Coated Piston Ring Pack and Cylinder Liner Elastodynamics in Correlation to Piston Subsystem Elastohydrodynamic: Through FEA Modelling

Abstract

1. Introduction

2. Materials and Methods

2.1. Coated Piston Subsystem Analysis: A Case Study

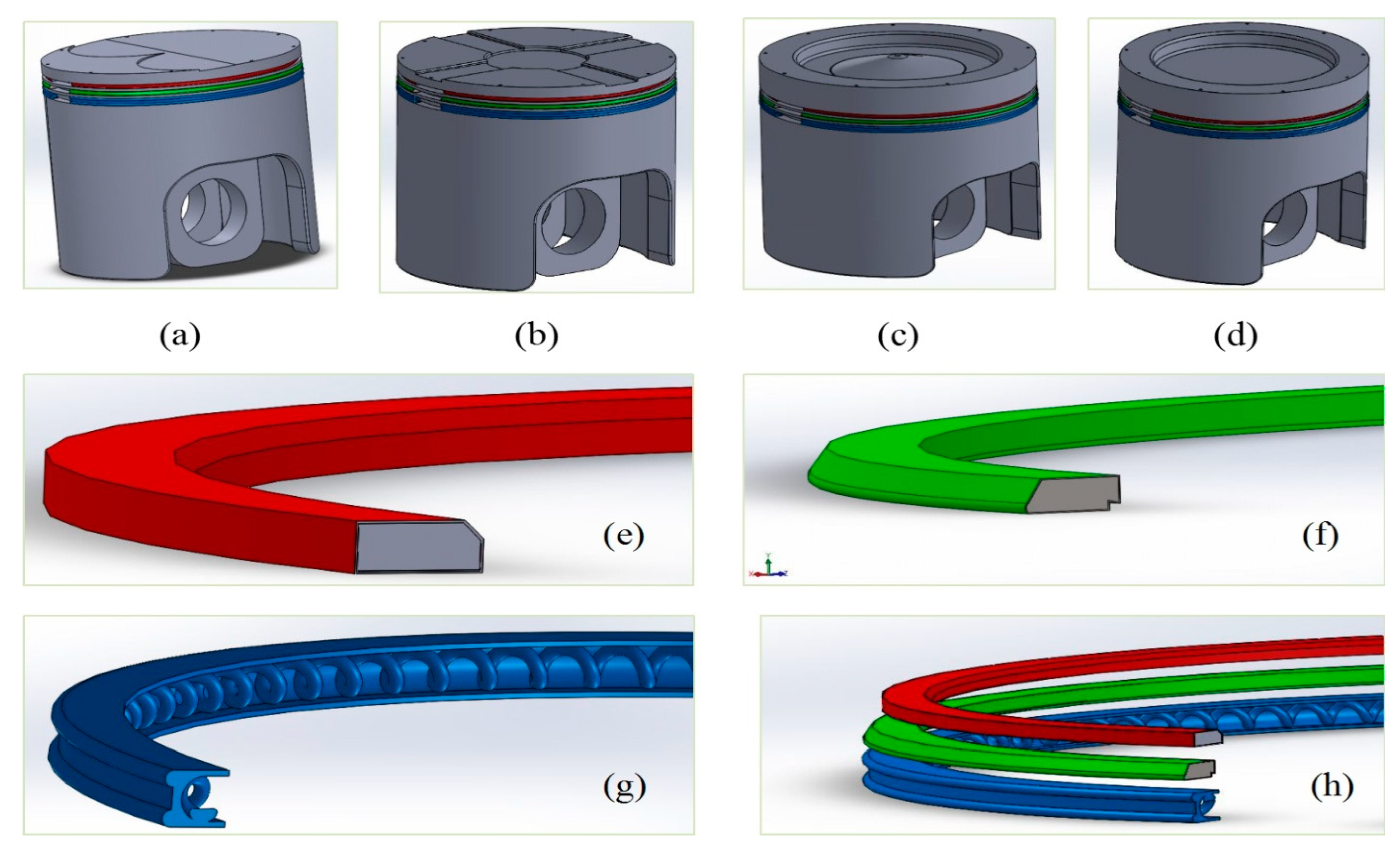

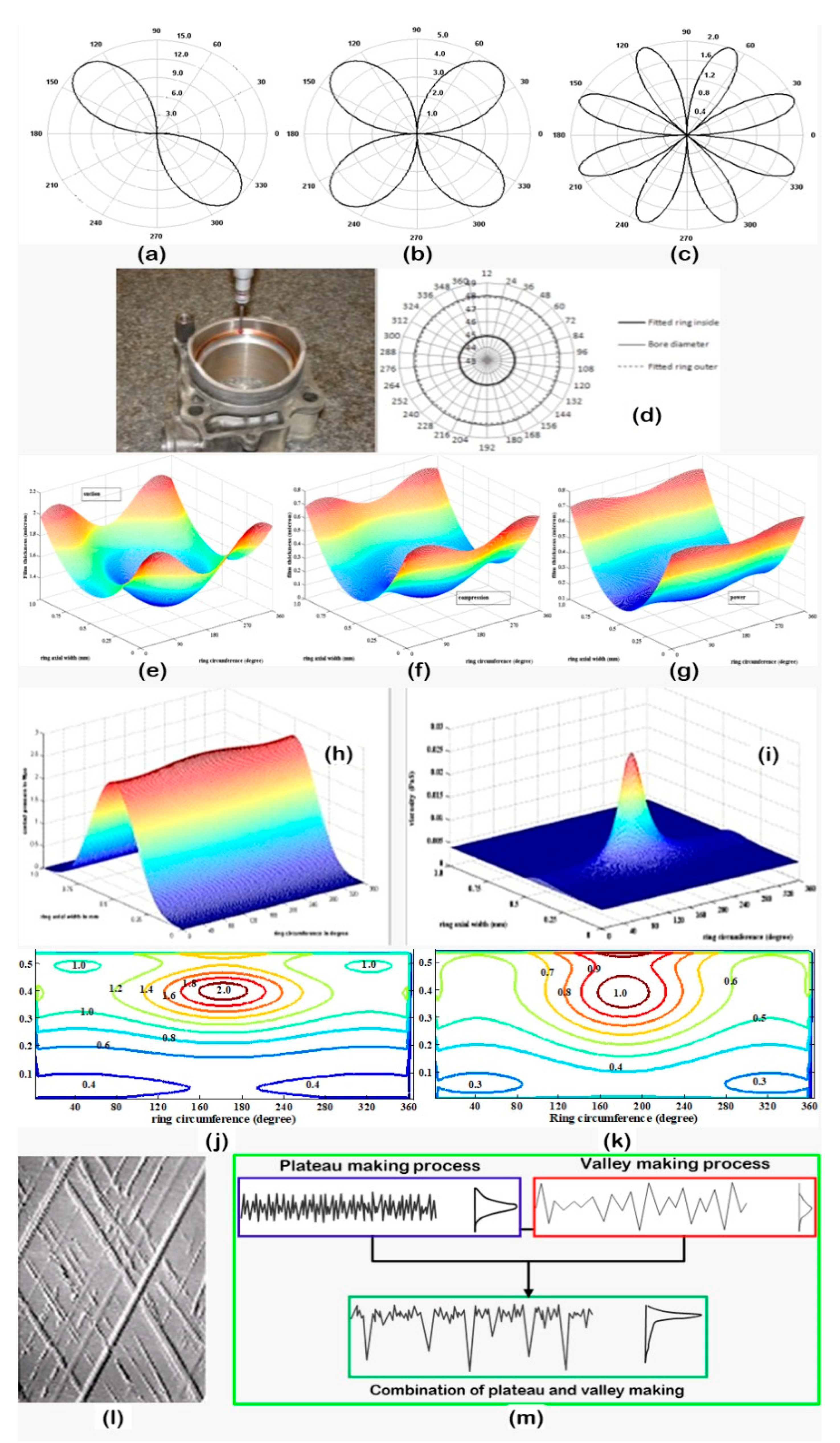

2.2. Solid Modeling for Variable Piston Crown and Ring Geometry

- High-temperature resistance: TiSiCN coating can withstand high temperatures up to 1200 °C, making it an excellent choice for applications that involve high-temperature environments.

- Wear and corrosion resistance: TiSiCN coating exhibits excellent wear and corrosion resistance properties, making it ideal for applications that involve abrasive and corrosive environments.

- High hardness: TiSiCN coating has a high hardness of up to 40 GPa, making it suitable for applications that require high wear resistance and durability.

- Low friction coefficient: TiSiCN coating has a low friction coefficient, which makes it ideal for applications that require reduced friction and wear.

- Material properties: The material properties of the coating need to be defined, including its thickness, density, elastic modulus, Poisson’s ratio, and other relevant mechanical properties. These properties can be obtained from experimental data or literature review.

- Mesh generation: A suitable mesh must be generated to accurately represent the coating’s geometry and thickness. The mesh should be fine enough to capture the coating’s behavior but not too fine, as it may increase the computational cost.

- Interface elements: Interface elements need to be defined to connect the coating to the substrate. Interface elements are used to model the adhesion behavior between the coating and substrate.

- Boundary conditions: Appropriate boundary conditions need to be defined to simulate the coating’s behavior under the given loading conditions. These boundary conditions may include applied loads, temperature changes, and other environmental factors.

- Verification: Once the FEM has been developed, it should be verified by comparing its results with experimental data or analytical solutions. This process helps to ensure that the FEM accurately represents the coating’s behavior under different loading conditions.

- Overall, characterizing a thin coating in an FEM requires careful consideration of the coating’s material properties, mesh generation, interface elements, boundary conditions, and verification methods. By following these steps, it is possible to develop an accurate FEM that can be used to study the coating’s behavior under different conditions.

2.3. TiSiCN Coating of Piston Ring

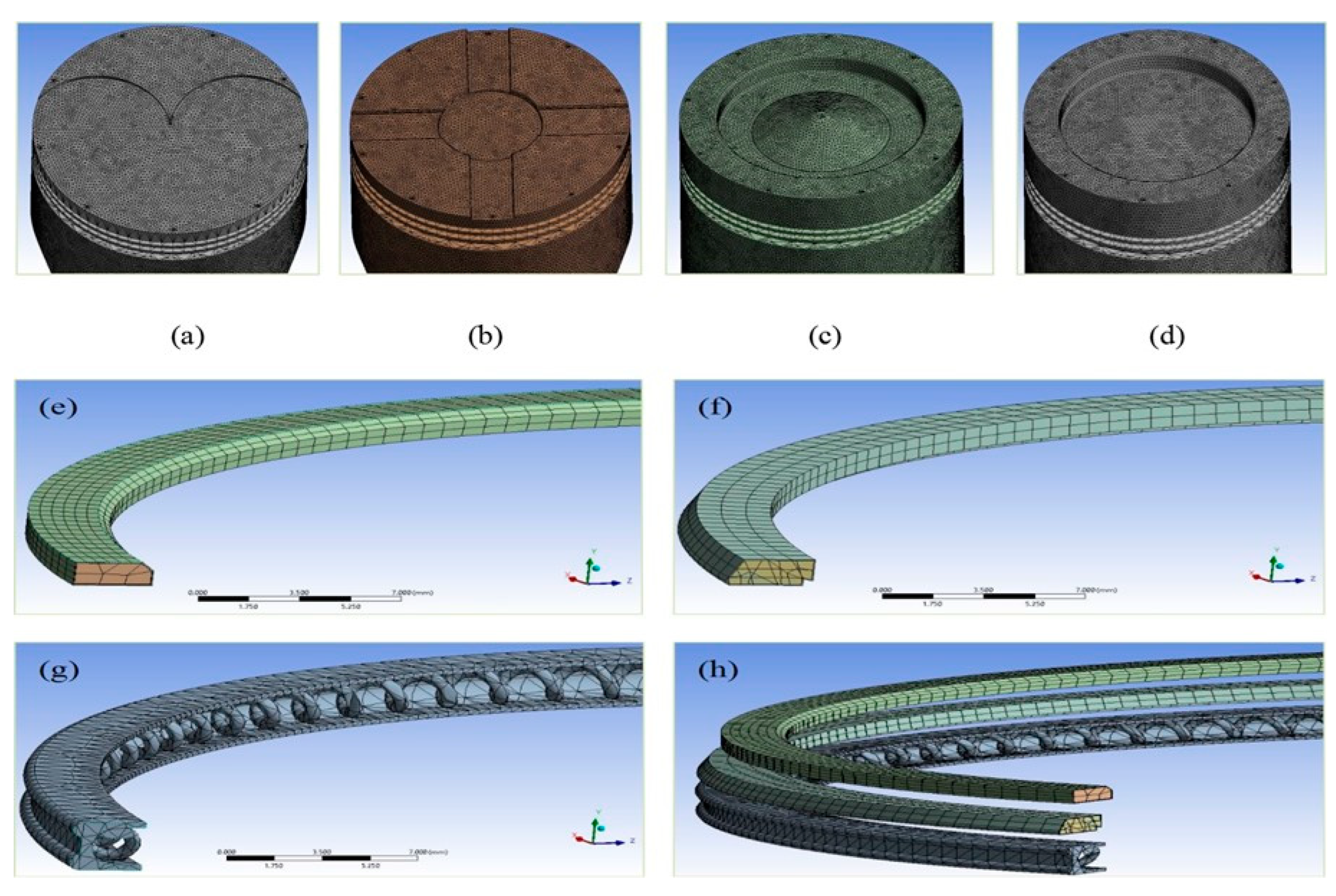

2.4. Meshing of Piston Subsystem Components

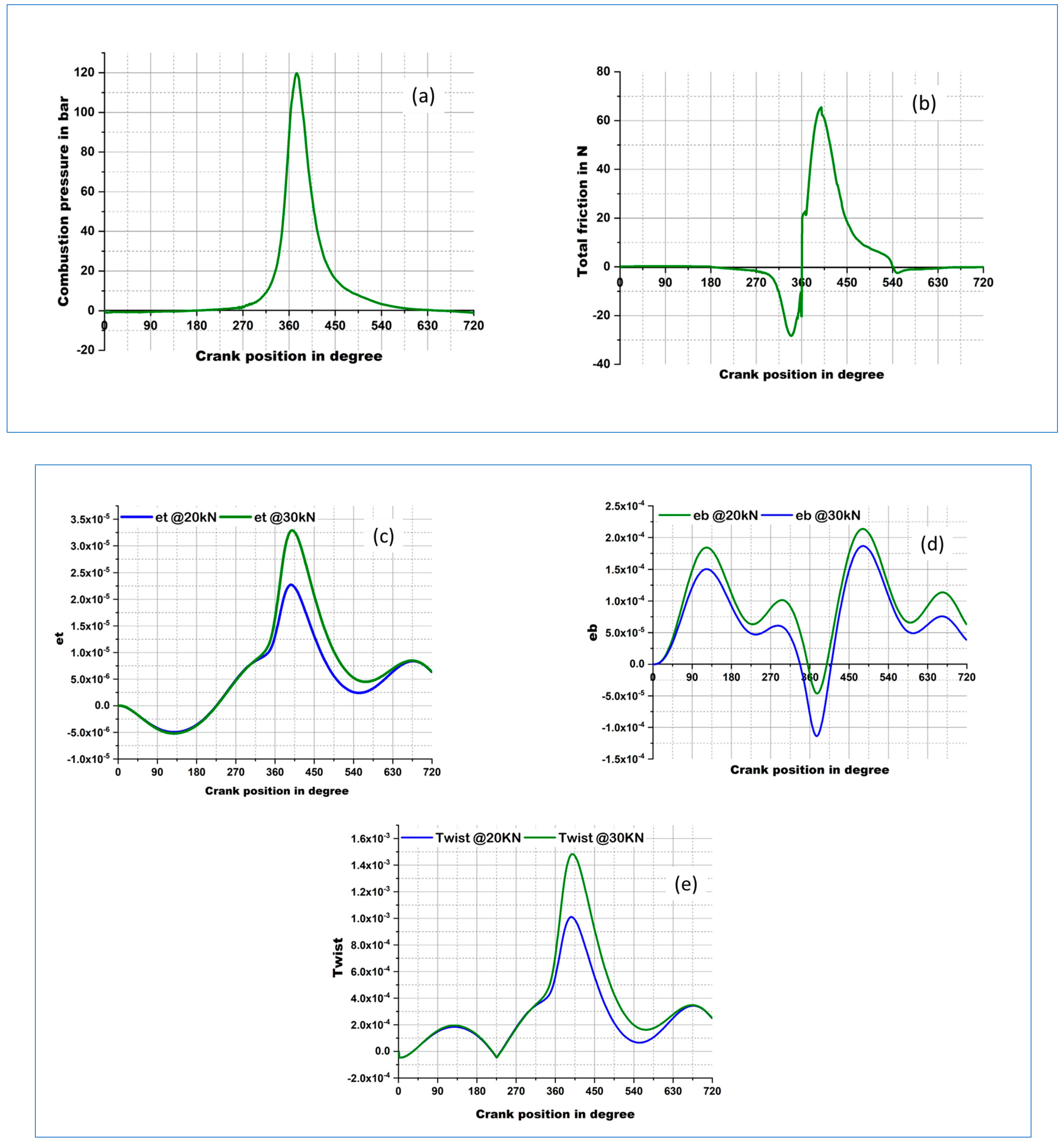

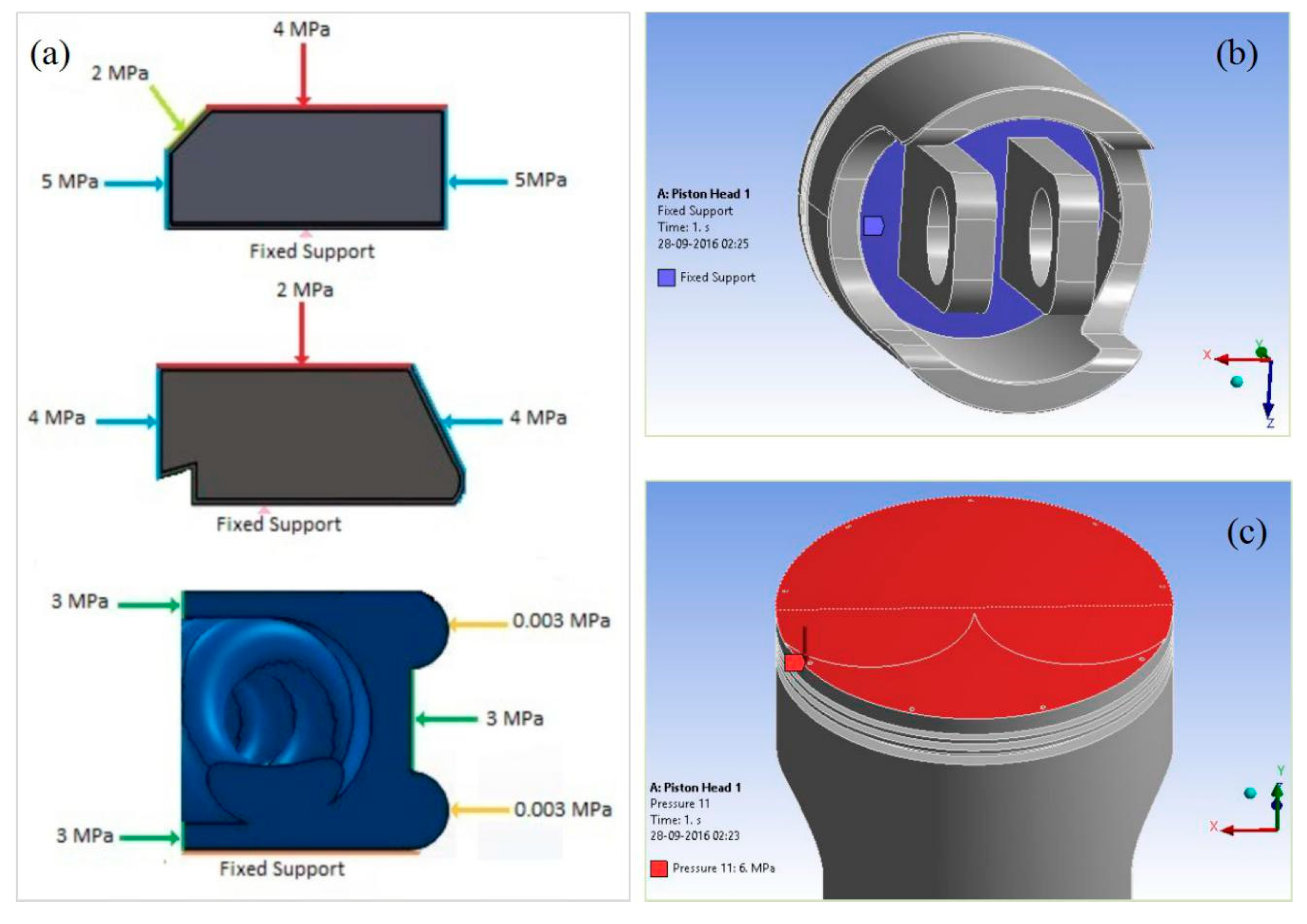

2.5. Loading Conditions in a Dynamic Piston Assembly and the Forces Affecting the FEA

2.6. Boundary Conditions for the Elastodynamics and Elastohydrodynamic Correlation Analysis

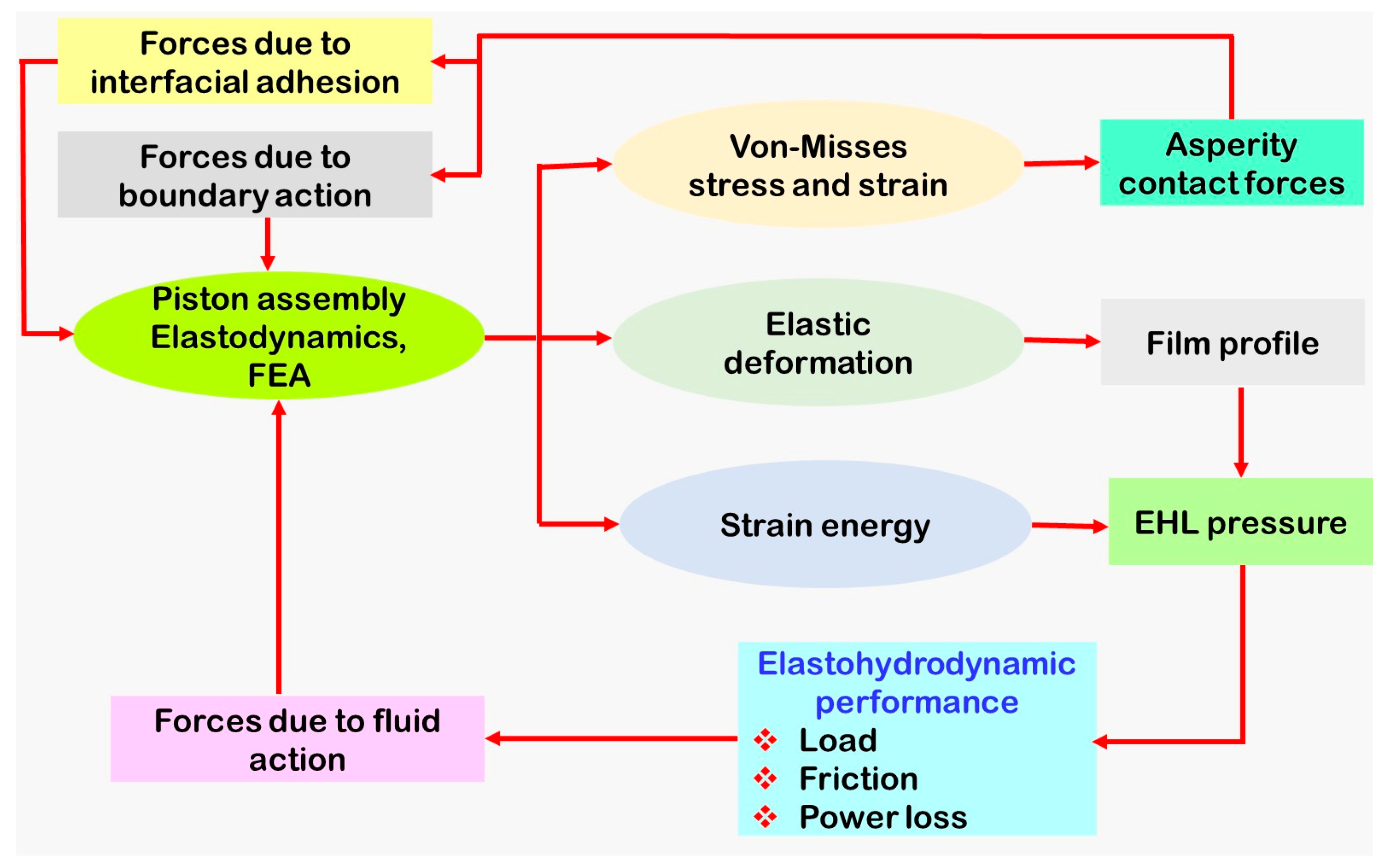

2.7. Fluid Structure Interactive Process Diagram

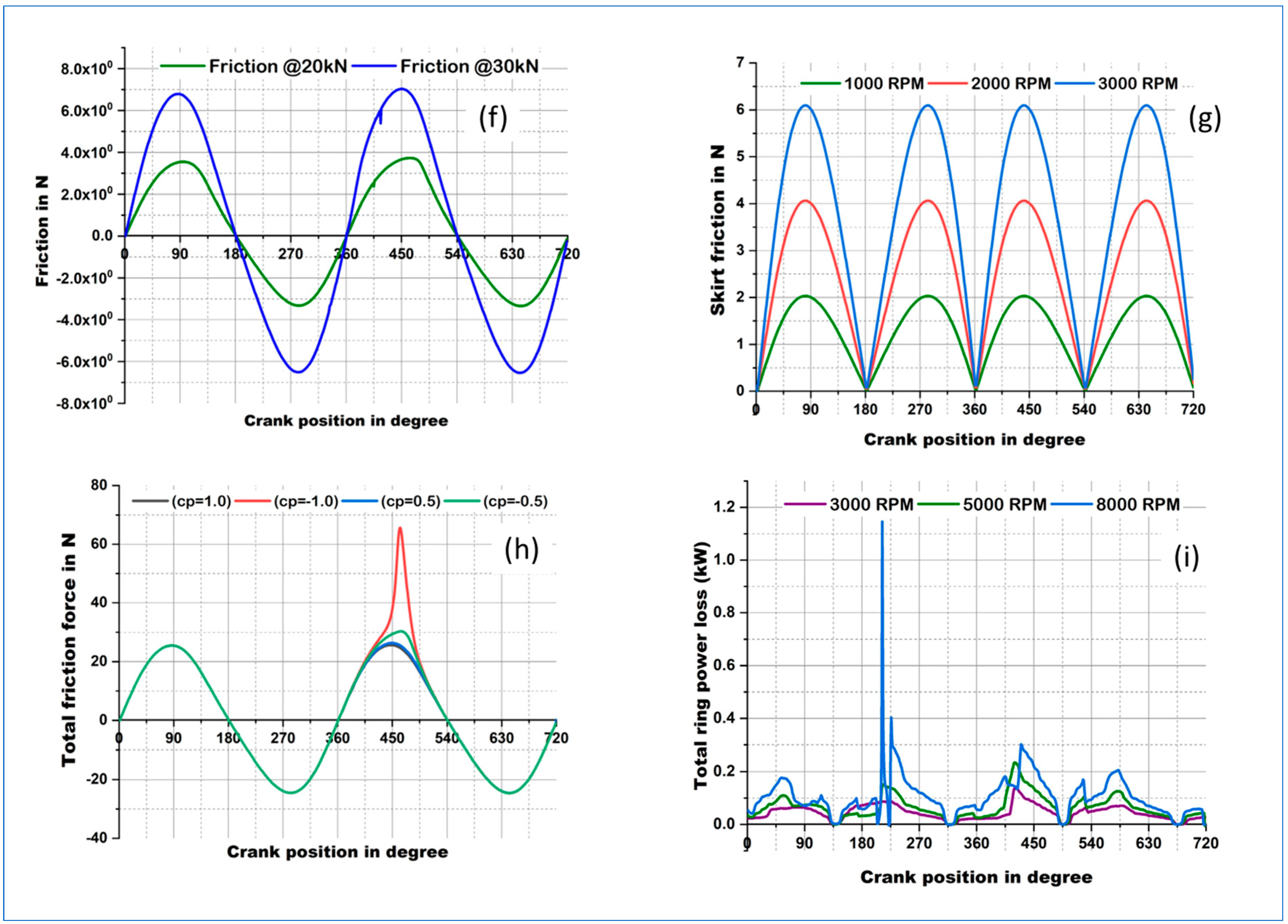

3. Results and Discussion

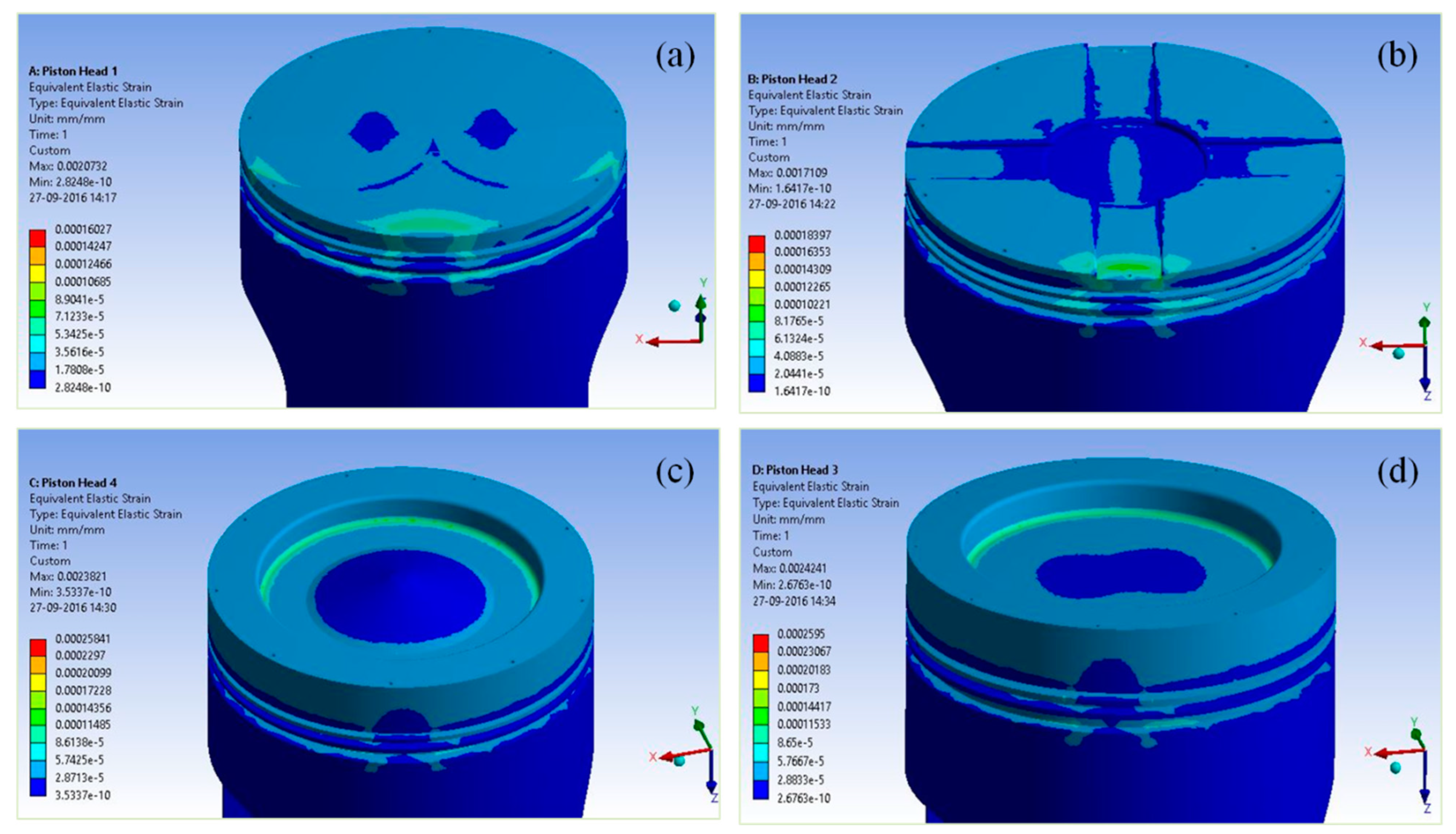

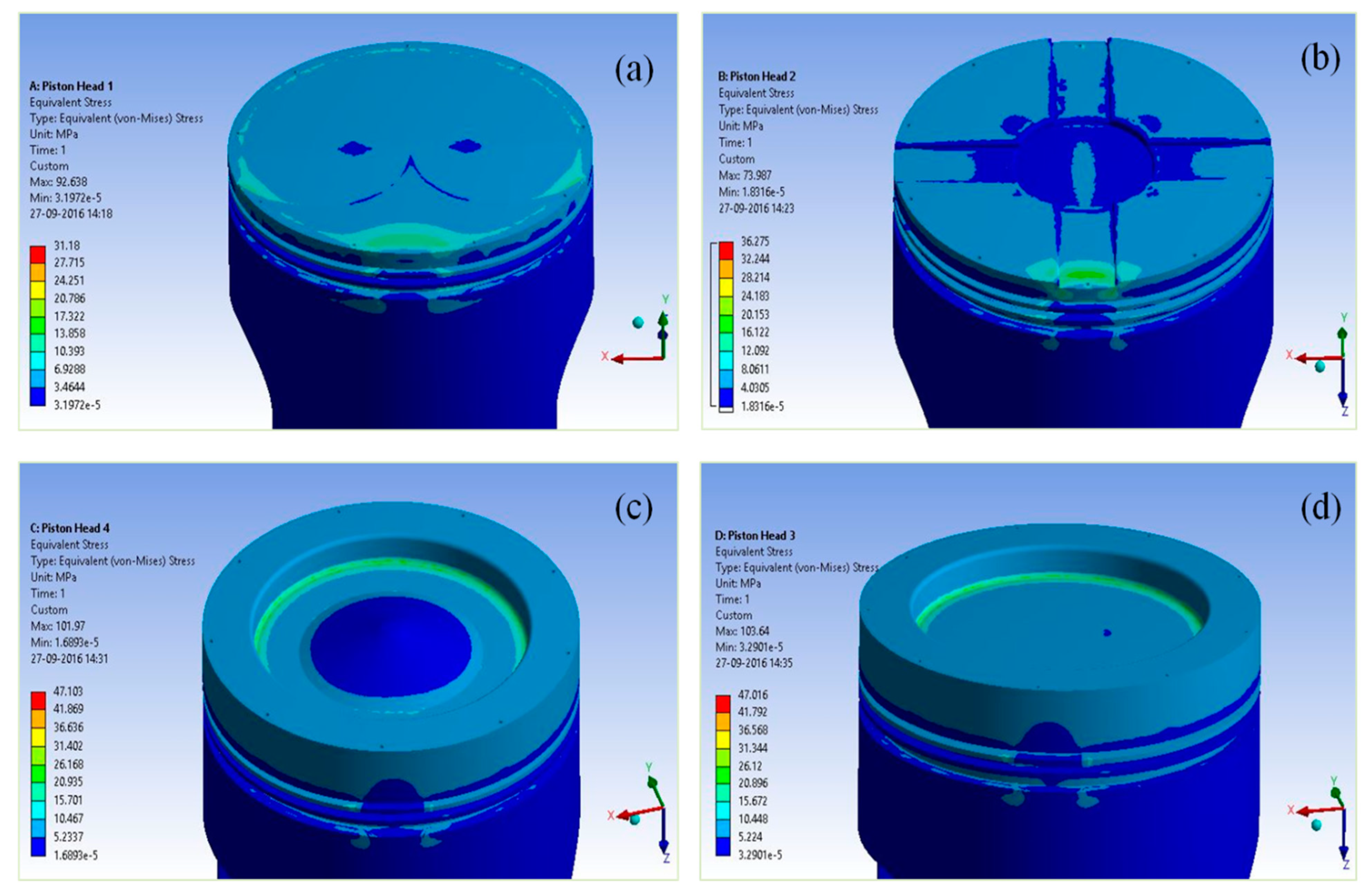

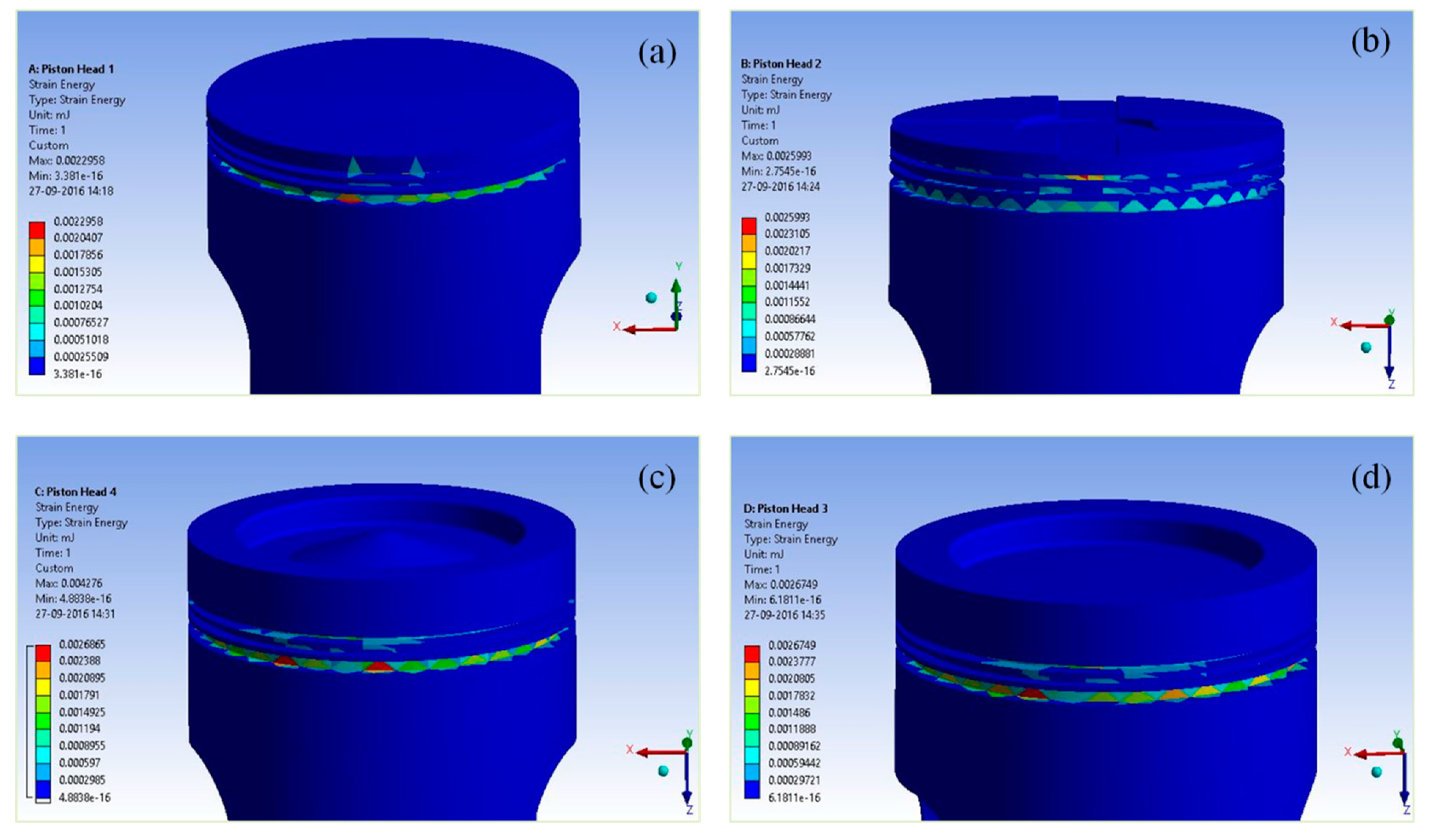

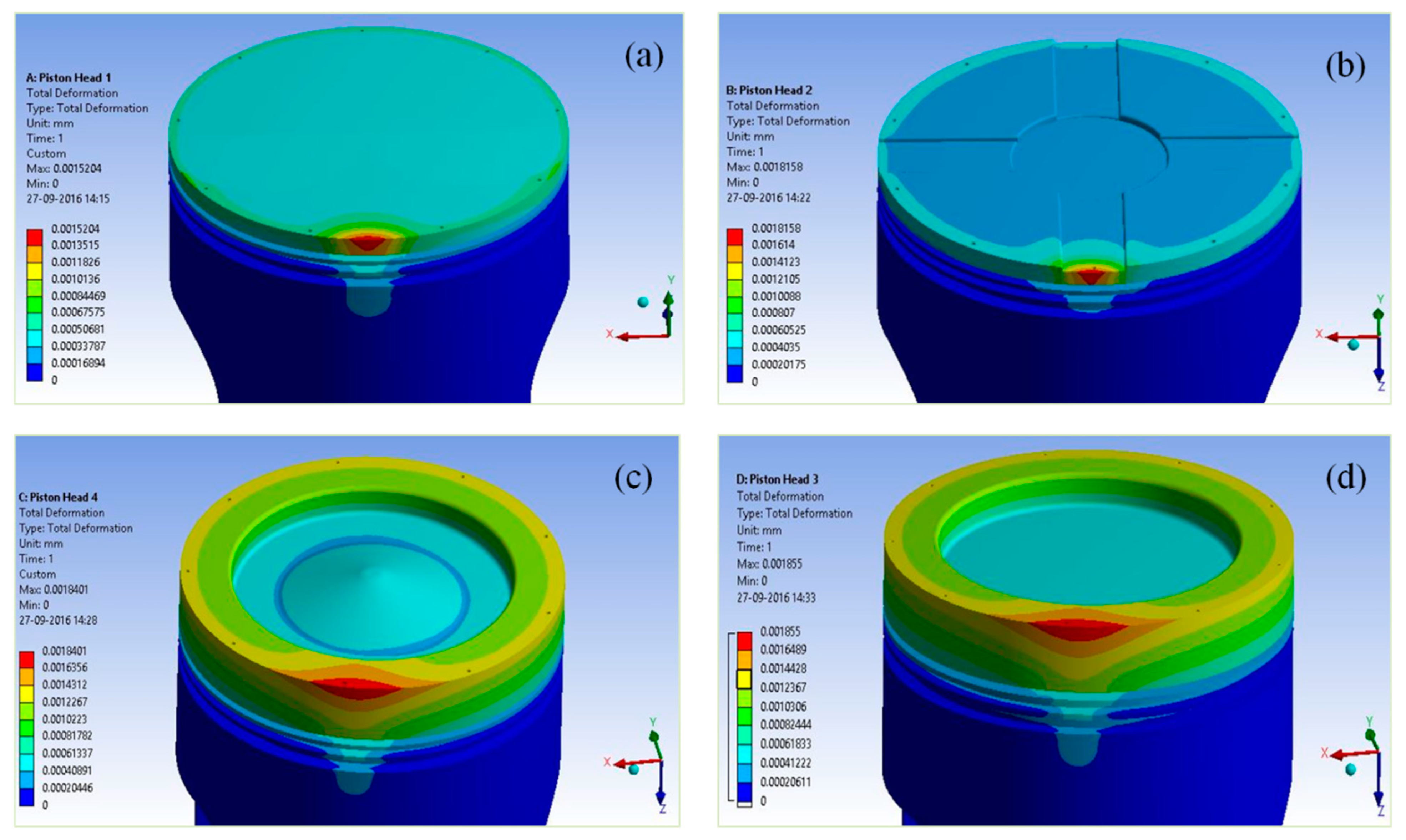

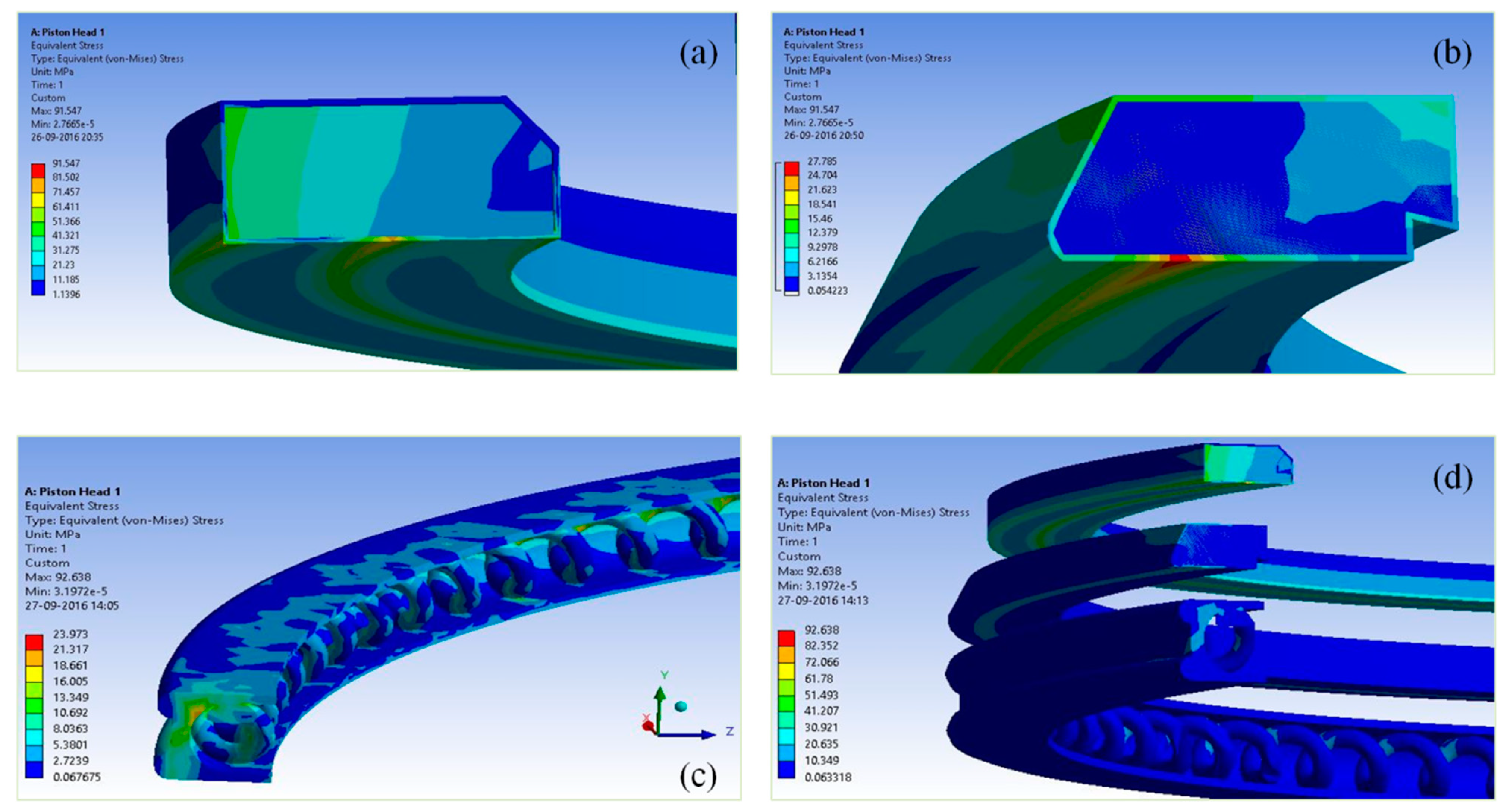

3.1. Structural Strength of Piston with Variable Crown

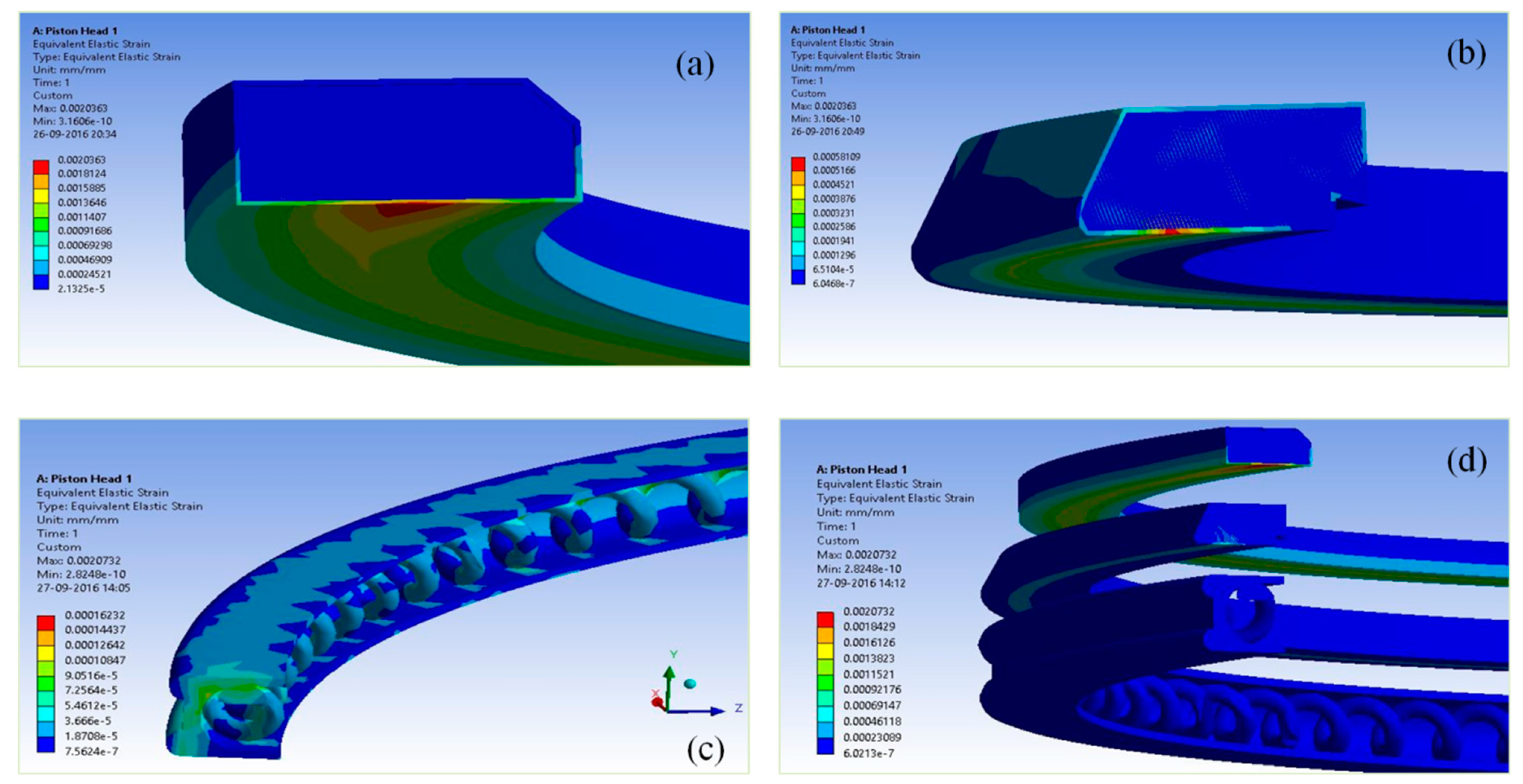

3.2. Structural Strength of Coated Piston Rings

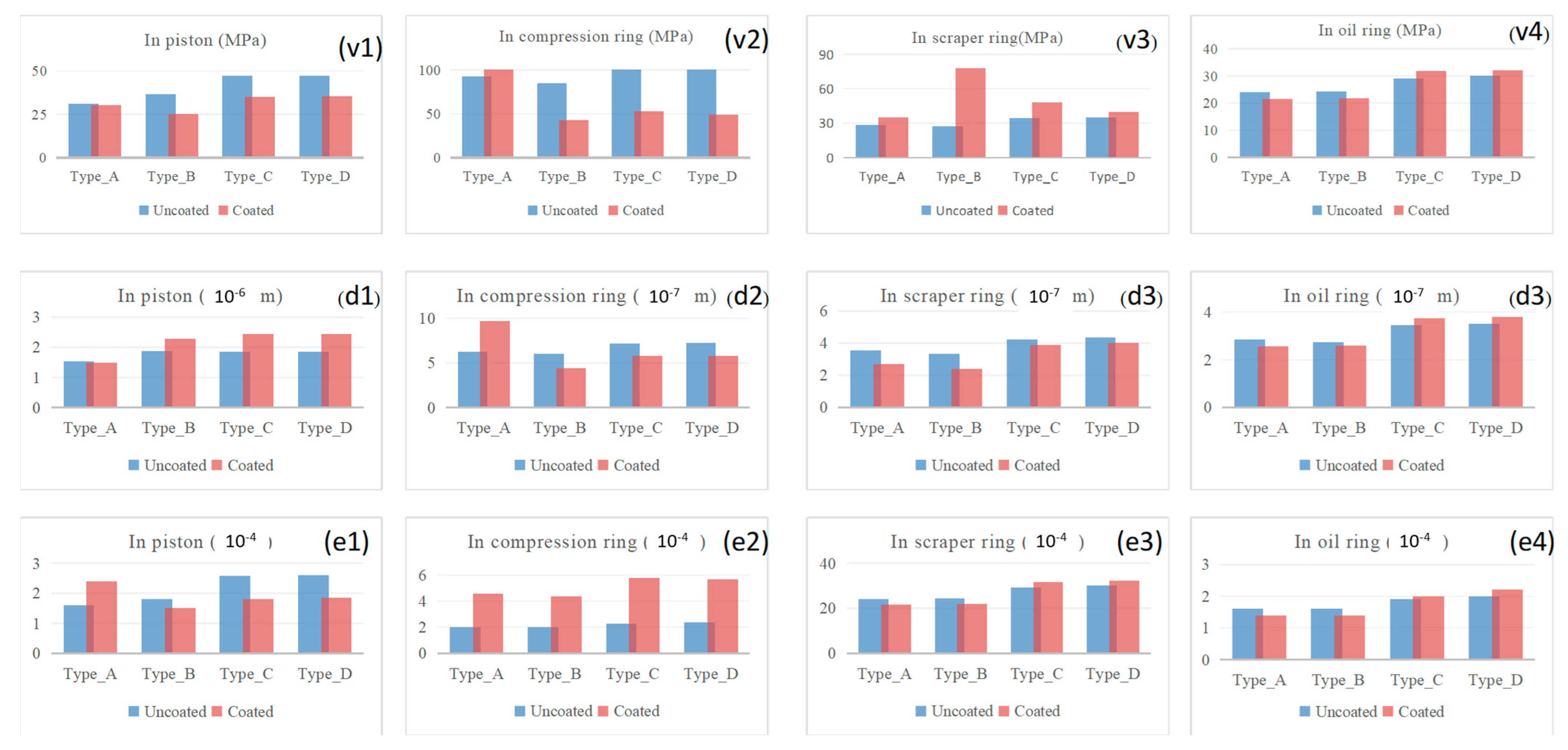

3.3. Summary of Uncoated and Coated Results

4. Conclusions

- Based on the strength analysis, the type-D design is found to be stronger than others because of favorable combustion dynamics due to such a crown shape;

- There is near to 50% variation in the strength of the compression ring observed due to coated against the uncoated condition. It is because of most force actions near the vicinity of the top ring, mostly combustion pressure force is more active;

- In most cases, elastic deformation and strain are more for coated components compared to uncoated ones. The compression ring suffers the most in deformation and strain reason being the highest back pressure on it due to its immediate presence in the combustion chamber;

- Crown design type-A resulted in less stress level because of producing better turbulence due to combustion, hence suggested.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saraeea, H.S.; Jafarmadar, S.; Sayadi, M.; Parikhani, A.; Kheyrollahi, J.; Pourvosoughi, N. Green fuel production from Pistacia Khinjuk and its engine test analysis as a promising alternative. J. Clean. Prod. 2017, 156, 106–113. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Liu, Y.; Yang, H.; Li, M.; Huisingh, D.; Wang, L. The ‘Internet of Things’ enabled real-time scheduling for remanufacturing of automobile engines. J. Clean. Prod. 2018, 185, 562–575. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Green product development: What does the country product space imply? J. Clean. Prod. 2018, 170, 1077–1088. [Google Scholar] [CrossRef]

- Chhabra, D.; Garg, S.; Singh, R.K. Analyzing alternatives for green logistics in an Indian automotive organization: A case study. J. Clean. Prod. 2017, 167, 962–969. [Google Scholar] [CrossRef]

- Oncel, S.S. Green energy engineering: Opening a green way for the future. J. Clean. Prod. 2017, 142, 3095–3100. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. Tribological study of imidazolium and phosphonium ionic liquid-based lubricants as additives in carboxylic acid-based natural oil: Advancements in environmentally friendly lubricants. J. Clean. Prod. 2018, 176, 241–250. [Google Scholar] [CrossRef]

- Zareh-Desari, B.; Davoodi, B. Assessing the lubrication performance of vegetable oil-based nano-lubricants for environmentally conscious metal forming processes. J. Clean. Prod. 2016, 135, 1198–1209. [Google Scholar] [CrossRef]

- Niketh, S.; Samuel, G. Surface texturing for tribology enhancement and its application on drill tool for the sustainable machining of titanium alloy. J. Clean. Prod. 2017, 167, 253–270. [Google Scholar] [CrossRef]

- Mishra, P.C.; Kumar, S. Modeling for Design Optimization of Piston Crown Geometry Through Structural Strength and Lubrication Performance Correlation Analysis. Front. Mech. Eng. 2019, 5, 17. [Google Scholar] [CrossRef]

- Baker, A.; Gazzard, S. Developments in materials for pistons. Mater. Des. 1988, 9, 28–33. [Google Scholar] [CrossRef]

- Carvalho, O.; Buciumeanu, M.; Madeira, S.; Soares, D.; Silva, F.; Miranda, G. Optimization of AlSi–CNTs functionally graded material composites for engine piston rings. Mater. Des. 2015, 80, 163–173. [Google Scholar] [CrossRef]

- Arsha, A.; Jayakumar, E.; Rajan, T.; Antony, V.; Pai, B. Design and fabrication of functionally graded in-situ aluminium composites for automotive pistons. Mater. Des. 2015, 88, 1201–1209. [Google Scholar] [CrossRef]

- Hazar, H. Characterization of MoN coatings for pistons in a diesel engine. Mater. Des. 2010, 31, 624–627. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z. On sustainable manufacturing of Cr-Ni alloy coatings by laser cladding and high-efficiency turning process chain and consequent corrosion resistance. J. Clean. Prod. 2017, 161, 676–687. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Mishra, P.C. Modeling the root causes of engine friction loss: Transient elastohydrodynamics of a piston subsystem and cylinder liner lubricated contact. Appl. Math Model 2015, 39, 2234–2260. [Google Scholar] [CrossRef]

- Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.P.; King, P.D. Thermo-Mixed Hydrodynamics of Piston Compression Ring Conjunction. Tribol. Lett. 2013, 51, 323–340. [Google Scholar] [CrossRef]

- Liu, K.; Xie, Y.B.; Gui, C.L. A comprehensive study of the friction and dynamic motion of the piston assembly. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 1998, 212, 221–226. [Google Scholar] [CrossRef]

- Bolander, N.W.; Steenwyk, B.D.; Sadeghi, F.; Gerber, G.R. Lubrication regime transitions at the piston ring-cylinder liner interface. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2005, 219, 19–31. [Google Scholar] [CrossRef]

- Ma, M.-T.; Smith, E.H.; Sherrington, I. A Three-Dimensional Analysis of Piston Ring Lubrication Part 1: Modelling. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 1995, 209, 1–14. [Google Scholar] [CrossRef]

- Ma, S.L.; Ma, D.Y.; Guo, Y.; Xu, B.; Wu, G.Z.; Xu, K.W.; Chu Paul, K. Synthesis and characterization of super hard, self-lubricating Ti–Si–C–N nanocomposite coatings. Acta Mater. 2007, 55, 6350–6355. [Google Scholar] [CrossRef]

- Froelund, K.; Schramm, J.; Tian, T.; Wong, V.; Hochgreb, S. Analysis of the piston ring/liner oil film development during warm-up for an SI-Engine. J. Eng. Gas Turb. Power–Trans. ASME 2001, 123, 109–116. [Google Scholar] [CrossRef]

- Chong, W.; Howell-Smith, S.; Teodorescu, M.; Vaughan, N. The influence of inter-ring pressures on piston-ring/liner tribological conjunction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 227, 154–167. [Google Scholar] [CrossRef]

- Akalin, O.; Newaz, G.M. Piston ring-cylinder bore friction modeling in mixed lubrication regime: Part I: Analytical results. Trans. ASME J. Tribol. 2001, 123, 211–218. [Google Scholar] [CrossRef]

- Mishra, P.C.; Balakrishnan, S.; Rahnejat, H. Tribology of compression ring-to cylinder contact at reversal. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 2008, 222, 815–826. [Google Scholar] [CrossRef]

- Usman, A.; Park, C.W. Numerical investigation of frictional behaviour and energy loss in mixed hydrodynamic contact of piston ring pack with deformed cylinder liner during warm up period of SI engine. Energy Conserv. Manag. 2016, 117, 115–131. [Google Scholar] [CrossRef]

- Prata, A.T.; Fernandes, J.R.S.; Fagotti, F. Dynamic Analysis of Piston Secondary Motion for Small Reciprocating Compressors. J. Tribol. 2000, 122, 752–760. [Google Scholar] [CrossRef]

- Dursunkaya, Z.; Keribar, R.; Ganapathy, V. A Model of Piston Secondary Motion and Elastohydrodynamic Skirt Lubrication. J. Tribol. 1994, 116, 777–785. [Google Scholar] [CrossRef]

- Mishra, P.C. Tribodynamic modelling of piston compression ring and cylinder liner conjunction in high pressure zone of engine cycle. Int. J. Adv. Manuf. Technol. 2012, 66, 1075–1085. [Google Scholar] [CrossRef]

- Morris, N.; Rahmani, R.; Rahnejat, H.; King, P.D.; Fitzsimons, B. Tribology of piston compression ring conjunction under transient thermal mixed regime of lubrication. Tribol. Int. 2013, 59, 248–258. [Google Scholar] [CrossRef]

- Akalin, O.; Newaz, G.M. Piston Ring-Cylinder Bore Friction Modeling in Mixed Lubrication Regime: Part II—Correlation With Bench Test Data. J. Tribol. 1999, 123, 219–223. [Google Scholar] [CrossRef]

- Pereira, O.; Martin-Alfonso, J.E.; Rodríguez, A.; Calleja-Ochoa, A.; Fernández-Valdivielso, A.; Lopez de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. Dry machining of nickel-based super alloy as a sustainable alternative using TiN/TiAlN coated tool. J. Clean. Prod. 2016, 129, 256–269. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Tian, T. Development and Application of Ring-Pack Model Integrating Global and Local Processes. Part 2: Ring-Liner Lubrication. SAE Int. J. Engines 2017, 10, 1969–1983. [Google Scholar] [CrossRef]

- Baker, C.; Theodossiades, S.; Rahmani, R.; Rahnejat, H.; Fitzsimons, B. On the Transient Three-Dimensional Tribodynamics of Internal Combustion Engine Top Compression Ring. J. Eng. Gas Turbines Power 2017, 139, 062801. [Google Scholar] [CrossRef]

- Durat, M.; Kapsiz, M.; Nart, E.; Ficici, F.; Parlak, A. The effects of coating materials in spark ignition engine design. Mater. Des. 2012, 36, 540–545. [Google Scholar] [CrossRef]

- Öner, C.; Hazar, H.; Nursoy, M. Surface properties of CrN coated engine cylinders. Mater. Des. 2009, 30, 914–920. [Google Scholar] [CrossRef]

- Biswal, S.; Mishra, P.C. Piston Compression Ring Elastodynamics and Ring–Liner Elastohydrodynamic Lubrication Correlation Analysis. Lubricants 2022, 10, 356. [Google Scholar] [CrossRef]

- Lin, J.; Wei, R.; Bitsis, D.C.; Lee, P.M. Development and evaluation of low friction TiSiCN nano composite coatings for piston ring applications. Surf. Coat. 2016, 298, 121–131. [Google Scholar] [CrossRef]

- Shypylenko, A.; Pshyk, A.; Grześkowiak, B.; Medjanik, K.; Peplinska, B.; Oyoshi, K.; Pogrebnjak, A.; Jurga, S.; Coy, E. Effect of ion implantation on the physical and mechanical properties of Ti-Si-N multifunctional coatings for biomedical applications. Mater. Des. 2016, 110, 821–829. [Google Scholar] [CrossRef]

- Abd, A.M.; Rahman, E.I.; Wei, R. A comparative study of conventional magnetron sputter deposited and plasma enhanced magnetron sputter deposited Ti–Si–C–N nanocomposite coatings. Surf. Coat. Technol. 2014, 258, 320–328. [Google Scholar]

- Morris, N.; Mohammadpour, M.; Rahmani, R.; Johns-Rahnejat, P.M.; Rahnejat, H.; Dowson, D. Effect of cylinder deactivation on tribological performance of piston compression ring and connecting rod bearing. Tribol. Int. 2018, 120, 243–254. [Google Scholar] [CrossRef]

- Guo, Y.; Shengli, M.; Xuand, K.; Bell, T. The nanostructured phase transition of superhard Ti–Si–C–N coatings. Nanotechnology 2008, 19, 215603. [Google Scholar] [CrossRef]

- Hadad, M.; Marot, G.; Démarécaux, P.; Chicot, D.; Lesage, J.; Rohr, L.; Siegmann, S. Adhesion tests for thermal spray coatings: Correlation of bond strength and interfacial toughness. Surf. Eng. 2007, 23, 279–283. [Google Scholar] [CrossRef]

- Di, Y.; Cai, Z.; Zhang, P. The Tribological Performance of CrMoN/MoS2 Solid Lubrication Coating on a Piston Ring. Lubricants 2017, 5, 13. [Google Scholar] [CrossRef]

- Wang, H.; Ou, Y.; Zhang, X.; Liao, B.; Ou, X.; Luo, J.; Pang, P.; Chen, L.; Hua, Q.; Bao, M. Tribocorrosion behaviors of TiSiCN nanocomposite coatings deposited by high power impulse magnetron sputtering. Mater. Res. Express 2020, 7, 076407. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Tripp, J.H. The Contact of Two Nominally Flat Rough Surfaces. Proc. Inst. Mech. Eng. 1970, 185, 625–633. [Google Scholar] [CrossRef]

| Design | Volume (in mm3) | Mass (in kg) |

|---|---|---|

| Piston assembly using type-A crown | 1.8737 × 105 | 1.463 |

| Piston assembly using type-B crown | 1.8572 ×105 | 1.4501 |

| Piston assembly using type-C crown | 2.1603 × 105 | 1.688 |

| Piston assembly using type-D crown | 2.1328 × 105 | 1.6665 |

| Design | No. of Elements | No. of Nodes | Transition Ratio | Minm Edge Length (in mm) | Growth Rate |

|---|---|---|---|---|---|

| Piston crown type-A | 239,158 | 467,948 | 0.272 | 8.3561 × 10−2 | 1.2 |

| Piston crown type-B | 245,079 | 478,703 | 0.272 | 8.3561 × 10−2 | 1.2 |

| Piston crown type-C | 262,226 | 506,905 | 0.272 | 8.3561 × 10−2 | 1.2 |

| Piston crown type-D | 261,052 | 505,647 | 0.272 | 8.3561 × 10−2 | 1.2 |

| Sl No. | Component | Material | Youngs Modulus, E (N/mm2) | Poisson’s Ratio, υ |

|---|---|---|---|---|

| 1 | Piston with crown design—A, B, C, D | Structural steel | 2.09 × 109 | 0.3 |

| 2 | Structural steel | 2.09 × 109 | 0.3 | |

| 3 | TiSiCN (Nikasil) | 0.5 × 109 | 0.2 |

| Sl. No. | Force Component | Governing Parameters | Formulation | Method of Evaluation |

|---|---|---|---|---|

| 1 | Gas dynamics force | Air fuel mixture, cylinder temperature, fuel type, etc. | Experimental method | Experimental [6] |

| 2 | Piston body inertial force (pin and piston) due to primary/reciprocating motion. | Piston mass, pin mass, primary reciprocation velocity/acceleration, crank location. | Numerical method through iterative algorithm. | Finite difference method |

| 3 | Piston body inertial force (pin and piston) due to secondary motion. | Piston mass, pin mass, secondary velocity/acceleration due to lateral tilting of the piston, crank location. | Numerical method through iterative algorithm | Finite difference method |

| 4 | Lubricant reaction force | Oil film, oil rheological parameters, contact surface roughness, sliding/rolling velocity. | Numerical method using iterative algorithm through pressure error convergence, load convergence through film relaxation | Finite difference method |

| 5 | Lubricant friction force | Film parameter, asperity density, asperity tip radius, surface roughness. | Numerical method using iterative algorithm through pressure error convergence, load convergence through film relaxation. | Finite difference method |

| 6 | Asperity contact force | Film parameter, asperity density, asperity tip radius, surface roughness. | Using a subroutine to the original code for lubricated contact analysis. | Finite difference method |

| 7 | Force due to asperity contact friction | Film parameter, asperity density, asperity tip radius, surface roughness. | Using a subroutine to the original code for lubricated contact analysis. | Numerical method through computer coding |

| 8 | Force due to ring elastic strength | Ring elasticity, ring geometry, tangential force. | Using a subroutine to the original code for lubricated contact analysis. | Numerical method through computer coding |

| 9 | Connecting rod force | Oscillatory dynamics of connecting rod, mass of connecting | Using a subroutine to the original code for lubricated contact analysis of skirt-liner contact. | Numerical method through computer coding. |

| SL. No. | Element Size (in mm) | No of Nodes | No. of Elements | Max/Min von Misses Stress (in MPa) | Max/Min Deformation (in mm) |

|---|---|---|---|---|---|

| 1 | 1 | 467,948 | 239,158 | (92.638/3.1972) × 10−5 | 0.00152/0 |

| 2 | 1.1 | 402,605 | 203,121 | (174.06/2.1519) × 10−5 | 0.0016017/0 |

| 3 | 1.2 | 343,983 | 173,757 | (121.91/1.9541) × 10−5 | 0.001625/0 |

| 4 | 1.3 | 304,700 | 153,617 | (111.89/1.2521) × 10−5 | 0.001429/0 |

| 5 | 1.4 | 279,002 | 139,987 | (174.65/2.3835) × 10−5 | 0.001495/0 |

| σvon misses (Max) Assembly 1 | σvon misses (Max) Assembly 2 | σvon misses (Max) Assembly 3 | σvon misses (Max) Assembly 4 | σvon misses (Min) Assembly 1 | σvon misses (Min) Assembly 2 | σvon misses (Min) Assembly 3 | σvon misses (Min) Assembly 4 | |

|---|---|---|---|---|---|---|---|---|

| Piston | 30.46 | 25.276 | 35.117 | 35.525 | 1.52 × 10−5 | 2.7371 × 10−5 | 3.8781 × 10−5 | 5.277 × 10−5 |

| Compression ring | 101.17 | 42.492 | 53.111 | 49.352 | 1.4377 | 1.422 | 0.43508 | 0.42835 |

| Scraper ring | 29.095 | 77.991 | 48.261 | 39.903 | 1.3493 | 0.037866 | 0.55647 | 0.55153 |

| Oil ring | 21.637 | 21.888 | 31.733 | 32.108 | 0.08996 | 0.071676 | 0.037985 | 0.040564 |

| ΔMax Assembly 1 | ΔMax Assembly 2 | ΔMax Assembly 3 | ΔMax Assembly 4 | εmax Assembly 1 | εmax Assembly 2 | εmax Assembly 3 | εmax Assembly 4 | |

|---|---|---|---|---|---|---|---|---|

| Piston | 1.48872 × 10−3 | 2.28785 × 10−3 | 2.4355 × 10−3 | 2.449 × 10−3 | 2.04953 × 10−4 | 1.54999 × 10−4 | 1.7867 × 10−4 | 2.449 × 10−4 |

| Compression ring | 5.38947 × 10−4 | 5.04377 × 10−4 | 6.22698 × 10−4 | 6.40207 × 10−4 | 9.69604 × 10−4 | 4.42675 × 10−4 | 5.82993 × 10−4 | 6.40207 × 10−5 |

| Scraper ring | 2.69453 × 10−4 | 2.39789 × 10−4 | 3.89758 × 10−4 | 4.03378 × 10−4 | 2.54789 × 10−4 | 4.84848 × 10−4 | 3.44125 × 10−4 | 4.03378 × 10−4 |

| Oil ring | 2.57333 × 10−4 | 2.58764 × 10−4 | 3.75095 × 10−4 | 3.81418 × 10−4 | 1.45373 × 10−4 | 1.46930 × 10−4 | 2.07970 × 10−4 | 3.81418 × 10−4 |

| σvon misses(Max) Assembly 1 | σvon misses (Max) Assembly 2 | σvon misses (Max) Assembly 3 | σvon misses (Max) Assembly 4 | σvon misses (Min) Assembly 1 | σvon misses (Min) Assembly 2 | σvon misses (Min) Assembly 3 | σvon misses (Min) Assembly 4 | |

|---|---|---|---|---|---|---|---|---|

| Piston | 31.18 | 36.679 | 47.103 | 47.016 | 3.1972 × 10−5 | 2.7371 × 10−5 | 1.6893 × 10−5 | 3.2901 × 10−5 |

| Compression ring | 92.638 | 85.063 | 101.97 | 103.64 | 1.1204 | 1.422 | 1.7901 | 1.8117 |

| Scraper ring | 28.519 | 27.208 | 34.205 | 34.758 | 0.063318 | 0.037866 | 0.056651 | 0.075169 |

| Oil ring | 23.973 | 24.255 | 29.096 | 30.192 | 0.067675 | 0.071676 | 0.056685 | 0.096292 |

| ΔMax Assembly 1 | ΔMax Assembly 2 | ΔMax Assembly 3 | ΔMax Assembly 4 | εmax Assembly 1 | εmax Assembly 2 | εmax Assembly 3 | εmax Assembly 4 | |

|---|---|---|---|---|---|---|---|---|

| Piston | 1.52043 × 10−3 | 1.86241 × 10−3 | 1.8401 × 10−3 | 1.85499 × 10−3 | 0.000160273 | 0.000185998 | 0.000258413 | 0.00025949 |

| Compression ring | 6.25745 × 10−4 | 6.04565 × 10−4 | 7.15219 × 10−4 | 7.22795 × 10−4 | 0.00207321 | 0.0019908 | 0.00238305 | 0.0024241 |

| Scraper ring | 3.53936 × 10−4 | 3.34378 × 10−4 | 4.22744 × 10−4 | 4.34028 × 10−4 | 0.000592947 | 0.000575232 | 0.000678607 | 0.000692927 |

| Oil ring | 2.86537 × 10−4 | 2.75348 × 10−4 | 3.45923 × 10−4 | 3.52729 × 10−4 | 0.000162325 | 0.000162526 | 0.00019685 | 0.000202129 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishra, P.C.; Roychoudhury, A.; Banerjee, A.; Saha, N.; Das, S.R.; Das, A. Coated Piston Ring Pack and Cylinder Liner Elastodynamics in Correlation to Piston Subsystem Elastohydrodynamic: Through FEA Modelling. Lubricants 2023, 11, 192. https://doi.org/10.3390/lubricants11050192

Mishra PC, Roychoudhury A, Banerjee A, Saha N, Das SR, Das A. Coated Piston Ring Pack and Cylinder Liner Elastodynamics in Correlation to Piston Subsystem Elastohydrodynamic: Through FEA Modelling. Lubricants. 2023; 11(5):192. https://doi.org/10.3390/lubricants11050192

Chicago/Turabian StyleMishra, Prakash Chandra, Arka Roychoudhury, Ayan Banerjee, Nutan Saha, Sudhansu Ranjan Das, and Anshuman Das. 2023. "Coated Piston Ring Pack and Cylinder Liner Elastodynamics in Correlation to Piston Subsystem Elastohydrodynamic: Through FEA Modelling" Lubricants 11, no. 5: 192. https://doi.org/10.3390/lubricants11050192

APA StyleMishra, P. C., Roychoudhury, A., Banerjee, A., Saha, N., Das, S. R., & Das, A. (2023). Coated Piston Ring Pack and Cylinder Liner Elastodynamics in Correlation to Piston Subsystem Elastohydrodynamic: Through FEA Modelling. Lubricants, 11(5), 192. https://doi.org/10.3390/lubricants11050192