Microstructure and Wear Performance of CeO2-Modified Micro-Nano Structured WC-CoCr Coatings Sprayed with HVOF

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Preparation

2.3. Characterization

2.4. Abrasion Wear Tests

3. Experimental Results

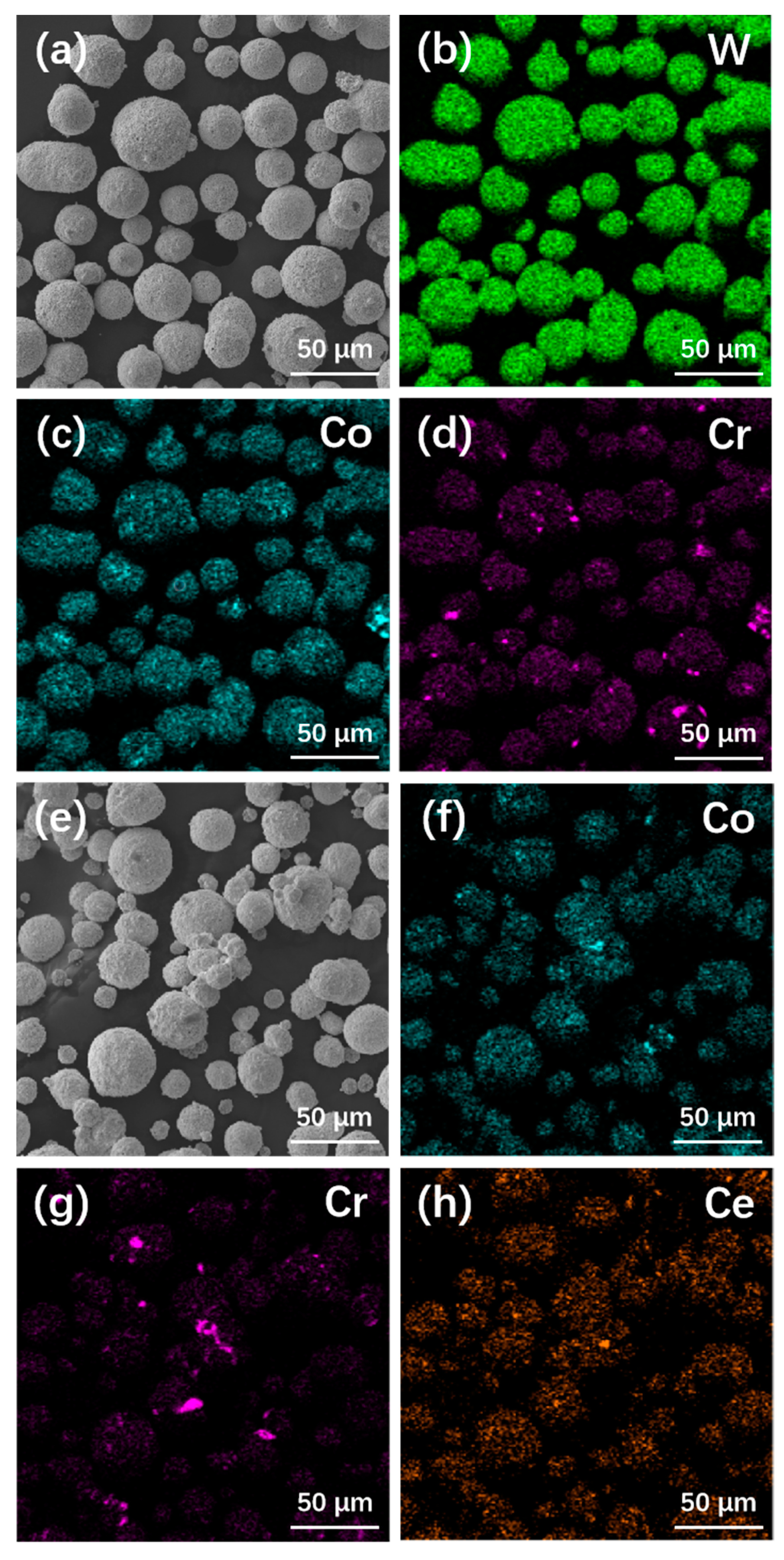

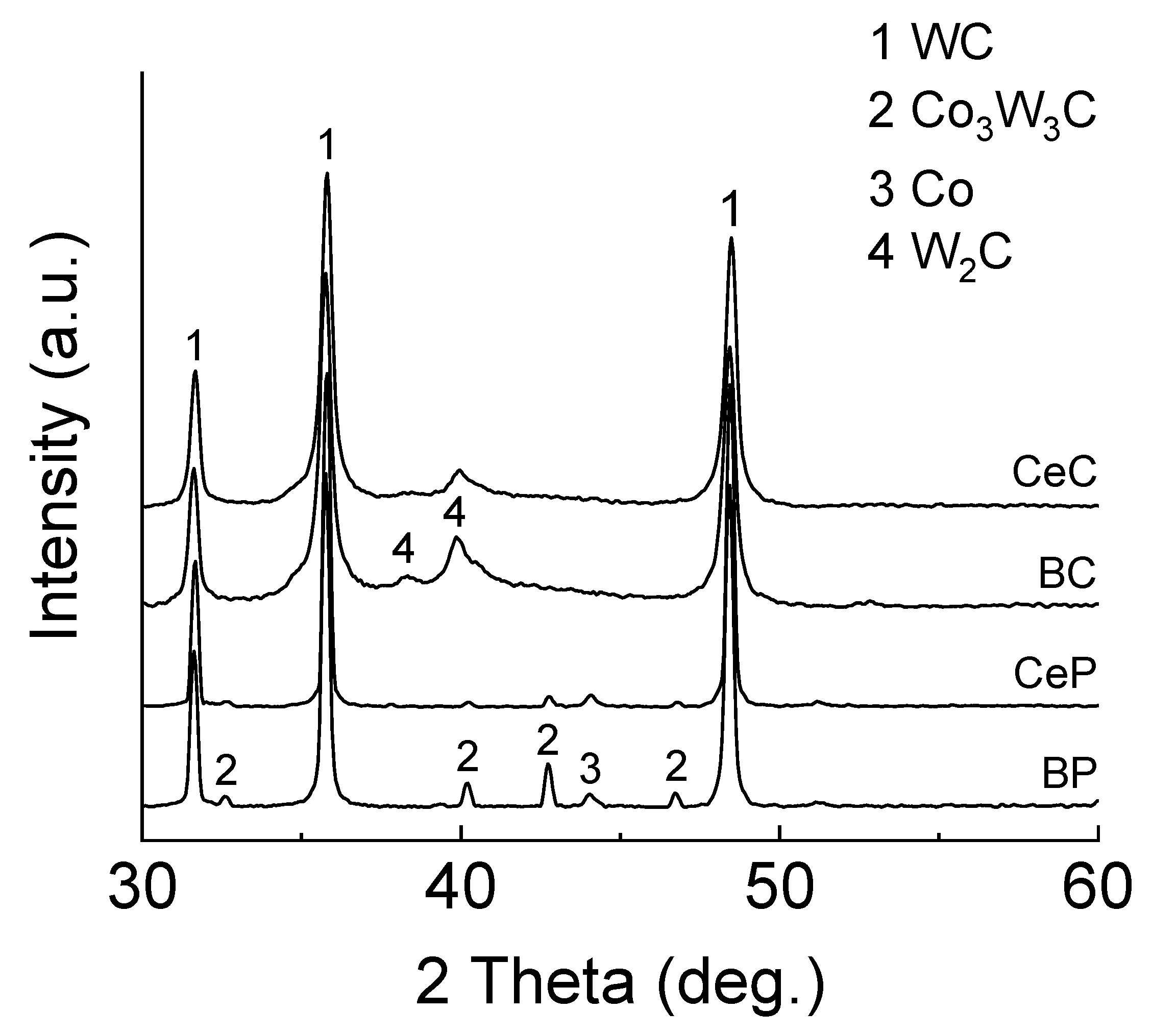

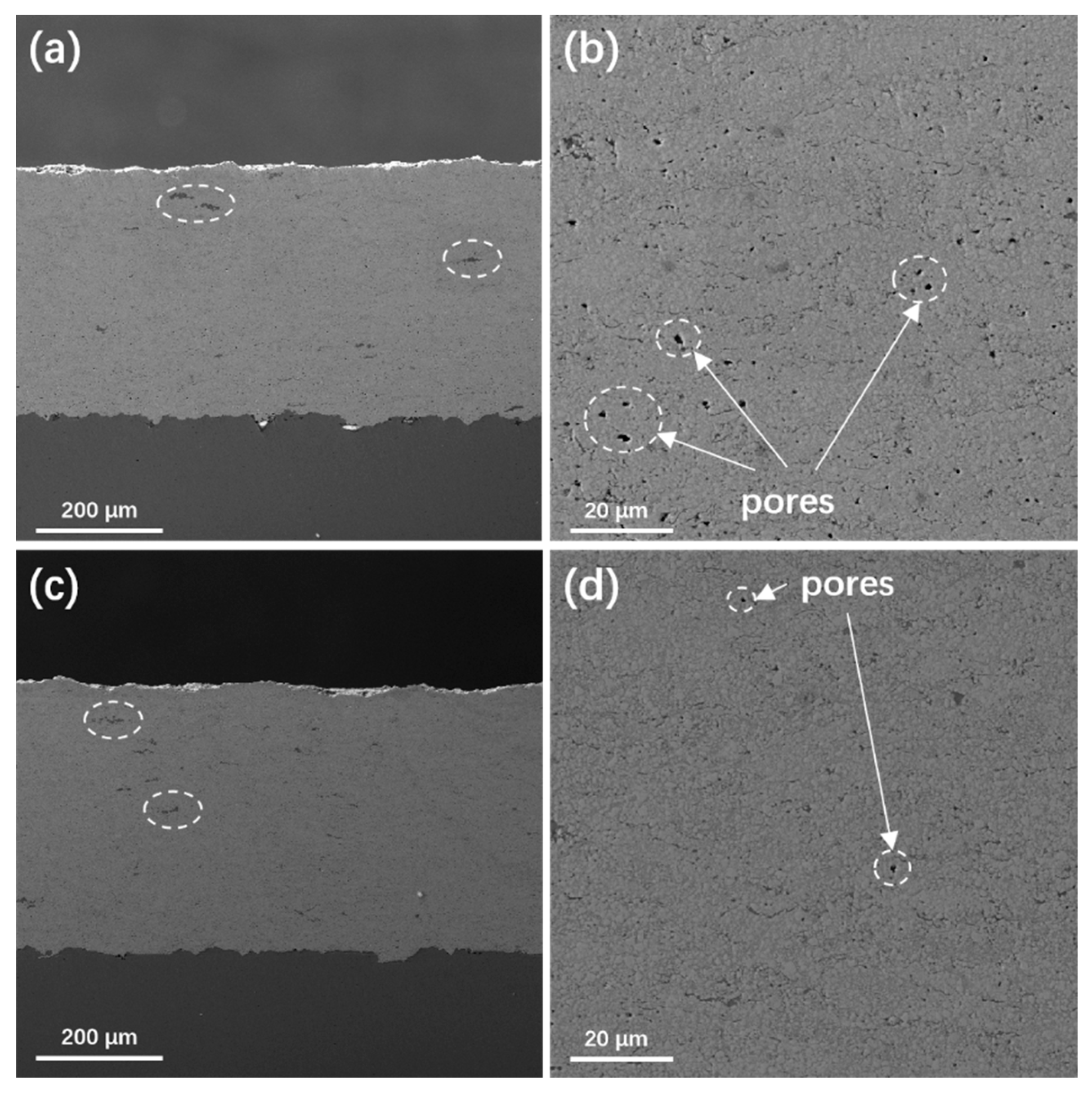

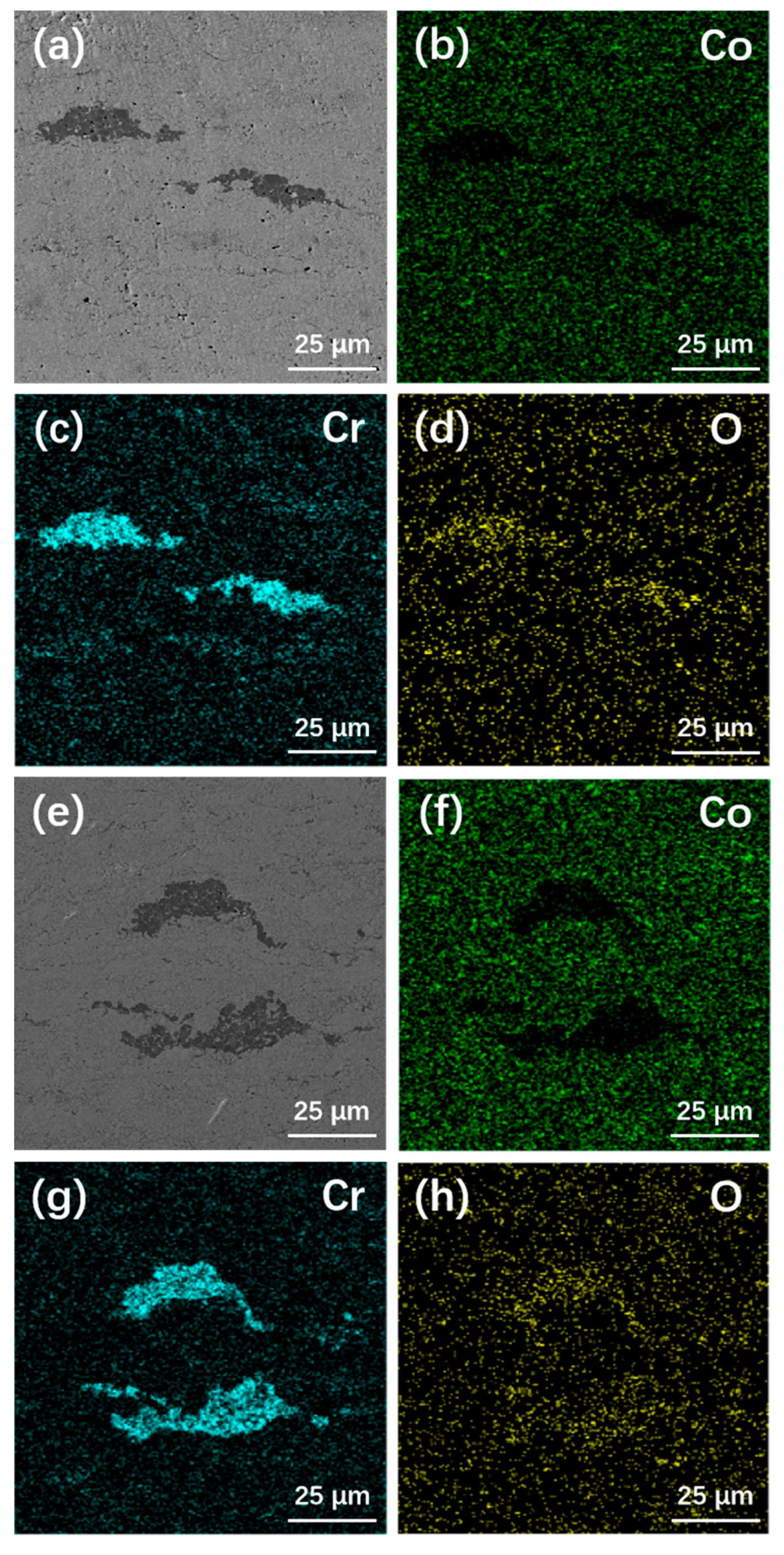

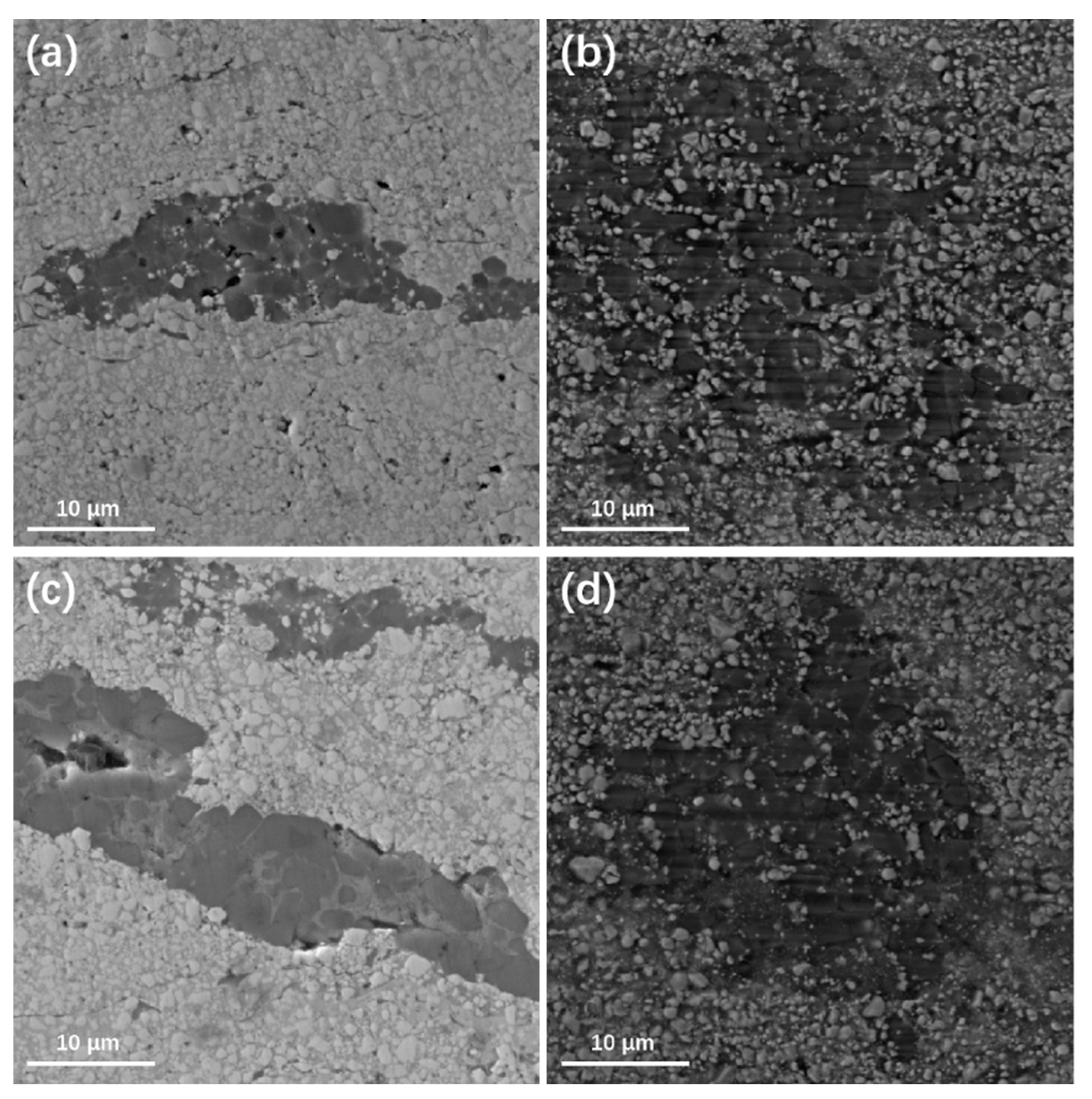

3.1. The Microstructure of the Powders and Coatings

3.2. The Mechanical Properties of the Coatings

3.3. Abrasive Wear Results

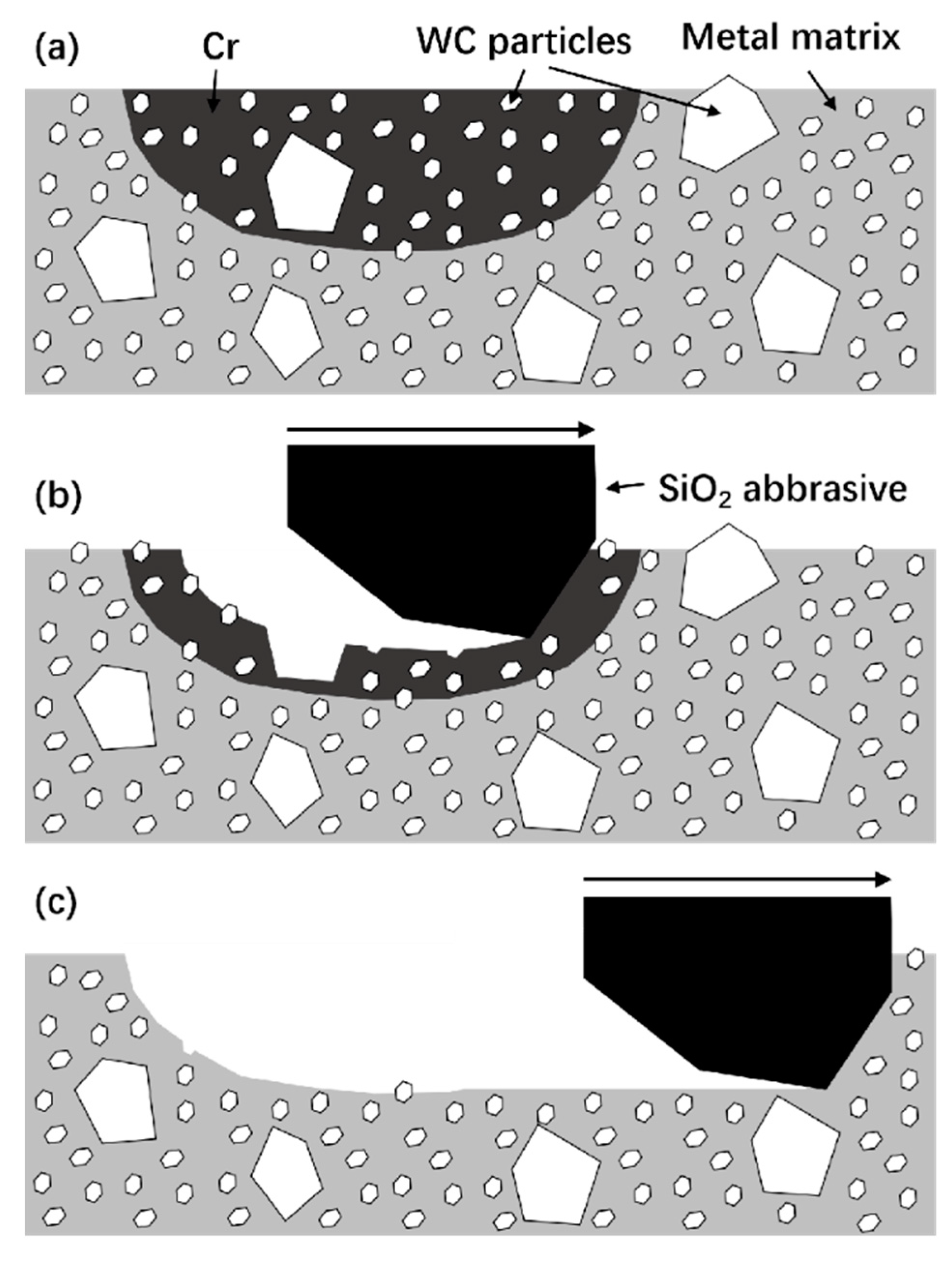

4. Discussions

5. Conclusions

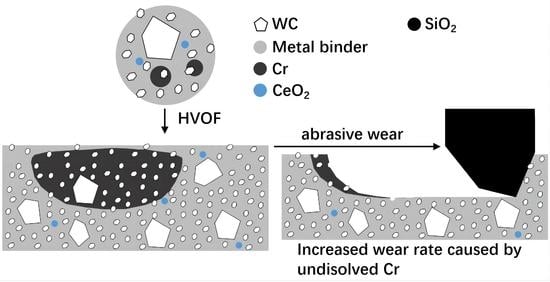

- The addition of CeO2 caused significant changes in the microstructure of both the WC-10Co4Cr powder and coating, such as impeding the formation of Co3W3C, W2C and CoCr alloy. The presence of CeO2 at the interface is expected to elevate the interface energy, leading to a reduction in chemical reaction rates between WC, Co, Cr and oxygen. There was a notable decrease in the porosity of the coating modified with CeO2, which also contained a significantly increased density of Cr-rich regions.

- The CeO2-modified coating showed comparable microhardness (1230 HV0.3) and fracture toughness (5.77 MPam1/2) to the bare coating, but with significantly reduced standard deviations, suggesting that the coating microstructure became more homogeneous as a result of CeO2 modification.

- Due to the weak cohesive strength between WC and Cr, the CeO2-modified coating that contained more Cr-rich areas suffered a faster wear rate, resulting in reduced abrasive wear resistance compared to the bare coating.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Davim, J.P. Tribology for Engineers: A Practical Guide; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Ahmed, R.; Ali, O.; Berndt, C.C.; Fardan, A. Sliding Wear of Conventional and Suspension Sprayed Nanocomposite WC-Co Coatings: An Invited Review. J. Therm. Spray Technol. 2021, 30, 800–861. [Google Scholar] [CrossRef]

- Davim, J.P. Progress in Green Tribology; De Gruyter: Berlin, Germany, 2017. [Google Scholar]

- Liu, Y.; Li, Z.; Li, G.; Tang, L. Friction and wear behavior of Ni-based alloy coatings with different amount of WC–TiC ceramic particles. J. Mater. Sci. 2023, 58, 1116–1126. [Google Scholar] [CrossRef]

- Roy, M. Thermal Sprayed Coatings and Their Tribological Performances; IGI Global: Hershey, PA, USA, 2015. [Google Scholar]

- Bhosale, D.G.; Rathod, W.S. Tribological behaviour of atmospheric plasma and high velocity oxy-fuel sprayed WC-Cr3C2-Ni coatings at elevated temperatures. Ceram. Int. 2020, 46, 12373–12385. [Google Scholar] [CrossRef]

- Wang, Q.; Luo, S.; Wang, S.; Wang, H.; Ramachandran, C.S. Wear, erosion and corrosion resistance of HVOF-sprayed WC and Cr3C2 based coatings for electrolytic hard chrome replacement. Int. J. Refract. Met. Hard Mater. 2019, 81, 242–252. [Google Scholar] [CrossRef]

- Liu, J.; Bai, X.; Chen, T.; Yuan, C. Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings. Coatings 2019, 9, 534. [Google Scholar] [CrossRef]

- Qiao, L.; Wu, Y.; Hong, S.; Long, W.; Cheng, J. Wet abrasive wear behavior of WC-based cermet coatings prepared by HVOF spraying. Ceram. Int. 2021, 47, 1829–1836. [Google Scholar] [CrossRef]

- Song, B.; Murray, J.W.; Wellman, R.G.; Pala, Z.; Hussain, T. Dry sliding wear behaviour of HVOF thermal sprayed WC-Co-Cr and WC-CrxCy-Ni coatings. Wear 2020, 442, 203114. [Google Scholar] [CrossRef]

- Ozkavak, H.V.; Sahin, S.; Sarac, M.F.; Alkan, Z. Comparison of wear properties of HVOF sprayed WC-Co and WC-CoCr coatings on Al alloys. Mater. Res. Express 2019, 6, 096554. [Google Scholar] [CrossRef]

- Shipway, P.H.; McCartney, D.G.; Sudaprasert, T. Sliding wear behaviour of conventional and nanostructured HVOF sprayed WC-Co coatings. Wear 2005, 259, 820–827. [Google Scholar] [CrossRef]

- Thakur, L.; Arora, N. A study of processing and slurry erosion behaviour of multi-walled carbon nanotubes modified HVOF sprayed nano-WC-10Co-4Cr coating. Surf. Coat. Technol. 2017, 309, 860–871. [Google Scholar] [CrossRef]

- Lekatou, A.; Sioulas, D.; Karantzalis, A.E.; Grimanelis, D. A comparative study on the microstructure and surface property evaluation of coatings produced from nanostructured and conventional WC-Co powders HVOF-sprayed on Al7075. Surf. Coat. Technol. 2015, 276, 539–556. [Google Scholar] [CrossRef]

- Kim, J.H.; Yang, H.S.; Baik, K.H.; Seong, B.G.; Lee, C.H.; Hwang, S.Y. Development and properties of nanostructured thermal spray coatings. Curr. Appl. Phys. 2006, 6, 1002–1006. [Google Scholar] [CrossRef]

- Li, C.J.; Yang, G.J. Relationships between feedstock structure, particle parameter, coating deposition, microstructure and properties for thermally sprayed conventional and nanostructured WC-Co. Int. J. Refract. Met. Hard Mater. 2013, 39, 2–17. [Google Scholar] [CrossRef]

- Al-Mutairi, S.; Hashmi, M.S.J.; Yilbas, B.S.; Stokes, J. Microstructural characterization of HVOF/plasma thermal spray of micro/nano WC-12%Co powders. Surf. Coat. Technol. 2015, 264, 175–186. [Google Scholar] [CrossRef]

- Yuan, J.; Ma, C.; Yang, S.; Yu, Z.; Li, H. Improving the wear resistance of HVOF sprayed WC-Co coatings by adding submicron-sized WC particles at the splats’ interfaces. Surf. Coat. Technol. 2016, 285, 17–23. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.-D.; Li, C.; Yu, X.; Ding, Z.-X.; Yuan, C.-Q. Microstructure and performance of multi-dimensional WC-CoCr coating sprayed by HVOF. Int. J. Adv. Manuf. Technol. 2018, 96, 1625–1633. [Google Scholar] [CrossRef]

- Liu, S.; De Ong, B.; Guo, J.; Liu, E.; Zeng, X. Wear performance of Y-doped nanolayered CrN/AlN coatings. Surf. Coat. Technol. 2019, 367, 349–357. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Xu, B.; Zhang, J.; Sun, M.; Li, D. Research progress on preparation technology of oxide dispersion strengthened steel for nuclear energy. Int. J. Extreme Manuf. 2021, 3, 032001. [Google Scholar] [CrossRef]

- Zhou, H.; Zhu, F.; Ma, G.; Xue, C.; Hu, Y. Effect of nano rare earth on corrosion resistance of thermal sprayed WC/12Co coating. Surf. Rev. Lett. 2018, 25, 1850114. [Google Scholar] [CrossRef]

- Shu, D.; Dai, S.; Wang, G.; Si, W.; Xiao, P.; Cui, X.; Chen, X. Influence of CeO2 content on WC morphology and mechanical properties of WC/Ni matrix composites coating prepared by laser in-situ synthesis method. J. Mater. Res. Technol. 2020, 9, 11111–11120. [Google Scholar] [CrossRef]

- Liu, Y.; Hang, Z.; Yang, G.; Fu, H.; Xi, N.; Chen, H. Influence of Rare Earth on the High-Temperature Sliding Wear Behavior of WC-12Co Coating Prepared by HVOF Spraying. J. Therm. Spray Technol. 2018, 27, 1143–1152. [Google Scholar] [CrossRef]

- Ma, W.; Ge, Y.; Zhang, L.; Chen, F.; Zheng, Y.; Qi, Z. Study on the Friction Performance of Cerium Oxide on Supersonic Flame-Sprayed WC-10Co-4Cr Coating. Coatings 2021, 11, 24. [Google Scholar] [CrossRef]

- Ponton, C.B.; Rawlings, R.D. Vickers indentation fracture toughness test Part 1 Review of literature and formulation of standardised indentation toughness equations. Mater. Sci. Technol. 1989, 5, 865–872. [Google Scholar] [CrossRef]

- Liu, J.; Chen, T.; Duan, H.; Yuan, C.; Bai, X. Mechanical Properties and Cavitation Erosion Behavior of CeO2-Modified Dual-scale WC-10Co-4Cr Coating Prepared by HVOF. J. Therm. Spray Technol. 2022, 31, 2463–2475. [Google Scholar] [CrossRef]

- Huang, Y.; Ding, X.; Yuan, C.-Q.; Yu, Z.-K.; Ding, Z.-X. Slurry erosion behaviour and mechanism of HVOF sprayed micro-nano structured WC-CoCr coatings in NaCl medium. Tribol. Int. 2020, 148, 106315. [Google Scholar] [CrossRef]

- Guilemany, J.; De Paco, J.; Miguel, J.; Nutting, J. Characterization of the W2C phase formed during the high velocity oxygen fuel spraying of a WC+ 12 pct Co powder. Metall. Mater. Trans. A 1999, 30, 1913–1921. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Y.; Ding, X.; Wang, S.; Ramachandran, C.S. Effect of WC Grain Size and Abrasive Type on the Wear Performance of HVOF-Sprayed WC-20Cr(3)C(2)-7Ni Coatings. Coatings 2020, 10, 660. [Google Scholar] [CrossRef]

| Kerosene (L/h) | Oxygen (m3/h) | Feed Rate (g/min) | Spraying Distance (mm) | Velocity (mm/s) |

|---|---|---|---|---|

| 22.7 | 55.2 | 75 | 380 | 500 |

| Coating | Porosity (%) | Defect Density (%) |

|---|---|---|

| BC | 0.85 ± 0.11 | 1.04 ± 0.17 |

| CeC | 0.23 ± 0.04 | 2.06 ± 0.37 |

| Coating | Hardness (HV0.3) | Fracture Toughness (MPam1/2) |

|---|---|---|

| BC | 1223 ± 27 | 6.19 ± 0.14 |

| CeC | 1230 ± 13 | 5.77 ± 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Wang, Q.; Tian, Y.; Yang, C.; Yuan, C.; Ramachandran, C.S. Microstructure and Wear Performance of CeO2-Modified Micro-Nano Structured WC-CoCr Coatings Sprayed with HVOF. Lubricants 2023, 11, 188. https://doi.org/10.3390/lubricants11050188

Ding X, Wang Q, Tian Y, Yang C, Yuan C, Ramachandran CS. Microstructure and Wear Performance of CeO2-Modified Micro-Nano Structured WC-CoCr Coatings Sprayed with HVOF. Lubricants. 2023; 11(5):188. https://doi.org/10.3390/lubricants11050188

Chicago/Turabian StyleDing, Xiang, Qun Wang, Yinghao Tian, Changchun Yang, Chengqing Yuan, and Chidambaram Seshadri Ramachandran. 2023. "Microstructure and Wear Performance of CeO2-Modified Micro-Nano Structured WC-CoCr Coatings Sprayed with HVOF" Lubricants 11, no. 5: 188. https://doi.org/10.3390/lubricants11050188

APA StyleDing, X., Wang, Q., Tian, Y., Yang, C., Yuan, C., & Ramachandran, C. S. (2023). Microstructure and Wear Performance of CeO2-Modified Micro-Nano Structured WC-CoCr Coatings Sprayed with HVOF. Lubricants, 11(5), 188. https://doi.org/10.3390/lubricants11050188