Research on Rolling Contact Fatigue Failure of the Bearing Used in High-Speed Electric Multiple Units’ Axle Box Based on a Damage-Coupled Elastic–Plastic Constitutive Model

Abstract

1. Introduction

2. Damage-Coupled Elastic–Plastic Constitutive Model

2.1. Governing Equations

2.2. Damage Evolution Model

2.3. Material Parameters

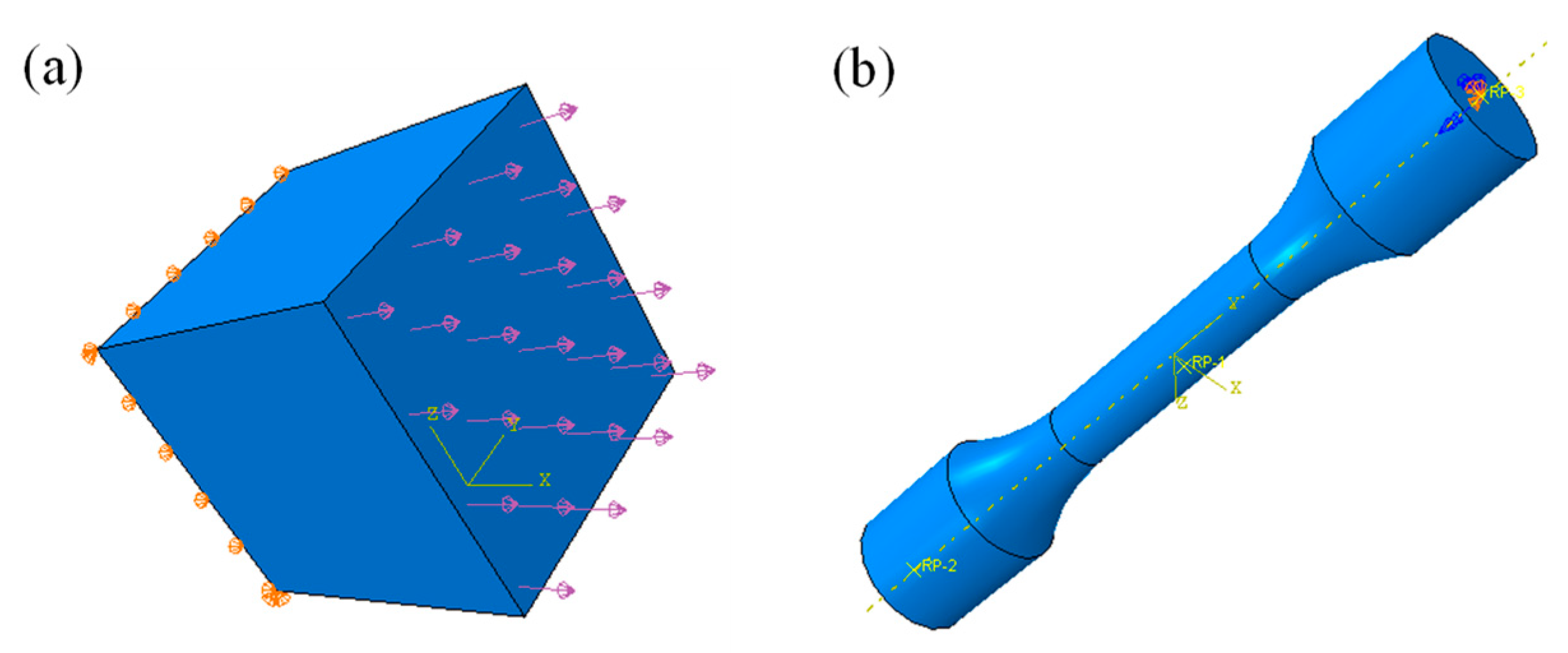

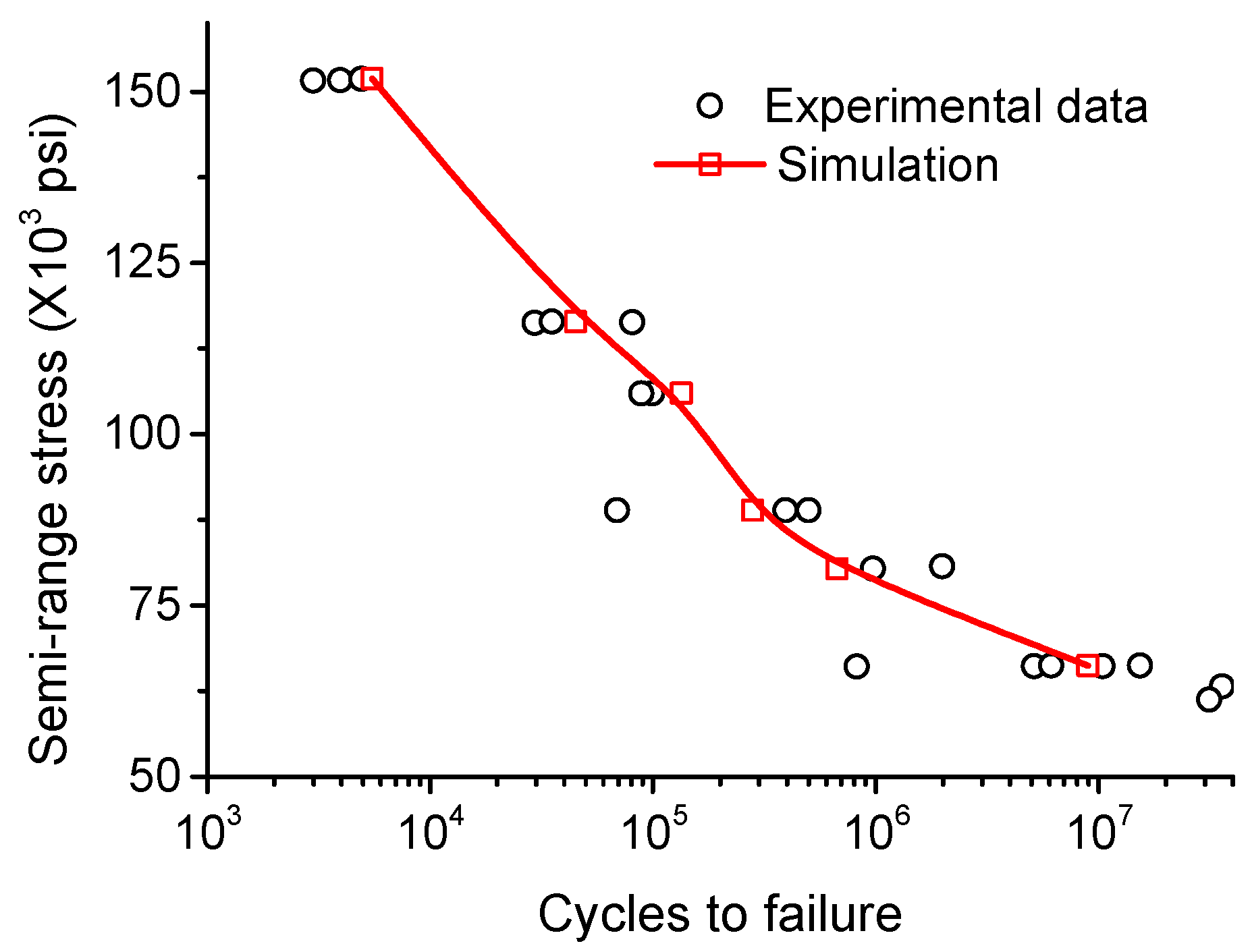

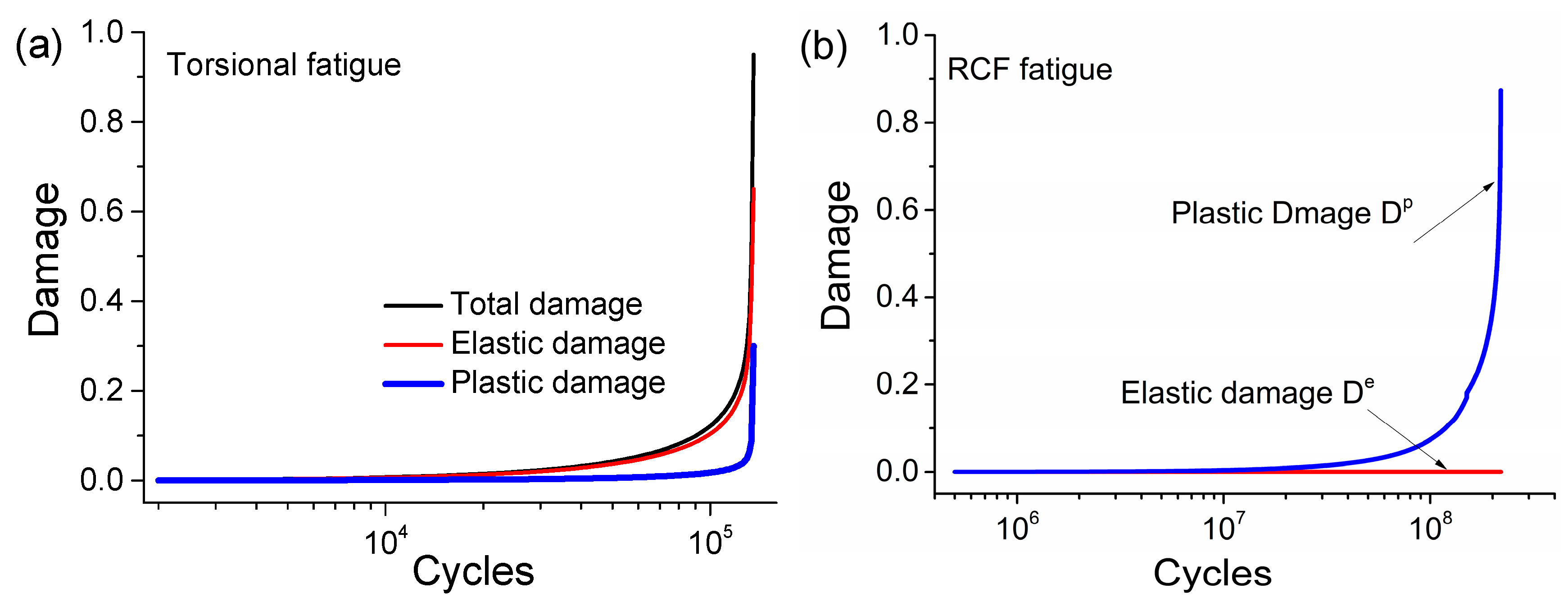

2.4. Validation

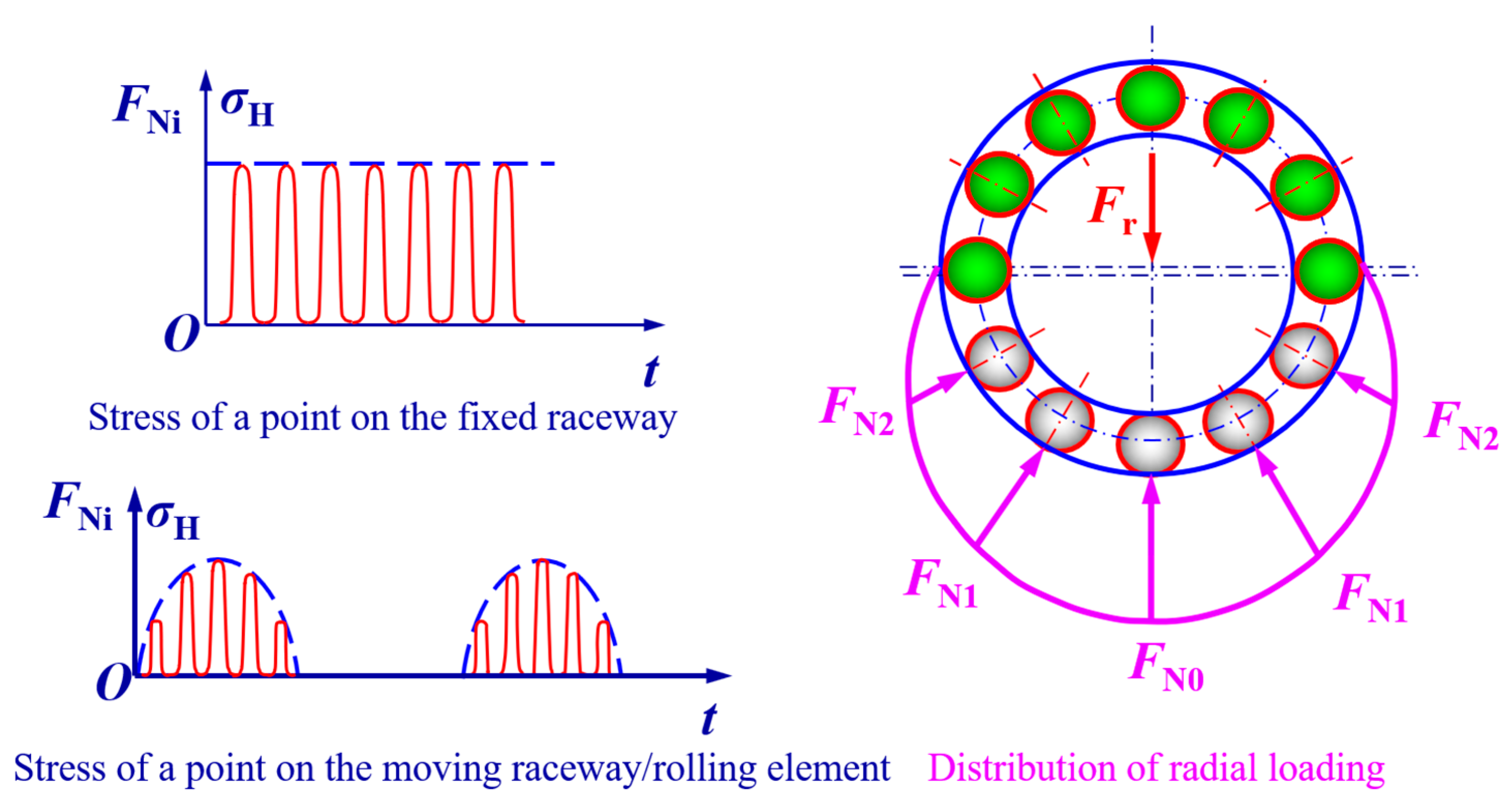

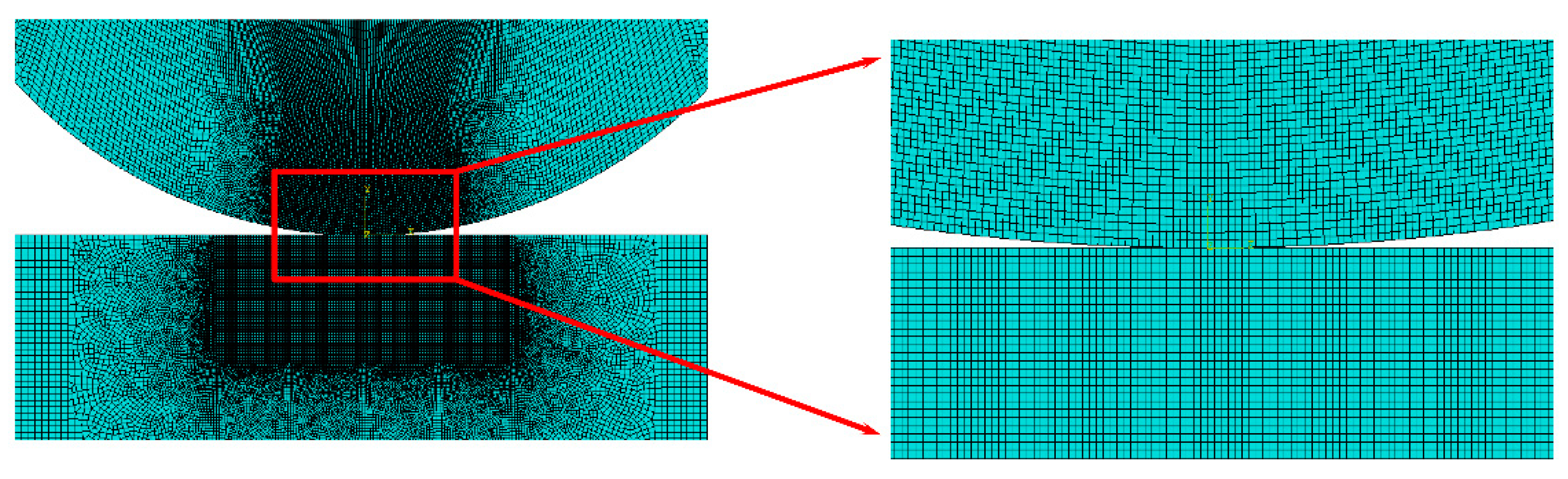

3. Rolling Contact Stress Simulation

3.1. The Finite Element Contact Model

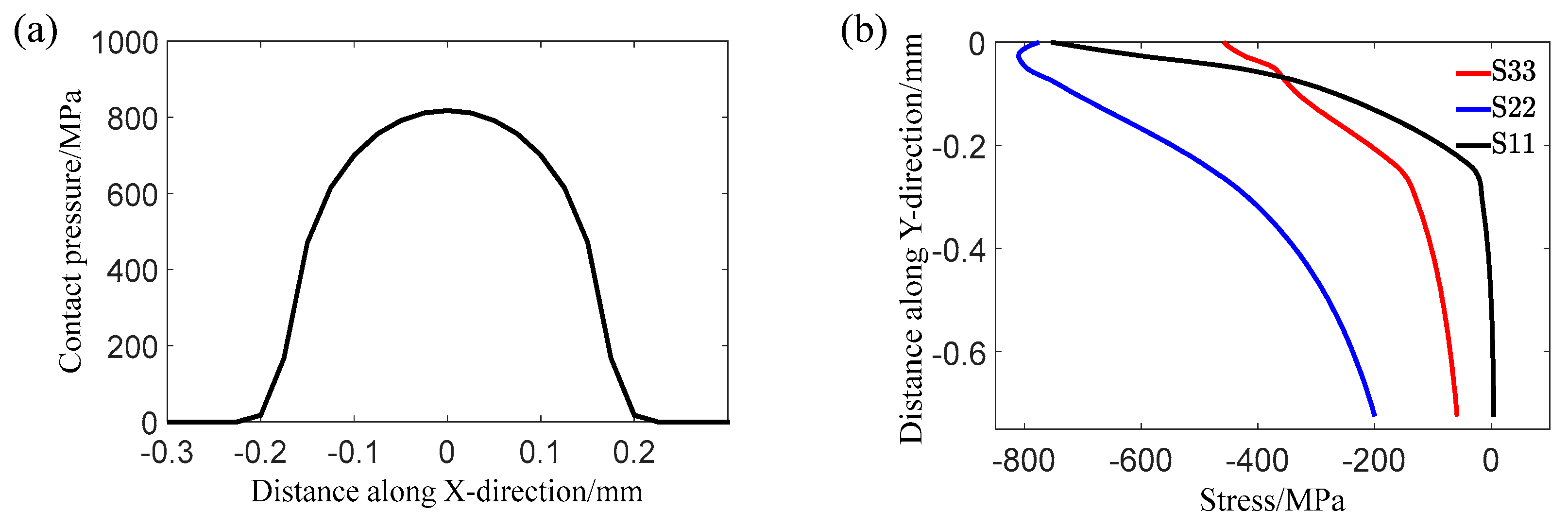

3.2. Simulation Results and Analysis

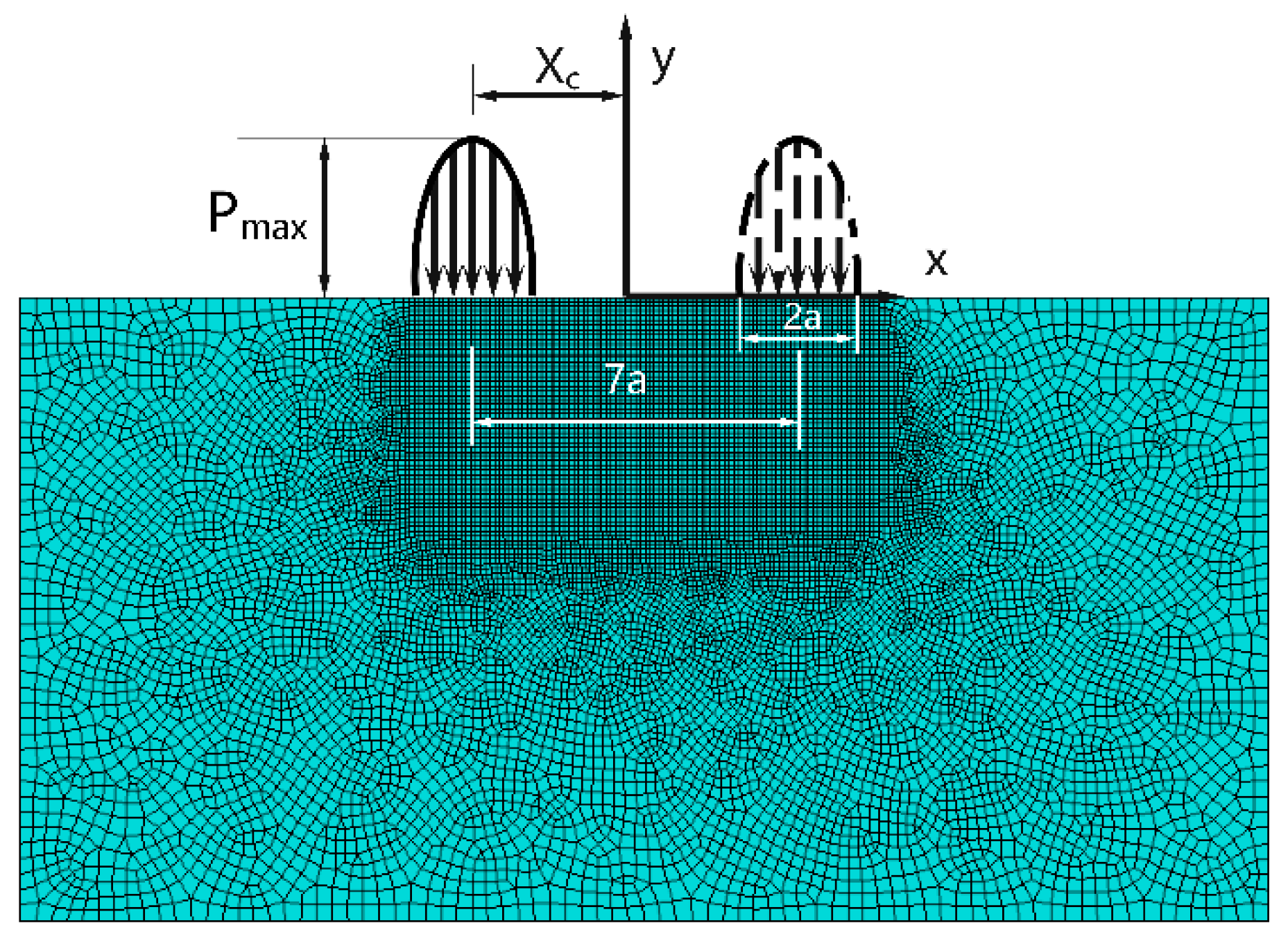

4. RCF Failure Analysis

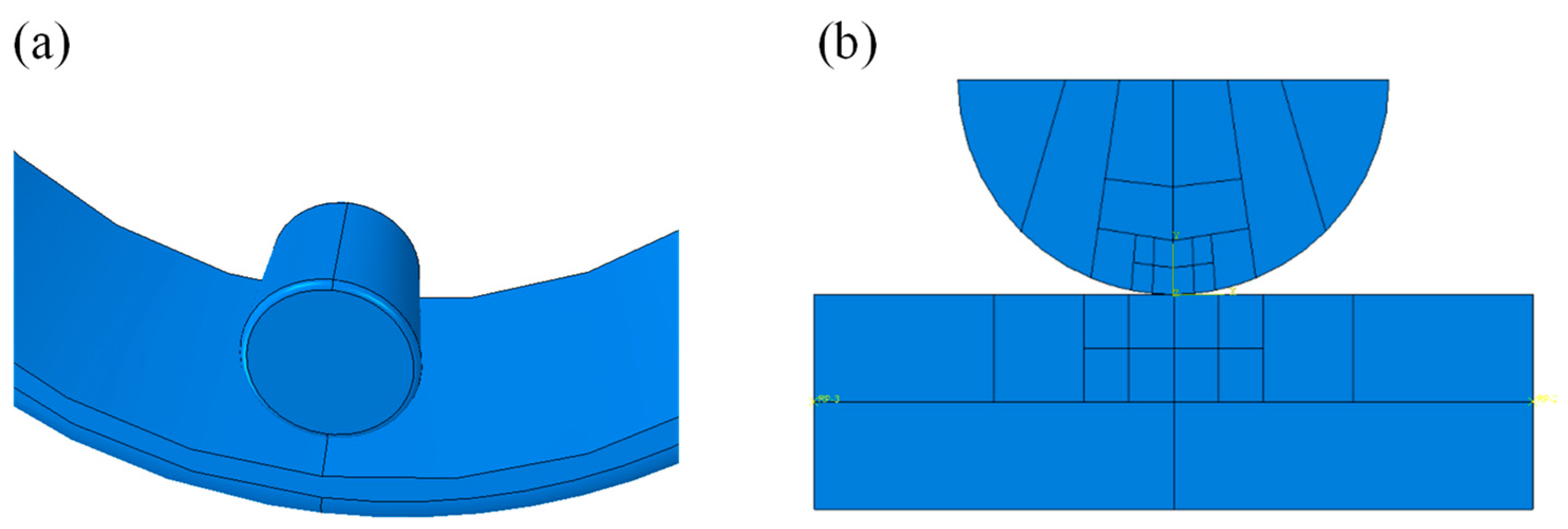

4.1. The Finite Element Contact Model

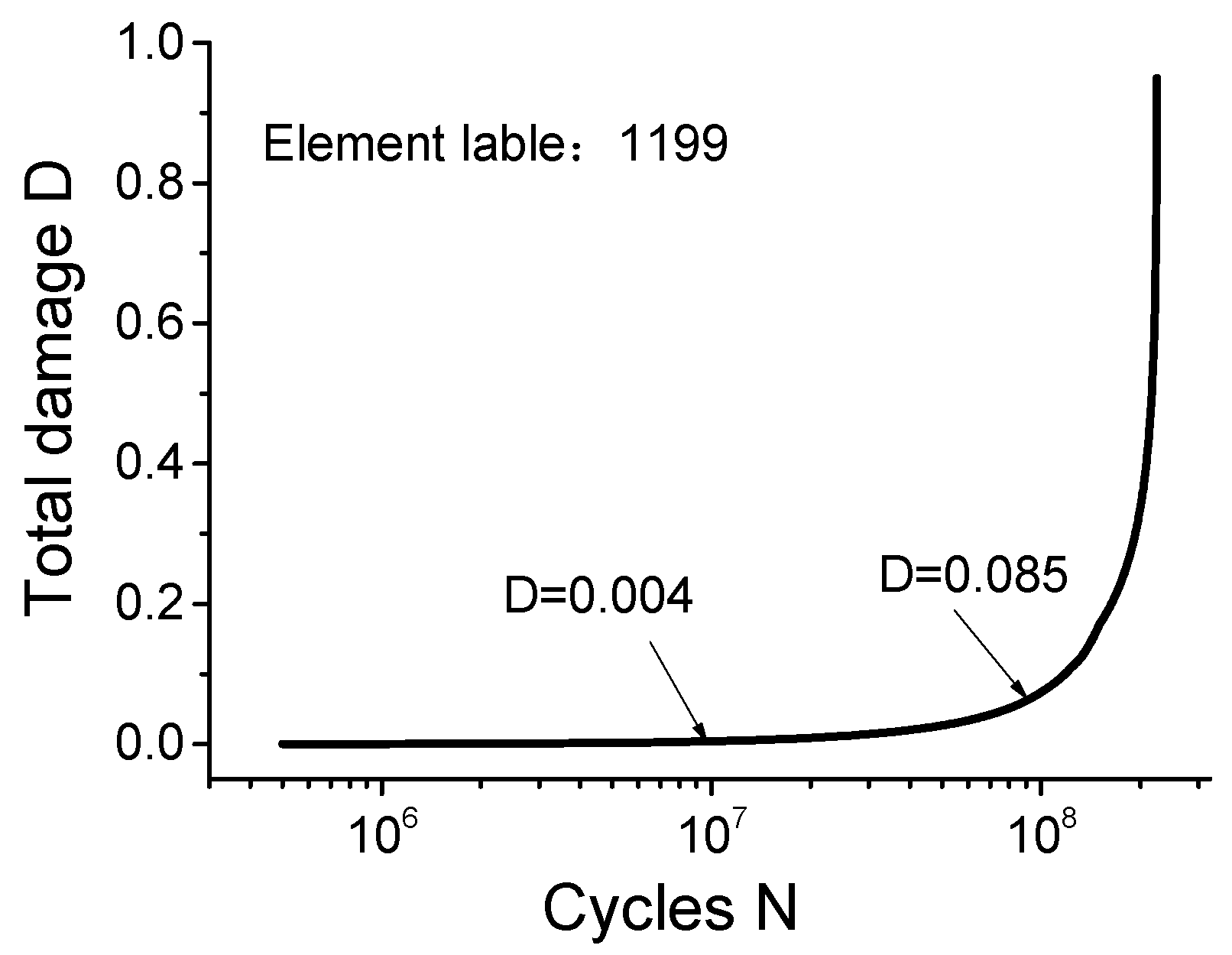

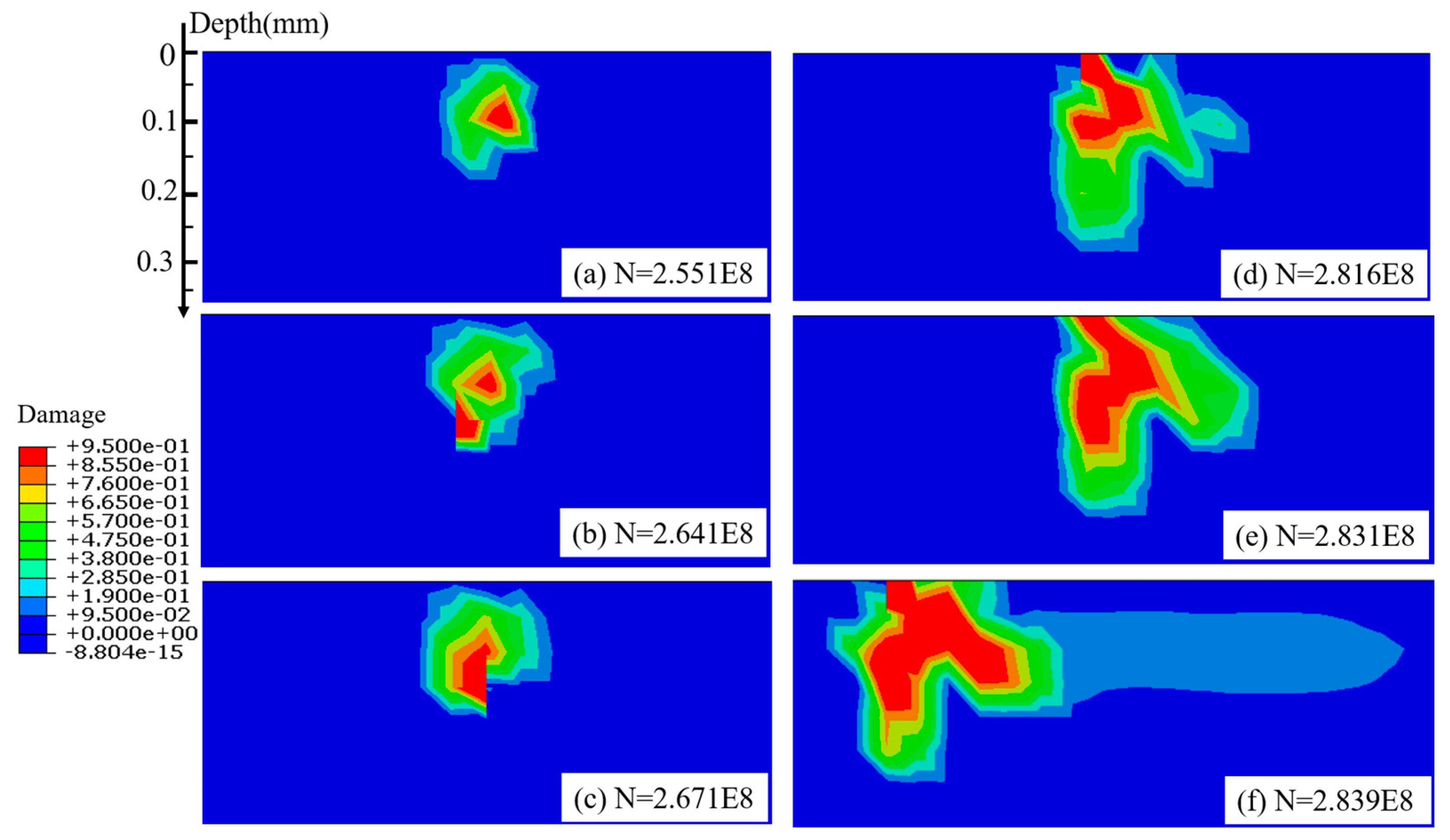

4.2. Results of the RCF Simulation

5. Discussion

6. Conclusions

- (1)

- The maximum contact pressure obtained from the proposed constitutive model is lower than the one calculated according to Hertz contact theory. This indicates that the presence of plastic deformation affects the contact behavior and reduces the maximum contact pressure.

- (2)

- The crack initiation occurs at the subsurface, at a depth of around 0.1 mm, approximately in the region of maximum Mises stress. The crack primarily extends towards the contact surface and then propagates parallel to the surface. This crack propagation behavior is consistent with experimental observations.

- (3)

- Since the contact loading is not heavy, there is only slight plastic damage generated during the early loading cycles. However, it finally becomes considerable because of the deterioration of material mechanical properties and gradual plastic deformation.

- (4)

- The predicted RCF life of the high-speed EMU axle box bearing using the proposed model is more reasonable. By considering both elastic and plastic damage, the model provides a more accurate estimation of the bearing’s fatigue life.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, H.; Cui, Y.; Zhang, C.; Zhang, H. Research progress of rolling contact fatigue of bearing steels. China Metall. 2020, 30, 13. [Google Scholar]

- El Laithy, M.; Wang, L.; Harvey, T.J.; Vierneusel, B.; Correns, M.; Blass, T. Further understanding of rolling contact fatigue in rolling element bearings—A review. Tribol. Int. 2019, 140, 105849. [Google Scholar] [CrossRef]

- El Laithy, M.; Wang, L.; Harvey, T.J.; Vierneusel, B. Re-investigation of dark etching regions and white etching bands in SAE 52100 bearing steel due to rolling contact fatigue. Int. J. Fatigue 2020, 136, 105591. [Google Scholar] [CrossRef]

- Kang, J.H.; Hosseinkhani, B.; Rivera-Diaz-Del-Castillo, P.E.J. Rolling contact fatigue in bearings: Multiscale overview. Mater. Sci. Technol. 2012, 28, 44–49. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Subhash, G.; Arakere, N. Evolution of subsurface plastic zone due to rolling contact fatigue of M-50 NiL case hardened bearing steel. Int. J. Fatigue 2014, 59, 102–113. [Google Scholar] [CrossRef]

- Pandkar, A.S.; Arakere, N.; Subhash, G. Microstructure-sensitive accumulation of plastic strain due to ratcheting in bearing steels subject to Rolling Contact Fatigue. Int. J. Fatigue 2014, 63, 191–202. [Google Scholar] [CrossRef]

- Pandkar, A.S.; Arakere, N.; Subhash, G. Ratcheting-based microstructure-sensitive modeling of the cyclic hardening response of case-hardened bearing steels subject to Rolling Contact Fatigue. Int. J. Fatigue 2015, 73, 119–131. [Google Scholar] [CrossRef]

- Ruijie, Z.; Chunlei, Z.; Bo, L.; Xubiao, W.; Xiaofeng, L.; Yanguo, L.; Fucheng, Z. Research progress on rolling contact fatigue damage of bainitic rail steel. Engi. Fail. Anal. 2023, 143, 106875. [Google Scholar] [CrossRef]

- Arakere, N.K. Gigacycle rolling contact fatigue of bearing steels: A review. Int. J. Fatigue 2016, 93, 238–249. [Google Scholar] [CrossRef]

- Dong, S.; Yu, Q.; Jiang, Y.; Dong, J.; Wang, F.; Jin, L.; Ding, W. Characteristic cyclic plastic deformation in ZK60 magnesium alloy. Int. J. Plast. 2017, 91, 25–47. [Google Scholar] [CrossRef]

- Bhatti, N.A.; Pereira, K.; Abdel Wahab, M. A continuum damage mechanics approach for fretting fatigue under out of phase loading. Tribol. Int. 2018, 117, 39–51. [Google Scholar] [CrossRef]

- Lorenz, S.J.; Sadeghi, F.; Trivedi, H.K.; Rosado, L.; Wang, C. A continuum damage mechanics finite element model for investigating effects of surface roughness on rolling contact fatigue. Int. J. Fatigue 2021, 143, 105986. [Google Scholar] [CrossRef]

- Yao, Y.; He, X.; Keer, L.M.; Fine, M.E. A continuum damage mechanics-based unified creep and plasticity model for solder materials. Acta Mater. 2015, 83, 160–168. [Google Scholar] [CrossRef]

- Shintaku, Y.; Tsutsumi, S.; Terada, K. A CDM-like constitutive law for predicting degradation of strength and ductility of steel subjected to cyclic loading. Int. J. Plast. 2022, 153, 103237. [Google Scholar] [CrossRef]

- Walvekar, A.A.; Paulson, N.; Sadeghi, F.; Weinzapfel, N.; Correns, M.; Dinkel, M. A New Approach for Fatigue Damage Modeling of Subsurface-Initiated Spalling in Large Rolling Contacts. J. Tribol. 2017, 139, 011101. [Google Scholar] [CrossRef]

- Li, F.; Hu, W.; Meng, Q.; Zhan, Z.; Shen, F. A new damage-mechanics-based model for rolling contact fatigue analysis of cylindrical roller bearing. Tribol. Int. 2018, 120, 105–114. [Google Scholar] [CrossRef]

- Warhadpande, A.; Sadeghi, F.; Kotzalas, M.N.; Doll, G. Effects of plasticity on subsurface initiated spalling in rolling contact fatigue. Int. J. Fatigue 2012, 36, 80–95. [Google Scholar] [CrossRef]

- He, H.; Liu, H.; Zhu, C.; Wei, P.; Sun, Z. Study of rolling contact fatigue behavior of a wind turbine gear based on damage-coupled elastic-plastic model. Int. J. Mech. Sci. 2018, 141, 512–519. [Google Scholar] [CrossRef]

- Shen, F.; Hu, W.; Meng, Q.; Zhang, M. A new damage mechanics based approach to fatigue life prediction and its engineering application. Acta Mech. Solida Sin. 2015, 28, 510–520. [Google Scholar] [CrossRef]

- Shen, F.; Hu, W.; Meng, Q. A damage mechanics approach to fretting fatigue life prediction with consideration of elastic–plastic damage model and wear. Tribol. Int. 2015, 82, 176–190. [Google Scholar] [CrossRef]

- Shen, F.; Zhou, K. An elasto-plastic-damage model for initiation and propagation of spalling in rolling bearings. Int. J. Mech. Sci. 2019, 161–162, 105058. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Zhao, B.; Shen, F.; Cui, Y.; Xie, Y.; Zhou, K. Damage analysis for an elastic-plastic body in cylindrical contact with a rigid plane. Tribol. Int. 2017, 115, 18–27. [Google Scholar] [CrossRef]

- Zhan, Z.; Meng, Q.; Hu, W.; Sun, Y.; Shen, F.; Zhang, Y. Continuum damage mechanics based approach to study the effects of the scarf angle, surface friction and clamping force over the fatigue life of scarf bolted joints. Int. J. Fatigue 2017, 102, 59–78. [Google Scholar] [CrossRef]

- Raje, N.; Sadeghi, F.; Rateick, R.G. A Statistical Damage Mechanics Model for Subsurface Initiated Spalling in Rolling Contacts. J. Tribol. 2008, 130, 786–791. [Google Scholar] [CrossRef]

- Koo, S.; Han, J.; Marimuthu, K.P.; Lee, H. Determination of Chaboche combined hardening parameters with dual backstress for ratcheting evaluation of AISI 52100 bearing steel. Int. J. Fatigue 2019, 122, 152–163. [Google Scholar] [CrossRef]

- Park, J.; Lee, K.; Kang, J.H.; Kang, J.Y.; Hong, S.H.; Kwon, S.W.; Lee, M.G. Hierarchical microstructure based crystal plasticity-continuum damage mechanics approach: Model development and validation of rolling contact fatigue behavior. Int. J. Plast. 2021, 143, 103025. [Google Scholar] [CrossRef]

- Styri, H. Fatigue strength of ball bearing races and heat-treated 52100 steel specimens. Proc. Am. Soc. Test. Mater. 1951, 51, 18. [Google Scholar]

- Liu, D. Life Prediction Method for EMU Axle Box Bearings Based on Actual Measured Loadings. Int. J. Mech. Eng. 2016, 52, 45. [Google Scholar] [CrossRef]

- Liu, D.; Li, Q.; Hu, W.; Pan, W. Fatigue life prediction of the axle box bearings for high-speed trains. DYNA 2017, 92, 7. [Google Scholar]

- Bhargava, V.; Hahn, G.T.; Rubin, C.A. An Elastic-Plastic Finite Element Model of Rolling Contact, Part 1: Analysis of Single Contacts. J. Appl. Mech. 1985, 52, 67–74. [Google Scholar] [CrossRef]

- Rosado, L.; Forster, N.H.; Thompson, K.L.; Cooke, J.W. Rolling Contact Fatigue Life and Spall Propagation of AISI M50, M50NiL, and AISI 52100, Part I: Experimental Results. Tribol. Trans. 2009, 53, 29–41. [Google Scholar] [CrossRef]

| Parameters |

|---|

| Number of Roller Rows | Number of Rollers in a Single-Row Bearing | Equivalent Length of Roller (mm) | Contact Angle between Roller and Inner Raceway (°) |

|---|---|---|---|

| 2 | 19 | 52.8 | 9 |

| Fillet diameter of roller (mm) | The maximum diameter of roller (mm) | The maximum diameter of roller (mm) | Contact angle between roller and outer raceway (°) |

| 185 | 27 | 25 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Liu, J.; Guo, F.; Li, X.; Zhang, X. Research on Rolling Contact Fatigue Failure of the Bearing Used in High-Speed Electric Multiple Units’ Axle Box Based on a Damage-Coupled Elastic–Plastic Constitutive Model. Lubricants 2023, 11, 330. https://doi.org/10.3390/lubricants11080330

Ma L, Liu J, Guo F, Li X, Zhang X. Research on Rolling Contact Fatigue Failure of the Bearing Used in High-Speed Electric Multiple Units’ Axle Box Based on a Damage-Coupled Elastic–Plastic Constitutive Model. Lubricants. 2023; 11(8):330. https://doi.org/10.3390/lubricants11080330

Chicago/Turabian StyleMa, Ling, Junyi Liu, Feng Guo, Xinming Li, and Xiaohan Zhang. 2023. "Research on Rolling Contact Fatigue Failure of the Bearing Used in High-Speed Electric Multiple Units’ Axle Box Based on a Damage-Coupled Elastic–Plastic Constitutive Model" Lubricants 11, no. 8: 330. https://doi.org/10.3390/lubricants11080330

APA StyleMa, L., Liu, J., Guo, F., Li, X., & Zhang, X. (2023). Research on Rolling Contact Fatigue Failure of the Bearing Used in High-Speed Electric Multiple Units’ Axle Box Based on a Damage-Coupled Elastic–Plastic Constitutive Model. Lubricants, 11(8), 330. https://doi.org/10.3390/lubricants11080330