Evaluation of Mango Kernel Seed (Mangifera indica) Oil as Cutting Fluid in Turning of AISI 1525 Steel Using the Taguchi-Grey Relation Analysis Approach

Abstract

:1. Introduction

2. Methodology

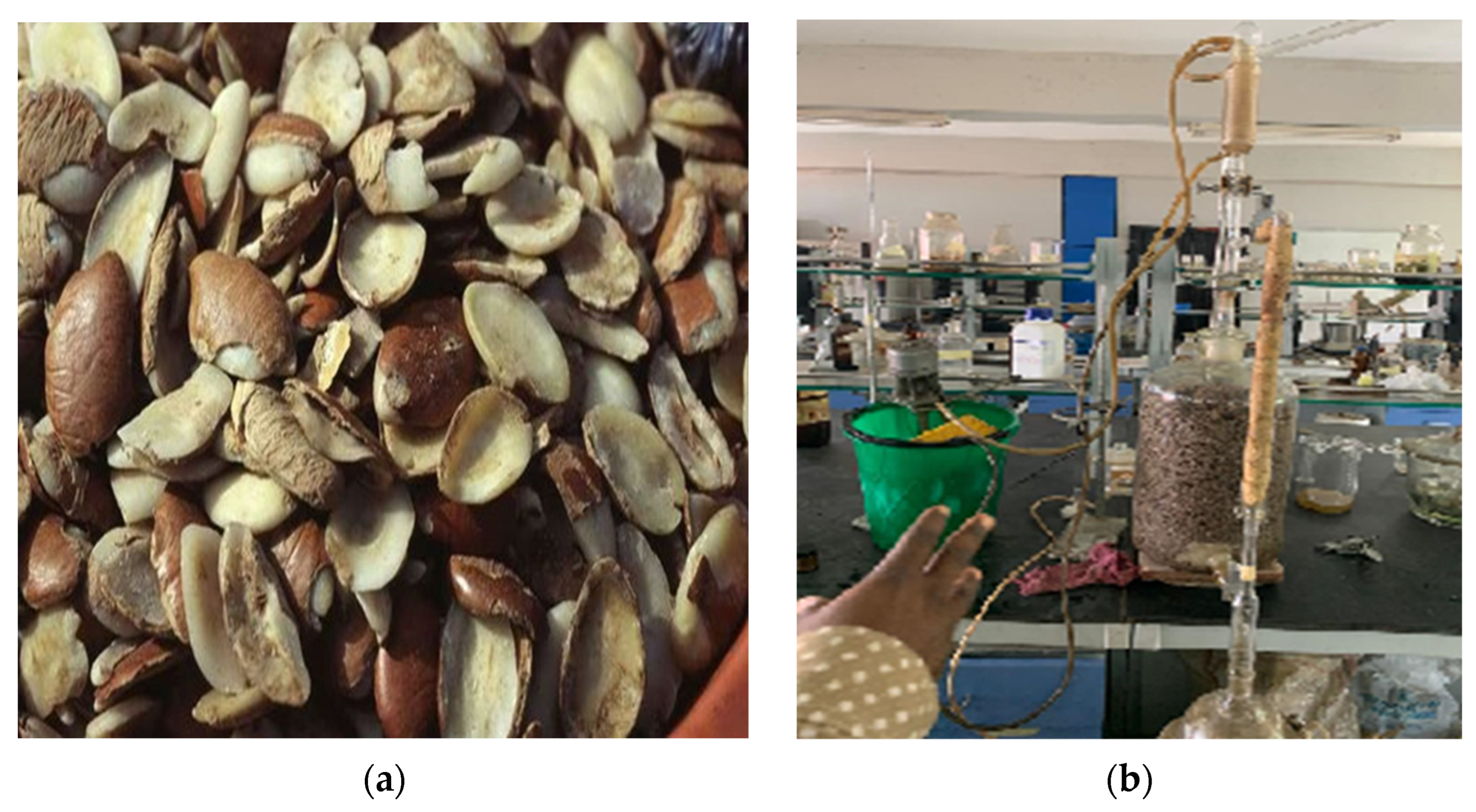

2.1. Seed Samples Description

2.2. Oil Extraction Process

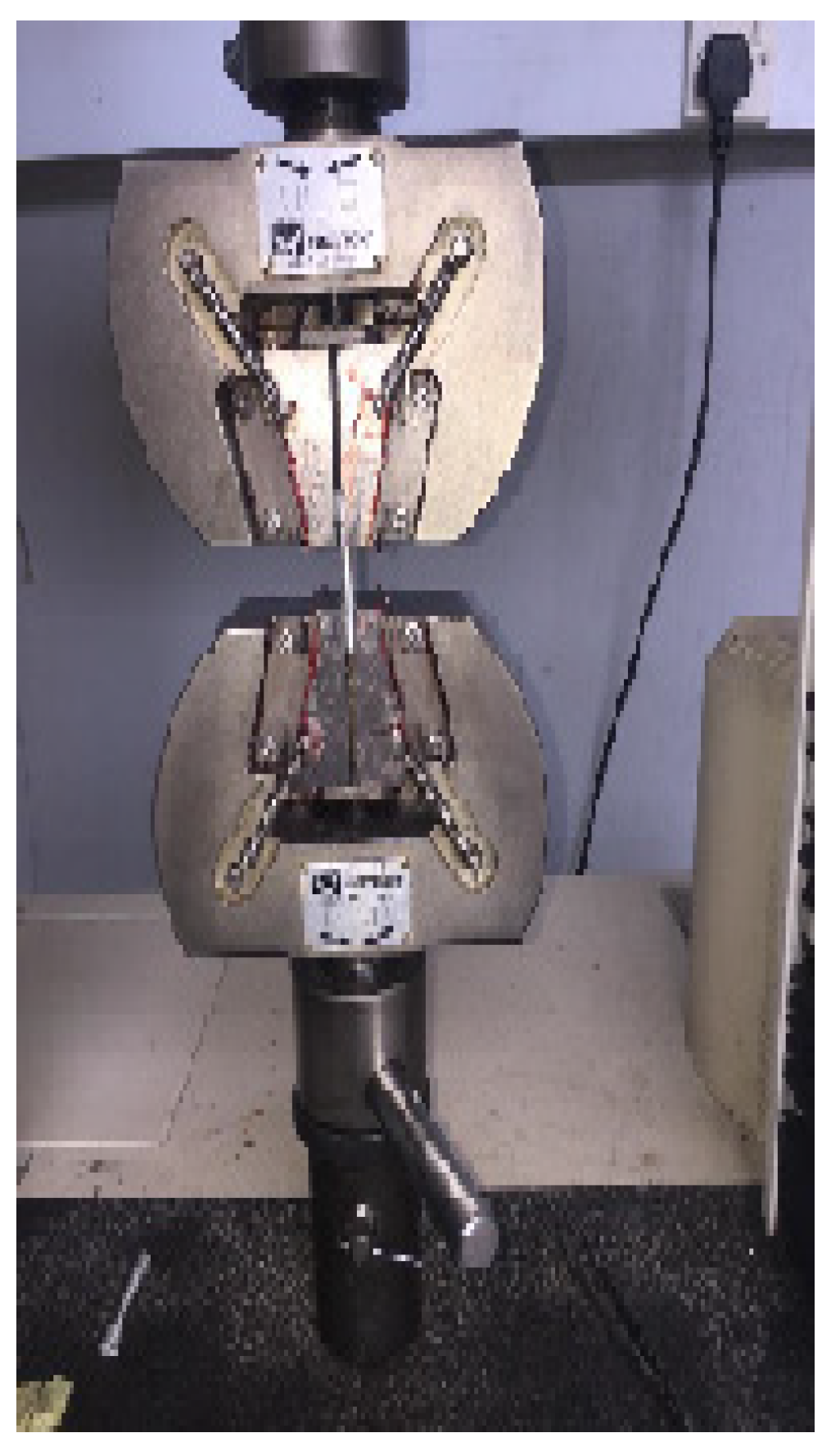

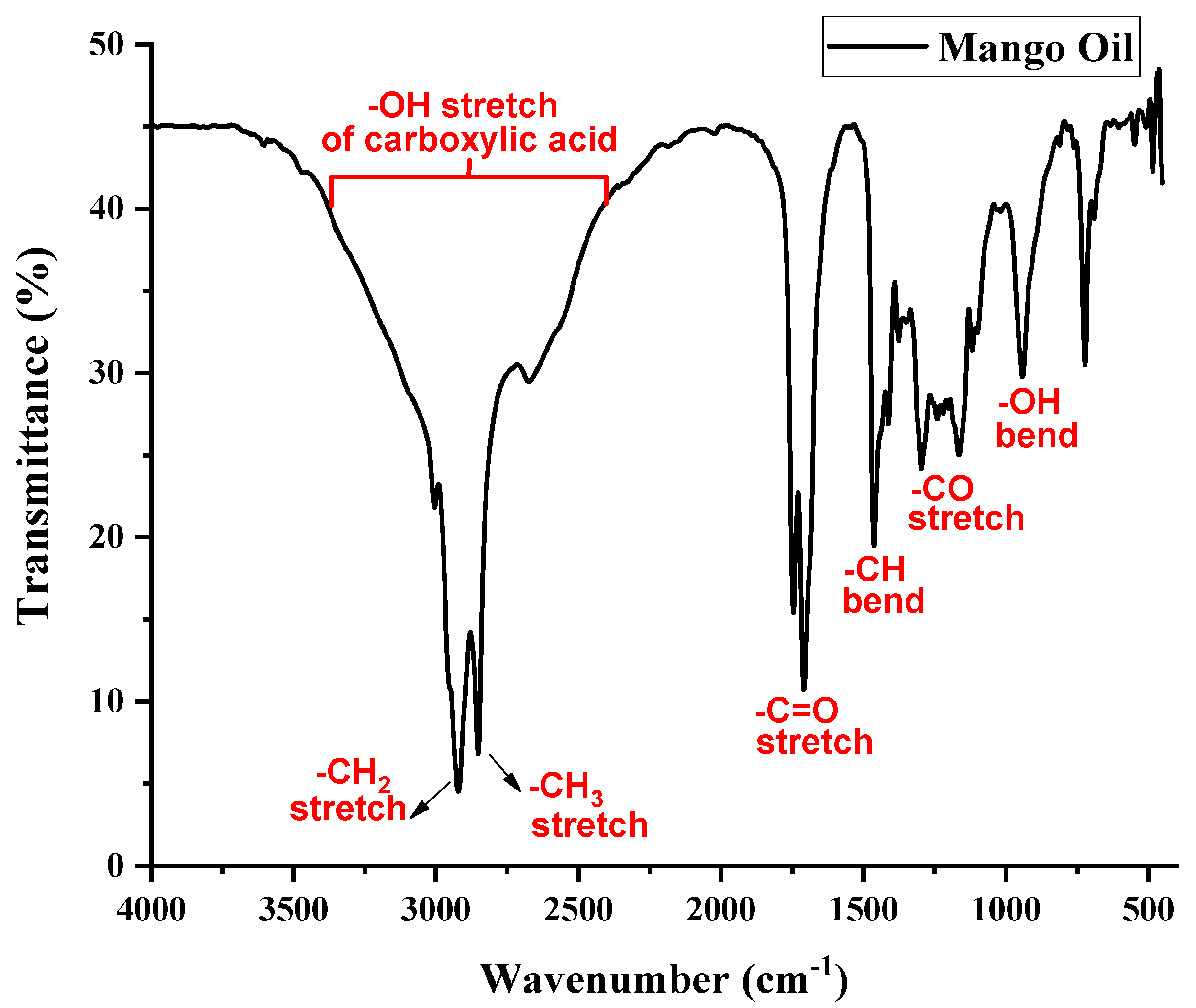

2.3. Characterization of Crude Oil Extracts

2.4. Formulation of Cutting Fluids Emulsion

2.5. Evaluation of pH of Emulsion Cutting Fluids

2.6. Machining Operations

2.7. Determination of Surface Roughness

2.7.1. Determination of Cutting Temperature

2.7.2. Determination of Machine Vibration

2.7.3. Determination of Machine Sound Level

3. Results and Discussion

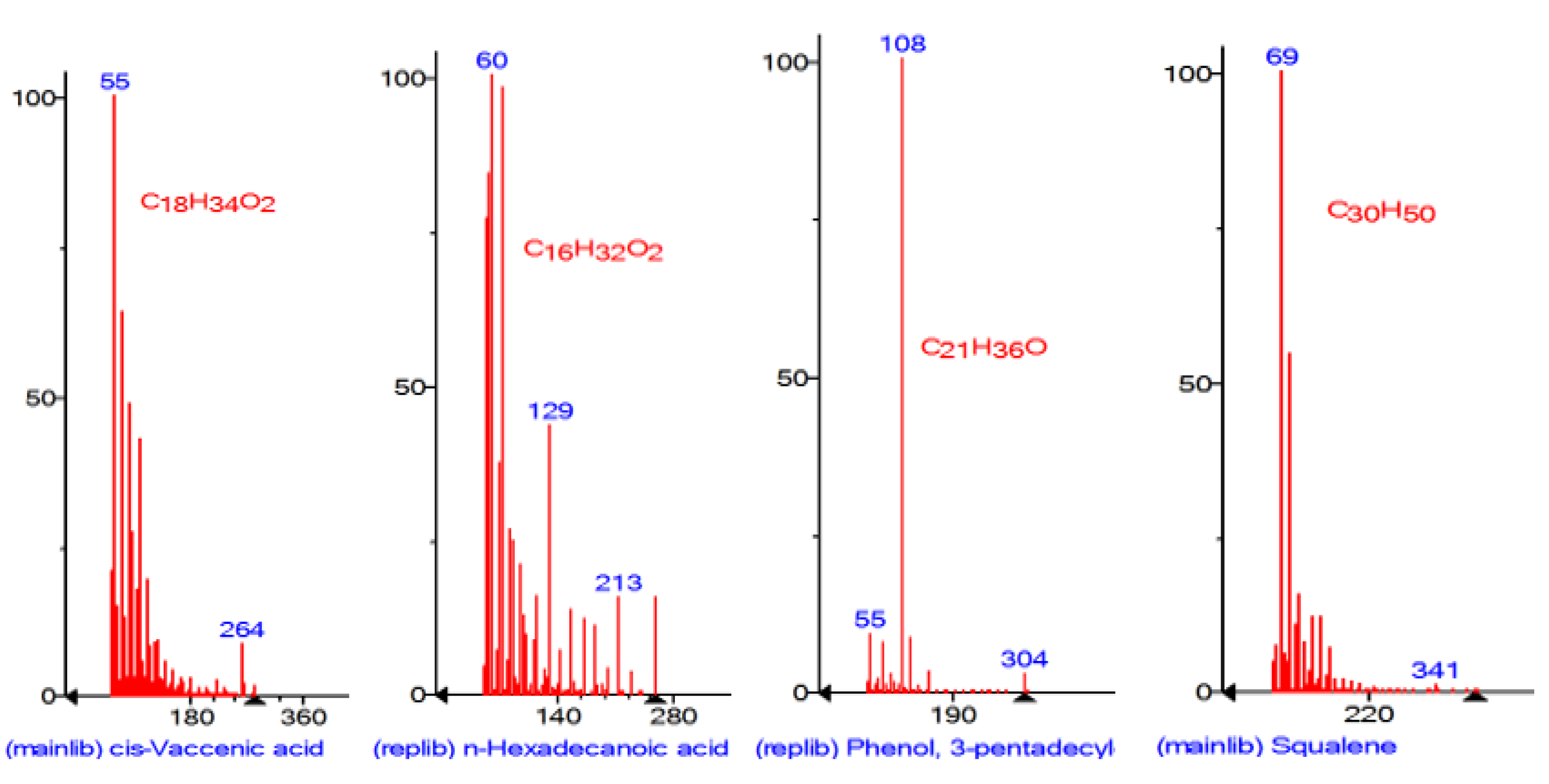

3.1. Phytochemical Characterization of MKSO Extracts

3.2. Physiochemical and Thermal Properties Characterization of MKSO Extracts

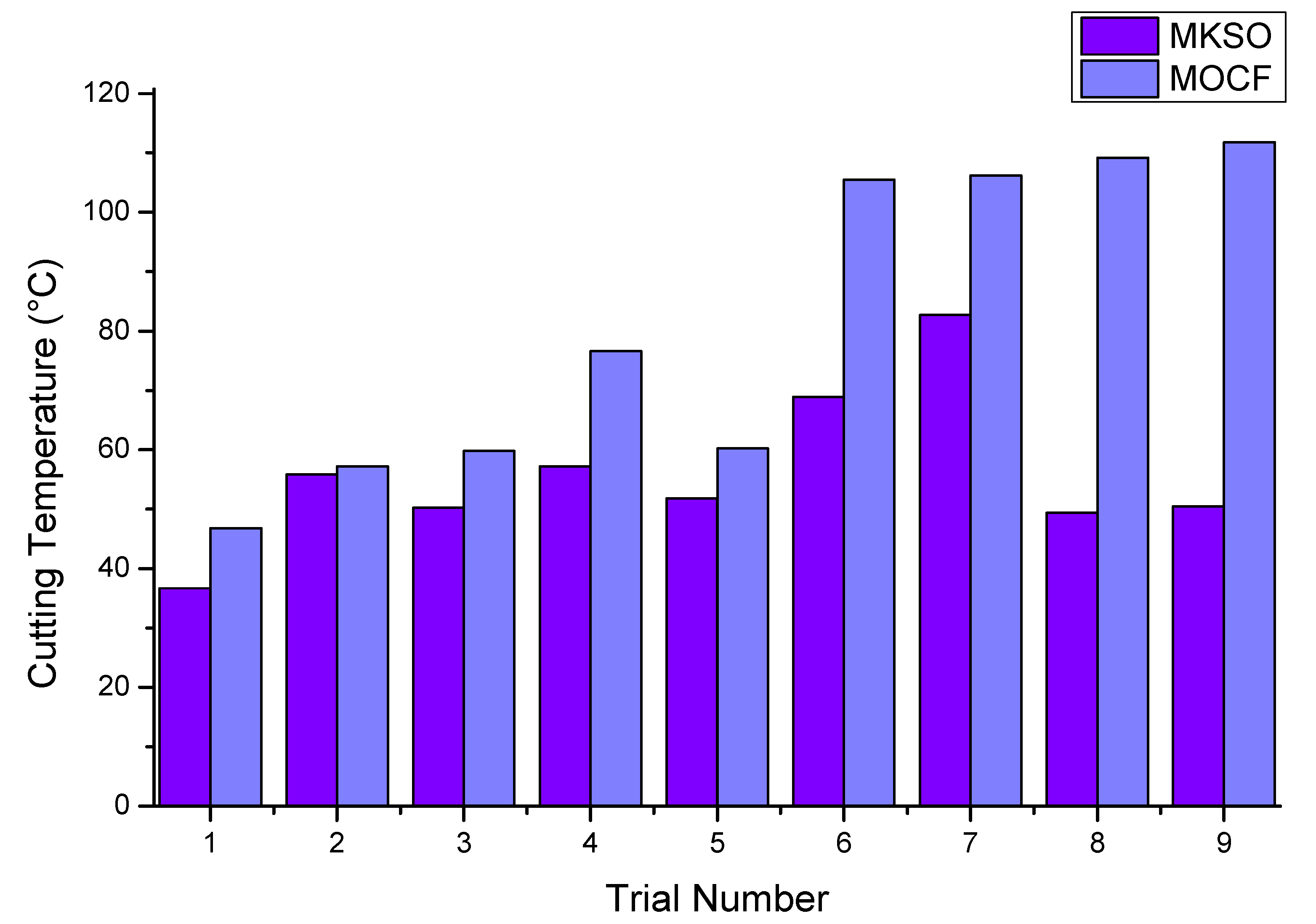

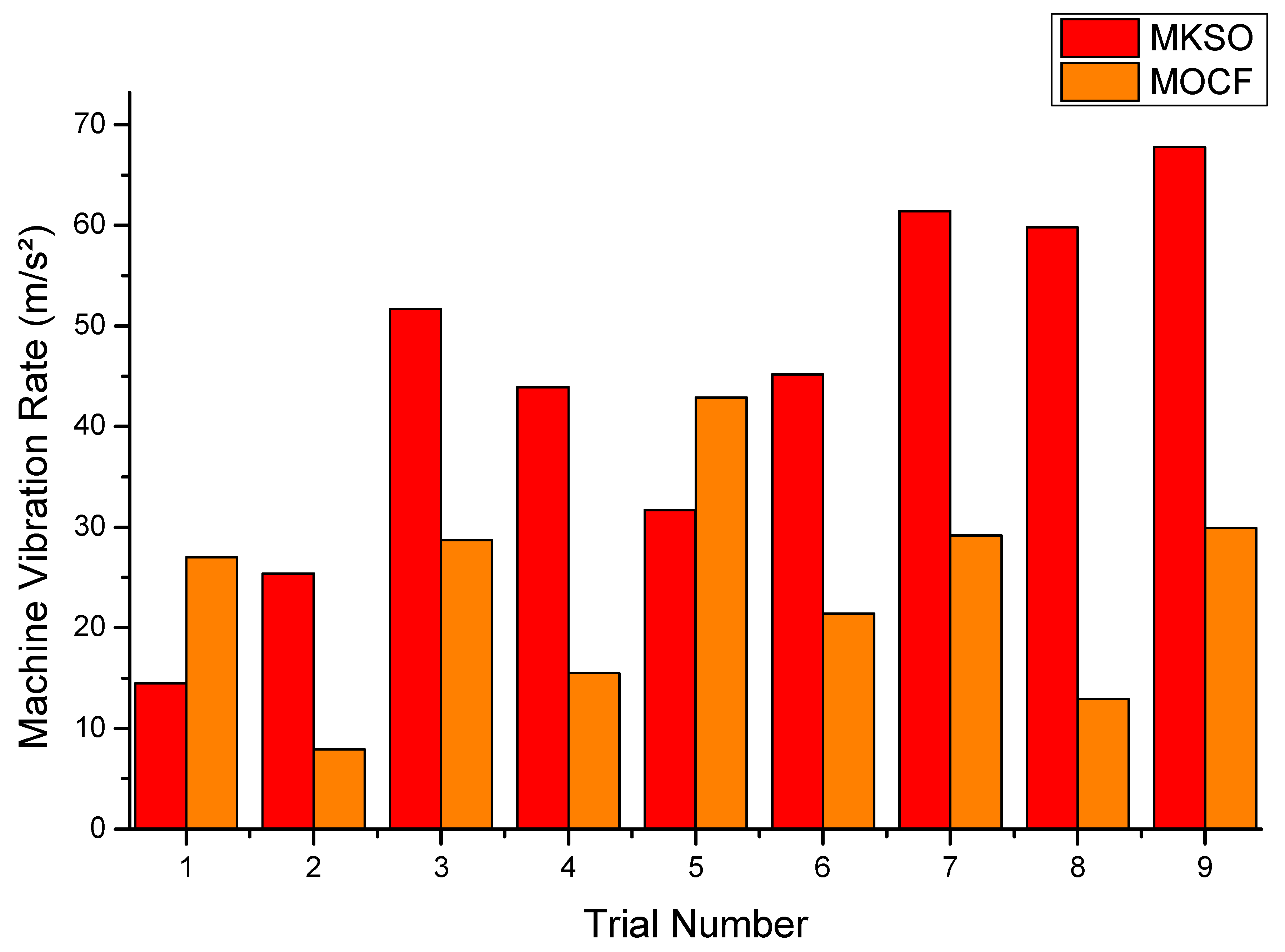

3.3. Experimental Results for AISI 1525 Steel Machining with Emulsion Cutting Fluids

3.4. Grey Relational Analysis

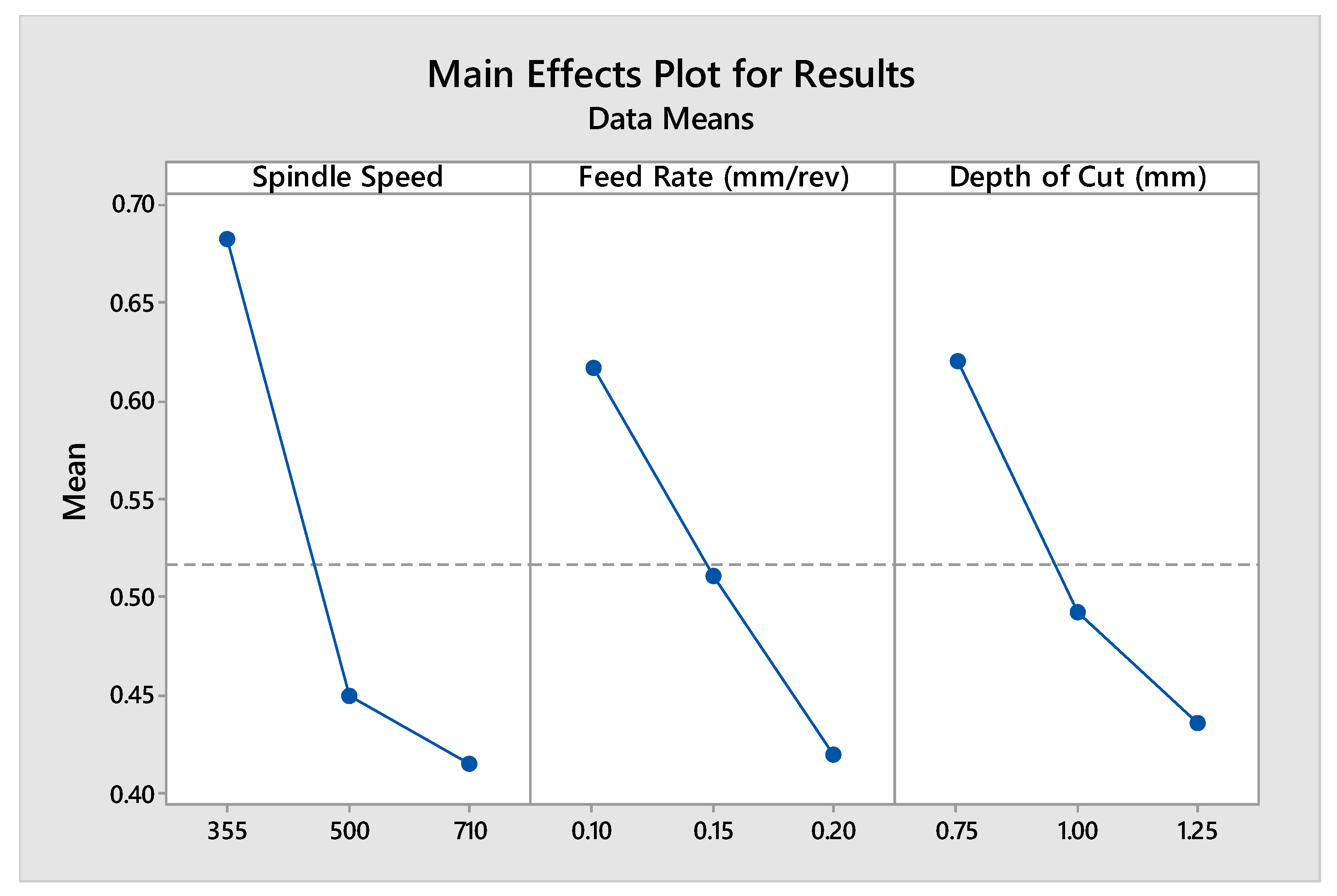

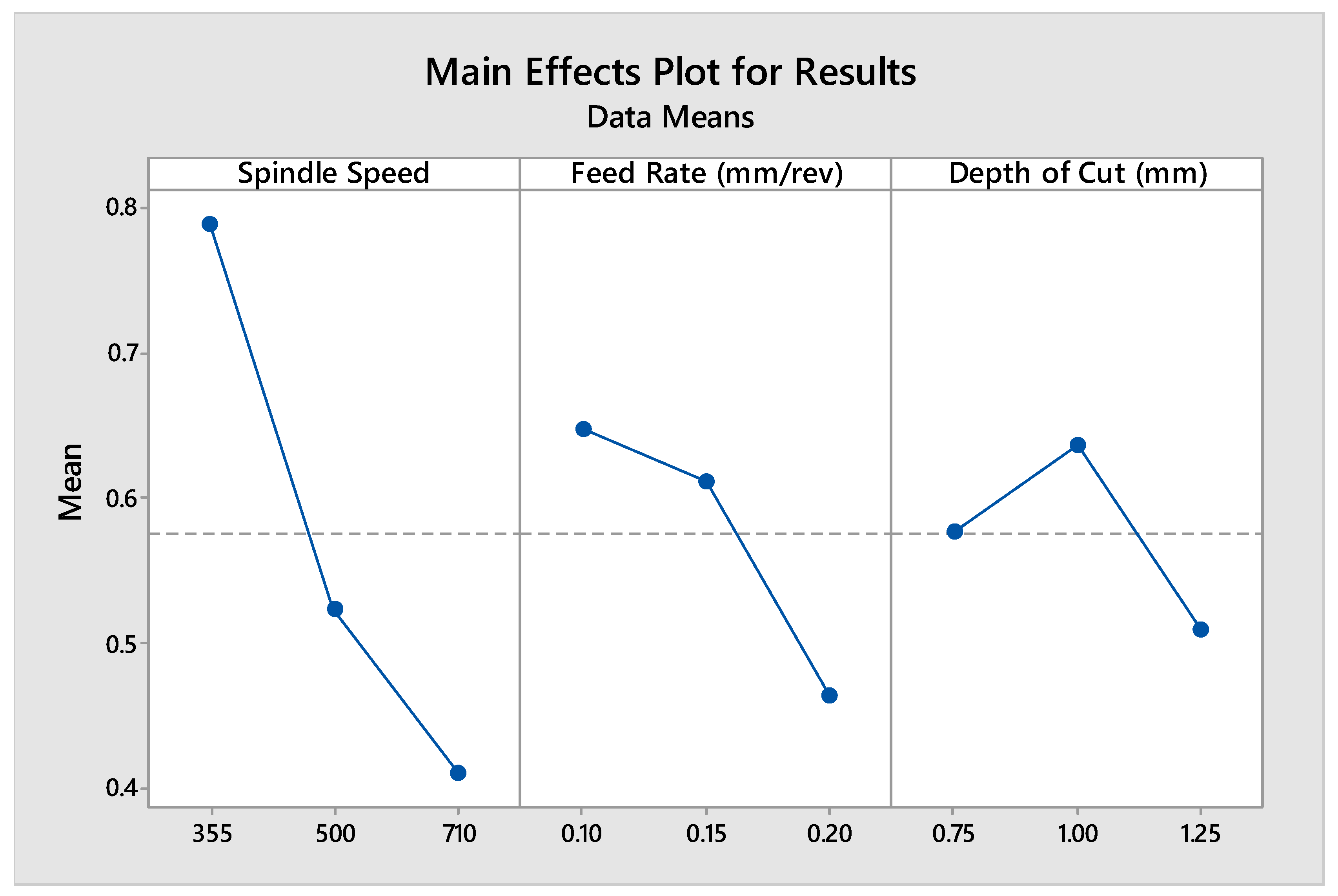

3.5. Application of Grey Relation Analysis to Obtain Multiple Responses Parametric Optimizations

3.6. Mathematical Model

4. Conclusions

- MKSO extracts were found to be enriched in four compounds: cis-vaccenic acid, hexadecanoic acid, 3-pentadactyl phenol, and squalene.

- MOCF outperformed MKSO by a significant margin in most conditions considered.

- The spindle speed of 0.683 rev/min, feed of 0.617 mm/rev, and depth of cut of 0.620 mm are the optimal characteristics for mango kernel seed oil, while 0.7898 rev/min spindle speed, 0.6483 mm/rev feed, and 0.6373 mm depth of cut are the best specifications for MOCF cutting fluid.

- Spindle speed had the greatest influence on multi-responses in turning operations with both cutting fluids.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oyinbo, S.T.; Ikumapayi, O.M.; Jen, T.C.; Ismail, S.O. Experimental and Numerical prediction of extrusion load at different lubricating conditions of aluminium 6063 alloy in backward cup extrusion. Eng. Solid Mech. 2020, 8, 119–130. [Google Scholar] [CrossRef]

- Adejuyigbe, S.B.; Ayodeji, S.P. Soybean oil as an alternative to soluble oil in machining mild steel materials. Niger. J. Pure Appl. Phys. 2000, 1, 17–23. [Google Scholar] [CrossRef]

- Irani, R.A.; Bauer, R.J.; Warkentin, A. A review of cutting fluid application in the grinding process. Int. J. Mach. Tools Manuf. 2005, 45, 1696–1705. [Google Scholar] [CrossRef]

- Ramana, M.V.; Rao, K.G.; Rao, H.D. Effect of process parameters on surface roughness in turning of titanium alloy under different conditions of lubrication. Recent Adv. Robot. Aeronaut. Mech. Eng. 2012, 3, 83–91. [Google Scholar]

- Singh, T.; Singh, P.; Dureja, J.S.; Dogra, M.; Singh, H.; Bhatti, M.S. A review of near dry machining/minimum quantity lubrication machining of difficult to machine alloys. Int. J. Mach. Mach. Mater. 2016, 18, 213–251. [Google Scholar] [CrossRef]

- Majak, D.; Olugu, E.U.; Lawal, S.A. Analysis of the effect of sustainable lubricants in the turning of AISI 304 stainless steel. Procedia Manuf. 2020, 43, 495–502. [Google Scholar] [CrossRef]

- Gunerkar, R.S.; Kuppan, P. Experimental investigation of vegetable oil-based cutting fluid during turning of SS316L. Int. J. Mech. Eng. Robot. (IJMER) 2013, 1, 46–52. [Google Scholar]

- Rapeti, P.; Pasam, V.K.; Gurram, K.M.R.; Revuru, R.S. Performance evaluation of vegetable oil-based nano cutting fluids in machining using a grey relational analysis-A step towards sustainable manufacturing. J. Clean. Prod. 2018, 172, 2862–2875. [Google Scholar] [CrossRef]

- Shaikh, J.B.; Sidhu, J.S. Experimental investigation and optimization of process parameters in turning of AISI D2 steel using different lubricants. Int. J. Eng. Adv. Technol. 2014, 5, 189. [Google Scholar]

- Kazeem, R.A.; Fadare, D.A.; Abutu, J.; Lawal, S.A.; Adesina, O.S. Performance evaluation of jatropha oil-based cutting fluid in turning AISI 1525 steel alloy. CIRP J. Manuf. Sci. Technol. 2020, 31, 418–430. [Google Scholar] [CrossRef]

- Ojolo, S.; Amuda, M.; Ogunmola, O.; Ononiwu, C. Experimental determination of the effect of some straight biological oils on cutting force during cylindrical turning. Matéria (Rio J.) 2008, 13, 650–663. [Google Scholar] [CrossRef]

- Bhowmik, P.; Arora, G.; Pal, N.; Bhardwaj, N. Improving the Surface Texture of Mild Steel using Vegetable Oil as Cutting Fluid. Int. J. Appl. Eng. Res. 2014, 9, 883–888. [Google Scholar]

- Ikumapayi, O.M.; Oyinbo, S.T.; Bodunde, O.P.; Afolalu, S.A.; Okokpujie, I.P.; Akinlabi, E.T. The effects of lubricants on temperature distribution of 6063 aluminium alloy during backward cup extrusion process. J. Mater. Res. Technol. 2019, 8, 1175–1187. [Google Scholar] [CrossRef]

- Kittiphoom, S.; Sutasinee, S. Mango seed kernel oil and its physicochemical properties. Int. Food Res. J. 2013, 20, 1145. [Google Scholar]

- Puravankara, D.; Boghra, V.; Sharma, R.S. Effect of antioxidant principles isolated from mango (Mangifera indica L.) seed kernels on oxidative stability of buffalo ghee (butter-fat). J. Sci. Food Agric. 2000, 80, 522–526. [Google Scholar] [CrossRef]

- Bhalerao, S.D.; Mulmuley, G.V.; Anathakrishna, S.M.; Potty, V.H. Wash and wastewater management in the food industry. Fruit Veg. Process. Indian Food Pack. 1989, 43, 5–11. [Google Scholar]

- Nzikou, J.M.; Kimbonguila, A.; Matos, L.; Loumouamou, B.; Pambou-Tobi, N.P.G.; Ndangui, C.B.; Abena, A.A.; Silou, T.H.; Scher, J.; Desobry, S. Extraction and characteristics of seed kernel oil from mango (Mangifera indica). Res. J. Environ. Earth Sci. 2010, 2, 31–35. [Google Scholar]

- Mohdaly, A.A.; Smetanska, I.; Ramadan, M.F.; Sarhan, M.A.; Mahmoud, A. Antioxidant potential of sesame (Sesamum indicum) cake extract in the stabilization of sunflower and soybean oils. Ind. Crops Prod. 2011, 34, 952–959. [Google Scholar] [CrossRef]

- Firestone, D. Official Methods and Recommended Practices of the AOCS; American Oil Chemists’ Society: Urbana, IL, USA, 1998; Volume I–II. [Google Scholar]

- ASTM D287. Standard Test Method for API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method); Annual Book of Standards; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D97. Standard Test Method for Pour Point of Petroleum Products. Annual Book of Standards; Annual Book of Standards; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D2500. Standard Test Method for Cloud Point of Petroleum Products; Annual Book of Standards; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM D92. Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester; Annual Book of Standards; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Muniz, C.A.S.; Dantas, T.N.C.; Moura, E.F.; Neto, A.D.; Gurgel, A. Novel formulations of cutting fluids using naphthenic basic oil. Braz. J. Pet. Gas 2009, 2, 143–153. [Google Scholar]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Azeez, T.M.; Adediran, A.A. Development of Bio-Cutting Fluid (Cirtullus lanatus) and its Performance Assessment on the Machining of AISI 1525 Steel Using Taguchi Technique and Grey Relational Analysis. Biointerface Res. Appl. Chem. 2022, 12, 5324–5346. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. Evaluation of vegetable and mineral oil-in-water emulsion metal cutting fluids in turning AISI 4340 steel with coated carbide tools. J. Clean. Prod. 2014, 66, 610–618. [Google Scholar] [CrossRef]

- Igwe, O.U.; Okwu, D.E. GC-MS Evaluation of bioactive compounds and antibacterial activity of the oil fraction from the seeds of Brachystegia eurycoma Harms. Asian J. Plant Sci. Res. 2013, 3, 47–54. [Google Scholar]

- Smith, T.J. Squalene: Potential chemopreventive agent. Expert Opin. Investig. Drugs 2000, 9, 1841–1848. [Google Scholar] [CrossRef] [PubMed]

- Owen, R.W.; Haubner, R.; Würtele, G.; Hull, W.E.; Spiegelhalder, B.; Bartsch, H. Olives and olive oil in cancer prevention. Eur. J. Cancer Prev. 2004, 13, 319–326. [Google Scholar] [CrossRef]

- Karunanithi, B.; Bogeshwaran, K.; Tripuraneni, M.; Krishna Reddy, S. Extraction of mango seed oil from mango kernel. Int. J. Eng. Res. Dev. 2015, 11, 32–41. [Google Scholar]

- Zhang, J.Z.; Rao, P.N.; Eckman, M. Experimental evaluation of a bio-based cutting fluid using multiple machining characteristics. Wear 2012, 12, 13–14. [Google Scholar]

- Adam, S.A.; Shuaib, N.A.; Hafiezal, M.R.M.; Suhaili, S.N. Study on Surface Roughness and Chip Formation during Milling Operation of Mild Steel Using Vegetable Based Oil as a Lubricant. Int. J. Eng. Technol. IJET-IJENS 2013, 13, 19–23. [Google Scholar]

- Aremu, M.O.; Ibrahim, H.; Bamidele, T.O. Physicochemical characteristics of the oils extracted from some Nigerian plant foods—A review. Chem. Process. Eng. Res. 2015, 32, 36–52. [Google Scholar]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Akinlabi, S.A.; Afolalu, S.A.; Akinlabi, E.T. Analysis of the Physicochemical Properties of Some Selected Non-Edible Vegetable Oil-Based Cutting Fluids Using the Design of Experiment (DOE) Approach. Lubricants 2022, 10, 16. [Google Scholar] [CrossRef]

- Belewu, M.; Adekola, F.; Adebayo, G.; Ameen, O.; Muhammed, N.; Olaniyan, A.; Musa, A. Physico-chemical characteristics of oil and biodiesel from Nigerian and Indian Jatropha curcas seeds. Int. J. Biol. Chem. Sci. 2010, 4, 524–529. [Google Scholar] [CrossRef]

- Panda, A.; Sahoo, A.; Rout, R. Multi-attribute decision making parametric optimization and modeling in hard turning using ceramic insert through grey relational analysis: A case study. Decis. Sci. Lett. 2016, 5, 581–592. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. Application of vegetable oil-based metalworking fluids in machining ferrous metals—A review. Int. J. Mach. Tools Manuf. 2012, 52, 1–12. [Google Scholar] [CrossRef]

- Mas’ud, F.; Mahendradatta, M.; Laga, A.; Zainal, Z. Optimization of mango seed kernel oil extraction using response surface methodology. OCL 2017, 24, D503. [Google Scholar] [CrossRef] [Green Version]

| S/N | Parameter | Methodology |

|---|---|---|

| 1 | Fourier transform infrared analysis | This was determined by using a PerkinElmer FT-IR Spectrum in the 4000–400 cm−1 range. The precision was eight and two scans. Sample extracts were spread on KBR cells, inserted into the cell holder, and placed in the FT-IR spectrophotometer |

| 2 | Gas chromatography | This was obtained with a combined 7890A Agilent Technology GC system. During the process, oil was split into its chemical constituents. The column features of this machinery are as follows: HP5MS, 30 m × 0.320 mm, 0.25 m width, helium carrier gas, and 2.5 mL/min flow rate. At a rate of 10 °C/min, the temperature range was configured between 80 and 280 °C. The splitless injector and detector were kept at 250 and 200 °C, respectively. |

| 3 | Crude oil pH | A digital pH meter was used to determine the pH of raw mango oil. |

| 4 | Specific gravity | This was obtained based on ASTM D287 procedure and was further calculated using Equation (1) [20]. |

| 5 | % Oil yield | The percentage oil yield was calculated using Equation (2). |

| 6 | Viscosity | This was determined using an Oswald kinematic viscometer in the temperature range of 40–80 °C, and was further evaluated using Equation (3). |

| 7 | Oil color | The color of the oil was evaluated using a spectrophotometer and the Cc 13c -50 AOCS standard technique was adopted. |

| 8 | Pour point | This was examined with a Stanhope–Seta pour and cloud point KT16 8AP machinery based on ASTM D97 standards [21]. |

| 9 | Cloud point | This was measured with Stanhope–Seta cloud/pour point KT16 8AP machinery and carried out according to ASTM D2500 [22]. |

| 10 | Flashpoint | The flashpoint was measured by using an ASTM D92 conventional method [23]. |

| 11 | Fire point | This was measured according to the ASTM D92 method with a Pensky–Martens setup. |

| Assay No | A (mL) | B (mL) | C (mL) | D (mL) | Vol. of Water (mL) |

|---|---|---|---|---|---|

| 1 | 8 | 1 | 0.5 | 0.5 | 70 |

| 2 | 12 | 1 | 0.5 | 0.5 | 66 |

| 3 | 8 | 2 | 0.5 | 0.5 | 69 |

| 4 | 12 | 2 | 0.5 | 0.5 | 65 |

| 5 | 8 | 1 | 1.0 | 0.5 | 69.5 |

| 6 | 12 | 1 | 1.0 | 0.5 | 65.5 |

| 7 | 8 | 2 | 1.0 | 0.5 | 68.5 |

| 8 | 12 | 2 | 1.0 | 0.5 | 64.5 |

| 9 | 8 | 1 | 0.5 | 1.0 | 69.5 |

| 10 | 12 | 1 | 0.5 | 1.0 | 65.5 |

| 11 | 8 | 2 | 0.5 | 1.0 | 68.5 |

| 12 | 12 | 2 | 0.5 | 1.0 | 64.5 |

| 13 | 8 | 1 | 1.0 | 1.0 | 69 |

| 14 | 12 | 1 | 1.0 | 1.0 | 65 |

| 15 | 8 | 2 | 1.0 | 1.0 | 68 |

| 16 | 12 | 2 | 1.0 | 1.0 | 64 |

| Trial No. | Cutting Parameter | ||

|---|---|---|---|

| Spindle Speed (rev/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | |

| 1 | 355 | 0.1 | 0.75 |

| 2 | 355 | 0.15 | 1.00 |

| 3 | 355 | 0.20 | 1.25 |

| 4 | 500 | 0.1 | 1.00 |

| 5 | 500 | 0.15 | 1.25 |

| 6 | 500 | 0.20 | 0.75 |

| 7 | 710 | 0.1 | 1.25 |

| 8 | 710 | 0.15 | 0.75 |

| 9 | 710 | 0.20 | 1.00 |

| Oil | Chromatography Peak | Compound Nomenclature | Molecular Formula | Molecular Weight | Retention Time (min) | Percentage Content |

|---|---|---|---|---|---|---|

| 1 | cis-vaccenic acid | C18H34O2 | 282 | 19.822 | 55.28 | |

| Mango kernel seed oil | 2 | n-hexadecanoic acid | C16H32O2 | 256 | 17.627 | 38.76 |

| 3 | 3-pentadecyl phenol | C21H36O | 304 | 26.488 | 4.18 | |

| 4 | Squalene | C30H50 | 410 | 29.898 | 2.51 |

| Parameter | Result |

|---|---|

| pH | 6.5 |

| Specific gravity | 0.833 |

| % Oil yield | 12.5 |

| Viscosity | 16.8 cP |

| Oil color | Brownish Yellow |

| Pour point | 36 |

| Cloud point | 39 |

| Flashpoint | 158 |

| Fire point | 167 |

| Element | % Composition |

|---|---|

| C | 0.2505 |

| Si | 0.2215 |

| Mn | 1.2340 |

| S | 0.0235 |

| P | 0.0135 |

| Cr | 0.1135 |

| Ni | 0.1155 |

| Cu | 0.0480 |

| Al | 0.0120 |

| Ti | 0.0395 |

| Fe | 97.9285 |

| Properties | Result |

|---|---|

| Tensile Strength | 604.74 MPa |

| Yield Strength | 7599.34 MPa |

| Elastic Modulus | 35106.19MPa |

| Energy at Maximum Tensile Stress | 31.24909 J |

| Energy at Break | 47.35634 J |

| Spindle Speed (rev/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

|---|---|---|---|---|---|---|

| 355 | 0.1 | 0.75 | 2.53 | 36.7 | 96.5 | 14.5 |

| 355 | 0.15 | 1 | 3.73 | 55.8 | 102.5 | 25.42 |

| 355 | 0.2 | 1.25 | 9.01 | 50.2 | 106.1 | 51.7 |

| 500 | 0.1 | 1 | 6.35 | 57.2 | 106.2 | 43.9 |

| 500 | 0.15 | 1.25 | 8.65 | 51.8 | 106.3 | 31.7 |

| 500 | 0.2 | 0.75 | 8.83 | 68.9 | 103.1 | 45.2 |

| 710 | 0.1 | 1.25 | 6.29 | 82.7 | 103.9 | 61.4 |

| 710 | 0.15 | 0.75 | 7.84 | 49.4 | 105.4 | 59.8 |

| 710 | 0.2 | 1 | 9.63 | 50.5 | 105.9 | 67.8 |

| Spindle Speed (rev/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

|---|---|---|---|---|---|---|

| 355 | 0.1 | 0.75 | 2.545 | 46.8 | 85.7 | 27.03 |

| 355 | 0.15 | 1 | 3.521 | 57.2 | 85.9 | 7.91 |

| 355 | 0.2 | 1.25 | 8.47 | 59.8 | 86 | 28.7 |

| 500 | 0.1 | 1 | 6.22 | 76.6 | 85.7 | 15.5 |

| 500 | 0.15 | 1.25 | 7.41 | 60.2 | 95.5 | 42.9 |

| 500 | 0.2 | 0.75 | 8.83 | 105.5 | 108.8 | 21.4 |

| 710 | 0.1 | 1.25 | 6.5 | 106.2 | 106.9 | 29.2 |

| 710 | 0.15 | 0.75 | 7.7 | 109.2 | 111.1 | 12.9 |

| 710 | 0.2 | 1 | 8.8 | 111.8 | 109 | 29.95 |

| Step | Action |

|---|---|

| 1. | To avoid using different units and to reduce variability, the data must first be standardized. It is generally required since the variation of one datum differs from other data. The array is made between 0 and 1 by calculating an appropriate value from the original value [37]. It is a way of converting original data to equivalent data in general. If the response is to be reduced, Equation (5) is used to normalize it into an appropriate range using smaller-is-better characteristics. From the relation, j = 1, …, u; n = 1, …, q; n is the number of responses, while p is the number of experimental results. yj (n) represents the real series, max yj (n) represents the highest value of yj (n), min yj (n) represents the lowest value of yj (n), y*j (n) represents the series after the result pre-processing, and y is the desired value [37]. |

| 2. | Equation (6) is used to compute the Grey relational coefficient, , from the normalized data. The in the equation is divergence series of the reference series and the comparability series and . refers to the reference series and is known as comparability series. χmax and χmin are the maximum and minimum values of the absolute differences χoj of all series being compared. is a distinguishing coefficient and ranges between 0 and 1. Most times, the value of is 0.5. |

| 3. | The Grey relational grade (GRG) is calculated with Equation (7). From the equation, is the necessary GRG for th trial and = no. of response characteristics. The GRG denotes the level of correlation between the comparability series and the reference series and is the all-encompassing representation of all qualitative attributes [37]. Therefore, using GRA and the Taguchi technique, the multiple response optimization models is reduced to just one response optimization model. |

| 4. | Then, using a higher GRG, an appropriate level of process variables is obtained, indicating the greater quality of the product. To determine this, the mean grade values for individual level of process parameters are to be obtained, which can be shown as a mean response chart. From the mean response chart, the greater value of mean grade values is selected as the best parametric combination for multiple responses. |

| 5. | After determining the best combination, the analysis of variance (ANOVA) is used to find the major parameters affecting the multiple responses at a 95% confidence level, providing useful information on the experimental results. Since the Taguchi technique cannot assess the influence of each parameter on multiple responses, the ANOVA will be useful in determining the percentage of contribution to evaluate the influence. The ANOVA approach divides the entire variability of the output (sum of squared deviations around the weighted score) into contributions from each parameter and error [37]. |

| Spindle Speed (rev/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

|---|---|---|---|---|---|---|

| 355 | 0.1 | 0.75 | 2.53 | 36.7 | 96.5 | 14.5 |

| 355 | 0.15 | 1 | 3.73 | 55.8 | 102.5 | 25.42 |

| 355 | 0.2 | 1.25 | 9.01 | 50.2 | 106.1 | 51.7 |

| 500 | 0.1 | 1 | 6.35 | 57.2 | 106.2 | 43.9 |

| 500 | 0.15 | 1.25 | 8.65 | 51.8 | 106.3 | 31.7 |

| 500 | 0.2 | 0.75 | 8.83 | 68.9 | 103.1 | 45.2 |

| 710 | 0.1 | 1.25 | 6.29 | 82.7 | 103.9 | 61.4 |

| 710 | 0.15 | 0.75 | 7.84 | 49.4 | 105.4 | 59.8 |

| 710 | 0.2 | 1 | 9.63 | 50.5 | 105.9 | 67.8 |

| Min | 2.53 | 36.7 | 96.5 | 14.5 | ||

| Max | 9.63 | 82.7 | 106.3 | 67.8 |

| Spindle Speed (rev/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

|---|---|---|---|---|---|---|

| 355 | 0.1 | 0.75 | 2.545 | 46.8 | 85.7 | 27.03 |

| 355 | 0.15 | 1 | 3.521 | 57.2 | 85.9 | 7.91 |

| 355 | 0.2 | 1.25 | 8.47 | 59.8 | 86 | 28.7 |

| 500 | 0.1 | 1 | 6.22 | 76.6 | 85.7 | 15.5 |

| 500 | 0.15 | 1.25 | 7.41 | 60.2 | 95.5 | 42.9 |

| 500 | 0.2 | 0.75 | 8.83 | 105.5 | 108.8 | 21.4 |

| 710 | 0.1 | 1.25 | 6.5 | 106.2 | 106.9 | 29.2 |

| 710 | 0.15 | 0.75 | 7.7 | 109.2 | 111.1 | 12.9 |

| 710 | 0.2 | 1 | 8.8 | 111.8 | 109 | 29.95 |

| Min | 2.545 | 46.8 | 85.7 | 7.91 | ||

| Max | 8.83 | 111.8 | 111.1 | 42.9 |

| Normalization | |||

|---|---|---|---|

| Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

| 1.000 | 1.000 | 1.000 | 1.000 |

| 0.831 | 0.585 | 0.388 | 0.795 |

| 0.087 | 0.707 | 0.020 | 0.302 |

| 0.462 | 0.554 | 0.010 | 0.448 |

| 0.138 | 0.672 | 0.000 | 0.677 |

| 0.113 | 0.300 | 0.327 | 0.424 |

| 0.470 | 0.000 | 0.245 | 0.120 |

| 0.252 | 0.724 | 0.092 | 0.150 |

| 0.000 | 0.700 | 0.041 | 0.000 |

| Normalization | |||

|---|---|---|---|

| Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

| 1.000 | 1.000 | 1.000 | 0.454 |

| 0.845 | 0.840 | 0.992 | 1.000 |

| 0.057 | 0.800 | 0.988 | 0.406 |

| 0.415 | 0.542 | 1.000 | 0.783 |

| 0.226 | 0.794 | 0.614 | 0.000 |

| 0.000 | 0.097 | 0.091 | 0.614 |

| 0.371 | 0.086 | 0.165 | 0.392 |

| 0.180 | 0.040 | 0.000 | 0.857 |

| 0.005 | 0.000 | 0.083 | 0.370 |

| Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

|---|---|---|---|

| 0.000 | 0.000 | 0.000 | 0.000 |

| 0.169 | 0.415 | 0.612 | 0.205 |

| 0.913 | 0.293 | 0.980 | 0.698 |

| 0.538 | 0.446 | 0.990 | 0.552 |

| 0.862 | 0.328 | 1.000 | 0.323 |

| 0.887 | 0.700 | 0.673 | 0.576 |

| 0.530 | 1.000 | 0.755 | 0.880 |

| 0.748 | 0.276 | 0.908 | 0.850 |

| 1.000 | 0.300 | 0.959 | 1.000 |

| Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) |

|---|---|---|---|

| 0.000 | 0.000 | 0.000 | 0.546 |

| 0.155 | 0.160 | 0.008 | 0.000 |

| 0.943 | 0.200 | 0.012 | 0.594 |

| 0.585 | 0.458 | 0.000 | 0.217 |

| 0.774 | 0.206 | 0.386 | 1.000 |

| 1.000 | 0.903 | 0.909 | 0.386 |

| 0.629 | 0.914 | 0.835 | 0.608 |

| 0.820 | 0.960 | 1.000 | 0.143 |

| 0.995 | 1.000 | 0.917 | 0.630 |

| Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) | Grade | Rank |

|---|---|---|---|---|---|

| 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1 |

| 0.747 | 0.546 | 0.450 | 0.709 | 0.613 | 2 |

| 0.354 | 0.630 | 0.338 | 0.417 | 0.435 | 6 |

| 0.482 | 0.529 | 0.336 | 0.475 | 0.455 | 4 |

| 0.367 | 0.604 | 0.333 | 0.608 | 0.478 | 3 |

| 0.360 | 0.417 | 0.426 | 0.465 | 0.417 | 7 |

| 0.486 | 0.333 | 0.398 | 0.362 | 0.395 | 9 |

| 0.401 | 0.644 | 0.355 | 0.370 | 0.443 | 5 |

| 0.333 | 0.625 | 0.343 | 0.333 | 0.409 | 8 |

| Surface Roughness (µm) | Cutting Temp. (°C) | Sound Level (dB) | Machine Vibration (m/s2) | Grade | Rank |

|---|---|---|---|---|---|

| 1.000 | 1.000 | 1.000 | 0.478 | 0.869 | 2 |

| 0.763 | 0.758 | 0.984 | 1.000 | 0.876 | 1 |

| 0.347 | 0.714 | 0.977 | 0.457 | 0.624 | 4 |

| 0.461 | 0.522 | 1.000 | 0.697 | 0.670 | 3 |

| 0.392 | 0.708 | 0.564 | 0.333 | 0.500 | 5 |

| 0.333 | 0.356 | 0.355 | 0.565 | 0.402 | 8 |

| 0.443 | 0.354 | 0.375 | 0.451 | 0.406 | 7 |

| 0.379 | 0.342 | 0.333 | 0.778 | 0.458 | 6 |

| 0.334 | 0.333 | 0.353 | 0.443 | 0.366 | 9 |

| Parameter | Level 1 | Level 2 | Level 3 | Max-Min | Rank |

|---|---|---|---|---|---|

| Spindle Speed | 0.683 | 0.450 | 0.415 | 0.267 | 1 |

| Feed Rate | 0.617 | 0.511 | 0.420 | 0.197 | 2 |

| Depth of Cut | 0.620 | 0.492 | 0.436 | 0.184 | 3 |

| Parameter | Level 1 | Level 2 | Level 3 | Max-Min | Rank |

|---|---|---|---|---|---|

| Spindle Speed | 0.7898 | 0.5239 | 0.4098 | 0.3800 | 1 |

| Feed Rate | 0.6483 | 0.6113 | 0.4639 | 0.1844 | 2 |

| Depth of Cut | 0.5766 | 0.6373 | 0.5096 | 0.1278 | 3 |

| Source | DF | Adj SS | Adj MS | F-Value | % Contribution |

|---|---|---|---|---|---|

| Spindle Speed (rev/min) | 2 | 0.12674 | 0.06337 | 2.16 | 42.7036 |

| Feed Rate (mm/rev) | 2 | 0.05810 | 0.02905 | 0.99 | 19.5761 |

| Depth of Cut (mm) | 2 | 0.05327 | 0.02664 | 0.91 | 17.9487 |

| Error | 2 | 0.05868 | 0.02934 | 19.7716 | |

| Total | 8 | 0.29679 | 100 |

| Source | DF | Adj SS | Adj MS | F-Value | % Contribution |

|---|---|---|---|---|---|

| Spindle Speed (rev/min) | 2 | 0.228100 | 0.114050 | 275.31 | 73.4513 |

| Feed Rate (mm/rev) | 2 | 0.057117 | 0.028559 | 68.94 | 18.3924 |

| Depth of Cut (mm) | 2 | 0.024501 | 0.012250 | 29.57 | 7.8897 |

| Error | 2 | 0.000829 | 0.000414 | 0.2669 | |

| Total | 8 | 0.310546 | 100 |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 1.40745 | 79.92% | 67.88% | 48.48% |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 14.0329 | 28.56% | 0.00% | 0.00% |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 1.35966 | 77.57% | 64.12% | 41.08% |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 11.0372 | 89.15% | 82.64% | 59.03% |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 2.1124 | 92.63% | 66.14% | 62.65% |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 114.4545 | 94.03% | 57.29% | 51.71% |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 3.2422 | 99.21% | 36.49% | 38.37% |

| S | R2 | R2 (adj) | R2 (pred) |

|---|---|---|---|

| 63.1425 | 98.21% | 47.92% | 72.01% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Akinlabi, S.A.; Akinlabi, E.T. Evaluation of Mango Kernel Seed (Mangifera indica) Oil as Cutting Fluid in Turning of AISI 1525 Steel Using the Taguchi-Grey Relation Analysis Approach. Lubricants 2022, 10, 52. https://doi.org/10.3390/lubricants10040052

Kazeem RA, Fadare DA, Ikumapayi OM, Akinlabi SA, Akinlabi ET. Evaluation of Mango Kernel Seed (Mangifera indica) Oil as Cutting Fluid in Turning of AISI 1525 Steel Using the Taguchi-Grey Relation Analysis Approach. Lubricants. 2022; 10(4):52. https://doi.org/10.3390/lubricants10040052

Chicago/Turabian StyleKazeem, Rasaq A., David A. Fadare, Omolayo M. Ikumapayi, Stephen A. Akinlabi, and Esther T. Akinlabi. 2022. "Evaluation of Mango Kernel Seed (Mangifera indica) Oil as Cutting Fluid in Turning of AISI 1525 Steel Using the Taguchi-Grey Relation Analysis Approach" Lubricants 10, no. 4: 52. https://doi.org/10.3390/lubricants10040052

APA StyleKazeem, R. A., Fadare, D. A., Ikumapayi, O. M., Akinlabi, S. A., & Akinlabi, E. T. (2022). Evaluation of Mango Kernel Seed (Mangifera indica) Oil as Cutting Fluid in Turning of AISI 1525 Steel Using the Taguchi-Grey Relation Analysis Approach. Lubricants, 10(4), 52. https://doi.org/10.3390/lubricants10040052