On the Wear Behavior of Bush Drive Chains: Part I—Characterization of Engine Damage Processes and Development of a Model Test Setup for Pin Wear

Abstract

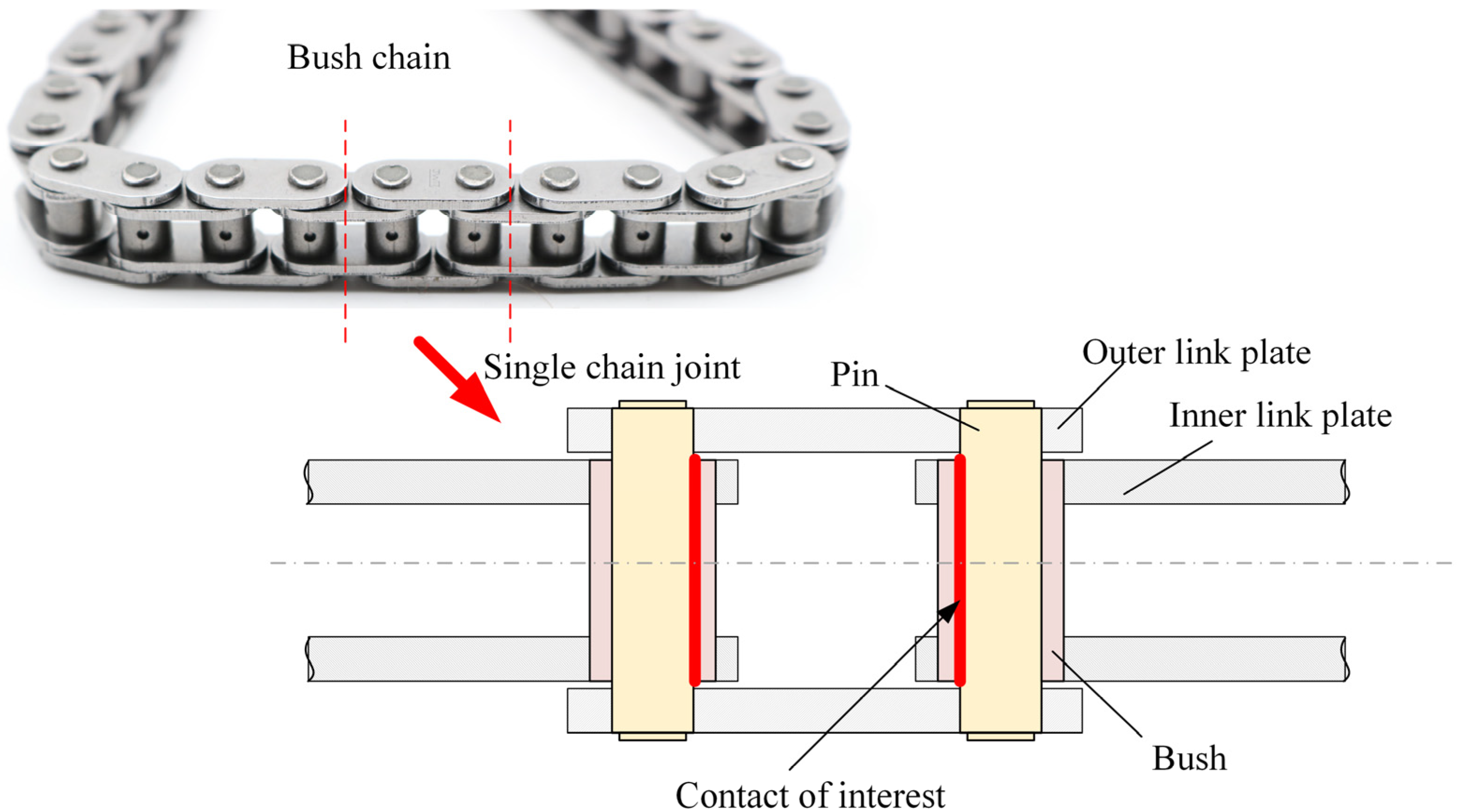

1. Introduction

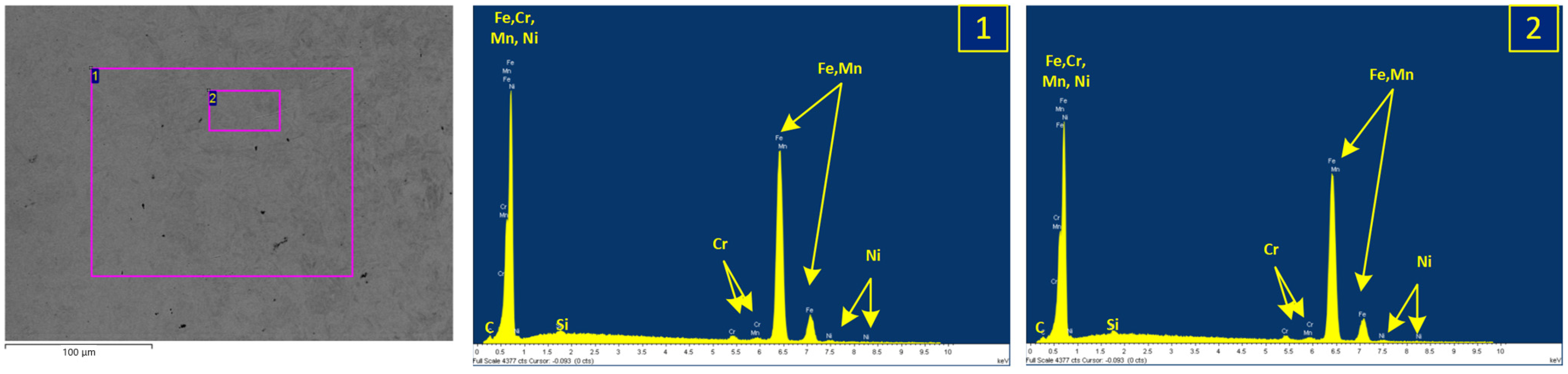

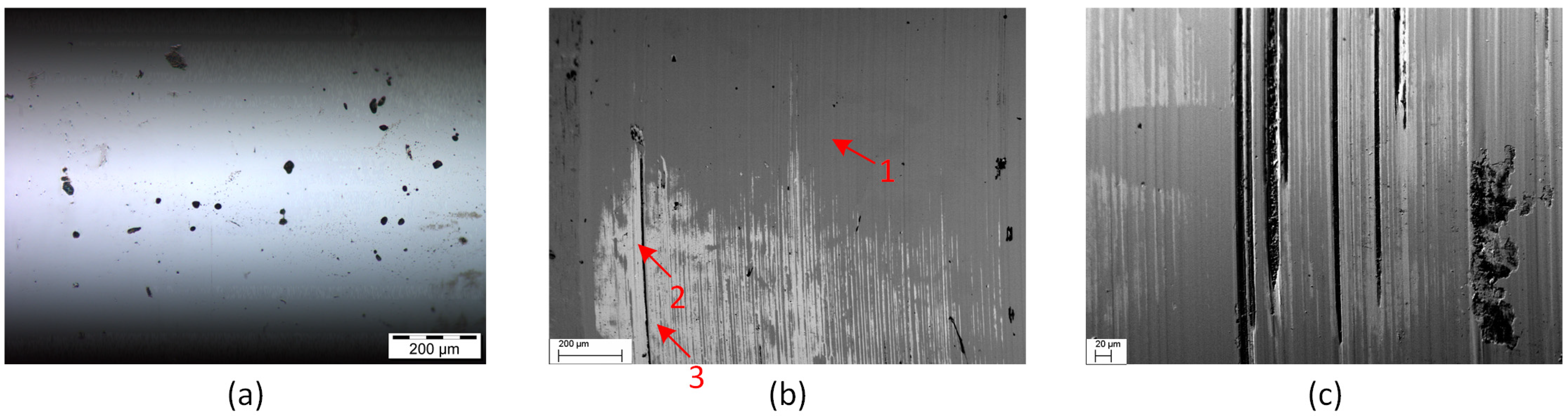

2. Analysis of Engine Parts

3. Experimental Method

3.1. Approach

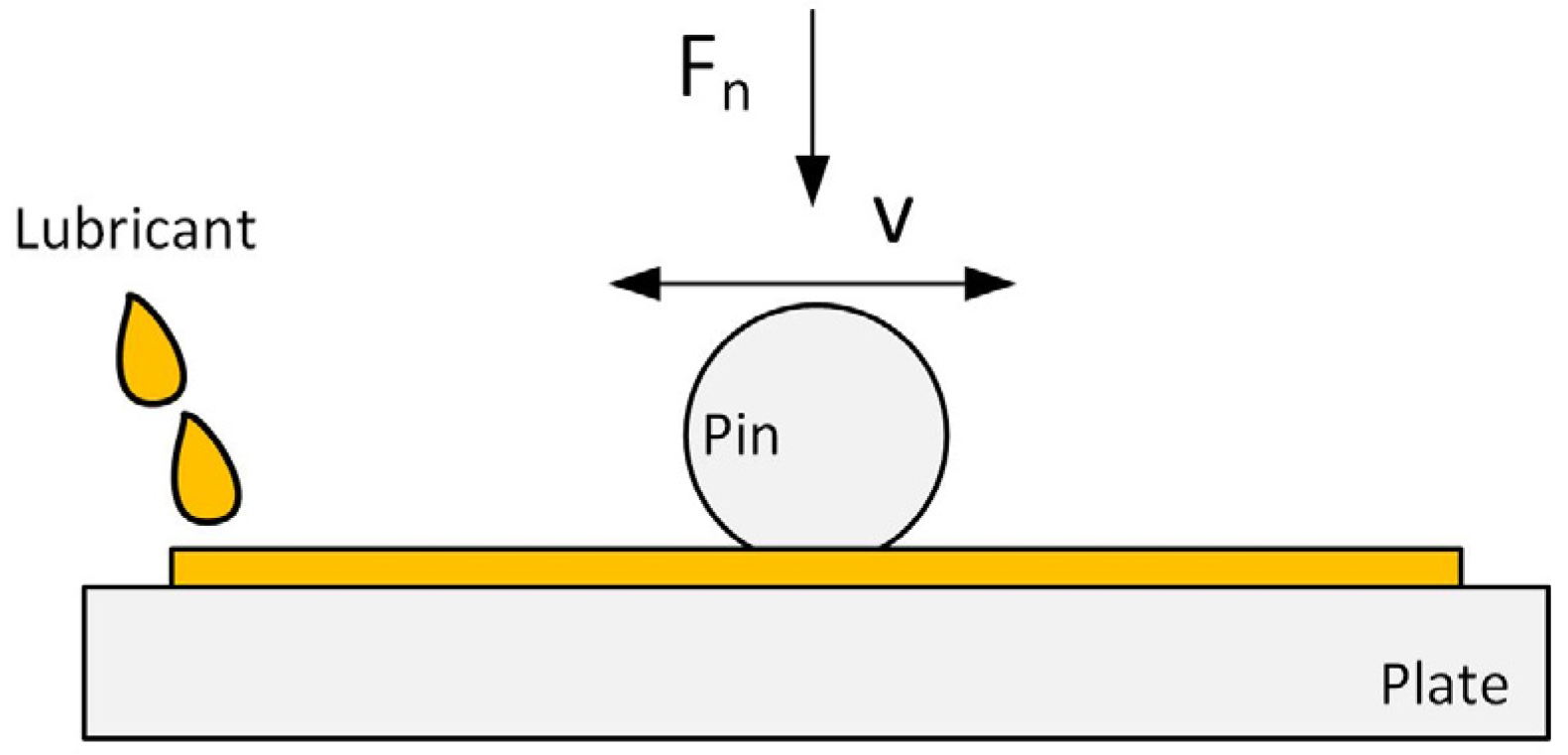

3.2. Test Rig and Setup Developed

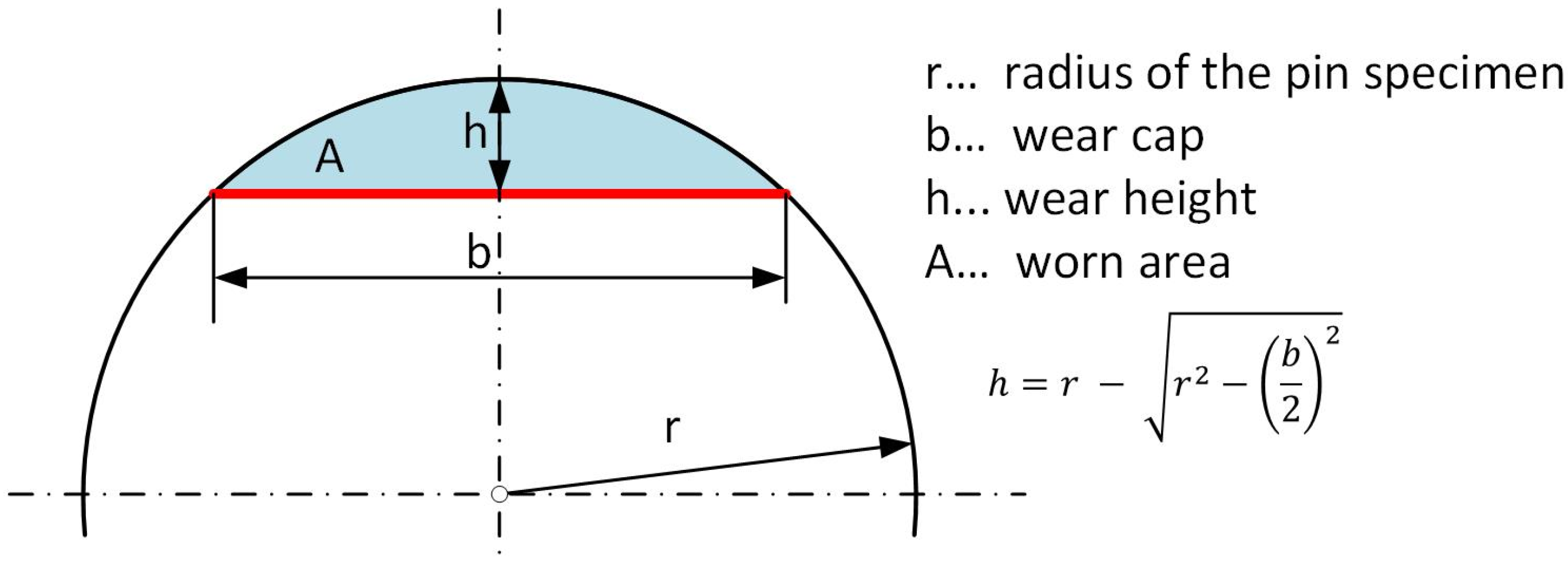

3.3. Wear Evaluation

3.4. Test Strategy

4. Experimental Test Results

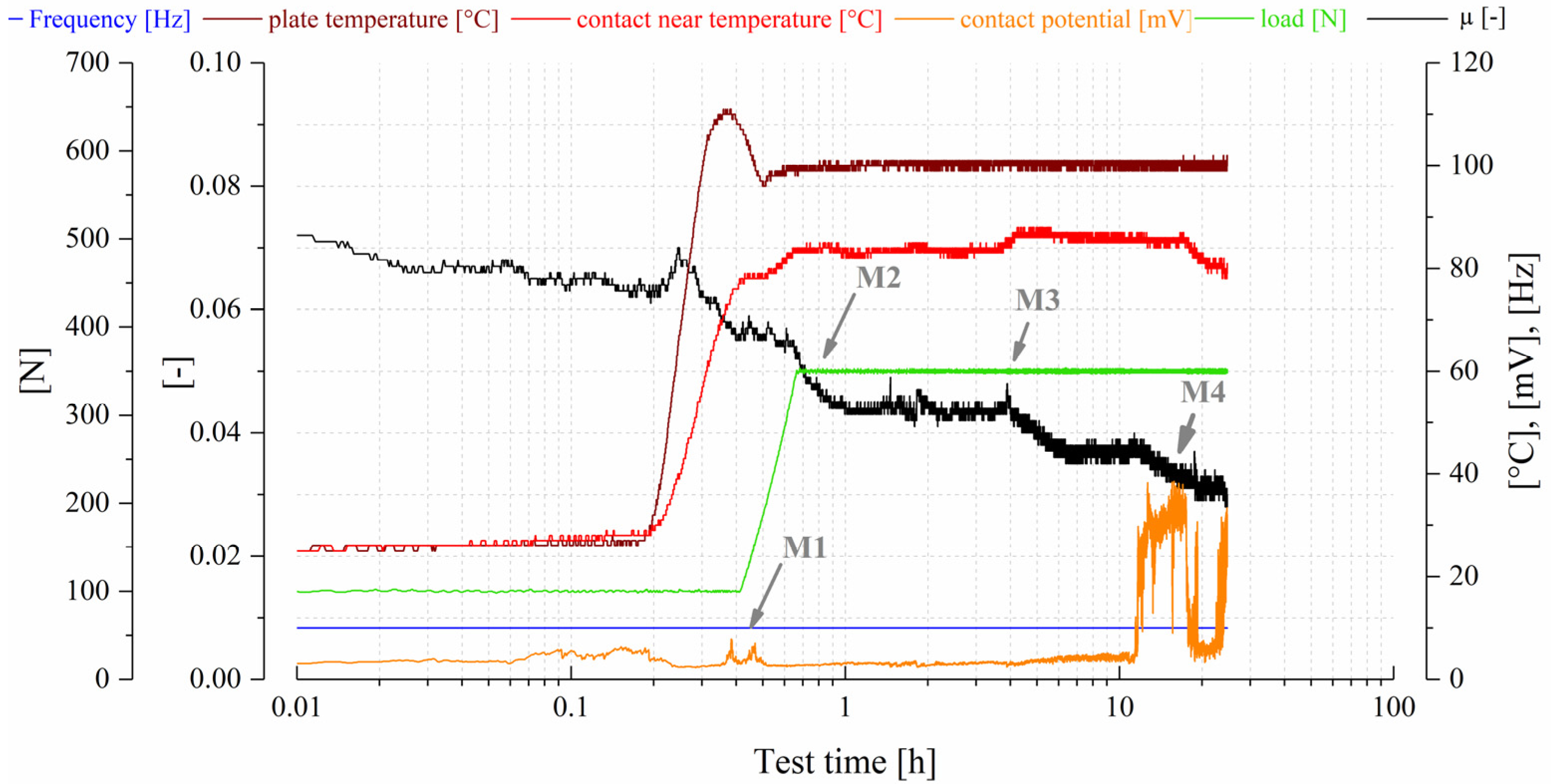

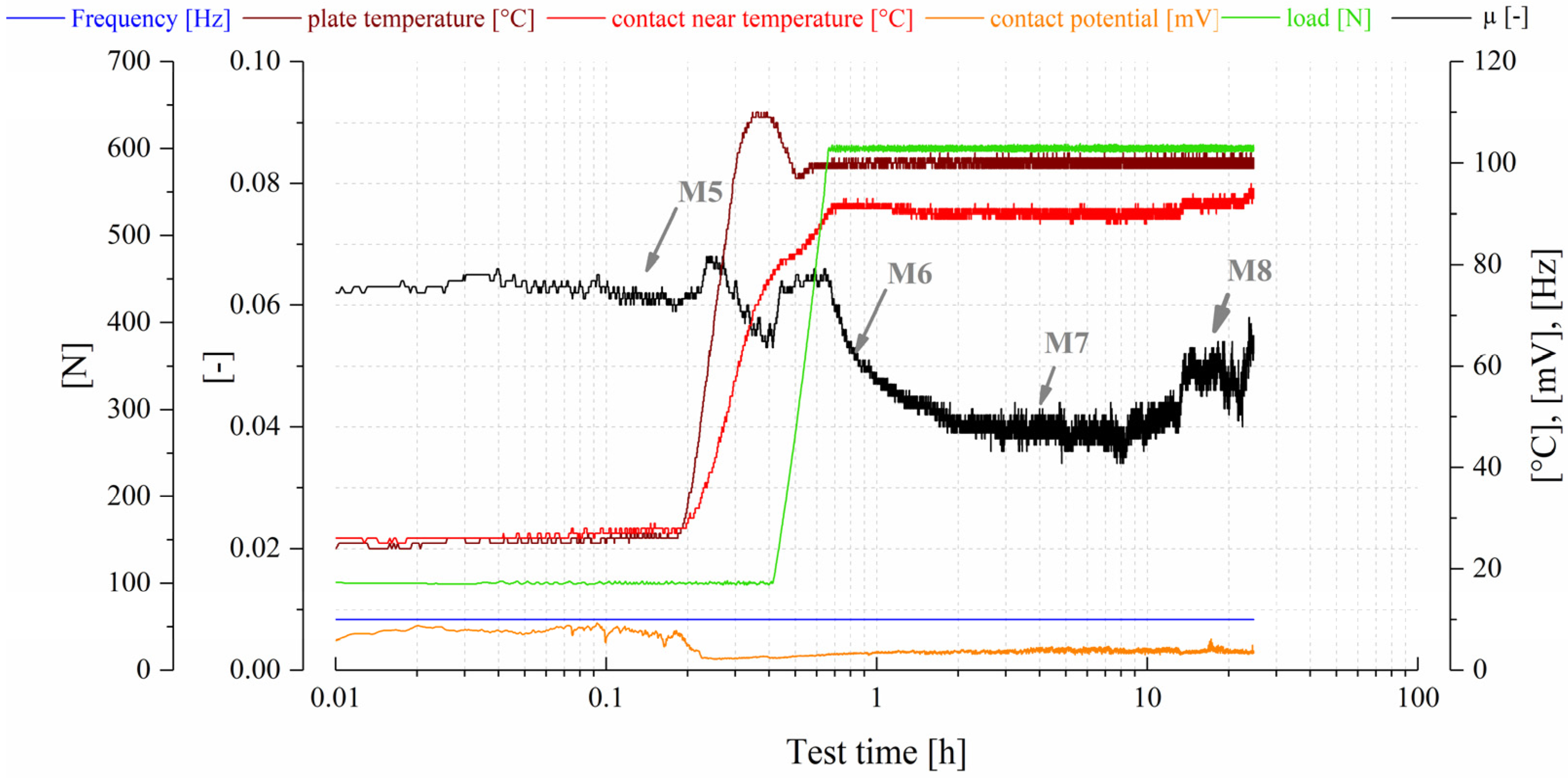

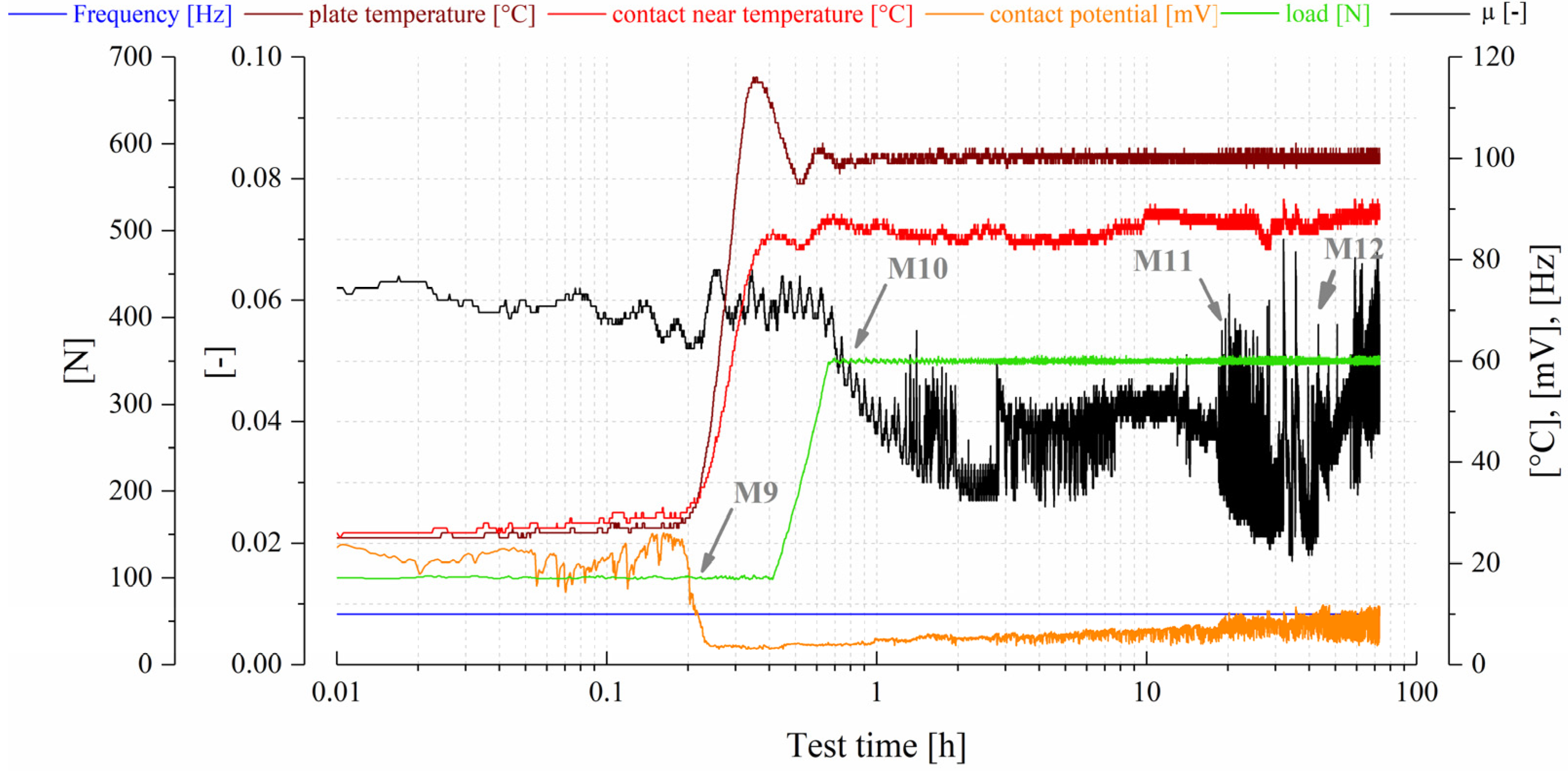

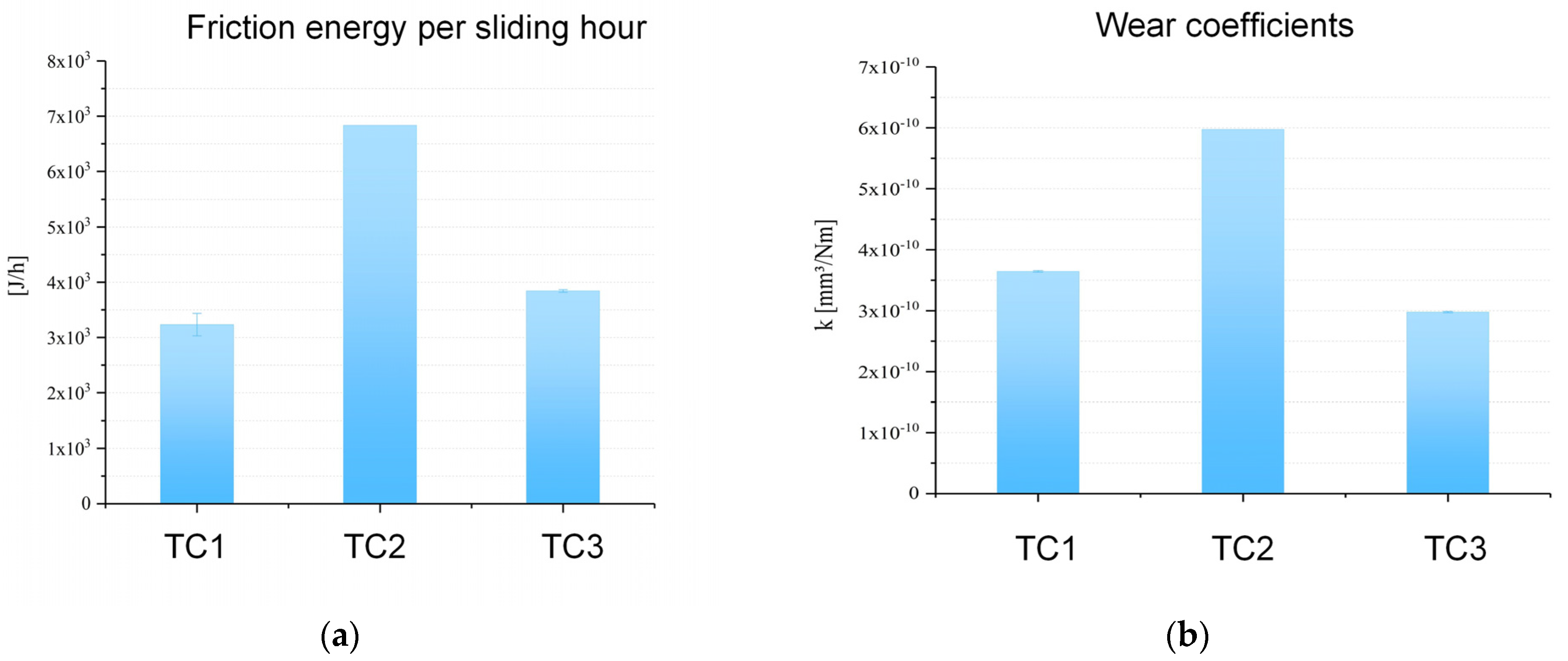

4.1. Tribometric Data

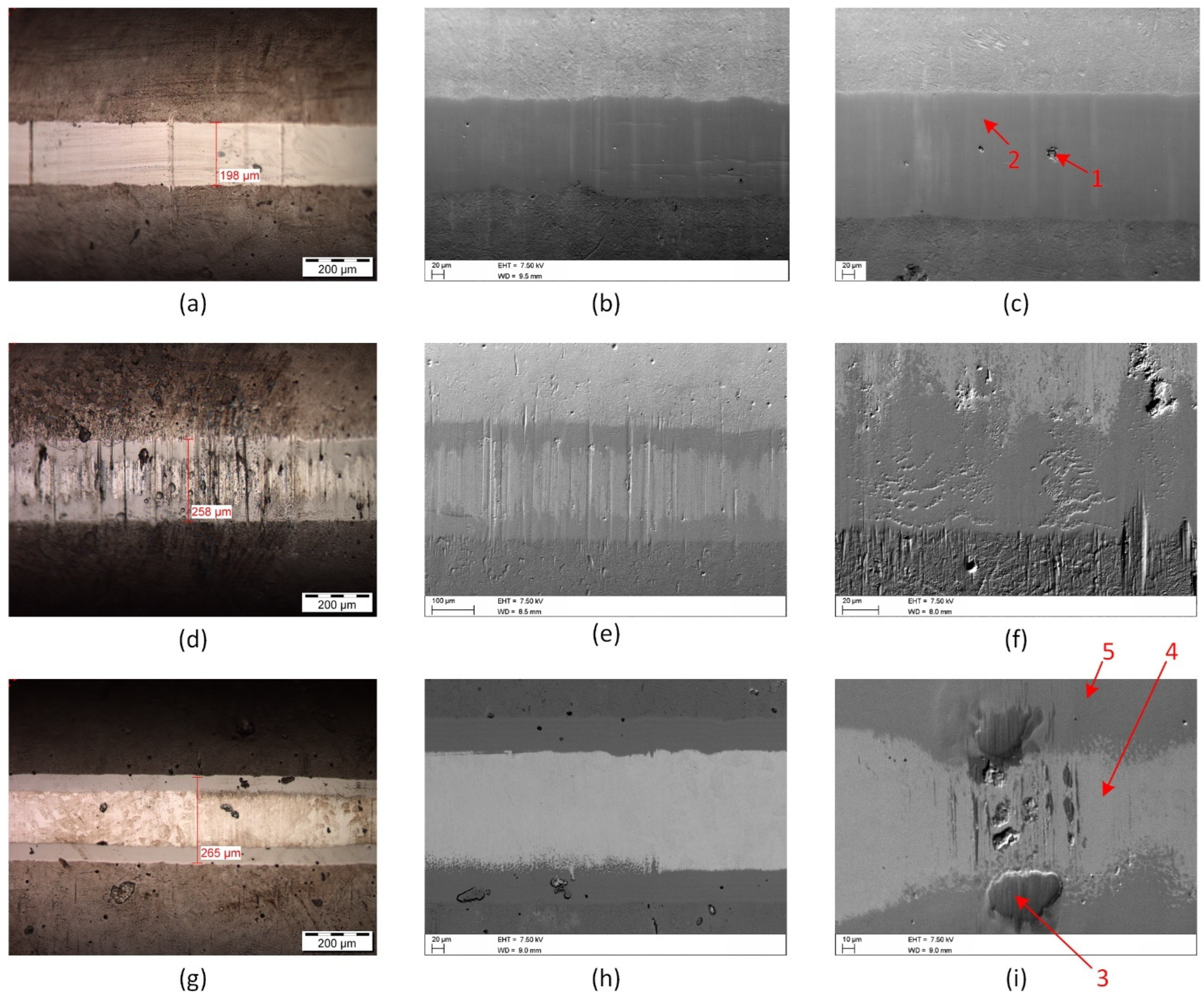

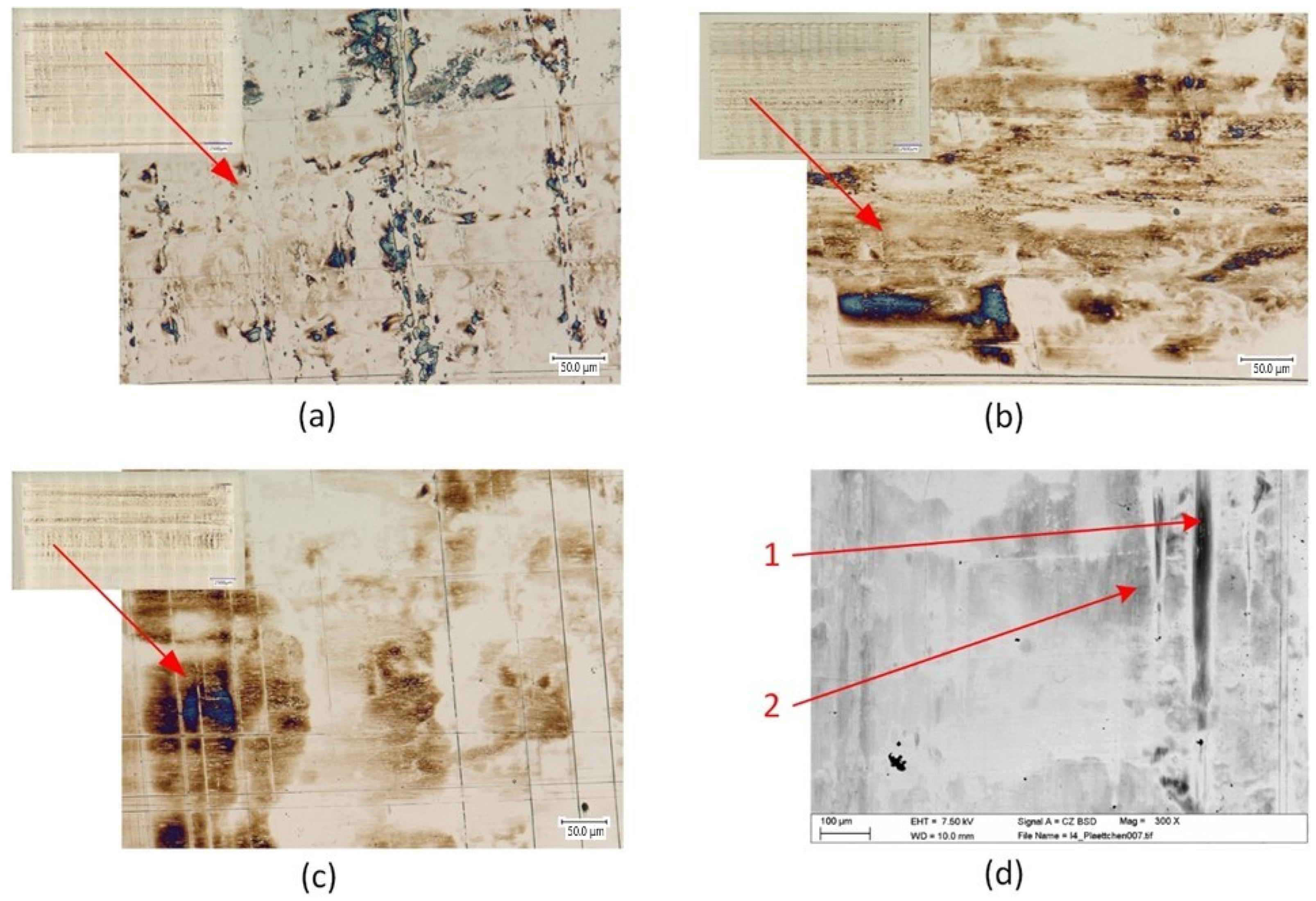

4.2. Damage Analysis of Test Parts

5. Discussion

6. Conclusions

- Although the contact conditions were different to the real engine conditions, similar tribological processes and damage phenomena were observed when comparing engine parts and the model test specimen, thus proving the legitimacy of the developed tester.

- Considering the conversion calculations for the normal loading between application and model setup, a large area chain pin wear can be produced at model scale. In this context, the wear processes for the pin/bush contact between a CrN steel shell surface and a flat steel mating surface can be resolved under mixed friction conditions. First, mirror polished CrN contact areas were observed for pin surfaces with an intact CrN coating sliding against the hardened steel, similarly to that seen for moderate wear conditions of the engine parts. In an advanced wear state, which was also similar between the engine condition and model tester, CrN coating break-outs, an exposed Fe substrate, and abrasive grooves prevailed on the pin surface. At model scale, these conditions led to an extraordinary wear of the steel plate counterpart. This agreed with observations of the engine components, where high chain link elongations were documented for such conditions. On the Fe-based steel plates, anti-wear additive layers including P, S, and Zn species were measured after test ended; whereby, in contrast, on the mating CrN surfaces, as well as on the exposed Fe substrate material of the pin, they were not found.

- A friction coefficient in the range between 0.05 and 0.03 was measured for the sliding system using a CrN coated steel pin against a hardened steel plate and an automotive fully formulated engine oil. In this regard, the COF trends were strongly connected with running processes and the state of wear, meaning that for the CrN coating after the test had ended, the corresponding COF values were 0.03, and for tests with exposed Fe substrates, the COF re-increased at test completion towards 0.06 and become more unstable. For higher loads, the coefficient of friction was in a similar range to the moderate load level, thus increased loading resulted in a significantly higher dissipated friction energy.

- Higher loadings not only increased the dissipated friction energy but also the wear (e.g., moderate load plate wear: 0.4/0.6 mg vs. high load plate wear: 15 mg) of the various wear evolution parameters, such as the linear wear intensity or wear coefficients according to Archard’s approach (pin wear comparison, see Figure 17b). For longer test durations, the wear coefficient was slightly lower, presumably due to the different pressure situation with an increased wear cap.

- Classification of the friction and wear processes according to Fleischer’s method was also performed and showed the good agreement of the present tribological system using a model test system for chain pins according to this approach. Thus, the tested systems provided an apparent friction energy density in the range of 2.5 × 107 and linear wear intensities between 1.9 × 10−10 and 9.4 × 10−11, which fall within mixed friction sliding conditions and moderate wear processes of mild wear, with deformation effect but no thermal energy accumulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taylor, C. Automobile engine tribology—Design considerations for efficiency and durability. Wear 1998, 221, 1–8. [Google Scholar] [CrossRef]

- Tung, S.; McMillan, M. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- van Basshuysen, R.; Schäfer, F. (Eds.) Handbuch Verbrennungsmotor: Grundlagen, Komponenten, Systeme, Perspektiven, 8th ed.; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Fink, T.; Hirschmann, V. Kettentriebe für den Einsatz in modernen Verbrennungsmotoren. MTZ Motortech Z 2001, 62, 796–806. [Google Scholar] [CrossRef]

- Fink, T.; Bodenstein, H. Möglichkeiten der Reibungsreduktion in Kettentrieben. MTZ Motortech Z 2011, 72, 582–587. [Google Scholar] [CrossRef]

- Belmer, S.; Fink, T.; Lorenz, I. Neukirchner, Steuertriebefür Verbrennungsmotoren. MTZ Motortech Z 2005, 66, 466–475. [Google Scholar] [CrossRef]

- Bozyazı, E.; Ürgen, M.; Çakır, A. Comparison of reciprocating wear behaviour of electrolytic hard chrome and arc-PVD CrN coatings. Wear 2004, 256, 832–839. [Google Scholar] [CrossRef]

- Tandler, R.; Bohn, N.; Gabbert, U.; Woschke, E. Experimental investigations of the internal friction in automotive bush chain drive systems. Tribol. Int. 2019, 140, 105871. [Google Scholar] [CrossRef]

- Meffert, D.; Oehler, M.; Sauer, B. Precise Friction Measurement in Drive Chains Using a Chain Joint Tribometer. Tribol. Online 2021, 16, 151–158. [Google Scholar] [CrossRef]

- Sappok, D.; Sauer, B. Wear Measurement on Chain Joint Components Using a Roundness Instrument. Period. Polytech. Mech. Eng. 2015, 59, 51–59. [Google Scholar] [CrossRef]

- Sappok, D.; Merz, R.; Sauer, B.; Kopnarski, M.; Dienwiebel, M. Surface Analysis of Chain Joint Components after Tribological Load and Usage of Antiwear Additives. Conf. Pap. Sci. 2015, 2015, 407048. [Google Scholar] [CrossRef]

- Thongjitr, P.; Ninpetch, P.; Kowitwarangkul, P. Wear resistance improvement of the roller chain parts at Thai Metro Industry (1973) Co., Ltd. Mater. Today Proc. 2018, 5, 9431–9439. [Google Scholar] [CrossRef]

- Tandler, R.; Bohn, N.; Gabbert, U.; Woschke, E. Analytical wear model and its application for the wear simulation in automotive bush chain drive systems. Wear 2020, 446–447, 203193. [Google Scholar] [CrossRef]

- Ferreira, R.; Carvalho, Ó.; Sobral, L.; Carvalho, S.; Silva, F. Influence of morphology and microstructure on the tribological behavior of arc deposited CrN coatings for the automotive industry. Surf. Coat. Technol. 2020, 397, 126047. [Google Scholar] [CrossRef]

- Tung, S.; Gao, H. Tribological characteristics and surface interaction between piston ring coatings and a blend of energy-conserving oils and ethanol fuels. Wear 2003, 255, 1276–1285. [Google Scholar] [CrossRef]

- Laxane, R.; Bhide, R.; Patil, A.; Sane, S. Characterisation of chromium nitride physical vapour deposition coating on diesel engine pistons. Surf. Eng. 2006, 22, 78–80. [Google Scholar] [CrossRef]

- Wan, S.; Li, D.; Zhang, G.; Tieu, A.; Zhang, B. Comparison of the scuffing behaviour and wear resistance of candidate engineered coatings for automotive piston rings. Tribol. Int. 2017, 106, 10–22. [Google Scholar] [CrossRef]

- Li, D.; Kong, N.; Zhang, B.; Zhang, B.; Li, R.; Zhang, Q. Comparative study on the effects of oil viscosity on typical coatings for automotive engine components under simulated lubrication conditions. Diam. Relat. Mater. 2021, 112, 108226. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.; Moore, J.; Lee, S.; Myers, S. High rate deposition of thick CrN and Cr2N coatings using modulated pulse power (MPP) magnetron sputtering. Surf. Coat. Technol. 2011, 205, 3226–3234. [Google Scholar] [CrossRef]

- Olomolehin, Y.; Kapadia, R.; Spikes, H. Antagonistic Interaction of Antiwear Additives and Carbon Black. Tribol. Lett. 2009, 37, 49. [Google Scholar] [CrossRef]

- Kontou, A.; Southby, M.; Morgan, N.; Spikes, H. Influence of Dispersant and ZDDP on Soot Wear. Tribol. Lett. 2018, 66, 157. [Google Scholar] [CrossRef]

- Kontou, A.; Southby, M.; Spikes, H. Effect of steel hardness on soot wear. Wear 2017, 390–391, 236–245. [Google Scholar] [CrossRef]

- Salehi, F.M.; Morina, A.; Neville, A. Zinc Dialkyldithiophosphate Additive Adsorption on Carbon Black Particles. Tribol. Lett. 2018, 66, 5488. [Google Scholar] [CrossRef]

- Salehi, F.M.; Morina, A.; Neville, A. The effect of soot and diesel contamination on wear and friction of engine oil pump. Tribol. Int. 2017, 115, 285–296. [Google Scholar] [CrossRef]

- Magyar, B.; Thielen, S.; Foko, F.F.; Becker, A.; Sauer, B. EHL Simulation of the Timing Chain Drive. In Proceedings of the 6th World Tribology Congress (WTC), Beijing, China, 17–22 September 2017. [Google Scholar]

- Kunz, J. Kontaktprobleme und ihre praktische Lösung. Konstruktion 2009, 11, 54–58. [Google Scholar]

- Moder, J.; Grün, F.; Summer, F.; Kohlhauser, M.; Wohlfahrt, M. Application of high performance composite polymers with steel counterparts in dry rolling/sliding contacts. Polym. Test. 2018, 66, 371–382. [Google Scholar] [CrossRef]

- Schiffer, J.; Gódor, I.; Grün, F.; Eichlseder, W. A Model Scale Test Method for the Piston Ring—Cylinder Liner Tribosystem of Internal Combustion Engines. Arch. Mech. Eng. 2010, 57, 211. [Google Scholar] [CrossRef]

- Pusterhofer, M.; Summer, F.; Wuketich, D.; Grün, F. Development of a Model Test System for a Piston Ring/Cylinder Liner-Contact with Focus on Near-to-Application Seizure Behaviour. Lubricants 2019, 7, 104. [Google Scholar] [CrossRef]

- Archard, J.; Hirst, W. The wear of metals under unlubricated conditions, Proceedings of the Royal Society of London. Series A. Math. Phys. Sci. 1956, 236, 397–410. [Google Scholar] [CrossRef]

- Fleischer, G. Energetische Methode der Bestimmung des Verschleißes. Schmierungstechnik 1993, 269–274. [Google Scholar]

| Indentation Depth (nm) | Modulus (GPa) | Hardness (GPa) | |

|---|---|---|---|

| Bush | 1000 | 232.8 ± 8.5 | 7.2 ± 0.28 |

| Pin (CrN coating) | 100 | 285.0 ± 25.2 | 22.7 ± 1.2 |

| Pin (substrate) | 1000 | 238.3 ± 5 | 7.74 ± 0.26 |

| Pin (substrate) | 100 | 247.6 ± 11.8 | 9.8 ± 0.75 |

| Spectrum | C | N | O | Cr | Fe |

|---|---|---|---|---|---|

| 1 | - | 48.2 | 2.8 | 49.1 | - |

| 2 | 8.7 | - | 3.3 | - | 88.0 |

| 3 | 11.3 | - | 3.1 | - | 85.7 |

| Spectrum | C | O | P | S | Ca | Fe | Zn |

|---|---|---|---|---|---|---|---|

| 1 | 14.6 | 19.7 | 2.4 | 1.2 | 3.3 | 57.7 | 1.2 |

| 2 | 14.4 | 2.6 | - | - | - | 83.0 | - |

| 3 | 13.9 | 2.1 | - | - | - | 84.1 | - |

| 4 | 76.2 | 19.5 | 0.2 | 1.5 | 0.5 | 1.6 | 0.4 |

| Abbreviation | Test Time (h) | Load Level during Phase E (N) | |

|---|---|---|---|

| Test category 1 | TC 1 | 25 | 350 |

| Test category 2 | TC 2 | 25 | 600 |

| Test category 3 | TC 3 | 73 | 350 |

| Spectrum | C | N | O | Si | P | S | Ca | Cr | Fe | Zn |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 15.33 | - | 4.55 | 0.55 | - | - | - | 4.41 | 75.16 | - |

| 2 | - | 47.65 | - | - | - | - | - | 52.35 | - | - |

| 3 | 4.90 | - | 60.86 | - | 9.73 | 1.46 | 7.58 | - | 12.6 | 2.87 |

| 4 | 9.04 | - | - | - | - | - | - | - | 90.96 | - |

| 5 | - | 49.34 | - | - | - | - | - | 50.66 | - | - |

| Spectrum | C | O | P | S | Ca | Fe | Zn |

|---|---|---|---|---|---|---|---|

| 1 | 4.8 | 34.4 | 5.8 | 1.0 | 5.8 | 46.1 | 2.0 |

| 2 | 4.8 | 21.2 | 1.7 | 0.6 | 2.3 | 68.8 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Summer, F.; Bergmann, P.; Grün, F. On the Wear Behavior of Bush Drive Chains: Part I—Characterization of Engine Damage Processes and Development of a Model Test Setup for Pin Wear. Lubricants 2023, 11, 85. https://doi.org/10.3390/lubricants11020085

Summer F, Bergmann P, Grün F. On the Wear Behavior of Bush Drive Chains: Part I—Characterization of Engine Damage Processes and Development of a Model Test Setup for Pin Wear. Lubricants. 2023; 11(2):85. https://doi.org/10.3390/lubricants11020085

Chicago/Turabian StyleSummer, Florian, Philipp Bergmann, and Florian Grün. 2023. "On the Wear Behavior of Bush Drive Chains: Part I—Characterization of Engine Damage Processes and Development of a Model Test Setup for Pin Wear" Lubricants 11, no. 2: 85. https://doi.org/10.3390/lubricants11020085

APA StyleSummer, F., Bergmann, P., & Grün, F. (2023). On the Wear Behavior of Bush Drive Chains: Part I—Characterization of Engine Damage Processes and Development of a Model Test Setup for Pin Wear. Lubricants, 11(2), 85. https://doi.org/10.3390/lubricants11020085