Tribological Properties of Attapulgite Nanofiber as Lubricant Additive for Electric-Brush Plated Ni Coating

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Electric-Brush Plated Ni Coating

2.3. Friction and Wear Test

2.4. Characterization and Analysis

3. Results

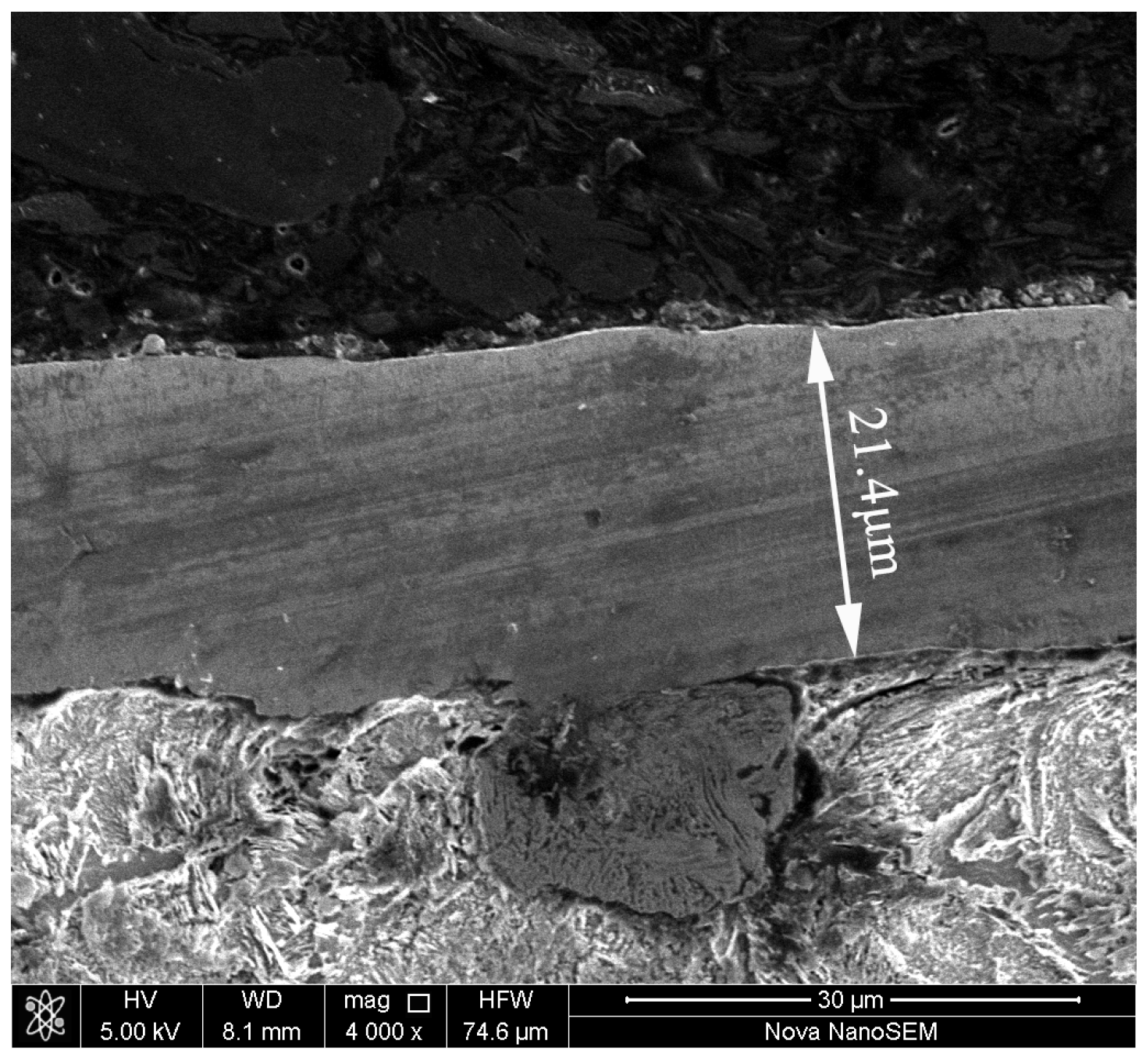

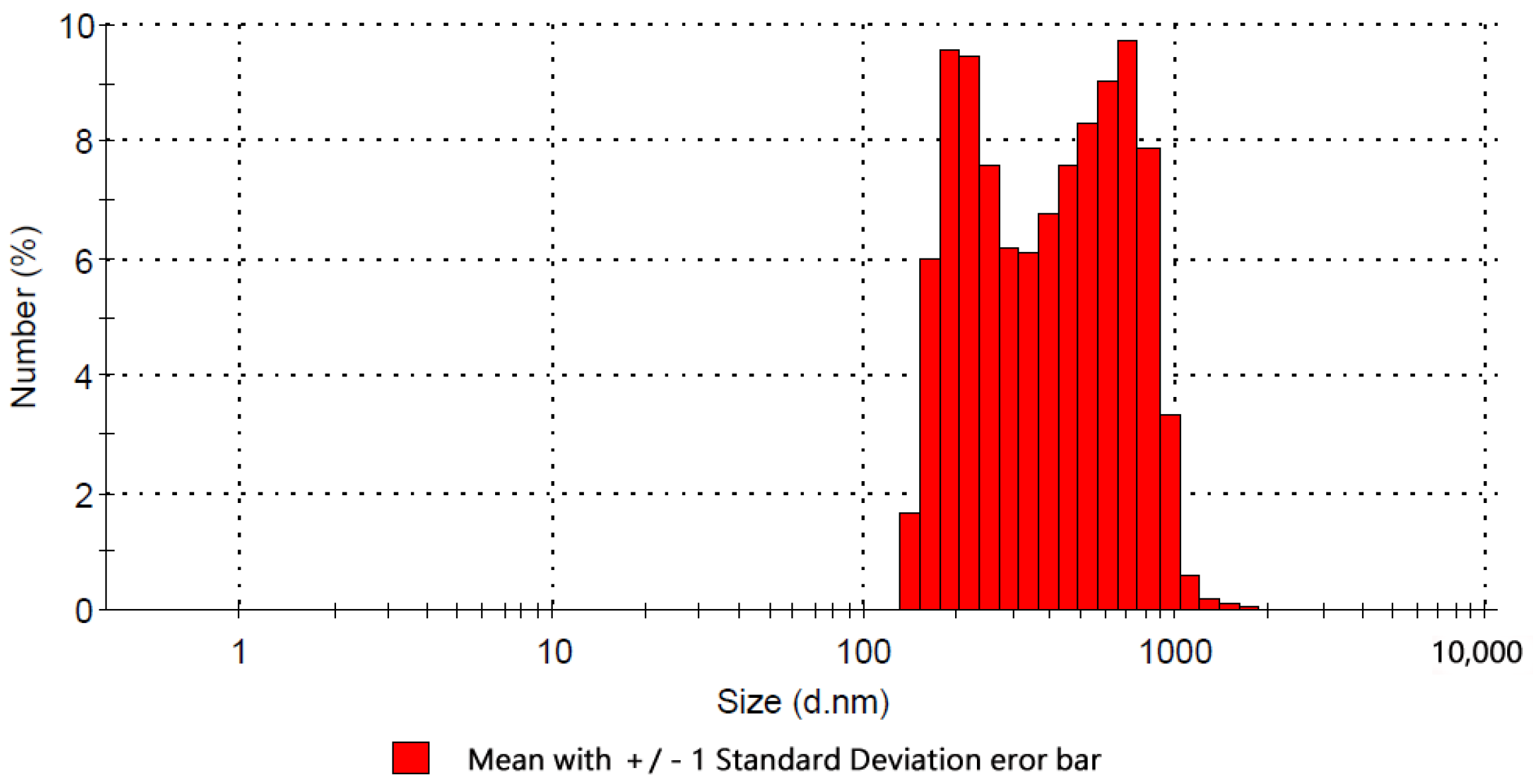

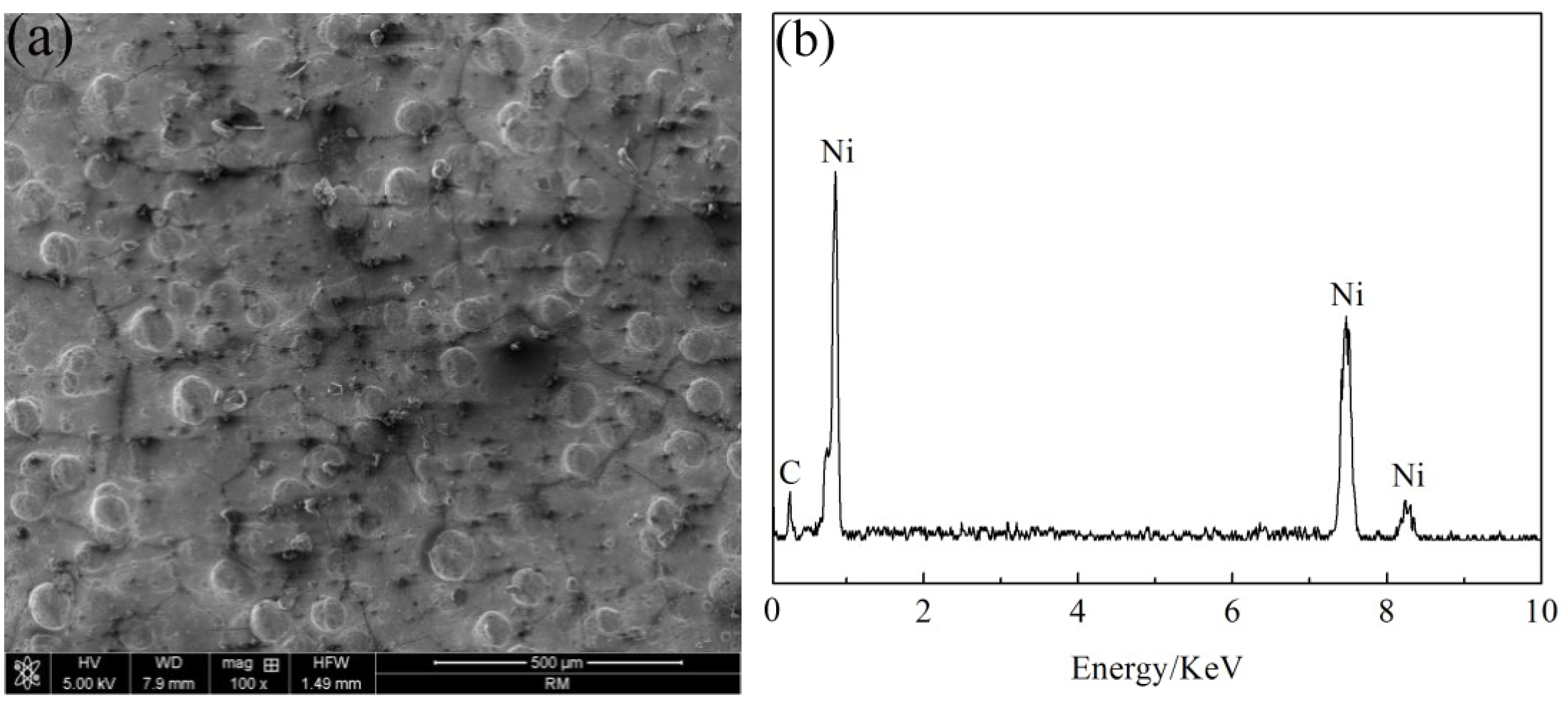

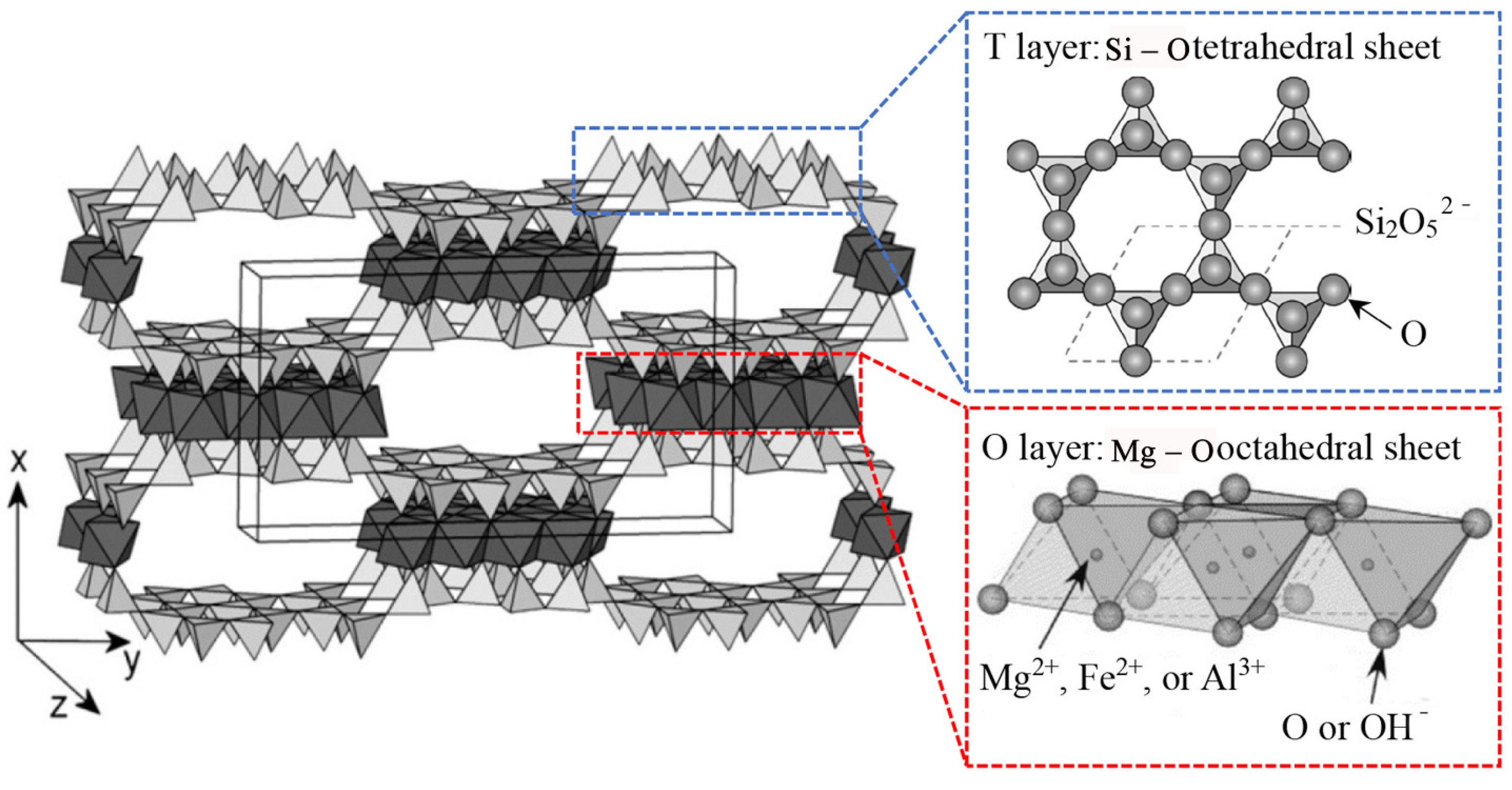

3.1. Characterization of ATP and Electric-Brush Plated Ni Coating

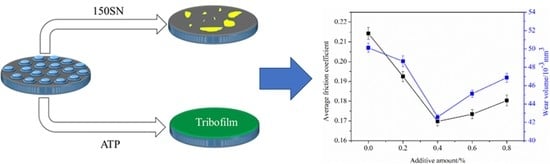

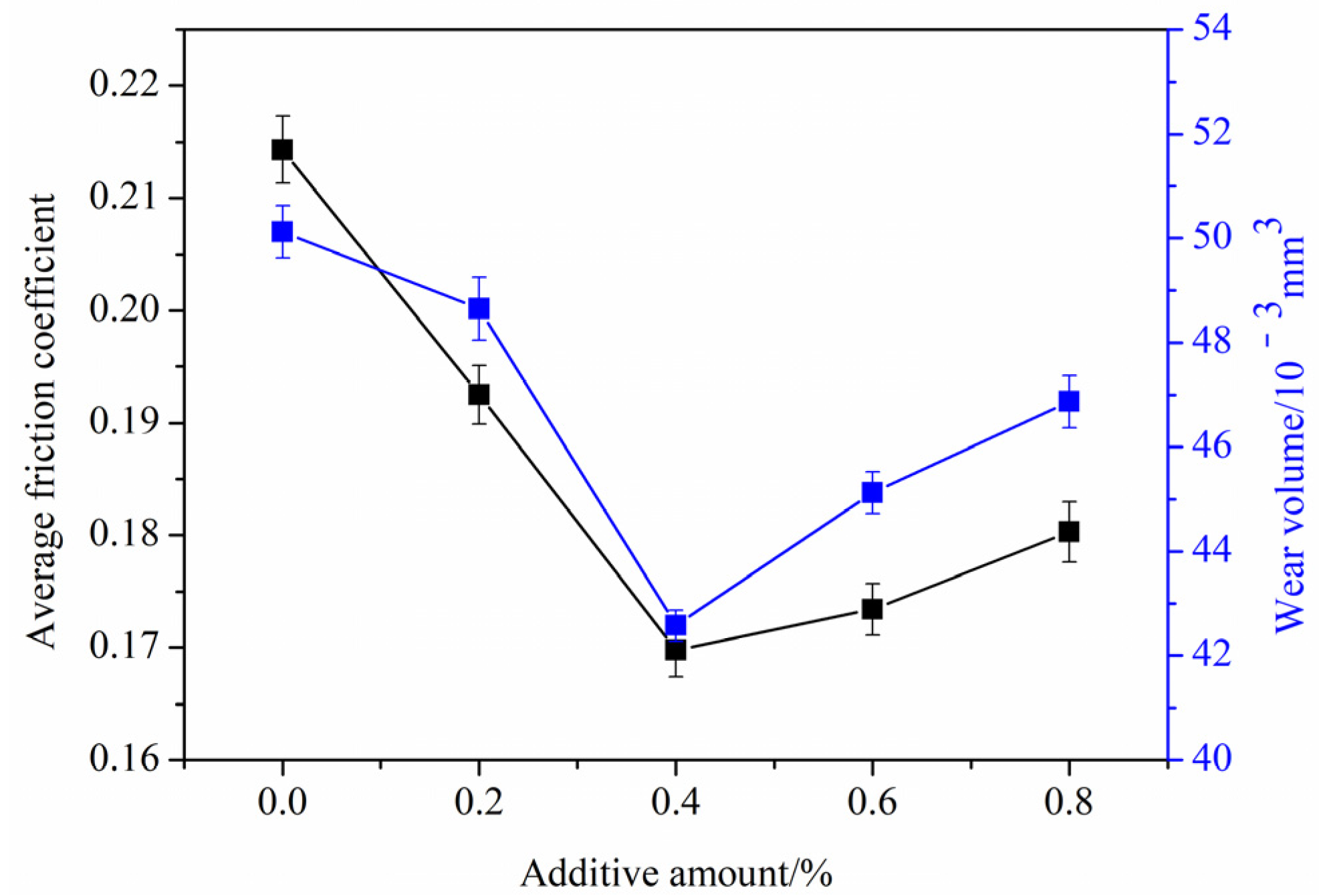

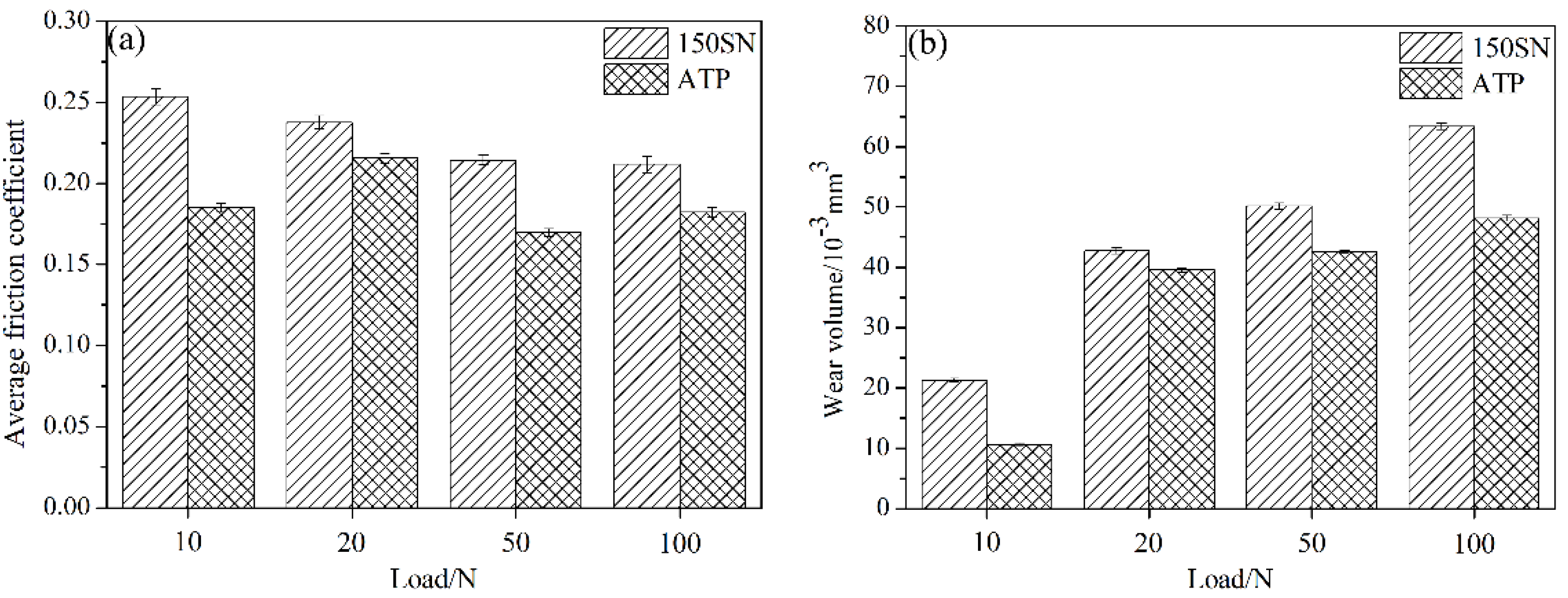

3.2. Friction and Wear Behavior

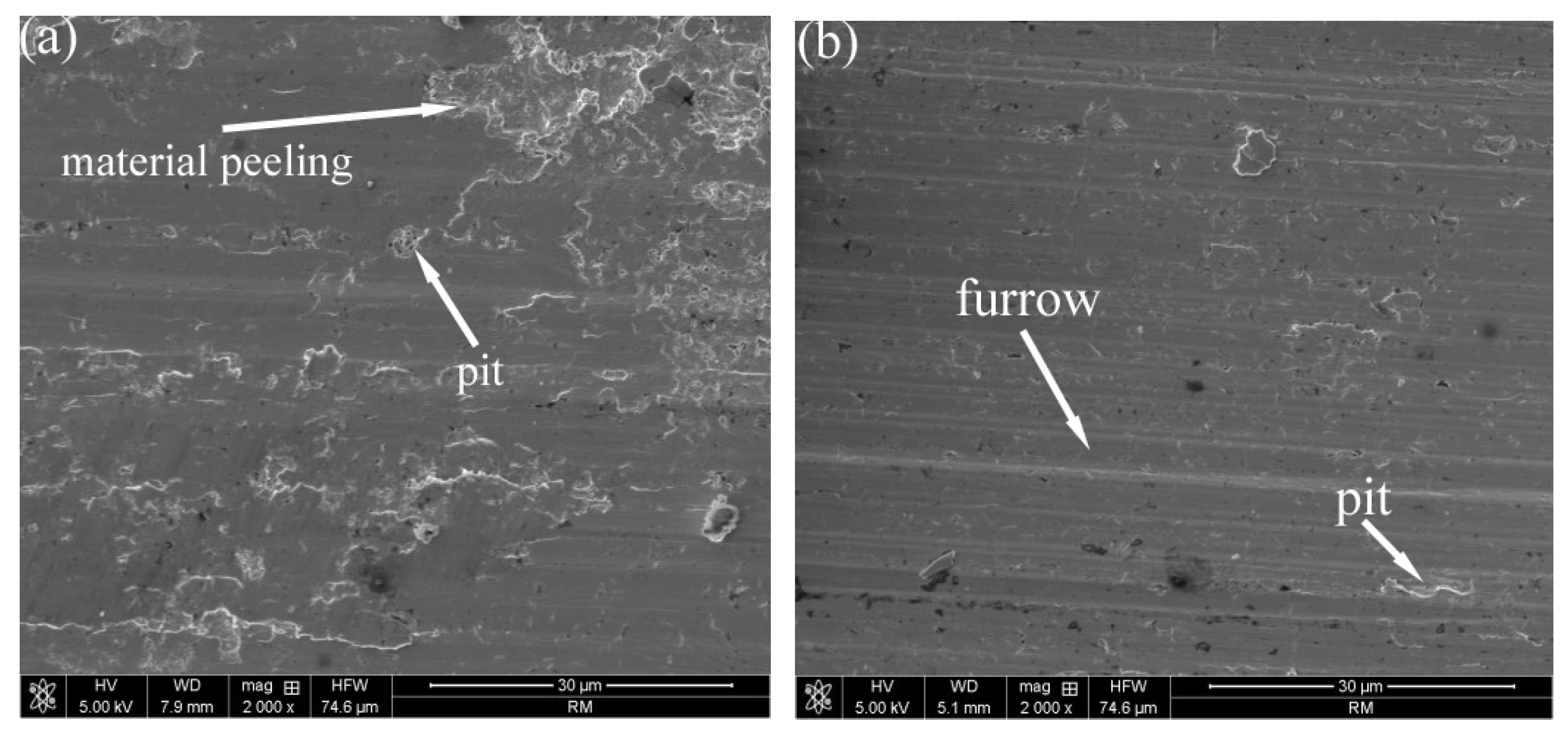

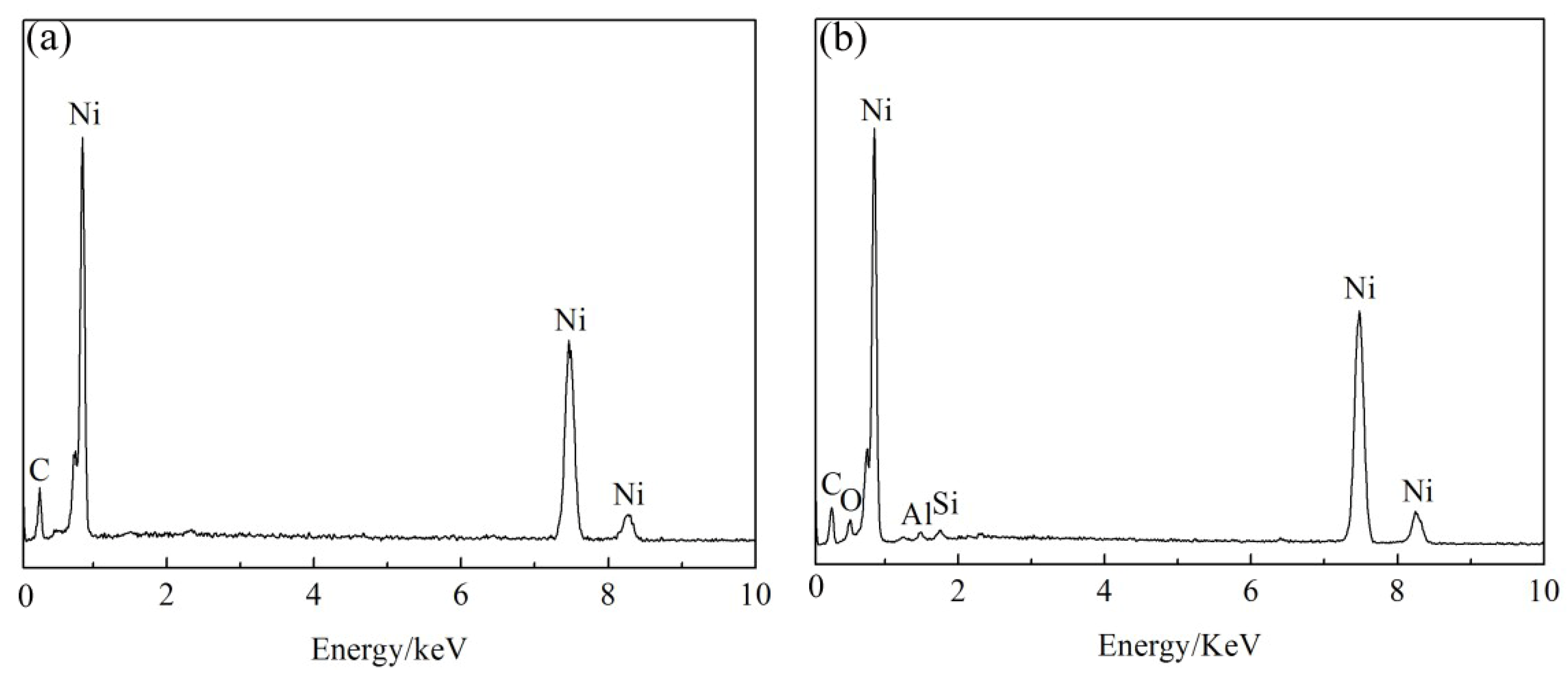

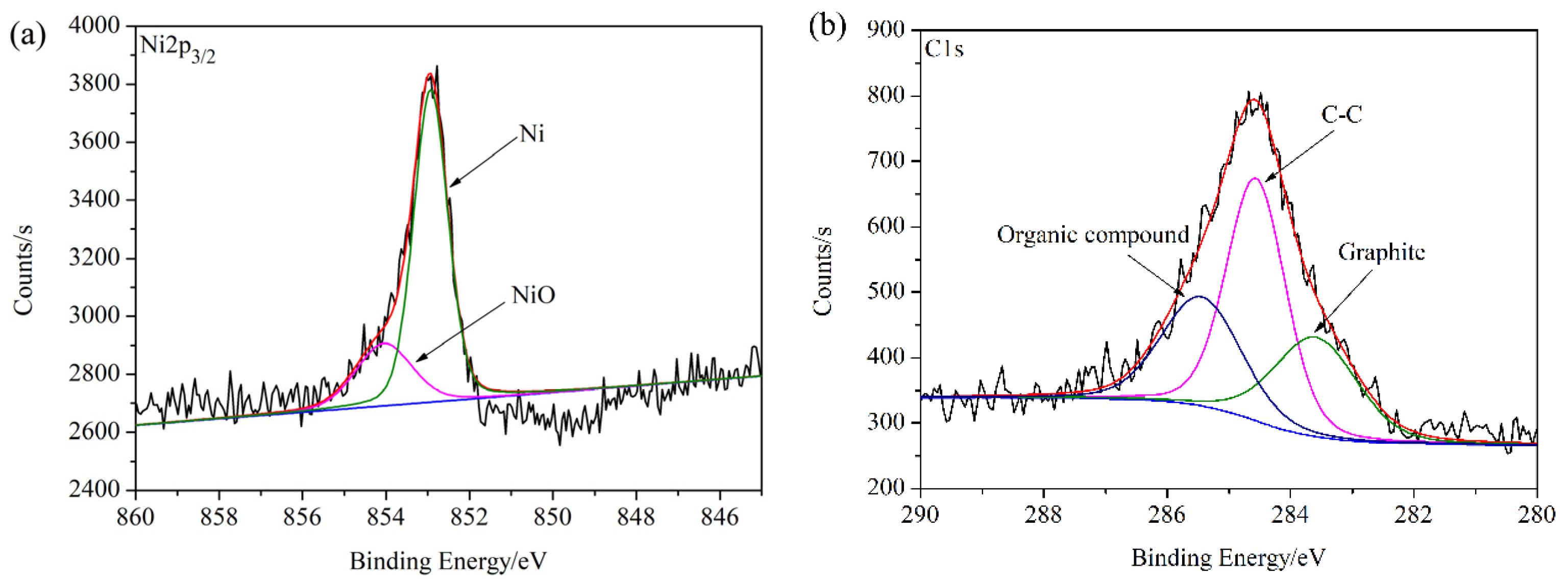

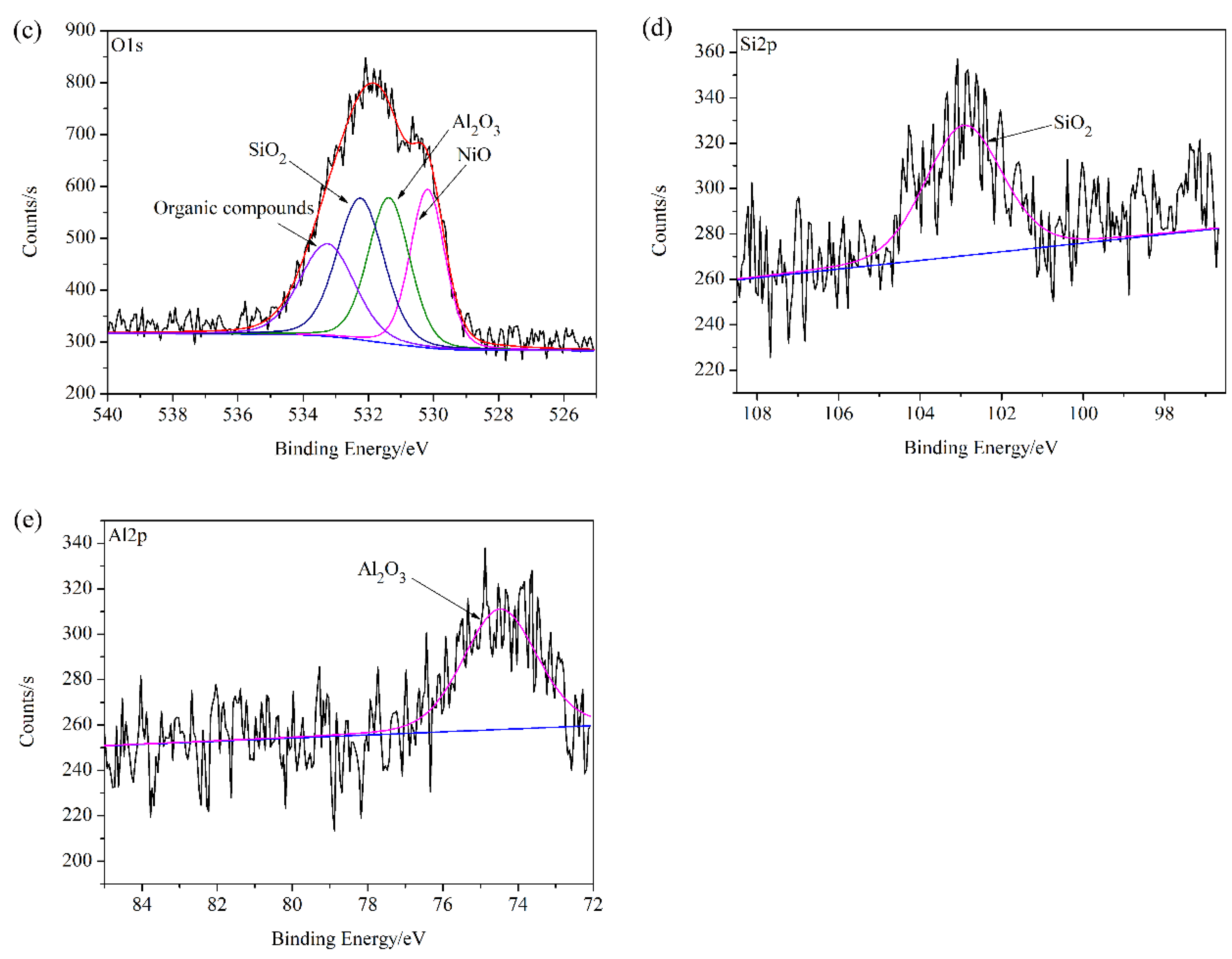

3.3. Worn Surface Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wen, S.Z.; Huang, P. Principles of Tribology, 3rd ed.; Tsinghua University Press: Beijing, China, 2008. (In Chinese) [Google Scholar]

- Jia, X.; Huang, J.; Li, Y.; Yang, J.; Song, H. Monodisperse Cu nanoparticles@MoS2 nanosheets as a lubricant additive for improved tribological properties. Appl. Surf. Sci. 2019, 494, 430–439. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, Z.; Liu, C.; Zhao, L.; Ni, J.; Li, Y.; Shao, X.; Wang, C. The synthesis and tribological properties of Ag/polydopamine nanocomposites as additives in polyalphaolefin. Tribol. Int. 2017, 114, 282–289. [Google Scholar] [CrossRef]

- Huang, J.; Tan, J.; Fang, H.; Gong, F.; Wang, J. Tribological and wear performances of graphene-oil nanofluid under industrial high-speed rotation. Tribol. Int. 2019, 135, 112–120. [Google Scholar] [CrossRef]

- Zhai, W.; Lu, W.; Liu, X.; Zhou, L. Nanodiamond as an effective additive in oil to dramatically reduce friction and wear for fretting steel/copper interfaces. Tribol. Int. 2019, 129, 75–81. [Google Scholar] [CrossRef]

- Asnida, M.; Hisham, S.; Awang, N.W.; Amirruddin, A.K.; Noor, M.M.; Kadirgama, K.; Ramasamy, D.; Najafi, G.; Tarlochan, F. Copper (II) oxide nanoparticles as additive in engine oil to increase the durability of piston-liner contact. Fuel 2018, 212, 656–667. [Google Scholar] [CrossRef]

- Kotia, A.; Ghosh, G.K.; Srivastava, I.; Deval, P.; Ghosh, S.K. Mechanism for improvement of friction/wear by using Al2O3 and SiO2/Gear oil nanolubricants. J. Alloys Compd. 2019, 782, 592–599. [Google Scholar] [CrossRef]

- Wang, Y.; Wan, Z.; Lu, L.; Zhang, Z.; Tang, Y. Friction and wear mechanisms of castor oil with addition of hexagonal boron nitride nanoparticles. Tribol. Int. 2018, 124, 10–22. [Google Scholar] [CrossRef]

- Jin, Y.S.; Li, S.H.; Zhang, Z.Y.; Yang, H.; Wang, F. In situ mechanochemical reconditioning of worn ferrous surfaces. Tribol. Int. 2004, 37, 561–567. [Google Scholar]

- Yu, Y.; Gu, J.; Kang, F.; Kong, X.; Mo, W. Surface restoration induced by lubricant additive of natural minerals. Appl. Surf. Sci. 2007, 253, 7549–7553. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, B.; Wang, C. Long-term surface restoration effect introduced by advanced silicate based lubricant additive. Tribol. Int. 2013, 57, 31–37. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, B.; Xu, Y.; Ba, Z.; Wang, Z. An amorphous Si–O film tribo-induced by natural hydrosilicate powders on ferrous surface. Appl. Surf. Sci. 2013, 285, 759–765. [Google Scholar] [CrossRef]

- Yu, H.L.; Xu, Y.; Shi, P.J.; Wang, H.M.; Zhao, Y.; Xu, B.S.; Bai, Z.M. Tribological behaviors of surface-coated serpentine ultrafine powders as lubricant additive. Tribol. Int. 2010, 43, 667–675. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, Y.; Gao, F.; Shi, P.; Xu, B.; Wu, Y. Sliding friction and wear behaviors of surface-coated natural serpentine mineral powders as lubricant additive. Appl. Surf. Sci. 2011, 257, 2540–2549. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Yan, J.; Ren, T.; Zhao, Y. Tribological behaviours of surface modified serpentine powder as lubricant additive. Ind. Lubric. Tribol. 2016, 68, 1–8. [Google Scholar] [CrossRef]

- Yin, Y.L.; Yu, H.L.; Wang, H.M.; Song, Z.Y.; Zhang, Z.; Ji, X.C.; Cui, T.H.; Wei, M.; Zhang, W. Friction and wear behaviors of steel/bronze tribopairs lubricated by oil with serpentine natural mineral additive. Wear 2020, 456, 203387. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Zhang, X.; Yin, H.; Xu, C.; Yuan, C. Anti-friction and self-repairing abilities of ultrafine serpentine, attapulgite and kaolin in oil for the cylinder liner-piston ring tribo-systems. Lubr. Sci. 2022, 3, 34. [Google Scholar] [CrossRef]

- Bai, Z.; Li, G.; Zhao, F.; Yu, H. Tribological Performance and Application of Antigorite as Lubrication Materials. Lubricants 2020, 8, 93. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Tang, X. Effect of natural attapulgite powders as lubrication additive on the friction and wear performance of a steel tribo-pair. Appl. Surf. Sci. 2014, 307, 86–91. [Google Scholar] [CrossRef]

- Yu, H.L.; Wang, H.M.; Yin, Y.L.; Song, Z.Y.; Zhou, X.Y.; Ji, X.C.; Wei, M.; Shi, P.J.; Bai, Z.M.; Zhang, W. Tribological behaviors of natural attapulgite nanofibers as an additive for mineral oil investigated by orthogonal test method. Tribol. Int. 2021, 153, 106562. [Google Scholar] [CrossRef]

- Nan, F.; Zhou, K.; Liu, S.; Pu, J.; Fang, Y.; Ding, W. Tribological properties of attapulgite/La2O3 nanocomposite as lubricant additive for a steel/steel contact. RSC Adv. 2018, 8, 16947–16956. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Li, Z. Tribological performance of attapulgite nano-fiber/spherical nano-Ni as lubricant additive. Tribol. Lett. 2014, 56, 531–541. [Google Scholar] [CrossRef]

- Subramanian, B.; Mohan, S.; Jayakrishnan, S.; Jayachandran, M. Structural and electrochemical characterization of Ni nanostructure films on steels with brush plating and sputter deposition. Curr. Appl. Phys. 2007, 7, 305–313. [Google Scholar] [CrossRef]

- Shang, T.; Zhang, H.Z.; Jiang, H.; Dai, L.; Zhang, G.L.; Liu, X.L. Fabrication of nanocrystalline nickel coatings by brush plating. Surf. Eng. 2013, 5, 342–345. [Google Scholar] [CrossRef]

- Wang, L.; Liu, W.; Wang, X. The preparation and tribological investigation of Ni–P amorphous alloy nanoparticles. Tribol. Lett. 2010, 2, 381–387. [Google Scholar] [CrossRef]

- Qiu, S.; Zhou, Z.; Dong, J.; Chen, G. Preparation of Ni nanoparticles and evaluation of their tribological performance as potential additives in oils. J. Tribol. 2001, 123, 441–443. [Google Scholar] [CrossRef]

- Wagner, C.D.; Riggs, W.M.; Davis, L.E.; Moulder, J.F.; Muilenberg, G.E. Handbook of X-ray Photoelectron Spectroscopy; Perkin-Elmer Corporation: Eden Prairie, MN, USA, 1979. [Google Scholar]

- Branley, W.F. The structural scheme of attapulgite. Am. Mineral. 1940, 25, 405–410. [Google Scholar]

- Bhushan, B. GeSR. Introduction to Tribology; China Machine Press: Beijing, China, 2007. (In Chinese) [Google Scholar]

- Nan, F.; Xu, Y.; Xu, B.; Gao, F.; Wu, Y.; Li, Z. Effect of Cu Nanoparticles on the Tribological Performance of Attapulgite Base Grease. Tribol. Trans. 2015, 58, 1031–1038. [Google Scholar] [CrossRef]

- Lee, J.; Cho, S.; Hwang, Y.; Lee, C.; Kim, S.H. Enhancement of lubrication properties of nano-oil by controlling the amount of fullerene nanoparticle additives. Tribol. Lett. 2007, 28, 203–208. [Google Scholar] [CrossRef]

| Process | Solution | Voltage/V | Plating Time/min | Movement Velocity of Plating pen/m·min−1 | |

|---|---|---|---|---|---|

| 1 | Electrical cleaning | Electing cleaning solutions | +12 | 1 | 6~8 |

| 2 | Intense activation | No. 2 activation solutions | −12 | 0.5 | 8~10 |

| 3 | Slight activation | No. 3 activation solutions | −18 | 0.5 | 6~8 |

| 4 | Pre-plating | Pre-plating nickel solutions | +12 | 1 | 8~10 |

| 5 | Plating | Nickel plating solutions | +12 | 5 | 10~12 |

| Component | Amount |

|---|---|

| NiSO4·6H2O | 20 g·L−1 |

| CH3COONH4 | 40 g·L−1 |

| (NH4)3C6H5O7 | 45 g·L−1 |

| NH3·H2O/(adjust pH to 7.3~7.5) | 100~130 mL·L−1 |

| Atomic% | |||||

|---|---|---|---|---|---|

| C | Ni | O | Si | Al | |

| Substrate | 57.80 | 42.20 | 0 | 0 | 0 |

| Lubricated with 150 SN | 64.14 | 35.86 | 0 | 0 | 0 |

| Lubricated with 150 SN with added ATP | 55.47 | 36.21 | 6.92 | 0.63 | 0.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nan, F.; Wang, D. Tribological Properties of Attapulgite Nanofiber as Lubricant Additive for Electric-Brush Plated Ni Coating. Lubricants 2023, 11, 204. https://doi.org/10.3390/lubricants11050204

Nan F, Wang D. Tribological Properties of Attapulgite Nanofiber as Lubricant Additive for Electric-Brush Plated Ni Coating. Lubricants. 2023; 11(5):204. https://doi.org/10.3390/lubricants11050204

Chicago/Turabian StyleNan, Feng, and Dong Wang. 2023. "Tribological Properties of Attapulgite Nanofiber as Lubricant Additive for Electric-Brush Plated Ni Coating" Lubricants 11, no. 5: 204. https://doi.org/10.3390/lubricants11050204

APA StyleNan, F., & Wang, D. (2023). Tribological Properties of Attapulgite Nanofiber as Lubricant Additive for Electric-Brush Plated Ni Coating. Lubricants, 11(5), 204. https://doi.org/10.3390/lubricants11050204