Influence of Tempering Temperature on Abrasive-Wear Performance of High-Chromium-Based Multicomponent White Cast Iron

Abstract

1. Introduction

2. Materials and Methods

3. Results

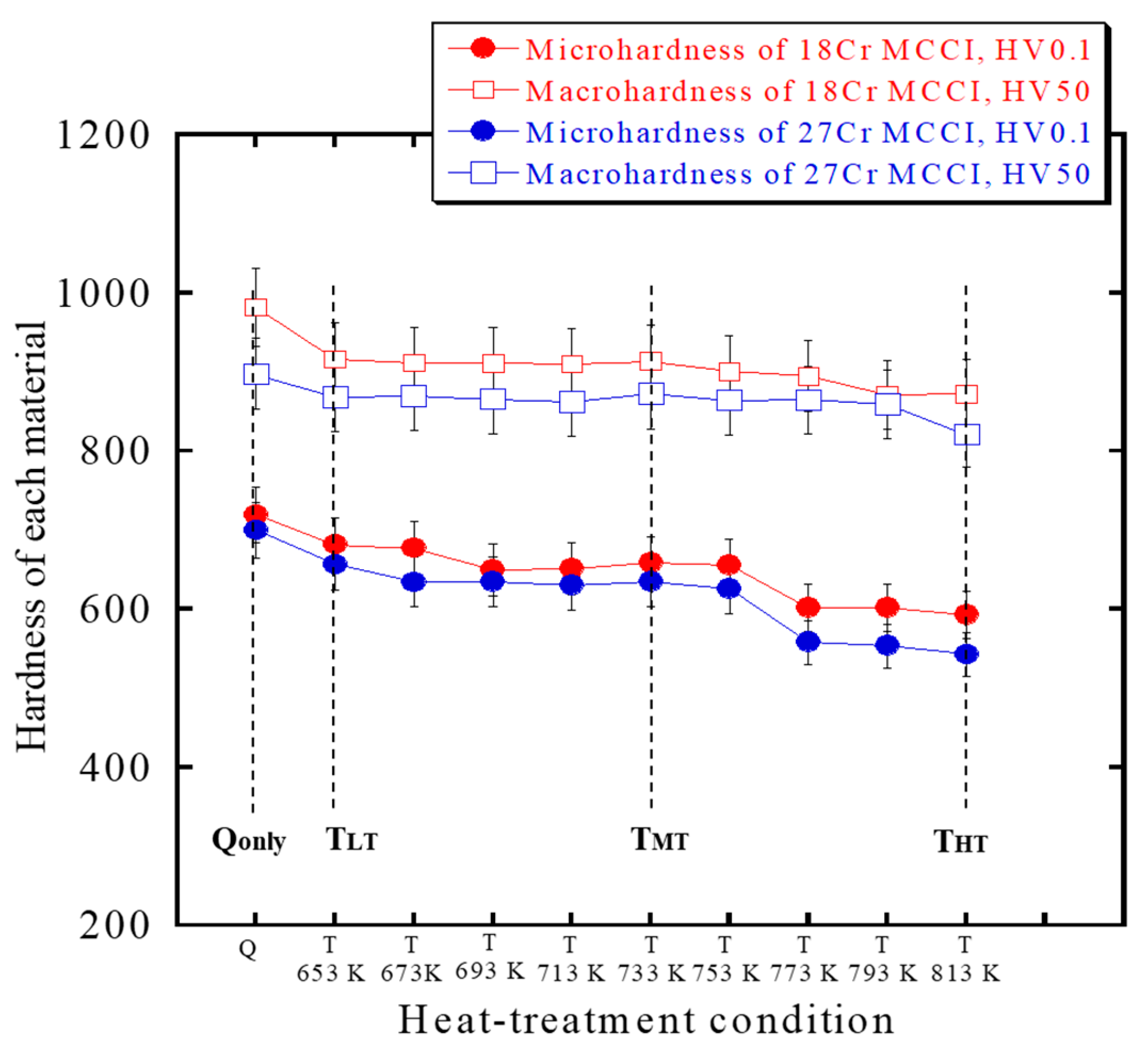

3.1. Hardness of Each Experimental Alloy

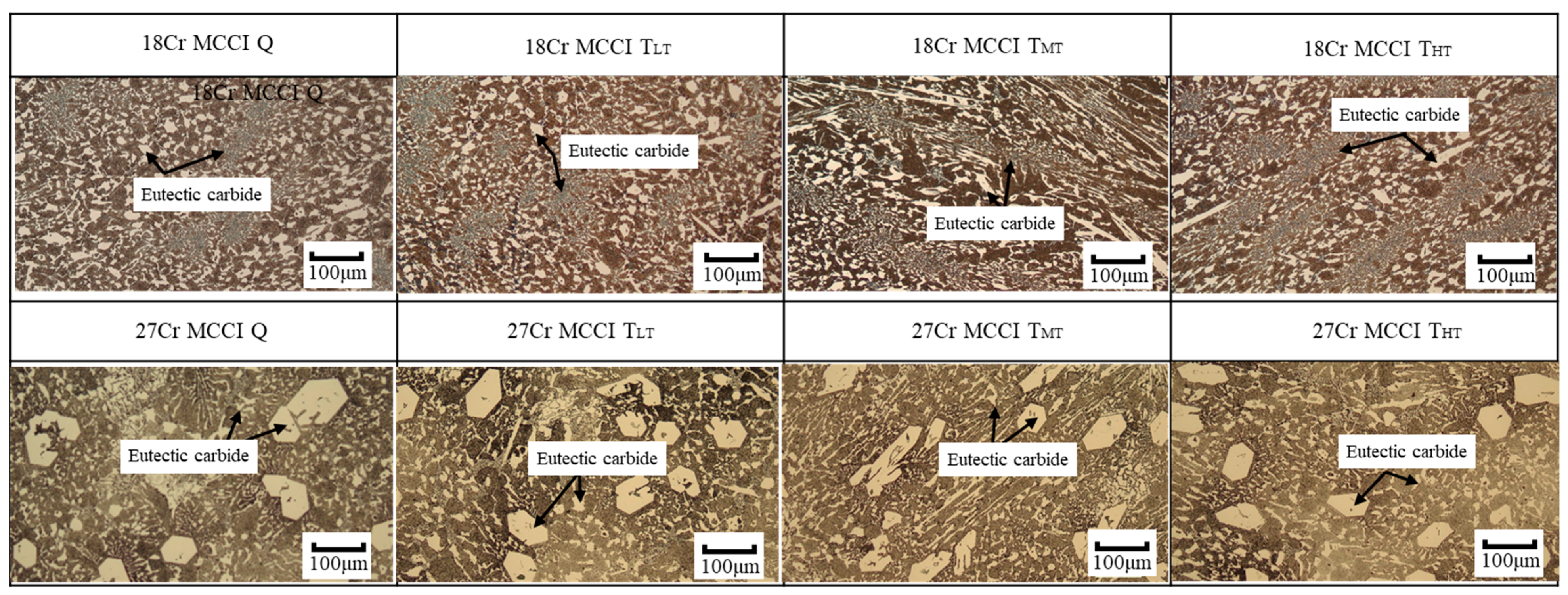

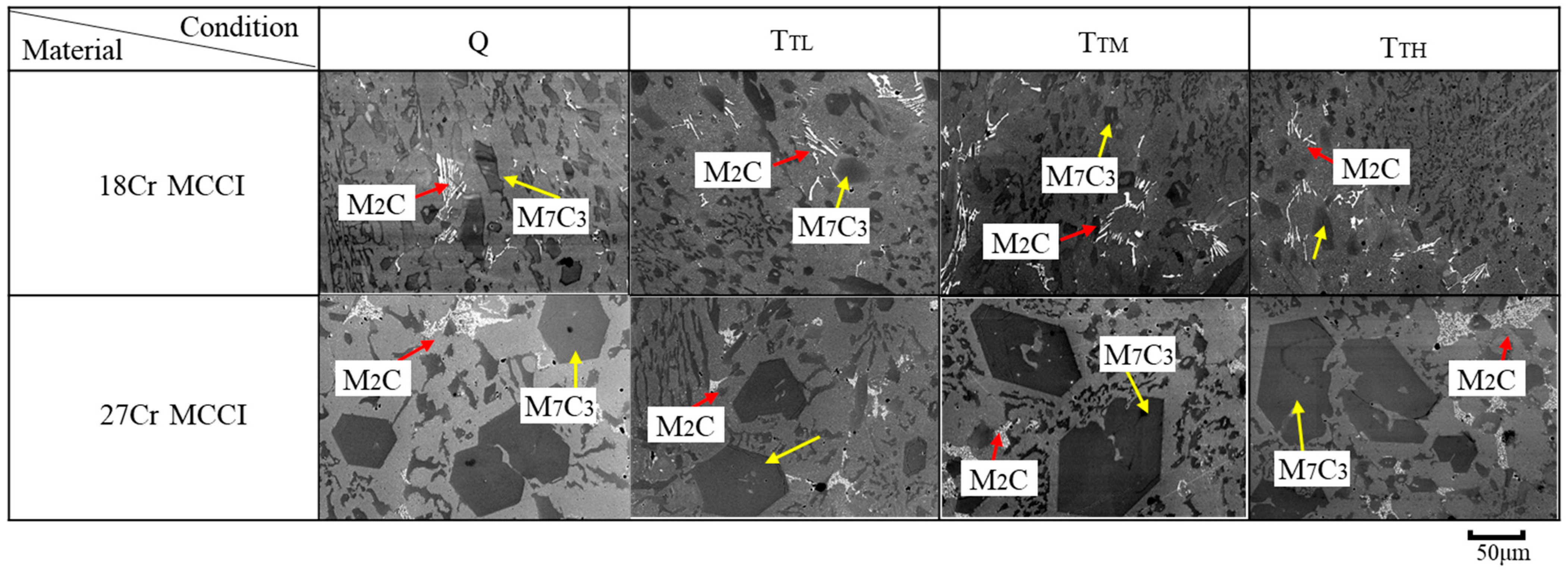

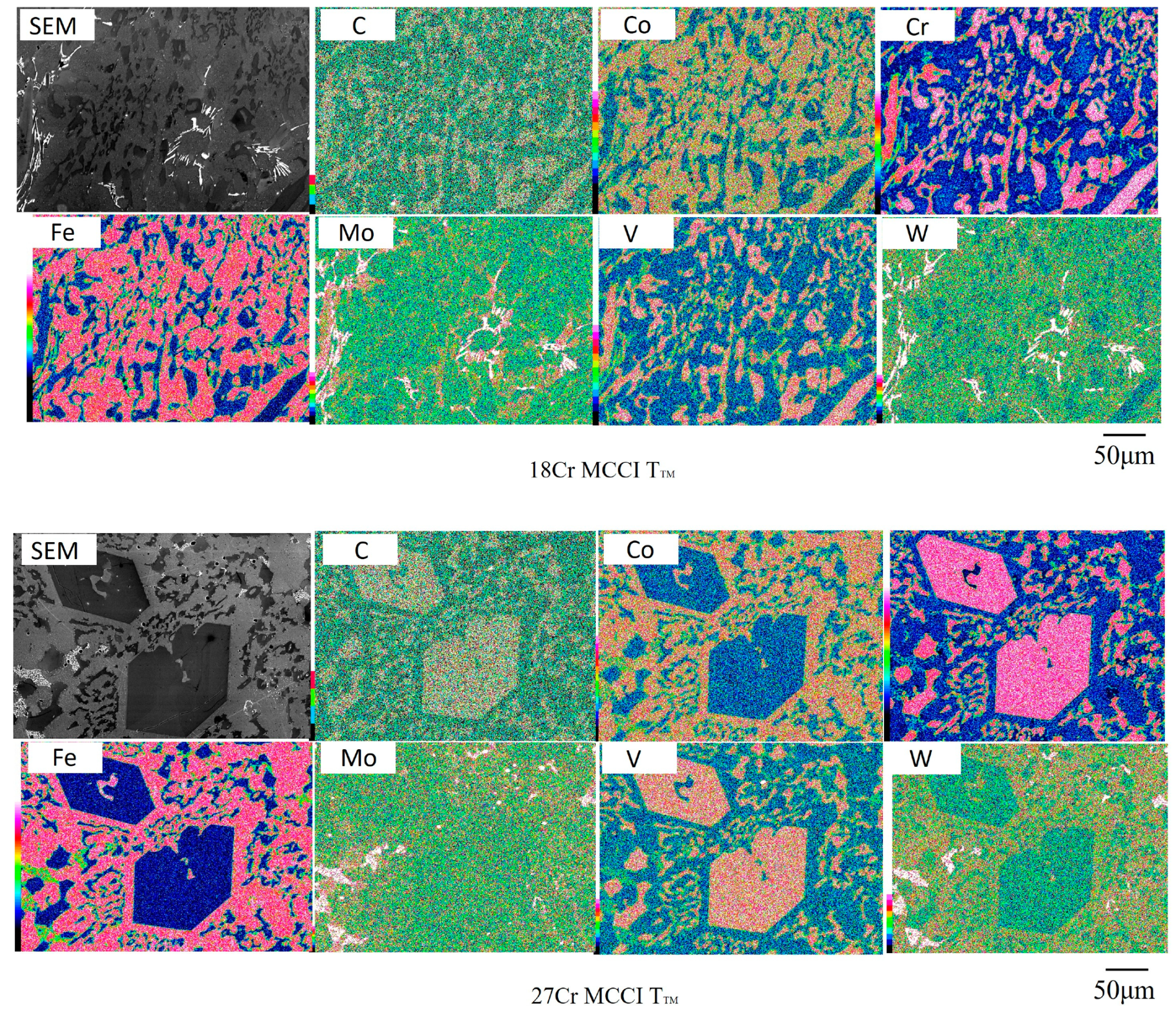

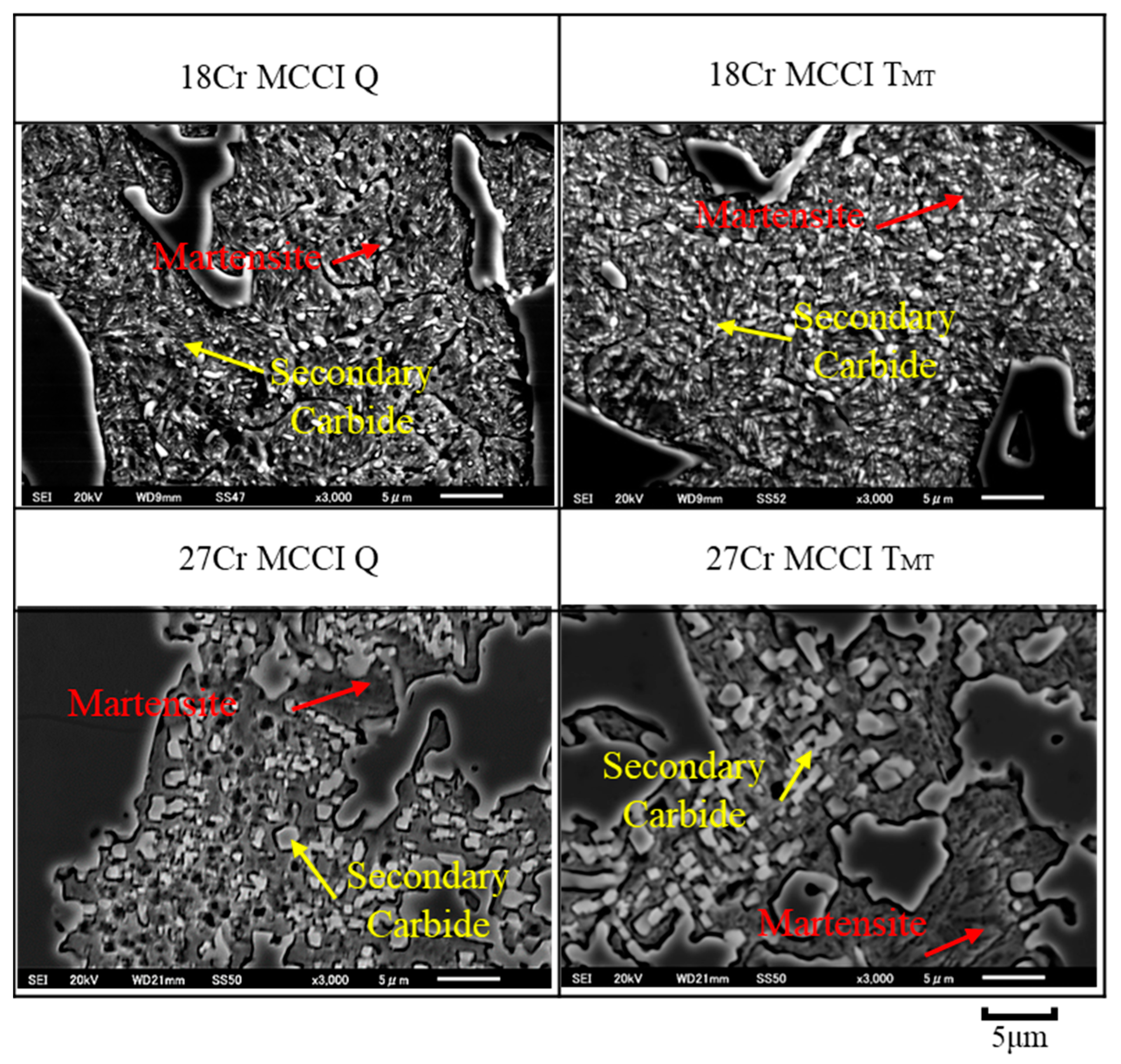

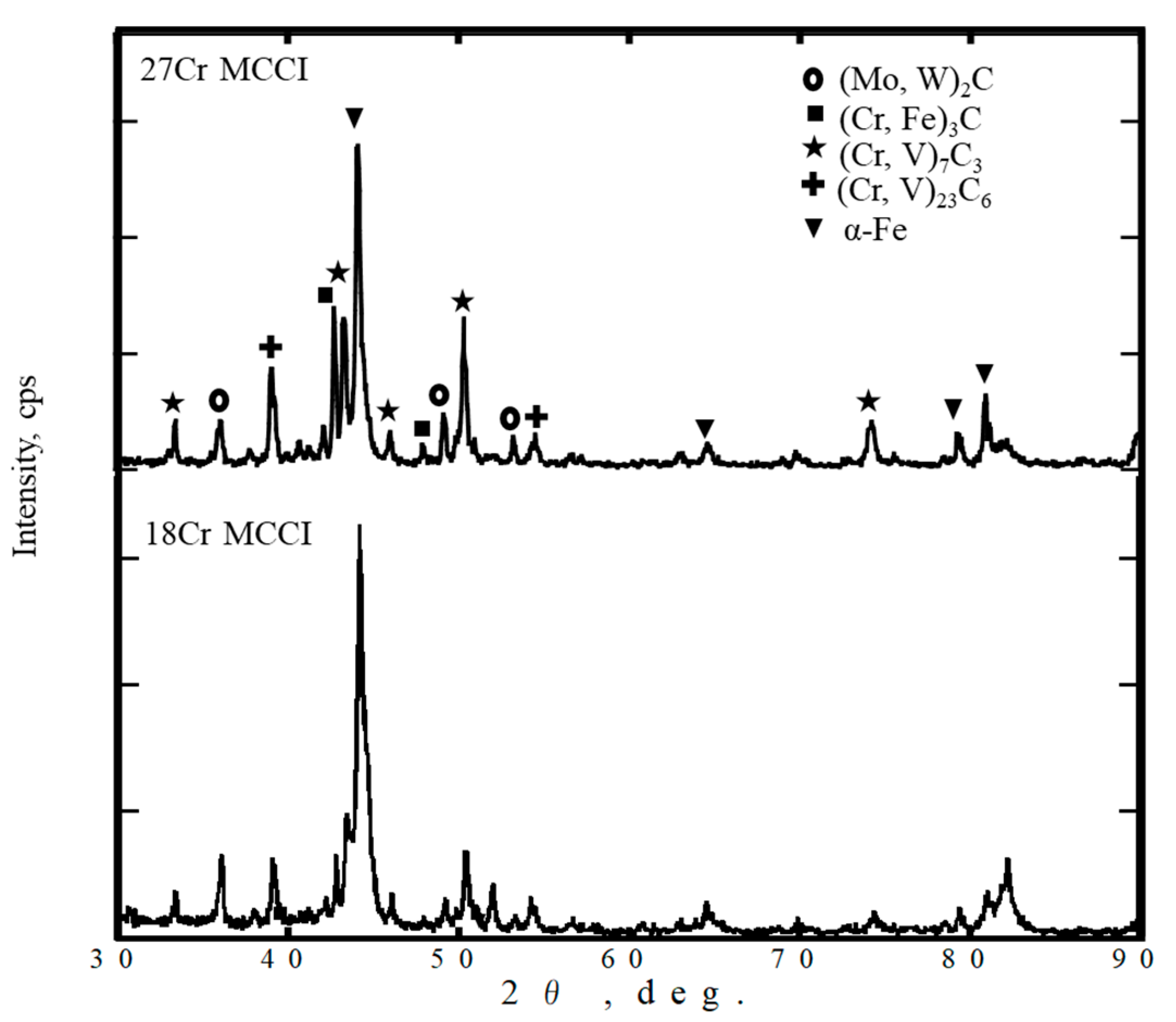

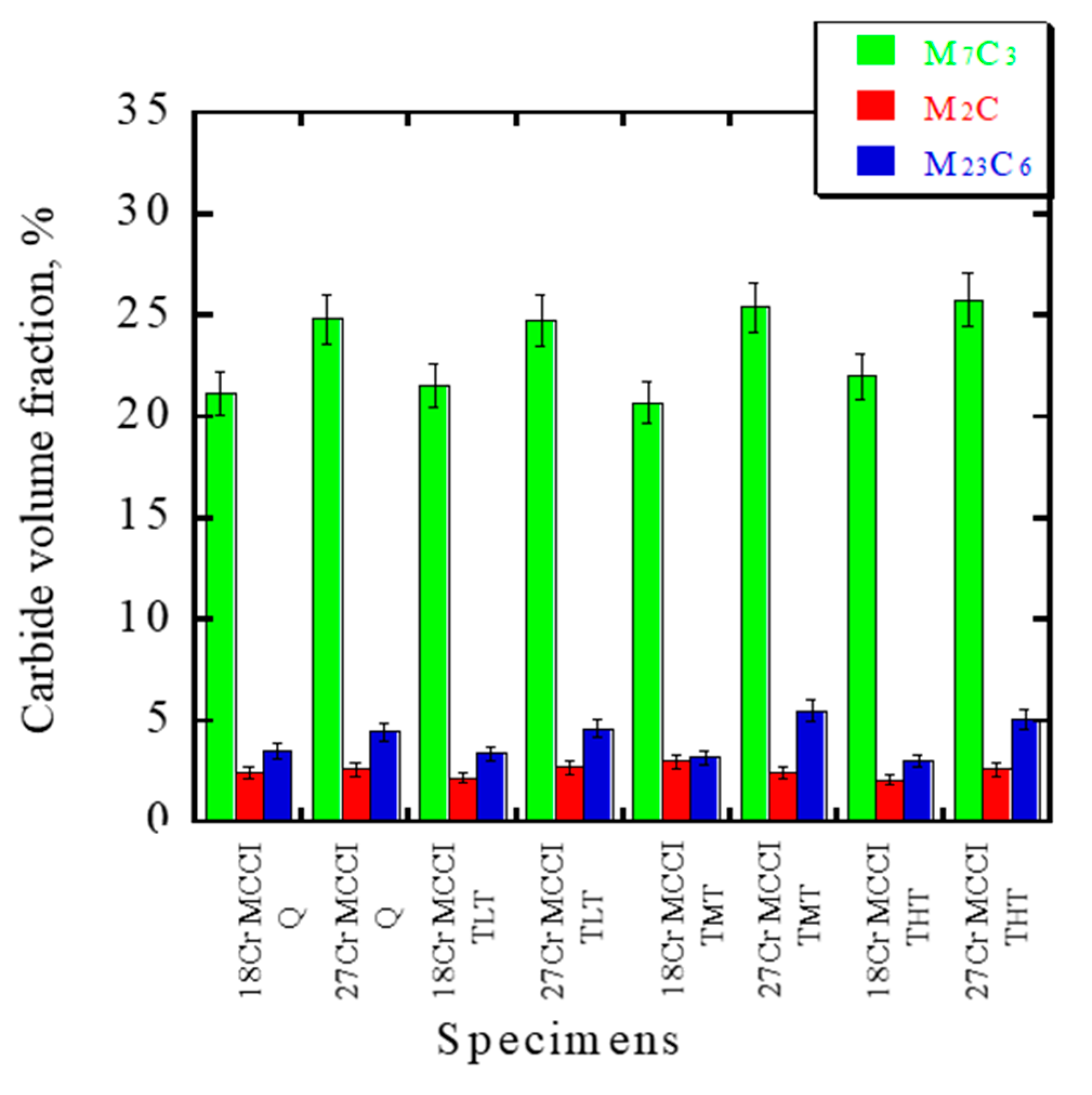

3.2. Microstructure of Experimental Alloys

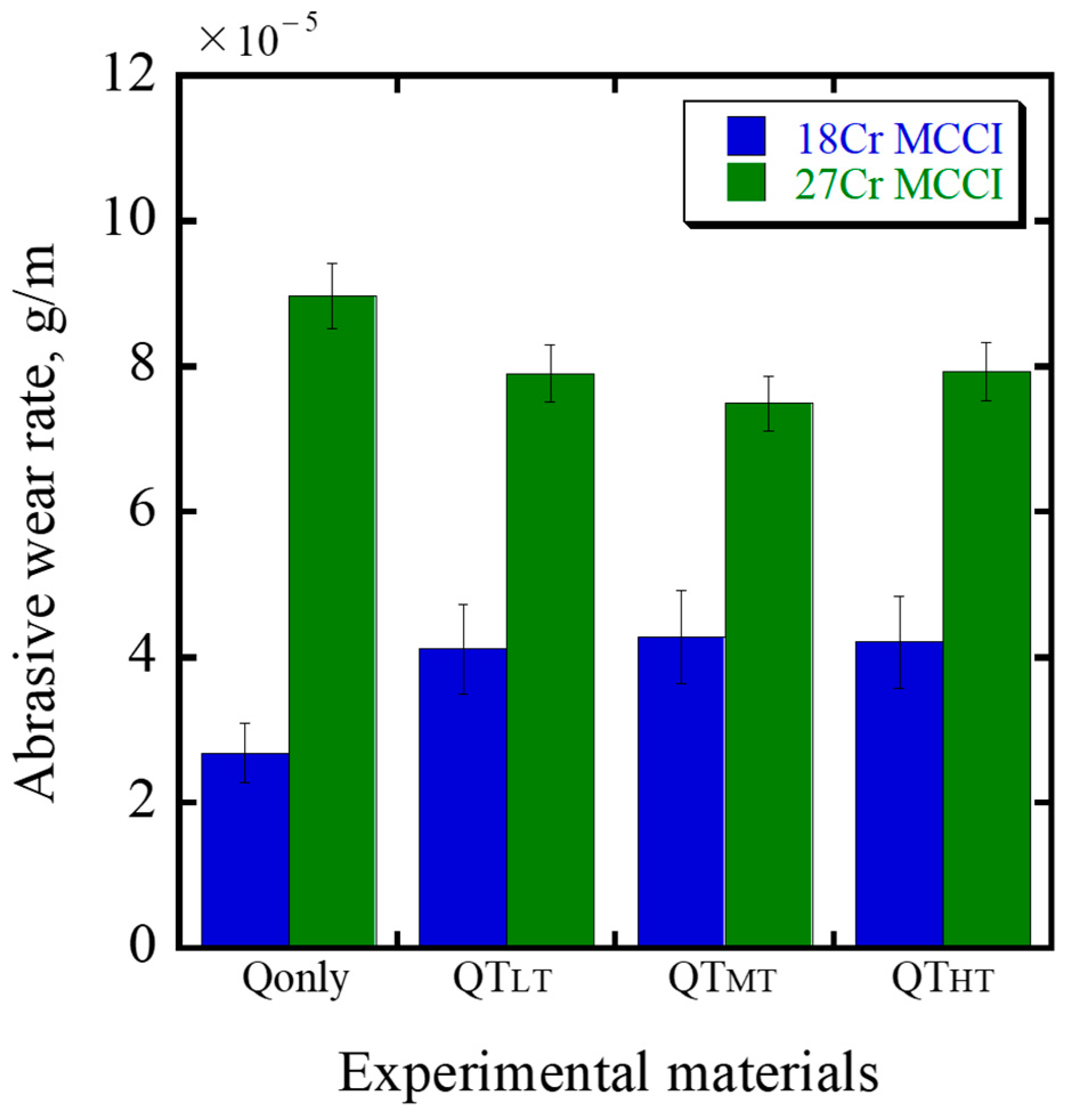

3.3. The Abrasive-Wear Rate of Each Experimental Alloy

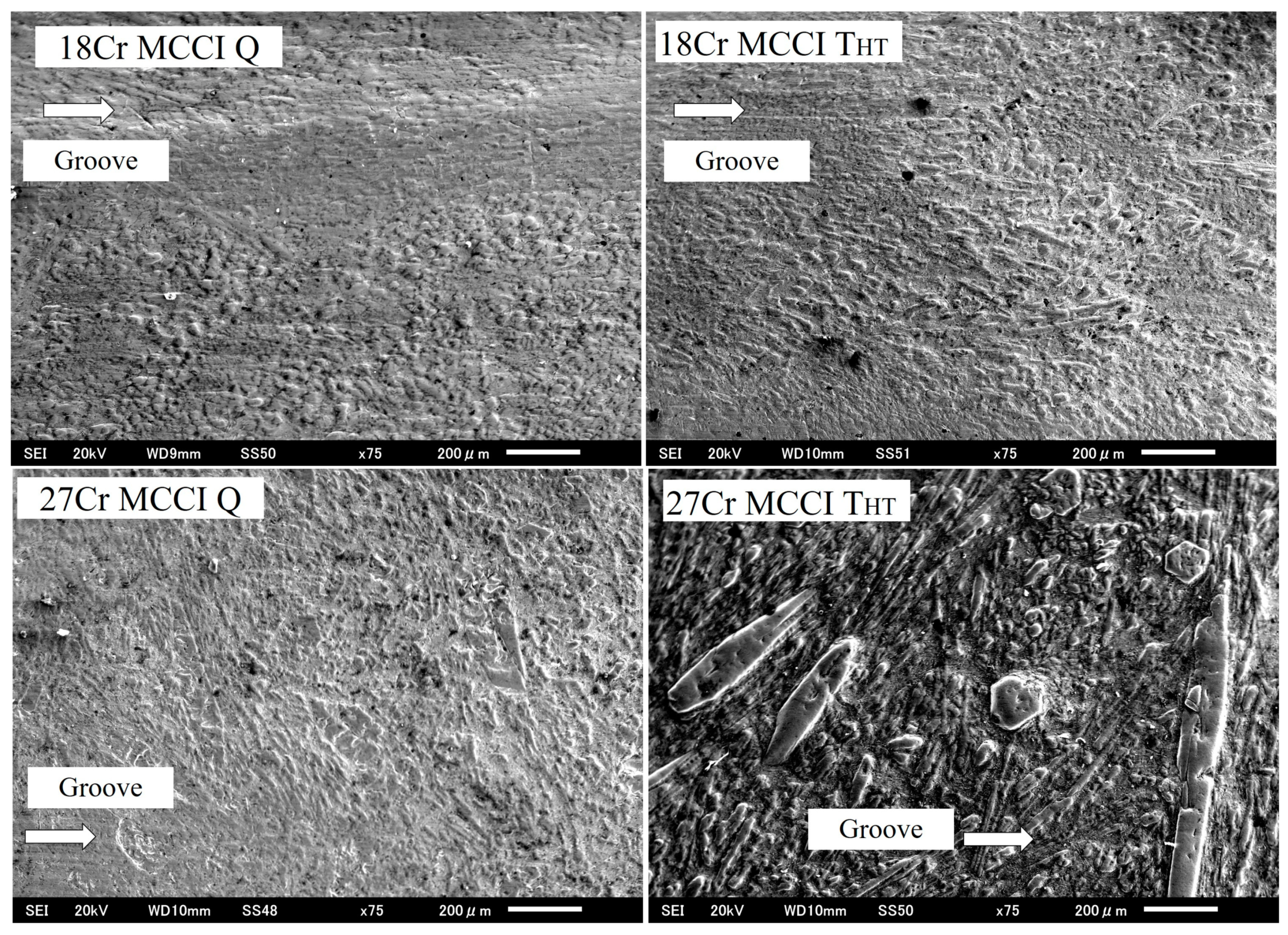

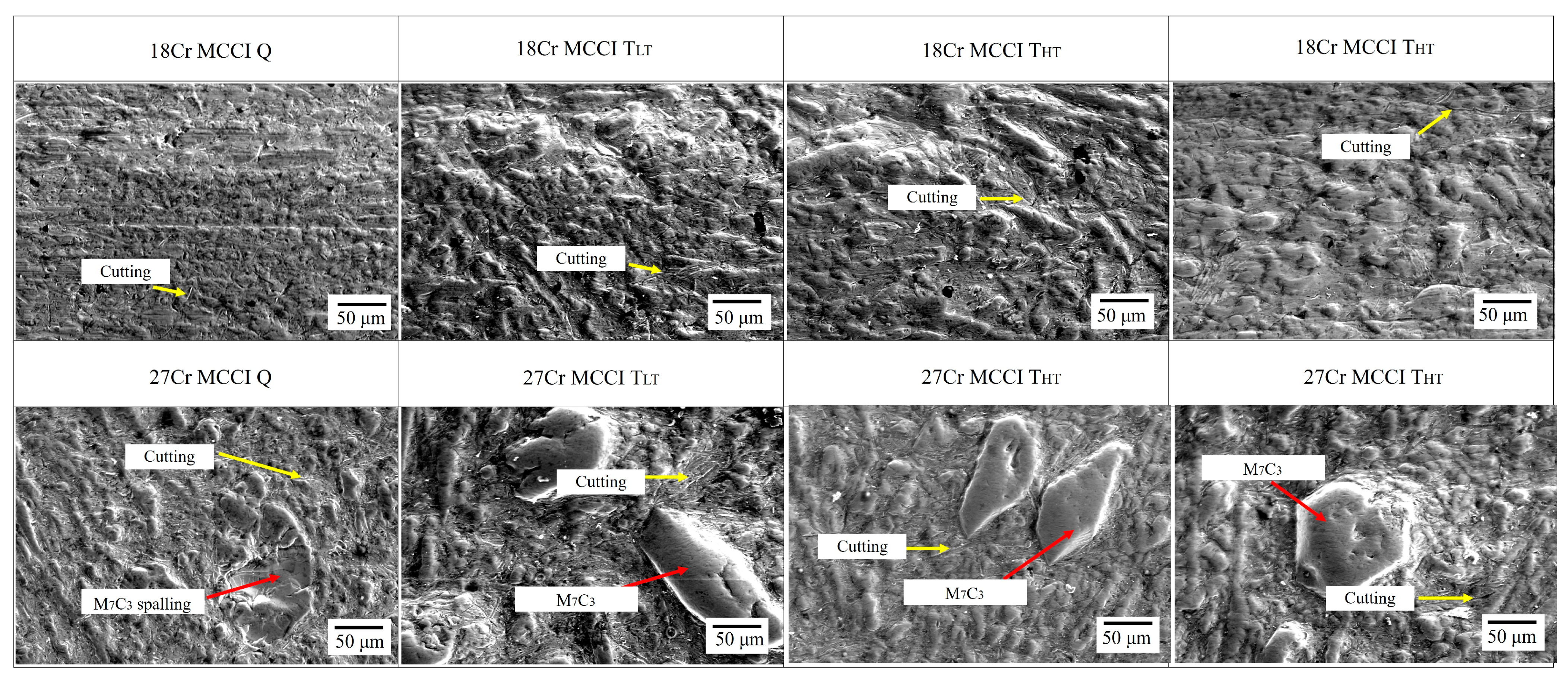

3.4. Abrasive-Wear Mechanisms of Each Experimental Alloy

3.5. Evaluation of the Properties of M7C3 Carbide

4. Conclusions

- 1.

- The size of M7C3 and secondary carbides (M23C6) is enlarged with an increased amount of Cr, which results in more CVF in total. However, there is no significant difference in the CVF of M2C between the two materials (18Cr MCCI and 27Cr MCCI) due to the same amount of Mo and W addition. In addition, there is no major difference in the matrix (mainly martensite) and CVF as the Cr addition and tempering temperature increase.

- 2.

- Although the main mechanism of abrasive wear is microcutting, the presence of carbide spalling in the case of 27Cr MCCI deteriorates the wear resistance of the alloy.

- 3.

- The wear resistance of 27Cr MCCI is improved by the tempering process, although its hardness decreases. This is due to the higher fracture toughness level of the M7C3 carbide. However, the opposite result will occur if the tempering temperature is too high. Therefore, QTMT has better wear resistance in the case of 27Cr MCCI.

- 4.

- The fracture toughness of the M7C3 carbide in the case of 18Cr MCCI also increases slightly with the tempering process. However, this does not lead to an increase in the wear resistance of the material. In general, the hardness of the material has a more pronounced effect on its wear resistance than the fracture toughness of separate carbide particles.

- 5.

- The material with the best wear resistance is 18Cr MCCI Q, while the worst is 27Cr MCCI Q among all experimental alloys.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Robert, J.K. Wood. Friction, lubrication, and wear technology. In ASM Handbook; ASM International: Phoenix, AZ, USA, 2017; Volume 18, pp. 266–289. [Google Scholar]

- Jain, A.S.; Chang, H.W.; Tang, X.H.; Hinckley, B.; Zhang, M.X. Refinement of primary carbides in hypereutectic high-chromium cast irons: A review. J. Mater. Sci. 2020, 56, 999–1038. [Google Scholar] [CrossRef]

- Siekaniec, D.; Kopycinski, D.; Tyrala, E.; Guzik, E.; Szczesny, A. Optimisation of Solidification Structure and Properties of Hypoeutectic Chromium Cast Iron. Materials 2022, 15, 6243. [Google Scholar] [CrossRef] [PubMed]

- Dogan, O.N.; Laird, G.; Hawk, J.A. Solidification structure and abrasion resistance of high chromium white cast irons. Metal. Meter. Trans. A 1997, 28, 1315–1328. [Google Scholar] [CrossRef]

- Liu, Q.; Shibata, H.; Hedström, P.; Jönsson, P.G.; Nakajima, K. Dynamic precipitation behavior of secondary M7C3 carbides in Ti-alloyed high chromium Cast Iron. ISIJ Int. 2013, 53, 1237–1244. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Guerra, F.V.; Mejia, I.; Zuno-Silva, J.; Rainforth, M. Abrasive wear of V-Nb-Ti alloyed high-chromium white irons. Wear 2015, 332, 1006–1011. [Google Scholar] [CrossRef]

- Chen, Z.; Guo, Q.; Fu, H.; Zhi, X. Effect of heat treatment on microstructure and properties of modified hypereutectic high chromium cast iron. Mater. Test. 2022, 64, 33–54. [Google Scholar] [CrossRef]

- Gundlach, R.B.; Parks, J.L. Influence of abrasive hardness on the wear resistance of high chromium irons. Wear 1978, 46, 97–108. [Google Scholar] [CrossRef]

- Kositsyana, I.I.; Sagaradze, V.V.; Makarov, A.V.; Kozlova, A.N.; Ustyuzhaninova, A.I. Effect of structure on the properties of white chromium cast irons. Mater. Sci. Heat Treat. 1996, 38, 149–152. [Google Scholar] [CrossRef]

- Wiengmoon, A.; Chairuangsri, T.; Chomsang, N.; Poolthong, N.; Pearce, J.T.H. Effects of heat treatment on hardness and dry wear properties of a semi-solid processed Fe-27wt%Cr–2.9wt%C cast Iron. J. Mater. Sci. Technol. 2008, 24, 330–334. [Google Scholar]

- Scandian, C.; Boher, C.; de Mello, J.D.B.; Rézaï-Aria, F. Effect of molybdenum and chromium contents in sliding wear of high chromium white cast iron: The relationship between microstructure and wear. Wear 2009, 267, 301–408. [Google Scholar] [CrossRef]

- Efremenko, V.; Shimizu, K.; Chabak, Y. Effect of Destabilizing Heat Treatment on Solid-State Phase Transformation in High-Chromium Cast Irons. Metall. Mater. Trans. A 2013, 44, 5434–5446. [Google Scholar] [CrossRef]

- González-Pociño, A.; Asensio-Lozano, J.; Álvarez-Antolín, F.; García-Diez, A. Improvement of Impact Toughness and Abrasion Resistance of a 3C-25Cr-0.5Mo Alloy Using a Design of Experiment Statistical Technique: Microstructural Correlations after Heat Treatments. Metals 2021, 11, 595. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.; Liu, H.; Yang, H.; Shen, B.; Gao, S.; Huang, S. The precipitation and transformation of secondary carbides in a high chromium cast iron. Mater. Charact. 2006, 56, 73–78. [Google Scholar] [CrossRef]

- Guitar, M.A.; Scheid, A.; Suárez, S.; Britz, D.; Guigou, M.D.; Mücklich, F. Secondary carbides in high chromium cast irons: An alternative approach to their morphological and spatial distribution characterization. Mater. Charact. 2018, 144, 621–630. [Google Scholar] [CrossRef]

- Jia, X.S.; Hao, Q.G.; Zuo, X.W.; Chen, N.L.; Rong, Y.H. High hardness and toughness of white cast iron: The proposal of a novel process. Mater. Sci. Eng. A 2014, 618, 96–103. [Google Scholar] [CrossRef]

- Zhi, X.; Xiang, J.; Fu, H.; Xiao, B. Effect of niobium on the as-cast microstructure of hypereutectic high chromium cast iron. Mater. Lett. 2008, 62, 857–860. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Wang, Q.; Nakajima, K. Effect of heat treatment on microstructure and mechanical properties of Ti-alloyed hypereutectic high chromium cast iron. ISIJ Int. 2012, 52, 2288–2294. [Google Scholar] [CrossRef]

- Ibrahim, K.M.; Nofal, A.A. Effect of titanium addition on structure and properties of the as-cast high Cr-Mo white iron. Int. J. Mater. Res. 2013, 103, 362–370. [Google Scholar] [CrossRef]

- Chung, R.J.; Tang, X.; Li, D.Y.; Hinckley, B.; Dolman, K. Effects of titanium addition on microstructure and wear resistance of hypereutectic high chromium cast iron Fe–25 wt%Cr–4 wt%C. Wear 2009, 267, 356–361. [Google Scholar] [CrossRef]

- Chung, R.J.; Tang, X.; Li, D.Y.; Hinckley, B.; Dolman, K. Microstructure refinement of hypereutectic high Cr cast irons using hard carbide-forming elements for improved wear resistance. Wear 2013, 301, 695–706. [Google Scholar] [CrossRef]

- Arnoldo, B.J.; Guerra, F.; Mejia, I.; Vera, U. Niobium additions to a 15%Cr–3%C white iron and its effects on the microstructure and on abrasive wear behavior. Metals 2019, 9, 1321. [Google Scholar] [CrossRef]

- Pourasiabi, H.; Gates, J.D. Effects of chromium carbide volume fraction on high-stress abrasion performance of NbC-bearing high chromium white cast irons. Wear 2022, 498–499, 204312. [Google Scholar] [CrossRef]

- Coronado, J.J. Effect of (Fe, Cr)7C3 carbide orientation on abrasive wear resistance and fracture toughness. Wear 2011, 270, 287–293. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y.; Yang, J.; Hao, F.; Li, D.; Ren, X.; Yang, Q. Effect of Ti additive on (Cr, Fe)7C3 carbide in arc surfacing layer and its refined mechanism. Appl. Surf. 2012, 258, 6653–6659. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Chabak, Y.G.; Lekatou, A.; Karantzalis, A.E.; Shimizu, K.; Fedun, V.I.; Azarkhov, A.Y.; Efremenko, A.V. Pulsed plasma deposition of Fe-C-Cr-W coating on high-Cr-cast iron: Effect of layered morphology and heat treatment on the microstructure and hardness. Surf. Coat. Technol. 2016, 304, 293–305. [Google Scholar] [CrossRef]

- Matsubara, Y.; Sasaguri, N.; Shimizu, K.; Yu, S.K. Solidification and abrasion wear of white cast irons alloyed with 20% carbide forming elements. Wear 2001, 250, 502–510. [Google Scholar] [CrossRef]

- de Mello, J.D.B.; Polycarpou, A.A. Abrasive wear mechanism of multi-components ferrous alloys abraded by soft, fine abrasive particles. Wear 2010, 269, 911–920. [Google Scholar] [CrossRef]

- Liu, T.; Sun, J.; Xiao, Z.; He, J.; Shi, W.; Cui, C. Effect of Multi-Element Microalloying on the Structure and Properties of HighChromium Cast Iron. Materials 2023, 16, 3292. [Google Scholar] [CrossRef]

- Kusumoto, K.; Shimizu, K.; Yaer, X.; Zhang, Y.; Ota, Y.; Ito, J. Abrasive wear characteristics of Fe-2C-5Cr-5Mo-5W-5Nb multi-component white cast iron. Wear 2017, 376–377, 22–29. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Gaqi, Y.; Huq, M.J. A study of the three-body abrasive wear resistance of 5V/5Nb-5Cr-5Mo-5W-5Co-Fe multicomponent cast alloys with different carbon percentages. Materials 2023, 16, 3102. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Gaqi, Y.; Todaka, T. Effect of boron addition on three-body abrasive wear charac-teristics of high chromium based multi-component white cast iron. Mater. Chem. Phys. 2022, 275, 125232. [Google Scholar] [CrossRef]

- Kulyk, V.; Duriagina, Z.; Vasyliv, B.; Vavrukh, V.; Kovbasiuk, T.; Lyutyy, P.; Vira, V. The Effect of Sintering Temperature on the Phase Composition, Microstructure, and Mechanical Properties of Yttria-Stabilized Zirconia. Materials 2022, 15, 2707. [Google Scholar] [CrossRef]

- Natarajan, S.; Anand, E.E.; Akhiles, K.S.; Rajagopal, A.; Nambiar, P.P. Effect of graphite addition on the microstructure, hardness, and abrasive weasr behavior of plasma spayed NiCrBSi coatings. Mater. Chem. Phys. 2016, 175, 100–106. [Google Scholar] [CrossRef]

- Fernández, I.; Belzunce, F. Wear and oxidation behaviour of high chromium white cast irons. Mater. Charact. 2008, 59, 669–674. [Google Scholar] [CrossRef]

- Tang, X.H.; Li, L.; Hinckley, B.; Dolman, K.; Parent, L.; Li, D.Y. Beneficial effects of the core-shell structure of primary carbides in high-Cr (45 wt%) white cast irons on their mechanical behavior and wear resistance. Tribol. Lett. 2015, 58, 44. [Google Scholar] [CrossRef]

- Filipovic, M.; Kamberovic, Z.; Korac, M.; Jordovic, B. Effect of niobium and vanadium additions on as-cast microstructure and properties of hypoeutectic Fe-Cr-C alloy. ISIJ Int. 2013, 53, 2160–2166. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Jafari, S.; Abdollah-pour, H. Abrasive wear behavior of high chromium cast iron and hadfield steel-a comparison. J. Iron Steel Res. Int. 2012, 19, 43–50. [Google Scholar] [CrossRef]

- El-Aziz, K.A.; Zohdy, K.; Saber, D.; Sallam, H.E.M. Wear and corrosion behavior of high-cr white cast iron alloys in different corrosive media. J. Bio-Tribo-Corros. 2015, 1, 25. [Google Scholar] [CrossRef]

- JIS R 1607:2010; Testing Method for Fracture Toughness of Fine Ceramics at Room Temperature. Japan Industrial Standard: Tokyo, Japan, 2010.

- Keough, J.R.; Hayrynen, K.L. Cast Iron Science and Technology ASM Handbook, 1A; ASM International: Phoenix, AZ, USA, 2017; pp. 275–283. [Google Scholar]

| Specimen | C | Cr | Mo | W | V | Co | Fe |

|---|---|---|---|---|---|---|---|

| 18Cr MCCI | 2.98 | 16.58 | 2.71 | 2.94 | 3.01 | 2.73 | Bal. |

| 27Cr MCCI | 3.10 | 27.04 | 2.90 | 2.88 | 2.75 | 2.84 | Bal. |

| Materials | Hardness (HV) | Fracture Toughness (MPa.m1/2) |

|---|---|---|

| 18Cr MCCI Q | 1567.13 39.44 | 2.74 0.1 |

| 18Cr MCCI TLT | 1432.06 55.13 | 3.49 0.5 |

| 18Cr MCCI TMT | 1428.67 47.04 | 3.50 0.3 |

| 18Cr MCCI THT | 1427.25 63.51 | 3.53 0.3 |

| 27Cr MCCI Q | 1677.51 77.39 | 1.32 0.7 |

| 27Cr MCCI TLT | 1599.63 45.47 | 2.05 0.2 |

| 27Cr MCCI TMT | 1560.44 87.47 | 2.24 0.4 |

| 27Cr MCCI THT | 1589.60 26.59 | 2.55 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Purba, R.H.; Kusumoto, K.; Shimizu, K.; Gaqi, Y.; Huq, M.J. Influence of Tempering Temperature on Abrasive-Wear Performance of High-Chromium-Based Multicomponent White Cast Iron. Lubricants 2023, 11, 285. https://doi.org/10.3390/lubricants11070285

Purba RH, Kusumoto K, Shimizu K, Gaqi Y, Huq MJ. Influence of Tempering Temperature on Abrasive-Wear Performance of High-Chromium-Based Multicomponent White Cast Iron. Lubricants. 2023; 11(7):285. https://doi.org/10.3390/lubricants11070285

Chicago/Turabian StylePurba, Riki Hendra, Kenta Kusumoto, Kazumichi Shimizu, Yila Gaqi, and Mohammad Jobayer Huq. 2023. "Influence of Tempering Temperature on Abrasive-Wear Performance of High-Chromium-Based Multicomponent White Cast Iron" Lubricants 11, no. 7: 285. https://doi.org/10.3390/lubricants11070285

APA StylePurba, R. H., Kusumoto, K., Shimizu, K., Gaqi, Y., & Huq, M. J. (2023). Influence of Tempering Temperature on Abrasive-Wear Performance of High-Chromium-Based Multicomponent White Cast Iron. Lubricants, 11(7), 285. https://doi.org/10.3390/lubricants11070285