Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear

Abstract

1. Introduction

2. Experimental Test Setup and Methodology

2.1. Experimental Setup

2.2. Experimental Procedure

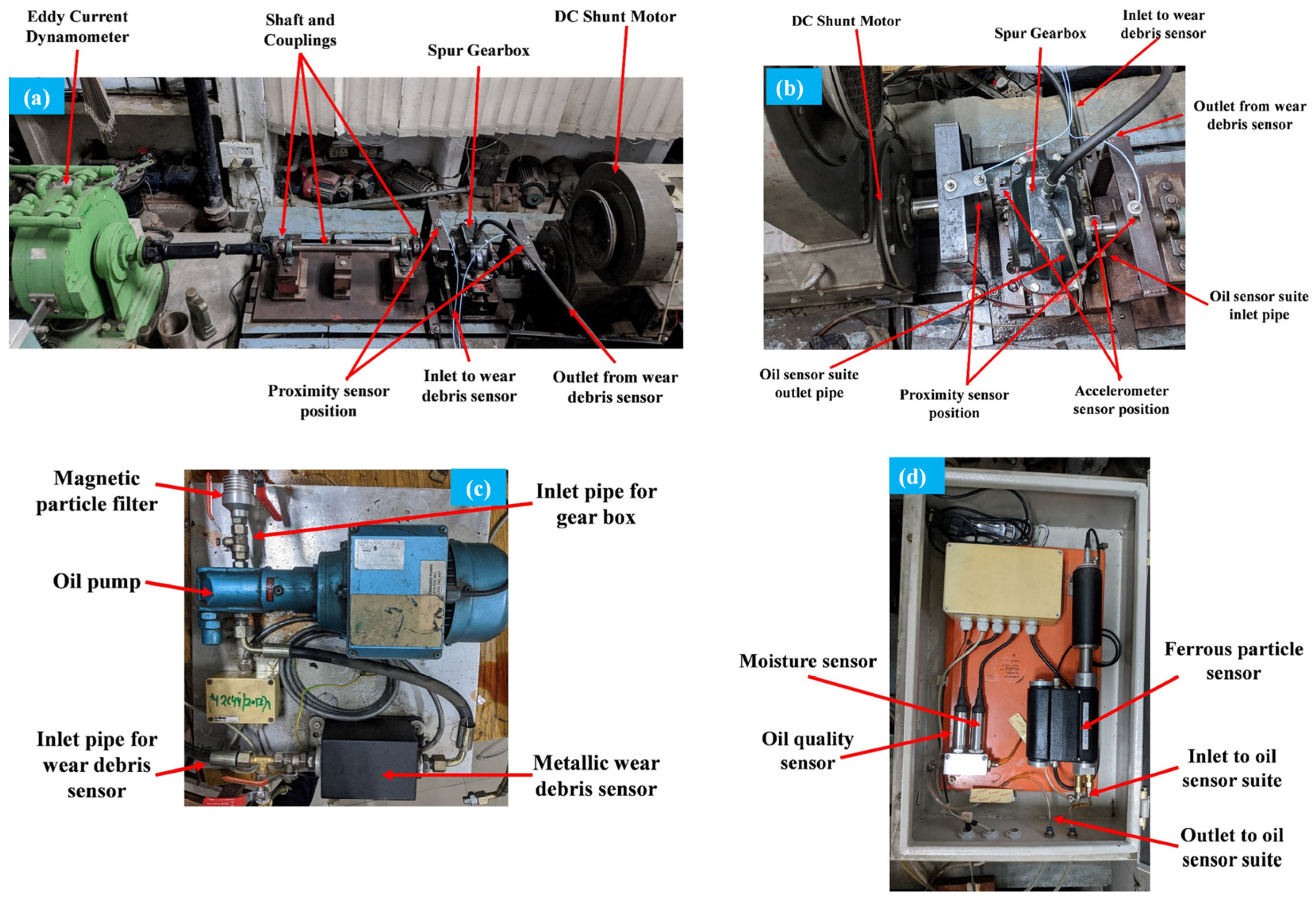

2.3. Description of Sensors, Instruments, and Data Processing

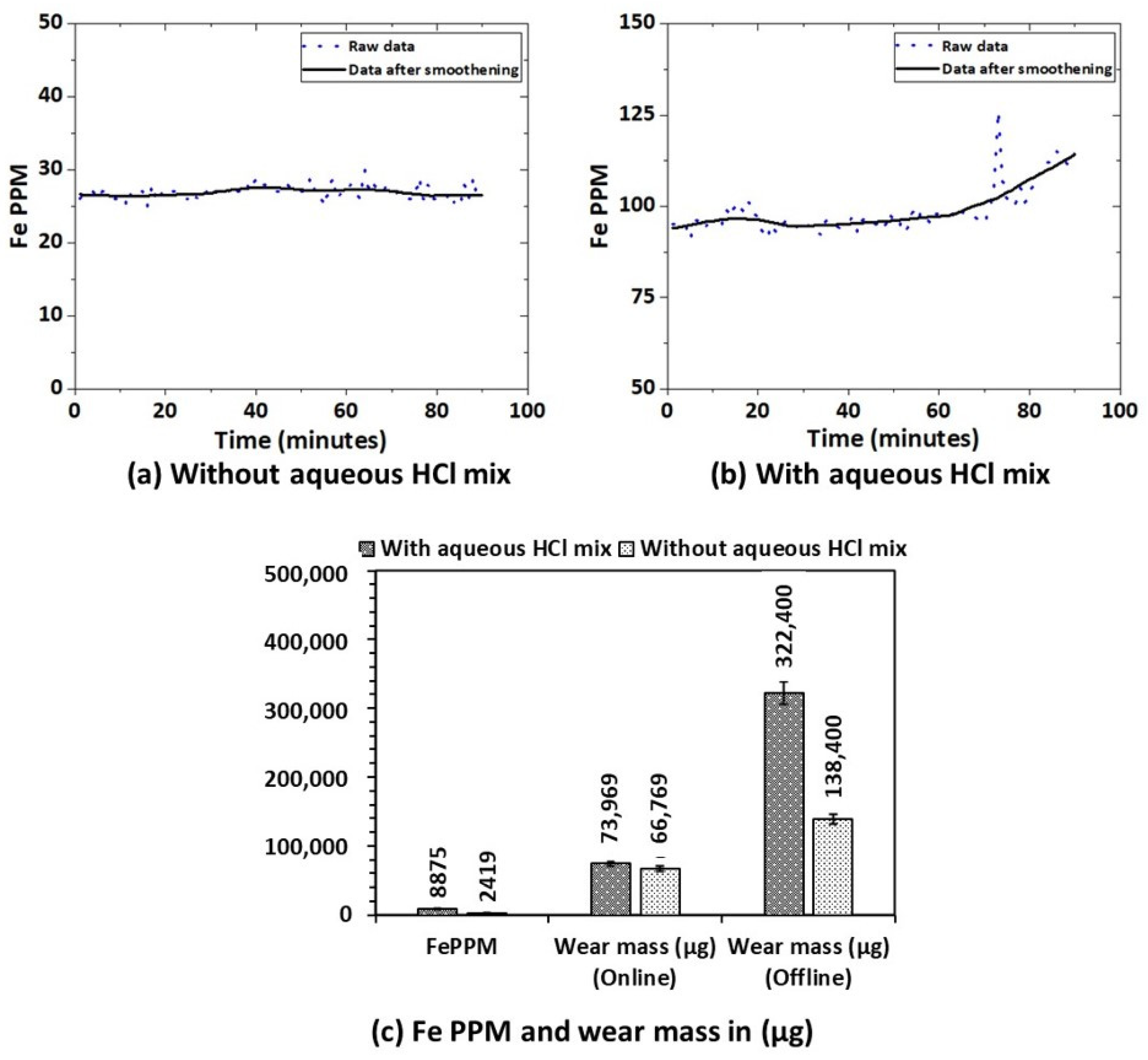

- Metallic wear debris sensor: There may be ferrous and non-ferrous debris from the gearbox. A metallic wear debris sensor (AS-19144-KW, shown in Figure 1c) was utilized to measure the ferrous (ranges from 40 µm to 400 µm) and non-ferrous (ranges from 135 µm to 450 µm) particles. The sensor is based on Biot-Savarts’ law and relates the change in magnetic field strength to the size of wear debris. Every minute, the sensor collected 12 samples.

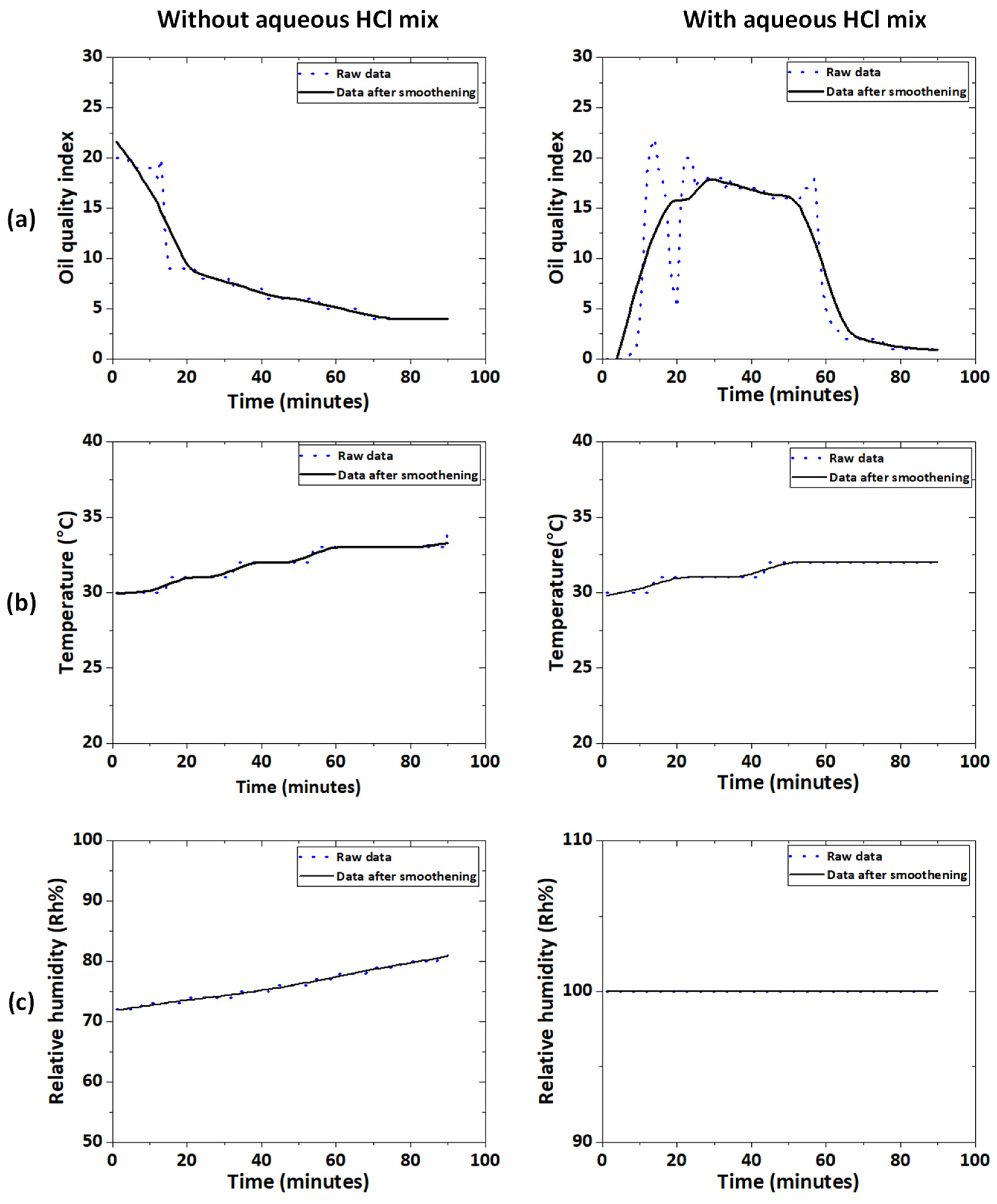

- Oil sensor suite (ANALEXrs): An oil sensor suite (Figure 1d) was utilized to measure total ferrous wear debris, oil degradation, and lubricant temperature. The oil degradation was evaluated according to the oil quality index (OQI) (1–100) indicated by the sensor, which operates on the principle of variation in dielectric constant. The sensor consists of a polymer coating that absorbs moisture and the change in dielectric constant and provides a percentage of the oil’s moisture content and the lubricant’s TAN value. Therefore, the oil quality index is a function of oil TAN, and oil degradation, represented by moisture. Every minute, the sensor collected one sample.

- pH-measuring instrument: The 916 Ti-touch variant of Metrohm, with a measuring range of −13 to +20 pH, 0.001 pH resolution, and 0.003 pH accuracy, was utilized.

- Rheometer: The oil viscosity was measured at a shear rate of 100 s−1 using an MCR 102 rheometer (torque up to 200 nNm, temperature range from −5 to 200 °C).

- Centrifuge: To isolate particles, a REMI CPR-24 plus centrifuge (maximum 7000 rpm) was utilized. After draining the oil and rinsing it with ethanol to remove the oil layer, particles were collected.

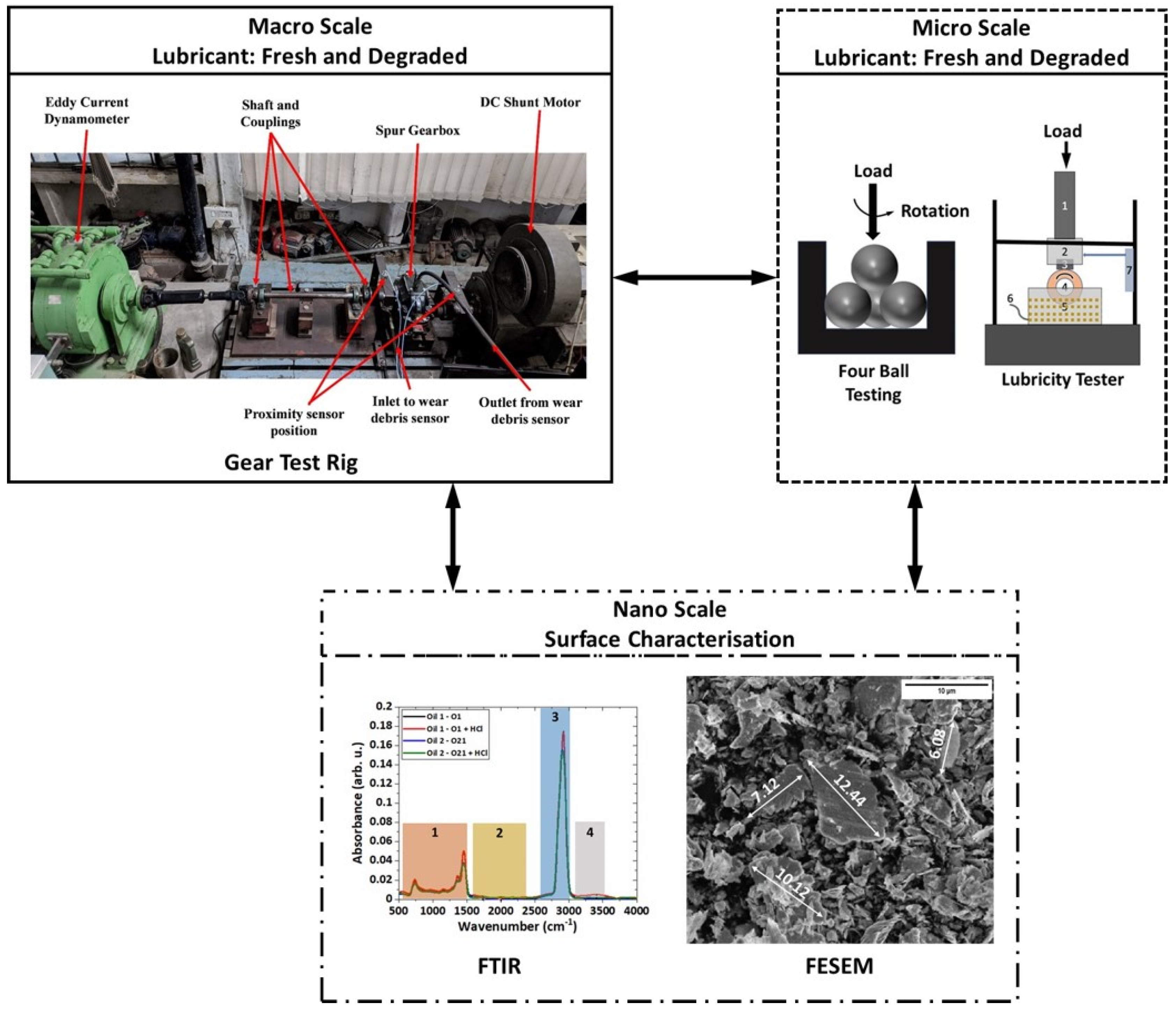

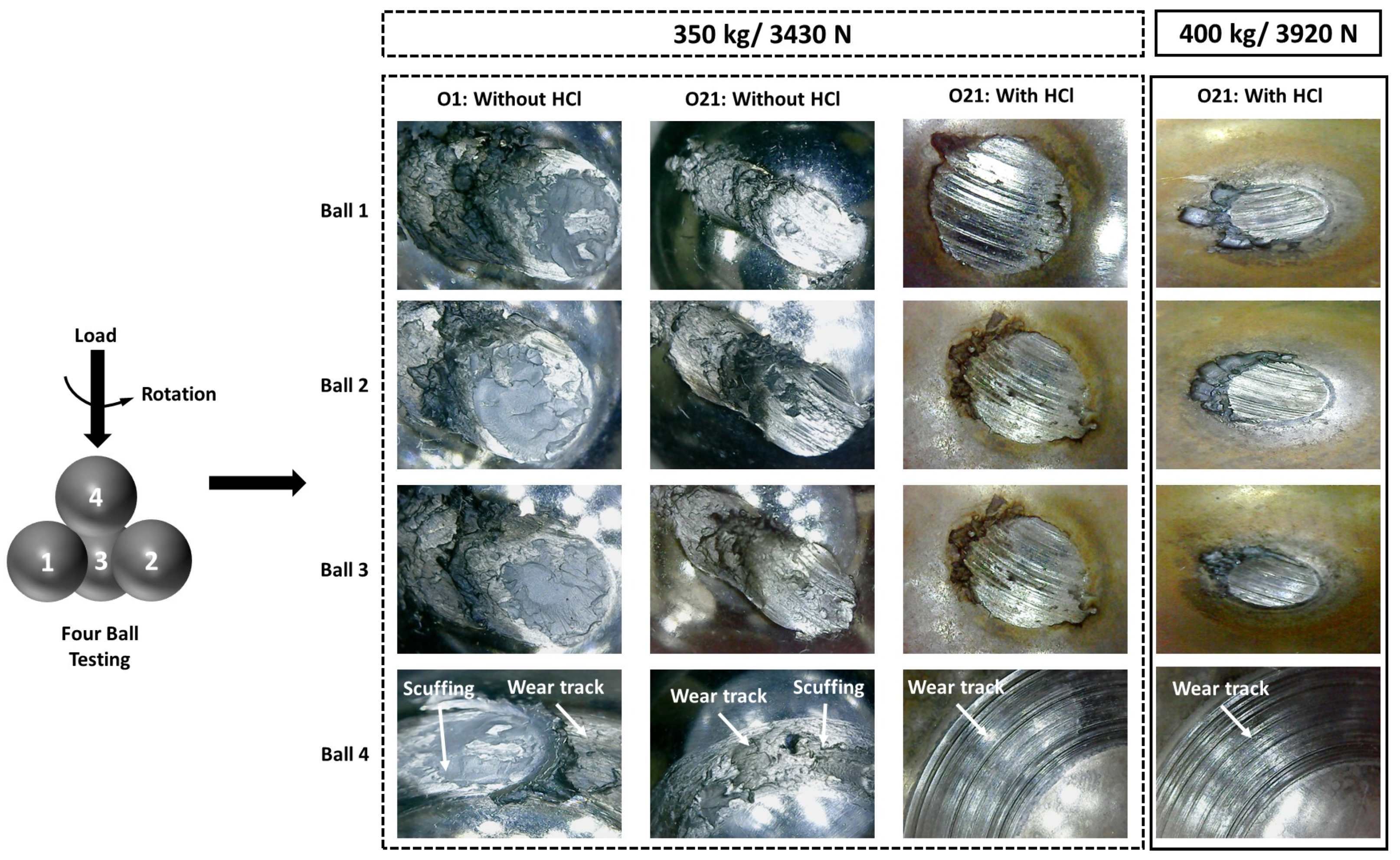

- Four ball wear tester: Using Ducom FBT-2, the anti-wear and EP (extreme pressure) effectiveness of lubricating lubricants were evaluated. The anti-wear performance was evaluated by conducting four-ball wear experiments at a temperature of 75 °C and a load of 392 N for sixty minutes. The extreme pressure performance was evaluated by performing four-ball EP experiments at 1760 rpm for 10 s at temperatures ranging from 18 to 35 °C in accordance with the ASTM D2783 standard. In addition, the IP-239 standard was used to affirm extreme pressure performance at 1450 rpm for 60 s at a room temperature of 27 ± 2 °C.

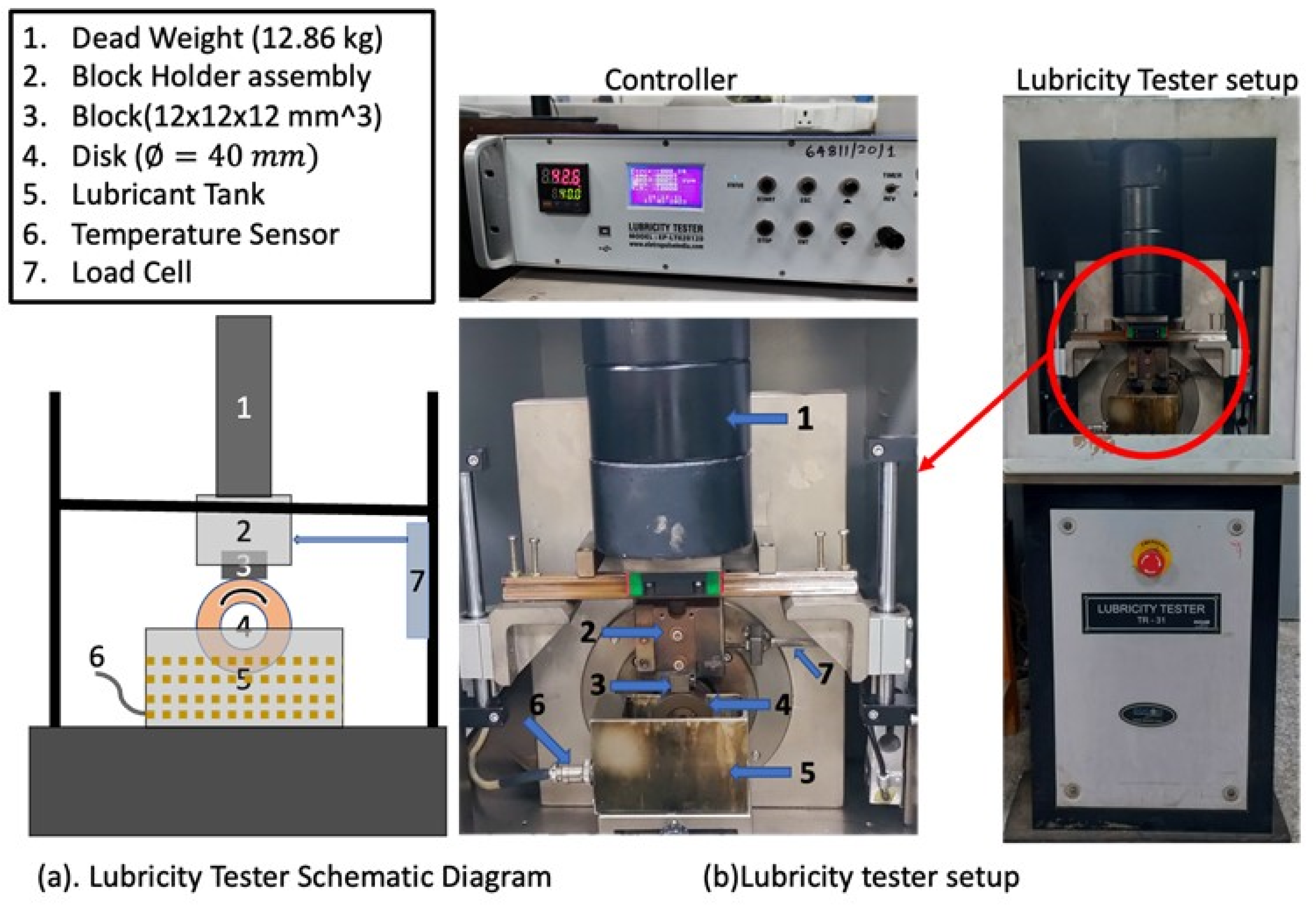

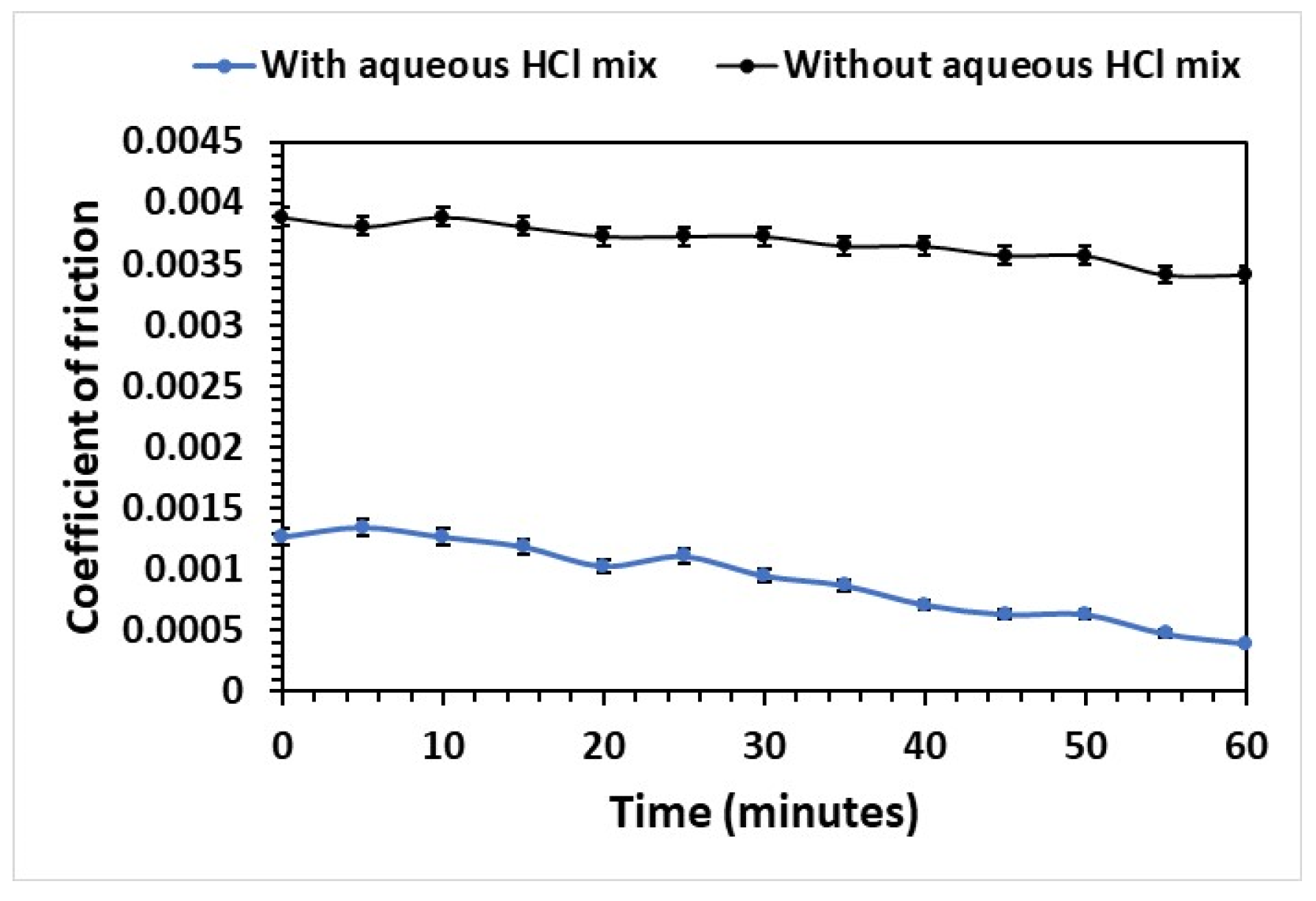

- Lubricity tester: This instrument is developed by Ducom Instruments, an Indian company. By simulating line contact between two surfaces, the anti-wear and friction qualities were assessed; the experimental setup utilized a block-on-disk configuration. The system was composed of a stationary disc and a block that moved back and forth over the disc’s surface, causing friction between the two surfaces. A counter surface in the form of a disc with a diameter of 40 mm and a breadth of 15 mm was utilized, and the test surface was a block with dimensions of 12 mm by 12 mm by 12 mm. The test was performed using the test block at a temperature of 40 ± 2 °C, a rotating speed of 100 rpm, and a dead weight of 12.86 kg. Every test was performed twice. Every five minutes, manual friction readings were obtained, and at the end of the experiment, wear loss was calculated using a weight balance with a minimum count of 10 µg.

- ATR-FTIR: Thermo-scientific instruments FTIR Nicolet iS50 were used for lubricant oil ATR investigations. The instrument has a resolution of 0.09 cm−1 and a scanning range of 400–4000 cm−1 for measuring absorbance and transmittance. The scan rate was maintained at 64 for improved resolution.

- Data smoothening: In this study, the data collected from various online sensors, such as the metallic wear debris sensor, oil sensor suite, and offline ATR-FTIR, were smoothed using the ‘Savitzky Golay’ method of a second-degree polynomial because it provides a good balance between capturing the overall trend and removing high-frequency noise. This method resulted in smoother data trends, allowing for more accurate analysis and interpretation of the results.

2.4. Comprehensive Framework of the Study

3. Results and Discussions

3.1. Test 1

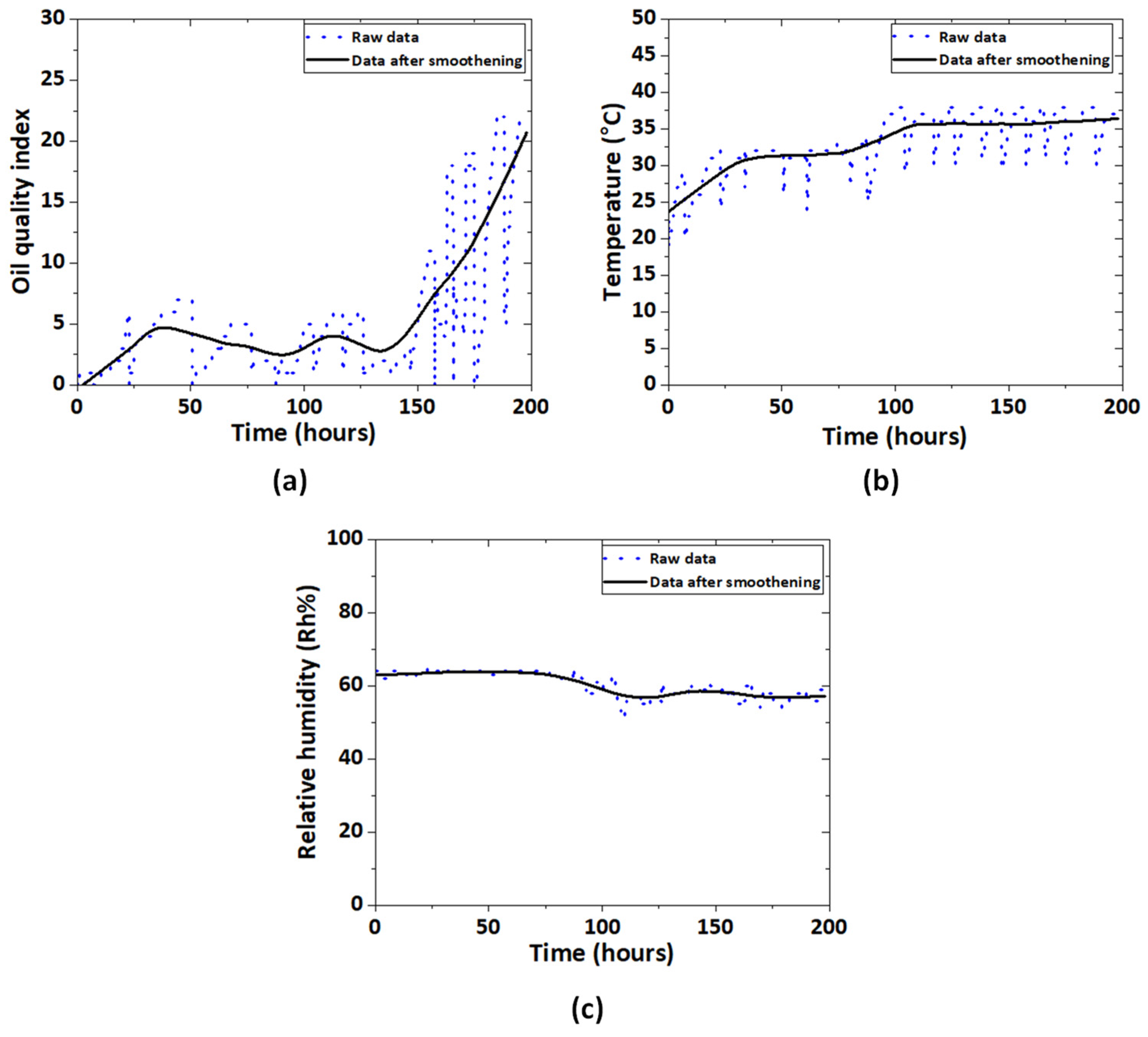

3.1.1. Test 1: Online Lubricant Analysis

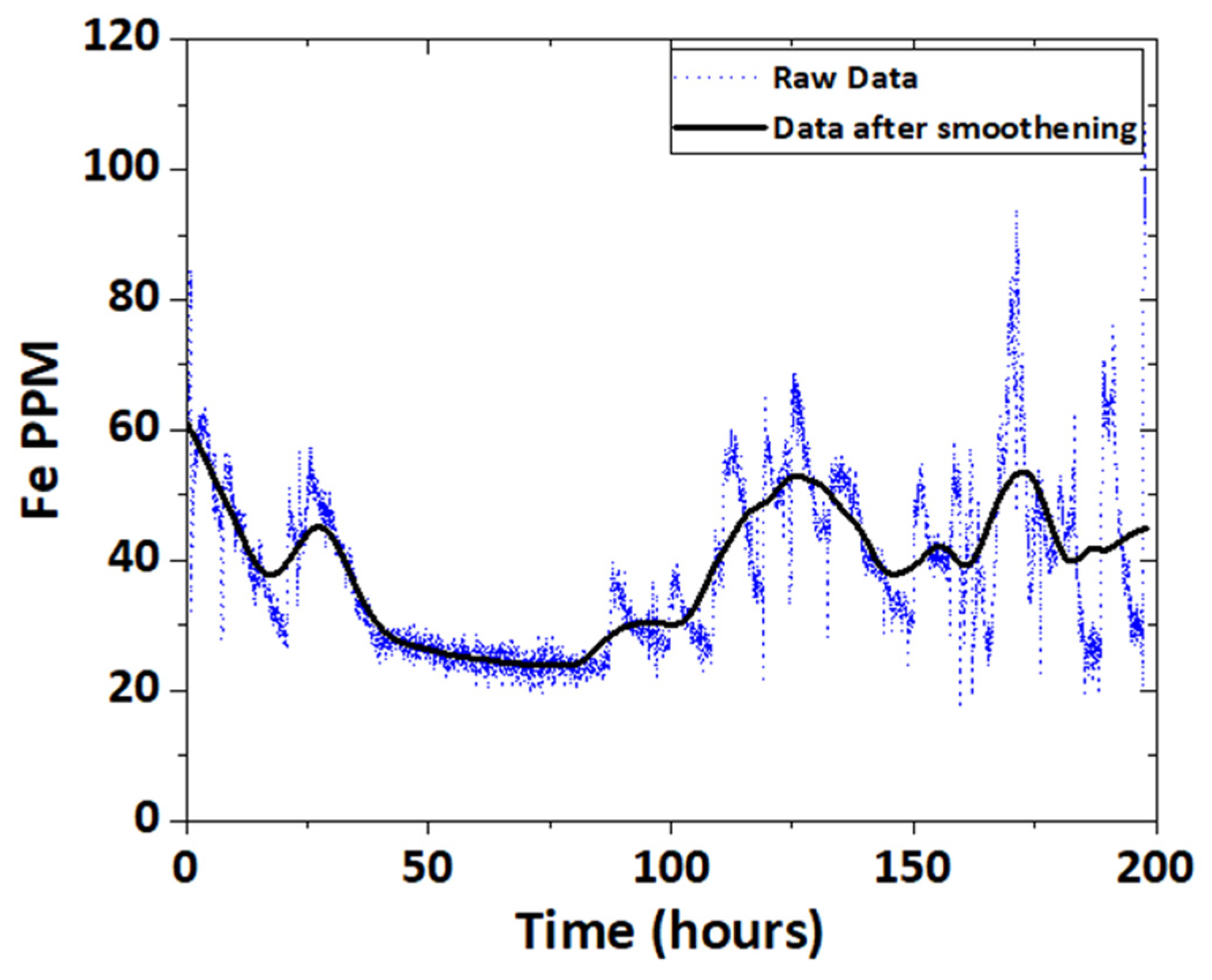

3.1.2. Test 1: Online Wear Debris Analysis

3.2. Lubricant Artificial Degradation, Physicochemical and Tribological Performance Evaluation

3.2.1. Artificial Lubricant Aging

3.2.2. Physicochemical and Tribological Evaluation

Physicochemical Properties of Oil

- The TAN value was low in fresh oil, indicating a low concentration of acidic components, whereas the TBN value was high, indicating a high concentration of basic components. As oil deteriorated over time, the TAN value increased as the acidic components of the oil increased, whereas the TBN value decreased as the basic components of the oil decreased.

- The addition of a minute amount of acid to oil samples accelerated degradation. As predicted, the TAN value rose, and the TBN value fell. Acid caused the oil to degrade more rapidly, resulting in the formation of more acidic components and the consumption of basic components.

- Comparing the O22 and O21 samples, it was observed that the TAN values were higher in O22, indicating that the oil had degraded more than in O21.

- The pH values of all oil samples followed a similar pattern, which was to be expected given that pH is a measure of the acidity or basicity of the oil. The pH decreased as the oil degraded and became more acidic.

Tribological Evaluation (Anti-Wear and Extreme Pressure Performance):

3.3. Test 2

3.3.1. Online and Offline Lubricant Analysis

3.3.2. Online and Offline Wear Debris Analysis

4. Conclusions

- In both tests studied in the present paper, ferrous particle content increased with no run-in stage of wear.

- The gear oil used had an adequate TAN value but low pH (acidic).

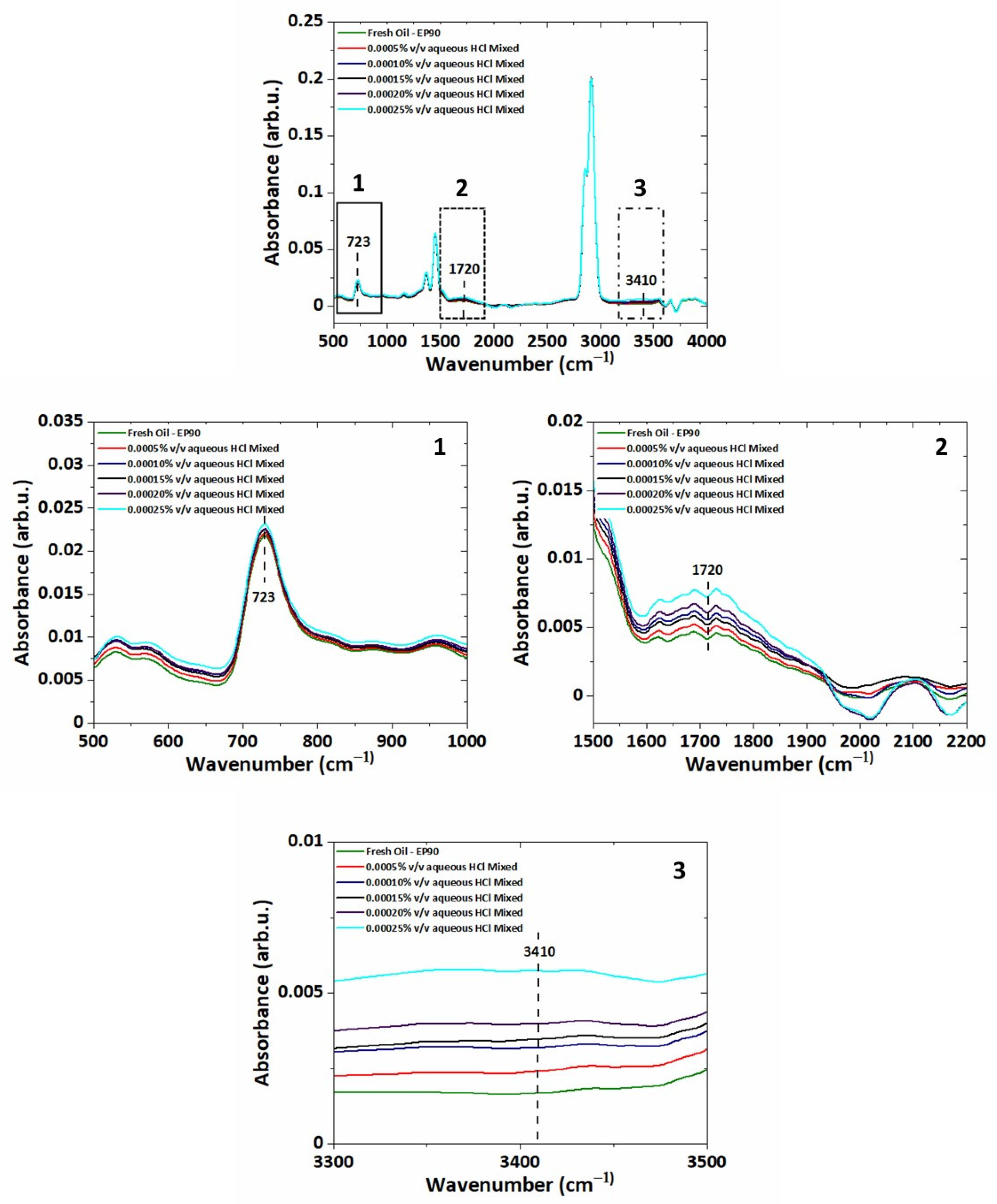

- Lubricant oil chemical aging lowered the pH from 5.742 to 4.786 and the TAN from 0.08 to 0.12. ATR-FTIR research has shown additive depletion, lubricant oxidation products, and water formation.

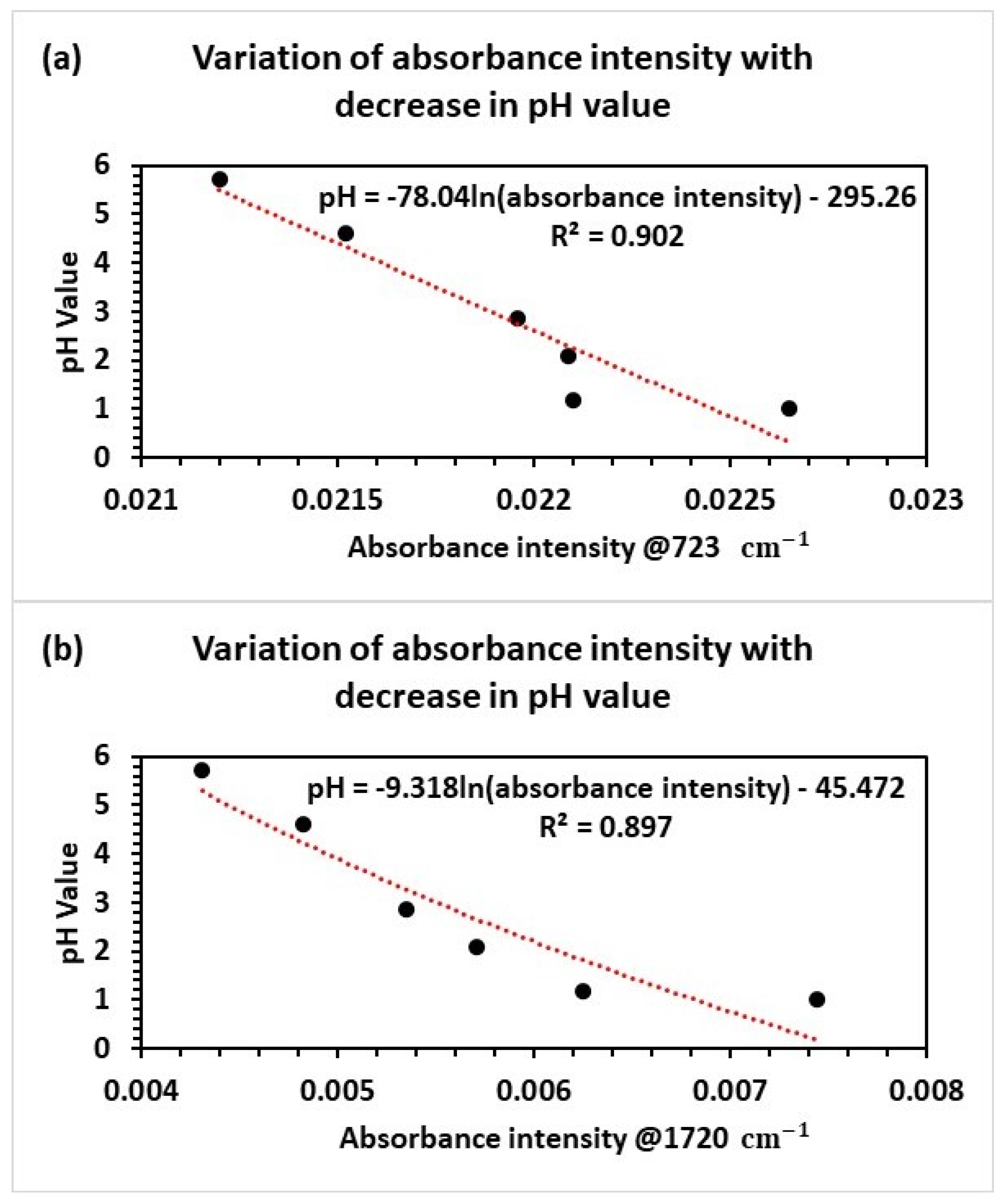

- A logarithmic relation between the pH value and ATR-FTIR absorbance intensity corresponding to the 723 and 1720 cm−1 was derived, which depicts the oxide formation and anti-wear additive depletion. The derived equations predict the pH value with an approximate deviation of ~8%.

- The formation of oxide layers, under aqueous HCl doped lubricant, on the interacting surfaces was responsible for the rise in weld load. This layer also acted as a friction modifier.

- The online oil quality sensor did not accurately reflect oil degradation because oil degrades in response to a decrease in pH value and oil viscosity, but the sensor did indicate an improvement in oil quality over time.

- The wear debris monitoring sensor did not show a significant rise in wear debris mass, but the extracted wear debris mass was ~2.32 times higher for Test 22 (with aqueous HCl mix) than Test 21 (without mix) in Test 2.

- ATR-FTIR analysis showed that adding aqueous HCl to lubricating oil and running it in the gear test rig increased water (3410 cm−1) and oxidation components (1050, 1090, and 1720 cm−1), and decreased base additive (2920 cm−1).

- The wear particle size for Test 22 was significantly larger than Test 21.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hirani, H.; Athre, K.; Biswas, S. Comprehensive design methodology for an engine journal bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 401–412. [Google Scholar] [CrossRef]

- ANSI/AGMA 9005-F16. Industrial Gear Lubrication. 2016. Available online: https://www.scribd.com/document/527146091/Ansi-Agma-9005-f16-Gear-Oils (accessed on 10 December 2022).

- Gosvami, N.N.; Bares, J.A.; Mangolini, F.; Konicek, A.R.; Yablon, D.G.; Carpick, R.W. Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts. Science 2015, 348, 102–106. [Google Scholar] [CrossRef] [PubMed]

- Minami, I. Molecular Science of Lubricant Additives. Appl. Sci. 2017, 7, 445. [Google Scholar] [CrossRef]

- Naveed, T.; Zahid, R.; Mufti, R.A.; Waqas, M.; Hanif, M.T. A review on tribological performance of ionic liquids as additives to bio lubricants. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1782–1806. [Google Scholar] [CrossRef]

- Bhaumik, S.; Kamaraj, M.; Paleu, V. Tribological analyses of a new optimized gearbox biodegradable lubricant blended with reduced graphene oxide nanoparticles. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 901–915. [Google Scholar] [CrossRef]

- Ribeiro, F.C.; Oliveira, A.S.; Araújo, A.S.; Marinho, W.; Schneider, M.P.; Pinto, L.; Gomes, A.D.A. Detection oxidative degradation in lubricating oil under storage conditions using digital images and chemometrics. Microchem. J. 2019, 147, 622–627. [Google Scholar] [CrossRef]

- Rezasoltani, A.; Khonsari, M. Experimental investigation of the chemical degradation of lubricating grease from an energy point of view. Tribol. Int. 2019, 137, 289–302. [Google Scholar] [CrossRef]

- Hirani, H.; Athre, K.; Biswas, S. Lubricant Shear Thinning Analysis of Engine Journal Bearings. Tribol. Trans. 2001, 44, 125–131. [Google Scholar] [CrossRef]

- Singh, A.; Gandra, R.T.; Schneider, E.W.; Biswas, S.K. Lubricant Degradation and Related Wear of a Steel Pin in Lubricated Sliding Against a Steel Disc. ACS Appl. Mater. Interfaces 2011, 3, 2512–2521. [Google Scholar] [CrossRef]

- Zzeyani, S.; Mikou, M.; Naja, J.; Elachhab, A. Spectroscopic analysis of synthetic lubricating oil. Tribol. Int. 2017, 114, 27–32. [Google Scholar] [CrossRef]

- Cantley, R.E. The Effect of Water in Lubricating Oil on Bearing Fatigue Life. ASLE Trans. 1977, 20, 244–248. [Google Scholar] [CrossRef]

- Ebersbach, S.; Peng, Z.; Kessissoglou, N. The investigation of the condition and faults of a spur gearbox using vibration and wear debris analysis techniques. Wear 2006, 260, 16–24. [Google Scholar] [CrossRef]

- Tan, C.K.; Irving, P.; Mba, D. A comparative experimental study on the diagnostic and prognostic capabilities of acoustics emission, vibration and spectrometric oil analysis for spur gears. Mech. Syst. Signal Process. 2007, 21, 208–233. [Google Scholar] [CrossRef]

- Loutas, T.; Roulias, D.; Pauly, E.; Kostopoulos, V. The combined use of vibration, acoustic emission and oil debris on-line monitoring towards a more effective condition monitoring of rotating machinery. Mech. Syst. Signal Process. 2011, 25, 1339–1352. [Google Scholar] [CrossRef]

- Dempsey, P.J. Integrating Oil Debris and Vibration Measurements for Intelligent Machine Health Monitoring. Ph.D. Thesis, The University of Toledo, Toledo, OH, USA, 2002. [Google Scholar]

- El-Naggar, A.; El-Adly, R.A.; Altalhi, T.A.; Alhadhrami, A.; Modather, F.; Ebiad, M.A.; Salem, A. Oxidation stability of lubricating base oils. Pet. Sci. Technol. 2017, 36, 179–185. [Google Scholar] [CrossRef]

- Jain, M.R.; Sawant, R.; Paulmer, R.; Ganguli, D.; Vasudev, G. Evaluation of thermo-oxidative characteristics of gear oils by different techniques: Effect of antioxidant chemistry. Thermochim. Acta 2005, 435, 172–175. [Google Scholar] [CrossRef]

- Jihua, C.; Shaojun, L.; Xiaozhou, H. A temperature measurement method for testing lubrication system or revealing scuffing failure mechanism of spur gear. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 233, 831–840. [Google Scholar] [CrossRef]

- Evans, H.; Snidle, R. Duncan Dowson: Pioneer of elastohydrodynamic lubrication of gears. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 2592–2603. [Google Scholar] [CrossRef]

- Peng, Q.; Zhou, C.; Gui, L.; Fan, Z. Investigation of the lubrication system in a vehicle axle: Numerical model and experimental validation. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 233, 1232–1244. [Google Scholar] [CrossRef]

- Inturi, V.; Sabareesh, G.; Supradeepan, K.; Penumakala, P. Integrated condition monitoring scheme for bearing fault diagnosis of a wind turbine gearbox. J. Vib. Control 2019, 25, 1852–1865. [Google Scholar] [CrossRef]

- Lopez, P.; Mabe, J.; Miró, G.; Etxeberria, L. Low Cost Photonic Sensor for in-Line Oil Quality Monitoring: Methodological Development Process towards Uncertainty Mitigation. Sensors 2018, 18, 2015. [Google Scholar] [CrossRef] [PubMed]

- Stoyanov, P.; Chromik, R.R. Scaling Effects on Materials Tribology: From Macro to Micro Scale. Materials 2017, 10, 550. [Google Scholar] [CrossRef]

- Broitman, E. The nature of the frictional force at the macro-, micro-, and nano-scales. Friction 2014, 2, 40–46. [Google Scholar] [CrossRef]

- Lim, K.F. Negative pH does exist. J. Chem. Educ. 2006, 83, 1465. [Google Scholar] [CrossRef]

- Gan, Z.; Yao, T.; Zhang, M.; Hu, J.; Liao, X.; Shen, Y. Effect of Temperature on the Composition of a Synthetic Hydrocarbon Aviation Lubricating Oil. Materials 2020, 13, 1606. [Google Scholar] [CrossRef]

- Wolak, A. Changes in Lubricant Properties of Used Synthetic Oils Based on the Total Acid Number. Meas. Control 2018, 51, 65–72. [Google Scholar] [CrossRef]

- Idros, M.M.; Ali, S.; Islam, M.S. Optical analysis for condition-based monitoring of oxidation degradation in lubricant oil. In Proceedings of the 2012 4th International Conference on Intelligent and Advanced Systems (ICIAS2012), Kuala Lumpur, Malaysia, 12–14 June 2012; Volume 2, pp. 735–740. [Google Scholar]

- Mujahid, A.; Dickert, F.L. Monitoring automotive oil degradation: Analytical tools and onboard sensing technologies. Anal. Bioanal. Chem. 2012, 404, 1197–1209. [Google Scholar] [CrossRef]

- Santos, J.C.O.; Lima, L.N.; Santos, I.M.G.; Souza, A.G. Thermal, spectroscopic and rheological study of mineral base lubricating oils. J. Therm. Anal. Calorim. 2007, 87, 639–643. [Google Scholar] [CrossRef]

- De Rivas, B.L.; Vivancos, J.-L.; Ordieres-Meré, J.; Capuz-Rizo, S.F. Determination of the total acid number (TAN) of used mineral oils in aviation engines by FTIR using regression models. Chemom. Intell. Lab. Syst. 2017, 160, 32–39. [Google Scholar] [CrossRef]

- Cao, W.; Yan, J.; Jin, Z.; Han, Z.; Zhang, H.; Qu, J.; Zhang, M. Image Denoising and Feature Extraction of Wear Debris for Online Monitoring of Planetary Gearboxes. IEEE Access 2021, 9, 168937–168952. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, H.; Wang, N.; Wang, H.W.; Peng, Z. The gearbox wears state monitoring and evaluation based on on-line wear debris features. Wear 2019, 426, 1719–1728. [Google Scholar] [CrossRef]

- Wang, S.; Wu, T.; Shao, T.; Peng, Z. Integrated model of BP neural network and CNN algorithm for automatic wear debris classification. Wear 2019, 426, 1761–1770. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, T.; Wang, S.; Peng, Z. Wear state identification using dynamic features of wear debris for on-line purpose. Wear 2017, 376, 1885–1891. [Google Scholar] [CrossRef]

- Ikhlef, B.; Rahmoune, C.; Toufik, B.; Benazzouz, D. Gearboxes fault detection under operation varying condition based on MODWPT, Ant colony optimization algorithm and Random Forest classifier. Adv. Mech. Eng. 2021, 13, 16878140211043004. [Google Scholar] [CrossRef]

- De Feo, M.; Minfray, C.; Bouchet, M.D.B.; Thiebaut, B.; Le Mogne, T.; Vacher, B.; Martin, J. Ageing impact on tribological properties of MoDTC-containing base oil. Tribol. Int. 2015, 92, 126–135. [Google Scholar] [CrossRef]

- Cen, H.; Morina, A.; Neville, A. Effect of lubricant ageing on lubricants’ physical and chemical properties and tribological performance; Part I: Effect of lubricant chemistry. Ind. Lubr. Tribol. 2018, 70, 385–392. [Google Scholar] [CrossRef]

- Nagy, A.L.; Rohde-Brandenburger, J.; Zsoldos, I. Artificial Aging Experiments of Neat and Contaminated Engine Oil Samples. Lubricants 2021, 9, 63. [Google Scholar] [CrossRef]

- Seidel, B.; Meyer, D. Influence of artificial aging on the lubricating ability of water miscible metalworking fluids. Prod. Eng. 2019, 13, 425–435. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, N.; Titovich, K.A.; Ivanovich, K.V.; Vyacheslavovich, S.A.; Dash, S. Lubrication properties of chemically aged reduced graphene-oxide additives. Surfaces Interfaces 2017, 7, 6–13. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, C.; Qiu, Q.; Yang, L. Effect of water on the diffusion of small molecular weight acids in nano-SiO2 modified insulating oil. J. Mol. Liq. 2020, 314, 113670. [Google Scholar] [CrossRef]

- Dong, J. Quantitative Condition Monitoring of Lubricating Oils by Fourier Transform Infrared (FTIR) Spectroscopy. Ph.D. Thesis, McGill University, Montréal, QC, Canada, 2000. [Google Scholar]

- Muniyappa, A.; Chandramohan, S.; Seethapathy, S. Detection and Diagnosis of Gear Tooth Wear through Metallurgical and Oil Analysis. Tribol. Online 2010, 5, 102–110. [Google Scholar] [CrossRef]

- Kattelus, J.; Miettinen, J.; Lehtovaara, A. Detection of gear pitting failure progression with on-line particle monitoring. Tribol. Int. 2018, 118, 458–464. [Google Scholar] [CrossRef]

- Feng, S.; Fan, B.; Mao, J.; Xie, Y. Prediction on wear of a spur gearbox by on-line wear debris concentration monitoring. Wear 2015, 336–337, 1–8. [Google Scholar] [CrossRef]

- Sheng, S. Monitoring of Wind Turbine Gearbox Condition through Oil and Wear Debris Analysis: A Full-Scale Testing Perspective. Tribol. Trans. 2016, 59, 149–162. [Google Scholar] [CrossRef]

- Hirani, H.; Jangra, D.; Sidh, K.N. Experimental Investigation on the Wear Performance of Nano-Additives on Degraded Gear Lubricant. Lubricants 2023, 11, 51. [Google Scholar] [CrossRef]

- Rezasoltani, A.; Khonsari, M.M. On monitoring physical and chemical degradation and life estimation models for lubri-cating greases. Lubricants 2016, 4, 34. [Google Scholar] [CrossRef]

- Available online: https://chem.libretexts.org/Bookshelves/Physical_and_Theoretical_Chemistry_Textbook_Maps/Supplemental_Modules_(Physical_and_Theoretical_Chemistry)/Acids_and_Bases/Acids_and_Bases_in_Aqueous_Solutions/The_pH_Scale (accessed on 20 April 2023).

- Singh, T.; Kumar, N. (R&D Centre, Bharat Petroleum Co., Ltd., Mumbai, India). Personal communication, October 2022.

- Spikes, H.A. Additive-additive and additive-surface interactions in lubrication. Lubr. Sci. 1989, 2, 3–23. [Google Scholar] [CrossRef]

- Hironaka, S.; Yahagi, Y.; Sakurai, T. Heats of Adsorption and Anti-wear Properties of Some Surface Active Substances. Bull. Jpn. Pet. Inst. 1975, 17, 201–205. [Google Scholar] [CrossRef]

- Studt, P. Zusammenhang zwischen Adsorbierbarkeit und Wirksamkeit von Hochdruckzusätzen in Schmierölen. Erdöl Kohle Erdgas Petrochem. 1968, 21, 784–785. [Google Scholar]

- Spikes, H.; Cameron, A. Additive Interference in Dibenzyl Disulfide Extreme Pressure Lubrication. ASLE Trans. 1974, 17, 283–289. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Yang, J.; Zhang, H.; Zhao, H. A Digital Twin-Based State Monitoring Method of Gear Test Bench. Appl. Sci. 2023, 13, 3291. [Google Scholar] [CrossRef]

- Hansen, E.; Vaitkunaite, G.; Schneider, J.; Gumbsch, P.; Frohnapfel, B. Establishment and Calibration of a Digital Twin to Replicate the Friction Behaviour of a Pin-on-Disk Tribometer. Lubricants 2023, 11, 75. [Google Scholar] [CrossRef]

| Parameters | Pinion | Gear |

|---|---|---|

| Material | EN24 | EN24 |

| Hardness (HRC) | 30 ± 2 | 30 ± 2 |

| Module (mm) | 2 | 2 |

| Pitch circle diameter (mm) | 54 | 106 |

| Base circle diameter (mm) | 50.74 | 99.60 |

| Tip radius (mm) | 58 | 110 |

| Pressure angle (°) | 20 | 20 |

| Face width (mm) | 33 | 33 |

| Number of teeth | 27 | 54 |

| Speed (rpm) | 1200, 500 | - |

| Torque (Nm) | 40, 50 | - |

| Contact ratio | 1.6 | 1.6 |

| Roughness (µm) (Ra) | 0.363 ± 0.027 | 0.357 ± 0.037 |

| Roughness (µm) (Rq) | 0.579 ± 0.066 | 0.556 ± 0.095 |

| Youngs Modulus (GPa) | 207 | 207 |

| Lubricant | O1: API GL-4 SAE 90 | |

| O21: API GL-4 EP 90 (March 2022) O22: API GL-4 EP 90 (January 2017) | ||

| Test description | ||

| Test 1 | “40 Nm, 1200 rpm, 198 h, O1” | |

| Test 2 | Test 21: “50 Nm, 500 rpm, 90 min, O21 (Fresh oil)” Test 22: “50 Nm, 500 rpm, 90 min, O21 (artificially degraded oil with aqueous HCl mixing)” | |

| Physicochemical and Tribological Tests | Lubricity tester: “load—12.86 kg, speed—100 rpm, the oil used—O21 with and without aqueous HCl | |

| Four ball testers: “Standard ASTM D2783 and IP-239 and the oil used O1 and O21 with and without aqueous HCl” | ||

| Aqueous HCl Concentration (v/v%) | pH Value (Std. Dev.) | Peak Intensity about 723 cm−1 | Peak Intensity about 1720 cm−1 | Peak Intensity about 3410 cm−1 |

|---|---|---|---|---|

| 0 | 5.703 (0.04) | 0.0212 | 0.00431 | 0.00168 |

| 0.0005 | 4.598 (0.02) | 0.02152 | 0.00483 | 0.0024 |

| 0.0010 | 2.866 (0.05) | 0.02196 | 0.00535 | 0.00319 |

| 0.0015 | 2.105 (0.02) | 0.02209 | 0.00571 | 0.00347 |

| 0.0020 | 1.179 (0.03) | 0.0221 | 0.00625 | 0.00398 |

| 0.0025 | 0.904 (0.06) | 0.02265 | 0.00744 | 0.00574 |

| TAN | Std. Dev. | TBN | Std. Dev. | pH | Std. Dev. | Absorbance Peak Intensity @723 cm−1 | pH Value Using ATR-FTIR Fit (Equation (1)) | Absorbance Peak Intensity @1720 cm−1 | pH Value Using ATR-FTIR Fit (Equation (2)) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| O1 | Without aqueous HCl | 0.039 | 0.002 | 0.06 | 0.003 | 5.762 | 0.01 | 0.02099 | 6.263 | 0.00434 | 5.216 |

| With aqueous HCl | 0.151 | 0.006 | 0.018 | 0.001 | 2.905 | 0.02 | 0.022 | 2.596 | 0.00542 | 3.146 | |

| O21 | Without aqueous HCl | 0.08 | 0.002 | 0.15 | 0.005 | 5.742 | 0.01 | 0.0211 | 5.855 | 0.00408 | 5.7924 |

| With aqueous HCl | 0.189 | 0.008 | 0.073 | 0.003 | 1.657 | 0.01 | 0.0222 | 1.890 | 0.00629 | 1.759 | |

| O22 | Without aqueous HCl | 0.12 | 0.005 | 0.127 | 0.004 | 4.786 | 0.01 | - | - | - | - |

| With aqueous HCl | 0.21 | 0.01 | 0.056 | 0.002 | 1.263 | 0.01 | - | - | - | - |

| Without Aqueous HCl Mix (Test 21) | With an Aqueous HCl Mix (Test 22) | Without Aqueous HCl Mix (Test 21) | With an Aqueous HCl Mix (Test 22) | |||||

|---|---|---|---|---|---|---|---|---|

| Time (Minutes) | pH Value | Std. Dev. | pH Value | Std. Dev. | Kinematic Viscosity (cSt@40 °C) | Std. Dev. | Kinematic Viscosity (cSt@40 °C) | Std. Dev. |

| 0 | 5.86 | 0.01 | 1.55 | 0.03 | 134.78 | 0.006 | 127.60 | 0.007 |

| 10 | 6.06 | 0.01 | 0.75 | 0.03 | 113.00 | 0.008 | 112.20 | 0.001 |

| 20 | 5.77 | 0.01 | 0.54 | 0.03 | 106.78 | 0.002 | 110.53 | 0.002 |

| 30 | 5.51 | 0.01 | −1.35 | 0.02 | 107.20 | 0.004 | 106.52 | 0.004 |

| 40 | 5.35 | 0.02 | −1.48 | 0.02 | 107.04 | 0.001 | 104.33 | 0.005 |

| 50 | 5.29 | 0.01 | −1.75 | 0.03 | 102.54 | 0.001 | 103.51 | 0.005 |

| 60 | 5.18 | 0.01 | −2.01 | 0.02 | 104.56 | 0.002 | 101.12 | 0.007 |

| 70 | 5.16 | 0.01 | −2.04 | 0.03 | 104.43 | 0.004 | 101.12 | 0.006 |

| 80 | 5.05 | 0.02 | −2.17 | 0.02 | 93.68 | 0.004 | 92.44 | 0.006 |

| 90 | 4.98 | 0.02 | −2.28 | 0.02 | 91.80 | 0.001 | 90.64 | 0.004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hirani, H.; Jangra, D.; Sidh, K.N. Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear. Lubricants 2023, 11, 201. https://doi.org/10.3390/lubricants11050201

Hirani H, Jangra D, Sidh KN. Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear. Lubricants. 2023; 11(5):201. https://doi.org/10.3390/lubricants11050201

Chicago/Turabian StyleHirani, Harish, Dharmender Jangra, and Kishan Nath Sidh. 2023. "Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear" Lubricants 11, no. 5: 201. https://doi.org/10.3390/lubricants11050201

APA StyleHirani, H., Jangra, D., & Sidh, K. N. (2023). Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear. Lubricants, 11(5), 201. https://doi.org/10.3390/lubricants11050201