Current and Future Trends in Tribological Research

Abstract

1. Introduction

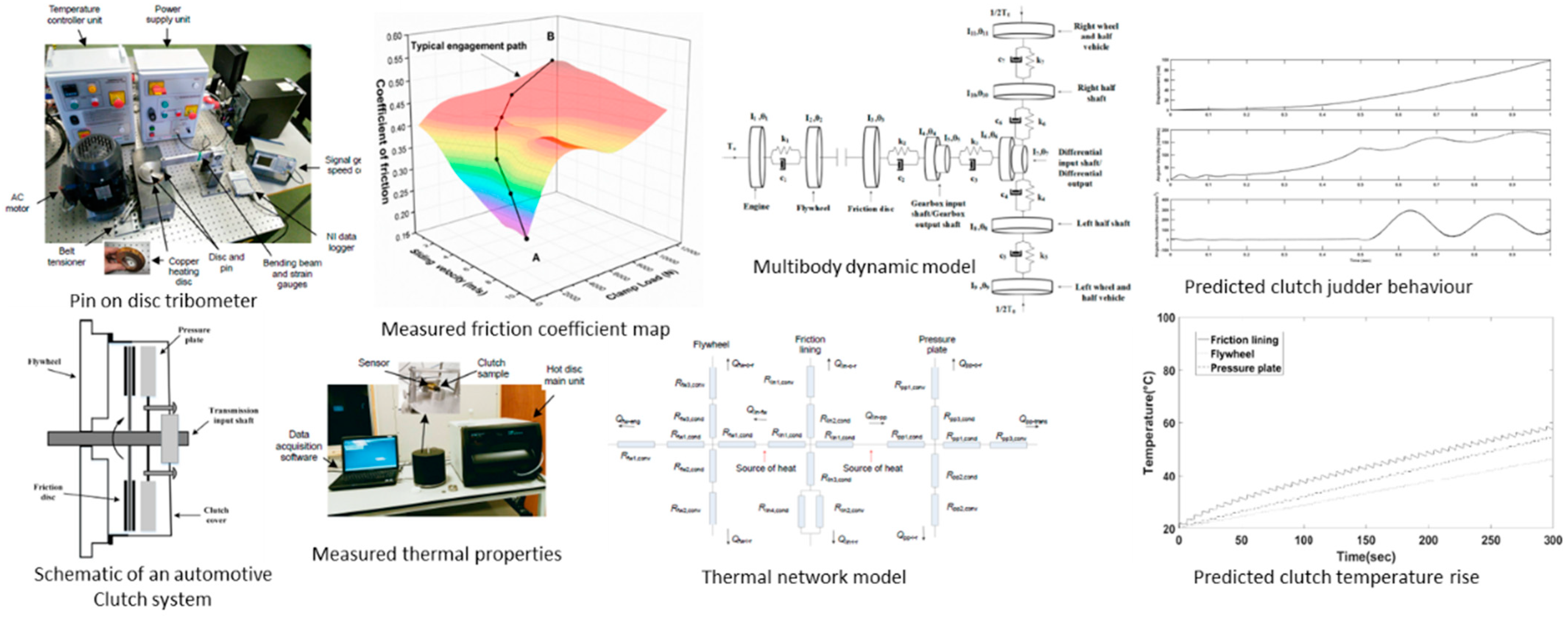

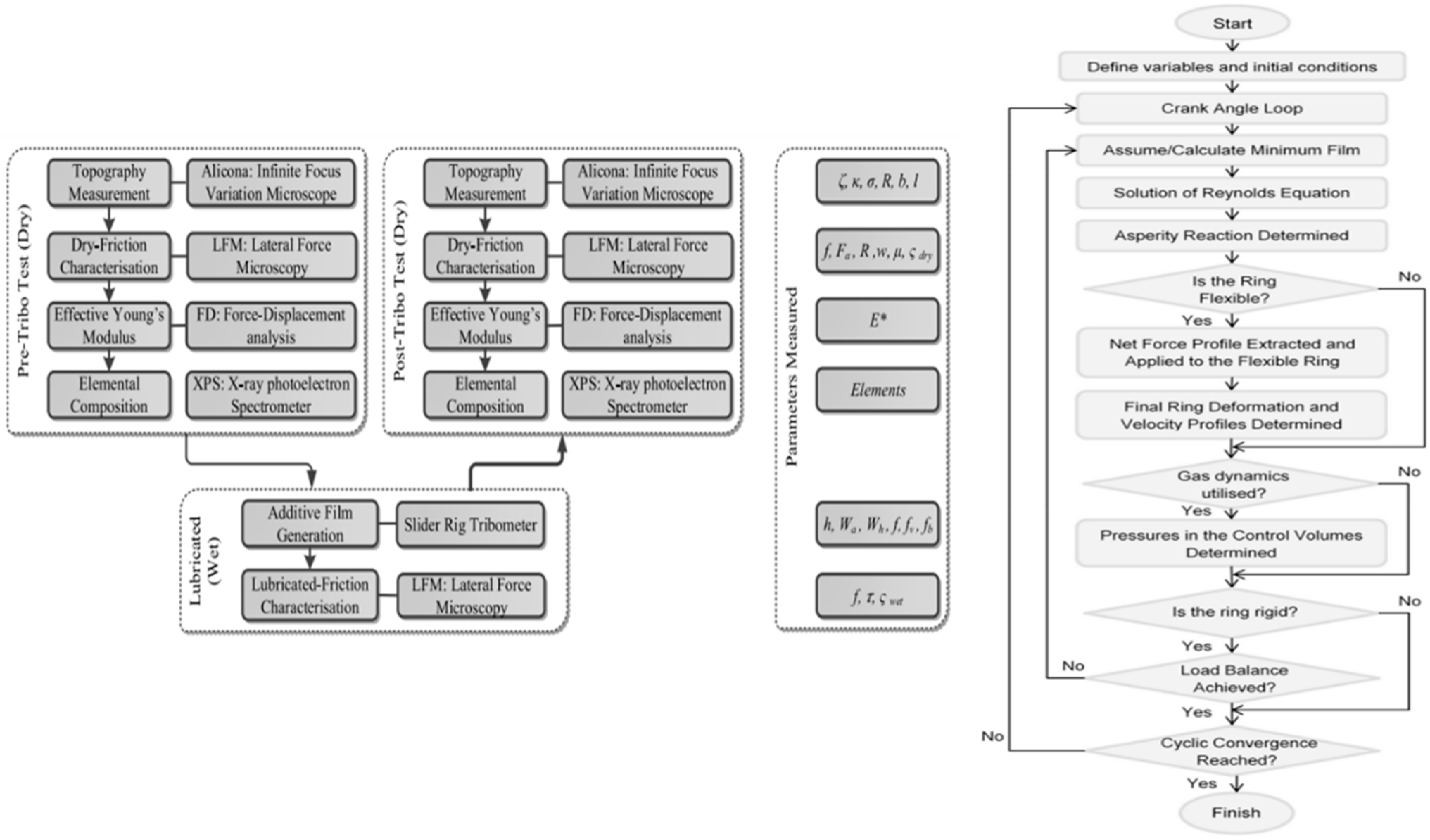

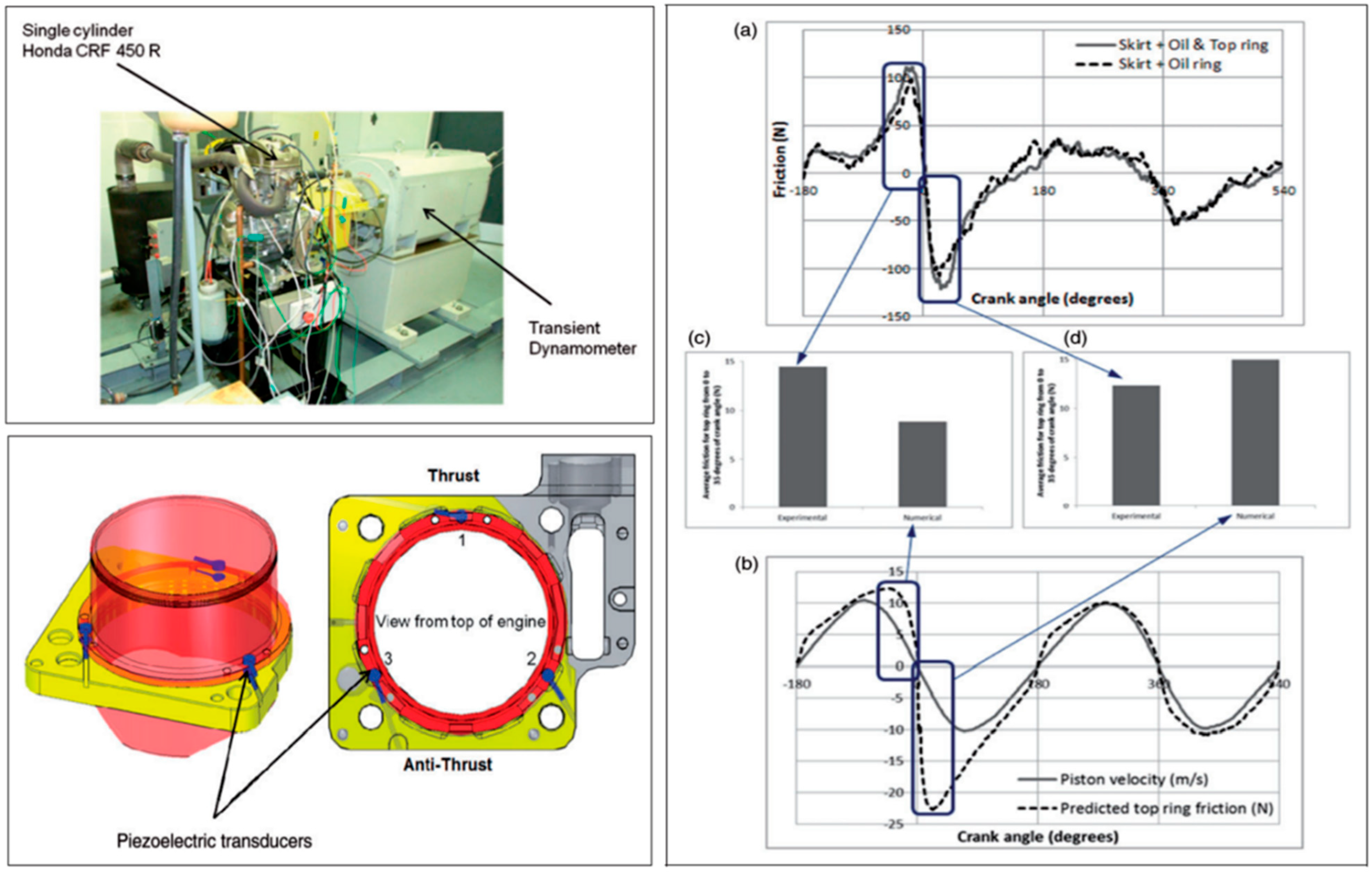

2. Tribodynamics

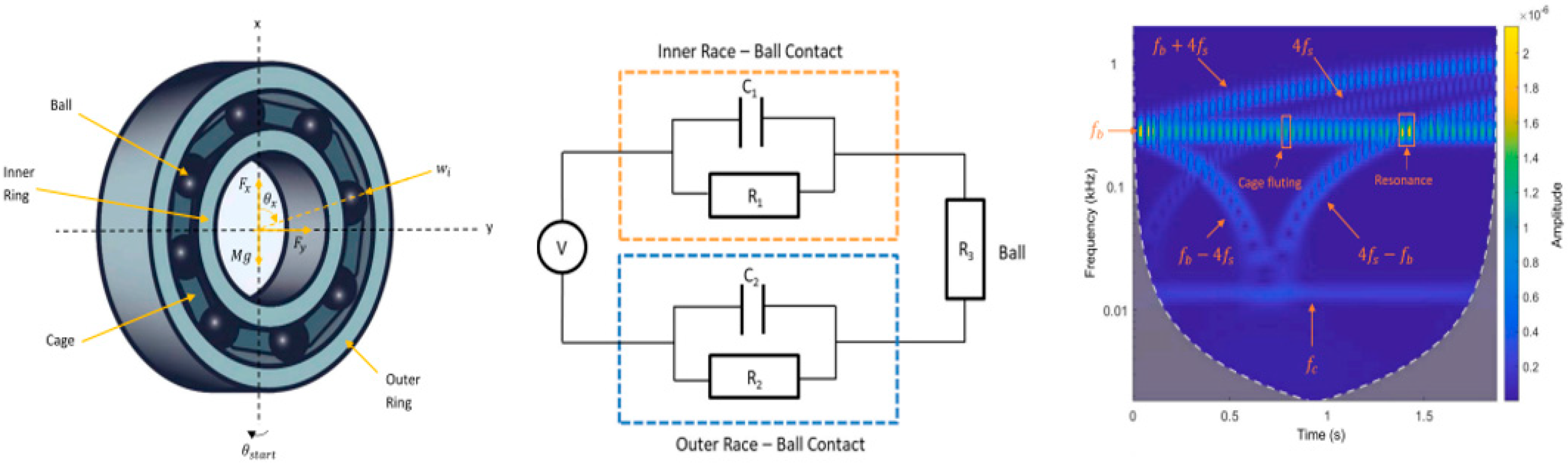

3. Electro-Tribodynamics of Modern Propulsion Systems

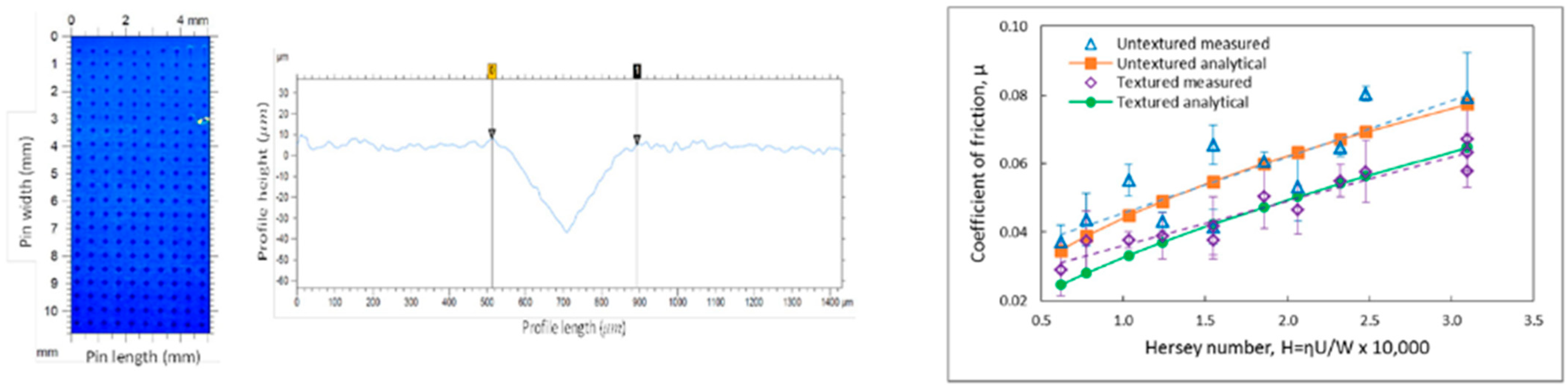

4. Tribology of Engineered Surfaces

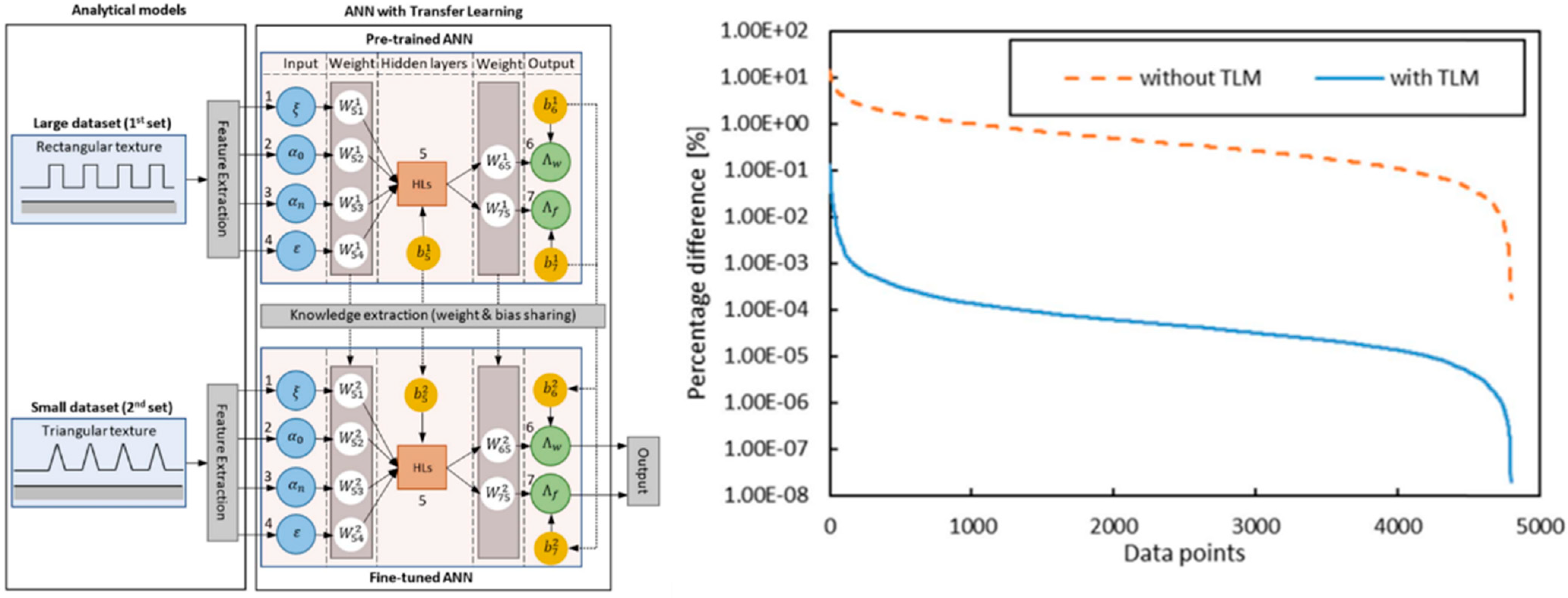

5. Artificial Intelligence in Tribology

6. Biotribology and Biomimetics

7. Nanotribology

8. Computational and Multi-Scale Tribology

9. Tribology in Space and Other Extreme Environments

10. Measurements, Monitoring, and Tribo-Sensing

11. Closure

Funding

Conflicts of Interest

References

- Chan, C.C. The state of the art of electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 704–718. [Google Scholar] [CrossRef]

- Fantin Irudaya Raj, E.; Appadurai, M. The hybrid electric vehicle (HEV)—An overview. In Emerging Solutions for E-Mobility and Smart Grids; Select Proc. ICRES 2020; Springer: Singapore, 2021; pp. 25–36. [Google Scholar]

- Wang, B.; Zhao, D.; Li, W.; Wang, Z.; Huang, Y.; You, Y.; Becker, S. Current technologies and challenges of applying fuel cell hybrid propulsion systems in unmanned aerial vehicles. Prog. Aerosp. Sci. 2020, 116, 100620. [Google Scholar] [CrossRef]

- Lajunen, A. Energy consumption and cost-benefit analysis of hybrid and electric city buses. Transp. Res. Part C Emerg. Technol. 2014, 38, 1–15. [Google Scholar] [CrossRef]

- Mahmoud, M.; Garnett, R.; Ferguson, M.; Kanaroglou, P. Electric buses: A review of alternative powertrains. Renew. Sustain. Energy Rev. 2016, 62, 673–684. [Google Scholar] [CrossRef]

- Brelje, B.J.; Martins, J.R. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2019, 104, 1–19. [Google Scholar] [CrossRef]

- Sorensen, A.J.; Skjetne, R.; Bo, T.; Miyazaki, M.R.; Johansen, T.A.; Utne, I.B.; Pedersen, E. Toward safer, smarter, and greener ships: Using hybrid marine power plants. IEEE Electrif. Mag. 2017, 5, 68–73. [Google Scholar] [CrossRef]

- Usman, M.; Hayat, N.; Bhutta, M.M.A. SI engine fueled with gasoline, CNG and CNG-HHO blend: Comparative evaluation of performance, emission and lubrication oil deterioration. J. Therm. Sci. 2021, 30, 1199–1211. [Google Scholar] [CrossRef]

- Shadidi, B.; Najafi, G.; Yusaf, T. A review of hydrogen as a fuel in internal combustion engines. Energies 2021, 14, 6209. [Google Scholar] [CrossRef]

- Boretti, A. Hydrogen internal combustion engines to 2030. Int. J. Hydrogen Energy 2020, 45, 23692–23703. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Butler, B. An overview of development and challenges in hydrogen powered vehicles. Int. J. Green Energy 2020, 17, 13–37. [Google Scholar] [CrossRef]

- Verhelst, S.; Wallner, T. Hydrogen-fueled internal combustion engines. Prog. Energy Combust. Sci. 2009, 35, 490–527. [Google Scholar] [CrossRef]

- Perveen, R.; Kishor, N.; Mohanty, S.R. Off-shore wind farm development: Present status and challenges. Renew. Sustain. Energy Rev. 2014, 29, 780–792. [Google Scholar] [CrossRef]

- Loisel, R.; Baranger, L.; Chemouri, N.; Spinu, S.; Pardo, S. Economic evaluation of hybrid off-shore wind power and hydrogen storage system. Int. J. Hydrogen Energy 2015, 40, 6727–6739. [Google Scholar] [CrossRef]

- Schallenberg-Rodríguez, J.; Notario-del Pino, J. Evaluation of on-shore wind techno-economical potential in regions and islands. Appl. Energy 2014, 124, 117–129. [Google Scholar] [CrossRef]

- Chang, C.C.; Ding, T.J.; Ping, T.J.; Chao, K.C.; Bhuiyan, M.A. Getting more from the wind: Recent advancements and challenges in generators development for wind turbines. Sustain. Energy Technol. Assess. 2022, 53, 102731. [Google Scholar]

- Hayat, M.B.; Ali, D.; Monyake, K.C.; Alagha, L.; Ahmed, N. Solar energy—A look into power generation, challenges, and a solar-powered future. Int. J. Energy Res. 2019, 43, 1049–1067. [Google Scholar] [CrossRef]

- Khan, J.; Arsalan, M.H. Solar power technologies for sustainable electricity generation–A review. Renew. Sustain. Energy Rev. 2016, 55, 414–425. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ghazvini, M.; Sadeghzadeh, M.; Alhuyi Nazari, M.; Kumar, R.; Naeimi, A.; Ming, T. Solar power technology for electricity generation: A critical review. Energy Sci. Eng. 2018, 6, 340–361. [Google Scholar] [CrossRef]

- Dowson, D. History of Tribology, 2nd ed.; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Gohar, R.; Rahnejat, H. Fundamentals of Tribology, 3rd ed.; World Scientific: Singapore, 2018. [Google Scholar]

- Bhushan, B. Introduction to Tribology; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology; Butterworth-Heinemann: Woburn, MA, USA, 2013. [Google Scholar]

- Wen, S.; Huang, P. Principles of Tribology; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Bhushan, B. (Ed.) Fundamentals of Tribology and Bridging the Gap between the Macro-and Micro/Nanoscales; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Rahnejat, H. Tribology and Dynamics of Engine and Powertrain: Fundamentals, Applications and Future Trends; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar]

- Boysal, A.; Rahnejat, H. Torsional vibration analysis of a multi-body single cylinder internal combustion engine model. Appl. Math. Model. 1997, 21, 481–493. [Google Scholar] [CrossRef]

- Zweiri, Y.H.; Whidborne, J.F.; Seneviratne, L.D. Dynamic simulation of a single-cylinder diesel engine including dynamometer modelling and friction. Proc. IMechE Part D J. Automob. Eng. 1999, 213, 391–402. [Google Scholar] [CrossRef]

- Guzzomi, A.L.; Hesterman, D.C.; Stone, B.J. The effect of piston friction on engine block dynamics. Proc. IMechE Part K J. Multi-Body Dyn. 2007, 221, 277–289. [Google Scholar] [CrossRef]

- Perera, M.S.; Theodossiades, S.; Rahnejat, H. Elasto-multi-body dynamics of internal combustion engines with tribological conjunctions. Proc. IMechE Part K J. Multi-Body Dyn. 2010, 224, 261–277. [Google Scholar] [CrossRef]

- Meuter, M.; Offner, G.; Haase, G. Multi-body engine simulation including elastohydrodynamic lubrication for non-conformal conjunctions. Proc. IMechE Part K J. Multi-Body Dyn. 2017, 231, 457–468. [Google Scholar] [CrossRef]

- Munyao, E.M.; Hu, Y.; Jiang, J. Numerical study of piston group and crosshead guide system dynamics for a two-stroke marine engine. Eng. Rep. 2022, 5, e12564. [Google Scholar] [CrossRef]

- Dowson, D.; Ruddy, B.L.; Economou, N. The elastohydrodynamic lubrication of piston rings. Proc. R. Soc. Lond. A Math. Phys. Sci. 1983, 386, 409–430. [Google Scholar]

- Knoll, G.D.; Peeken, H.J. Hydrodynamic lubrication of piston skirts. J. Lubr. Tech. 1982, 104, 504–508. [Google Scholar] [CrossRef]

- Howell-Smith, S.; Rahnejat, H.; King, D.; Dowson, D. Reducing in-cylinder parasitic losses through surface modification and coating. Proc. IMechE Part D J. Automob. Eng. 2014, 228, 391–402. [Google Scholar] [CrossRef]

- Baker, C.; Theodossiades, S.; Rahmani, R.; Rahnejat, H.; Fitzsimons, B. On the transient three-dimensional tribodynamics of internal combustion engine top compression ring. J. Eng. Gas Turbines Power 2017, 139, 062801. [Google Scholar] [CrossRef]

- Delprete, C.; Razavykia, A. Piston dynamics, lubrication and tribological performance evaluation: A review. Int. J. Engine Res. 2020, 21, 725–741. [Google Scholar] [CrossRef]

- Forero, J.D.; Ochoa, G.V.; Alvarado, W. Study of the piston secondary movement on the tribological performance of a single cylinder low-displacement diesel engine. Lubricants 2020, 8, 97. [Google Scholar] [CrossRef]

- Zavos, A. Effect of coating and Low viscosity oils on piston ring friction under mixed regime of lubrication through analytical modelling. Lubricants 2021, 9, 124. [Google Scholar] [CrossRef]

- Gao, L.; Cui, Y.; Xu, Z.; Fu, Y.; Liu, S.; Li, Y.; Hou, X. A fully coupled tribo-dynamic model for piston-ring-liner system. Tribol. Int. 2023, 178, 107998. [Google Scholar] [CrossRef]

- Tung, S.C.; Gao, H. Tribological characteristics and surface interaction between piston ring coatings and a blend of energy-conserving oils and ethanol fuels. Wear 2003, 255, 1276–1285. [Google Scholar] [CrossRef]

- Lenauer, C.; Tomastik, C.; Wopelka, T.; Jech, M. Piston ring wear and cylinder liner tribofilm in tribotests with lubricants artificially altered with ethanol combustion products. Tribol. Int. 2015, 82, 415–422. [Google Scholar] [CrossRef]

- Rahmani, R.; Dolatabadi, D.; Rahnejat, H. Multiphysics performance assessment of hydrogen fuelled engines. Int. J. Engine Res. 2023, 14680874231182211. [Google Scholar] [CrossRef]

- Rahmani, R.; Rahnejat, H.; Fitzsimons, B.; Dowson, D. The effect of cylinder liner operating temperature on frictional loss and engine emissions in piston ring conjunction. Appl. Energy 2017, 191, 568–581. [Google Scholar] [CrossRef]

- Faizal, M.; Chuah, L.S.; Lee, C.; Hameed, A.; Lee, J.; Shankar, M. Review of hydrogen fuel for internal combustion engines. J. Mech. Eng. Res. Dev. 2019, 42, 36–46. [Google Scholar]

- Stępień, Z. A comprehensive overview of hydrogen-fueled internal combustion engines: Achievements and future challenges. Energies 2021, 14, 6504. [Google Scholar] [CrossRef]

- Kushwaha, M.; Rahnejat, H.; Jin, Z.M. Valve-train dynamics: A simplified tribo-elasto-multi-body analysis. Proc. IMechE Part K J. Multi-Body Dyn. 2000, 214, 95–110. [Google Scholar] [CrossRef]

- Kushwaha, M.; Rahnejat, H. Transient elastohydrodynamic lubrication of finite line conjunction of cam to follower concentrated contact. J. Phys. D Appl. Phys. 2002, 35, 2872. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Teodorescu, M.; Kushwaha, M.; Rahnejat, H.; Taraza, D. Elastodynamic transient analysis of a four-cylinder valvetrain system with camshaft flexibility. Proc. IMechE Part K J. Multi-Body Dyn. 2005, 219, 13–25. [Google Scholar] [CrossRef]

- Jamali, H.U.; Al-Hamood, A.; Abdullah, O.I.; Senatore, A.; Schlattmann, J. Lubrication analyses of cam and flat-faced follower. Lubricants 2019, 7, 31. [Google Scholar] [CrossRef]

- Shirzadegan, M.; Almqvist, A.; Larsson, R. Fully coupled EHL model for simulation of finite length line cam-roller follower contacts. Tribol. Int. 2016, 103, 584–598. [Google Scholar] [CrossRef]

- Hu, B.; Zhou, C.; Chen, S. Elastic dynamics modelling and analysis for a valve train including oil film stiffness and dry contact stiffness. Mech. Mach. Theory 2019, 131, 33–47. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, W.; Zou, D. Investigation of dynamic characteristics of a valve train system. Mech. Mach. Theory 2011, 46, 1950–1969. [Google Scholar] [CrossRef]

- Teodorescu, M.; Kushwaha, M.; Rahnejat, H.; Rothberg, S.J. Multi-physics analysis of valve train systems: From system level to microscale interactions. Proc. IMechE Part K J. Multi-Body Dyn. 2007, 221, 349–361. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Johns-Rahnejat, M.; Gohar, R. Point contact elastohydrodynamic pressure distribution and sub-surface stress field. In Proceedings of the Tri-annual Conference on Multi-Body Dynamics: Monitoring and Simulation Techniques, Bradford, UK, 15 March 1997. [Google Scholar]

- Bomidi, J.A.; Sadeghi, F. Three-dimensional finite element elastic–plastic model for subsurface initiated spalling in rolling contacts. J. Tribol. 2014, 136, 011402. [Google Scholar] [CrossRef]

- Sadeghi, F. Elastohydrodynamic lubrication. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 171–226e. [Google Scholar]

- Johns-Rahnejat, M.; Dolatabadi, N.; Rahnejat, H. Analytical elastostatic contact mechanics of highly-loaded contacts of varying conformity. Lubricants 2020, 8, 89. [Google Scholar] [CrossRef]

- Rahnejat, H.; Rahmani, R.; Mohammadpour, M.; Johns-Rahnejat, P.M. Tribology of power train systems. In Friction, Lubrication, and Wear Technology; Totten, G.E., Ed.; ASM: Washington, DC, USA, 2017; Volume 18, pp. 916–934. [Google Scholar]

- Zhang, G.; Su, B.; Liu, F.; Zhang, W.; Yang, H. Thermal Analysis Based on Dynamic Performance of Rocker Arm Full-Type Needle Bearings. Lubricants 2022, 10, 104. [Google Scholar] [CrossRef]

- Booker, J.F.; Boedo, S.; Bonneau, D. Conformal elastohydrodynamic lubrication analysis for engine bearing design: A brief review. Proc. IMechE Part C J. Mech. Eng. Sci. 2010, 224, 2648–2653. [Google Scholar] [CrossRef]

- Balakrishnan, S.; McMinn, C.; Baker, C.E.; Rahnejat, H. Fundamentals of Crank and Camshaft Support Journal Bearings. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 591–614. [Google Scholar]

- Mohammadpour, M.; Rahmani, R.; Rahnejat, H. Effect of cylinder deactivation on the tribo-dynamics and acoustic emission of overlay big end bearings. Proc. IMechE Part K J. Multi-Body Dyn. 2014, 228, 138–151. [Google Scholar] [CrossRef]

- Gebretsadik, D.W.; Hardell, J.; Prakash, B. Tribological performance of tin-based overlay plated engine bearing materials. Tribol. Int. 2015, 92, 281–289. [Google Scholar] [CrossRef]

- Repka, M.; Dörr, N.; Brenner, J.; Gabler, C.; McAleese, C.; Ishigo, O.; Koshima, M. Lubricant-surface interactions of polymer-coated engine journal bearings. Tribol. Int. 2017, 109, 519–528. [Google Scholar] [CrossRef]

- Lorenz, N.; Offner, G.; Knaus, O. Thermal analysis of hydrodynamic lubricated journal bearings in internal combustion engines. Proc. IMechE Part K J. Multi-Body Dyn. 2017, 231, 406–419. [Google Scholar] [CrossRef]

- Cao, J.; Huang, H.; Li, S.; Wu, X.; Yin, Z.; Abbas, Z. Tribological and mechanical behaviors of engine bearing with CuSn10 layer and h-BN/graphite coating prepared by spraying under different temperatures. Tribol. Int. 2020, 152, 106445. [Google Scholar] [CrossRef]

- Summer, F.; Grün, F.; Ravenhill, E.R. Friction and wear performance of various polymer coatings for journal bearings under stop start sliding. Lubricants 2019, 8, 1. [Google Scholar] [CrossRef]

- Krasnyy, V.A.; Osminko, D.A. Improving the wear resistance of bushings through polymer coatings. Key Eng. Mater. 2020, 836, 136–141. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Uehara, S.; Costa, S.M.C.; da Silva Praça, M.S.; dos Santos Ferreira, M. New Polymeric Coated Engine Bearings for Marginal Lubrication Conditions; SAE Technical Paper: Warrendale, PA, USA, 2011; No. 2011-36-0189. [Google Scholar]

- Kelly, P.; Menday, M. Various forms of transmission rattle in automotive powertrains. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 839–856. [Google Scholar]

- Doğan, S.N. Rattle and clatter noise in powertrains–automotive transmissions. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 793–838. [Google Scholar]

- Brancati, R.; Rocca, E.; Russo, R. A gear rattle model accounting for oil squeeze between the meshing gear teeth. Proc. IMechE Part D J. Automob. Eng. 2005, 219, 1075–1083. [Google Scholar] [CrossRef]

- Theodossiades, S.; Tangasawi, O.; Rahnejat, H. Gear teeth impacts in hydrodynamic conjunctions promoting idle gear rattle. J. Sound Vib. 2007, 303, 632–658. [Google Scholar] [CrossRef]

- Tangasawi, O.; Theodossiades, S.; Rahnejat, H.; Kelly, P. Non-linear vibro-impact phenomenon belying transmission idle rattle. Proc. IMechE Part C J. Mech. Eng. Sci. 2008, 222, 1909–1923. [Google Scholar] [CrossRef]

- Russo, R.; Brancati, R.; Rocca, E. Experimental investigations about the influence of oil lubricant between teeth on the gear rattle phenomenon. J. Sound Vib. 2009, 321, 647–661. [Google Scholar] [CrossRef]

- Fernandez-Del-Rincon, A.; Diez-Ibarbia, A.; Theodossiades, S. Gear transmission rattle: Assessment of meshing forces under hydrodynamic lubrication. Appl. Acoust. 2019, 144, 85–95. [Google Scholar] [CrossRef]

- De la Cruz, M.; Theodossiades, S.; Rahnejat, H. An investigation of manual transmission drive rattle. Proc. IMechE Part K J. Multi-Body Dyn. 2010, 224, 167–181. [Google Scholar] [CrossRef]

- De la Cruz, M.; Chong, W.W.F.; Teodorescu, M.; Theodossiades, S.; Rahnejat, H. Transient mixed thermo-elastohydrodynamic lubrication in multi-speed transmissions. Tribol. Int. 2012, 49, 17–29. [Google Scholar] [CrossRef]

- Baumann, A.; Bertsche, B. Experimental study on transmission rattle noise behaviour with particular regard to lubricating oil. J. Sound Vib. 2015, 341, 195–205. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhu, C.; Parker, R.G. Effects of lubrication on gear performance: A review. Mech. Mach. Theory 2020, 145, 103701. [Google Scholar] [CrossRef]

- Donmez, A.; Kahraman, A. Characterization of Nonlinear Rattling Behavior of a Gear Pair Through a Validated Torsional Model. J. Comput. Nonlinear Dyn. 2022, 17, 041006. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, M.; Wang, J.; Wan, Y. Point Contact Thermal Mixed-EHL under Short Period Intermittent Motion. J. Tribol. 2023, 145, 1–24. [Google Scholar] [CrossRef]

- Plank, D.; Hong, H.J.; Gehringer, M.; Hill, W. Multi Body Dynamics Modeling of Launch Shudder in Electric Vehicles; SAE Technical Paper: Warrendale, PA, USA, 2022; No. 2022-01-0308. [Google Scholar]

- Yu, X.; Hou, Q.; Zhen, R.; Shangguan, W. Transmission Efficiency Analysis of High-Efficiency Constant Velocity Joint. SSAE Technical Paper: Warrendale, PA, USA, 2021; No. 2021-01-0705. [Google Scholar]

- Marter, P.; Daniel, C.; Duvigneau, F.; Woschke, E. Numerical Analysis Based on a Multi-Body Simulation for a Plunging Type Constant Velocity Joint. Appl. Sci. 2020, 10, 3715. [Google Scholar] [CrossRef]

- Serveto, S.; Mariot, J.-P.; Diaby, M. Secondary Torque in Automotive Drive Shaft Ball Joints: Influence of Geometry and Friction. Proc. IMechE Part K J. Multi-Body Dyn. 2008, 222, 215–227. [Google Scholar] [CrossRef]

- Simpson, M.; Dolatabadi, N.; Rahmani, R.; Morris, N.; Jones, D.; Craig, C. Multibody dynamics of cross groove constant velocity ball joints for high performance racing applications. Mech. Mach. Theory 2023, 188, 105407. [Google Scholar] [CrossRef]

- Simpson, M.; Dolatabadi, N.; Morris, N.; Rahmani, R.; Jones, D.; Craig, C. Analysis of a cross groove constant velocity joint mechanism designed for high performance racing conditions. Proc. IMechE Part K J. Multi-Body Dyn. 2023, 237, 16–33. [Google Scholar] [CrossRef]

- Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.; Dowson, D. Big end bearing losses with thermal cavitation flow under cylinder deactivation. Tribol. Lett. 2015, 57, 2. [Google Scholar] [CrossRef]

- Santos, N.D.; Roso, V.R.; Faria, M.T. Review of engine journal bearing tribology in start-stop applications. Eng. Fail. Anal. 2020, 108, 104344. [Google Scholar] [CrossRef]

- Turnbull, R.; Dolatabadi, N.; Rahmani, R.; Rahnejat, H. Energy loss and emissions of engine compression rings with cylinder deactivation. Proc. IMechE Part D J. Automob. Eng. 2021, 235, 1930–1943. [Google Scholar] [CrossRef]

- Orjuela Abril, S.; Fonseca-Vigoya, M.D.; García, C. Study of the Cylinder Deactivation on Tribological Parameters and Emissions in an Internal Combustion Engine. Lubricants 2022, 10, 60. [Google Scholar] [CrossRef]

- Gkinis, T.; Rahmani, R.; Rahnejat, H. Integrated thermal and dynamic analysis of dry automotive clutch linings. Appl. Sci. 2019, 9, 4287. [Google Scholar] [CrossRef]

- Gkinis, T.; Rahmani, R.; Rahnejat, H.; O’Mahony, M. Heat generation and transfer in automotive dry clutch engagement. J. Zhejiang Univ. Sci. A 2018, 19, 175–188. [Google Scholar] [CrossRef]

- Xu, J.; Hong, H.; Yuan, X.; Zhao, Z. Tribo-dynamics analysis of satellite-bone multi-axis linkage system. J. Appl. Nonlinear Dyn. 2015, 4, 239–250. [Google Scholar] [CrossRef]

- Cheng, S.; Meng, X.; Li, R.; Liu, R.; Zhang, R.; Sun, K.; Ye, W.; Zhao, F. Rough surface damping contact model and its space mechanism application. Int. J. Mech. Sci. 2022, 214, 106899. [Google Scholar] [CrossRef]

- Wu, T.; Du, Y.; Li, Y.; Wang, S.; Zhang, Z. Synthesized multi-station tribo-test system for bio-tribological evaluation in vitro. Chin. J. Mech. Eng. 2016, 29, 853–861. [Google Scholar] [CrossRef]

- Farnham, M.S.; Ortved, K.F.; Burris, D.L.; Price, C. Articular cartilage friction, strain, and viability under physiological to pathological benchtop sliding conditions. Cell. Mol. Bioeng. 2021, 14, 349–363. [Google Scholar] [CrossRef]

- Yan, Q.; Li, R.; Meng, X. Tribo-dynamic analysis and motion control of a rotating manipulator based on the load and temperature dependent friction model. Proc. IMechE Part J J. Eng. Tribol. 2021, 235, 1335–1352. [Google Scholar] [CrossRef]

- Zaspa, Y. Competition of modes and self-modulation instability in dynamics of coherent friction: A review. J. Frict. Wear 2013, 34, 317–327. [Google Scholar] [CrossRef]

- Turnbull, R.; Dolatabadi, N.; Rahmani, R.; Rahnejat, H. Nonlinear tribodynamics of an elastic shaft with a flexible bearing outer race. Proc. IMechE Part K J. Multi-Body Dyn. 2023, 237, 290–306. [Google Scholar] [CrossRef]

- Mughal, H.; Sivayogan, G.; Dolatabadi, N.; Rahmani, R. An efficient analytical approach to assess root cause of nonlinear electric vehicle gear whine. Nonlinear Dyn. 2022, 9, 3167–3186. [Google Scholar] [CrossRef]

- Waite, C. UK Greenhouse Gas Emissions. 2018. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/863325/2018-final-emissions-statistics-summary.pdf (accessed on 30 July 2023).

- Department for Transport Decarbonising Transport Setting the Challenge. 2020. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/932122/decarbonising-transport-setting-the-challenge.pdf (accessed on 11 November 2021).

- Department for Business, Energy & Industrial Strategy. The Ten Point Plan for a Green Industrial Revolution. 2020. Available online: https://www.gov.uk/government/publications/the-ten-point-plan-for-a-green-industrial-revolution/title#point-4-accelerating-the-shift-to-zero-emission-vehicles (accessed on 10 March 2022).

- Costello, M.J. Shaft voltages and rotating machinery. IEEE Tran. Ind. Appl. 1993, 29, 419–426. [Google Scholar] [CrossRef]

- Becker, A.; Abanteriba, S. Electric discharge damage in aircraft propulsion bearings. Proc. IMechE Part J J. Eng. Tribol. 2014, 228, 104–113. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, H.; Fan, Y.; Shangguan, L.; Yang, Y. A Review of Research on Wind Turbine Bearings’ Failure Analysis and Fault Diagnosis. Lubricants 2023, 11, 14. [Google Scholar] [CrossRef]

- Tischmacher, H.; Gattermann, S. Multiple signature analysis for the detection of bearing currents and the assessment of the resulting bearing wear. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 20–22 June 2012; pp. 1354–1359. [Google Scholar]

- Tischmacher, H. Systemanalysen Zur Elektrischen Belastung Von Wälzlagern Bei Umrichtergespeisten Elektromotoren. Ph.D. Thesis, Gottfried Wilhelm Leibniz Universität, Hannover, Germany, 2017; p. X-225. [Google Scholar]

- Loos, J.; Bergmann, I.; Goss, M. Influence of high electrical currents on WEC formation in rolling bearings. Tribol. Trans. 2021, 64, 708–720. [Google Scholar] [CrossRef]

- Busse, D.; Erdman, J.; Kerkman, R.J.; Schlegel, D.; Skibinski, G. System electrical parameters and their effects on bearing currents. IEEE Trans. Ind. Appl. 1997, 33, 577–584. [Google Scholar] [CrossRef]

- Joshi, A. Electrical Characterisations of Bearings. Ph.D. Thesis, High Voltage Engineering, Electrical Engineering, Chalmers University, Gothenburg, Sweden, 2019. [Google Scholar]

- Turnbull, R.; Rahmani, R.; Paul, S.; Rahnejat, H. Electrotribodynamics of ball bearings in electrical machines. Tribol. Int. 2023, 188, 108817. [Google Scholar] [CrossRef]

- ISO 15243; Rolling Bearings, Damage and Failures, Terms, Characteristics and Causes. International Organization for Standardization: Geneva, Switzerland, 2017.

- Gould, B.; Demas, N.; Erck, R.; Lorenzo-Martin, M.C.; Ajayi, O.; Greco, A. The effect of electrical current on premature failures and microstructural degradation in bearing steel. Int. J. Fatigue 2021, 145, 106078. [Google Scholar] [CrossRef]

- Sprecher, A.F.; Mannan, S.L.; Conrad, H. Overview 49: On the mechanism for the electroplastic effect in metals. Acta Metall. 1986, 34, 1145–1162. [Google Scholar] [CrossRef]

- Schneider, V.; Behrendt, C.; Höltje, P.; Cornel, D.; Becker-Dombrowsky, F.M.; Puchtler, S.; Gutiérrez Guzmán, F.; Ponick, B.; Jacobs, G.; Kirchner, E. Electrical Bearing Damage, A Problem in the Nano-and Macro-Range. Lubricants 2022, 10, 194. [Google Scholar] [CrossRef]

- Schneider, V.; Liu, H.C.; Bader, N.; Furtmann, A.; Poll, G. Empirical formulae for the influence of real film thickness distribution on the capacitance of an EHL point contact and application to rolling bearings. Tribol. Int. 2021, 154, 106714. [Google Scholar] [CrossRef]

- Jackson, R.L.; Angadi, S. Modelling of lubricated electrical contacts. Lubricants 2022, 10, 32. [Google Scholar] [CrossRef]

- Morris, S.A.; Leighton, M.; Morris, N.J. Electrical Field Strength in Rough Infinite Line Contact Elastohydrodynamic Conjunctions. Lubricants 2022, 10, 87. [Google Scholar] [CrossRef]

- Bhushan, B.; Peng, W. Contact mechanics of multilayered rough surfaces. Appl. Mech. Rev. 2002, 55, 435–480. [Google Scholar] [CrossRef]

- McGuiggan, M.; Wallace, J.S.; Smith, D.T.; Sridhar, I.; Zheng, Z.W.; Johnson, K.L. Contact mechanics of layered elastic materials: Experiment and theory. J. Phys. D Appl. Phys. 2007, 40, 5984. [Google Scholar] [CrossRef]

- Teodorescu, M.; Rahnejat, H.; Gohar, R.; Dowson, D. Harmonic decomposition analysis of contact mechanics of bonded layered elastic solids. Appl. Math. Model. 2009, 33, 467–485. [Google Scholar] [CrossRef]

- Teodorescu, M.; Votsios, V.; Rahnejat, H. Fundamentals of impact dynamics of semi-infinite and layered solids. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 105–132e. [Google Scholar]

- Menga, N.; Putignano, C.; Afferrante, L.; Carbone, G. The contact mechanics of coated elastic solids: Effect of coating thickness and stiffness. Tribol. Lett. 2019, 67, 24. [Google Scholar] [CrossRef]

- Wallace, E.R.; Chaise, T.; Nelias, D. Three-dimensional rolling/sliding contact on a viscoelastic layered half-space. J Mech. Phys. Solids 2020, 143, 104067. [Google Scholar] [CrossRef]

- Hua, D.Y.; Farhang, K.; Seitzman, L.E. A multi-scale system analysis and verification for improved contact fatigue life cycle of a cam-roller system. J. Tribol. 2007, 129, 321–325. [Google Scholar] [CrossRef]

- Teodorescu, M.; Rahnejat, H. Mathematical modelling of layered contact mechanics of cam–tappet conjunction. Appl. Math. Model. 2007, 31, 2610–2627. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Stahl, K.; Michaelis, K.; Mayer, J.; Hinterstoißer, M. Friction reduction of highly-loaded rolling-sliding contacts by surface modifications under elasto-hydrodynamic lubrication. Wear 2015, 328, 217–228. [Google Scholar] [CrossRef]

- Beilicke, R.; Bobach, L.; Bartel, D. Transient thermal elastohydrodynamic simulation of a DLC coated helical gear pair considering limiting shear stress behavior of the lubricant. Tribol. Int. 2016, 97, 136–150. [Google Scholar] [CrossRef]

- Arshad, W.; Hanif, M.A.; Bhutta, M.U.; Mufti, R.A.; Shah, S.R.; Abdullah, M.U.; Najeeb, M.H. Technique developed to study camshaft and tappet wear on real production engine. Ind. Lubr. Tribol. 2017, 69, 174–181. [Google Scholar] [CrossRef]

- Ziegltrum, A.; Lohner, T.; Stahl, K. TEHL simulation on the influence of lubricants on the frictional losses of DLC coated gears. Lubricants 2018, 6, 17. [Google Scholar] [CrossRef]

- Katiyar, J.K.; Bhattacharya, S.; Patel, V.K.; Kumar, V. Introduction of automotive tribology. In Automotive Tribology; Springer: Singapore, 2019; pp. 3–13. [Google Scholar] [CrossRef]

- Humphrey, E.; Morris, N.J.; Rahmani, R.; Rahnejat, H. Multiscale boundary frictional performance of diamond like carbon coatings. Tribol. Int. 2020, 149, 105539. [Google Scholar] [CrossRef]

- Patzer, G.; Woydt, M.; Shah, R.; Miller, C.; Iaccarino, P. Test modes for establishing the tribological profile under slip-rolling. Lubricants 2020, 8, 59. [Google Scholar] [CrossRef]

- Balakrishnan, S.; Rahnejat, H. Isothermal transient analysis of piston skirt-to-cylinder wall contacts under combined axial, lateral and tilting motion. J. Phys. D Appl. Phys. 2005, 38, 787. [Google Scholar] [CrossRef]

- Gore, M.; Rahmani, R.; Rahnejat, H.; King, D. Assessment of friction from compression ring conjunction of a high-performance internal combustion engine: A combined numerical and experimental study. Proc. IMechE Part C J. Mech. Eng. Sci. 2016, 230, 2073–2085. [Google Scholar] [CrossRef]

- Turturro, A.; Rahmani, R.; Rahnejat, H.; Delprete, C.; Magro, L. Assessment of friction for cam-roller follower valve train system subjected to mixed non-Newtonian regime of lubrication. In Proceedings of the ASME Internal Combustion Engine Division Spring Technical Conference, Torino, Piemonte, Italy, 6 May 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; Volume 44663, pp. 917–923. [Google Scholar]

- Kushwahu, M. Tribological issues in cam–tappet contacts. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 545–566. [Google Scholar]

- Elias, J.V.; Venkatesh, N.; Lawrence, K.D.; Mathew, J. Tool texturing for micro-turning applications–an approach using mechanical micro indentation. Mater. Manuf. Process. 2021, 36, 84–93. [Google Scholar] [CrossRef]

- Teo, W.J.; Dolatabadi, N.; Rahmani, R.; Morris, N.; Rahnejat, H. Combined analytical and experimental evaluation of frictional performance of lubricated untextured and partially textured sliders. Lubricants 2018, 6, 88. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Some innovative surface texturing techniques for tribological purposes. Proc. IMechE Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef]

- Qian, S.; Ji, F.; Qu, N.; Li, H. Improving the localization of surface texture by electrochemical machining with auxiliary anode. Mater. Manuf. Process. 2014, 29, 1488–1493. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, R.; Kango, S.; Sharma, V.S. Recent progresses and applications in laser-based surface texturing systems. Mater. Today Commun. 2021, 26, 101736. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Trib. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Morris, N.; Leighton, M.; De la Cruz, M.; Rahmani, R.; Rahnejat, H.; Howell-Smith, S. Combined numerical and experimental investigation of the micro-hydrodynamics of chevron-based textured patterns influencing conjunctional friction of sliding contacts. Proc. IMechE Part J J. Eng. Tribol. 2015, 229, 316–335. [Google Scholar] [CrossRef]

- Etsion, I. Surface texturing for in-cylinder friction reduction. Tribol. Dyn. Engine Powertrain 2010, 458–470e. [Google Scholar] [CrossRef]

- Kligerman, Y.; Etsion, I.; Shinkarenko, A. Improving tribological performance of piston rings by partial surface texturing. J. Tribol. 2005, 127, 632–638. [Google Scholar] [CrossRef]

- Miao, C.; Guo, Z.; Yuan, C. Tribological behavior of co-textured cylinder liner-piston ring during running-in. Friction 2022, 10, 878–890. [Google Scholar] [CrossRef]

- Tala-Ighil, N.; Fillon, M.; Maspeyrot, P. Effect of textured area on the performances of a hydrodynamic journal bearing. Tribol. Int. 2011, 44, 211–219. [Google Scholar] [CrossRef]

- Galda, L.; Sep, J.; Olszewski, A.; Zochowski, T. Experimental investigation into surface texture effect on journal bearings performance. Tribol. Int. 2019, 136, 372–384. [Google Scholar] [CrossRef]

- Morris, N.J.; Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C. Combined experimental and multiphase computational fluid dynamics analysis of surface textured journal bearings in mixed regime of lubrication. Lubr. Sci. 2018, 30, 161–173. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Cep, R.; Pradhan, B.B.; Sharma, A. Laser surface texturing for biomedical applications: A review. Coatings 2021, 11, 124. [Google Scholar] [CrossRef]

- Shah, R.; Gashi, B.; Hoque, S.; Marian, M.; Rosenkranz, A. Enhancing mechanical and biomedical properties of protheses-surface and material design. Surf. Interfaces 2021, 27, 101498. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Peng, D.C.; Han, J.; Ren, F.B.; Jiang, S.C.; Tseng, M.C.; Ruan, Y.J.; Zuo, J.; Wu, W.Y.; Wu, D.S.; et al. Effect of substrate temperature on properties of AlN buffer layer grown by remote plasma ALD. Surf. Interfaces 2023, 36, 102589. [Google Scholar] [CrossRef]

- Shi, Z.; Shum, P.; Wasy, A.; Zhou, Z.; Li, L.K.Y. Tribological performance of few layer graphene on textured M2 steel surfaces. Surf. Coat. Technol. 2016, 296, 164–170. [Google Scholar] [CrossRef]

- Marchetto, D.; Rota, A.; Calabri, L.; Gazzadi, G.C.; Menozzi, C.; Valeri, S. AFM investigation of tribological properties of nano-patterned silicon surface. Wear 2008, 265, 577–582. [Google Scholar] [CrossRef]

- Horsfall, M.; Simpson, M.; Rahmani, R.; Nekouie-Esfahani, R. Effect of surface texture positioning in grease lubricated contacts. Tribol. Int. 2023, 185, 108523. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J. Tribological performance of surface texturing in mechanical applications—A review. Surf. Topogr. Metrol. Prop. 2020, 8, 043001. [Google Scholar] [CrossRef]

- Rahmani, R. An Investigation into Analysis and Optimisation of Textured Slider Bearings with Application in Piston-Ring/Cylinder Liner Contact. Ph.D. Thesis, Anglia Ruskin University, Cambridge, UK, 2008. [Google Scholar]

- Rahmani, R.; Mirzaee, I.; Shirvani, A.; Shirvani, H. An analytical approach for analysis and optimisation of slider bearings with infinite width parallel textures. Tribol. Int. 2010, 43, 1551–1565. [Google Scholar] [CrossRef]

- Echavarri Otero, J.; de la Guerra Ochoa, E.; Bellon Vallinot, I.; Chacon Tanarro, E. Optimising the design of textured surfaces for reducing lubricated friction coefficient. Lubr. Sci. 2017, 29, 183–199. [Google Scholar] [CrossRef]

- Caciu, C.; Decencière, E.; Jeulin, D. Parametric optimization of periodic textured surfaces for friction reduction in combustion engines. Tribol. Trans. 2008, 51, 533–541. [Google Scholar] [CrossRef]

- Segu, D.Z.; Lu, C.; Hwang, P.; Kang, S.W. Optimization of tribological characteristics of a combined pattern textured surface using Taguchi design. J. Mater. Eng. Perform. 2021, 30, 3786–3794. [Google Scholar] [CrossRef]

- Rahmani, R.; Rahnejat, H. Enhanced performance of optimised partially textured load bearing surfaces. Tribol. Int. 2018, 117, 272–282. [Google Scholar] [CrossRef]

- Mousavirad, S.J.; Rahmani, R.; Dolatabadi, N. A transfer learning based artificial neural network in geometrical design of textured surfaces for tribological applications. Surf. Topogr. Metrol. Prop. 2023, 11, 025001. [Google Scholar] [CrossRef]

- Wang, B.; Lai, W.; Li, S.; Huang, S.; Zhao, X.; You, D.; Tong, X.; Li, W.; Wang, X. Self-lubricating coating design strategy for titanium alloy by additive manufacturing. Appl. Surf. Sci. 2022, 602, 154333. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, X.; Lu, S.; Yang, H.; Huang, X.; Qin, L.; Dong, G. Tribological properties of flexible composite surfaces through direct ink writing for durable wearing devices. Surf. Coat. Technol. 2022, 441, 128573. [Google Scholar] [CrossRef]

- Peng, Y.; Serfass, C.M.; Hill, C.N.; Hsiao, L.C. Bending of soft micropatterns in elastohydrodynamic lubrication tribology. Exp. Mech. 2021, 61, 969–979. [Google Scholar] [CrossRef]

- Li, C.J.; Wu, S.M. On-line detection of localized defects in bearings by pattern recognition analysis. J. Eng. Ind. 1989, 111, 331–336. [Google Scholar] [CrossRef]

- Benhadj, R.; Sadeque, S.; Rahnejat, H. A knowledge-based system for sensor interaction and real-time component control. Int. J. Adv. Manuf. Technol. 1988, 3, 77–102. [Google Scholar] [CrossRef]

- Hu, M. Visual pattern recognition by moment invariants. IEEE Trans. Inf. Theory 1998, 20, 1254–1259. [Google Scholar]

- Flusser, J.; Zitova, B.; Suk, T. Moments and Moment Invariants in Pattern Recognition; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Chiou, Y.S.; Tavakoli, M.; Liang, S. Bearing fault detection based on multiple signal features using neural network analysis. In Proceedings of the International Modal Analysis Conference, San Diego, CA, USA, 3–7 February 1992; Volume 1, pp. 60–64. [Google Scholar]

- Liu, T.I.; Iyer, N.R. Diagnosis of roller bearing defects using neural networks. Int. J. Adv. Manuf. Technol. 1993, 8, 210–215. [Google Scholar] [CrossRef]

- Subrahmanyam, M.; Sujatha, C. Using neural networks for the diagnosis of localized defects in ball bearings. Tribol. Int. 1997, 30, 739–752. [Google Scholar] [CrossRef]

- Peng, Z.; Kirk, T.B. Automatic wear-particle classification using neural networks. Tribol. Lett. 1998, 5, 249–257. [Google Scholar] [CrossRef]

- Sinha, A.N.; Mukherjee, S.; De, A. Assessment of useful life of lubricants using artificial neural network. Ind. Lubr. Tribol. 2000, 52, 105–109. [Google Scholar] [CrossRef]

- Frangu, L.; Ripa, M. Artificial Neural Networks Applications in Tribology—A Survey. NATO Advanced Study Institute on Neural Networks for Instrumentation, Measurement, and Related Industrial Applications: Study Cases. 2001, 35–42. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=26585c4bc8e40a48b52fc09af0f6c0545cf781f7 (accessed on 30 July 2023).

- Sinanoğlu, C.; Kurban, A.O.; Yildirim, Ş.A. Analysis of pressure variations on journal bearing system using artificial neural network. Ind. Lubr. Tribol. 2004, 56, 74–87. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S. Current trends and applications of machine learning in tribology—A review. Lubricants 2021, 9, 86. [Google Scholar] [CrossRef]

- Paturi, U.M.R.; Palakurthy, S.T.; Reddy, N.S. The Role of Machine Learning in Tribology: A Systematic Review. Arch. Comput. Methods Eng. 2022, 30, 1345–1397. [Google Scholar] [CrossRef]

- Sose, A.T.; Joshi, S.Y.; Kunche, L.K.; Wang, F.; Deshmukh, S.A. A review of recent advances and applications of machine learning in tribology. Phys. Chem. Chem. Phys. 2023, 25, 4408–4443. [Google Scholar] [CrossRef]

- Choudhary, A.; Mian, T.; Fatima, S. Convolutional neural network based bearing fault diagnosis of rotating machine using thermal images. Measurement 2021, 176, 109196. [Google Scholar] [CrossRef]

- Kumbhar, S.G.; Desavale, R.G.; Dharwadkar, N.V. Fault size diagnosis of rolling element bearing using artificial neural network and dimension theory. Neural Comput. Appl. 2021, 33, 16079–16093. [Google Scholar] [CrossRef]

- Leighton, M.; Nicholls, T.; De la Cruz, M.; Rahmani, R.; Rahnejat, H. Combined lubricant–surface system perspective: Multi-scale numerical–experimental investigation. Proc. IMechE Part J J. Eng. Tribol. 2017, 231, 910–924. [Google Scholar] [CrossRef]

- Bhaumik, S.; Pathak, S.D.; Dey, S.; Datta, S. Artificial intelligence based design of multiple friction modifiers dispersed castor oil and evaluating its tribological properties. Tribol. Int. 2019, 140, 105813. [Google Scholar] [CrossRef]

- Campillo, N.E.; Talavante, P.; Ponzoni, I.; Soto, A.J.; Martínez, M.J.; Naveiro, R.; Gómez-Arrayas, R.; Franco, M.; Lee, S.H.K.; Mauleón, P.; et al. Artificial Intelligence in Tribology: Design of new dispersants using artificial intelligence tools. In Proceedings of the 23rd International Colloquium Tribology: Industrial and Automotive Lubrication, Ostfildern, Germany, 25–27 February 2022; p. 423. [Google Scholar]

- Rosenkranz, A.; Marian, M.; Profito, F.J.; Aragon, N.; Shah, R. The use of artificial intelligence in tribology—A perspective. Lubricants 2020, 9, 2. [Google Scholar] [CrossRef]

- Marian, M.; Mursak, J.; Bartz, M.; Profito, F.J.; Rosenkranz, A.; Wartzack, S. Predicting EHL film thickness parameters by machine learning approaches. Friction 2023, 11, 992–1013. [Google Scholar] [CrossRef]

- Singh, A.; Wolf, M.; Jacobs, G.; König, F. Machine learning based surrogate modelling for the prediction of maximum contact temperature in EHL line contacts. Tribol. Int. 2023, 179, 108166. [Google Scholar] [CrossRef]

- Charnley, J. The Lubrication of Animal Joints in Relation to Surgical Reconstruction by Arthroplasty. Ann. Rheum. Dis. 1960, 19, 10–19. [Google Scholar] [CrossRef] [PubMed]

- MacConaill, M.A. The Function of Intra-Articular Fibrocartilages, with Special Reference to the Knee and Inferior Radio-Ulnar Joints. J. Anat. 1932, 66, 210–227. [Google Scholar] [PubMed]

- McCutchen, C.W. Physiological Lubrication. Proc. IMechE Conf. 1966, 181, 55–62. [Google Scholar]

- Dowson, D. Paper R2: Review of Symposium on Lubrication and Wear in Living and Artificial Human Joints. Proc. IMechE. Conf. 1966, 181, 226–231. [Google Scholar]

- Dowson, D. Tribology: An Inaugural Lecture; University of Leeds Press: Leeds, UK, 1968. [Google Scholar]

- Walker, S.; Dowson, D.; Longfield, M.D.; Wright, V. Boosted lubrication in synovial joints by fluid entrapment and enrichment. Ann. Rheum. Dis. 1968, 27, 512–520. [Google Scholar] [CrossRef]

- Dowson, D.; Unsworth, A.; Wright, V. Analysis of ‘Boosted Lubrication’ in Human Joints. J. Mech. Eng. Sci. 1970, 12, 364–369. [Google Scholar] [CrossRef]

- Charnley, J. The Long-Term Results of Low-Friction Arthroplasty of the Hip Performed as a Primary Intervention. J. Bone Jt. Surg. Br. 1972, 54, 61–76. [Google Scholar] [CrossRef]

- Charnley, J.; Kamangar, A.; Longfield, M.D. The optimum size of prosthetic heads in relation to the wear of plastic sockets in total replacement of the hi Med. Boil. Eng. 1969, 7, 31–39. [Google Scholar]

- Dowling, J.; Atkinson, J.R.; Dowson, D.; Charnley, J. The characteristics of acetabular cups worn in the human body. J. Bone Jt. Surg. Br. 1978, 60, 375–382. [Google Scholar] [CrossRef]

- Dowson, D. New joints for the Millennium: Wear control in total replacement hip joints. Proc. IMechE Part H J. Eng. Med. 2001, 215, 335–358. [Google Scholar] [CrossRef]

- Auger, D.D.; Dowson, D.; Fisher, J.; Jin, Z.M. Friction and Lubrication in Cushion Form Bearings for Artificial Hip Joints. Proc. IMechE Part H J. Eng. Med. 1993, 207, 25–33. [Google Scholar] [CrossRef]

- Auger, D.D.; Dowson, D.; Fisher, J. Cushion form bearings for total knee joint replacement. Proc. IMechE Part H J. Eng. Med. 1995, 209, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Dowson, D.; Jin, Z.M. Micro-Elastohydrodynamic Lubrication of Synovial Joints. Proc. IMechE Part H J. Eng. Med. 1986, 15, 63–65. [Google Scholar] [CrossRef] [PubMed]

- Dowson, D. Elastohydrodynamic and micro-elastohydrodynamic lubrication. Wear 1995, 190, 125–138. [Google Scholar] [CrossRef]

- Morris, N.J.; Johns-Rahnejat, M.; Rahnejat, H. Tribology and Dowson. Lubricants 2020, 8, 63. [Google Scholar] [CrossRef]

- Dowson, D. A tribological day. Proc. IMechE Part J J. Eng. Tribol. 2009, 223, 261–273. [Google Scholar] [CrossRef]

- Dėdinaitė, A. Biomimetic lubrication. Soft Matter 2012, 8, 273–284. [Google Scholar] [CrossRef]

- Samaroo, K.J.; Tan, M.; Putnam, D.; Bonassar, L.J. Binding and lubrication of biomimetic boundary lubricants on articular cartilage. J. Orthop. Res. 2017, 35, 548–557. [Google Scholar] [CrossRef]

- Zhao, T.; Wei, Z.; Zhu, W.; Weng, X. Recent developments and current applications of hydrogels in osteoarthritis. Bioengineering 2020, 9, 132. [Google Scholar] [CrossRef] [PubMed]

- Gombert, Y.; Simič, R.; Roncoroni, F.; Dübner, M.; Geue, T.; Spencer, N.D. Structuring hydrogel surfaces for tribology. Adv. Mater. Interfaces 2019, 6, 1901320. [Google Scholar] [CrossRef]

- Lanza, A.; Ruggiero, A.; Sbordone, L. Tribology and dentistry: A commentary. Lubricants 2019, 7, 52. [Google Scholar] [CrossRef]

- Zheng, Y.; Bashandeh, K.; Shakil, A.; Jha, S.; Polycarpou, A.A. Review of dental tribology: Current status and challenges. Tribol. Int. 2022, 166, 107354. [Google Scholar] [CrossRef]

- Jin, Z.M.; Zheng, J.; Li, W.; Zhou, Z.R. Tribology of medical devices. Biosurface Biotribol. 2016, 2, 173–192. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Jin, Z. A review of the bio-tribology of medical devices. Friction 2022, 10, 4–30. [Google Scholar] [CrossRef]

- Bhushan, B. (Ed.) Tribology Issues and Opportunities in MEMS. In Proceedings of the NSF/AFOSR/ASME Workshop on Tribology Issues and Opportunities in MEMS, Columbus, OH, USA, 9–11 November 1997; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Bhushan, B. MEMS/NEMS and BioMEMS/BioNEMS: Tribology, Mechanics, Materials and Devices. In Springer Handbook of Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1331–1416. [Google Scholar]

- Teodorescu, M.; Theodossiades, S.; Rahnejat, H. Impact dynamics of rough and surface protected MEMS gears. Tribol. Int. 2009, 42, 197–205. [Google Scholar] [CrossRef][Green Version]

- DelRio, F.W.; Carraro, C.; Maboudian, R. Adhesion and surface engineering in small-scale systems. In Tribology and Dynamics of Engine and Powertrain System; Woodhead Publishing: Cambridge, UK, 2010; pp. 960–989. [Google Scholar]

- Teodorescu, S.; Theodossiades, H.; Rahnejat, H. Microengines and microgears. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 947–959. [Google Scholar]

- Feynman, R. There’s Plenty of Room at the Bottom: An Invitation to Enter a New Field of Physics; Miniaturization, Reinhold 1961; CRC Press: Boca Raton, FL, USA, 2002; Available online: TaylorFrancis.com (accessed on 10 August 2023).

- Matsuoka, H.; Kato, T. An ultra-thin liquid film lubrication theory—Calculation method of solvation pressure and its application to the EHL problem. J. Tribol. 1997, 119, 217–226. [Google Scholar] [CrossRef]

- Al-Samieh, M.; Rahnejat, H. Ultra-thin lubricating films under transient conditions. J. Phys. D Appl. Phys. 2001, 34, 2610–2621. [Google Scholar] [CrossRef]

- Al-Samieh, M.F.; Rahnejat, H. Physics of lubricated impact of a sphere on a plate in a narrow continuum to gaps of molecular dimensions. J. Phys. D Appl. Phys. 2002, 35, 2311–2326. [Google Scholar] [CrossRef]

- Chan, D.Y.C.; Horn, R.G. The drainage of thin liquid films between solid surfaces. J. Chem. Phys. 1984, 83, 5311–5324. [Google Scholar] [CrossRef]

- Israelachvili, J.N. Intermolecular and Surface Forces; Academic Press: New York, NY, USA, 1992. [Google Scholar]

- Arzt, E.; Gorb, S.; Spolenak, R. From micro to nano contacts in biological attachment devices. Proc. Natl. Acad. Sci. USA 2003, 100, 10603–10606. [Google Scholar] [CrossRef]

- Autumn, K. How Gecko toes stick. Am. Sci. 2006, 94, 124–132. [Google Scholar] [CrossRef]

- Spolenak, R.; Gorb, S.; Gao, H.; Arzt, E. Effects of contact shape on the scaling of biological attachments. Proc. R. Soc. 2005, 461, 305–319. [Google Scholar] [CrossRef]

- Autumn, K.; Chang, W.; Fearing, R.; Hsieh, T.; Kenny, T.; Liang, I.; Zesch, W.; Full, R.J. Adhesive force of a single gecko foot-hair. Nature 2000, 405, 681–685. [Google Scholar] [CrossRef] [PubMed]

- Autumn, K.; Sitti, M.; Liang, Y.A.; Peattie, A.M.; Hansen, W.H.; Sponberg, S.; Kenny, T.W.; Fearing, R.; Israelachvili, J.N.; Full, R. Evidence for van der Waals adhesion in gecko setae. Proc. Natl. Acad. Sci. USA 2002, 99, 12252–12256. [Google Scholar] [CrossRef]

- Bhushan, B.; Israelachvili, J.N.; Landman, U. Nanotribology: Friction, wear and lubrication at the atomic scale. Nature 1995, 374, 607–616. [Google Scholar] [CrossRef]

- Tambe, N.S.; Bhushan, B. Scale dependence of micro/nano-friction and adhesion of MEMS/NEMS materials, coatings and lubricants. Nanotechnology 2004, 15, 1561. [Google Scholar] [CrossRef]

- Teodorescu, M.; Rahnejat, H. Dry and wet nano-scale impact dynamics of rough surfaces with or without a self-assembled monolayer. Proc. IMechE Part N J. Nanoeng. Nanosyst. 2007, 221, 49–58. [Google Scholar] [CrossRef]

- Rahnejat, H.; Johns-Rahnejat, M.; Teodorescu, M.; Votsios, V.; Kushwaha, M. A review of some tribo-dynamics phenomena from micro-to nano-scale conjunctions. Tribol. Int. 2009, 42, 1531–1541. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Multiscale friction mechanisms and hierarchical surfaces in nano-and bio-tribology. Mater. Sci. Eng. R Rep. 2007, 58, 162–193. [Google Scholar] [CrossRef]

- Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.; Balodimos, N. Thermohydrodynamics of lubricant flow with carbon nanoparticles in tribological contacts. Tribol. Int. 2017, 113, 50–57. [Google Scholar] [CrossRef]

- Dolatabadi, N.; Rahmani, R.; Rahnejat, H.; Garner, C. Thermal conductivity and molecular heat transport of nanofluids. RSC Adv. 2019, 9, 2516–2524. [Google Scholar] [CrossRef] [PubMed]

- Dolatabadi, N.; Rahmani, R.; Rahnejat, H.; Garner, C.; Brunton, C. Performance of poly alpha olefin nanolubricant. Lubricants 2020, 8, 17. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G.R. A numerical solution to the elasto-hydrodynamic problem. J. Mech. Eng. Sci. 1959, 1, 6–15. [Google Scholar] [CrossRef]

- Vakis, A.I.; Yastrebov, V.A.; Scheibert, J.; Nicola, L.; Dini, D.; Minfray, C.; Almqvist, A.; Paggi, M.; Lee, S.; Limbert, G.; et al. Modeling and simulation in tribology across scales: An overview. Tribol. Int. 2018, 125, 169–199. [Google Scholar] [CrossRef]

- Ewen, J.; Fernández, E.R.; Smith, E.R.; Dini, D. Nonequilibrium molecular dynamics simulations of tribological systems. In Modeling and Simulation of Tribological Problems in Technology; Springer: Cham, Switzerland, 2020; pp. 95–130. [Google Scholar]

- Kudish, I.I.; Covitch, M.J. Modeling and Analytical Methods in Tribology; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Styles, G.; Rahmani, R.; Rahnejat, H.; Fitzsimons, B. In-cycle and life-time friction transience in piston ring–liner conjunction under mixed regime of lubrication. Int. J. Engine Res. 2014, 15, 862–876. [Google Scholar] [CrossRef]

- Dolatabadi, N.; Forder, M.; Morris, N.; Rahmani, R.; Rahnejat, H.; Howell-Smith, S. Influence of advanced cylinder coatings on vehicular fuel economy and emissions in piston compression ring conjunction. Appl. Energy 2020, 259, 114129. [Google Scholar] [CrossRef]

- Umer, J.; Morris, N.; Leighton, M.; Rahmani, R.; Balakrishnan, S.; Rahnejat, H. Nano and microscale contact characteristics of tribofilms derived from fully formulated engine oil. Tribol. Int. 2019, 131, 620–630. [Google Scholar] [CrossRef]

- Turnbull, R.; Dolatabadi, N.; Rahmani, R.; Rahnejat, H. An assessment of gas power leakage and frictional losses from the top compression ring of internal combustion engines. Tribol. Int. 2020, 142, 105991. [Google Scholar] [CrossRef]

- Babuska, T.F.; Curry, J.F.; Dugger, M.T.; Lu, P.; Xin, Y.; Klueter, S.; Kozen, A.C.; Grejtak, T.; Krick, B.A. Role of Environment on the Shear-Induced Structural Evolution of MoS2 and Impact on Oxidation and Tribological Properties for Space Applications. ACS Appl. Mater. Interfaces 2022, 14, 13914–13924. [Google Scholar] [CrossRef]

- Mukhtar, S.H.; Wani, M.F.; Sehgal, R.; Sharma, M.D. Nano-mechanical and nano-tribological characterisation of self-lubricating MoS2 nano-structured coating for space applications. Tribol. Int. 2023, 178, 108017. [Google Scholar] [CrossRef]

- Bashandeh, K.; Tsigkis, V.; Lan, P.; Polycarpou, A.A. Extreme environment tribological study of advanced bearing polymers for space applications. Tribol. Int. 2021, 153, 106634. [Google Scholar] [CrossRef]

- Nyberg, E.; Schneidhofer, C.; Pisarova, L.; Dörr, N.; Minami, I. Ionic liquids as performance ingredients in space lubricants. Molecules 2021, 26, 1013. [Google Scholar] [CrossRef] [PubMed]

- Dörr, N.; Merstallinger, A.; Holzbauer, R.; Pejaković, V.; Brenner, J.; Pisarova, L.; Stelzl, J.; Frauscher, M. Five-Stage Selection Procedure of Ionic Liquids for Lubrication of Steel–Steel Contacts in Space Mechanisms. Tribol. Lett. 2019, 67, 1–18. [Google Scholar] [CrossRef]

- Tolansky, S. The measurement of thin film thickness by interferometry. JOSA 1951, 41, 425–426. [Google Scholar] [CrossRef]

- Kirk, M.T. Hydrodynamic lubrication of ‘perspex’. Nature 1962, 194, 965–966. [Google Scholar] [CrossRef]

- Gohar, R.; Cameron, A. Optical measurement of oil film thickness under elasto-hydrodynamic lubrication. Nature 1963, 200, 458–459. [Google Scholar] [CrossRef]

- Bahadoran, H.; Gohar, R. Oil film thickness in lightly-loaded roller bearings. J. Mech. Eng. Sci. 1974, 16, 386–390. [Google Scholar] [CrossRef]

- Wymer, D.G.; Cameron, A. Elastohydrodynamic lubrication of a line contact. Proc. IMechE J. Mech. Eng. Sci. 1974, 188, 221–238. [Google Scholar] [CrossRef]

- Ciulli, E.; Pugliese, G.; Fazzolari, F. Film thickness and shape evaluation in a cam-follower line contact with digital image processing. Lubricants 2019, 7, 29. [Google Scholar] [CrossRef]

- Jalali-Vahid, D.; Rahnejat, H.; Gohar, R.; Jin, Z.M. Comparison between experiments and numerical solutions for isothermal elastohydrodynamic point contacts. J. Phys. D Appl. Phys. 1998, 31, 2725. [Google Scholar] [CrossRef]

- Kushwaha, M.; Rahnejat, H.; Gohar, R. Aligned and misaligned contacts of rollers to races in elastohydrodynamic finite line conjunctions. Proc. IMechE Part C J. Mech. Eng. Sci. 2002, 216, 1051–1070. [Google Scholar] [CrossRef]

- Sivayogan, G.; Rahmani, R.; Rahnejat, H. Transient analysis of isothermal elastohydrodynamic point contacts under complex kinematics of combined rolling, spinning and normal approach. Lubricants 2020, 8, 81. [Google Scholar] [CrossRef]

- Venner, C.H.; Wijnant, Y.H. Validation of EHL contact predictions under time varying load. Proc. IMechE Part J J. Eng. Tribol. 2005, 219, 249–261. [Google Scholar] [CrossRef]

- Carli, M.; Sharif, K.J.; Ciulli, E.; Evans, H.; Snidle, R.W. Thermal point contact EHL analysis of rolling/sliding contacts with experimental comparison showing anomalous film shapes. Tribol. Int. 2009, 42, 517–525. [Google Scholar] [CrossRef]

- Wolf, M.; Sperka, P.; Fryza, J.; Fatemi, A. Film Thickness in Elastohydrodynamically Lubricated Slender Elliptic Contacts: Part II–Experimental Validation and Minimum Film Thickness. Proc. IMechE Part J J. Eng. Tribol. 2022, 236, 2477–2490. [Google Scholar] [CrossRef]

- Sugimura, J.; Jones, W.R.; Spikes, H.A. EHD film thickness in non-steady state contact conditions. J. Tribol. 1998, 120, 442–452. [Google Scholar] [CrossRef]

- Sugimura, J.; Okumura, T.; Yamamoto, Y.; Spikes, H.A. Simple equation for elastohydrodynamic film thickness under acceleration. Tribol. Int. 1999, 32, 117–123. [Google Scholar] [CrossRef]

- Palacio, M.; Bhushan, B. A review of ionic liquids for green molecular lubrication in nanotechnology. Tribol. Lett. 2010, 40, 247–268. [Google Scholar] [CrossRef]

- Gao, M.; Li, H.; Ma, L.; Gao, Y.; Ma, L.; Luo, J. Molecular behaviors in thin film lubrication—Part two: Direct observation of the molecular orientation near the solid surface. Friction 2019, 7, 479–488. [Google Scholar] [CrossRef]

- Watts, K.E.; Blackburn, T.J.; Pemberton, J.E. Optical spectroscopy of surfaces, interfaces, and thin films: A status report. Anal. Chem. 2019, 91, 4235–4265. [Google Scholar] [CrossRef]

- Bridgman, W. Physics of High Pressure; Bell & Sons Ltd.: London, UK, 1958. [Google Scholar]

- Kannel, J.W.; Bell, J.C.; Allen, C.M. Methods for determining pressure distributions in lubricated rolling contact. Trans. ASLE 1965, 8, 250–270. [Google Scholar] [CrossRef]

- Kannel, J.W. Paper 11: Measurements of Pressures in Rolling Contact. Proc. Inst. Mech. Eng. 1965, 180, 135–146. [Google Scholar] [CrossRef]

- Johns-Rahnejat, M.; Karami, G.; Aini, R.; Rahnejat, H. Fundamentals and advances in elastohydrodynamics: The role of Ramsey Gohar. Lubricants 2021, 9, 120. [Google Scholar] [CrossRef]

- Safa, M.M.A.; Anderson, J.C.; Leather, J.A. Transducers for pressure, temperature and oil film thickness measurement in bearings. Sens. Actuators 1982, 3, 119–128. [Google Scholar] [CrossRef]

- Gohar, R.; Safa, M.M.A. Measurement of contact pressure under elastohydrodynamic lubrication conditions. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 222–245. [Google Scholar]

- Johns-Rahnejat, M. Pressure and Stress Distribution under Elastohydrodynamic Point Contacts. Ph.D. Thesis, Imperial College of Science and Technology, University of London, London, UK, 1988. [Google Scholar]

- Johns-Rahnejat, M.; Gohar, R. Measuring contact pressure distributions under elastohydrodynamic point contacts. Tribotest 1994, 1, 33–53. [Google Scholar] [CrossRef]

- Safa, M.M.A.; Gohar, R. Pressure distribution under a ball impacting a thin lubricant layer. J. Tribol. 1986, 108, 372–376. [Google Scholar] [CrossRef]

- Mohammadpour, M.; Johns-Rahnejat, M.; Rahnejat, H.; Gohar, R. Boundary conditions for elastohydrodynamics of circular point contacts. Tribol. Lett. 2014, 53, 107–118. [Google Scholar] [CrossRef]

- Sherrington, I.; Smith, E.H. Experimental methods for measuring the oil-film thickness between the piston-rings and cylinder-wall of internal combustion engines. Tribol. Int. 1985, 18, 315–320. [Google Scholar] [CrossRef]

- Grice, N.; Sherrington, I. An Experimental Investigation into the Lubrication of Piston Rings in an Internal Combustion Engine-Oil Film Thickness Trends, Film Stability and Cavitation; SAE Technical Paper: Warrendale, PA, USA, 1993; No. 930688. [Google Scholar]

- Takiguchi, M.; Sasaki, R.; Takahashi, I.; Ishibashi, F.; Furuhama, S.; Kai, R.; Sato, M. Oil Film Thickness Measurement and Analysis of a Three Ring Pack in an Operating Diesel Engine; SAE Technical Paper: Warrendale, PA, USA, 2000; No. 2000-06-19. [Google Scholar]

- Nouri, J.M.; Vasilakos, I.; Yan, Y.; Reyes-Aldasoro, C.C. Effect of viscosity and speed on oil cavitation development in a single piston-ring lubricant assembly. Lubricants 2019, 7, 88. [Google Scholar] [CrossRef]

- Notay, R.S.; Priest, M.; Fox, M.F. The influence of lubricant degradation on measured piston ring film thickness in a fired gasoline reciprocating engine. Tribol. Int. 2019, 129, 112–123. [Google Scholar] [CrossRef]

- Thirouard, B.; Tian, T.; Hart, D. Investigation of oil transport mechanisms in the piston ring pack of a single cylinder diesel engine, using two dimensional laser induced fluorescence. SAE Trans. 1998, 107, 2007–2015. [Google Scholar]

- Arcoumanis, C.; Duszynski, M.; Lindenkamp, H.; Preston, H. Measurements of the lubricant film thickness in the cylinder of a firing diesel engine using LIF. SAE Trans. 1998, 107, 898–906. [Google Scholar]

- Sherrington, I. Measurement techniques for piston-ring tribology. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 387–425. [Google Scholar]

- Dellis, P. Laser-induced fluorescence measurements in a single-ring test rig: Evidence of cavitation and the effect of different operating conditions and lubricants in cavitation patterns and initiation. Int. J. Engine Res. 2020, 21, 1597–1611. [Google Scholar] [CrossRef]

- Cheong, J.; Wigger, S.; Fuesser, H.J.; Kaiser, S.A. High-resolution LIF-Imaging of the oil film thickness in the piston-ring/cylinder-liner contact in an optical tribometer. Tribol. Int. 2020, 147, 106230. [Google Scholar] [CrossRef]

- Dwyer-Joyce, R.S.; Green, D.A.; Harper, P.; Lewis, R.; Balakrishnan, S.; King, D.; Rahnejat, H.; Howell-Smith, S. The measurement of liner-piston skirt oil film thickness by an ultrasonic means. SAE Trans. 2006, 115, 348–353. [Google Scholar]

- Dwyer-Joyce, R.S. An ultrasonic approach for the measurement of oil films in the piston zone. In Tribology and Dynamics of Engine and Powertrain; Woodhead Publishing: Cambridge, UK, 2010; pp. 426–457. [Google Scholar]

- Littlefair, B.; De la Cruz, M.; Theodossiades, S.; Mills, R.; Howell-Smith, S.; Rahnejat, H.; Dwyer-Joyce, R.S. Transient tribo-dynamics of thermo-elastic compliant high-performance piston skirts. Tribol. Lett. 2014, 53, 51–70. [Google Scholar] [CrossRef]

- Kæseler, R.L.; Johansen, P. Adaptive ultrasound reflectometry for lubrication film thickness measurements. Meas. Sci. Technol. 2019, 31, 025108. [Google Scholar] [CrossRef]

- Dou, P.; Jia, Y.; Zheng, P.; Wu, T.; Yu, M.; Reddyhoff, T.; Peng, Z. Review of ultrasonic-based technology for oil film thickness measurement in lubrication. Tribol. Int. 2022, 165, 107290. [Google Scholar] [CrossRef]

- Furuhama, S.; Takiguchi, M. Measurement of Piston Friction Force in Actual Operating Diesel Engine; SAE Technical Paper: Warrendale, PA, USA, 1980; No. 790855. [Google Scholar]

- Furuhama, S.; Sasaki, S. New Device for the Measurement of Piston Frictional Forces in Small Engines; SAE Technical Paper: Warrendale, PA, USA, 1983; No. 831284. [Google Scholar]

- Gore, M.; Howell-Smith, S.J.; King, D.; Rahnejat, H. Measurement of in-cylinder friction using the floating liner principle. In Proceedings of the ASME Internal Combustion Engine Division Spring Technical Conference, Torino, Piemonte, Italy, 6 May 2012; Volume 44663, pp. 901–906. [Google Scholar]

- Gore, M.; Theaker, M.; Howell-Smith, S.; Rahnejat, H.; King, D. Direct measurement of piston friction of internal-combustion engines using the floating-liner principle. Proc. IMechE Part D J. Automob. Eng. 2014, 228, 344–354. [Google Scholar] [CrossRef]

- Söderfjäll, M.; Almqvist, A.; Larsson, R. Component test for simulation of piston ring–cylinder liner friction at realistic speeds. Tribol. Int. 2016, 104, 57–63. [Google Scholar] [CrossRef]

- Nagano, Y.; Ito, A.; Okamoto, D.; Yamasaka, K. A Study on the Feature of Several Types of Floating Liner Devices for Piston Friction Measurement; SAE Technical Paper: Warrendale, PA, USA, 2019; No. 2019-01-0177. [Google Scholar]

- Youssef, A.M.; Calderbank, G.; Sherrington, I.; Smith, E.H.; Rahnejat, H. A critical review of approaches to the design of floating-liner apparatus for instantaneous piston assembly friction measurement. Lubricants 2021, 9, 10. [Google Scholar] [CrossRef]

- Akalin, O.; Newaz, G.M. Piston ring-cylinder bore friction modeling in mixed lubrication regime: Part I—Analytical results. J. Tribol. 2001, 123, 211–218. [Google Scholar] [CrossRef]

- Akalin, O.; Newaz, G.M. Piston ring-cylinder bore friction modeling in mixed lubrication regime: Part II—Correlation with bench test data. J. Tribol. 2001, 123, 219–223. [Google Scholar] [CrossRef]

- Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.; King, D. Thermo-mixed hydrodynamics of piston compression ring conjunction. Tribol. Lett. 2013, 51, 323–340. [Google Scholar] [CrossRef]

- Macián, V.; Tormos, B.; Bermúdez, V.; Bastidas, S. Development of a floating liner test rig and lubrication model for the study of the piston compression ring friction force under fully flooded and starved lubrication. Tribol. Int. 2021, 160, 107034. [Google Scholar] [CrossRef]

- Lu, P.; Powrie, H.E.; Wood, R.J.; Harvey, T.J.; Harris, N.R. Early wear detection and its significance for condition monitoring. Tribol. Int. 2021, 159, 106946. [Google Scholar] [CrossRef]

- Cao, R.; Pu, X.; Du, X.; Yang, W.; Wang, J.; Guo, H.; Zhao, S.; Yuan, Z.; Zhang, C.; Li, C.; et al. Screen-printed washable electronic textiles as self-powered touch/gesture tribo-sensors for intelligent human–machine interaction. ACS Nano 2018, 12, 5190–5196. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Xing, Y.; Li, C. Woven Wearable Electronic Textiles as Self-Powered Intelligent Tribo-Sensors for Activity Monitoring. Glob. Chall. 2019, 3, 1900070. [Google Scholar] [CrossRef]

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.; Wang, Z.L. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126–138. [Google Scholar] [CrossRef]

- Cheng, T.; Gao, Q.; Wang, Z.L. The current development and future outlook of triboelectric nanogenerators: A survey of literature. Adv. Mater. Technol. 2019, 4, 1800588. [Google Scholar] [CrossRef]

- Dharmasena, R.D.I.G.; Silva, S.R. Towards optimized triboelectric nanogenerators. Nano Energy 2019, 62, 530–549. [Google Scholar] [CrossRef]

- Zhou, Y.; Deng, W.; Xu, J.; Chen, J. Engineering materials at the nanoscale for triboelectric nanogenerators. Cell Rep. Phys. Sci. 2020, 1, 40. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Johns-Rahnejat, P.M.; Rahmani, R.; Rahnejat, H. Current and Future Trends in Tribological Research. Lubricants 2023, 11, 391. https://doi.org/10.3390/lubricants11090391

Johns-Rahnejat PM, Rahmani R, Rahnejat H. Current and Future Trends in Tribological Research. Lubricants. 2023; 11(9):391. https://doi.org/10.3390/lubricants11090391

Chicago/Turabian StyleJohns-Rahnejat, Patricia M., Ramin Rahmani, and Homer Rahnejat. 2023. "Current and Future Trends in Tribological Research" Lubricants 11, no. 9: 391. https://doi.org/10.3390/lubricants11090391

APA StyleJohns-Rahnejat, P. M., Rahmani, R., & Rahnejat, H. (2023). Current and Future Trends in Tribological Research. Lubricants, 11(9), 391. https://doi.org/10.3390/lubricants11090391