Tribological Performance of Steel/W-DLC and W-DLC/W-DLC in a Solid–Liquid Lubrication System Additivated with Ultrathin MoS2 Nanosheets

Abstract

:1. Introduction

2. Materials and Methods

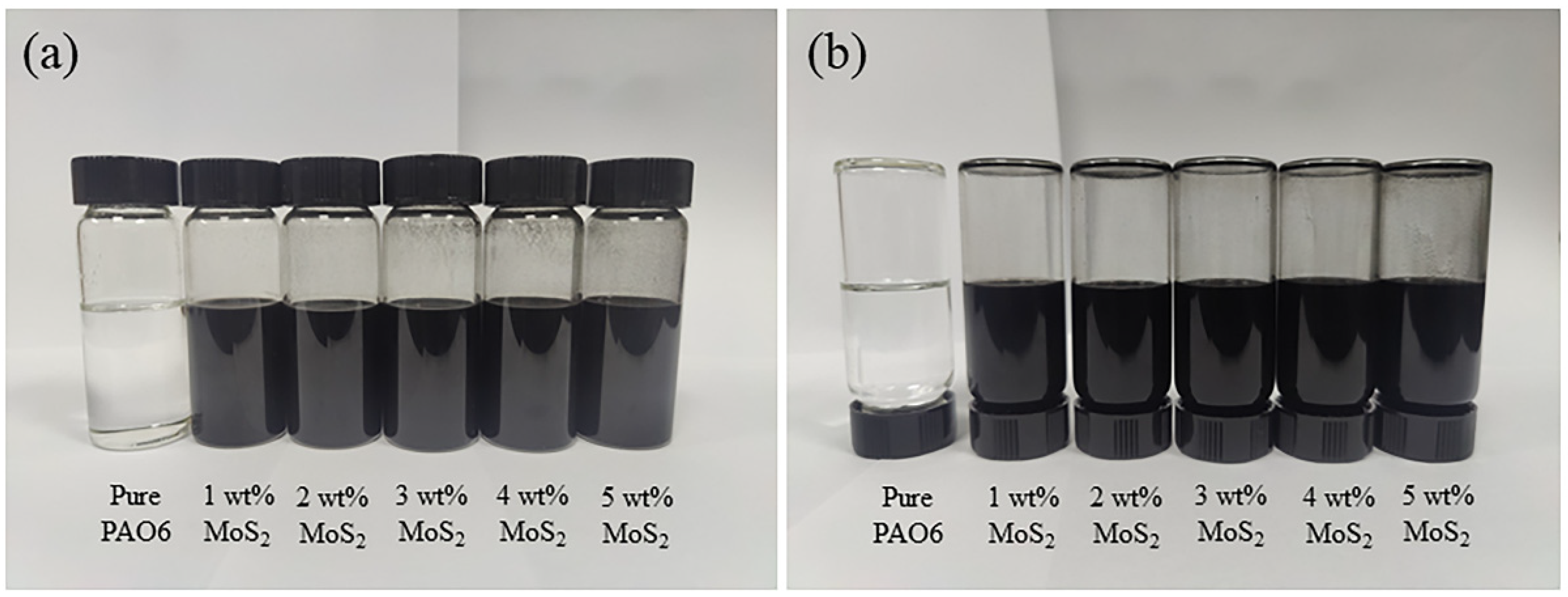

2.1. Lubricants and Additives

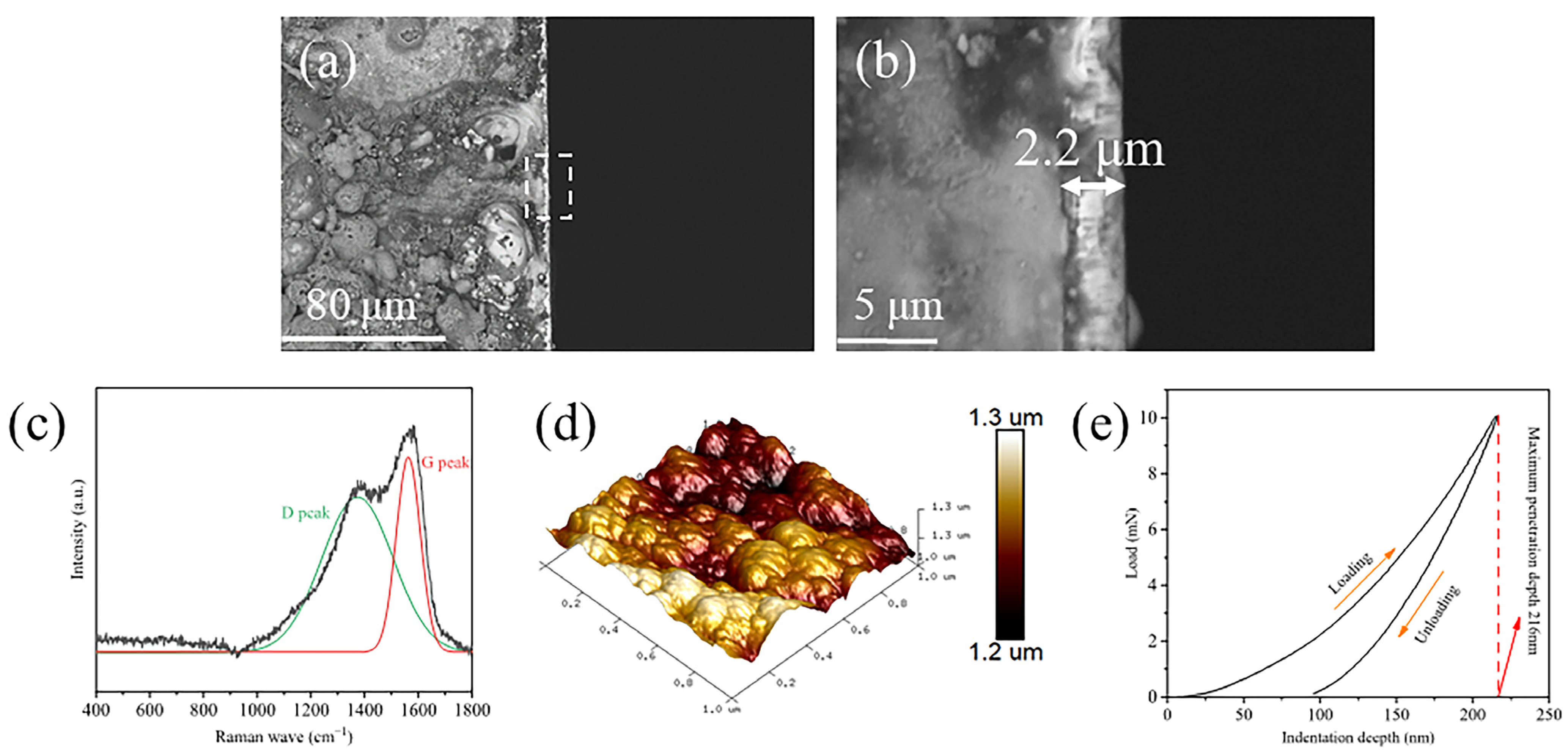

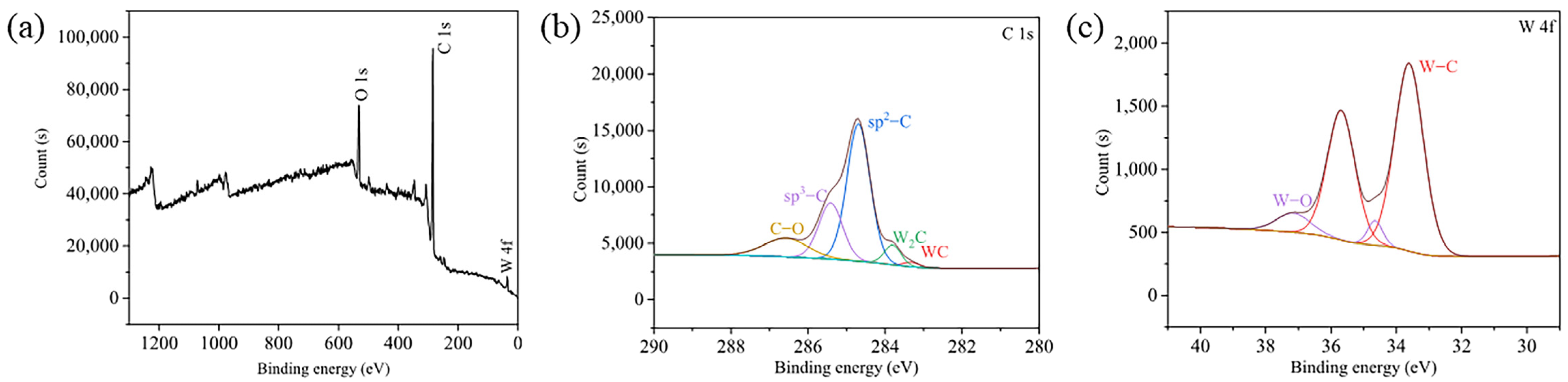

2.2. Preparation and Characterization of W-DLC Coating

2.3. Friction Test

3. Results and Discussion

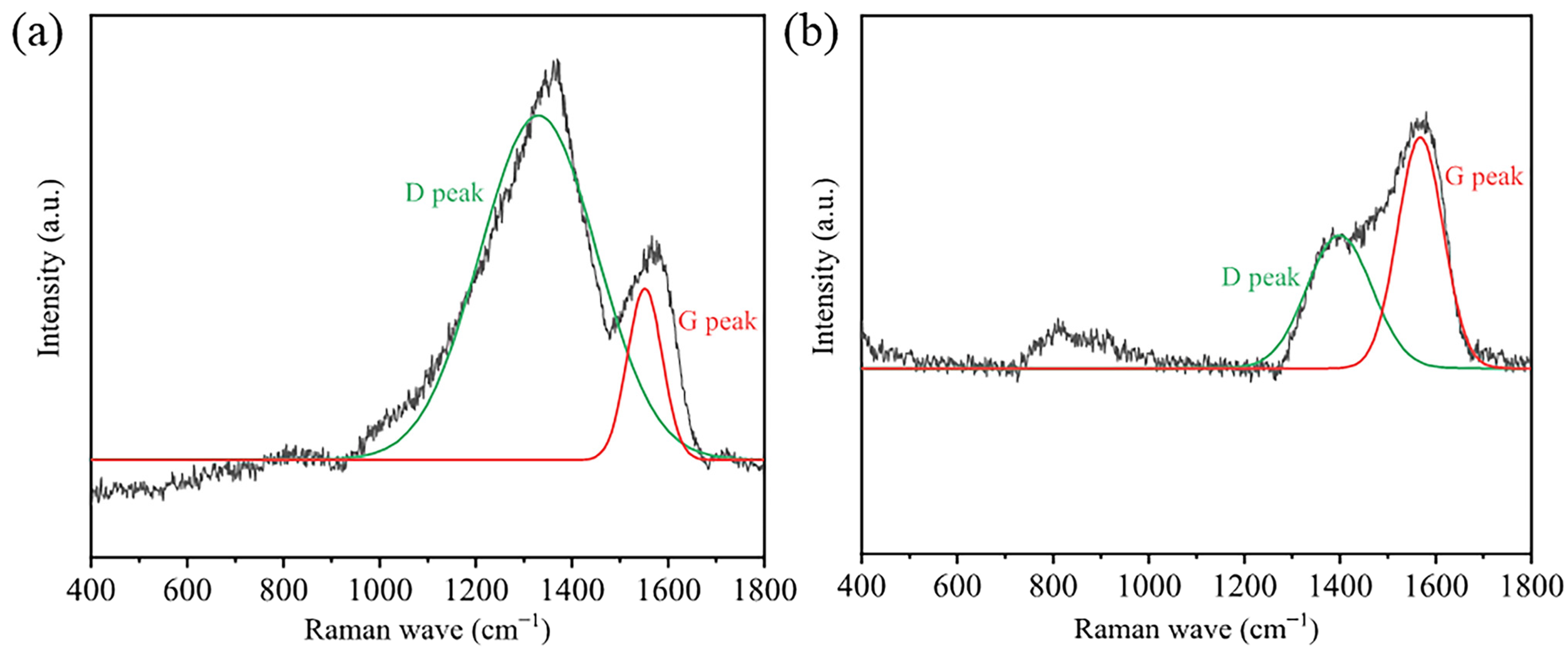

3.1. Structure and Morphology

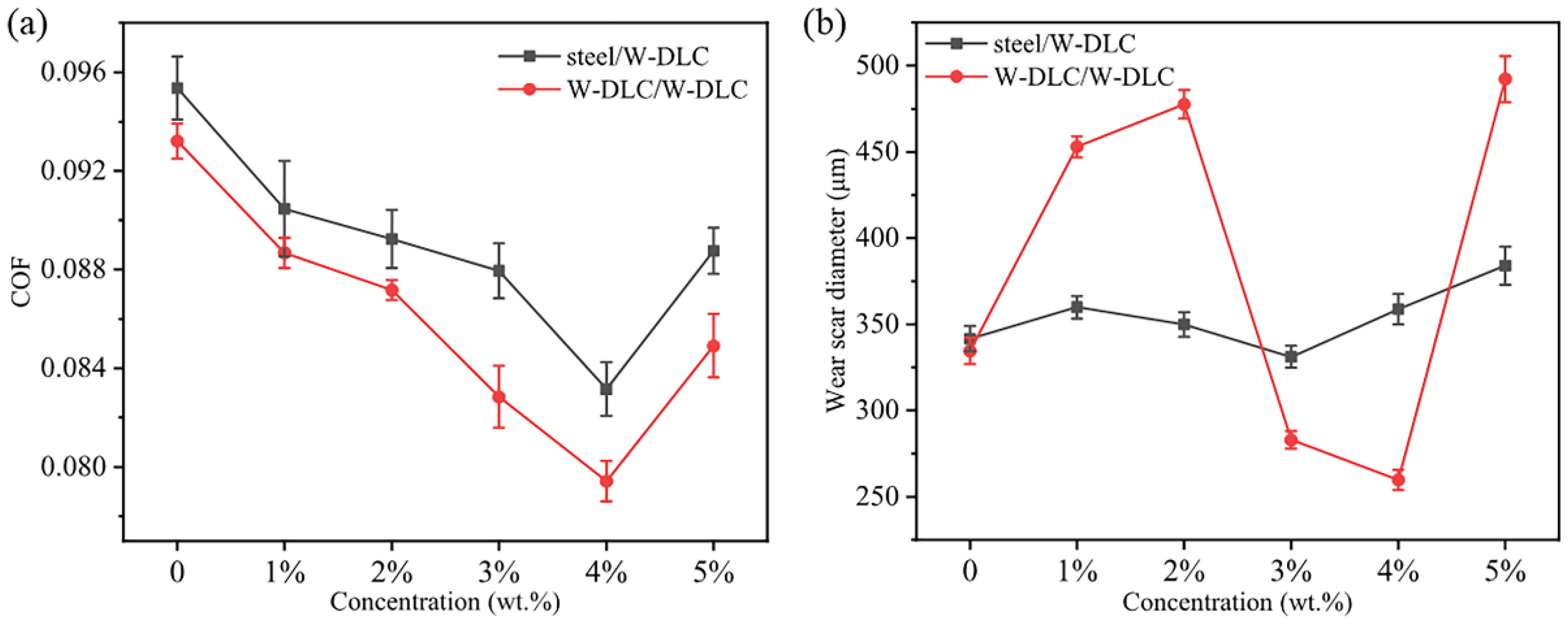

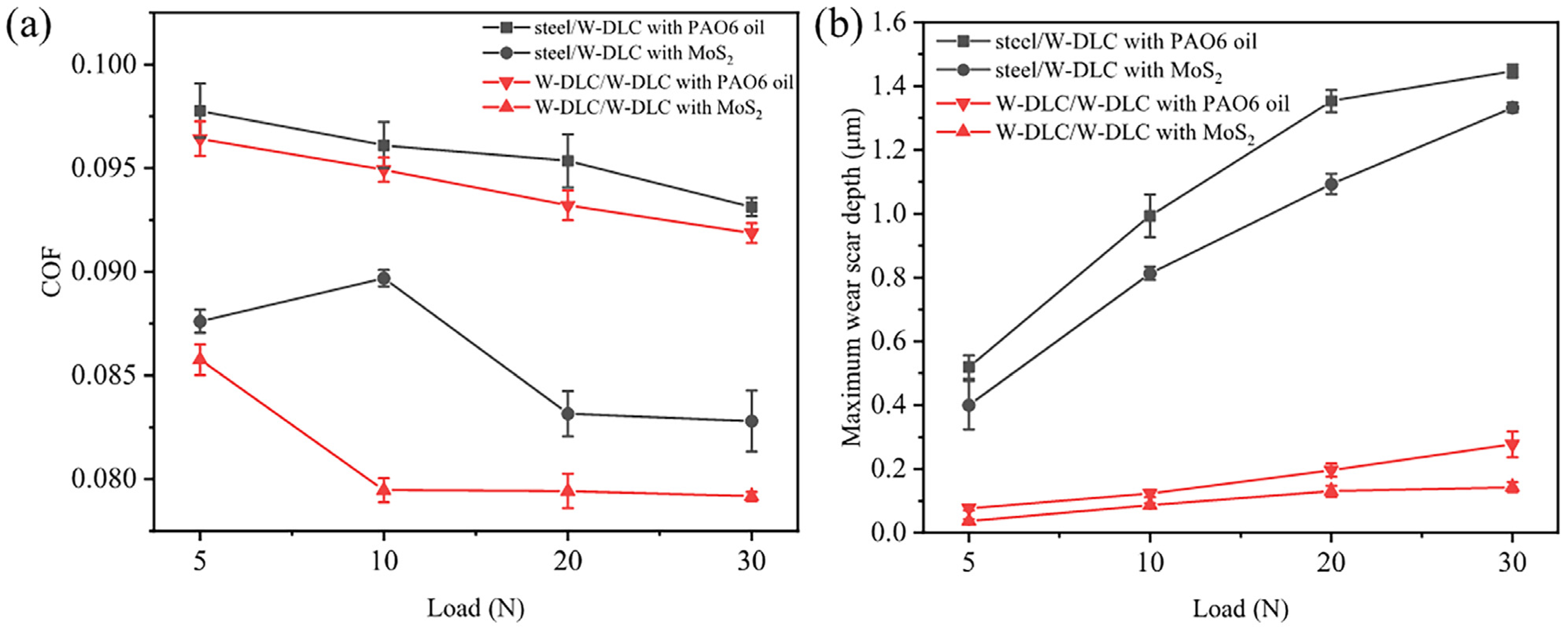

3.2. Tribological Property

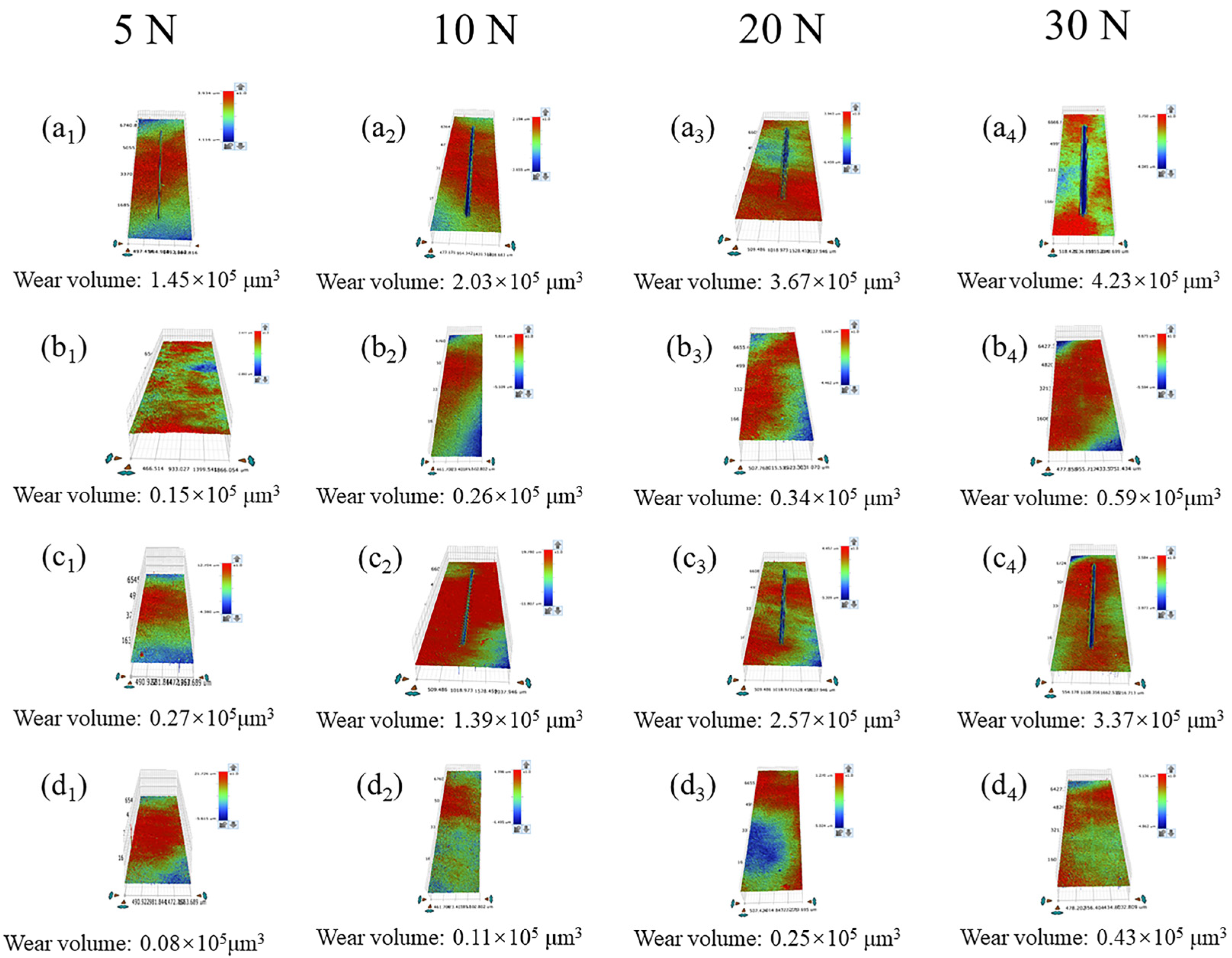

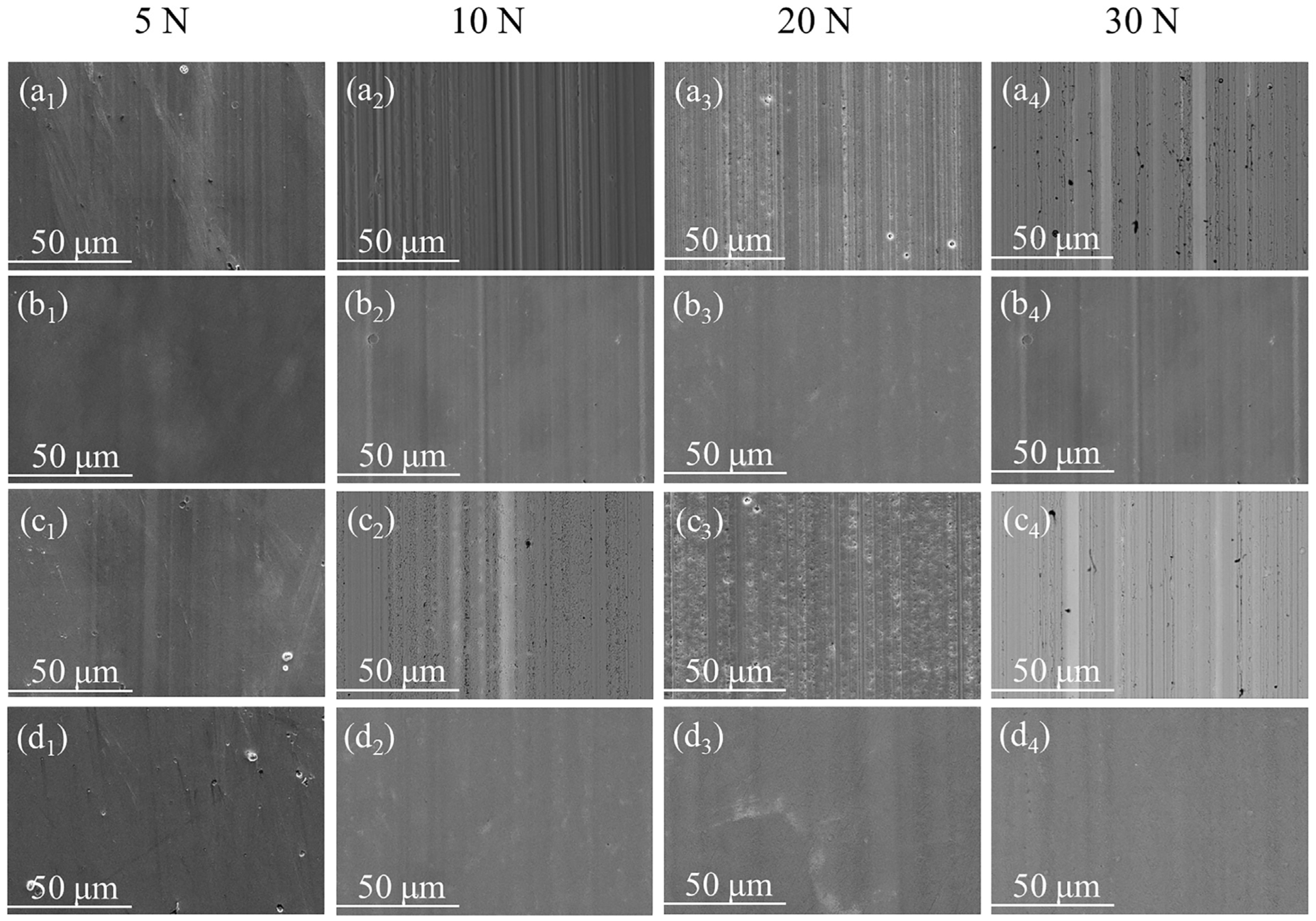

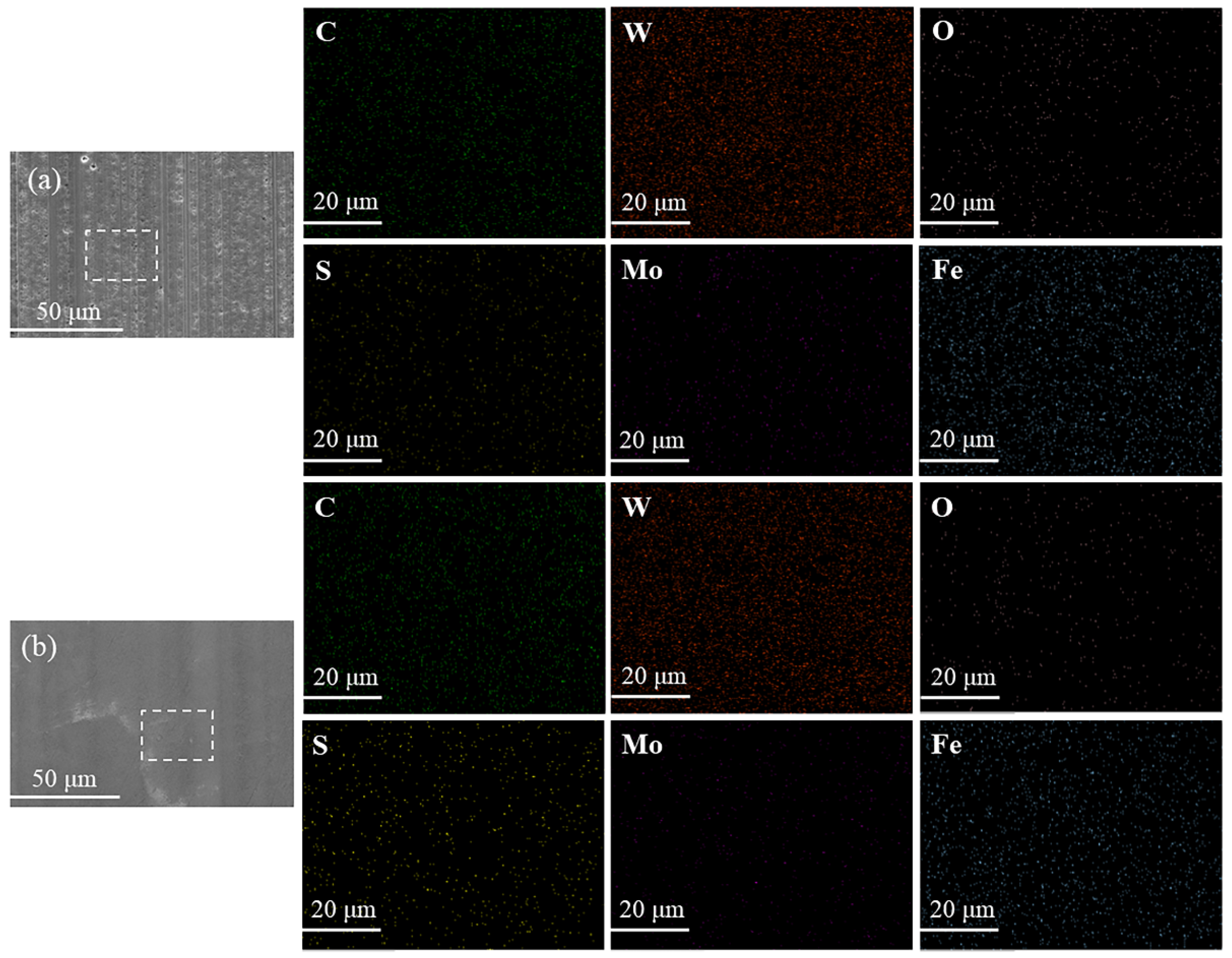

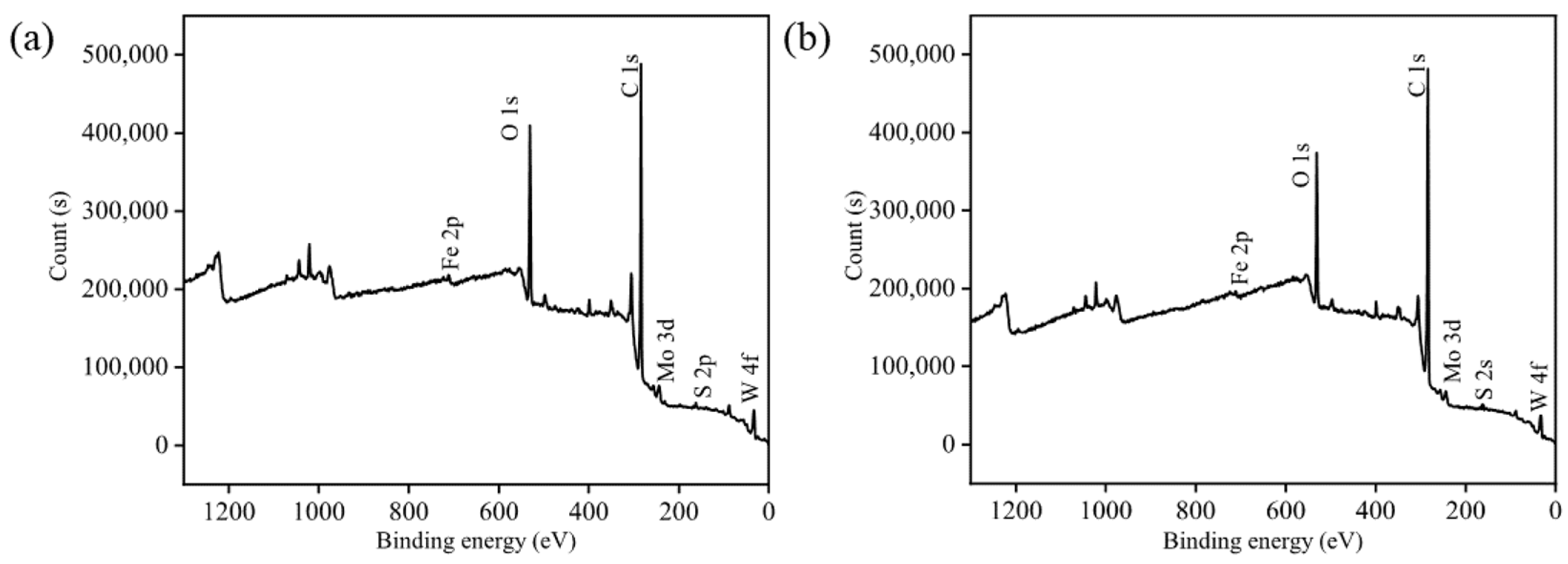

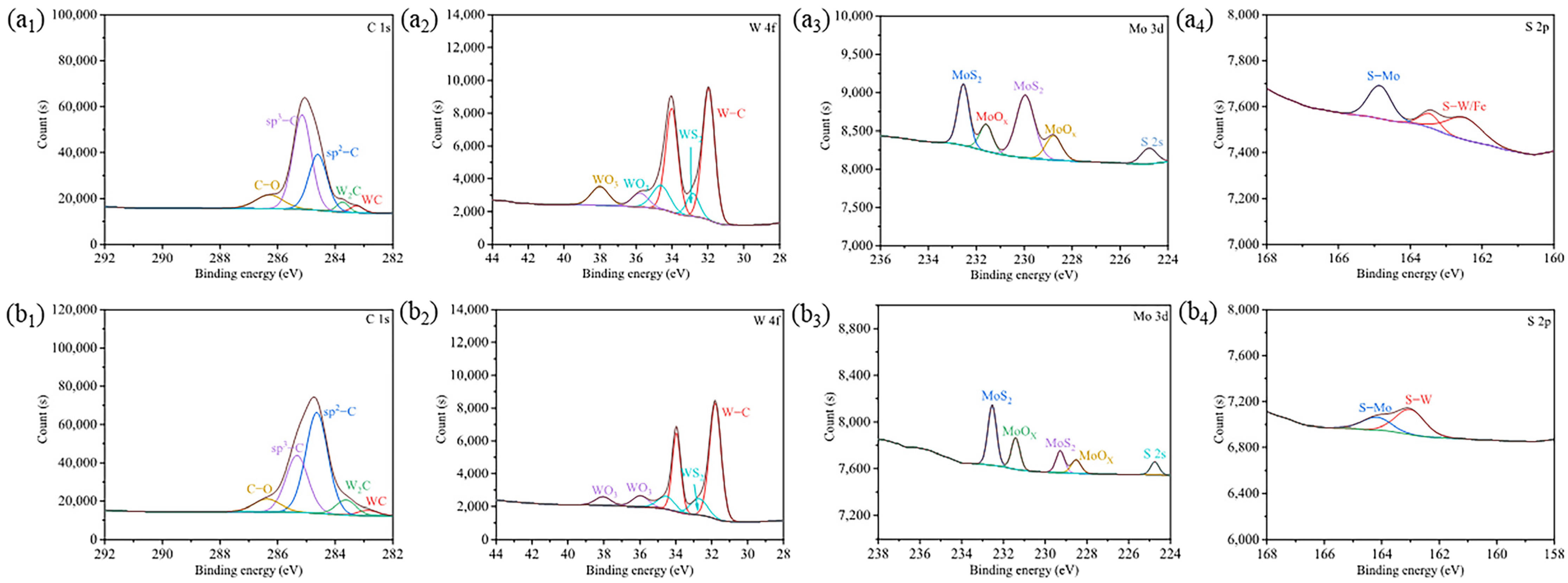

3.3. Wear Surface Analysis

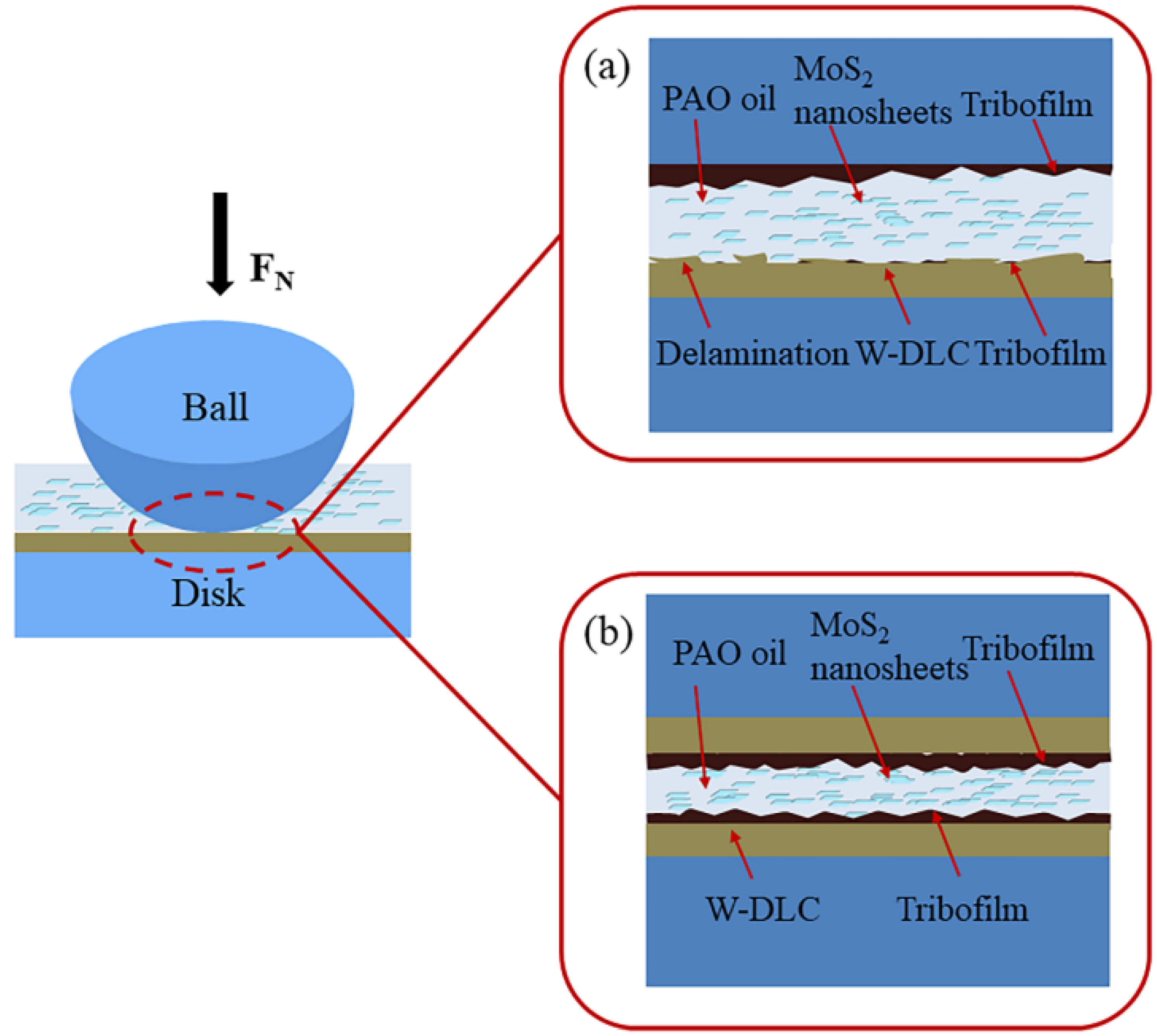

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qi, J.; Wang, L.; Yan, F.; Xue, Q. The tribological performance of DLC-based coating under the solid-liquid lubrication system with sand-dust particles. Wear 2013, 297, 972–985. [Google Scholar]

- Fan, X.; Xue, Q.; Wang, L. Carbon-based solid-liquid lubricating coatings for space applications: A review. Friction 2015, 3, 191–207. [Google Scholar]

- Zhang, T.; Wan, Z.; Ding, J.; Zhang, S.; Wang, Q.; Kim, K. Microstructure and high-temperature tribological properties of Si-doped hydrogenated diamond-like carbon films. Appl. Surf. Sci. 2018, 435, 963–973. [Google Scholar]

- Liu, Y.; Zhang, H. The synergistic mechanism between graphitized tribofilm and graphitized surface of diamond-like carbon film under different temperature environments. Diam. Relat. Mater. 2022, 123, 108875. [Google Scholar]

- Liu, Y.; Zhang, H. Roles of transfer layer and surface adhesion on superlubricity behaviors of diamond-like carbon film depending on rotating and reciprocating motion. Appl. Surf. Sci. 2022, 604, 154538. [Google Scholar]

- Tannous, J.; Dassenoy, F.; Lahouij, I.; Le Mogne, T.; Vacher, B.; Bruhacs, A.; Tremel, W. Understanding the tribochemical mechanisms of IF-MoS2 nanoparticles under boundary lubrication. Tribol Lett. 2011, 41, 55–64. [Google Scholar]

- Kalin, M.; Kogovsek, J.; Remskar, M. Nanoparticles as novel lubricating additives in a green, physically based lubrication technology for DLC coatings. Wear 2013, 303, 480–485. [Google Scholar]

- Patel, J.; Kiani, A. Effects of reduced graphene oxide (rGO) at different concentrations on tribological properties of liquid base lubricants. Lubricants 2019, 7, 11. [Google Scholar]

- Wang, J.; Zhang, H.; Hu, W.; Li, J. Modified Ni nanoparticles as additives in various greases: Assessment of comparative performance potential. Lubricants 2022, 10, 367. [Google Scholar]

- Freschi, M.; Di Virgilio, M.; Zanardi, G.; Mariani, M.; Lecis, N.; Dotelli, G. Employment of micro- and nano-WS2 Structures to enhance the tribological properties of copper matrix composites. Lubricants 2021, 9, 53. [Google Scholar]

- Li, Z.; Chang, Q.; Meng, Y.; Yang, H.; Hao, L. In situ visualization study of tribofilm growth process from magnesium silicate hydroxide nanoparticles. Tribol. Int. 2023, 187, 108725. [Google Scholar]

- Saffari, H.; Soltani, R.; Alaei, M.; Soleymani, M. Tribological properties of water-based drilling fluids with borate nanoparticles as lubricant additives. J. Pet. Sci. Eng. 2018, 171, 253–259. [Google Scholar] [CrossRef]

- Yi, M.; Zhang, C. The synthesis of MoS2 particles with different morphologies for tribological applications. Tribol. Int. 2017, 116, 285–294. [Google Scholar]

- Chen, J.; Xu, Z.; Hu, Y.; Yi, M. PEG-assisted solvothermal synthesis of MoS2 nanosheets with enhanced tribological property. Lubr. Sci. 2020, 32, 273–282. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Liu, Y.; Gunsel, S.; Luo, J. Ultrathin MoS2 Nanosheets with Superior Extreme Pressure Property as Boundary Lubricants. Sci. Rep. 2015, 5, 12869. [Google Scholar]

- Yi, M.; Qiu, J.; Xu, W. Tribological performance of ultrathin MoS2 nanosheets in formulated engine oil and possible friction mechanism at elevated temperatures. Tribol. Int. 2022, 167, 107426. [Google Scholar] [CrossRef]

- Zahid, R.; Masjuki, H.; Varman, M.; Mufti, R.; Kalam, M.; Gulzar, M. Effect of lubricant formulations on the tribological performance of self-mated doped DLC contacts: A review. Tribol Lett. 2015, 58, 32. [Google Scholar]

- Shang, L.; Gou, C.; Li, W.; He, D.; Wang, S. Effect of microstructure and mechanical properties on the tribological and electrochemical performances of Si/DLC films under HCl corrosive environment. Diam. Relat. Mater. 2021, 116, 108385. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, G.; Lu, Z.; Shang, L.; Zhang, G. Corrosion and wear behaviors of Si-DLC films coated on inner surface of SS304 pipes by hollow cathode PECVD. Surf. Topogr. Metrol. Prop. 2018, 6, 034010. [Google Scholar] [CrossRef]

- Yi, M.; Zhang, C. The synthesis of two-dimensional MoS2 nanosheets with enhanced tribological properties as oil additives. RSC Adv. 2018, 8, 9564–9573. [Google Scholar] [CrossRef]

- Li, D.; Kong, N.; Li, R.; Zhang, B.; Zhang, Y.; Wu, Z.; Zhang, Q. The tribological performance of W-DLC in solid–liquid lubricationsystem addivated with Cu nanoparticles. Surf. Topogr. Metrol. Prop. 2021, 9, 045043. [Google Scholar]

- Rawat, S.; Harsha, A.; Agarwal, P.; Kumari, S.; Khatri, P. Pristine and alkylated MoS2 nanosheets for enhancement of tribological performance of paraffin grease under boundary lubrication regime. J. Tribol. 2019, 141, 072102. [Google Scholar]

- Chouhan, A.; Sarkar, K.; Kumari, S.; Vemuluri, S.; Khatri, P. Synergistic lubrication performance by incommensurately stacked ZnO-decorated reduced graphene oxide/MoS2 heterostructure. J. Colloid Inter. Sci. 2020, 580, 730–739. [Google Scholar]

- Kumari, S.; Chouhan, A.; Sharma, P.; Kuriakose, S.; Tawfik, A.; Spencer, S.; Walia, S.; Sugimura, H.; Khatri, P. Structural defects-mediated grafting of alkylamine on few-layer MoS2 and its potential for enhancement of tribological properties. ACS. Appl. Mater. Inter 2020, 12, 30720–30730. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhang, Q.; Yap, C.; Tay, B.; Edwin, T.; OlivIer, A.; Baillargeat, D. From bulk to monolayer MoS2: Evolution of Raman scattering. Adv. Funct. Mater. 2012, 22, 1385–1390. [Google Scholar] [CrossRef]

- Ma, C.; Qi, X.; Chen, B.; Bao, S.; Yin, Z.; Wu, X.; Luo, Z.; Wei, J.; Zhang, H.; Zhang, H. MoS2 nanoflower-decorated reduced graphene oxide paper for high-performance hydrogen evolution reaction. Nanoscale 2014, 6, 5624–5629. [Google Scholar]

- Wang, H.; Wang, B.; Wang, D.; Lu, L.; Wang, J.; Jiang, Q. Facile synthesis of hierarchical worm-like MoS2 structures assembled with nanosheets as anode for lithium ion batteries. RSC Adv. 2015, 5, 58084–58090. [Google Scholar]

- Gao, K.; Zhang, L.; Wang, J.; Zhang, B.; Zhang, J. Further improving the mechanical and tribological properties of low content Ti-doped DLC film by W incorporating. Appl. Surf. Sci. 2015, 353, 522–529. [Google Scholar]

- Takeno, T.; Komiyama, T.; Miki, H.; Takagi, T.; Aoyama, T. XPS and TEM study of W-DLC/DLC double-layered film. Thin Solid Film 2009, 517, 5010–5013. [Google Scholar] [CrossRef]

- Habibi, A.; Khoie, S.; Mahboubi, F.; Urgen, M. Raman spectroscopy of thin DLC film deposited by plasma electrolysis process. Surf. Coat. Technol. 2017, 309, 945–950. [Google Scholar]

- Wong, P.; He, F.; Zhou, X. Interpretation of the hardness of worn DLC particles using micro-raman spectroscopy. Tribol. Int. 2010, 43, 1806–1810. [Google Scholar] [CrossRef]

- Wen, S.; Huang, P. Principles of Tribology; Tsinghua University Press: Beijing, China, 2012. [Google Scholar]

- Miyake, S.; Saito, T.; Yasuda, Y.; Okamoto, Y.; Kano, M. Improvement of boundary lubrication properties of diamond-like carbon (DLC) films due to metal addition. Tribol. Int. 2004, 37, 751–761. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Sun, D.; Yang, G.; Gao, C.; Zhou, C.; Zhang, C.; Zhang, P. Wide adaptability of Cu nano-additives to the hardness and composition of DLC coatings in DLC /PAO solid-liquid composite lubricating system. Tribol. Int. 2019, 138, 184–195. [Google Scholar] [CrossRef]

- Mannan, A.; Sabri, M.; Kalam, M.; Hassan, M. Tribological performance of DLC/DLC and steel/DLC contacts in the presence of additivated oil. Int. J. Surf. Sci. Eng. 2018, 12, 60–75. [Google Scholar] [CrossRef]

| Elements | C | O | W |

|---|---|---|---|

| Content, % | 83.34 | 15.56 | 0.1 |

| Elements | C, % | O, % | W, % | S, % | Mo, % | Fe, % |

|---|---|---|---|---|---|---|

| steel/W-DLC | 79.09 | 19.52 | 0.03 | 0.3 | 0.05 | 1.01 |

| W-DLC/W-DLC | 81.01 | 17.81 | 0.02 | 0.23 | 0.03 | 0.9 |

| Lubrication Conditions | Steel/W-DLC | W-DLC/W-DLC | ||||

|---|---|---|---|---|---|---|

| Load, N | 10 | 20 | 30 | 10 | 20 | 30 |

| Oil film thickness, nm | 45.7 | 43.6 | 42.4 | 46.6 | 44.5 | 43.1 |

| Composite roughness, nm | 55.90 | 55.90 | 55.90 | 50.64 | 50.64 | 50.64 |

| λinitial | 0.82 | 0.78 | 0.77 | 0.92 | 0.88 | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, M.; Wang, T.; Liu, Z.; Lei, J.; Qiu, J.; Xu, W. Tribological Performance of Steel/W-DLC and W-DLC/W-DLC in a Solid–Liquid Lubrication System Additivated with Ultrathin MoS2 Nanosheets. Lubricants 2023, 11, 433. https://doi.org/10.3390/lubricants11100433

Yi M, Wang T, Liu Z, Lei J, Qiu J, Xu W. Tribological Performance of Steel/W-DLC and W-DLC/W-DLC in a Solid–Liquid Lubrication System Additivated with Ultrathin MoS2 Nanosheets. Lubricants. 2023; 11(10):433. https://doi.org/10.3390/lubricants11100433

Chicago/Turabian StyleYi, Meirong, Taoping Wang, Zizheng Liu, Jin Lei, Jiaxun Qiu, and Wenhu Xu. 2023. "Tribological Performance of Steel/W-DLC and W-DLC/W-DLC in a Solid–Liquid Lubrication System Additivated with Ultrathin MoS2 Nanosheets" Lubricants 11, no. 10: 433. https://doi.org/10.3390/lubricants11100433

APA StyleYi, M., Wang, T., Liu, Z., Lei, J., Qiu, J., & Xu, W. (2023). Tribological Performance of Steel/W-DLC and W-DLC/W-DLC in a Solid–Liquid Lubrication System Additivated with Ultrathin MoS2 Nanosheets. Lubricants, 11(10), 433. https://doi.org/10.3390/lubricants11100433