1. Introduction

Standardised bolt sets are most commonly used to create bolted connections for which preloading is required [

1,

2,

3]. They are used to join not only steel, but also composite [

4,

5] or additively manufactured [

6,

7] components. Among the most advanced sets are HV high-strength bolt sets [

8], which can be used in a wide range of structures exposed to various, including aggressive, environmental conditions. For this purpose, such sets are usually coated with hot-dip zinc [

9].

Before bolt sets are used for assembly, they are subjected to actual operating conditions and processes onsite, caused by high or low temperatures, as well as storage conditions under varying atmospheric conditions. These different temperature extremes, as well as moisture on the threads of the bolt components, affect the friction coefficients and thus the tightening behaviour of the bolt sets. A change in the tribological properties of the bolts can result in a lower bolt preload being achieved during assembly, or in too high a force being achieved at low torque values, leading to the tensile strength of the bolt being exceeded. All of these effects can lead to bolt failures, resulting in costly and time-consuming failure analyses and assembly interruptions [

8,

10].

No further specific definitions are provided in the bolting standards [

11,

12], other than the general requirement that the bolt set should be adequately lubricated as supplied to ensure that seizure does not occur when the set is tightened and that the required preload is achieved. The exception to this is the DASt-Richtlinie 024 standard [

13], which requires the protection of sets from dirt and moisture, which affect the quality of lubrication. However, this wording is not precise and allows for overinterpretation. Consequently, there are no precise recommendations in the current standards regarding the effect of specific atmospheric or site conditions on the preload and tightening of bolt sets.

In the generally available scientific and technical literature, the effect of various atmospheric conditions on the tightening behaviour of bolted connections has not been exhaustively studied. Wen et al. [

14] identified corrosion occurring under the influence of the external environment as one of the factors that alter the mechanical properties of bolts, accelerating their failure. This phenomenon also occurs in the case of galvanised bolts [

15,

16]. Nah et al. [

17] estimated the tensile forces of high-strength bolts subjected to temperatures ranging from −10 °C to 50 °C. Underwater tightening and preload behaviour of a bolted connection and determination of the slip factor under water was described by Ripsch and Henkel [

18]. They developed a test system to determine the slip factor using different media for all traditional types of surface coatings. Omura [

19] investigated the susceptibility to hydrogen embrittlement (delayed fracture) of high-strength steel bolts under atmospheric exposure conditions. The hydrogen permeability under atmospheric conditions showed a strong dependence on time of day, season and exposure location. The mechanism of hydrogen penetration was investigated by measuring hydrogen permeation under laboratory wet–dry cyclic conditions. The dominant factors controlling hydrogen penetration were temperature, relative humidity and the amount of sea salt on the steel surface. Stranghöner et al. [

10] studied the effect of atmospheric conditions on the preload behaviour of HV and HR bolt sets based on a tightening test of the sets at different temperatures (−20 °C, +23 °C, +50 °C) and selected humidity conditions (including dry, frost, minor direct/indirect rain, variable dry/wet conditions). However, this study did not examine the effect of storage on the quality of the resulting bolted connection. The variation in friction coefficient [

20,

21] as a function of the point of contact of the different elements of the bolted connection was also not tested.

In order to investigate the effect of atmospheric conditions on the tightening behaviour of HV bolts in structural bolt sets, this article describes the results of experimental tests performed for bolt sets of a selected type stored under different atmospheric conditions. These tests were carried out to examine the validity of the research hypothesis that autumn and winter atmospheric conditions have an effect on the reduction in friction coefficient values in bolt sets. The most important results of this study, which distinguish it from other studies, led to the demonstration of the variability in friction coefficient depending on the place where the friction phenomenon is considered, with a distinction between phenomena occurring between the joining elements on the threaded surfaces as well as between the bolt head and the bearing surface of the nut and the washer.

2. Materials and Methods

The tests were carried out on the EN 14399-4-HV-M24 × 140-10.9/10-tZn-K1 bolt set (

Figure 1) supplied by a single manufacturer [

12].

The mechanical property class of the set elements was confirmed using tests included in ISO 898-1 [

22] and ISO 898-2 [

23], and the HV hardness of the washers according to ISO 898-3 [

24]. The hot-dip zinc coating applied to the components met the requirements of ISO 10684 [

11] and ranged from 50 to 80 µm. After the threading process, the nuts were coated with molybdenum disulphide by the manufacturer. In order to confirm the compliance of the HV bolt set, a connection suitability test was carried out in accordance with EN 14399-2 [

25] using the scheme shown in

Table 1.

The following designations are used in

Table 1:

Fp,C—the required preload calculated according to the formula [

26]:

where

fub is the nominal tensile strength and

As is the nominal stress area of the bolt.

- 2.

ΔΘ2i,min—the minimum required value of angle difference specified in the relevant product standard according to the formula:

where

Θ2i is the individual value of the angle of rotation of the nut relative to the bolt and

Θpi is the individual value of the angle of rotation of the nut relative to the bolt at which the bolt force has first reached the value of

Fp,C.

A connection suitability test was carried out using a Kistler machine of type 5413-2777 (

Figure 2) according to the parameters provided in

Table 2. The parameters of the M24 thread outline are provided in

Table 3. The expected clamping force and torque for M24 × 140 bolts in class 10.9 were within the ranges of the selected sensors.

The following coefficients were checked as additional parameters:

µth—the coefficient of friction between the threaded surfaces of the joining elements;

µb—the coefficient of friction between the bolt head and the bearing surfaces;

µtot—the coefficient of total friction.

Tightening was performed through the nut; therefore, the friction coefficients were evaluated sequentially, first determining µth, then µb.

Extending this study to include µth and µb values allowed for a more detailed analysis of the effect of storage conditions on the behaviour of the nut coating. In order to determine the value of the friction coefficient on the bearing surface, it was important to determine the average value of the mean diameter of the bearing surface. Two standards were used to determine the properties of the connection suitability:

- 2.

Total friction coefficient based on the Kellermann–Klein formula (for comparison, see [

27]):

where

T is the individual value of the tightening torque at which the bolt force has first reached the value of

Fp,C,

F denotes the clamping force,

d is the nominal thread diameter of the bolt,

P denotes the thread pitch,

d2 is the basic pitch diameter of thread,

Do denotes the outer bearing surface diameter and

dh is washer hole diameter.

TestXpert II software [

28] was used to prepare the connection suitability test. The results were generated in .xlsx format, allowing for easy evaluation of the assembly methods. For the assessment, the requirements contained in EN 14399-2 [

25] were adopted, as well as the requirements for the combined method K1 according to EN 1090-2 [

29] and the modified method according to DASt-Richtlinie 024 [

13] (

Table 4). For the assembly methods, the achievement of the required preload was verified. In addition, the occurrence of overextension of the bolt was examined by assessing the exceedance of the maximum value of the clamping force obtained in the tests for the assembly method. Exceeding the maximum tensile strength in a bolted connection results in a reduction in the strength of the connection subjected to the load [

30].

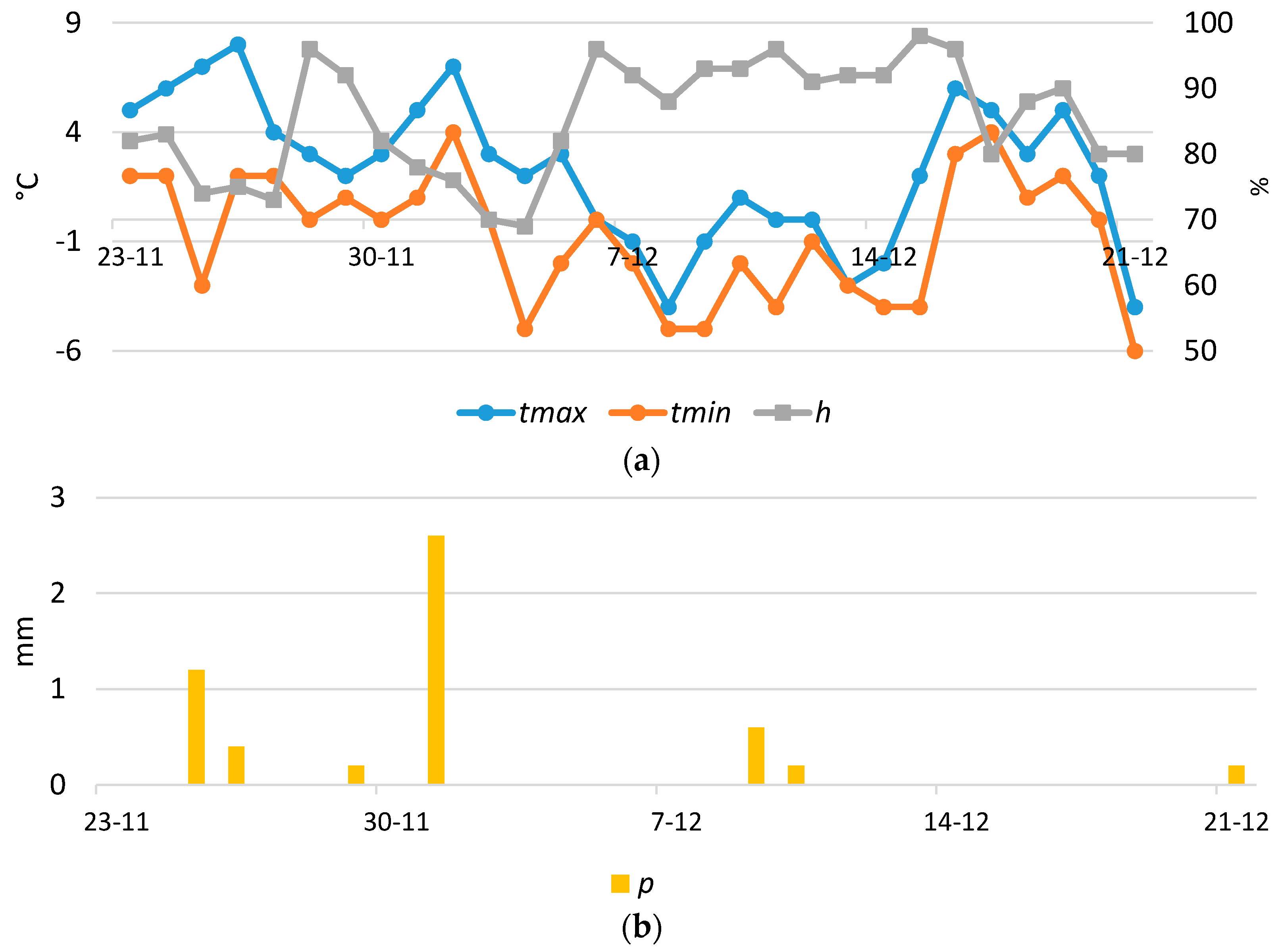

In order to determine the effect of atmospheric conditions on the bolt set, an autumn–winter period was chosen. The conditions occurring at this time at the test site located in Lancut (Poland) are presented in

Figure 3. As can be seen, there was both rain and snow. The temperature took on positive and negative values. Humidity was high, above 70%, throughout the tests.

Bolt sets stored under different conditions were tested, as described in

Table 5 and shown in

Figure 4. The test results for the bolt sets stored in the defined manner were compared with the results of tests carried out according to EN 14399-2 [

25], marked V0.

Six versions of bolt product protection were adopted. The sets were stored in a box or directly on the concrete floor. In this way, the most common means of protection were mapped. In addition, it was decided to protect the nuts with VCI anticorrosion foils, bearing in mind the direct influence of the surface condition of the nuts on the assembly parameters. The research carried out aimed to answer the following questions:

Do wet conditions result in lower k-factors and friction coefficients?

Does the reduction in k-factor lead to a case where the required torque is not achieved for the modified tightening procedure?

Do additional protective measures minimise the environmental effect on the connection assembly?

Is the bolt set still functional after 4 weeks of being outdoors?

3. Results and Discussion

Due to the complexity of the research, the results obtained were divided into two blocks for the purpose of analysis. The focus was on the functionality of the connection, i.e., compliance with the requirements set by industry standards for HV bolts, and on the assessment of changes in the friction coefficient under the effects of atmospheric conditions and storage time.

3.1. Analysis of Storage Methods

The first block analyses the storage methods and the results obtained for the assembly methods. This block can be called functional. The evaluation of sets can be performed in three ways, depending on the function of the evaluator, which may be:

From the point of view of the bolt set manufacturer, the test according to EN 14399-2 [

25] is crucial to evaluation. The results presented in

Table A1 (in

Appendix A) summarise the parameters:

F, K1 and k-factor, corresponding to the first stage of the tests, in which the value of the k-factor and the variance of this parameter were determined by assembling the sets with the force Fp,C (fulfilment of the K1 condition occurs when the k-factor values are between 0.100 and 0.160);

Fbi,max, which occurs in the second stage of assembly (for the M24 thread outline, the minimum value of this force is 317.7 kN);

Angle of rotation ΔΘ2i,min, the achievement of which allows for the connection efficiency and strength of the threaded connection to be checked.

From the manufacturer’s point of view, the bolts maintained compliance with the applicable requirements for four weeks. Importantly, a change of approximately 0.02 in the k-factor was between the requirements of 0.100 and 0.160. This change did not affect the maximum force achieved or the additional angle of rotation.

At the second point of the assessment, attention should be paid to the requirement to achieve a minimum force

Fp,C or

Fp,C *. The force requirement

Fp,C must be met for type B and C shear connections as well as for a type E preloaded connection. In contrast, the force requirement

Fp,C * must be satisfied for type A and D connections according to EN 1993-1-8 [

31].

Table A1 (in

Appendix A) shows the results for the combined K1 and modified methods. In the case of the first method, the minimum value of

Fp,C should be 247.1 kN, while for the second method, the minimum

Fp,C * is 220 kN. However, simply assessing the strength achieved at the end of the procedure is only a superficial check. This is due to the fact that for the combined K1 method, the assembly ends when the additional angle of rotation is reached, while for the modified method, the required torque value is reached. The principle adopted is that if the assembly is completed and

Fp,C or

Fp,C * is determined after

Fbi,max has been exceeded, the connection is no longer functional and safe. After exceeding the maximum value for the force

Fbi,max, the clamping force in the connection decreases, which is caused by a reduction in the bolt neck diameter or deformation of the thread. In the tests, all bolts reached the required clamping force before exceeding the

Fbi,max value, so the sets were properly preloaded.

The third point of assessment is the observation of the user of the bolt sets, who assembles the connection. Under assembly conditions, it should be assumed that the sets supplied meet the requirements contained on the label and are as ordered. The assembler may note the aspect of potential breakage of the sets resulting from elongation of the bolts in the neck or excessive torsional stresses. Breakage of the connection can occur as a result of inadequate fit of the threaded parts being joined. On the other hand, if the coating degrades and the friction coefficient increases, the torque increases and, consequently, the torsional stresses increase. This can lead to the destruction of the bolted connection in the threaded part of the bolt immediately in front of the nut. Such an incident did not occur during the tests. Another aspect, which only applies to the modified method, is the failure to achieve the required MA value. Such a case may occur when the k-factor is too low. In such a case, a significantly higher clamping force is obtained for the MA value. It may therefore happen that the Fbi,max value is exceeded and, further down the assembly, the torque decreases as the force decreases. This would lead to an inability to reach the MA value and destruction of the thread or the formation of a neck in the threaded part of the bolt.

An evaluation of the bolt sets under the conditions of four weeks and direct exposure (

Figure 5) also highlights possible signs of corrosion, damage to the boxes or deterioration of label visibility. The hot-dip zinc coating on the surface of the set parts protected them from environmental influences for the stated period of time. In turn, the batch identification system on the head of the bolt and nut, even when the boxes or labels are damaged, makes it possible to identify the production batch and match it with the certificates sent by the manufacturer.

3.2. Analysis of Friction Coefficients

The second block of evaluation was the analysis of the friction coefficient parameters. HV bolt sets are mainly analysed by paying attention only to the value of the

k-factor. To determine the clamping force, this parameter is sufficient and easy to establish. When analysing the molybdenum disulphide coating process or assessing the storage method, it may not be enough. In the case of HV bolt sets, due to the size of the bearing surface of the nut and contact with the washer, the significance of the friction coefficient on the bearing surface is much higher than for standard ISO 4014 bolt [

32] and ISO 4032 nut [

33] connections. This also affects the evaluation of the individual parameters and, in particular, more attention should be paid to the

µb coefficient.

The data in

Table A2 (in

Appendix A) present a summary for the

k-factor,

µtot,

µth and

µb parameters determined in the first part of the tests according to EN 14399-2 [

25] after the

Fp,C force has been reached.

The changes over a four-week period should be referred to the V0 test. After the first week, characterised by temperatures in the range of −3 to 8 °C, humidity in the range of 73 and 96% and rainfall not exceeding 2 mm for three days, friction coefficients decreased.

The

k-factor and

µtot parameters shown in

Figure 6 and

Figure 7 correspond to each other. The

µtot coefficient is the extended equivalent of

k-factor. When analysing the change in the

µtot coefficient over successive weeks, it reached an average value of 0.084. In contrast, for the sets taken from the warehouse, the coefficient varied between 0.102 and 0.113. The spread between individual test values was 0.032, with a maximum score of 0.100 and a minimum score of 0.068.

The variation in the

µth and

µb coefficients is summarised in

Figure 8 and

Figure 9. An important result is that the

k-factor does not fall below 0.100. The lowest friction coefficient values were read after 2 weeks when the sets were under snow. In this case, the products contained in the boxes had the lowest friction coefficients values on the bearing surface.

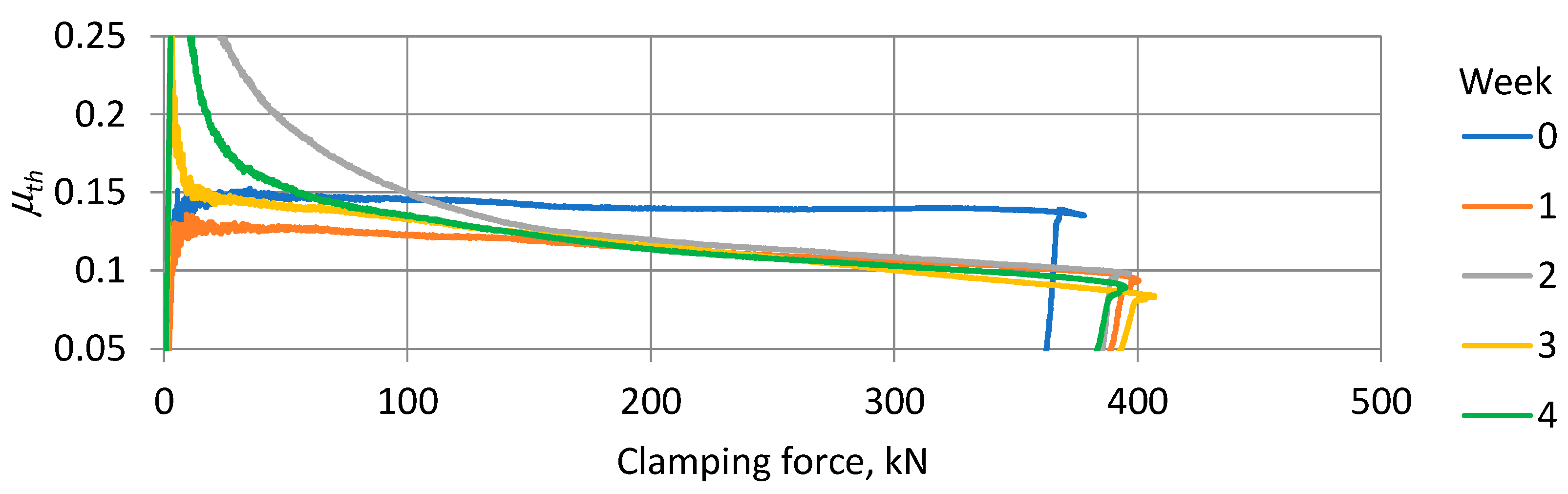

The effect of atmospheric conditions on the performance of the coating on the joining elements is presented for the chosen method of storing the bolt sets in the graphs in

Figure 10,

Figure 11 and

Figure 12. The graphs show the changes in the friction coefficients under clamping force for the first sets of variant V1, starting with the initial test marked as 0 and illustrating the subsequent weeks as 1, 2, 3 and 4. The reduction in friction increased the value of the maximum clamping force achieved.

The change in the

k-factor value between 0.100 to 0.160 (

Figure 6) for the four weeks of testing was achieved by a small change in

µb coefficient (

Figure 12). The

µth coefficient varied as shown in

Figure 11, where, due to changes in storage time, friction decreased as clamping force increased. The

µb value changed on average by 0.011 and

µth by 0.039.

Analysing all the results obtained, also for other methods of storing the bolt sets, it can be concluded that the method of packaging and storing the bolt sets had little effect on the results. Temperature drop, precipitation and increased humidity affected the tested sets in a similar way. The research showed that the nut coating method adopted and the process requirements used satisfactorily reduced variations.

4. Concluding Remarks

The following conclusions can be drawn from the research carried out:

Tests performed in autumn and winter conditions show that the HV bolt sets are still functional for assembly according to the combined method K1 [

29] and the modified method [

13];

It was found that the friction coefficient for the bolt sets was reduced as a result of the autumn and winter weather conditions in Poland. Thus, the research hypothesis posed in the introduction to this article was proven. The achieved average difference for the k-factor is 0.028 between sets from storage and those exposed to atmospheric conditions;

Despite the large effect of friction on the bearing surface on the µtot values, the largest changes occurred for the µth parameter.

The authors see room for improvement and a greater reduction in existing changes in the friction coefficient values obtained, especially for the

µth parameter. As a new research direction, it is possible to point out the investigation of the effect of the application of the topcoat coating [

34], widely used in fasteners for the automotive industry, on the variation of the friction coefficient.

The research presented in this article relates to autumn and winter conditions in Poland and the temperature changes that occur there. However, the presented test procedure can be successfully applied to the investigation of bolt sets in temperature conditions occurring in other parts of the world.