpa were reduced by up to 67%, as shown in Figure 7c. The presence of the ultra-high tribological property was ascribed to the growth of nanostructured tribofilms with high resilience on the surfaces. More importantly, the physiochemical products of the attapulgite nanofibers played an important role in the growth of a resilient tribofilm. As shown in Figure 7d, during the running-in process, more and more attapulgite nanofibers were released from the hybrid nanocomposite to the sliding interface, thus feeding the growth of a high-resilience tribofilm. It is worth noting that, by virtue of the high flash temperature, the friction products of attapulgite, residual PEEK, and abraded iron oxide were finally “tribo-sintered” into a solid tribofilm, thus providing prominent solid lubrication.

Han et al. [135] investigated the effects of CNTs in a reinforcing phase on the micro-structure and wear properties of an interstitial CoCrFeNi-CNTs coating. The results showed that, compared with that of a CoCrFeNi coating (10.54 × 10−5 mm3 N−1 m−1), the wear rate of the CoCrFeNi-CNTs coating (2.18 × 10−5 mm3 N−1 m−1) was significantly reduced. These improvements in wear performance stem from the strengthening of the solution of carbon on the grains and the precipitation strengthening of (Fe, Cr)7C3 carbides on the grain boundaries. In addition, as shown in Figure 7e,f, the lower friction coefficients and the average friction coefficients further demonstrate that the wear resistance of the CoCrFeNi-CNTs coating could be markedly enhanced by the addition of CNTs. Correspondingly, the microstructure evolution of the CoCrFeNi-CNTs coating on a worn surface is shown in Figure 7g. More specifically, in Figure 7g(I), the CoCrFeNi-CNTs coating exhibited pronounced groove and delamination characteristics on the surface undergoing initial wear. Thus, the wear mechanisms exhibited characteristics of both abrasive wear and fatigue wear during this period. In Figure 7g(II), carbides showed exfoliation in large quantities but were redeposited at a rapid rate. At this stage, the predominant wear mechanism was abrasive wear. In Figure 7g(III), carbide hardening layer was fully formed on the worn surface. Concurrently, the degree of carbide exfoliation was also significantly reduced. The wear mechanism underwent a transformation from an initial combination of strong abrasive wear and fatigue wear to a predominantly weak abrasive wear [136]. In general, during the wear process, the lamellar (Fe, Cr)7C3/α eutectics were deposited on the worn surface and ultimately formed a carbide-hardening layer structure, thus preventing the grievous wear of the CoCrFeNi-CNTs coating.

In conclusion, 1D nano-additives with a high aspect ratio fail to provide a repair function; instead, their use results one-way rolling only due to their unique structure. The high aspect ratio and outstanding mechanical properties endow one-dimensional materials with a stress-transfer effect, which provides an effective approach for improving the bearing capacity and lubrication performance of tribological chemical films under dry friction. Furthermore, in liquid lubrication systems, the surface defects of 1D nano-additives are readily reactive with water molecules or oxygen in the liquid, dispersing uniformly and stably on the friction surface. Under the influence of an external load, these defects gradually gather and compact, forming a thick boundary lubrication film that exhibits excellent anti-wear characteristics. Lubrication films that are rich in one-dimensional materials can effectively prevent the direct contact of friction pairs and reduce the adhesion of worn surfaces, which provides an effective strategy of restraining the friction stress concentration. For one-dimensional nanomaterials, the key parameters controlling the friction and wear behavior are the uniformity of the dispersion and the stability of nanomaterials. Evenly dispersed nano-additives can form high-performance tribofilms with low shear strengths under a high load, which provides a feasible strategy for preventing the direct collision of the friction pairs.

4. Two-Dimensional Nano-Additives in Tribology

Two-dimensional nano-additives have the following advantages: ultra-thin structure; high specific surface area; good thermal stability; low surface energy; smooth surface atoms [137,138]. Attributing to their unique layered structure and their excellent mechanical and self-lubricating properties, 2D nano-additives are effective in reducing friction coefficients via the interlayer slip, and they can form friction adsorption films that repair and protect sliding contact surfaces [139,140]. This section mainly discusses recent progress in research on 2D nano-additives (such as 2D-graphene and its derivatives, 2D-MoS2, and 2D-MXenes) under dry/liquid friction conditions. Details of such studies are presented in Table 3. Note that the focus here will be on significant achievements in the field, and studies on the ulteriorly correlative wear mechanisms of 2D nano-additives are included.

Table 3.

Tribological performance of 2D nano-additives under dry/liquid friction.

4.1. Contributions of 2D Nano-Additives on Lubrication Films under Dry Wear

The ultra-thin structure and high specific surface area of 2D nanomaterials provides a viable solution for improving both wear resistance and antifriction properties in tribofilms [149,150]. Two-dimensional nano-additives have attracted much attention due to their outstanding tribological potential [151,152,153]. The exceptional qualities of 2D nano-additives, including their high mechanical strength, superior thermal stability, and low surface energy, as well as their atomically smooth surface, have obtained significant interest due to their potential uses in tribology applications.

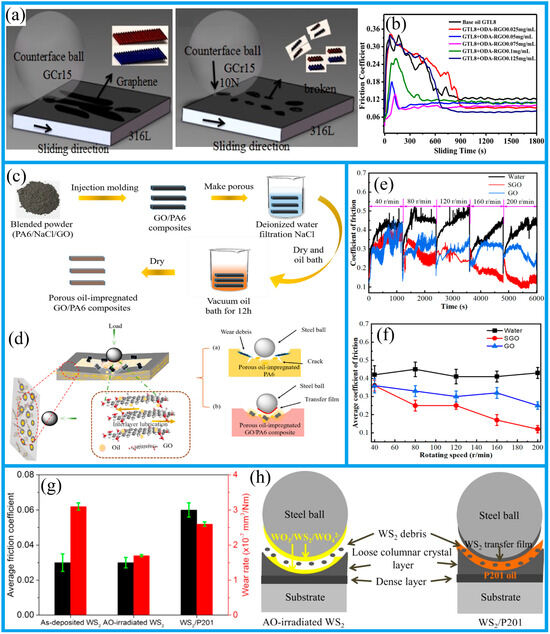

Research into macroscale and nanoscale applications of 2D nano-additives performs an important role in exploring effective strategies for reducing wear and friction. Recently, Wang et al. [154]. comparatively investigated the macroscopic tribological properties of a graphene oxide (GO)-based coating using ball-on-disk tests in different environments (including air, nitrogen gas, and vacuum). The results demonstrated that a GO-based coating showed superior tribological properties in a dry nitrogen environment and in a vacuum environment, due to the formation of special carbon nanoparticles, in comparison to a humid air environment. In addition to the macroscale applications, the frictional behaviors of graphene at the nanoscale also play a vital role in the advancement of micro- and nanomechanical systems. The frictional behavior of graphene on stainless steel was investigated via molecular dynamics simulations [155]. The simulation results evidenced the effect of the multilayer structure and strong adsorption effect of graphene on stainless-steel, revealing the primary source of the super-low friction of graphene.

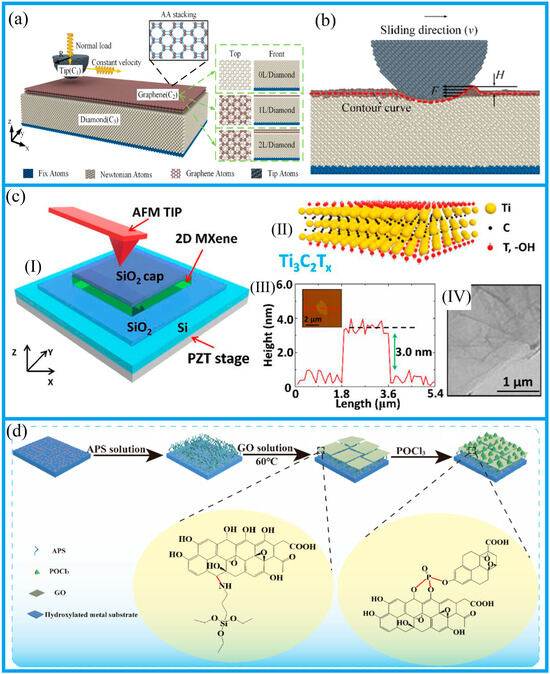

When a solid lubricant film is present, the shear behavior of the contact interface is governed by the shear strength of solid lubricants [156]. A graphene–diamond interfacial structure was built to improve the mechanical properties of the diamond substrate [157]. Three types of graphene–diamond interface structures were constructed to investigate the properties and mechanisms of the suppression of the frictional wear of the diamond substrates by graphene, as shown in Figure 8a. With the increase in the number of layers, the increase in the rigidity outside the layer reduced the elastic deformation at the contact point, thus reducing the “wrinkling” effect. The wrinkling effect of graphene was analyzed to investigate the suppression mechanism of the surface friction and the subsurface wear of the diamond by graphene, as shown in Figure 8b. The potential energy of the graphene sliding with the indenter was formed. It is worth noting that the surface defects and the occurrence of other terminating groups may influence the frictional behavior of graphene.

MoS2, an advanced 2D nanomaterial, has been increasingly used in improving tribological properties owing to its lamellar shear and high mechanical strength. Mohammad’s group [158] demonstrated that the addition of 2.5 wt% MoS2 (optimal concentration) into a copper matrix caused a decrease in the wear loss and frictional coefficient, synchronously improving the wear resistance of the tribo systems; this was mainly attributed to the generation of tribofilms. As for Ni-based coatings, a new interface structure with a 19.63% micropore density facilitated a reduction of 20% in the friction coefficient and a decrease of 65% in the wear rate [159]. The prominent tribological property was ascribed to the cooperative interaction between the MoS2 lubrication layer and the hard Ni-based coating.

In comparison to other 2D nanomaterials, MXene has outstanding characteristics, such as a larger outer surface area, better thermal conductivity, high porosity, and environmental friendliness [160]. As a result, MXene has commonly been used in a number of remedial settings for the treatment of groundwater pollution, surface water, industrial and municipal effluents, and seawater desalination [161,162]. An effect of fewer monolayers on tribological pairs was observed for MXene; they have thicker monolayers in comparison with other 2D materials. These results were helpful in building an understanding of the mechanisms of friction that occur during MXene use, revealing the potentiality of MXene as a tunable lubricant at the nanoscale. To prove frictional behaviors between the surfaces of SiO2 and Ti3C2Tx MXene, the layer-number-dependent friction coefficient of the MXene sheet was measured by an atomic force microscope [163]. Figure 8c(I–IV) shows that the MXene/SiO2 heterostructure has a strong friction anisotropy with a six-fold symmetry. The increase in the layer number was found to significantly reduce the friction anisotropy, and a number of layers higher than 10 was no longer related to the thickness of the film. In addition, the multidimensional site friction system, consisting of MXenes and other additives, reflected the lubrication mechanism for tribofilms through complex synergies [164,165]. In addition, the synergistic effect between conductive polyaniline and MXene was utilized to combine them together to improve the electrical conductivity for the composite, thus enhancing the wave absorption performance of the composite [166].

Through the application of an assembly technology, GO-based composites show excellent tribological properties; this provides valuable guidance for the design of metal-based composite films. A GO-based composite grafted with POCl3 was fabricated onto a metal substrate [141], as shown in Figure 8d. Tests were conducted to determine the tribological properties of the GO-POCl3 nanocomposite; the results demonstrated that the friction coefficient and wear volume were reduced for the nanocomposite in comparison with bare-metal substrates. The main results for the tribological properties for GO-POCl3 nanocomposites are listed in Table 3. The excellent friction-reduction performance was ascribed to the tribo–chemical reaction, forming tribofilms and a transfer layer. A formed tribofilm consisting of GO nanoflakes and metallic phosphate was discovered as a friction process in which the layered GO nanosheets aligned along the direction of the friction, which was dominated by the tribological properties. Similarly, Zhang et al. [142] successfully fabricated a nickel/GO nanocomposite coating via ultrasonic-assisted electrodeposition. They gradually improved the tribological behavior of the nickel/GO coating; this was recorded through the increasing ultrasonic power. The main reason for this was grain refinement and the improved surface quality of the composite coatings. The specific details of the tribological performances of the nickel/GO composite coatings are listed in Table 3.

Figure 8.

(a) Simulation model of diamond-coating graphene; (b) graphene wrinkle effect during sliding; reproduced with permission from the authors of [157]. (c) Investigation on frictional behavior between SiO2 surface with Ti3C2Tx Mxene: including (I) the experimental AFM diagram, (II) structural monolayer for the Ti3C2Tx Mxene, (III) height profiles image of tested Ti3C2Tx sheet, and (IV) TEM image for thin MXene monolayer. Reproduced with permission from the authors of [163]. (d) Fabrication process for SS-APS-GO-POCl3. Reproduced with permission from the authors of [141].

The tribological behavior of a WC/Co/graphene platelet (GPL) composite was investigated using a ball-on-disc tribometer [167]. The results showed that the frictional coefficients and the wear rates of the WC/Co/GPL nanocomposites were reduced to 0.343 and 1.38 × 10−6 mm3 (mN)−1, respectively. The tribological properties of the WC/Co/GPL nanocomposites were attained through the formation of tribofilms. Enhancing the tribological properties of the tribofilms required that the adhesion of GO to the substrate was strengthened [168]. The composite film Si-APS-GO-HOAF, formed through a self-assembly technique driven by chemical bonds consisting of GO and hexafluoropropylene-oxide oligomer acid fluorides (HOAF), displayed outstanding tribological properties; strong interfacial interaction of chemical bonds was observed, alongside the synergistic effect between GO and HOAF. However, the formation of carbon oxide fragments and silicon oxides resulted in damage to the assembled layers, thereby causing lubrication failure.

The tribological behavior of the epoxy (EP) nanocomposite reinforced with a g-C3N4 nanosheet was investigated by Yu et al. [143] via plate-on-ring tests. Compared with pure EP, a 27% decrease in the frictional coefficient and an obvious 83% reduction in wear rate were obtained for the 1% g-C3N4-reinforced nanocomposite, as shown in Table 3. Excellent tribological nanocomposite properties were ascribed to the formation of a robust tribofilm consisting of g-C3N4, EP molecules, and graphitic carbonaceous materials. In a similar report [144], 1 wt% g-C3N4 nanosheets/phenolic coatings were proved to exhibit optimal tribological properties at a loading of 320 N and a sliding speed of 2.5 m/s, as shown in Table 3. The improvement of the friction-reduction and anti-wear properties of the phenolic composite coatings was attributed to two crucial factors: the formation of uniform tribofilms; the strong interfacial adhesion. In conclusion, in contrast with 1D materials, the presence of a larger surface area and a unique layered structure ensure that 2D nano-additives can easily cover worn surfaces, thereby promoting the formation of high-performance adsorption membranes. Lubricating films consisting of physical deposition films as well as tribological chemical films have excellent tribological properties. Nevertheless, under high frictional stress and heat, the decomposition of the functional groups for the additive surfaces leads to the tribofilms having decreased lubrication capacity; 2D nano-additives with a high friction coefficient should be studied further.

4.2. Enhancements of 2D Nano-Additives on Lubrication Films under Liquid Wear

Extensive studies have shown that the structures and shapes of nano-additives play vital roles in reducing friction and wear [169,170]. Due to the double-layer structure and the excellent self-lubricating properties of 2D nano-additives, they have received growing attention in the tribological field; this has extended to applications in improving the efficiency, durability, and environmental compatibility of mechanical systems.

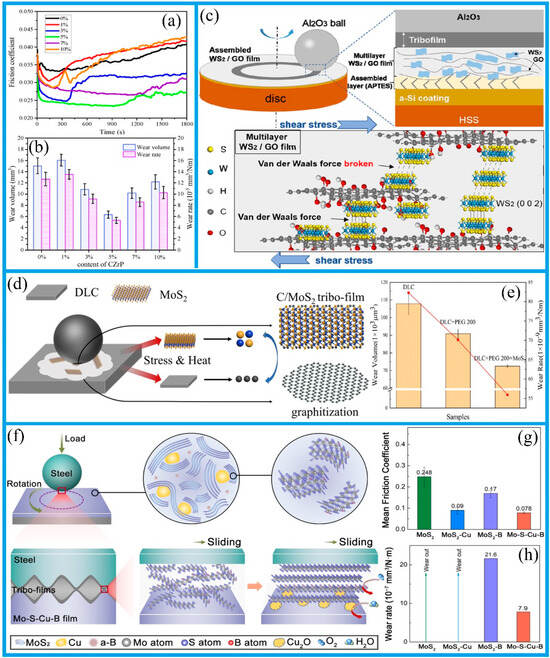

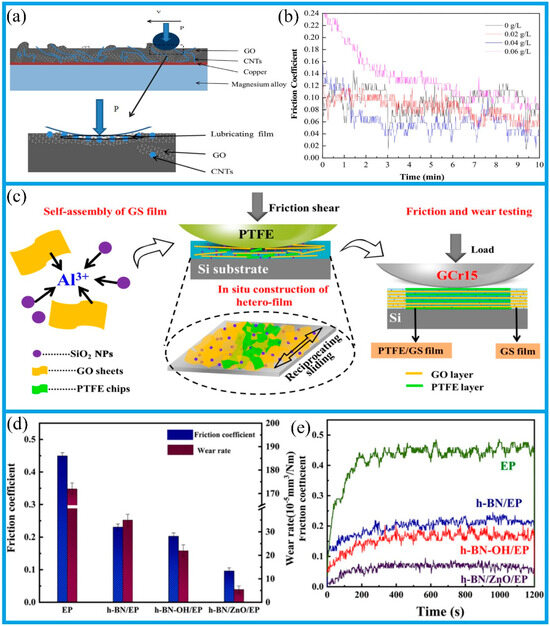

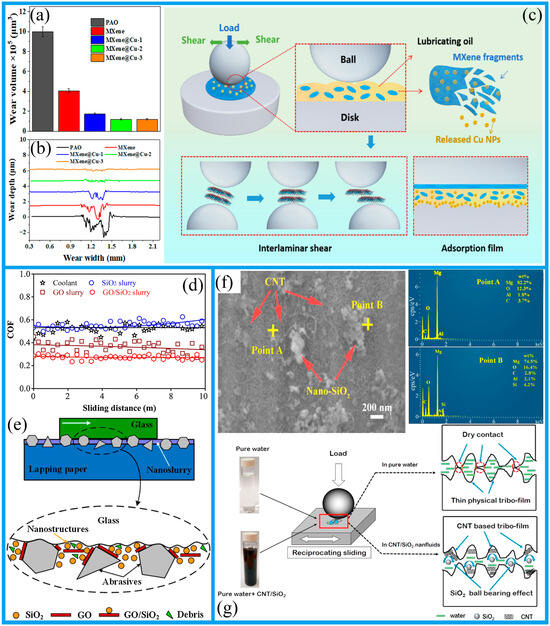

Adding an amount of 2D nano-additives to a lubricating oil can effectively decrease frictional coefficients through an interlayer slip or the formation of adsorption films. Protective tribofilms enable nano-additives to repair and protect sliding contact surfaces, thus significantly improving the antifriction and wear resistance of lubricants [171]. The test results showed that the addition of some elements in the friction area resulted in the formation of protective films through tribo–chemical reactions, which prevented the direct contact of tribological pairs, decreasing friction and wear.