Investigation on Surface Integrity in Hard Turning of AISI 4140 Steel with SPPP-AlTiSiN Coated Carbide Insert under Nano-MQL

Abstract

1. Introduction

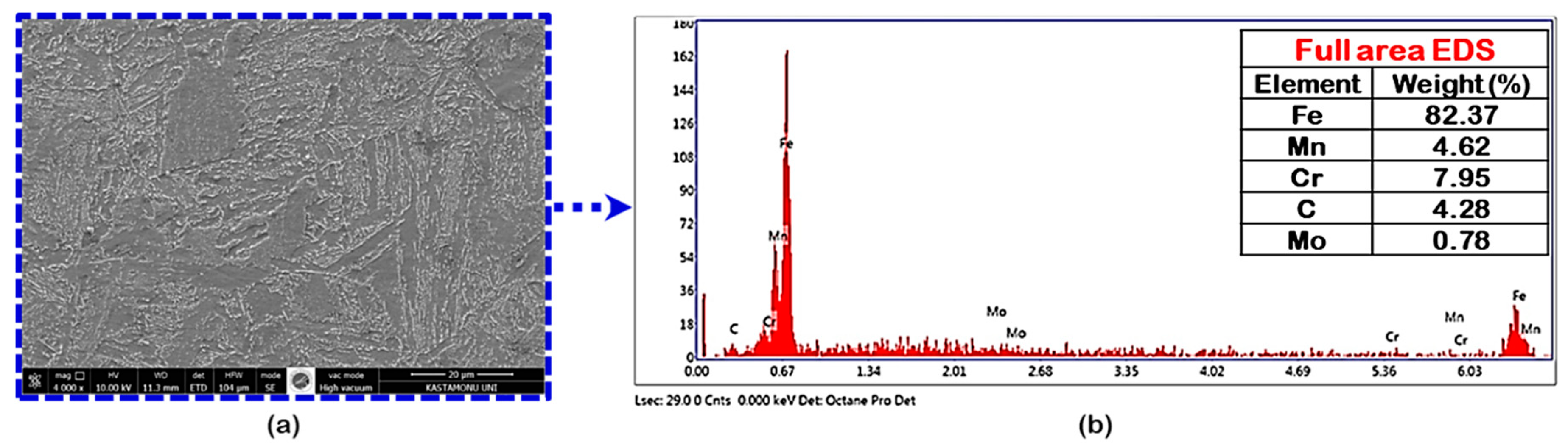

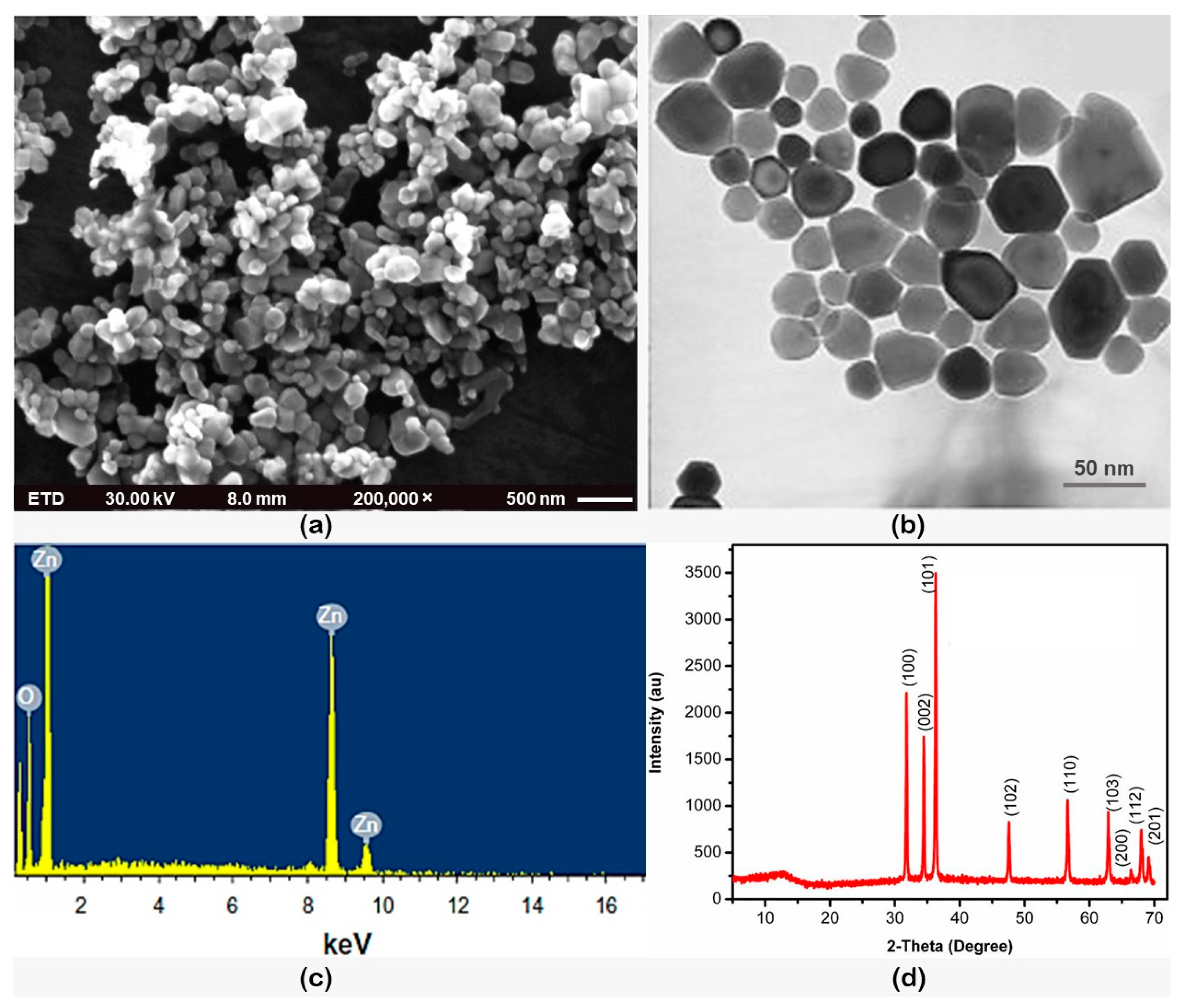

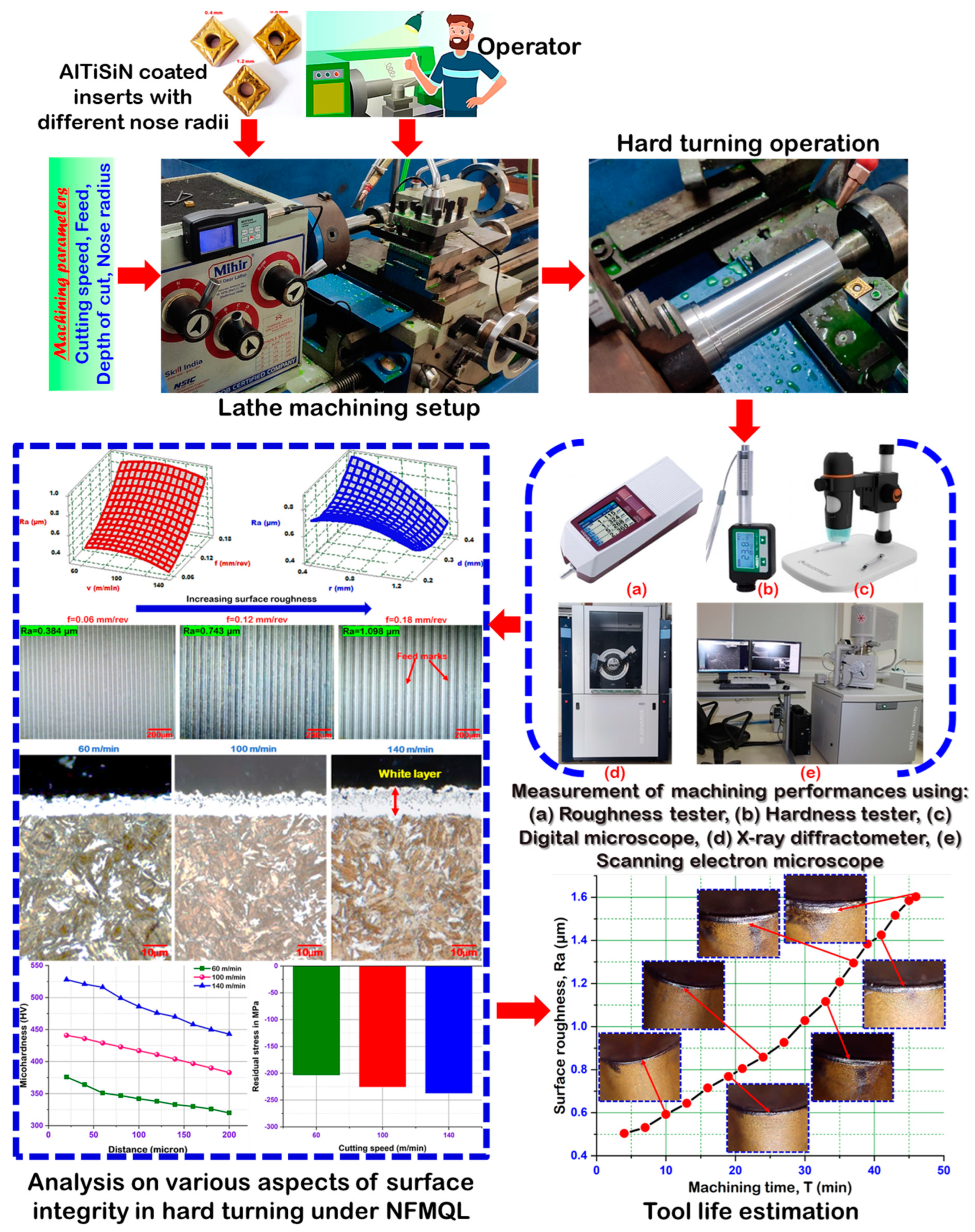

2. Experimental Setup and Procedure

3. Results and Discussion

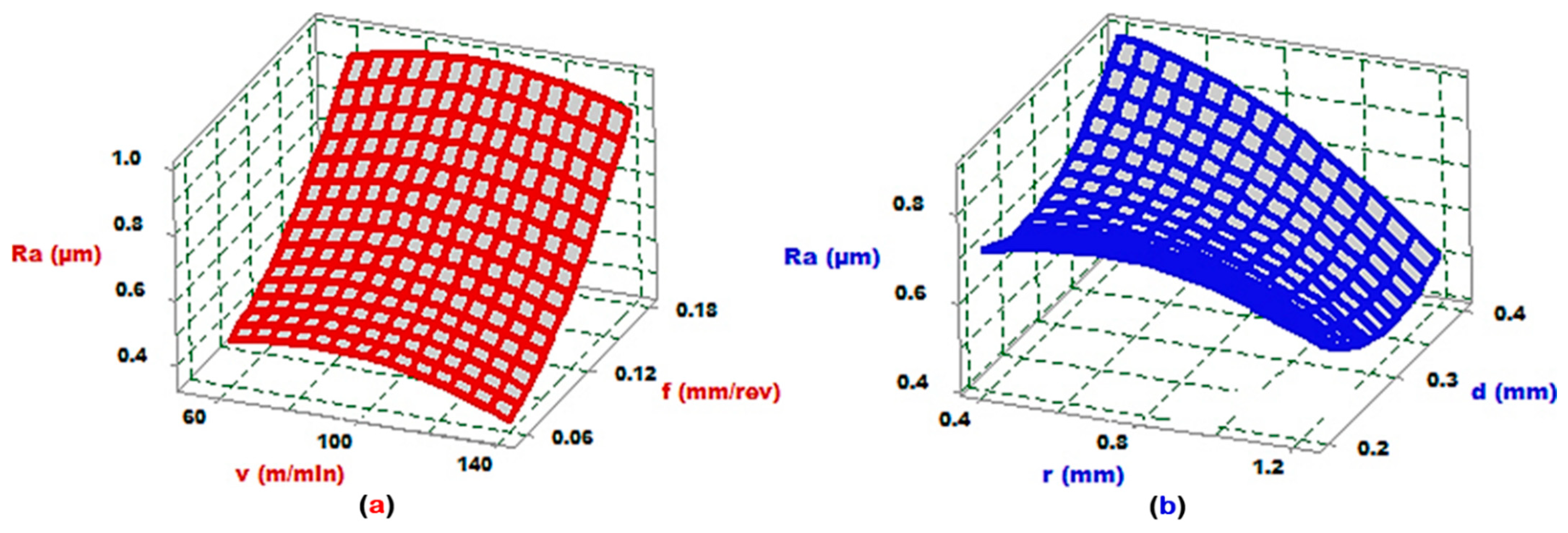

3.1. Model Prediction Using the Response Surface Method

R-sq = 97.50%, R-sq (adj.) = 95.17%

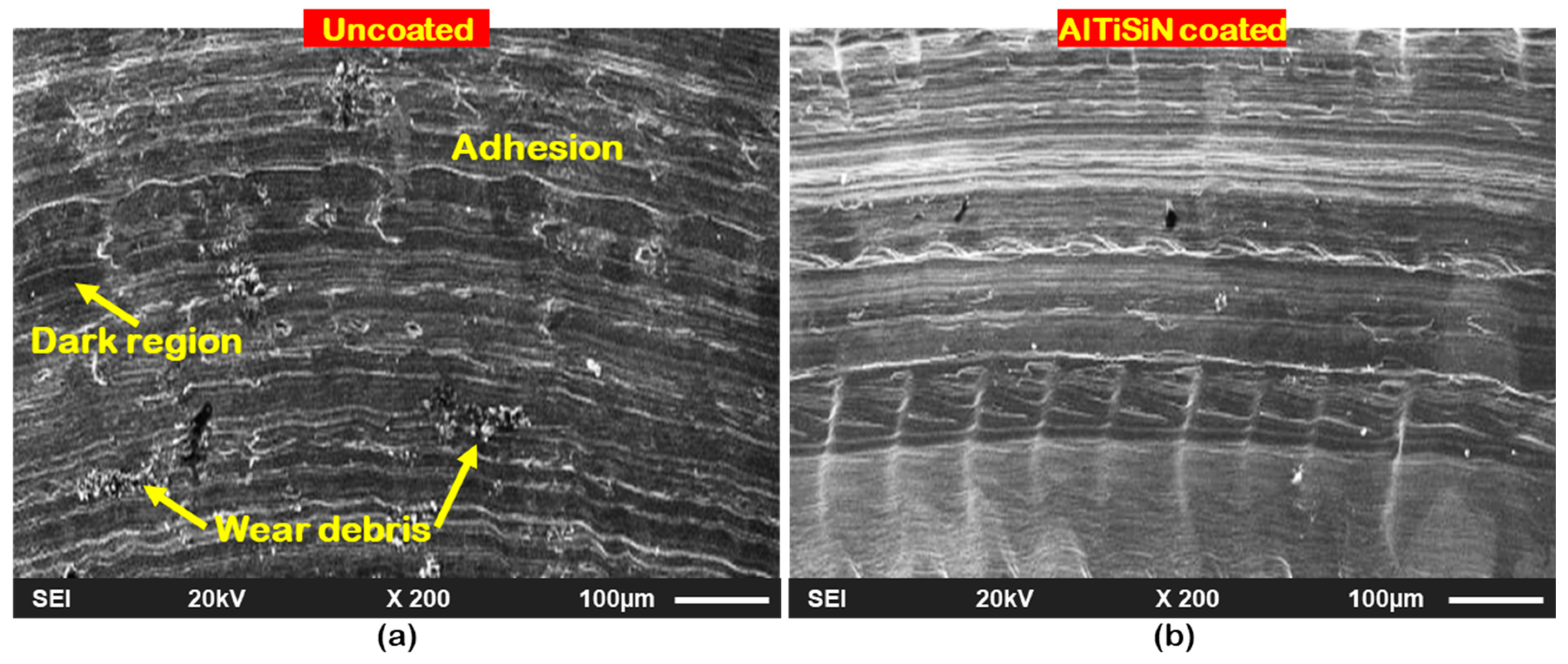

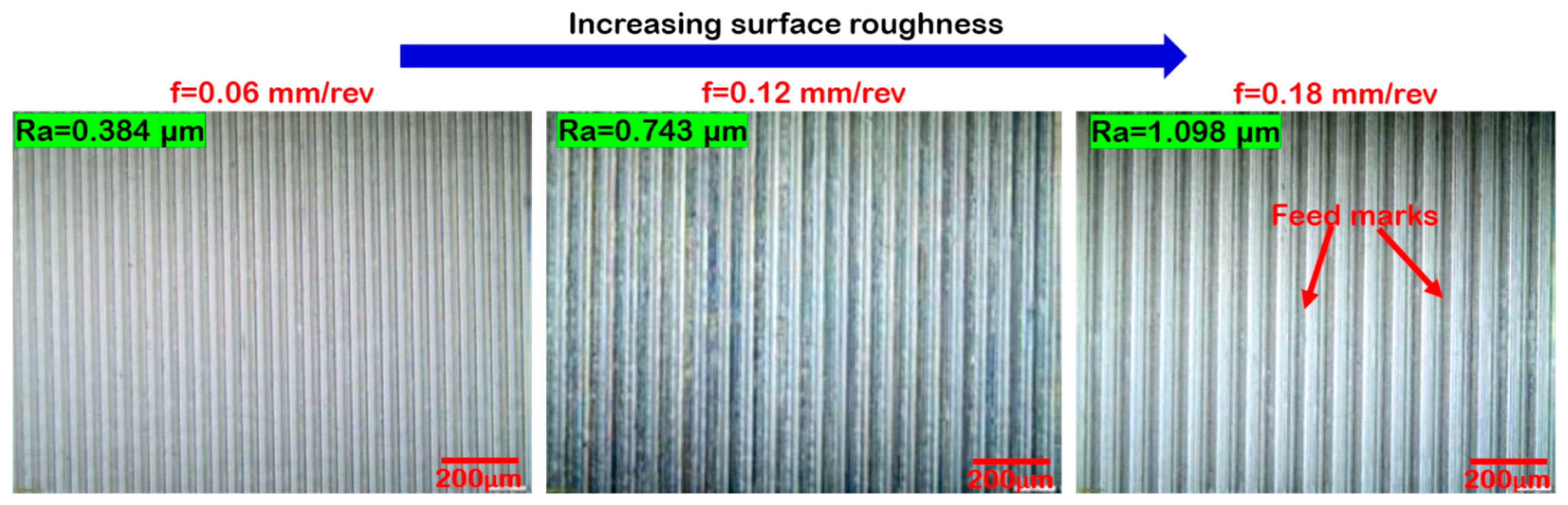

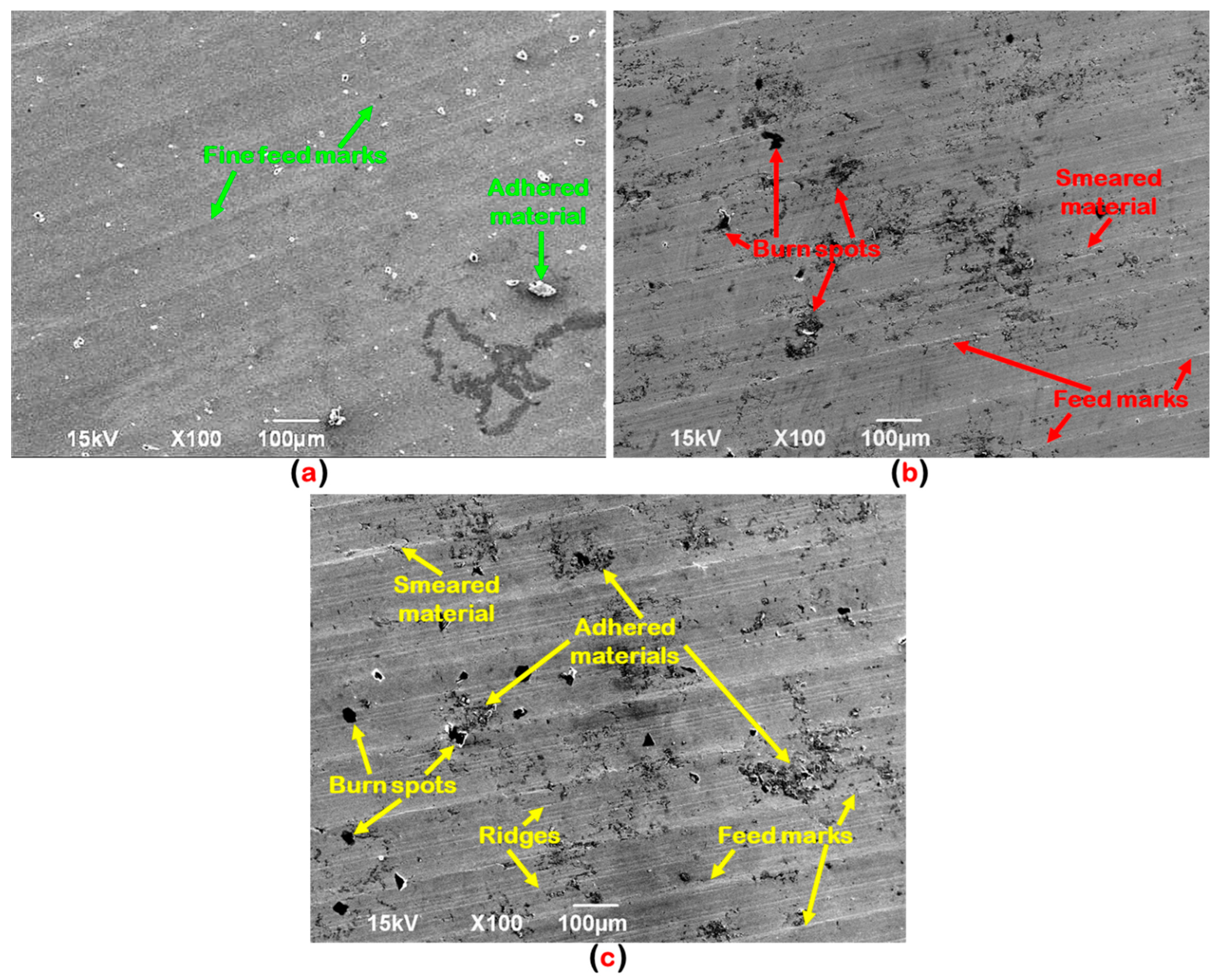

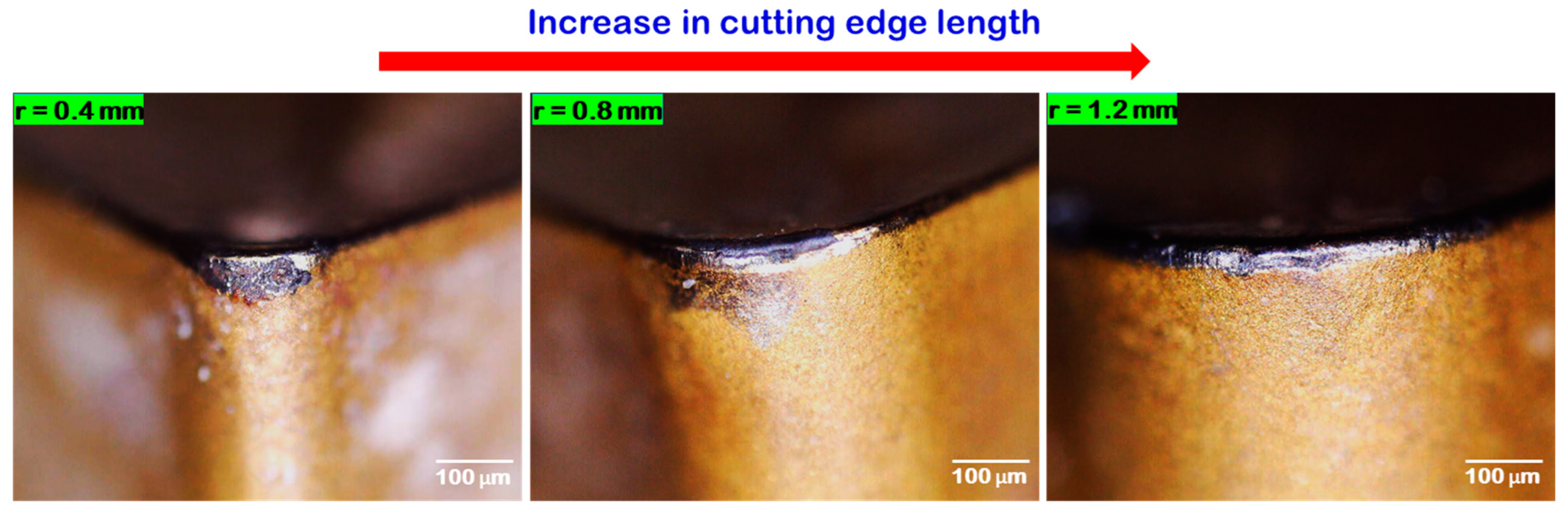

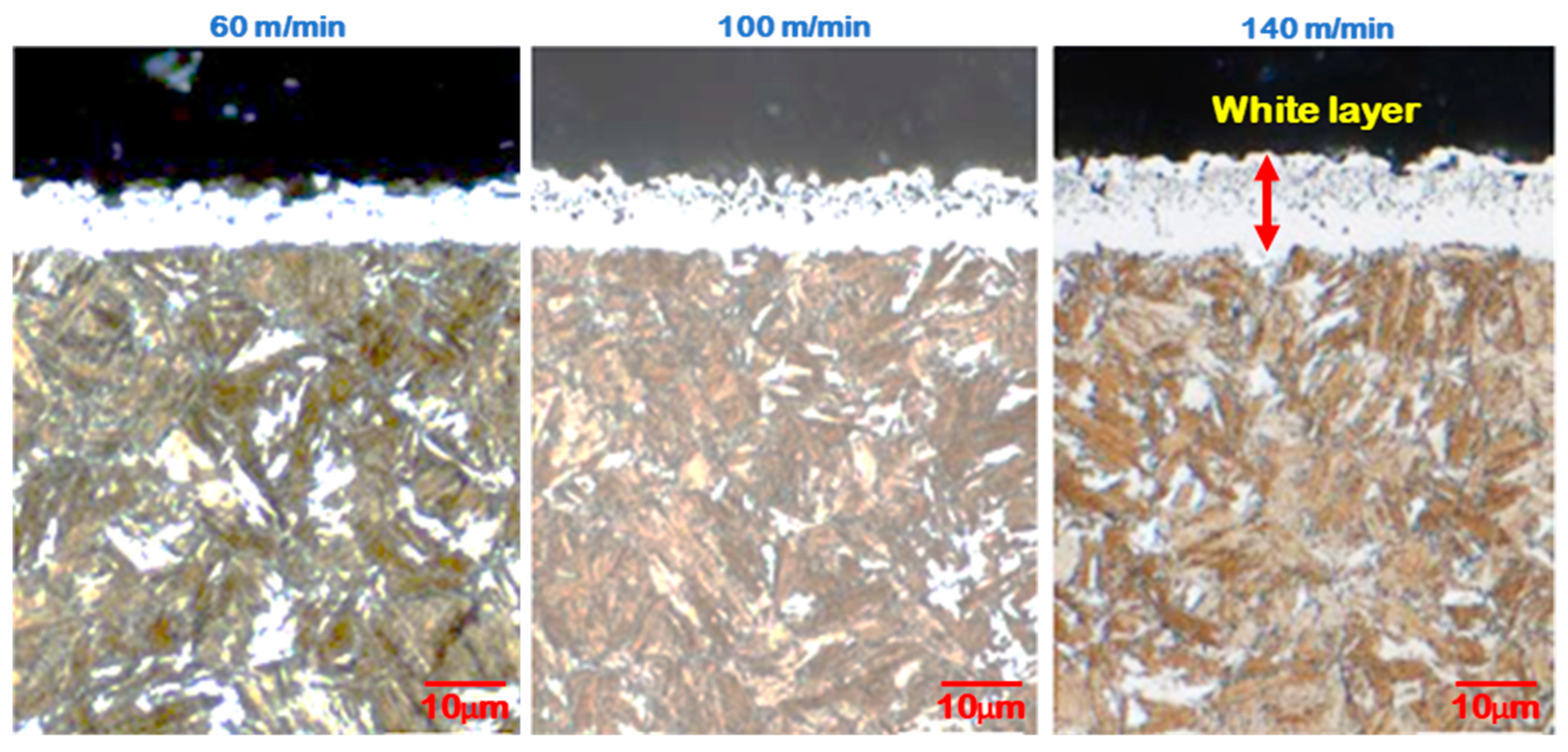

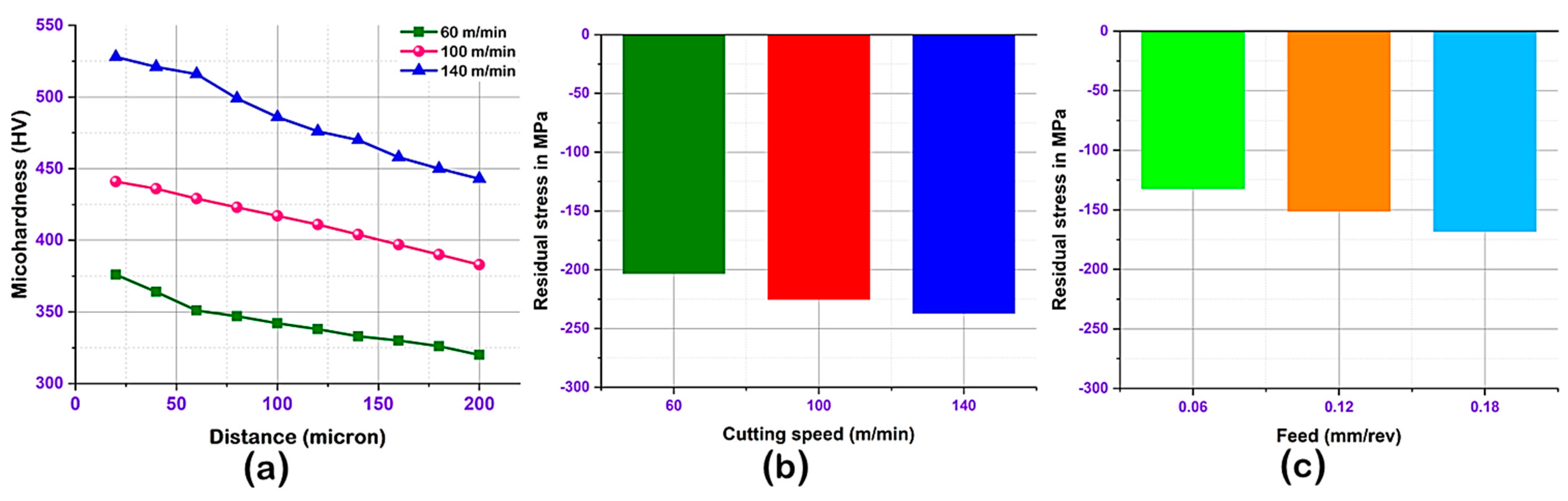

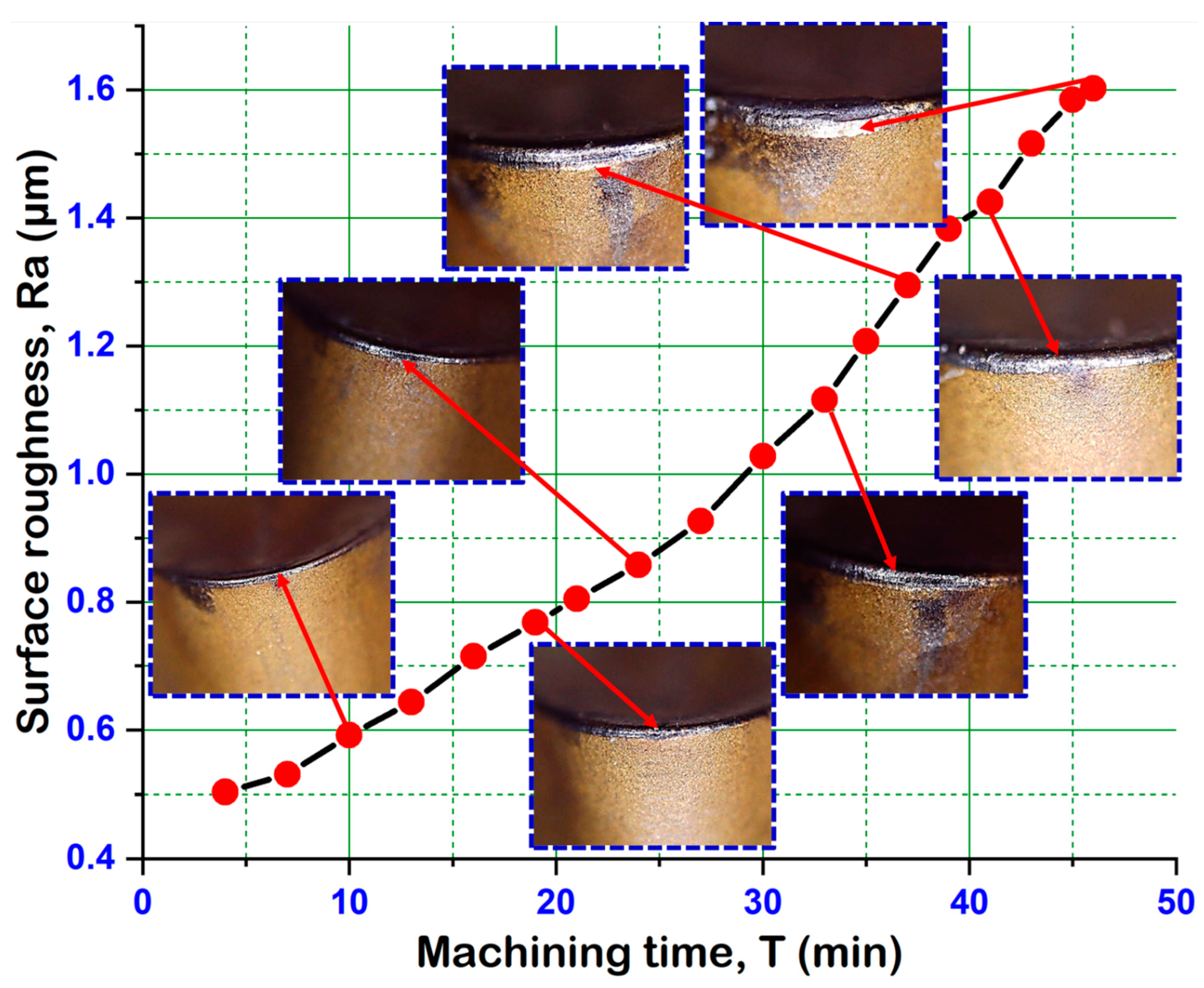

3.2. Analysis on the Surface Integrity

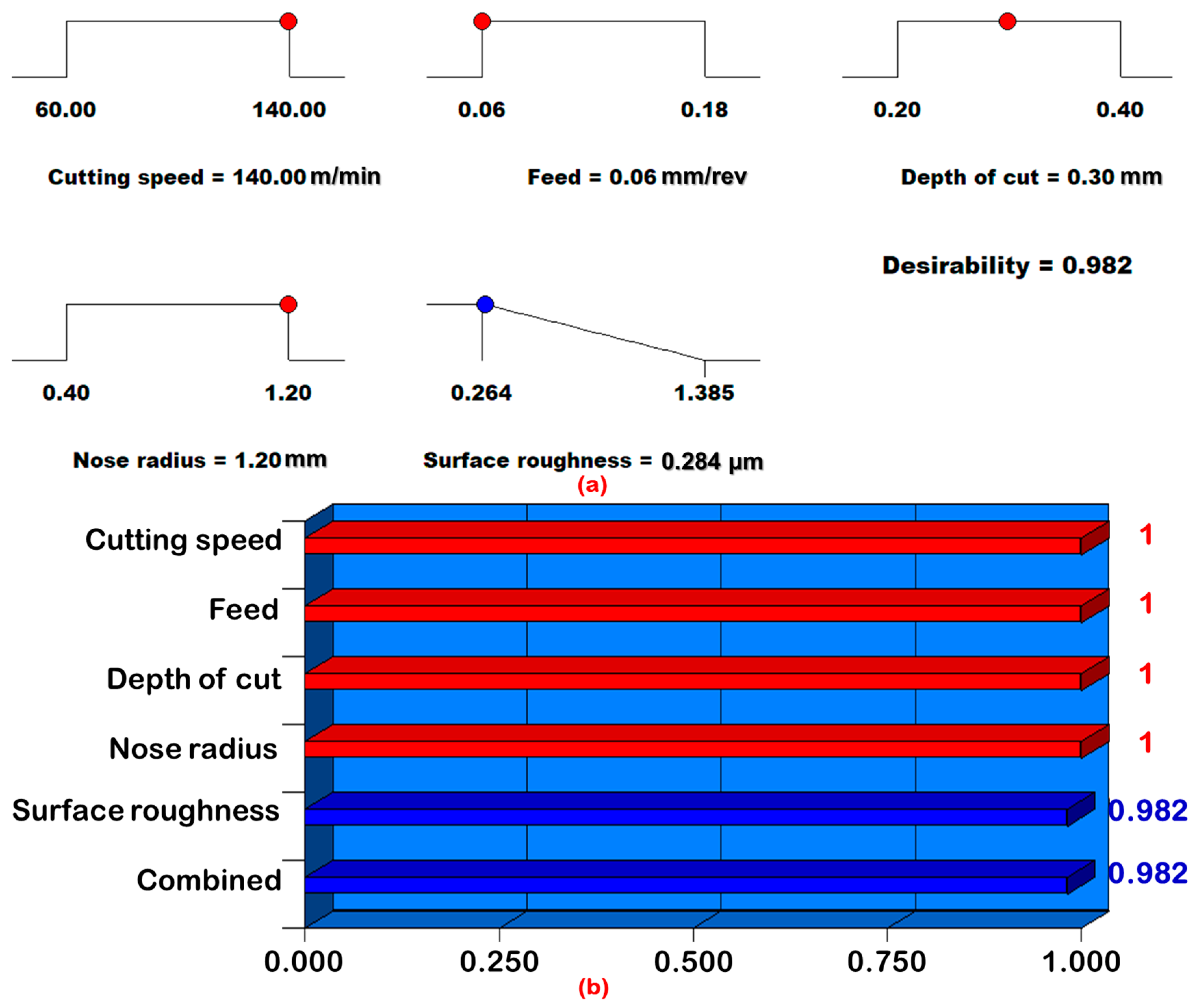

3.3. Optimization Using the RSM

3.4. Cost Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Das, S.R.; Dhupal, D.; Kumar, A. Experimental Investigation into Machinability of Hardened AISI 4140 Steel Using TiN Coated Ceramic Tool. Meas. J. Int. Meas. Confed. 2015, 62, 108–126. [Google Scholar] [CrossRef]

- Liew, P.J.; Shaaroni, A.; Sidik, N.A.C.; Yan, J. An Overview of Current Status of Cutting Fluids and Cooling Techniques of Turning Hard Steel. Int. J. Heat Mass Transf. 2017, 114, 380–394. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental Friendly Cutting Fluids and Cooling Techniques in Machining: A Review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Naigade, D.M.; Patil, D.H.; Sadaiah, M. Some Investigations in Hard Turning of AISI 4340 Alloy Steel in Different Cutting Environments by CBN Insert. Int. J. Mach. Mach. Mater. 2013, 14, 165–173. [Google Scholar] [CrossRef]

- Sahu, S.K.; Mishra, P.C.; Orra, K.; Sahoo, A.K. Performance Assessment in Hard Turning of AISI 1015 Steel under Spray Impingement Cooling and Dry Environment. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 251–265. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S.K. Hard Turning Using HiPIMS-Coated Carbide Tools: Wear Behavior under Dry and Minimum Quantity Lubrication (MQL). Meas. J. Int. Meas. Confed. 2014, 55, 536–548. [Google Scholar] [CrossRef]

- Sharma, P.; Sidhu, B.S.; Sharma, J. Investigation of Effects of Nanofluids on Turning of AISI D2 Steel Using Minimum Quantity Lubrication. J. Clean. Prod. 2015, 108, 72–79. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Optimization of Surface Roughness and Cutting Temperature in High-Pressure Coolant-Assisted Hard Turning Using Taguchi Method. Int. J. Adv. Manuf. Technol. 2017, 88, 739–753. [Google Scholar] [CrossRef]

- Abbas, A.T.; Benyahia, F.; El Rayes, M.M.; Pruncu, C.; Taha, M.A.; Hegab, H. Towards Optimization of Machining Performance and Sustainability Aspects When Turning AISI 1045 Steel under Different Cooling and Lubrication Strategies. Materials 2019, 12, 3023. [Google Scholar] [CrossRef]

- Elbah, M.; Laouici, H.; Benlahmidi, S.; Nouioua, M.; Yallese, M. Comparative Assessment of Machining Environments (Dry, Wet and MQL) in Hard Turning of AISI 4140 Steel with CC6050 Tools. Int. J. Adv. Manuf. Technol. 2019, 105, 2581–2597. [Google Scholar] [CrossRef]

- Masoudi, S.; Esfahani, M.J.; Jafarian, F.; Mirsoleimani, S.A. Comparison the Effect of MQL, Wet and Dry Turning on Surface Topography, Cylindricity Tolerance and Sustainability. Int. J. Precis. Eng. Manuf.-Green Technol. 2019. [Google Scholar] [CrossRef]

- Das, A.; Das, S.R.; Patel, S.K.; Biswal, B.B. Effect of MQL and Nanofluid on the Machinability Aspects of Hardened Alloy Steel. Mach. Sci. Technol. 2020, 24, 291–320. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.K.; Biswal, B.B.; Sahoo, N.; Pradhan, A. Performance Evaluation of Various Cutting Fluids Using MQL Technique in Hard Turning of AISI 4340 Alloy Steel. Measurement 2020, 150, 107079. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Jamil, M.; Singh, R.; Singla, A.K.; Song, Q.; Liu, Z.; Khan, A.M.; Rahman, M.A.; Sarikaya, M. Machinability Investigations of Hardened Steel with Biodegradable Oil-Based MQL Spray System. Int. J. Adv. Manuf. Technol. 2020, 108, 735–748. [Google Scholar] [CrossRef]

- Öndin, O.; Kıvak, T.; Sarıkaya, M.; Yıldırım, Ç.V. Investigation of the Influence of MWCNTs Mixed Nanofluid on the Machinability Characteristics of PH 13-8 Mo Stainless Steel. Tribol. Int. 2020, 148, 106323. [Google Scholar] [CrossRef]

- Królczyk, G.M.; Maruda, R.W.; Królczyk, J.B.; Wojciechowski, S.; Mia, M.; Niesłony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Maruda, R.W.; Legutko, S.; Krolczyk, G.M.; Hloch, S.; Michalski, M. An influence of active additives on the formation of selected indicators of the condition of the X10CrNi18-8 stainless steel surface layer in MQCL conditions. Int. J. Surf. Sci. Eng. 2015, 9, 452–465. [Google Scholar] [CrossRef]

- Shah, P.; Khanna, N.; Zadafiya, K.; Bhalodiya, M.; Maruda, R.W.; Krolczyk, G.M. In-house development of eco-friendly lubrication techniques (EMQL, Nanoparticles+EMQL and EL) for improving machining performance of 15–5 PHSS. Tribol. Int. 2020, 151, 106476. [Google Scholar] [CrossRef]

- Sankaranarayanan, R.; Rajesh Jesudoss Hynes, N.; Senthil Kumar, J.; Krolczyk, G.M. A comprehensive review on research developments of vegetable-oil based cutting fluids for sustainable machining challenges. J. Manuf. Process. 2021, 67, 286–313. [Google Scholar]

- Kumar, R.; Sahoo, A.K.; Mishra, P.C.; Das, R.K. Comparative Investigation towards Machinability Improvement in Hard Turning Using Coated and Uncoated Carbide Inserts: Part I Experimental Investigation. Adv. Manuf. 2018, 6, 52–70. [Google Scholar] [CrossRef]

- Goindi, G.S.; Sarkar, P. Dry Machining: A Step towards Sustainable Machining—Challenges and Future Directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G. Recent Advances in Turning Processes Using Coated Tools—A Comprehensive Review. Metals 2020, 10, 170. [Google Scholar] [CrossRef]

- Mondal, K.; Das, S. An Investigation on Machinability during Turning Hardened Steel in Dry Condition. J. Inst. Eng. Ser. C 2018, 99, 637–644. [Google Scholar] [CrossRef]

- Sargade, V.G.; Gangopadhyay, S.; Paul, S.; Chattopadhyay, A.K. Effect of Coating Thickness on the Characteristics and Dry Machining Performance of Tin Film Deposited on Cemented Carbide Inserts Using Cfubms. Mater. Manuf. Process. 2011, 26, 1028–10338. [Google Scholar] [CrossRef]

- Selvam, M.D.; Senthil, P. Investigation on the Effect of Turning Operation on Surface Roughness of Hardened C45 Carbon Steel. Aust. J. Mech. Eng. 2016, 14, 131–137. [Google Scholar] [CrossRef]

- Ginting, A.; Skein, R.; Cuaca, D.; Herdianto; Pieter; Masyithah, Z. The Characteristics of CVD- and PVD-Coated Carbide Tools in Hard Turning of AISI 4340. Meas. J. Int. Meas. Confed. 2018, 129, 548–557. [Google Scholar] [CrossRef]

- Kara, F.; Öztürk, B. Comparison and Optimization of PVD and CVD Method on Surface Roughness and Flank Wear in Hard-Machining of DIN 1.2738 Mold Steel. Sens. Rev. 2019, 39, 24–33. [Google Scholar] [CrossRef]

- Boing, D.; de Oliveira, A.J.; Schroeter, R.B. Evaluation of Wear Mechanisms of PVD and CVD Coatings Deposited on Cemented Carbide Substrates Applied to Hard Turning. Int. J. Adv. Manuf. Technol. 2020, 106, 5441–5451. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Kovalev, A.I.; Aguirre, M.H.; Beake, B.D.; Yamamoto, K.; Veldhuis, S.C.; Endrino, J.L.; Wainstein, D.L.; Rashkovskiy, A.Y. Design and Performance of AlTiN and TiAlCrN PVD Coatings for Machining of Hard to Cut Materials. Surf. Coat. Technol. 2009, 204, 489–496. [Google Scholar] [CrossRef]

- Bovas Herbert Bejaxhin, A.; Paulraj, G.; Jayaprakash, G.; Vijayan, V. Measurement of Roughness on Hardened D-3 Steel and Wear of Coated Tool Inserts. Trans. Inst. Meas. Control 2021, 43, 528–536. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S.K. Experimental Investigations to Optimise and Compare the Machining Performance of Different Coated Carbide Inserts during Turning Hardened Steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1104–1117. [Google Scholar] [CrossRef]

- Bhandarkar, L.R.; Behera, M.; Mohanty, P.P.; Sarangi, S.K. Experimental Investigation and Multi-Objective Optimization of Process Parameters during Machining of AISI 52100 Using High Performance Coated Tools. Meas. J. Int. Meas. Confed. 2021, 172, 108842. [Google Scholar] [CrossRef]

- Das, A.; Mohapatra, S.; Gajrani, K.K.; Das, S.R.; Patel, S.K. Comparative Performance Evaluation between HSN2-TiAlxN and TiCN Coated Carbide Tools in Hard Turning of AISI D6 Steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022. [Google Scholar] [CrossRef]

- Das, A.; Kamal, M.; Das, S.R.; Patel, S.K.; Panda, A.; Rafighi, M.; Biswal, B.B. Comparative Assessment between AlTiN and AlTiSiN Coated Carbide Tools towards Machinability Improvement of AISI D6 Steel in Dry Hard Turning. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 3174–3197. [Google Scholar] [CrossRef]

- Das, A.; Das, S.R.; Panda, A.; Patel, S.K. Experimental Investigation into Machinability of Hardened AISI D6 Steel Using Newly Developed AlTiSiN Coated Carbide Tools under Sustainable Finish Dry Hard Turning. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 1889–1905. [Google Scholar] [CrossRef]

- Mahapatra, S.; Das, A.; Jena, P.C.; Das, S.R. Turning of Hardened AISI H13 Steel with Recently Developed S3P-AlTiSiN Coated Carbide Tool Using MWCNT Mixed Nanofluid under Minimum Quantity Lubrication. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 095440622211263. [Google Scholar] [CrossRef]

- Sayuti, M.; Sarhan, A.A.D.; Salem, F. Novel uses of SiO2 nano-lubrication system in hard turning process of hardened steel AISI4140 for less tool wear, surface roughness and oil consumption. J. Clean. Prod. 2014, 67, 265–276. [Google Scholar] [CrossRef]

- Babu, M.N.; Anandan, V.; Parthasarathi, N.L.; Yildirim, C.V.; Babu, M.D.; Das, S.R. Performance analysis in turning of D3 tool steel using silver nanoplatelets as additives under MQL. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 591. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles, 2nd ed.; Oxford University Press: New York, NY, USA, 2005; pp. 558–559. [Google Scholar]

- Bouacha, K.; Terrab, A. Hard Turning Behavior Improvement Using NSGA-II and PSO-NN Hybrid Model. Int. J. Adv. Manuf. Technol. 2016, 86, 3527–3546. [Google Scholar] [CrossRef]

- Rafighi, M.; Özdemir, M.; Das, A.; Das, S.R. Machinability Investigation of Cryogenically Treated Hardened Aisi 4140 Alloy Steel Using Cbn Insert under Sustainable Finish Dry Hard Turning. Surf. Rev. Lett. 2022, 29, 2250047. [Google Scholar] [CrossRef]

- Keblouti, O.; Boulanouar, L.; Azizi, M.W.; Bouziane, A. Multi Response Optimization of Surface Roughness in Hard Turning with Coated Carbide Tool Based on Cutting Parameters and Tool Vibration. Struct. Eng. Mech. 2019, 70, 395–405. [Google Scholar]

- Das, A.; Padhan, S.; Das, S.R.; Alsoufi, M.S.; Ibrahim, A.M.M.; Elsheikh, A. Performance Assessment and Chip Morphology Evaluation of Austenitic Stainless Steel under Sustainable Machining Conditions. Metals 2021, 11, 1931. [Google Scholar] [CrossRef]

- Das, A.; Gupta, M.K.; Das, S.R.; Panda, A.; Patel, S.K.; Padhan, S. Hard Turning of AISI D6 Steel with Recently Developed HSN2-TiAlxN and Conventional TiCN Coated Carbide Tools: Comparative Machinability Investigation and Sustainability Assessment. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 138. [Google Scholar] [CrossRef]

- Das, A.; Gautam, A.; Panda, A.; Das, S.R.; Debnath, K.; Ramakrishna, C.; Patel, S.K. Comparative Performance Evaluation between Uncoated and TiAlN + AlCrN Coated Carbide Tools in Hard Turning of AISI H11 Steel. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022. [Google Scholar] [CrossRef]

- Dash, L.; Padhan, S.; Das, S.R. Experimental Investigations on Surface Integrity and Chip Morphology in Hard Tuning of AISI D3 Steel under Sustainable Nanofluid-Based Minimum Quantity Lubrication. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 500. [Google Scholar] [CrossRef]

- Panda, A.; Das, S.R.; Dhupal, D. Surface Roughness Analysis for Economical Feasibility Study of Coated Ceramic Tool in Hard Turning Operation. Process Integr. Optim. Sustain. 2017, 1, 237–249. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Effect of Cutting Parameters on the Degree of Work Hardening and Tool Life during High-Speed Machining of Inconel 718. Int. J. Adv. Manuf. Technol. 2012, 59, 483–489. [Google Scholar] [CrossRef]

- Das, S.R.; Panda, A.; Dhupal, D. Experimental Investigation of Surface Roughness, Flank Wear, Chip Morphology and Cost Estimation during Machining of Hardened AISI 4340 Steel with Coated Carbide Insert. Mech. Adv. Mater. Mod. Process. 2017, 3, 9. [Google Scholar] [CrossRef]

- Dash, L.; Padhan, S.; Das, A.; Das, S.R. Machinability Investigation and Sustainability Assessment in Hard Turning of AISI D3 Steel with Coated Carbide Tool under Nanofluid Minimum Quantity Lubrication-Cooling Condition. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6496–6528. [Google Scholar] [CrossRef]

- Leppert, T.; Peng, R.L. Residual Stresses in Surface Layer after Dry and MQL Turning of AISI 316L Steel. Prod. Eng. 2012, 6, 367–374. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Z.; Zhang, G.; Liu, L. The Effect of Cutting Speed on Residual Stresses When Orthogonal Cutting TC4. EPJ Web Conf. 2015, 94, 01035. [Google Scholar] [CrossRef]

- Naik, S.; Das, S.R.; Dhupal, D. Experimental Investigation, Predictive Modeling, Parametric Optimization and Cost Analysis in Electrical Discharge Machining of Al-SiC Metal Matrix Composite. Silicon 2021, 13, 1017–1040. [Google Scholar] [CrossRef]

- More, A.S.; Jiang, W.; Brown, W.D.; Malshe, A.P. Tool Wear and Machining Performance of CBN-TiN Coated Carbide Inserts and PCBN Compact Inserts in Turning AISI 4340 Hardened Steel. J. Mater. Process. Technol. 2006, 180, 253–262. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, A.K.; Mishra, P.C.; Das, R.K. Comparative Study on Machinability Improvement in Hard Turning Using Coated and Uncoated Carbide Inserts: Part II Modeling, Multi-Response Optimization, Tool Life, and Economic Aspects. Adv. Manuf. 2018, 6, 155–175. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Density (×1000 kg/m3) | 7.7–8.03 |

| Poisson’s ratio | 0.27–0.30 |

| Elastic modulus (GPa) | 190–210 |

| Yield strength (MPa) | 417.1 |

| Tensile strength (MPa) | 655 |

| Elongation (%) | 25.7 |

| Reduction in area (%) | 56.9 |

| Characteristics | Value |

|---|---|

| Appearance | Green |

| Density at 20 °C | 1.12 g/cm3 |

| Viscosity at 20 °C | 1.98 × 10−2 Pa·s |

| Freezing point | −35 °C |

| Boiling point | 108 °C |

| Refractive index | 1.43 |

| pH value | 5.5–7.5 |

| Specific heat capacity | 2.433 J/g °C |

| Parameters | Levels | ||

|---|---|---|---|

| Feed, f (mm/rev) | 0.06 | 0.12 | 0.18 |

| Cutting speed, v (m/min) | 60 | 100 | 140 |

| Nose radius, r (mm) | 0.4 | 0.8 | 1.2 |

| Depth of cut, d (mm) | 0.2 | 0.3 | 0.4 |

| Run No. | Machining Parameters | Machining Output | |||

|---|---|---|---|---|---|

| v (m/min) | f (mm/rev) | d (mm) | r (mm) | Ra (µm) | |

| 1 | 60 | 0.06 | 0.2 | 0.4 | 0.384 |

| 2 | 140 | 0.06 | 0.2 | 0.4 | 0.415 |

| 3 | 60 | 0.18 | 0.2 | 0.4 | 1.098 |

| 4 | 140 | 0.18 | 0.2 | 0.4 | 1.010 |

| 5 | 60 | 0.06 | 0.4 | 0.4 | 0.481 |

| 6 | 140 | 0.06 | 0.4 | 0.4 | 0.417 |

| 7 | 60 | 0.18 | 0.4 | 0.4 | 1.308 |

| 8 | 140 | 0.18 | 0.4 | 0.4 | 1.385 |

| 9 | 60 | 0.06 | 0.2 | 1.2 | 0.722 |

| 10 | 140 | 0.06 | 0.2 | 1.2 | 0.452 |

| 11 | 60 | 0.18 | 0.2 | 1.2 | 0.724 |

| 12 | 140 | 0.18 | 0.2 | 1.2 | 0.695 |

| 13 | 60 | 0.06 | 0.4 | 1.2 | 0.367 |

| 14 | 140 | 0.06 | 0.4 | 1.2 | 0.264 |

| 15 | 60 | 0.18 | 0.4 | 1.2 | 0.761 |

| 16 | 140 | 0.18 | 0.4 | 1.2 | 0.666 |

| 17 | 100 | 0.12 | 0.3 | 0.8 | 0.655 |

| 18 | 100 | 0.12 | 0.3 | 0.8 | 0.591 |

| 19 | 100 | 0.12 | 0.3 | 0.8 | 0.642 |

| 20 | 100 | 0.12 | 0.3 | 0.8 | 0.550 |

| 21 | 60 | 0.12 | 0.3 | 0.8 | 0.615 |

| 22 | 140 | 0.12 | 0.3 | 0.8 | 0.606 |

| 23 | 100 | 0.06 | 0.3 | 0.8 | 0.565 |

| 24 | 100 | 0.18 | 0.3 | 0.8 | 0.961 |

| 25 | 100 | 0.12 | 0.2 | 0.8 | 0.757 |

| 26 | 100 | 0.12 | 0.4 | 0.8 | 0.804 |

| 27 | 100 | 0.12 | 0.3 | 0.4 | 0.733 |

| 28 | 100 | 0.12 | 0.3 | 1.2 | 0.490 |

| 29 | 100 | 0.12 | 0.3 | 0.8 | 0.614 |

| 30 | 100 | 0.12 | 0.3 | 0.8 | 0.663 |

| Source | F-Value | p-Value | Contr. % |

|---|---|---|---|

| Model | 41.80 | 0.000 | 97.50 |

| Linear | 107.23 | 0.000 | 71.47 |

| Cutting speed, v | 5.12 | 0.039 | 0.85 |

| Feed, f | 349.19 | 0.000 | 58.18 |

| Depth of cut, d | 0.65 | 0.433 | 0.11 |

| Nose radius, r | 73.97 | 0.000 | 12.32 |

| Square | 5.12 | 0.008 | 3.41 |

| v2 | 3.65 | 0.076 | 0.12 |

| f2 | 5.65 | 0.031 | 1.72 |

| d2 | 8.22 | 0.012 | 0.98 |

| r2 | 3.54 | 0.079 | 0.59 |

| Two-way interaction | 22.62 | 0.000 | 22.62 |

| v*f | 1.40 | 0.255 | 0.23 |

| v*d | 0.56 | 0.467 | 0.09 |

| v*r | 3.91 | 0.067 | 0.65 |

| f*d | 20.49 | 0.000 | 3.41 |

| f*r | 81.08 | 0.000 | 13.51 |

| d*r | 28.31 | 0.000 | 4.72 |

| Error | - | - | 2.50 |

| Sl. No. | Production Costs and Times | SPPP-AlTiSiN Coated Tool |

|---|---|---|

| 1 | Machine and operator cost (x) per min | Rs.4.00 |

| 2 | Machining time per finished part () | 3.03 min |

| 3 | Machining cost per finished part, | Rs.12.12 |

| 4 | Machine downtime () | 3 min |

| 5 | Life of coated tool (T) | 46 min |

| 6 | Tool replacement cost per finished part, | Rs.0.79 |

| 7 | Cost of coated cutting insert | Rs.620 |

| 8 | Cost of each cutting edge (y) | Rs.155 |

| 9 | Tooling cost per component, | Rs.10.21 |

| 10 | Overall machining cost expenditure per finished component, | Rs.23.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Padhan, S.; Wagri, N.K.; Dash, L.; Das, A.; Das, S.R.; Rafighi, M.; Sharma, P. Investigation on Surface Integrity in Hard Turning of AISI 4140 Steel with SPPP-AlTiSiN Coated Carbide Insert under Nano-MQL. Lubricants 2023, 11, 49. https://doi.org/10.3390/lubricants11020049

Padhan S, Wagri NK, Dash L, Das A, Das SR, Rafighi M, Sharma P. Investigation on Surface Integrity in Hard Turning of AISI 4140 Steel with SPPP-AlTiSiN Coated Carbide Insert under Nano-MQL. Lubricants. 2023; 11(2):49. https://doi.org/10.3390/lubricants11020049

Chicago/Turabian StylePadhan, Smita, Naresh Kumar Wagri, Lalatendu Dash, Anshuman Das, Sudhansu Ranjan Das, Mohammad Rafighi, and Priyaranjan Sharma. 2023. "Investigation on Surface Integrity in Hard Turning of AISI 4140 Steel with SPPP-AlTiSiN Coated Carbide Insert under Nano-MQL" Lubricants 11, no. 2: 49. https://doi.org/10.3390/lubricants11020049

APA StylePadhan, S., Wagri, N. K., Dash, L., Das, A., Das, S. R., Rafighi, M., & Sharma, P. (2023). Investigation on Surface Integrity in Hard Turning of AISI 4140 Steel with SPPP-AlTiSiN Coated Carbide Insert under Nano-MQL. Lubricants, 11(2), 49. https://doi.org/10.3390/lubricants11020049