Abstract

Lubrication is a basic and relatively effective way to reduce friction in sheet metal forming operations. The drive to eliminate synthetic and mineral oils, which are difficult to recycle, from the manufacturing process has opened up opportunities for the use of vegetable-based bio-lubricants. This article presents a comparison of the lubrication performance of two non-edible oils (karanja and moringa) with the most frequently tested edible oils (sunflower and rape-seed). Deep drawing quality low-carbon steel sheets DC04, commonly used in the automotive industry, were used as the test material. Friction tests were carried out under various lubricants and normal pressures in the range between 3 and 12 MPa using the strip drawing test. Furthermore, a study was also made of the effect of a change in the surface topography and the mechanical properties of the sheet metal due to plastic deformation resulting from friction. It was found that under the most favorable lubrication conditions (sample pre-strain 21%, nominal pressure 6 MPa), karanja oil reduced the coefficient of friction by approximately 33%. Both non-edible lubricants provided the best lubrication when testing samples pre-strained at 7% under the whole range of nominal pressures. It was also revealed that in the case of the smallest pre-straining of the specimens (7%), karanja oil was the most effective within nominal pressures of 3–6 MPa, while at higher pressures (9–12 MPa), the moringa oil lowered the value of the coefficient of friction to a greater extent.

1. Introduction

Friction should be understood as a set of phenomena occurring in the area of contact between two moving bodies. The physical quantity that characterizes the friction force is the coefficient of friction (COF) [1,2]. In general, friction in sheet metal forming processes is an unfavorable phenomenon affecting the increase in forming force, reduction in the surface quality of the drawpiecesm and reduction in the forming limits in conventional sheet metal processes [3,4,5] and single point incremental forming [6,7,8]. COF depends on several parameters including [9,10] the materials of the friction pair, the friction conditions, the temperature, the topographies of the tool and workpiece, and the sliding speed. The most effective way to reduce friction is to use lubricants [11,12]. Due to the different conditions in which sheet metal forming processes are carried out and the wide range of properties of deformed materials, the selection of technological lubricants should be taken into account [13,14,15] such as the strain rate, the grade of deformed material and tool material, the range of normal pressures, the surface roughness of the sheet and tool as well as the forming temperature.

Mineral oils from petroleum refining and synthetic oils are normally usually used in sheet metal forming plants [16]. Lubricants based on petroleum raw materials are characterized by favorable operational properties, however, they pose a significant threat to the natural environment due to the emission to the environment of harmful products due to changes arising during use and the necessity of expensive recycling [17,18].

In recent years, due to the tightening of environmental protection legislation, interest in natural oils as substitutes for petroleum oils has increased due to their favorable operational and ecological properties. Vegetable oils lead in this respect due to their non-toxicity and high degree of biodegradation [19]. Compared to mineral oils, vegetable oils possess high lubricity and a high viscosity index. However, poor oxidative and hydrolytic stability have been suggested to be the limitations of vegetable oils for their use as lubricants in sheet metal forming [20]. Vegetable oils also contain minor amounts of waxes, tocopherols, and phytosterols that affect their quality. These compounds are not regularly analyzed due to the need for expensive instruments for testing [21].

Over the years, many authors have focused on replacing petroleum oils with their biological counterparts. Trzepieciński [22] examined the effectiveness of different lubricants based on a combination of boric acid and edible vegetable oils in the reduction in the COF of low carbon steel sheets in the strip drawing test. It was found that the addition of H3BO3 to vegetable oils led to an increase in the lubrication efficiency compared to non-modified oils. In another paper, Trzepieciński [23] analyzed the COF of deep drawing quality steel sheets tested with the presence of cotton seed, soybean, palm, sunflower, linseed, and coconut oils. The analysis of variance showed that an increase in the viscosity of the oil caused a reduction in the value of the COF. Among all of the bio-based edible lubricants considered, linseed oil had the most unfavorable properties. Trzepieciński and Szpunar [24] analyzed the friction properties of Ti–6Al–4V titanium alloy sheets using bio-degradable (palm and rape-seed) and mineral oils with the addition of boric acid (5 wt%). It was found that high kinematic viscosity and low density of the oil led to a high COF. Furthermore, an increase in the density of the lubricant caused a reduction in the COF. Karthik [25] experimentally tested the feasibility of utilizing pongamia and jatropha oils as forming lubricants to draw EN AW-6061 aluminium alloy cups. The punch load under jatropha raw oil was the lowest. However, the maximum draw-in-length was found with lubrication with raw pongamia oil. Carcel et al. [26] studied the performance of some vegetable oils (corn, soybean, olive, and sunflower) under boundary lubrication during the stamping of car body parts from extra deep drawing quality steel sheets. Strip drawing tests showed that better control of the topography would permit the use of special high viscosity press oils to be eliminated or allow for the use of vegetable oils with smaller quantities of additives. Syahrullail and Afifah [27] concluded in their review paper that vegetable oil had a great potential to replace the currently-used petroleum-based oils. Shashidhara and Jayaram [28] investigated jatropha and pongamia vegetable oils as metal forming lubricants when forming drawpieces of 304L steel sheet. Cups drawn under jatropha oil had a uniform wall thickness profile compared to pongamia oil. It was also observed that better material flow was noticed when lubricating with vegetable oil, while early rupture was observed under mineral oil. Więckowski and Dyja [29] investigated the friction properties of Grade 2 titanium sheets in the strip drawing test when lubricating using vegetable oils (i.e., olive oil, sunflower oil, and rapeseed oil), with the addition of boric acid. The results revealed that the use of vegetable oils allowed a reduction in the COF. A significant reduction in the COF was found compared with commercial mineral oil. Keshtiban et al. [30] investigated the lubrication efficiency of vegetable oil nano-lubricants with the addition of SiO2 nanoparticles. The EN AW-2024 aluminium alloy was used as the test material. The results revealed that the presence of SiO2 nanoparticles in the base lubricants significantly increased the lubrication efficiency and reduced both the surface roughness and COF.

Many authors researching the value of COF of deep-drawing steel sheets have focused on the use of petroleum-based lubricants. Of course, as the literature review has shown, attempts are being made to use vegetable oils as alternatives to mineral and synthetic oils. Nevertheless, the vast majority of studies concern edible oils, while in the face of the growing food crisis (food versus energy debate), more emphasis should be placed on non-edible oils of vegetable origin. As a novelty, this article compares the lubrication performance of two of the most frequently tested non-edible oils (karanja and moringa) with the most frequently tested edible oils (sunflower and rape-seed). The lubrication performance of bio-based oils was tested using the strip drawing test, which is commonly used to test the frictional properties of sheets at the sheet metal-blankholder interface in sheet metal forming. Moreover, the vast majority of authors have studied the frictional properties of sheets in the as-received state. At the same time, the sheet topography is constantly evolving during sheet metal forming. Therefore, to increase the novelty of this research, studies were also made of the effect of the change in the surface topography and the work hardening phenomenon due to the plastic deformation on friction.

2. Material and Methods

2.1. Test Materials

Low-carbon cold-rolled DC04 steel sheets were used as the test material. Sheets of this grade are commonly used in the automotive industry because they are characterized by very good drawability. The sheet thickness was 0.83 mm. The DC04 steel sheets were manufactured in accordance with the requirements of EN 10,130:2006 [31]. The mechanical properties of the sheets were determined according to the EN ISO 6892-1:2020 [32] using the Zwick/Roell Z100 uniaxial tensile testing machine with five repetitions. The values of yield stress Rp0.2, ultimate tensile strength Rm, and elongation A50 are as follows: 184.2 MPa, 303.9 MPa, and 42%, respectively.

The deep-drawing quality steel sheets showed a strong work hardening effect. Therefore, the true stress–true strain relations were approximated by the strain hardening (Hollomon) equation σ = K·εn, where σ is the true stress; K is the strain hardening coefficient; ε is the true strain; and n is the strain hardening exponent. The values of the strain hardening parameters were K = 489.0 MPa and n = 0.186.

A Vickers hardness tester Qness 60 Evo was used to test the as-received sheet metals according to the ISO 6507-1:2018 standard [33]. The force applied was 49.03 N. Six indentations were made and the mean hardness of the as-received material was determined to be 97 HV5. Due to the work hardening phenomenon, the hardness of the as-received material was changed during pre-straining. Therefore, the Vickers hardness of the pre-strained samples was also tested.

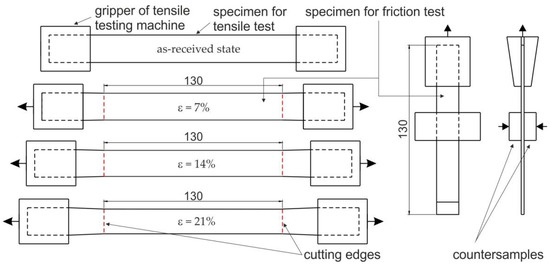

To analyze the influence of changes in the sheet surface topography caused by plastic strain on the value of the COF and lubrication efficiency, the as-received specimens were pre-strained with strains of 7, 14, and 21% (Figure 1). Strips with a length of 205 mm and width of 20 mm were used for the pre-straining test. For friction testing using a strip drawing test, samples in the form of strips with a length of 130 mm were cut out from the pre-strained sheet metals (Figure 1).

Figure 1.

A schematic diagram of the sample preparation for the friction test.

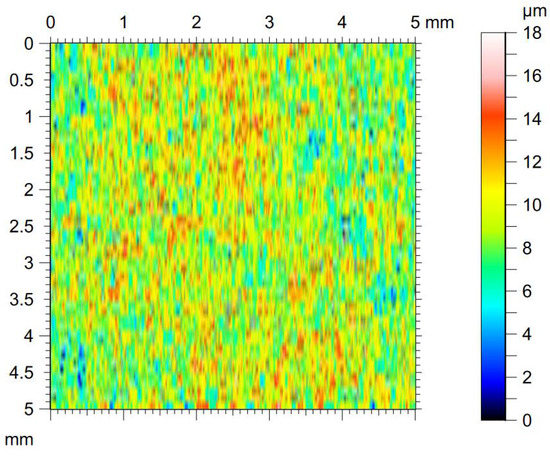

The topographies of the specimens in the as-received state (Figure 2) and after pre-straining were measured using a T8000RC profilometer in accordance with the requirements of the ISO 25,178 standard [34]. The main surface roughness parameters of the DC04 steel sheet in the as-received state were as follows: Sq = 2.29 µm, Ssk = −0.022, Sku = 2.70. The surface topographies of the specimens after the friction tests were also measured.

Figure 2.

The topography of the specimen surface in the as-received state.

The morphology of the specimens subjected to friction tests was examined using a scanning electron microscope (SEM) MIRA 3 TESCAN equipped with a Schottky field emission gun.

Countersamples for the friction test were fabricated from 145Cr6 cold-worked tool steel with a hardness of 215 HV10. The roughness parameters of the countersamples were as follows: Sa = 0.636 µm, Sq = 0.81 µm, Ssk = −0.544, Sku = 3.76, Sp = 4.89 µm, Sz = 10.0 µm, Sv = 5.11 µm.

2.2. Friction Test

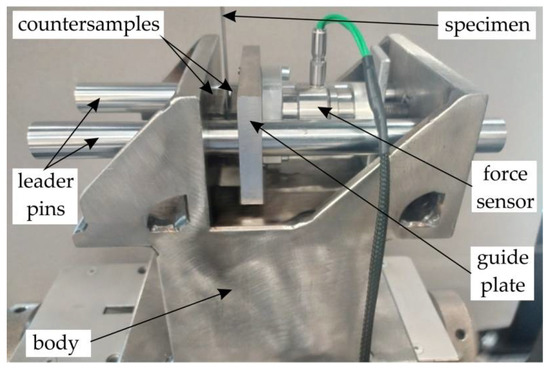

The flat die strip drawing test used in the research consisted of pulling a sheet metal strip between two countersamples with flat surfaces. The test apparatus (Figure 3) consisted of a body that was mounted in the lower holder of the Zwick/Roell Z100 uniaxial tensile testing machine. One of the countersamples was placed in the body of the device and was fixed. The second countersample waas seated in the guide plate sliding on the surface of the leader pins. The task of the leader pins was to ensure that the rubbing surfaces of the counter samples were parallel. A Kistler type 9345B force sensor was positioned between the guide plate and the body wall to measure the normal force. The pulling force was measured by the measuring system of the Zwick/Roell Z100 tensile testing machine.

Figure 3.

A photo of the friction simulator.

LabVIEW software integrated with a force sensor was used to record the clamping force of the countersamples. Both forces (clamping FC and pulling FP) were correlated in the LabVIEW program. Then, the COF was determined according to the relationship:

The tests were carried out in conditions of dry friction and lubrication of the sheet surface with two types of edible vegetable oils (sunflower and rape-seed) and two types of non-edible vegetable oils, karanja obtained from Millettia pinnata and moringa squeezed from Moringa oleifera seeds. The basic physical properties of the oils are shown in Table 1. A glass capillary kinematic viscometer was used to determine the kinematic viscosity of the oils according to ISO 3105:1994 [35]. The density and flash point were taken from the product specification sheets provided by the manufacturers. The strip drawing test was used to simulate friction conditions occurring in the sheet metal-blankholder interface in the conventional deep drawing processes. In this region of the tools, the pressures did not exceed 10–12 MPa. Too much pressure could stop the sheet from moving from the sheet-metal blankholder region into the punch interaction zone, and thus cause the sheet to break prematurely. Therefore, the tests were carried out for the following nominal pressures of 3, 6, 9, and 12 MPa.

Table 1.

The basic physical properties of the tested oils.

3. Results and Discussion

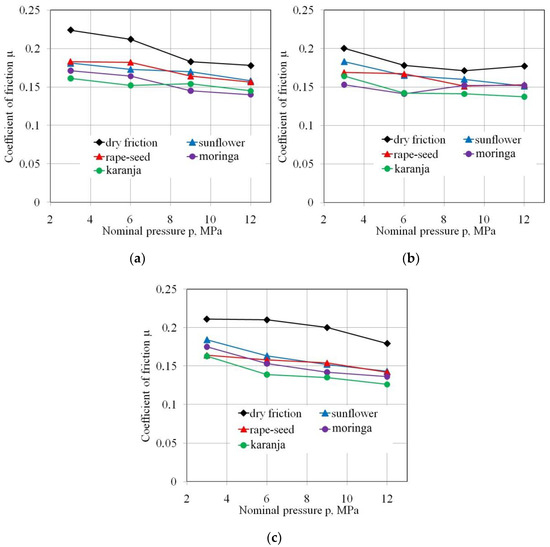

The value of the COF decreased with increasing nominal pressure in the range between 3 and 12 MPa (Figure 4). A similar trend of decreasing COF with increasing pressure was also observed by various researchers [36,37,38,39,40]. It was observed that in terms of relatively small normal pressures, the friction force does not change in proportion to the normal force. This is due to the occurrence of small plastic deformations of the surface asperities. Therefore, apart from the resistances related to the resistance to friction, the friction force also included resistance to plastic deformation of the summits of the surface roughness. It is known from tribological principles that the actual contact area of solid friction increases with an increase in the normal load. Since the magnitude of the increase in friction force is smaller than the increase in the normal load, the COF decreases with increasing normal load [40]. Due to this mechanism, friction in sheet metal forming differs from friction in kinematic pairs, where the friction of two materials of the same or similar strength occurs. In sheet metal forming, the cooperation of two bodies takes place, one of which is very hard (tool) and the other of which exhibits much lower strength.

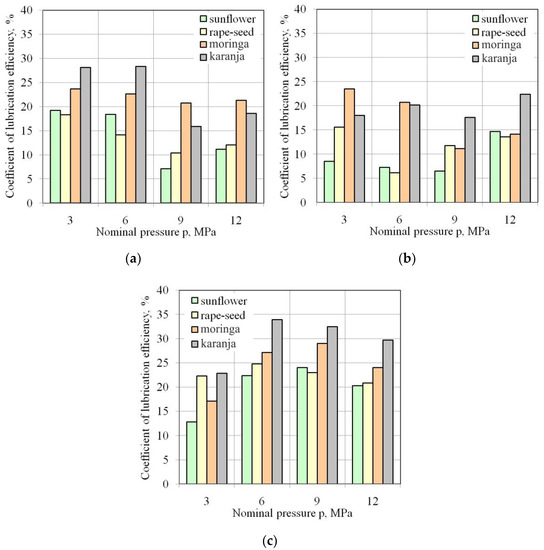

Figure 4.

The effect of nominal pressure and lubrication conditions on the COF for specimens pre-strained at (a) 7%, (b) 14%, and (c) 21%.

As expected, the COF value was highest under the dry friction conditions (Figure 4). It was also clear that, in general, the moringa and karanja oils achieved the lowest friction values. The results obtained confirm that the lubricating film of the oils that were tested was not broken within the nominal pressures investigated. Breakage of the lubricating film was accompanied by an increase in the value of the COF due to the dominance of metal-to-metal contact. Depending on the characteristics of the materials of the friction pair, the properties of oils and the value of pressures, the increase in the value of the COF due to film breakage may be of a greater or lesser character [41,42]. Previous investigations [22] on friction testing of the DC04 steel sheet using traditional and edible oils have shown that heavy-draw 1150 oil provided the best lubricating properties. Machine oil LAN-46 and deep-drawing mineral lubricants qualitatively reduced the friction to the same level as sunflower oil. In addition, the tendency for the coefficient of friction to the change value during lubrication was the most stable with this oil over a wide range of values of applied pressure. Rape-seed oil was the most effective vegetable lubricant.

The effectiveness of the lubricant used was assessed on the basis of a comparison of the COF obtained under lubrication conditions and under dry friction conditions, introducing the coefficient of lubrication efficiency (CLE):

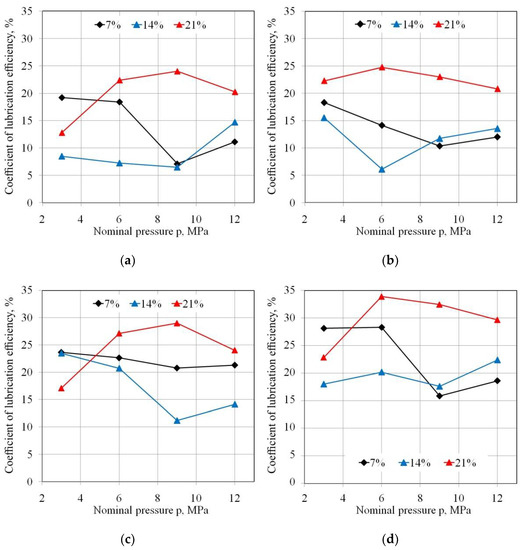

Figure 5 shows the changes in the CLE depending on the nominal pressure and lubricant type. Under the most favorable lubrication conditions, karanja oil reduced the COF by approximately 33% (Figure 5c). The lubrication efficiency of sunflower oil ranged between approximately 6 and 19%, 3.5 and 14.9%, and 12.9 and 23.9%, for the specimens pre-strained at 7% (Figure 5a), 14% (Figure 5b), and 21% (Figure 5c), respectively. Under the same conditions, the lubrication efficiency of rape-seed oil was between 10.5 and 23.4% (Figure 5a), 6.5 and 13.8% (Figure 5b), and 10.5 and 24.9% (Figure 5c). Non-edible oils showed the best efficiency in the whole range of pressures examined when testing samples pre-strained at 7% (Figure 5a). A similar situation occurred during the friction of pre-strained samples at 21% (Figure 5c), but only in the nominal pressure range of 6–12 MPa.

Figure 5.

The effect of nominal pressure and lubrication conditions on the coefficient of lubrication efficiency for specimens pre-strained at (a) 7%, (b) 14%, and (c) 21%.

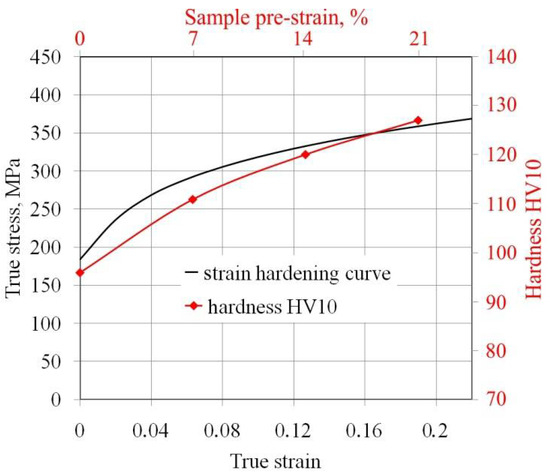

To better understand the mechanism of influence of a given lubricant on the COF value, the effect of nominal pressure on the CLE is presented separately for all of the oils tested in Figure 6. All of the oils tested showed a similar effect of lowering the frictional resistance depending on the degree of pre-straining of the samples. Under conditions of dry friction of the samples pre-strained with the lowest degree of deformation (7%), an initial decrease in the CLE value was observed followed by its continuous increase in the largest nominal pressures (Figure 6a,b). Similarly, the curves of the lubrication efficiency of sheets pre-deformed to the value of 14% showed a certain minimum, after exceeding which the value of the CLE started to increase. The position of the minimum value of the CLE depends on the degree of pre-straining of the sheet. The sheet deformation causes an increase in the area of valleys in the surface topography due to the stretching of the bearing profile [5,40]. Additionally, plastic deformation of the sheet changes the mechanical properties of the sheet material through the work hardening effect. Increasing the hardness of the material of the metal sheet is strongly related to the strain hardening curve (Figure 7). The harder the plate, the less susceptible it is to ploughing and flattening mechanisms [2,13]. Thus, under normal pressure, the surface asperities of the pre-strained sheets are less prone to deformation under pressure. Limiting the real contact area in sheet metal forming processes is very beneficial since it minimizes metal-to-metal contact. The lubrication efficiency of oils was different in the case of the highest degree of the pre-straining of specimens (red lines in Figure 6) when compared to the pre-strained sheets at 7 and 14%. After an initial increase in the value of the CLE, its value declined for the highest value of nominal pressure.

Figure 6.

The effect of the nominal pressure and pre-straining value on the coefficient of lubrication efficiency for lubrication using the following oils: (a) sunflower, (b) rape-seed, (c) moringa, and (d) karanja.

Figure 7.

A comparison of the true stress–true strain relation with the hardness of sheet metal.

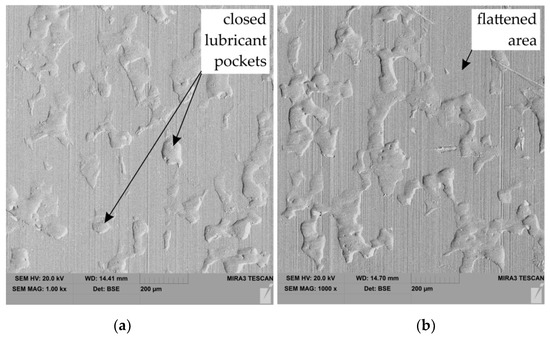

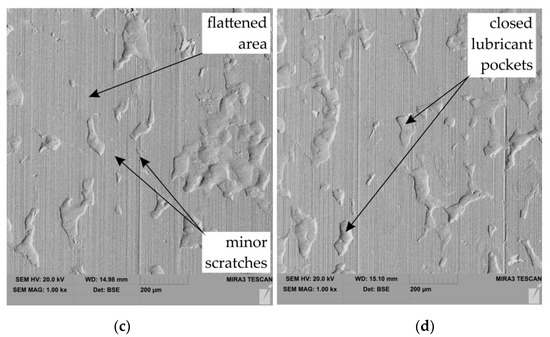

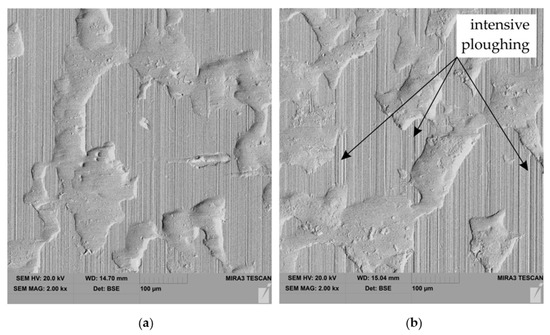

At low nominal pressures, even under lubrication conditions, the highest summits of the roughness flatten and interpenetrate with the summits of the tool surface. In addition, due to high asperities, the lubricant is not able to build up sufficient hydrostatic pressure in closed lubricant pockets. It should be emphasized that the sheet deformed with a pre-strain degree of 21% showed a greater hardness than the other two types of pre-strained specimens considered. After the contact surface stabilized with a normal pressure increase, the lubricant entrapped in closed lubricant pockets [43,44] (as a result of the increase in normal load) generated an appropriate pressure that could effectively separate the rubbing surfaces. Unfortunately, such a situation lasts only up to a certain pressure value, above which intensive mechanical flattening of the summits of asperities begins to dominate, reducing the volume of the closed lubricant pockets (Figure 8).

Figure 8.

The SEM micrograph of the sheet surface after friction tests were carried out under a nominal pressure of 12 MPa: (a) sunflower oil, (b) rape-seed oil, (c) moringa oil and (d) karanja oil.

Lubrication in sheet metal forming is closely related to the volume of the lubricant pockets resulting from the plastic deformation of the sheet and the interaction of the surface asperities of the tool. The sheet topography is constantly evolving during forming. This effect can be attributed to the formability of the sheet material [45,46]. Formability is the property of metals determining the ability of a given metal workpiece to undergo plastic deformation without being damaged [47]. The formability of sheet metals is not only dependent on the type of material [48] and the forming temperature [49], but also on the method by which the load that is applied causes deformation [50]. Moreover, cold rolling has a detrimental effect on the formability of sheet metals [51]. The plastic deformation capacity of metallic sheets is subject to certain limits, and if these are exceeded, the material could experience fracture [52]. Forming limit diagrams (FLDs) are the most appropriate tools to describe the formability of sheet metals [53]. FLDs represent the formability limits in the coordinate system of major and minor principal strain [54,55]. When the limit of deformability is reached, the material breaks up and the drawpiece is destroyed [56]. Therefore, it is very important to learn the limit of deformability since this permits the precise design of the plastic forming processes of metals and alloys so that they can be carried out without decohesion of the material [57,58]. It should be emphasized that the deformation value that can be achieved in the technological process may not only be limited by the deformability of the material, but also by the phenomena of the loss of stability (preceding the decohesion process), the strength of the forming tools or other phenomena (e.g., related to friction on the contact interface of the tool with deformed material). Among the many methods of evaluating the drawability of sheet metals developed by, among others, Duncan, Engelhardt, and Gross, Olsen, Fukui, Guillera, Avera, and Jovignot, the Erichsen method [59] conducted according to the ISO 20,482 standard [60] is the most common. In this method, the value representing the susceptibility of the sheet metal to drawing is the depth to which a ball or spherical punch with a diameter in the range of 3–20 mm, selected depending on the thickness of the sheet, is pressed into a specimen until a crack appears in it.

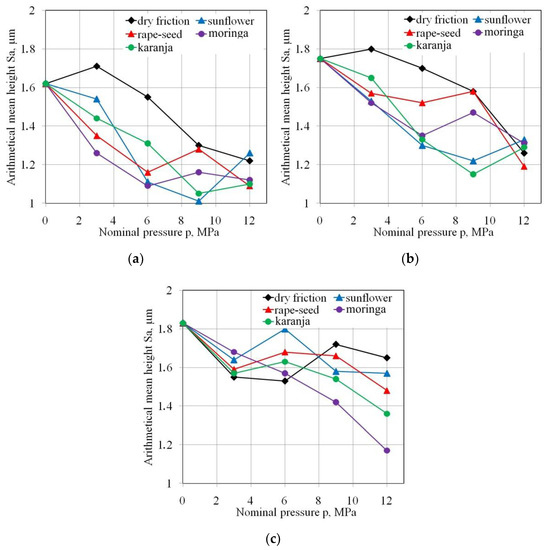

The process of sheet deformation in the as-received state caused an increase in the arithmetical mean height Sa of the sample surfaces. The value of the arithmetical mean height Sa showed a tendency to decrease in relation to the sample not subjected to the friction process (nominal pressure 0 MPa in Figure 9a,b). At the highest pressure, in addition to flattening (Figure 10), a ploughing mechanism was revealed, which consisted in the formation of scratches (Figure 11) as a result of the impact of the highest asperities of the roughness of the hard tool. This effect was visible for strain hardened sheets with a deformation degree of 7 and 14% (Figure 9a,b). The specimen pre-strained with a deformation degree of 21% was too hard to show the grooving effect of the sheet metal surface, so in the case of lubricated conditions, the value of the Sa parameter decreased in the range of nominal pressures between 6 and 12 MPa (Figure 9c).

Figure 9.

The effect of nominal pressure and lubrication conditions on the arithmetical mean height Sa for the specimens pre-strained at (a) 7%, (b) 14%, and (c) 21%.

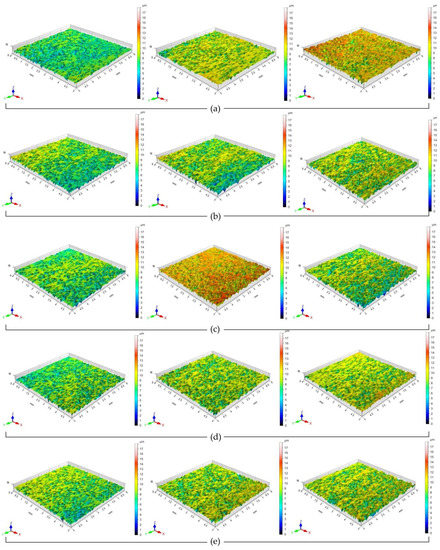

Figure 10.

The surface topographies of the samples pre-strained with a value of deformation of 7% (left subfigures), 14% (middle subfigures), and 21% (right subfigures) tested at a nominal pressure of 12 MPa and in the following friction conditions: (a) dry friction, (b) sunflower oil, (c) rape-seed oil, (d) moringa oil, and (e) karanja oil.

Figure 11.

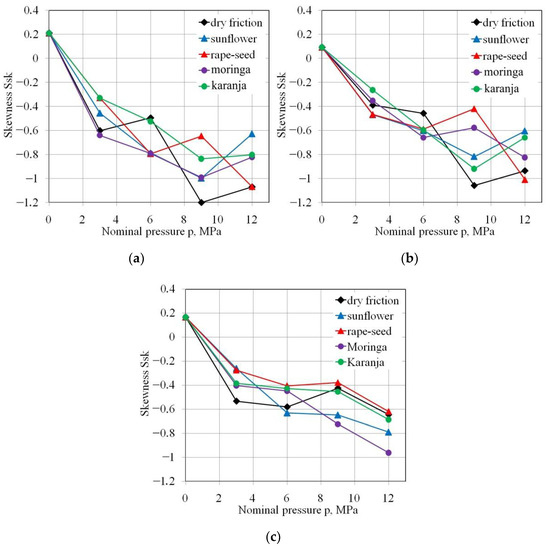

The effect of the nominal pressure and lubrication conditions on the skewness Ssk for the specimens pre-strained at (a) 7%, (b) 14%, and (c) 21%.

The arithmetical mean height is commonly used and provides a very good overall description of height variations, but it is not sensitive to small changes in profile and it does not give any information on the wavelengths. Sedláček et al. [61] showed that in the case of friction in the lubrication regime, skewness and kurtosis are more appropriate to describe the tribological phenomena occurring during sheet metal forming. Moreover, Wang et al. [62] found that kurtosis and skewness had a great effect on the contact parameters of mixed lubrication, which dominates in sheet metal forming. Apart from the arithmetical mean height, kurtosis and skewness are the parameters most frequently used to describe the surface roughness of sheet metals in industrial practice [63]. Therefore, the variation of both skewness and kurtosis are presented in Figure 11 and Figure 12. The friction process changed the value of the skewness parameter from positive to negative (Figure 11). Negative Ssk indicates a predominance of sharp valleys and rounded peaks (Figure 13) due to the friction process. It is clear that with an increase in the amount of pre-straining, the sheet metal puts more resistance to flattening the summits of the asperities, especially when the nominal pressure is greater than 6 MPa.

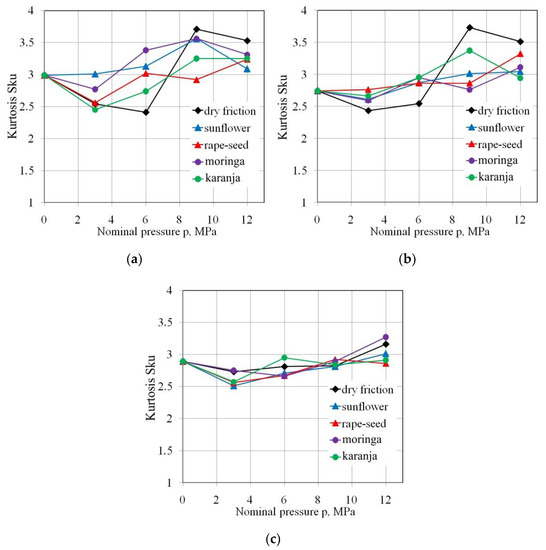

Figure 12.

The effect of the nominal pressure and lubrication conditions on kurtosis Sku for the specimens pre-strained at (a) 7%, (b) 14%, and (c) 21%.

Figure 13.

The negative and positive skewness.

Kurtosis Sku describes the probability density sharpness of the profile. For surfaces with low peaks and low valleys, kurtosis amounts to less than 3, and for surfaces with high peaks and low valleysm it is more than 3 [61,64]. Specimens pre-strained with 7% of deformation showed a kurtosis of more than 3 in most of the conditions tested (Figure 12). There was a clear relation between the degree of pre-straining and skewness. As the nominal pressure increased, the sheet was more resistant to the production of low peaks and low valleys caused by friction.

An interesting relationship, confirmed for all degrees of pre-strain, was observed for dry friction. First, the kurtosis was slightly decreased for a nominal pressure of 3 MPa (as for all lubrication conditions investigated), then it increased, and then decreased again after exceeding the pressure of 9 MPa. Therefore, after the initial flattening of the peaks of the roughness, the highest surface asperities of the hard tool mechanically affected the tool, which caused scratches on the sheet surface and the creation of high peaks and low valleys, especially in dry friction conditions (Figure 14). If the nominal pressure was large enough (p = 12 MPa in Figure 12a,b), the contact area of the tool with the sheet increased, thus further limiting flattening of the surface roughness profile and bringing the surface asperities to a normal distribution. As can also be seen in Figure 11c, lubrication had the least effect in changing the skewness for the specimens pre-strained at 21%. The deviation of the strip drawing test results was the smallest for all of the nominal pressures and friction conditions (Figure 12c).

Figure 14.

The SEM micrograph of the sheet surface after the friction tests carried out under dry friction conditions: (a) nominal pressure of 6 MPa and (b) nominal pressure of 9 MPa.

4. Conclusions

This paper investigated the effect of nominal pressure and bio-lubricant type on the value of the COF of the DC04 steel sheets determined in the strip drawing test. Based on the research results, the following conclusions can be drawn:

- The value of the COF decreased with increasing nominal pressure in the range of pressures considered between 3 and 12 MPa.

- In general, the moringa and karanja oil-based bio-lubricants achieved the lowest COF values. The results obtained showed no breakage of the lubricating film during the friction process within the nominal pressures analyzed.

- Under the most favorable lubrication conditions, karanja oil reduced the COF by approximately 33% (sample pre-strain 21%, nominal pressure of 6 MPa). Both non-edible lubricants provided the best lubrication during testing: (i) samples pre-strained at 7% in the whole range of nominal pressures, and (ii) samples pre-strained at 21% within the nominal pressures between 6 and 12 MPa. In the case of the smallest pre-straining of the specimens, karanja oil was the most effective within the nominal pressures of 3–6 MPa, while at higher pressures, the moringa oil lowered the COF value to a greater extent.

- The lubrication efficiency of the sunflower and rape-seed oils ranged between approximately 6 and 23.4%, 3.5 and 14.9%, and 10.5 and 24.9%, for the specimens pre-strained at 7%, 14%, and 21%, respectively.

- The lubrication efficiency of oils was different in the case of the highest degree of pre-straining of specimens (21%) when compared to the pre-strained sheets at 7 and 14%. After an initial increase in the value of the CLE, its value declined for the highest value of nominal pressure.

- The value of the Sa parameter showed a tendency to decrease in relation to the sample not subjected to the friction process. In addition to flattening, a ploughing mechanism was revealed at the highest pressure, which consisted in the formation of scratches as a result of the impact of the highest asperities of the roughness of a hard tool.

- It was found that with an increase in the amount of pre-straining, the sheet metal put more resistance to flattening the summits of the asperities, especially when the nominal pressure was greater than 6 MPa. Pre-strained specimens at 7% of deformation showed a kurtosis of more than 3 in most of the tested conditions.

- The negative values of skewness confirmed that as the nominal pressure increased, the sheet was more resistant to the production of low peaks and low valleys caused by friction.

Author Contributions

Conceptualization, T.T.; Methodology, T.T., M.S. and K.S.; Software, M.S. and K.S.; Validation, T.T., M.S. and K.S.; Investigation, T.T., M.S. and K.S.; Data curation, T.T., M.S. and K.S.; Writing—original draft preparation, T.T.; Writing—review and editing, T.T., M.S. and K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Trzepieciński, T.; Kubit, A.; Fejkiel, R.; Chodoła, Ł.; Ficek, D.; Szczęsny, I. Modelling of Friction Phenomena Existed in Drawbead in Sheet Metal Forming. Materials 2021, 14, 5887. [Google Scholar] [CrossRef] [PubMed]

- Bay, N.; Olsson, D.D.; Andreasen, J.L. Lubricant test methods for sheet metal forming. Tribol. Int. 2008, 41, 844–853. [Google Scholar] [CrossRef]

- Krawiec, S. Kompozycje Smarów Plastycznych i Stałych w Procesie Tarcia Stalowych Węzłów Maszyn; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2011. [Google Scholar]

- Żaba, K.; Trzepieciński, T.; Rusz, S.; Puchlerska, S.; Balcerzak, M. Full-Field Temperature Measurement of Stainless Steel Specimens Subjected to Uniaxial Tensile Loading at Various Strain Rates. Materials 2021, 14, 5259. [Google Scholar] [CrossRef] [PubMed]

- Hol, J.; Wiebenga, J.H.; Varleer, B. Friction and lubrication modelling in sheet metal forming: Influence of lubrication amount, tool roughness and sheet coating on product quality. Mater. Sci. Eng. 2017, 896, 012026. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Oleksik, V.; Pepelnjak, T.; Najm, S.M.; Paniti, I.; Maji, K. Emerging trends in single point incremental sheet forming of lightweight metals. Metals 2021, 11, 1188. [Google Scholar] [CrossRef]

- Żaba, K.; Głodzik, M.; Puchlerska, S.; Pociecha, D.; Nowosielski, M.; Kwiatkowski, M. Analysis of the aluminium formability in the incremental sheet forming process. In Proceedings of the METAL 2015 Conference, Brno, Czech, 3–5 June 2015; pp. 1–6. [Google Scholar]

- Slota, J.; Šiser, M.; Gajdoš, I. Failure prediction of axisymmetric cup in deep drawing and expansion processes. Open Eng. 2018, 8, 354–362. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Fejkiel, R.; Kubit, A.; Bochnowski, W. Evaluation of friction coefficient of an auto-body steel sheet. Zesz. Nauk. Politech. Rzesz. Mech. 2016, 88, 247–258. [Google Scholar] [CrossRef]

- Evin, E.; Ábel, M.; Viňáš, J.; Tkáčová, J.; Antoszewski, B. Tribological characteristics of stamping dies with coatings. Zesz. Nauk. Politech. Rzesz. Mech. 2013, 85, 129–137. [Google Scholar] [CrossRef]

- Jivan, R.B.; Eskandarzade, M.; Bewsher, S.R.; Leighton, M.; Mohammadpour, M.; Saremi-Yarahmadi, S. Application of solid lubricant for enhanced frictional efficiency of deep drawing process. J. Mech. Eng. Sci. 2021, 236, 624–634. [Google Scholar] [CrossRef]

- Mousavi, A.; Sperk, T.; Gietzelt, T.; Kunze, T.; Lasagni, A.F.; Brosius, A. Effect of contact area on friction force in sheet metal forming operations. Key Eng. Mater. 2018, 767, 77–84. [Google Scholar] [CrossRef]

- Wilson, W.R.D. Friction and lubrication in sheet metal forming. In Mechanics of Sheet Metal Forming; Koistinen, D.P., Wang, N.M., Eds.; Springer: Boston, MA, USA, 1978; pp. 157–177. [Google Scholar]

- Behrens, B.A.; Maier, H.J.; Hübner, S.; Bonk, C.; Almohallami, A.; Lummer, C.; Schein, P.; Scheland, H.; Moritz, M.C. Wear behavior of MoS2 lubricant layers during sheet metal forming. Procedia Eng. 2017, 183, 357–362. [Google Scholar] [CrossRef][Green Version]

- Lee, K.; Moon, C.; Lee, M.G. A Review on friction and lubrication in automotive metal forming: Experiment and modeling. Int. J. Automot. Technol. 2021, 22, 1743–1761. [Google Scholar] [CrossRef]

- Bucur, A.; Lazarecu, L.; Pop, G.M.; Achimas, G.; Gebhardt, A. A tribological performance of biodegradable lubricants under different surface roughness of tools. Acdemic J. Manuf. Eng. 2019, 17, 1–7. [Google Scholar]

- Nowak, P.; Kucharska, K.; Kamiński, M. Ecological and health effects of lubricant oils emitted into the environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef] [PubMed]

- Aluyor, E.O.; Obahiagbon, K.O.; Ori-jesu, M. Biodegradation of vegetable oils: A review. Sci. Res. Essay 2009, 4, 543–548. [Google Scholar]

- Drabik, J. Charakterystyki tribologiczne smarów plastycznych wytworzonych na modyfikowanych olejach roślinnych. Tribologia 2015, 2, 31–40. [Google Scholar]

- Woma, T.Y.; Lawal, S.A.; Abdulrahman, A.S.; Olutoye, M.A.; Ojapah, M.M. Vegetable oil based lubricants: Challenges and prospects. Tribol. Online 2019, 14, 60–70. [Google Scholar] [CrossRef]

- Dunford, N.T. Edible Oil Quality. Available online: https://extension.okstate.edu/fact-sheets/edible-oil-quality.html (accessed on 20 July 2022).

- Trzepieciński, T. Tribological performance of environmentally friendly bio-degradable lubricants based on a combination of boric acid and bio-based oils. Materials 2020, 13, 3892. [Google Scholar] [CrossRef]

- Trzepieciński, T. Polynomial multiple regression analysis of the lubrication effectiveness of deep drawing quality steel sheets by eco-friendly vegetable oils. Materials 2022, 15, 1151. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Szpunar, M. Assessment of the effectiveness of lubrication of Ti-6Al-4V titanium alloy sheets using radial basis function neural networks. Acta Polytech. 2021, 61, 489–496. [Google Scholar] [CrossRef]

- Karthik, A.V. Vegetable oil as a forming lubricant for deep drawing of AA6061. Int. J. Eng. Sci. Comput. 2016, 6, 1580–1582. [Google Scholar]

- Carcel, A.C.; Palomares, D.; Rodilla, E.; Pérez Puig, M.A. Evaluation of vegetable oils as pre-lube oils for stamping. Mater. Des. 2005, 26, 587–593. [Google Scholar] [CrossRef]

- Syahrullail, S.; Afifah, Z.N. Bio-lubricant for metal forming. Mytribos Symp. 2017, 2, 54–56. [Google Scholar]

- Shashidhara, Y.M.; Jayaram, S.R. Deep drawing of 304 L steel sheet using vegetable oils as forming lubricants. Int. J. Adv. Res. Technol. 2012, 1, 1–5. [Google Scholar]

- Więckowski, W.; Dyja, K. The effect of the use of technological lubricants based on vegetable oils on the process of titanium sheet metal forming. Arch. Metall. Mater. 2017, 62, 489–494. [Google Scholar] [CrossRef][Green Version]

- Keshtiban, P.M.; Ghaleh, S.S.G.; Alimirzaloo, V. Lubrication efficiency of vegetable oil nano-lubricants and solid powder lubricants. J. Mater. Des. Appl. 2018, 233, 1384–1392. [Google Scholar] [CrossRef]

- EN 10130: 2006; Cold Rolled Low Carbon Steel Flat Products for Cold Forming—Technical Delivery Conditions. European Committee for Standardization: Brussels, Belgium, 2006.

- EN ISO 6892-1:2020; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 25178:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 3105:1994; Glass Capillary Kinematic Viscometers—Specifications and Operating Instructions. International Organization for Standardization: Geneva, Switzerland, 1994.

- Trzepieciński, T.; Fejkiel, R. On the influence of deformation of deep drawing quality steel sheet on surface topography and friction. Tribol. Int. 2017, 115, 78–88. [Google Scholar] [CrossRef]

- Vollertsen, F.; Hu, Z. Tribological size effects in sheet metal forming measured by a strip drawing test. CIRP Ann. 2006, 55, 291–294. [Google Scholar] [CrossRef]

- Kirkhorn, L.; Frogner, K.; Andersson, M.; Stahl, J.E. Improved tribotesting for sheet metal forming. Procedia CIRP 2012, 3, 507–512. [Google Scholar] [CrossRef]

- Ten Thije, R.H.W.; Akkerman, R.; van der Meer, L.; Ubbink, M.P. Tool-ply friction in thermoplastic composite forming. Int. J. Mater. Form. 2008, 1, 953–956. [Google Scholar] [CrossRef]

- Dou, S.; Xia, J. Analysis of Sheet Metal Forming (Stamping Process): A Study of the Variable Friction Coefficient on 5052 Aluminum Alloy. Metals 2019, 9, 853. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, L.; Politis, D.J.; Zhang, J.; Gharbi, M.M.; Leyvraz, D.; Wang, L. Experimental and modelling studies of the transient tribological behaviour of a two-phase lubricant under complex loading conditions. Friction 2022, 10, 911–926. [Google Scholar] [CrossRef]

- van der Heide, E. Lubricant Failure in Sheet Metal Forming Processes. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 12 April 2002. [Google Scholar]

- Wang, C.; Guo, B.; Shan, D. Friction related size-effect in microforming—A review. Manuf. Rev. 2014, 1, 23. [Google Scholar] [CrossRef]

- Dubar, L.; Hubert, C.; Christiansen, P.; Bay, N.; Dubois, A. Analysis of fluid lubrication mechanisms in metal forming at mesoscopic scale. CIRP Ann. 2012, 61, 271–274. [Google Scholar] [CrossRef]

- Shao, Z.; Li, N.; Lin, J.; Dean, T. Formability evaluation for sheet metals under hot stamping conditions by a novel biaxial testing system and a new materials model. Int. J. Mech. Sci. 2017, 120, 149–158. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Z. The effects of through-thickness shear stress on the formability of sheet metal–A review. J. Manuf. Processes 2021, 71, 269–289. [Google Scholar] [CrossRef]

- Banabic, D. Sheet Metal Forming Processes; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Dariani, B.M.; Liaghat, G.H.; Gerdooei, M. Experimental investigation of sheet metal formability under various strain rates. J. Eng. Manuf. 2009, 223, 703–712. [Google Scholar] [CrossRef]

- Reddy, A.C.S.; Rajesham, S.; Reddy, P.R.; Umamaheswar, A.C. Formability: A review on different sheet metal tests for formability. AIP Conf. Proc. 2020, 2269, 030026. [Google Scholar]

- Bhatt, M.R.; Buch, S. Prediction of formability for sheet metal component using artificial intelligent technique. In Proceedings of the 2nd International Conference on Signal Processing and Integrated Networks (SPIN), Noida, India, 19–20 February 2015; pp. 388–393. [Google Scholar]

- Xie, Y.; Wu, Y.; Jalali, A.; Zhou, H.; Khadimallah, M.A. Effects of thickness reduction in cold rolling process on the formability of sheet metals using ANFIS. Sci. Rep. 2022, 12, 10434. [Google Scholar] [CrossRef]

- Kumar, J.P.; Kumar, R.U.; Ramakrishna, B.; Ramu, B.; Saheb, K.B. Formability of sheet metals—A review. Mater. Sci. Eng. 2018, 455, 012081. [Google Scholar]

- Tisza, M.; Kovács, Z.P. New methods for predicting the formability of sheet metals. Prod. Processes Syst. 2012, 5, 45–54. [Google Scholar]

- Magrinho, J.P.; Silva, M.B.; Reis, L.; Martins, P.A.F. Formability limits, fractography and fracture toughness in sheet metal forming. Materials 2019, 12, 1493. [Google Scholar] [CrossRef] [PubMed]

- Chhikara, S.; Khatta, R.; Verma, S.P.; Shamrao, D.M. Review on sheet metal formability. Int. J. Adv. Res. Innov. 2020, 8, 82–85. [Google Scholar]

- Jaremenko, C.; Ravikumar, N.; Affronti, E.; Merklein, M.; Maier, A. Determination of forming limits in sheet metal forming using deep learning. Materials 2019, 12, 1051. [Google Scholar] [CrossRef]

- Wankhede, P.; Suresh, K. A review on the evaluation of formability in sheet metal forming. Adv. Mater. Processing Technol. 2020, 6, 458–485. [Google Scholar] [CrossRef]

- Emments, W.C. Formability, A Review of Parameters and Processes That Control, Limit or Enhance the Formability of Sheet Metal; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- Erichsen, A.M. Process and Apparatus for Testing Metal Sheets and Plater. GB Patent no. 91228571 (A), 6 January 1913. [Google Scholar]

- ISO 20482:2013; Sheet and Strip—Erichsen Cupping Test. International Organization for Standardization: Geneva, Switzerland, 2013.

- Sedlaček, M.; Vilhena, L.M.S.; Podgornik, B.; Vižintin, J. Surface topography modelling for reduced friction. Stroj. Vestn. J. Mech. Eng. 2011, 57, 674–680. [Google Scholar] [CrossRef]

- Wang, W.Z.; Che, H.; Hu, Y.Z.; Wang, H. Effect of surface roughness parameters on mixed lubrication characteristics. Tribol. Int. 2006, 39, 522–527. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Influence of surface preparation on roughness parameters, friction and wear. Wear 2009, 266, 482–487. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).