Chemically Modified Silicone Oil with Enhanced Tribological and Anti-Foaming Properties

Abstract

1. Introduction

2. Experimental

2.1. Materials

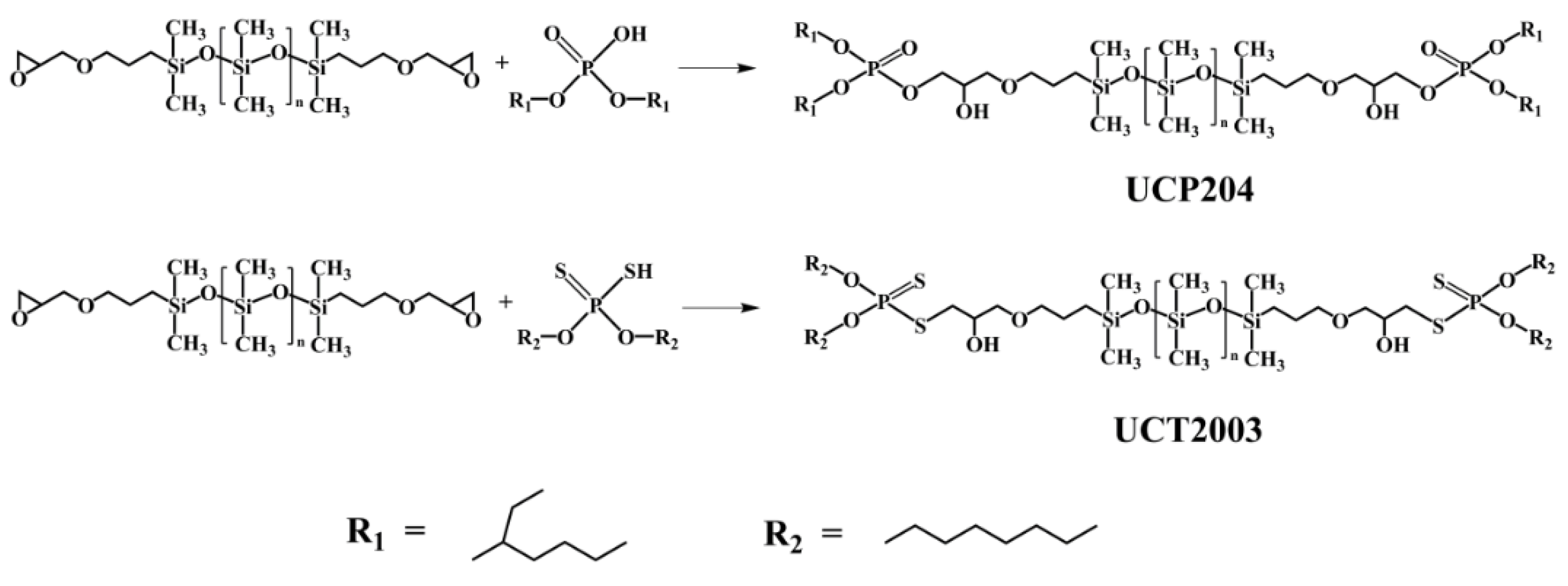

2.2. Synthesis of the Chemically Modified Silicone Oil

2.3. Characterization and Measurements

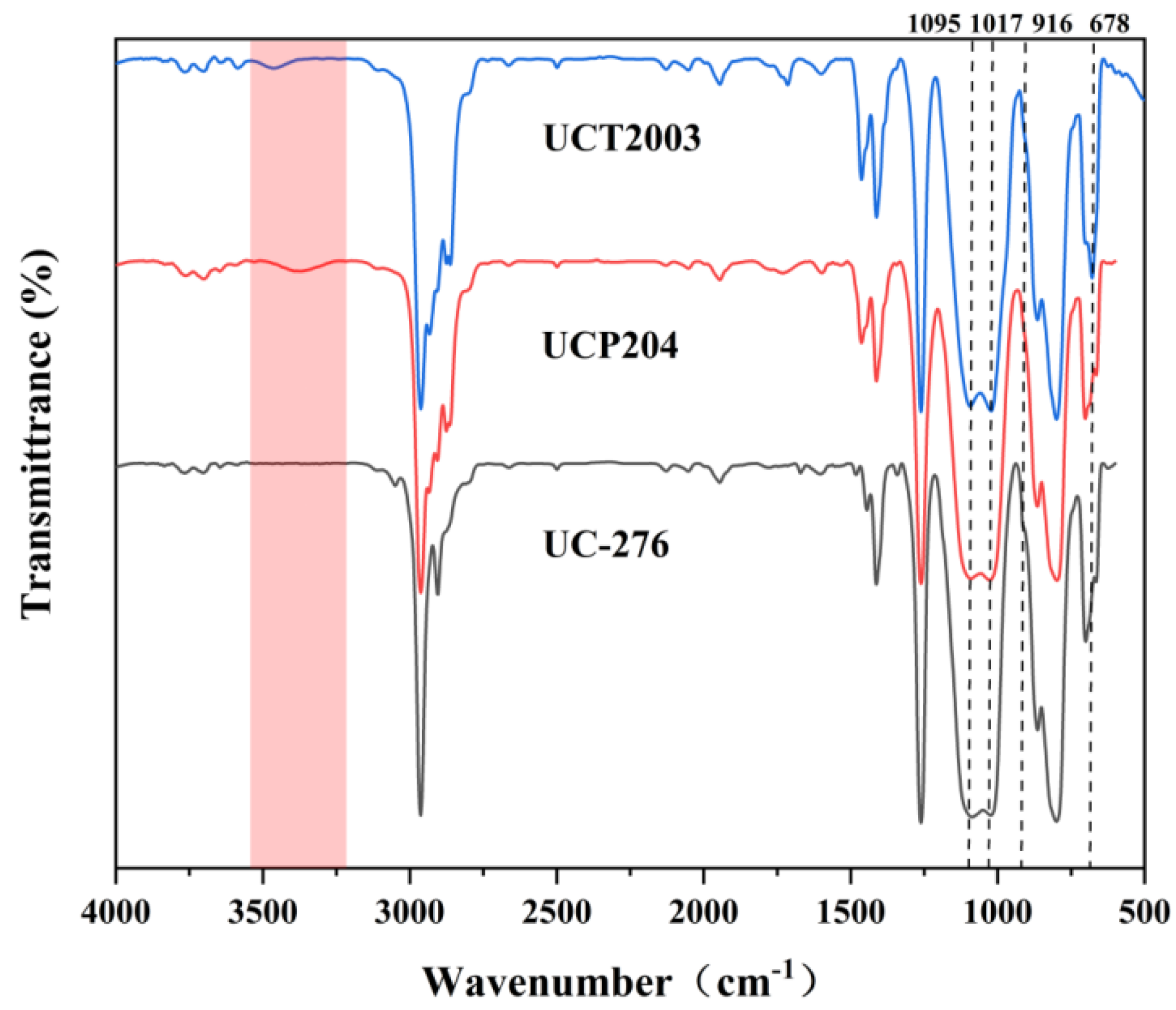

2.3.1. FTIR Analysis

2.3.2. Tribological Tests

2.3.3. Surface Analysis

2.3.4. Anti-Foaming Performance

3. Results and Discussion

3.1. Characterization of Chemically Modified Silicone Oil

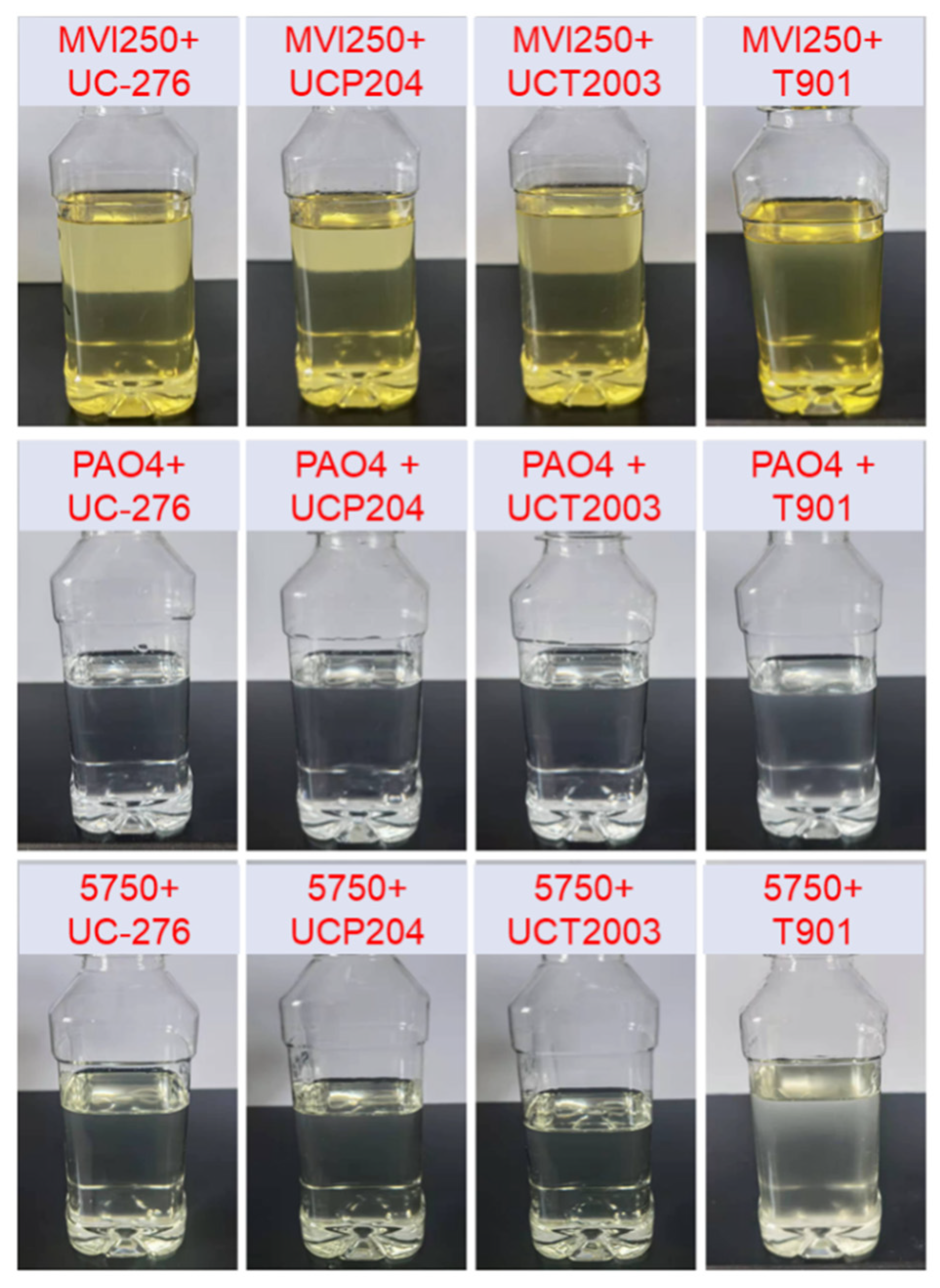

3.2. Dispersion Stability Test

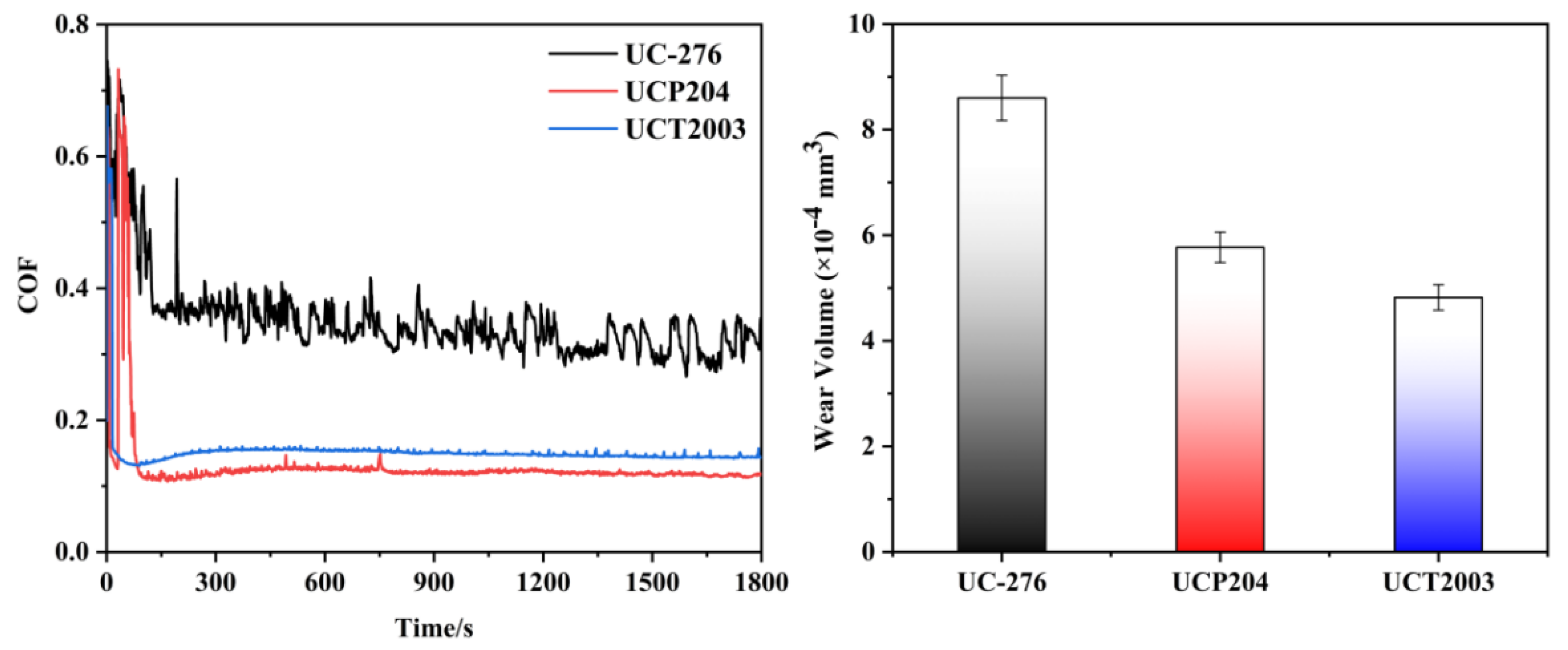

3.3. Tribological Properties

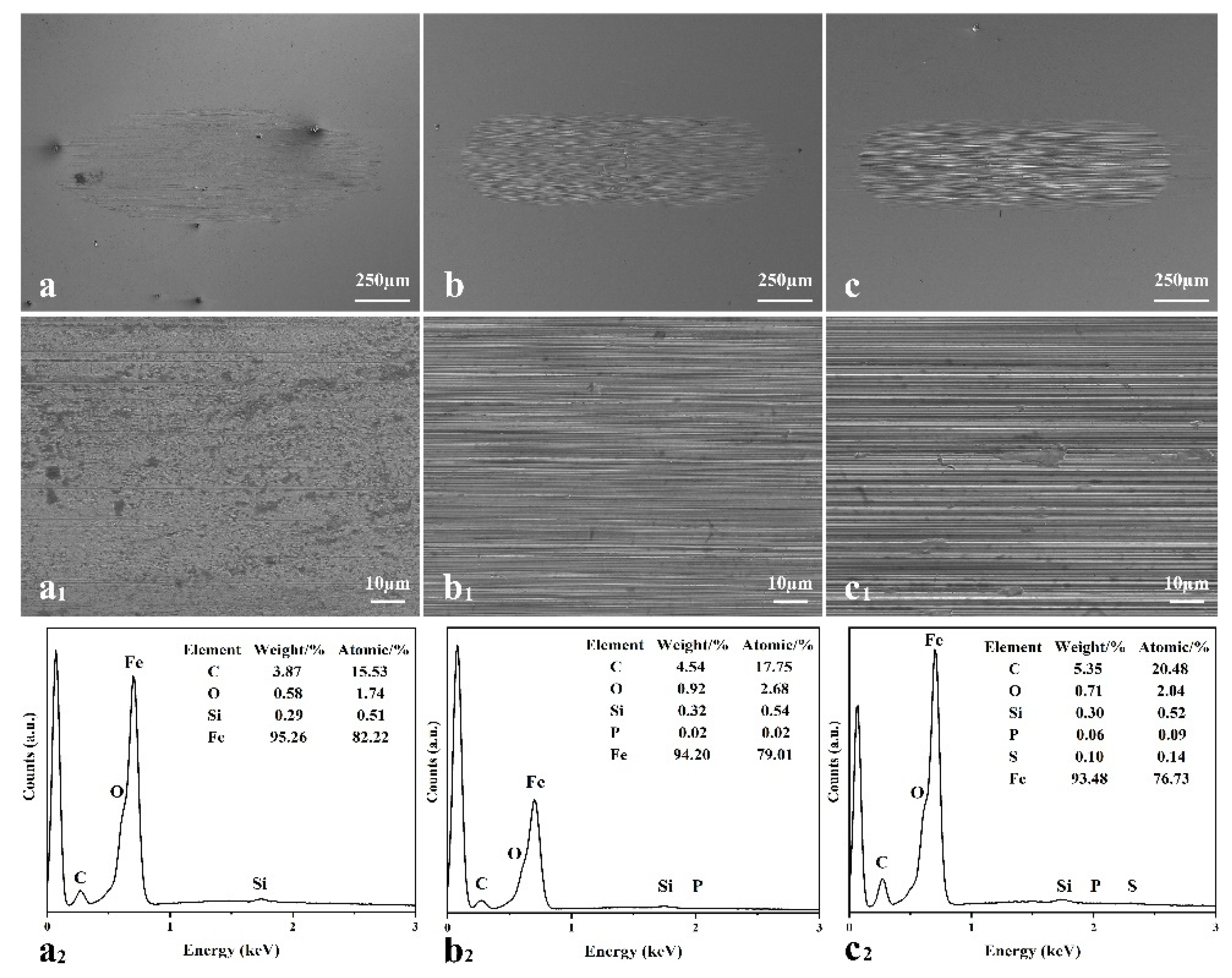

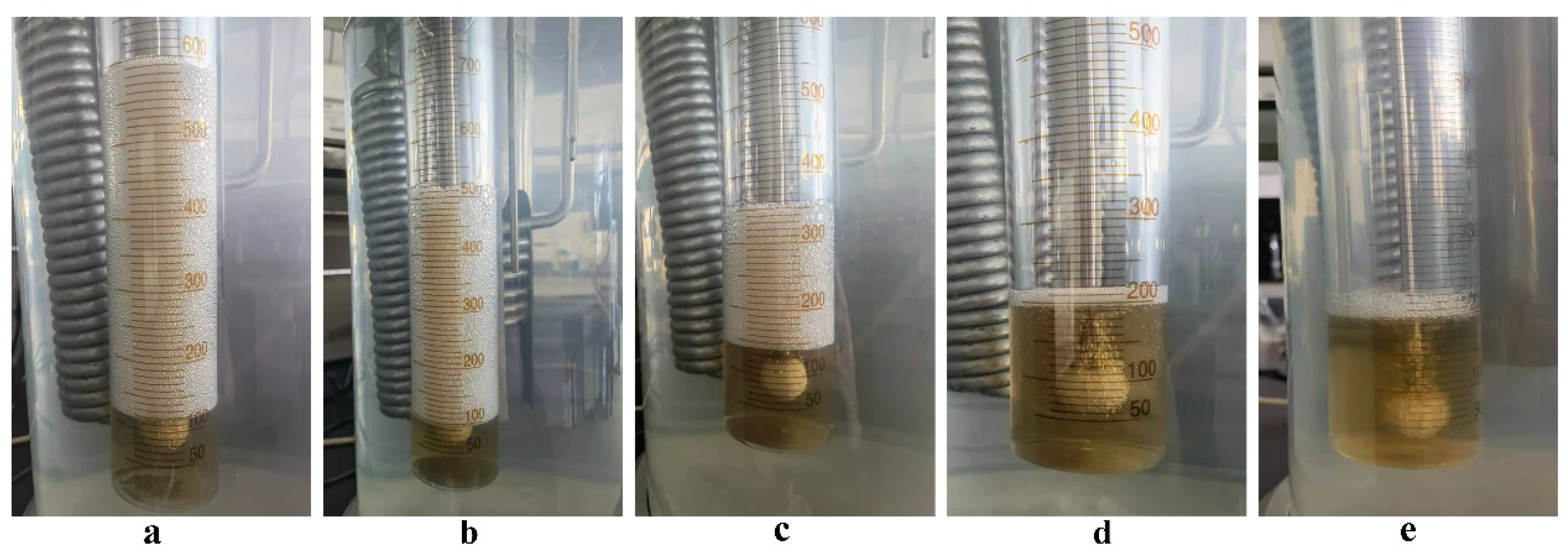

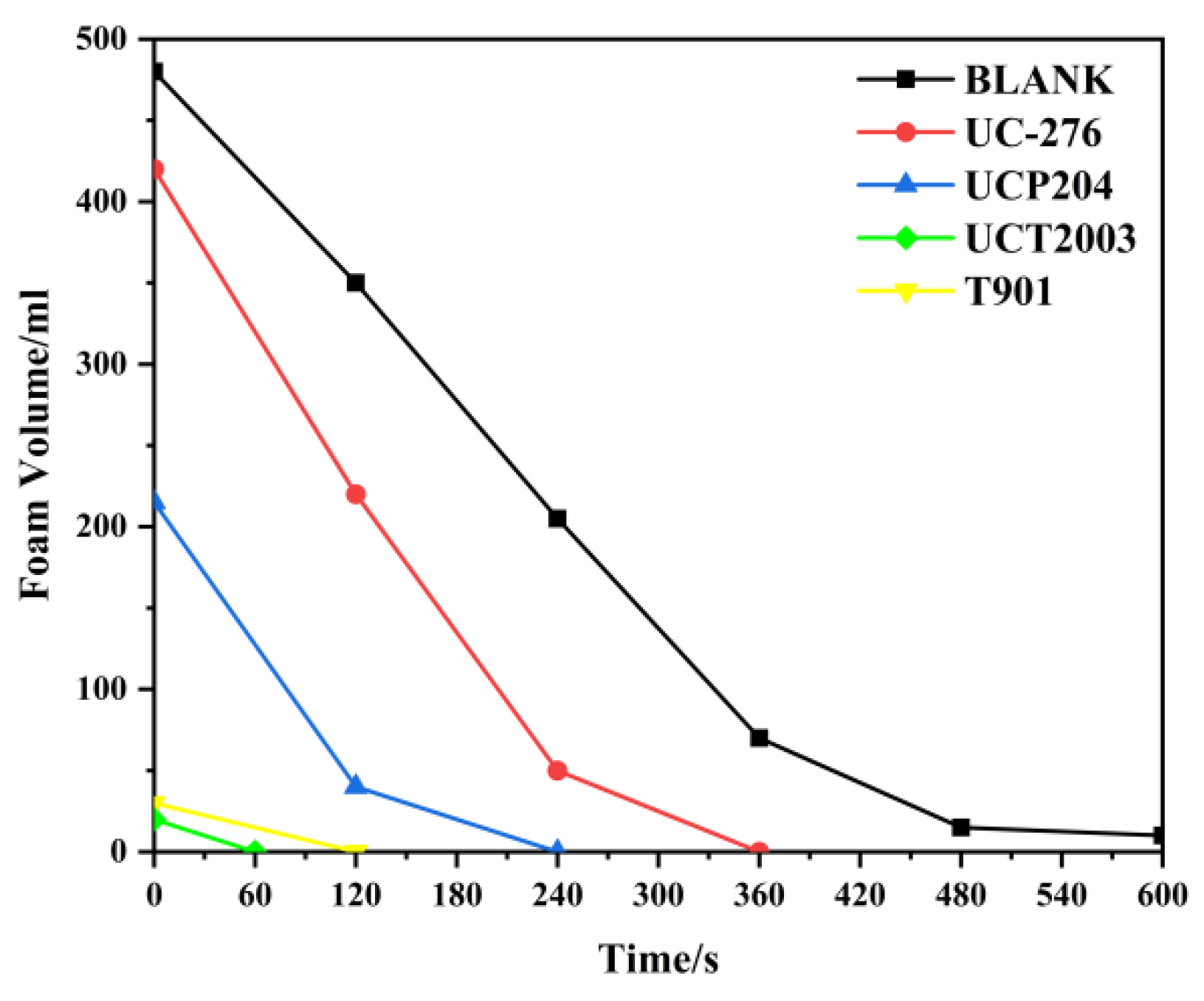

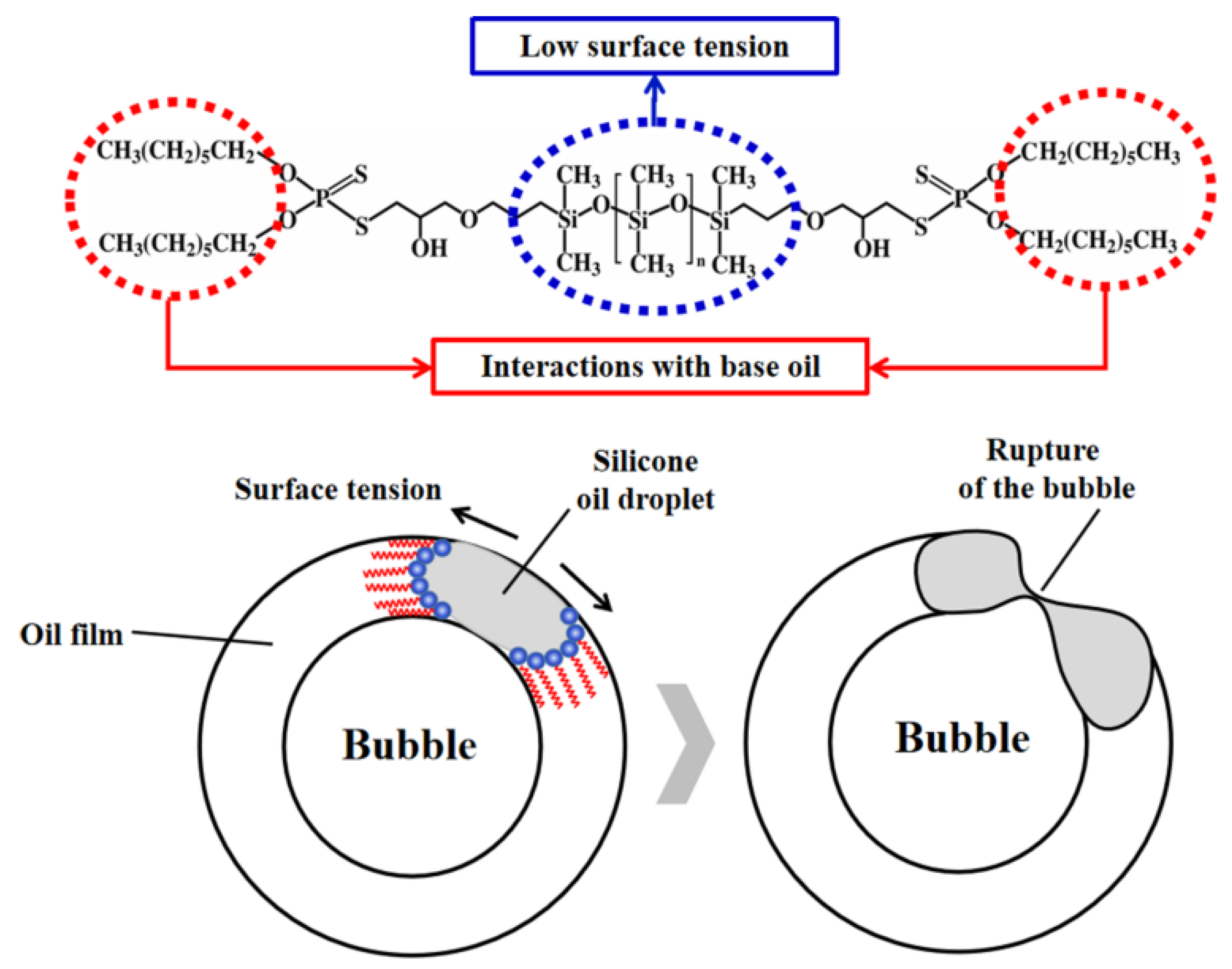

3.4. Worn Surface Analysis

3.5. Anti-Foaming Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aziz, T.; Fan, H.; Khan, F.U.; Haroon, M.; Cheng, L. Modified silicone oil types, mechanical properties and applications. Polym. Bull. 2019, 76, 2129–2145. [Google Scholar] [CrossRef]

- Partenhauser, A.; Laffleur, F.; Rohrer, J.; Bernkop-Schnürch, A. Thiolated silicone oil: Synthesis, gelling and mucoadhesive properties. Acta Biomater. 2015, 16, 169–177. [Google Scholar] [CrossRef]

- Hu, Z.; Liao, M.; Chen, Y.; Cai, Y.; Meng, L.; Liu, Y.; Lv, N.; Liu, Z.; Yuan, W. A novel preparation method for silicone oil nanoemulsions and its application for coating hair with silicone. Int. J. Nanomed. 2012, 7, 5719–5724. [Google Scholar]

- Jiang, X.; Hu, H.; Bai, Y.; Tian, X.; Huang, D.; Wang, S. Synthesis and properties of the vinyl silicone oil modified polyacrylate core-shell latex as a binder for pigment printing. J. Adhes. Sci. Technol. 2013, 27, 154–164. [Google Scholar] [CrossRef]

- Dresp, J.H.; Menz, D.H. The phenomenon of “sticky” silicone oil. Graefe’s Arch. Clin. Exp. Ophthalmol. 2007, 245, 863–868. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Sun, C.; Ding, F.; Yi, Y. Study on the synthesis of fluoroalkyl and polyether co-modified polysiloxane and appraisal of its foam-breaking and -inhibiting performance. J. Chin. Chem. Soc. 2017, 64, 674–682. [Google Scholar] [CrossRef]

- Haut, J.; Larricart, J.P.; van Effenterre, G.; Pinon-Pignero, F.L. Some of the most important properties of silicone oil to explain its action. Ophthalmologica 1985, 191, 150–153. [Google Scholar] [CrossRef] [PubMed]

- Aslfattahi, N.; Samylingam, L.; Abdelrazik, A.S.; Arifutzzaman, A.; Saidur, R.J.S.E.M. Mxene based new class of silicone oil nanofluids for the performance improvement of concentrated photovoltaic thermal collector. Sol. Energy Mater. Sol. Cells 2020, 211, 110526. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, H.S.; Guan, R.F.; Zhou, C.J. Preparation and characterization of hyperbranched silicone oil by hydrosilylation reaction. Appl. Mech. Mater. 2013, 395–396, 363–366. [Google Scholar]

- Sun, N.; Xiao, Z. Improvement of the thermostability of silicone oil/polystyrene microcapsules by embedding TiO2/Si3N4 nanocomposites as outer shell. J. Mater. Sci. 2017, 52, 10800–10813. [Google Scholar] [CrossRef]

- Lonsky, P. Some characteristics of silicones developed as lubricants. J. Synchrotron Radiat. 1985, 1, 302–313. [Google Scholar] [CrossRef]

- Miller, A.A. Radiation stabilities of arylmethylsiloxanes. IEC Prod. Res. Dev. 1964, 3, 252–256. [Google Scholar] [CrossRef]

- Barca, F.; Caporossi, T.; Rizzo, S. Silicone oil: Different physical proprieties and clinical applications. BioMed Res. Int. 2014, 2014, 502143. [Google Scholar] [CrossRef] [PubMed]

- Partenhauser, A.; Netsomboon, K.; Leonaviciute, G.; Bernkop-Schnürch, A. Evaluation of thiolated silicone oil as advanced mucoadhesive antifoaming agent. Drug Deliv. 2016, 23, 2711–2719. [Google Scholar] [CrossRef] [PubMed]

- Han, S.S.; Xu, J.Y.; Zheng, G.; Sun, Y. A dissertation on polysiloxane-antifoaming-agents: Antifoaming principles, synthesis and compound. Adv. Mater. Res. 2011, 301–303, 26–30. [Google Scholar]

- Németh, Z.; Rácz, G.; Koczo, K. Foam control by silicone polyethers—Mechanisms of “cloud point antifoaming”. J. Colloid Interface Sci. 1998, 207, 386–394. [Google Scholar] [CrossRef]

- Yoo, S.S.; Kim, D.E. Minimum lubrication technique using silicone oil for friction reduction of stainless steel. Int. J. Precis. Eng. Manuf. 2013, 14, 875–880. [Google Scholar] [CrossRef]

- Gu, G.; Wu, Z.; Zhang, Z.; Qing, F. Tribological properties of fluorine-containing additives of silicone oil. Tribol. Int. 2009, 42, 397–402. [Google Scholar] [CrossRef]

- Weng, L.; Wang, H.; Feng, D.; Liu, W.; Xue, Q. Tribological behavior of the synthetic chlorine-and fluorine-containing silicon oil as aerospace lubricant. Ind. Lubr. Tribol. 2008, 60, 216–221. [Google Scholar] [CrossRef]

- Gainer, G.C. Silicone oils for lubricating steel versus steel. Ind. Eng. Chem. 1954, 46, 2355–2362. [Google Scholar] [CrossRef]

- Tabor, D.; Willis, R.F. Thin film lubrication with substituted silicones-role of physical and chemical factors. Wear 1968, 11, 145–162. [Google Scholar] [CrossRef]

- Mannheimer, R. Factors that influence the coalescence of bubbles in oils that contain silicone antifoamants. Chem. Eng. Commun. 1992, 113, 183–196. [Google Scholar] [CrossRef]

- Chen, J.; Huang, X.; He, L.; Luo, X. Foaming of oils: Effect of poly(dimethylsiloxanes) and silica nanoparticles. ACS OMEGA 2019, 4, 6502–6510. [Google Scholar] [CrossRef] [PubMed]

- Ewers, W.; Sutherland, K. The role of surface transport in the stability and breakdown of foams. Aust. J. Chem. 1952, 5, 697–710. [Google Scholar] [CrossRef]

- Kekevi, B.; Berber, H.; Yıldırım, H. Synthesis and characterization of silicone-based surfactants as anti-foaming agents. J. Surfactants Deterg. 2012, 15, 73–81. [Google Scholar] [CrossRef]

- Rutnakornpituk, M.; Ngamdee, P. Surface and mechanical properties of microporous membranes of poly(ethylene glycol)–polydimethylsiloxane copolymer/chitosan. Polymer 2006, 47, 7909–7917. [Google Scholar] [CrossRef]

- Fraga, A.K.; Santos, R.F.; Mansur, C.R.E. Evaluation of the efficiency of silicone polyether additives as antifoams in crude oil. J. Appl. Polym. Sci. 2012, 124, 4149–4156. [Google Scholar] [CrossRef]

- Owen, M.J.; Groh, J.L. Fluorosilicone antifoams. J. Appl. Polym. Sci. 1990, 40, 789–797. [Google Scholar] [CrossRef]

- Wu, F.; Cai, C.; Wang, L.; Cao, Z.P.; Yi, W.B. Breaking and inhibiting foam performance of modified silicone oils in oil-based systems. J. Dispers. Sci. Technol. 2008, 29, 792–795. [Google Scholar] [CrossRef]

- Xiu, N.I.; Mei, Y.G.; Li, C.S.; Cheng, Y. Synthesis and compounding of polyether modified polysiloxane crude oil defoamer. Oilfield Chem. 2009, 26, 153–157. [Google Scholar]

- Hassan, A.; Jumbri, K.; Ramli, A.; Borhan, N. Physio-chemical analysis of amide and amine poly(dimethylsiloxane)-modified defoamer for efficient oil-water separation. ACS OMEGA 2021, 6, 14806–14818. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zhuang, G.; Chen, Z.; Wei, J. Experimental study on the micromorphology and strength formation mechanism of epoxy asphalt during the curing reaction. Appl. Sci. 2020, 10, 2610. [Google Scholar] [CrossRef]

- Wang, T.; Ye, H.; Zhang, X.; Cheng, J. Uv-curable epoxy silicone with a high refractive index and self-photosensitizing effect. Ind. Eng. Chem. Res. 2012, 51, 15832–15838. [Google Scholar] [CrossRef]

- Pelton, R. A review of antifoam mechanisms in fermentation. J. Ind. Microbiol. Biotechnol. 2002, 29, 149–154. [Google Scholar] [CrossRef]

- Pelton, R. A model of foam growth in the presence of antifoam emulsion. Chem. Eng. Sci. 1996, 51, 4437–4442. [Google Scholar] [CrossRef]

- Said, Z.; Sundar, L.S.; Tiwari, A.K.; Ali, H.M.; Sheikholeslami, M.; Bellos, E.; Babar, H. Recent advances on the fundamental physical phenomena behind stability, dynamic motion, thermophysical properties, heat transport, applications, and challenges of nanofluids. Phys. Rep. 2022, 946, 1–94. [Google Scholar] [CrossRef]

- Yu, F.; Chen, Y.; Liang, X.; Xu, J.; Lee, C.; Liang, Q.; Tao, P.; Deng, T. Dispersion stability of thermal nanofluids. Prog. Nat. Sci. Mater. Int. 2017, 27, 531–542. [Google Scholar] [CrossRef]

- Bakthavatchalam, B.; Habib, K.; Wilfred, C.D.; Saidur, R.; Saha, B.B. Comparative evaluation on the thermal properties and stability of mwcnt nanofluid with conventional surfactants and ionic liquid. J. Therm. Anal. Calorim. 2022, 147, 393–408. [Google Scholar] [CrossRef]

- Chakraborty, S.; Panigrahi, P.K. Stability of nanofluid: A review. Appl. Therm. Eng. 2020, 174, 115259. [Google Scholar] [CrossRef]

- Denkov, N.D. Mechanisms of foam destruction by oil-based antifoams. LANGMUIR 2004, 20, 9463–9505. [Google Scholar] [CrossRef]

- Aveyard, R.; Cooper, P.; Fletcher, P.D.I.; Rutherford, C.E. Foam breakdown by hydrophobic particles and nonpolar oil. LANGMUIR 1993, 9, 604–613. [Google Scholar] [CrossRef]

- Frye, G.C.; Berg, J.C. Mechanisms for the synergistic antifoam action by hydrophobic solid particles in insoluble liquids. J. Colloid Interface Sci. 1989, 130, 54–59. [Google Scholar] [CrossRef]

- Jha, B.K.; Christiano, S.P.; Shah, D.O. Silicone antifoam performance: Correlation with spreading and surfactant monolayer packing. LANGMUIR 2000, 16, 9947–9954. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, X.; Zhang, E.; Chen, Y.; Ma, R.; Gong, K.; Li, W.; Wang, X. Chemically Modified Silicone Oil with Enhanced Tribological and Anti-Foaming Properties. Lubricants 2022, 10, 364. https://doi.org/10.3390/lubricants10120364

Luan X, Zhang E, Chen Y, Ma R, Gong K, Li W, Wang X. Chemically Modified Silicone Oil with Enhanced Tribological and Anti-Foaming Properties. Lubricants. 2022; 10(12):364. https://doi.org/10.3390/lubricants10120364

Chicago/Turabian StyleLuan, Xiaosheng, Enhui Zhang, Yunlong Chen, Rui Ma, Kuiliang Gong, Weimin Li, and Xiaobo Wang. 2022. "Chemically Modified Silicone Oil with Enhanced Tribological and Anti-Foaming Properties" Lubricants 10, no. 12: 364. https://doi.org/10.3390/lubricants10120364

APA StyleLuan, X., Zhang, E., Chen, Y., Ma, R., Gong, K., Li, W., & Wang, X. (2022). Chemically Modified Silicone Oil with Enhanced Tribological and Anti-Foaming Properties. Lubricants, 10(12), 364. https://doi.org/10.3390/lubricants10120364