Study on Friction Characteristics of Slipper Pair of Large Displacement High-Pressure Piston Pump

Abstract

1. Introduction

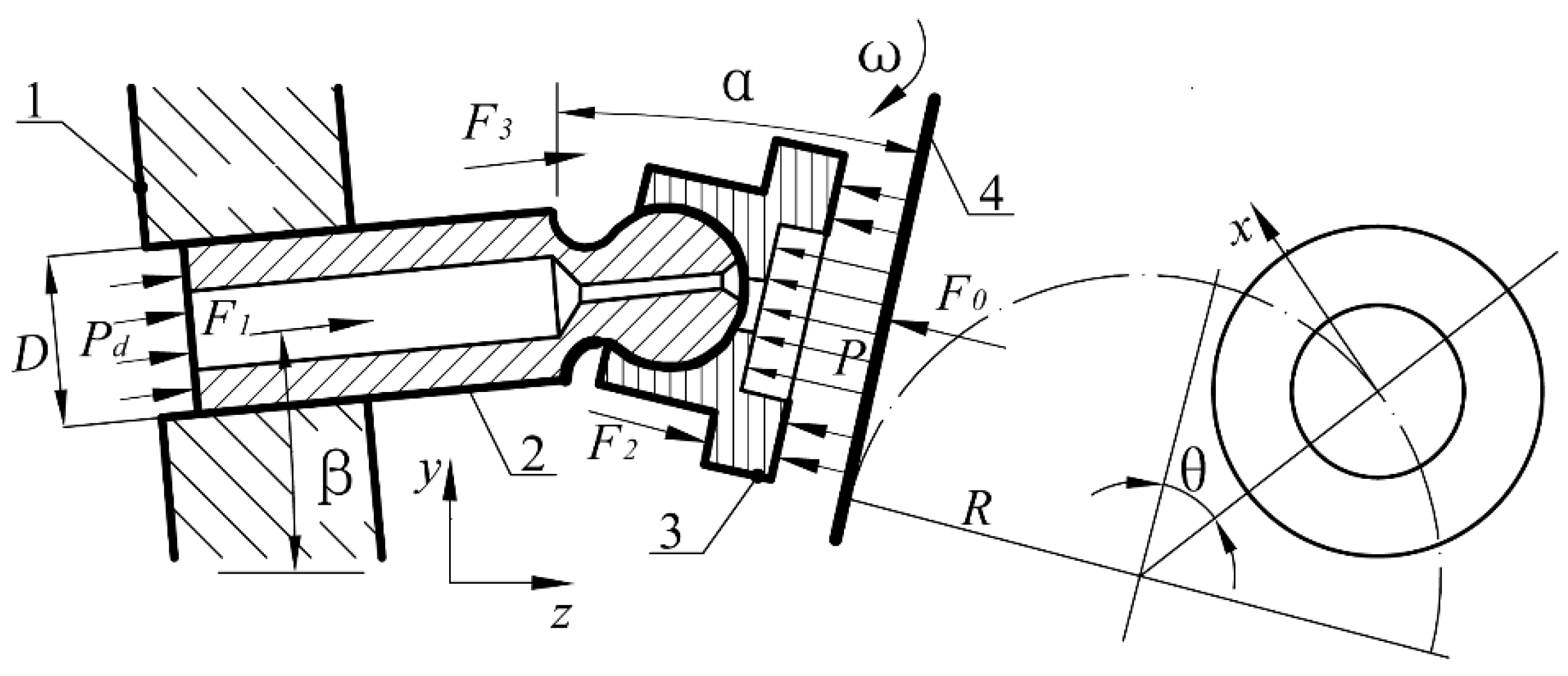

2. Mathematical Model Establishment

2.1. Modified Model of Oil Film Thickness

2.2. Calculation Model of Equivalent Friction Coefficient

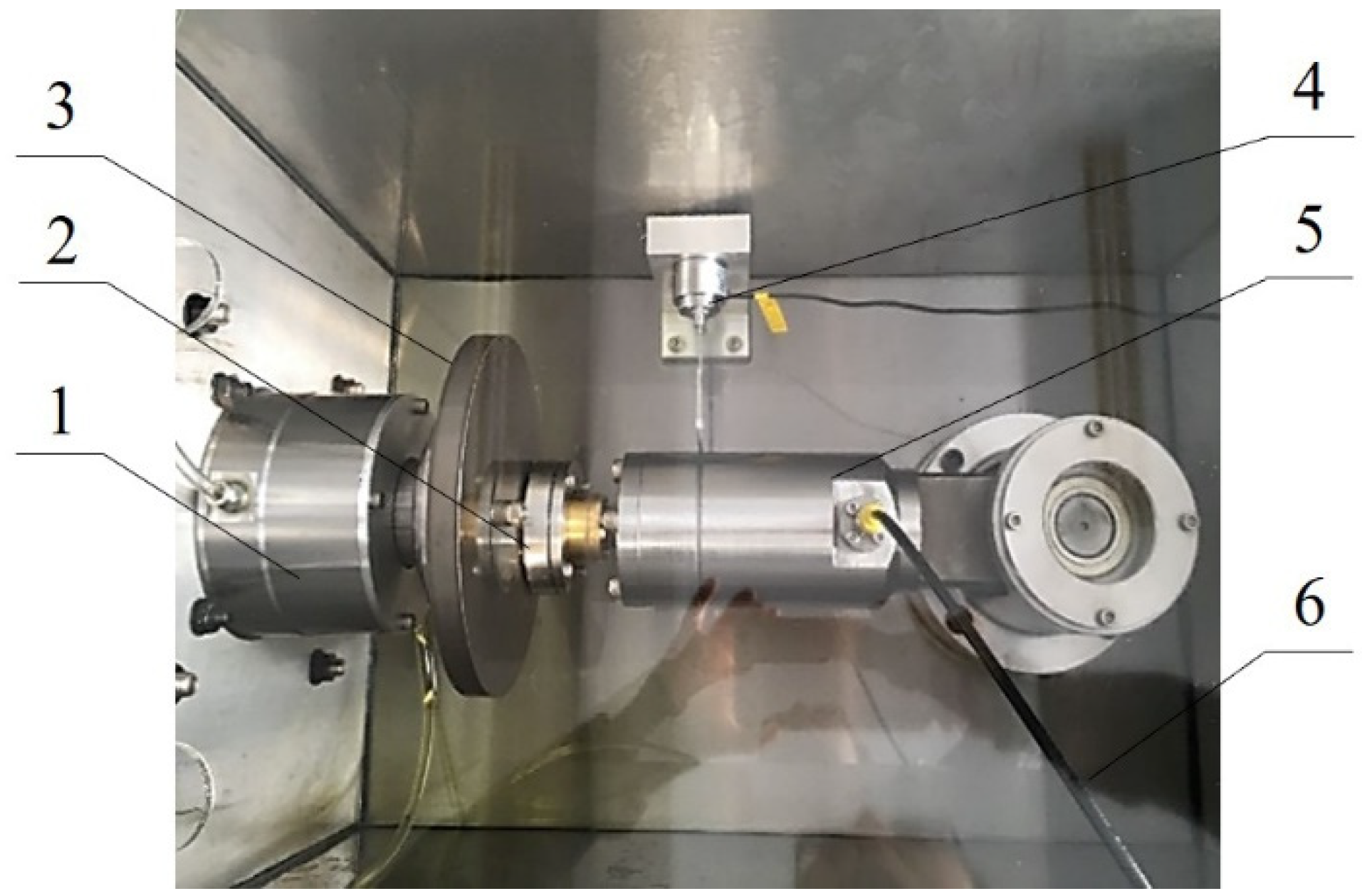

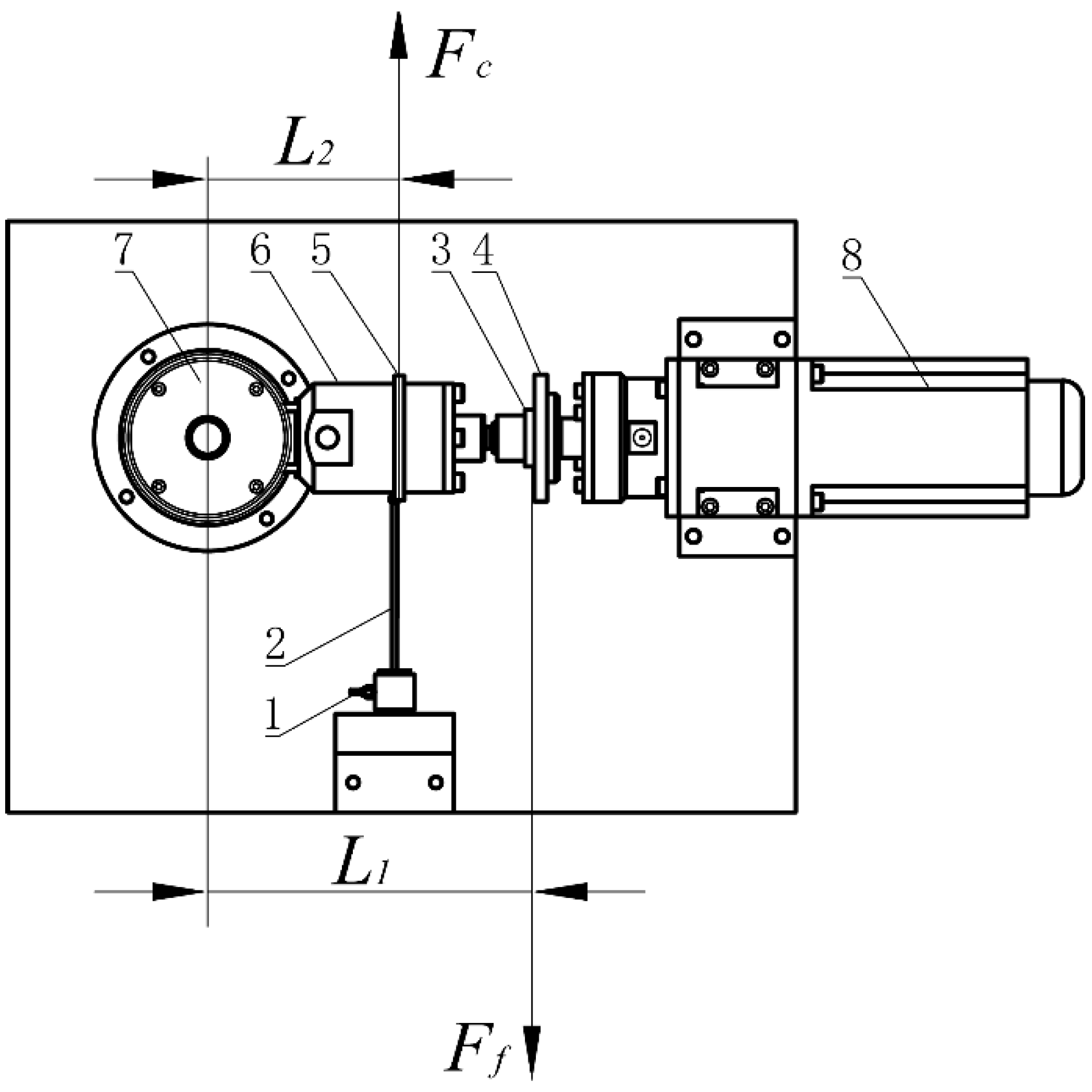

3. Testing Apparatus

3.1. Test Bench Structure

3.2. Friction Test Principle

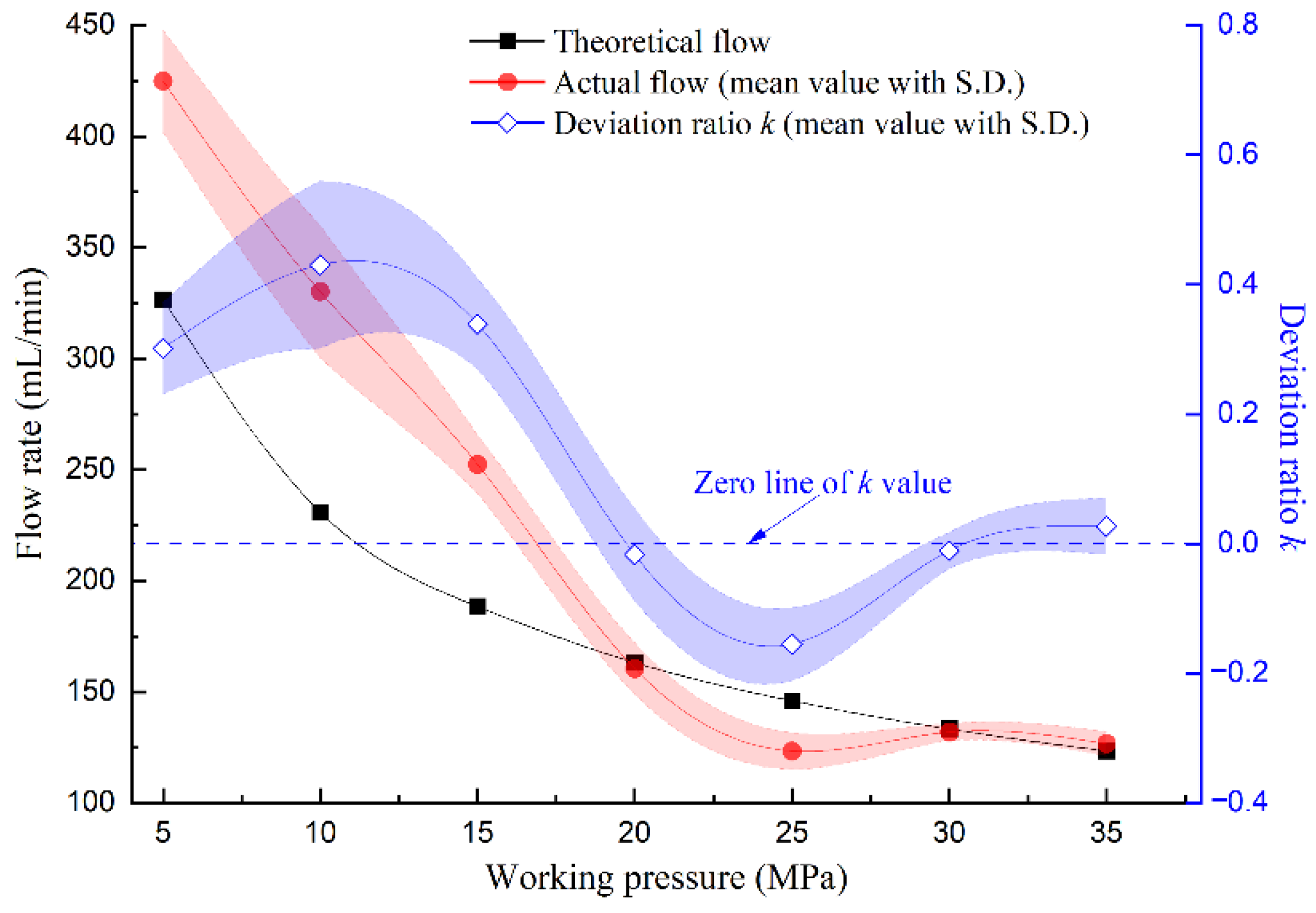

4. Test Analysis

- The oil temperature is set to a constant temperature of 40 °C (close to the temperature of long-term operation under actual working conditions).

- The working pressure is set to 5, 10, 15, 20, 25, 30, 35 MPa.

- The swashplate speed is set to 1000, 1400, 1800, 2200 r/min.

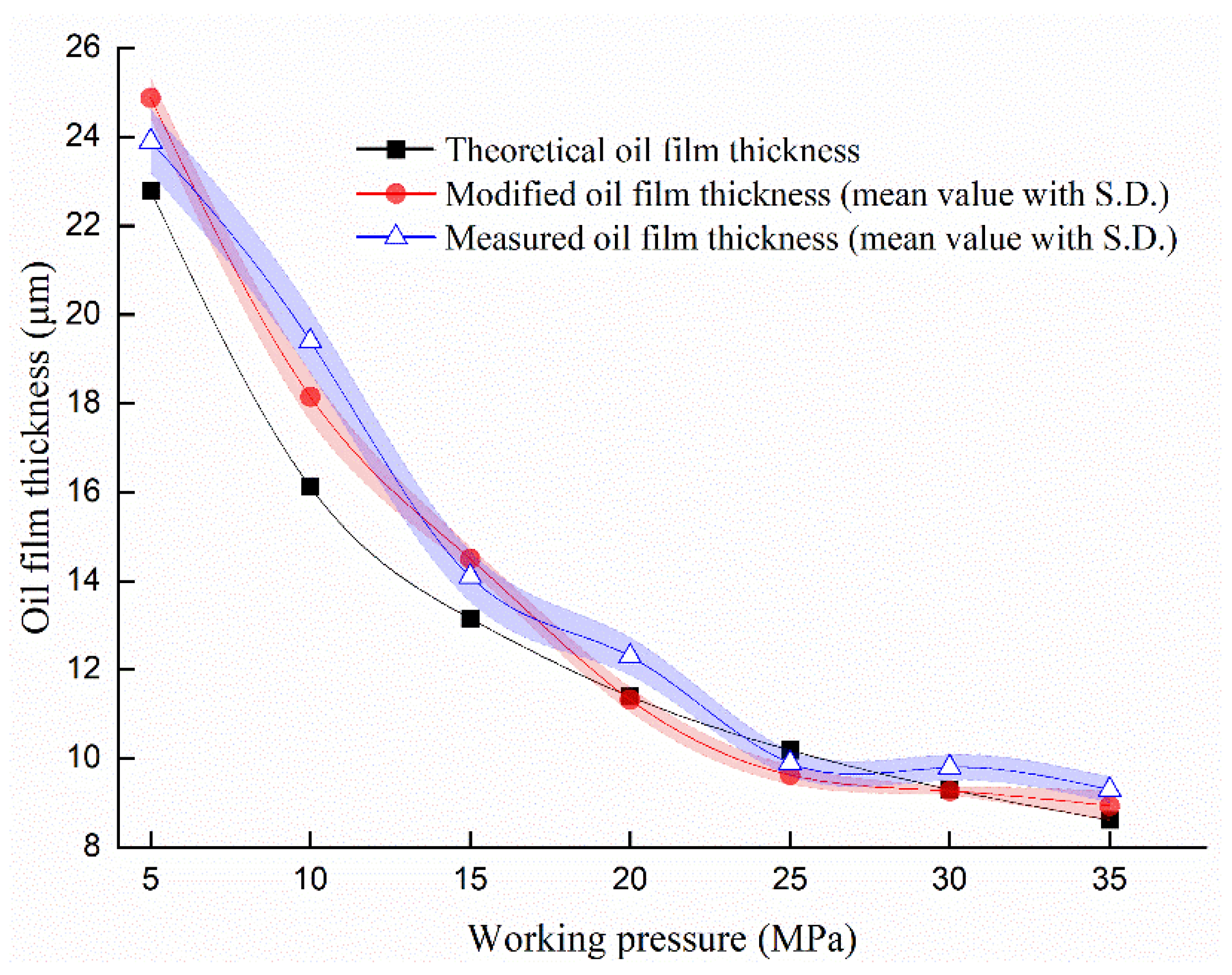

4.1. Oil Film Thickness Analysis

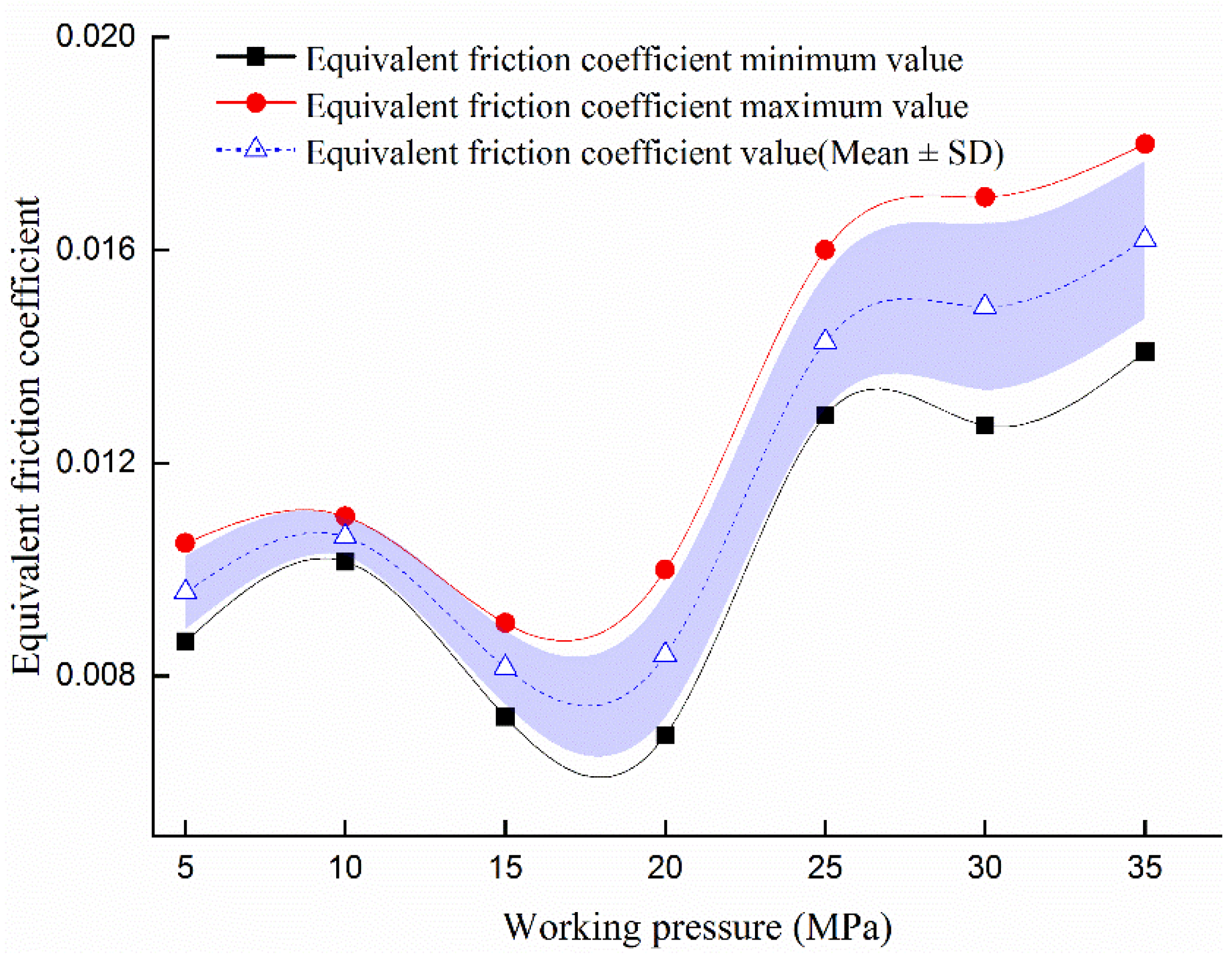

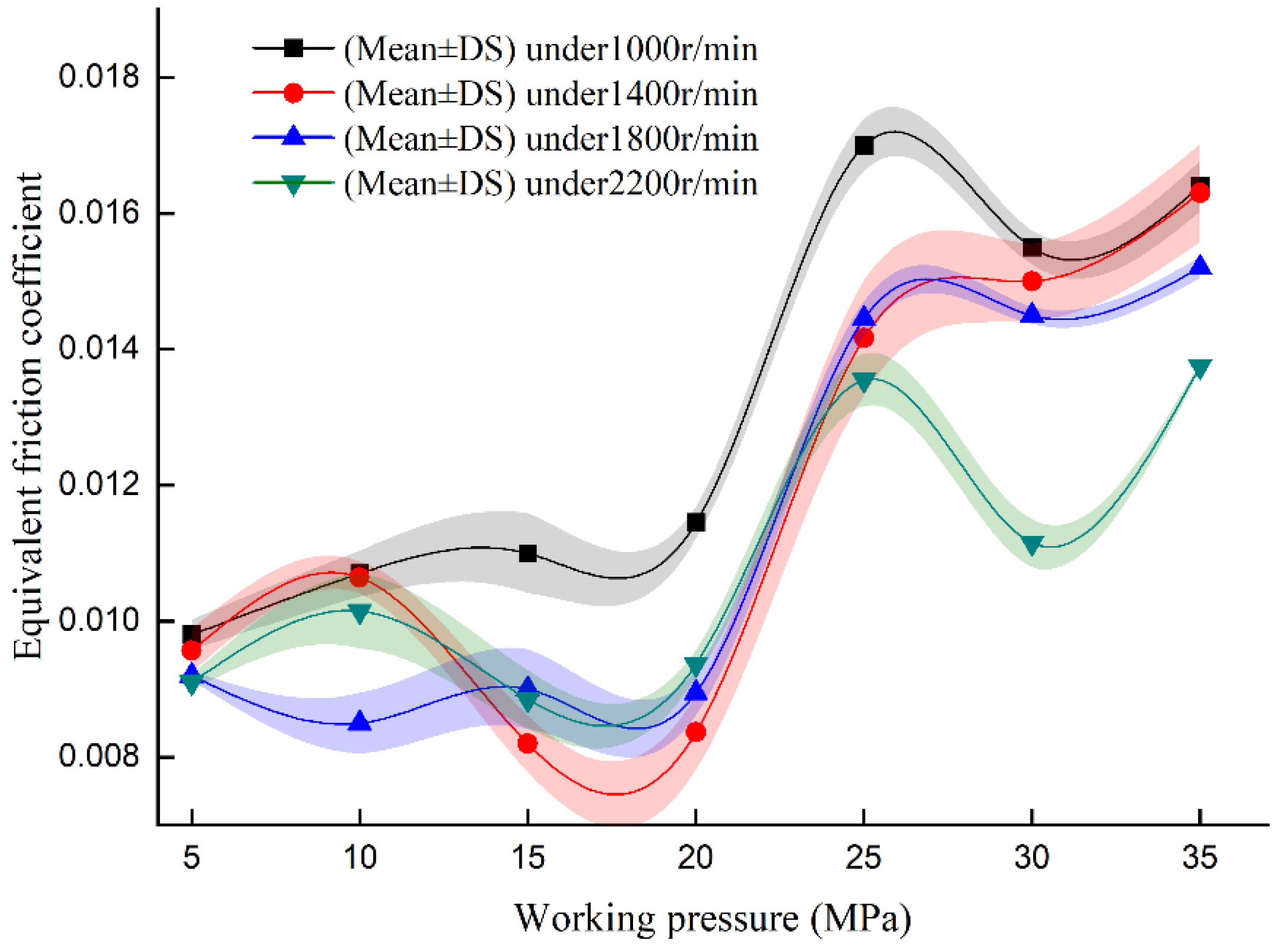

4.2. Equivalent Friction Coefficient Analysis

5. Conclusions

- (1)

- The mean deviation ratio between the modified oil film thickness value and the measured value is mainly within 6%, while that of the theoretical method is mainly from 6% to 8%, and the mean of the difference between the two deviation ratios is about 3%, indicating that it is feasible to improve the calculated value of oil film thickness to some extent by using the modified method. However, since the benefit of the modified method may be weakened considering the standard deviation, it is necessary to study the specific applicable conditions of this modified method further.

- (2)

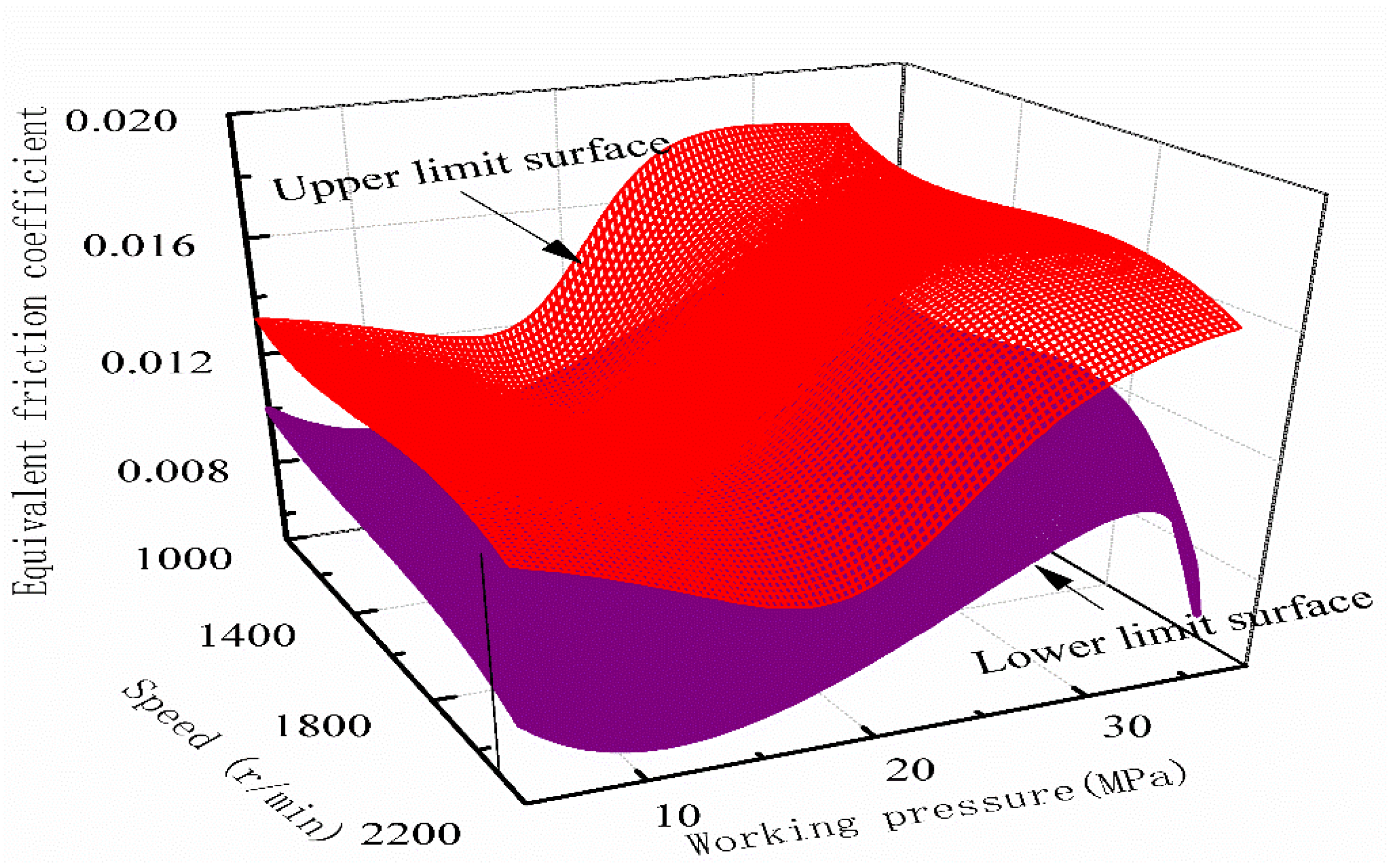

- The equivalent friction coefficient of the slipper pair fluctuates in the range of 0.006~0.018 and is affected more significantly by the working pressure with a difference of 0.004~0.010 between the fluctuation values than that of rotational speed with a difference of 0.002~0.004, suggesting that the working pressure can be given priority as the design basis of the friction coefficient for the pump.

- (3)

- The modified method established in this paper can be used to correct the theoretical oil film thickness of the slipper pair as a reference for the 750 mL/r displacement piston pump design by using the deviation ratio under corresponding working conditions. Correspondingly, the upper and lower limits of the fitting surface of the equivalent friction coefficient can provide a more accurate design boundary for the friction coefficient of the slipper pair of the pump, and the designer can select the friction coefficient value between the upper and lower reference according to the working conditions during the development of 750 mL/r displacement piston pumps.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergada, J.M.; Kumar, S.; Davies, D.L.; Watton, J. A complete analysis of axial piston pump leakage and output flow ripples. Appl. Math. Model. 2011, 36, 1731–1751. [Google Scholar] [CrossRef]

- Xu, B.; Hu, M.; Zhang, J.-Z.; Mao, Z.-B. Distribution characteristics and impact on pump’s efficiency of hydro-mechanical losses of axial piston pump over wide operating ranges. J. Cent. South Univ. 2017, 24, 609–624. [Google Scholar] [CrossRef]

- D’Andrea, D.; Epasto, G.; Bonanno, A.; Guglielmino, E.; Benazzi, G. Failure analysis of anti-friction coating for cylinder blocks in axial piston pumps. Eng. Fail. Anal. 2019, 104, 126–138. [Google Scholar] [CrossRef]

- Deng, H.; Hu, C.; Wang, Q.; Wang, L.; Wang, C. Friction and wear analysis of the external return spherical bearing pair of axial piston pump/motor. Mech. Ind. 2020, 21, 104. [Google Scholar] [CrossRef]

- Shen, H.; Zhou, Z.; Guan, D.; Liu, Z.; Jing, L.; Zhang, C. Dynamic Contact Analysis of the Piston and Slipper Pair in Axial Piston Pump. Coatings 2020, 10, 1217. [Google Scholar] [CrossRef]

- Li, S. Analysis of Instantaneous Flow and Slipper Pair Dynamics of High Pressure and Large Displacement Radial Piston Pump. Ph.D. Thesis, Lanzhou University of Technology, Lanzhou, China, 2021. [Google Scholar]

- Li, S.; Yang, P.; Bao, S.; Li, Y. Numerical simulation of fluid-structure-thermal coupling of slipper pair in high-pressure and large-displacement radial piston pump. J. Drain. Irrig. Mach. Eng. 2022, 40, 887–894. [Google Scholar]

- Hooke, C.J.; Kakoullis, Y.P. The effects of non-flatness on the performance of slipper in axial piston pumps. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1988, 197, 239–247. [Google Scholar] [CrossRef]

- Hooke, C.J.; Li, K.Y. The lubrication of slippers in axial piston pumps and motors-the effect of tilting couples. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1989, 203, 343–350. [Google Scholar] [CrossRef]

- Koc, E.; Hooke, C.; Li, K. Slipper balance in axial piston pumps and motors. J. Tribol. 1992, 114, 766–772. [Google Scholar] [CrossRef]

- Koc, E.; Hooke, C. Investigation into the effects of orifice size, offset and overclamp ratio on the lubrication of slipper bearings. Tribol. Int. 1996, 29, 299–305. [Google Scholar] [CrossRef]

- Harris, R.; Edge, K.; Tilley, D. Predicting the behavior of slipper pads in swashplate-type axial piston pump. J. Dyn. Sys. Meas. Control. 1996, 118, 41–47. [Google Scholar] [CrossRef]

- Zhao, K.; He, T.; Wang, C.; Chen, Q.; Li, Z. Lubrication characteristics analysis of slipper pair of digital valve distribution axial piston pump. Adv. Mech. Eng. 2022, 14, 16878132221085442. [Google Scholar] [CrossRef]

- Sun, Y.; Jiang, J.; Liu, C. Oil film characteristics and power consumption of slipper pair under redundant pressing force. J. South China Univ. Technol. (Nat. Sci.) 2011, 39, 6. [Google Scholar]

- Shen, R.; Pan, Y. Friction characteristic analysis of slipper pair in A11VO190 axial piston pumps. Chin. J. Eng. Des. 2014, 21, 51–55. [Google Scholar]

- He, B.; Sun, J.; Ye, Z. Calculation and analysis of film thickness for slipper pair and valve plate pair in fuel piston pump. J. Aerosp. Power 2010, 25, 1437–1442. [Google Scholar]

- Liu, H.; Yuan, S.; Peng, Z. Dynamic Simulation of Slipper Bearings in Axial Piston Pumps. Trans. Beijing Inst. Technol. 2011, 11, 1282–1286. [Google Scholar]

- Tang, H.; Yin, Y.; Li, J. Characteristics of clearance leakage and friction torque of slipper pair in axial piston pump. J. South China Univ. Technol. (Nat. Sci.) 2014, 42, 74–79. [Google Scholar]

- Lin, S.; Hu, J. Tribo-dynamic model of slipper bearings. Appl. Math. Model. 2015, 39, 548–558. [Google Scholar] [CrossRef]

- Kazama, T. Mixed Lubrication Characteristics of Dynamically Loaded Hydrostatic Spherical Bearings (Numerical Simulation at Operating Conditions of Piston Pumps/Motors). Trans. Jpn. Soc. Mech. Eng. Ser. C 2003, 69, 2200–2205. [Google Scholar] [CrossRef]

- Ernst, M.; Ivantysynova, M. Axial Piston Machine Cylinder Block Bore Surface Profile for High-Pressure Operating Conditions with Water as Working Fluid. In Proceedings of the 2018 Global Fluid Power Society PHD Symposium (GFPS), Samara, Russia, 18–20 July 2018; pp. 1–7. [Google Scholar]

- Pelosi, M.; Ivantysynova, M. A geometric multigrid solver for the piston-cylinder interface of axial piston machines. Tribol. Trans. 2012, 55, 163–174. [Google Scholar] [CrossRef]

- Tang, H.; Ren, Y.; Xiang, J. A Novel Model for Predicting Thermoelastohydrodynamic Lubrication Characteristics of Slipper Pair in Axial Piston Pump. Int. J. Mech. Sci. 2017, 124–125, 109–121. [Google Scholar] [CrossRef]

- Wang, Z.; Han, B.; Sun, L. Analysis of Elastohydrodynamic Lubrication (EHL) Characteristics of Port Plate Pair of a Piston Pump. Machines 2022, 10, 1109. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, H.; Jing, C. Hydrodynamic lubrication characteristics of slipper/swash plate pair in axial piston pumps-theory and experiment. Trans. Beijing Inst. Technol. 2018, 38, 229–234. [Google Scholar]

- Xu, L.; Lu, Y.; Liu, Q.; Lin, L.; Mu, J. Experimental Study on Frictional Pairs of Piston Pumps. J. Fail. Anal. and Prev. 2022, 22, 738–749. [Google Scholar] [CrossRef]

- Li, X. Research on the Effect of Varying Load on the Characteristics of Oil Film for Slipper Pair of Radial Piston Pumps. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2018. [Google Scholar]

- Tang, H.S.; Yin, Y.B.; Ren, Y.; Xiang, J.; Chen, J. Impact of the thermal effect on the load-carrying capacity of a slipper pair for an aviation axial-piston pump. Chin. J. Aeronaut. 2018, 31, 195–209. [Google Scholar] [CrossRef]

- Xu, B.; Li, Y.; Zhang, B.; Zhang, J. Numerical simulation of overturning phenomenon of axial piston pump slipper pair. J. Mech. Eng. 2010, 46, 161–168. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Z.; Wang, K. Analysis Method of Slipper /Swash Plate Pair Film Characters Considering Bearing Force of Rough Surface. Chin. Hydraul. Pneum. 2022, 46, 101–108. [Google Scholar]

- Tang, H.; Ren, Y.; Xiang, J.; Anil, K. Evaluation and optimization of axial piston pump textured slipper bearings with spherical dimples based on hybrid genetic algorithm. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1719–1741. [Google Scholar] [CrossRef]

- Chen, F.; Wu, X.; Cha, P.; Yin, F. Numerical Simulation of Dynamic Characteristics of Slipper Pair Oil Film of Piston Pump. Mach. Tool Hydraul. 2022, 50, 127–134. [Google Scholar]

- Ma, J.; Li, Q.; Ren, C.; Chen, J. Influence factors analysis on wear of hydraulic axial piston pump/slipper pair. J. Beijing Univ. Aeronaut. Astronaut. 2015, 41, 405–410. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, X. Research on the Oil Film Characteristics of Slipper Pair and Piston Pair in Aviation Axial-Piston Pump. Master’s Thesis, Zhejiang University, Hangzhou, China, 2016. [Google Scholar]

- Fisher, M.J. A Theoretical Determination of Some Characteristics of a Tilted Hydrostatic Slipper Bearing; British Hydromechanics Research Association: Bedfordshire, UK, 1962. [Google Scholar]

- Hashemi, S.; Kroker, A.; Bobach, L.; Bartel, D. Multibody dynamics of pivot slipper pad thrust bearing in axial piston machines incorporating thermal elastohydrodynamics and mixed lubrication model. Tribol. Int. 2016, 96, 57–76. [Google Scholar] [CrossRef]

- Pang, Z.; Zhai, W.J.; Shun, J.W. The Study of Hydrostatic Lubrication of the Slipper in a High-pressure Plunger Pump. Tribol. Trans. 1993, 36, 316–320. [Google Scholar] [CrossRef]

- Manring, N.D.; Wray, C.L.; Dong, Z. Experimental Studies on the Performance of Slipper Bearings within Axial-Piston Pumps. J. Tribol. 2004, 126, 511–522. [Google Scholar] [CrossRef]

- Tang, H.; Li, J.; Yin, Y. Power loss characteristics of slipper/swash plate pair in axial piston pump. J. Cent. South Univ. (Sci. Technol.) 2017, 48, 361–370. [Google Scholar]

- Bergada, J.M.; Haynes, J.M.; Watton, J. Leakage and groove pressure of an axial piston pump slipper with multiple lands. Tribol. Trans. 2008, 51, 469–482. [Google Scholar] [CrossRef]

| Measuring Instruments | Technical Parameters | |

|---|---|---|

| Measurement Range | Accuracy | |

| Flowmeter | 0–1000 mL/min | ±0.01% |

| Temperature sensor | 0–100 °C | ±0.05 °C |

| Pressure sensor | 0–50 MPa | ±0.1% |

| Electric-eddy-type micro displacement sensor | 0–200 μm | ±0.005% |

| Tension sensor | 0–500 N | ±0.02% |

| Speed (r/min) | Working Pressure (MPa) | Deviation Ratio of Theoretical Method (A) | Deviation Ratio of Modified Method | Difference between the Two Methods (C) | Mean of the Difference C | |

|---|---|---|---|---|---|---|

| Mean (B) | SD | B-A | Mean ± SD | |||

| 1000 | 10 | 7.52% | 4.69% | 0.26% | −2.83% | −2.98% ± 1.95% |

| 15 | 6.81% | 5.94% | 0.68% | −0.87% | ||

| 20 | 10.05% | 5.98% | 0.38% | −4.07% | ||

| 25 | 6.01% | 6.93% | 0.52% | 0.92% | ||

| 30 | 4.56% | 4.52% | 0.36% | −0.04% | ||

| 1400 | 10 | 14.08% | 9.64% | 0.69% | −4.44% | |

| 15 | 6.71% | 4.66% | 0.32% | −2.05% | ||

| 20 | 7.41% | 7.95% | 0.33% | 0.54% | ||

| 25 | 7.15% | 4.47% | 0.53% | −2.68% | ||

| 30 | 5.16% | 2.01% | 0.25% | −3.15% | ||

| 1800 | 10 | 8.02% | 4.51% | 0.42% | −3.51% | |

| 15 | 6.07% | 6.84% | 0.39% | 0.77% | ||

| 20 | 8.05% | 3.94% | 0.37% | −4.11% | ||

| 25 | 6.79% | 4.01% | 0.46% | −2.78% | ||

| 30 | 15.26% | 8.62% | 0.41% | −6.64% | ||

| 2200 | 10 | 14.40% | 6.04% | 0.38% | −8.36% | |

| 15 | 7.15% | 4.97% | 0.49% | −2.18% | ||

| 20 | 9.43% | 3.13% | 0.40% | −6.30% | ||

| 25 | 6.05% | 7.10% | 0.58% | 1.05% | ||

| 30 | 14.97% | 6.10% | 0.21% | −8.87% | ||

| Mean ± SD | Speed (r/min) | ||||

|---|---|---|---|---|---|

| 1000 | 1400 | 1800 | 2200 | ||

| Working pressure (MPa) | 5 | 27.42 ± 2.97 | 23.46 ± 1.69 | 20.85 ± 1.98 | 17.96 ± 1.39 |

| 10 | 57.36 ± 3.74 | 45.12 ± 1.41 | 49.70 ± 2.74 | 28.84 ± 1.80 | |

| 15 | 63.49 ± 2.01 | 49.87 ± 3.72 | 40.39 ± 2.07 | 32.72 ± 2.28 | |

| 20 | 83.73 ± 1.27 | 65.45 ± 6.87 | 66.43 ± 1.84 | 60.38 ± 2.19 | |

| 25 | 149.52 ± 2.83 | 142.30 ± 12.21 | 136.35 ± 1.33 | 127.66 ± 2.03 | |

| 30 | 203.55 ± 1.78 | 192.37 ± 2.79 | 184.65 ± 4.27 | 177.95 ± 1.92 | |

| 35 | 238.52 ± 3.57 | 241.50 ± 4.29 | 231.31 ± 3.31 | 225.90 ± 1.82 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Xu, S.; Gong, G.; Bi, Y.; Xu, L.; Zhang, L.; Ren, Z. Study on Friction Characteristics of Slipper Pair of Large Displacement High-Pressure Piston Pump. Lubricants 2022, 10, 363. https://doi.org/10.3390/lubricants10120363

Li Z, Xu S, Gong G, Bi Y, Xu L, Zhang L, Ren Z. Study on Friction Characteristics of Slipper Pair of Large Displacement High-Pressure Piston Pump. Lubricants. 2022; 10(12):363. https://doi.org/10.3390/lubricants10120363

Chicago/Turabian StyleLi, Zekui, Shunhai Xu, Guofang Gong, Yankun Bi, Liping Xu, Liang Zhang, and Zhen Ren. 2022. "Study on Friction Characteristics of Slipper Pair of Large Displacement High-Pressure Piston Pump" Lubricants 10, no. 12: 363. https://doi.org/10.3390/lubricants10120363

APA StyleLi, Z., Xu, S., Gong, G., Bi, Y., Xu, L., Zhang, L., & Ren, Z. (2022). Study on Friction Characteristics of Slipper Pair of Large Displacement High-Pressure Piston Pump. Lubricants, 10(12), 363. https://doi.org/10.3390/lubricants10120363