Effects of Tempering Temperature on Mechanical and Tribological Behavior of Ductile Iron

Abstract

1. Introduction

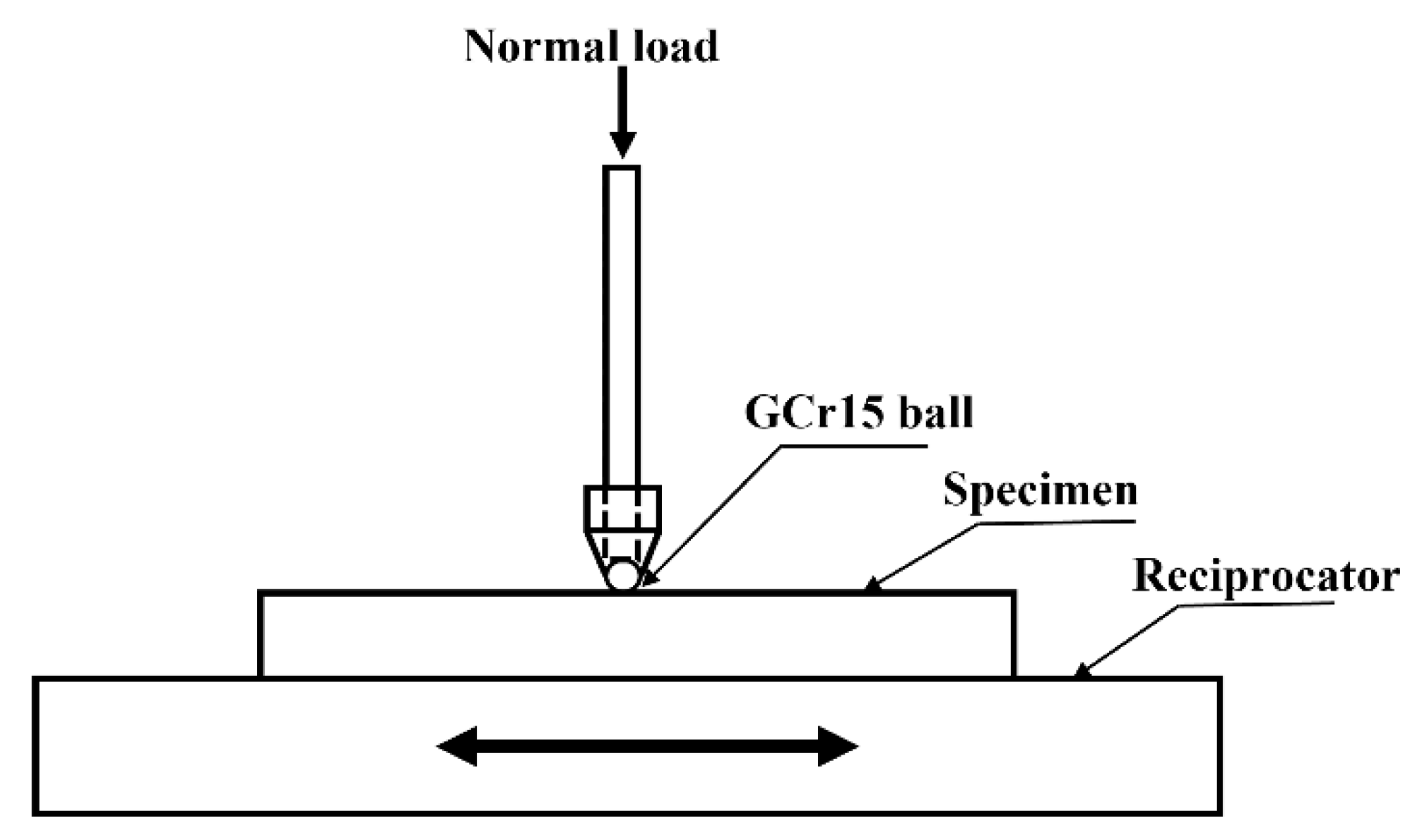

2. Materials and Methods

3. Results and Discussions

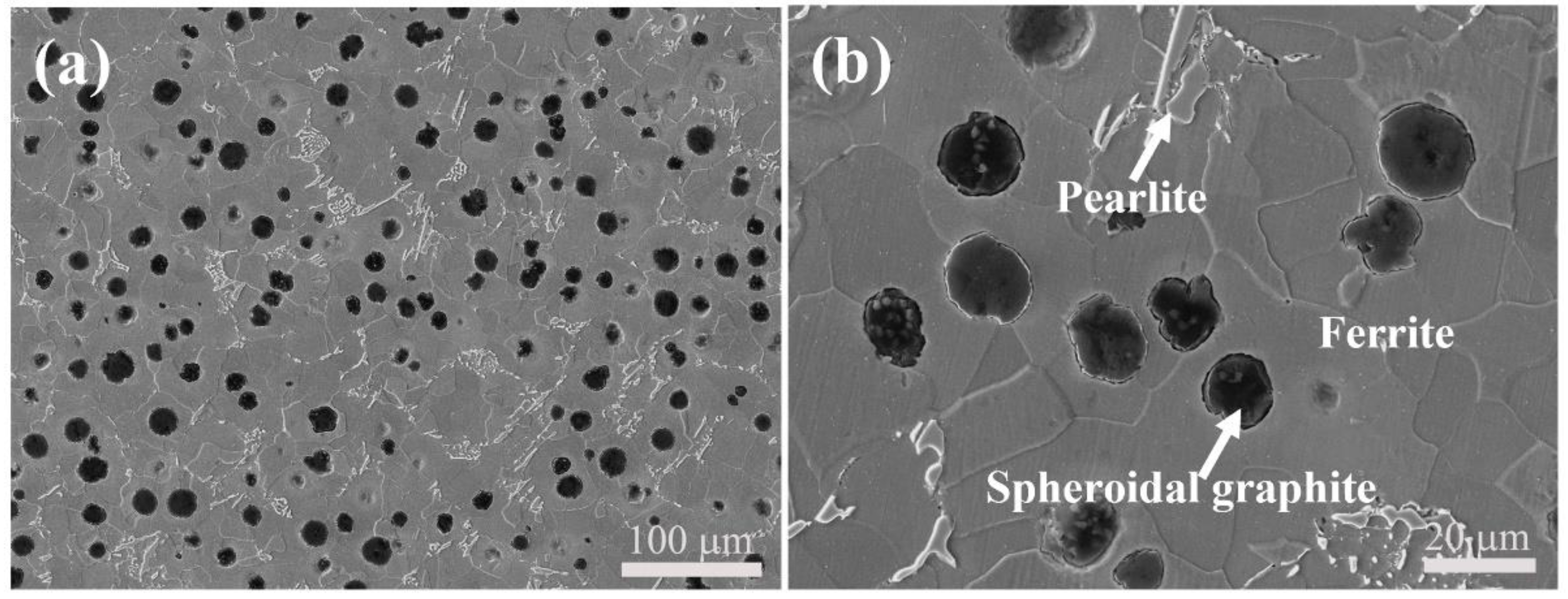

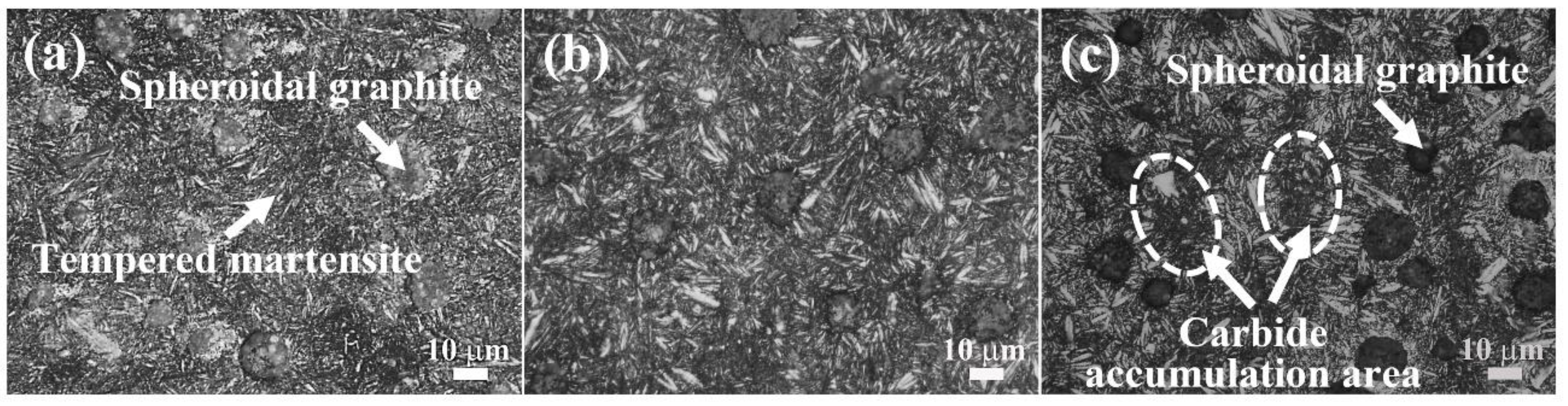

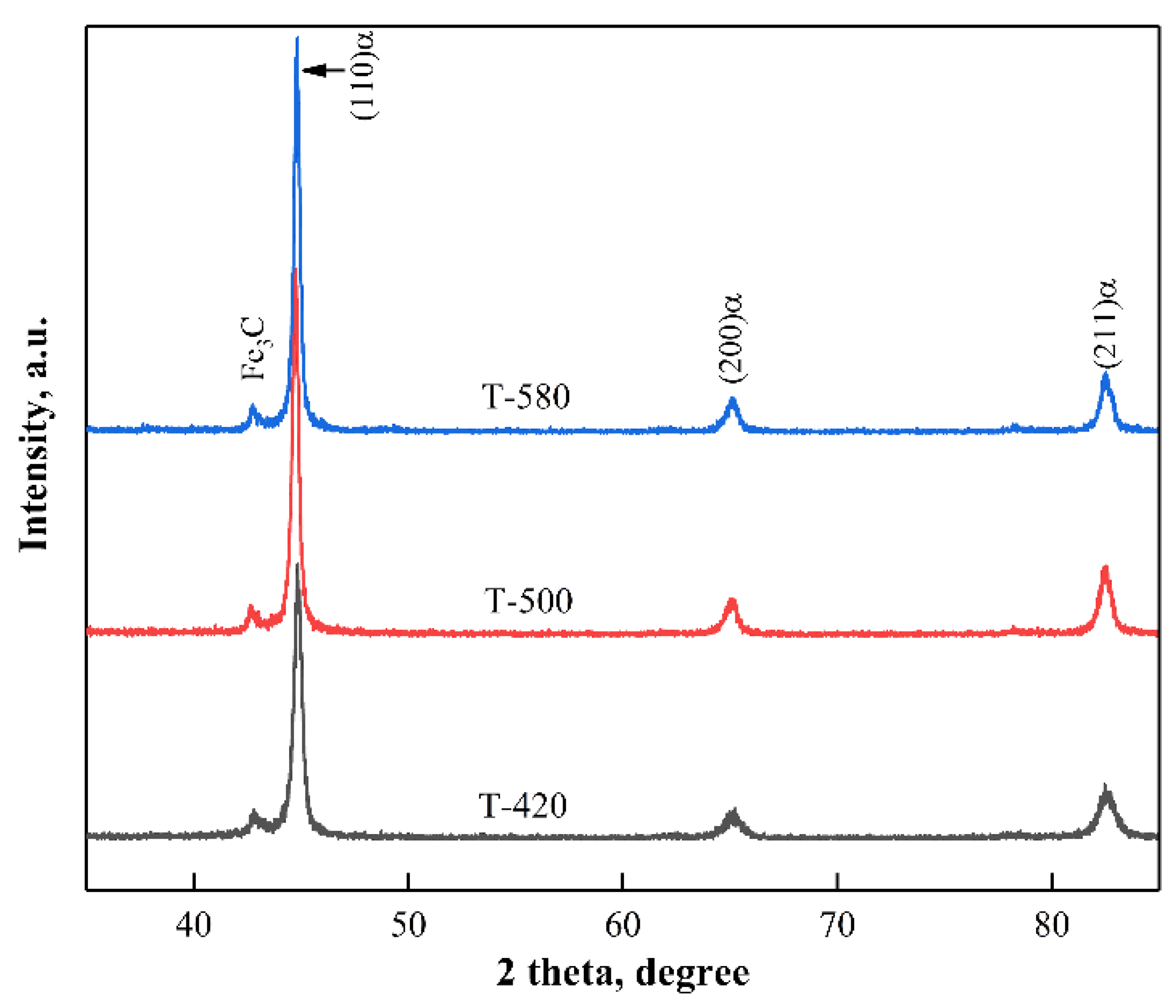

3.1. Effects of Tempering Temperature on Microstructure

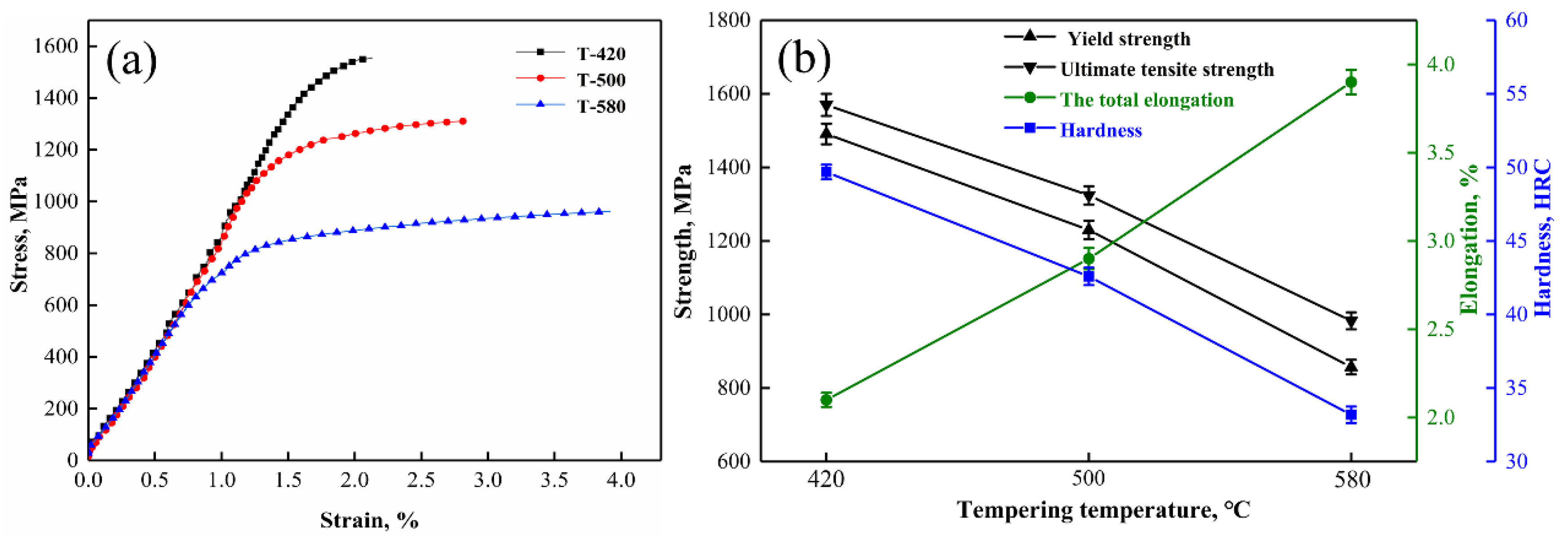

3.2. Effects of Tempering Temperature on Mechanical Properties

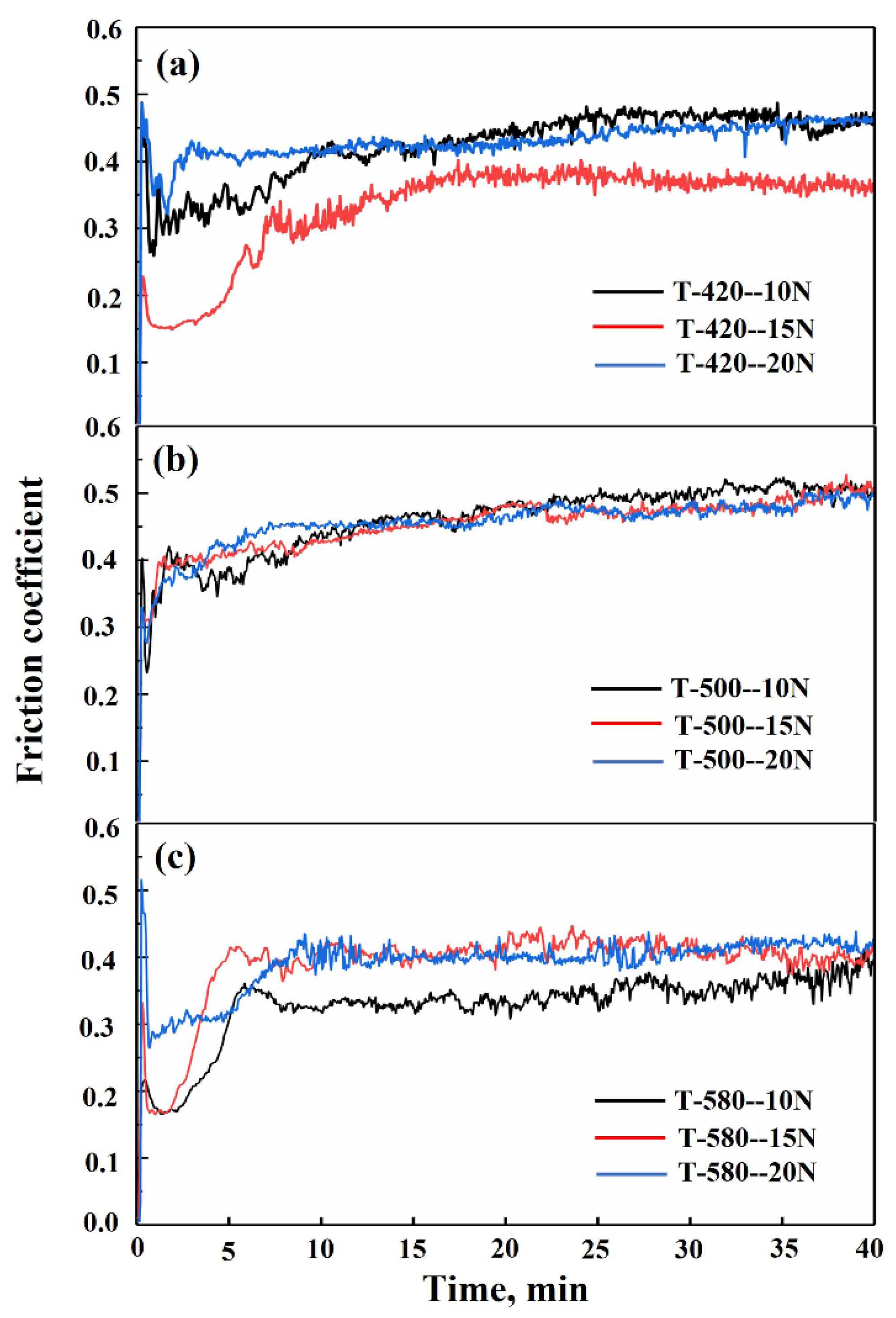

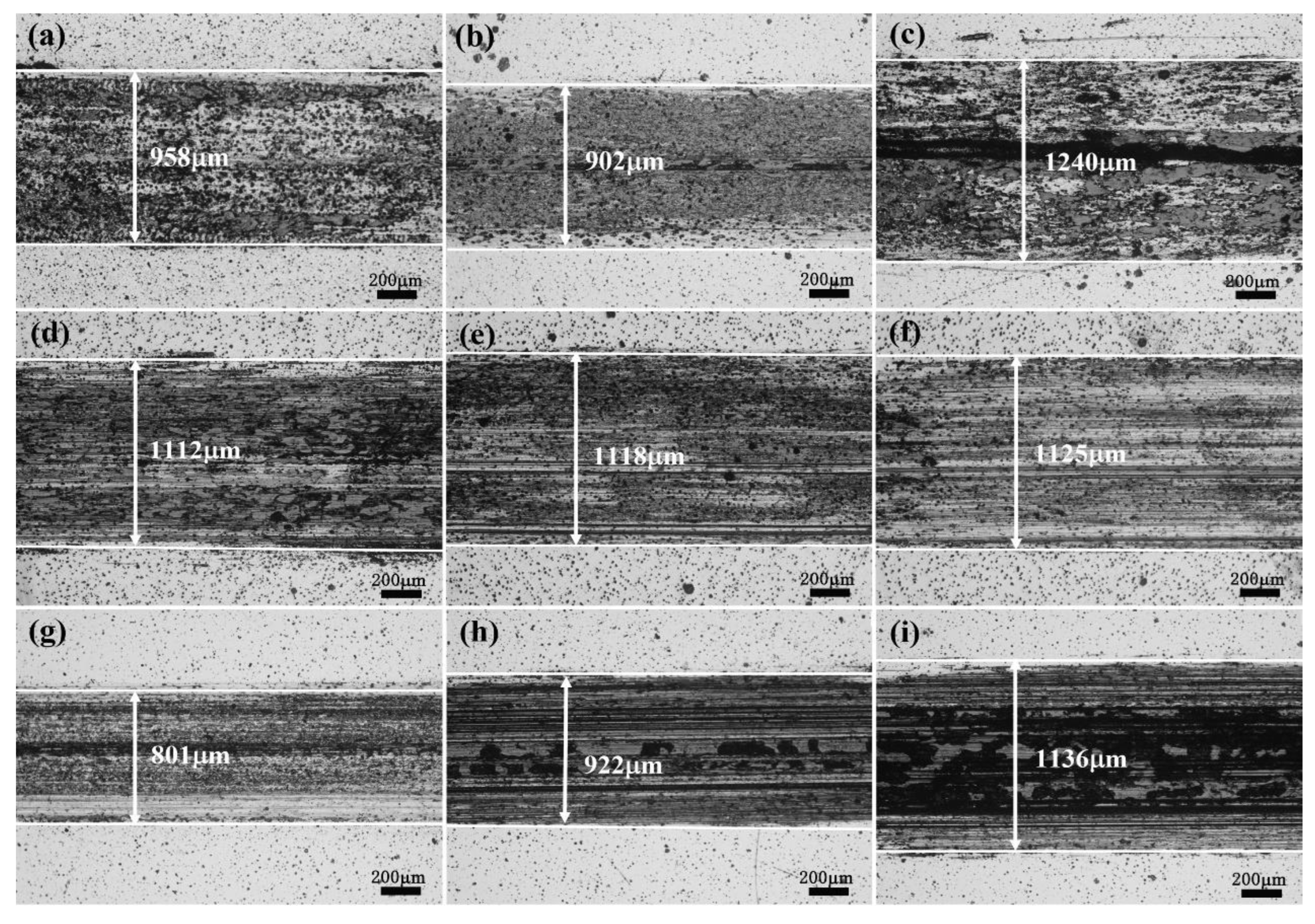

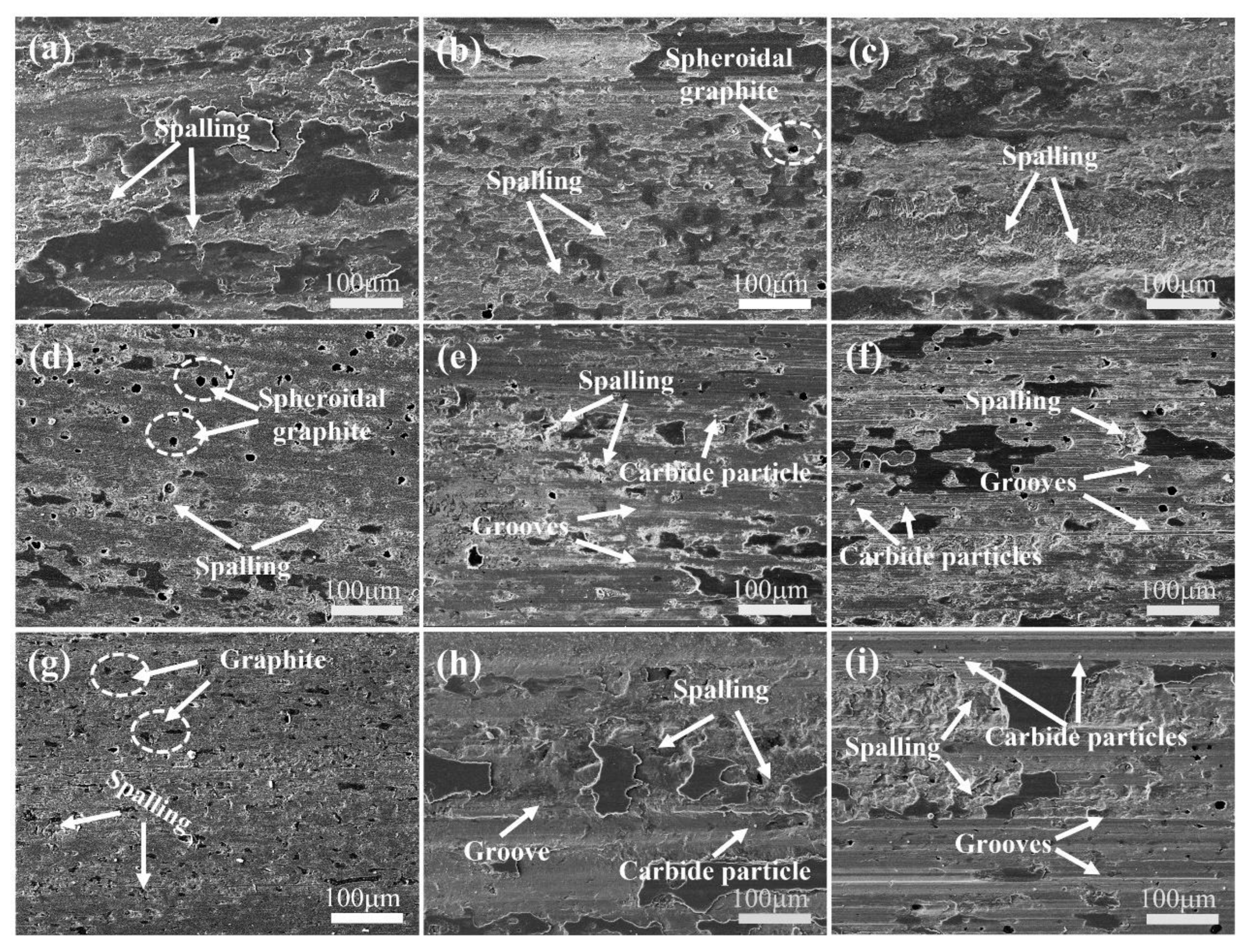

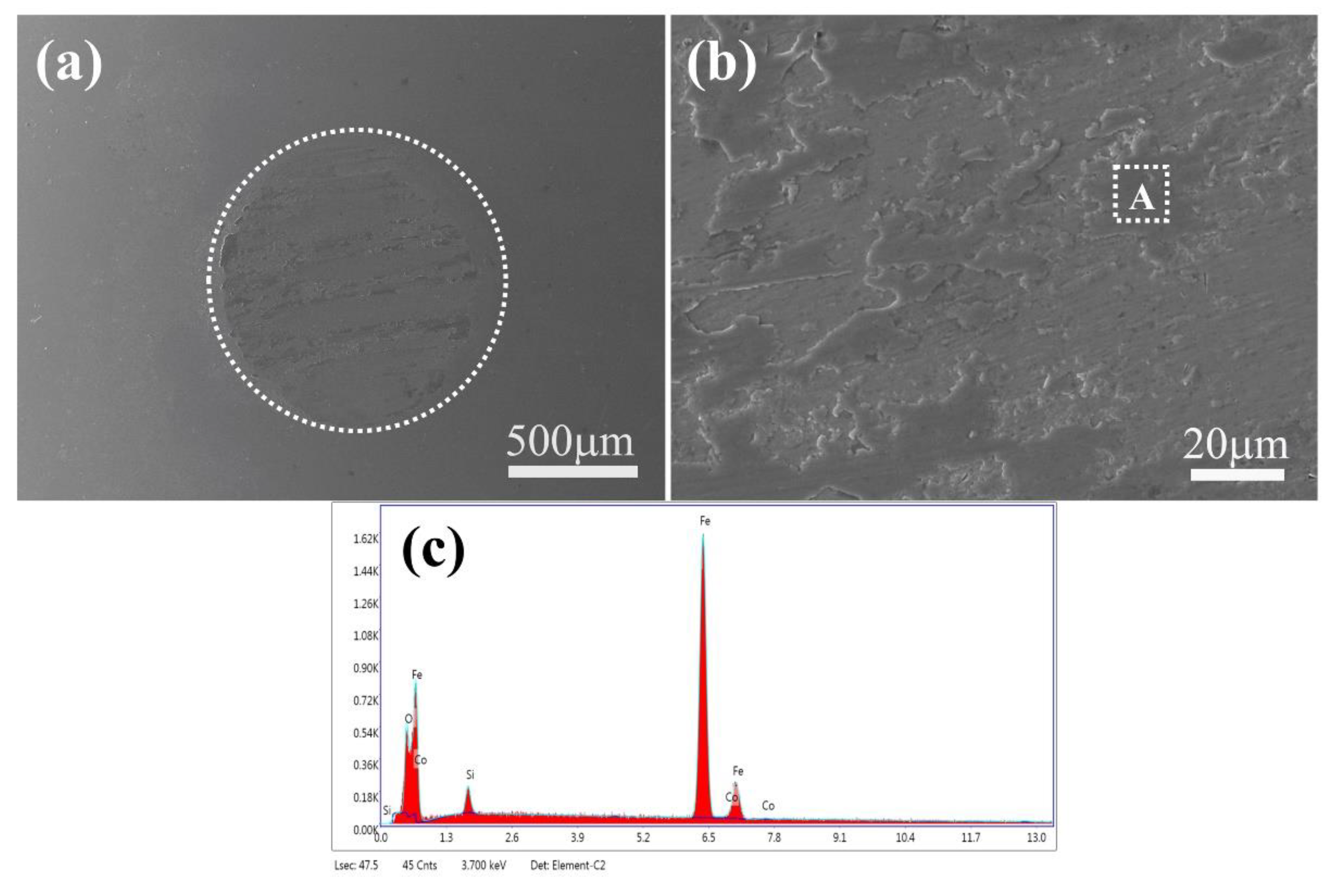

3.3. Effects of Tempering Temperature on Tribological Behavior

4. Conclusions

- The tempered ductile iron was composed of α phase, carbides, and spheroidal graphite.

- The strength and hardness of ductile iron decreased linearly with the increase of tempering temperature, but the plasticity was increased, which was mainly attributed to the carbide’s precipitation causing the gradual decomposition of martensite.

- The friction coefficient of the tempered samples differed significantly. The friction coefficient of the sample with high hardness tempered at 420 °C increased first and then decreased with increasing loads; no obvious change was detected for the friction coefficient of the sample tempered at 500 °C at different loads, and the friction coefficient of the sample tempered at 580 °C increased with the increase of loads.

- The wear rate was increased with the increasing of tempering temperature, indicating that hardness is the determined factor for wear properties for the tempered ductile iron under the wear conditions.

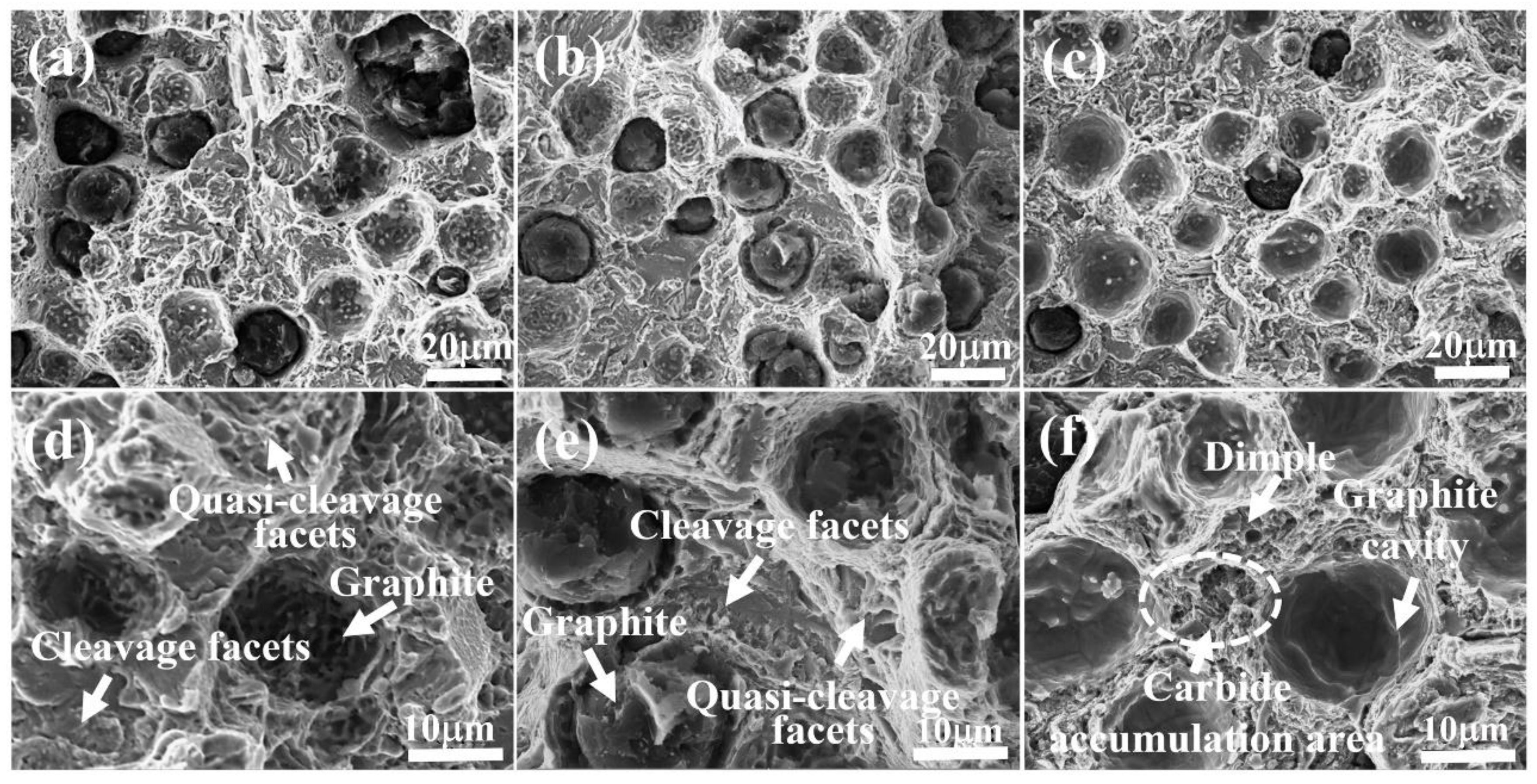

- The main wear mechanism of tempered ductile iron was adhesive and abrasive wear. Adhesive wear was dominant for the sample tempered at 420 °C, and the abrasive wear predominated for the samples tempered at 500 °C and 580 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balachandran, G.; Vadiraj, A.; Kamaraj, M.; Kazuya, E. Mechanical and wear behavior of alloyed gray cast iron in the quenched and tempered and austempered conditions. Mater. Des. 2011, 32, 4042–4049. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.C.; Tao, C.; Han, X.; Sun, X. Tribological Performance of Austempered and Tempered Ductile Iron. Metall. Mater. Trans. B 2018, 49, 2261–2269. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.C.; Qiu, F.; Zou, Q.; Yang, H. A review: Phase transformation and wear mechanisms of single-step and dual-step austempered ductile irons. J. Mater. Res. Technol. 2019, 9, 1054–1069. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.-X.; Li, Q.-J.; Hong, X. Effect of matrix structure on mechanical properties and dry rolling–sliding wear performance of alloyed ductile iron. J. Iron Steel Res. Int. 2019, 26, 888–897. [Google Scholar] [CrossRef]

- Ghassemali, E.; Heretnando, J.C.; Stefanescu, D.M.; Dioszegi, A.; Jarfors, A.E.W.; Dluhoš, J.; Petrenec, M. Revisiting the graphite nodule in ductile iron. Scr. Mater. 2019, 161, 66–69. [Google Scholar] [CrossRef]

- Kobayashi, T.; Yamamoto, H. Development of High Toughness in Austempered Type Ductile Cast Iron and Evaluation of Its Properties. Metall. Mater. Trans. A 1988, 19, 319–327. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Edmonds, D.V. The mechanism of bainite formation in steels. Acta Metall. 1980, 28, 1265–1273. [Google Scholar] [CrossRef]

- Wang, X.; Du, Y.; Liu, B.; Jiang, B. Enhanced plasticity of austempered ductile iron (ADI) by partitioning treatment. Mater. Sci. Eng. A 2021, 804, 140513. [Google Scholar] [CrossRef]

- Nishikawa, A.S.; Miyamoto, G.; Furuhara, T.; Tschiptschin, A.P.; Goldenstein, H. Phase transformation mechanisms during of a ductile cast iron. Acta Mater. 2019, 179, 1–16. [Google Scholar] [CrossRef]

- Sahin, Y.; Erdogan, M.; Cerah, M. Effect of martensite volume fraction and tempering time on abrasive wear of ferritic ductile iron with dual matrix. Wear 2008, 265, 196–202. [Google Scholar] [CrossRef]

- Kocatepe, K.; Cerah, M.; Erdogan, M. Effect of martensite volume fraction and its morphology on the tensile properties of ferritic ductile iron with dual matrix structures. J. Mater. Process. Technol. 2006, 178, 44–51. [Google Scholar] [CrossRef]

- Wu, H.D.; Miyamoto, G.; Yang, Z.G.; Zhang, C.; Chen, H.; Furuhara, T. Incomplete bainite transformation in Fe-Si-C alloys. Acta Mater. 2017, 133, 1–9. [Google Scholar] [CrossRef]

- Veerababu, R.; Satya Prasad, K.; Phani, S.K.; Balamuralikrishnan, R.; Karthikeyan, S. Austenite stability and M2C carbide decomposition in experimental secondary hardening ultra-high strength steels during high temperature austenitizing treatments. Mater. Charact. 2018, 144, 191–204. [Google Scholar] [CrossRef]

- Zhou, W.; Northwood, D.O.; Liu, C. A steel-like unalloyed multiphase ductile iron. J. Mater. Res. Technol. 2021, 15, 3836–3849. [Google Scholar] [CrossRef]

- Clarke, A.J.; Speer, J.G.; Miller, M.K.; Hackenberg, R.E.; Edmonds, D.V.; Matlock, D.K. Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: A critical assessment. Acta Mater. 2008, 56, 16–22. [Google Scholar]

- Ravi, A.M.; Sietsma, J.; Santofimia, M.J. The role of grain-boundary cementite in bainite formation in high-carbon steels. Scr. Mater. 2020, 185, 7–11. [Google Scholar] [CrossRef]

- Nishikawa, A.S.; Santofimia, M.J.; Sietsma, J.; Goldenstein, H. Influence of bainite reaction on the kinetics of carbon redistribution during the Quenching and Partitioning process. Acta Mater. 2018, 142, 142–151. [Google Scholar] [CrossRef]

- Fontanari, V.; Benedetti, M.; Girardi, C.; Giordanino, L. Investigation of the lubricated wear behavior of ductile cast iron and quenched and tempered alloy steel for possible use in worm gearing. Wear 2016, 350, 68–73. [Google Scholar] [CrossRef]

- Morsdorf, L.; Emelina, E.; Gault, B.; Herbig, M.; Tasan, C.C. Carbon redistribution in quenched and tempered lath martensite. Acta Mater. 2021, 205, 116521. [Google Scholar] [CrossRef]

- Tao, Q.; Wang, J.; Galindo-Nava, E.I. Effect of low-temperature tempering on confined precipitation and mechanical properties of carburised steels. Mater. Sci. Eng. A 2021, 822, 141688. [Google Scholar] [CrossRef]

- Sun, C.; Liu, S.L.; Misra, R.D.K.; Li, Q.; Li, D.H. Influence of intercritical tempering temperature on impact toughness of a quenched and tempered medium-Mn steel: Intercritical tempering versus traditional tempering. Mater. Sci. Eng. A 2018, 711, 484–491. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Liu, Y. Influence of carbides on the high-temperature tempered martensite embrittlement of martensitic heat-resistant steels. Mater. Sci. Eng. A 2016, 670, 256–263. [Google Scholar] [CrossRef]

- Li, S.; He, M.; Hu, G.; Tian, Y.; Wang, C.; Jing, B.; Ping, D. Pearlite formation via martensite. Compos. Part B Eng. 2022, 238, 109859. [Google Scholar] [CrossRef]

- Zhang, N.; Zhang, J.; Lu, L.; Zhang, M.; Zeng, D.; Song, Q. Wear and friction behavior of austempered ductile iron as railway wheel material. Mater. Des. 2016, 89, 815–822. [Google Scholar] [CrossRef]

- Du, Y.; Gao, X.; Wang, X.; Wang, X.; Ge, Y.; Jiang, B. Tribological behavior of austempered ductile iron (ADI) obtained at different austempering temperatures. Wear 2020, 456–457, 203396. [Google Scholar] [CrossRef]

- Akinribide, O.J.; Akinwamide, S.O.; Obadele, B.A.; Ogundare, O.D.; Ayeleru, O.O.; Olubambi, P.A. Tribological behaviour of ductile and austempered grey cast iron under dry environment. Mater. Today Proc. 2020, 38, 1174–1182. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Stachowiak, A.; Wieczorek, A.N. Comparative tribocorrosion tests of 30CrMo12 cast steel and ADI spheroidal cast iron. Tribol. Int. 2021, 155, 106763. [Google Scholar] [CrossRef]

- Kayali, Y.; Yalçin, Y.; Taktak, Ş. Adhesion and wear properties of boro-tempered ductile iron. Mater. Des. 2011, 32, 4295–4303. [Google Scholar] [CrossRef]

- Xu, C.J.; Xu, X.F.; Zhao, Z.; Ma, M.; Zhang, Z.M.; Liu, Y.H. Horizontal Continuous Casting Technology of Cast Iron and Application of Dense Bars. Foundry Technol. 2017, 38, 2559–2564. [Google Scholar]

- Sun, C.; Fu, P.-X.; Ma, X.-P.; Liu, H.-H.; Du, N.-Y.; Cao, Y.-F.; Liu, H.; Li, D. Effect of matrix carbon content and lath martensite microstructures on the tempered precipitates and impact toughness of a medium-carbon low-alloy steel. J. Mater. Res. Technol. 2020, 9, 7701–7710. [Google Scholar] [CrossRef]

- Sun, J.; Jiang, T.; Wang, Y.; Guo, S.; Liu, Y. Effect of grain refinement on high-carbon martensite transformation and its mechanical properties. Mater. Sci. Eng. A 2018, 726, 342–349. [Google Scholar] [CrossRef]

- Rashidi, A.M.; Moshrefi-Torbati, M. Effect of tempering conditions on the mechanical properties of ductile cast iron with dual matrix structure (DMS). Mater. Lett. 2000, 45, 203–207. [Google Scholar] [CrossRef]

- Pereira, L.; do Amaral, R.F.; Wolfart, M.; de Barcellos, V.K. Microstructural and mechanical properties of Cu-Ni-Mn-Mo austempered ductile iron obtained from two-step hot air austempering. J. Mater. Res. Technol. 2020, 9, 3055–3063. [Google Scholar] [CrossRef]

- Melado, A.C.; Nishikawa, A.S.; Goldenstein, H.; Giles, M.A.; Reed, P.A.S. Effect of microstructure on fatigue behaviour of advanced high strength ductile cast iron produced by quenching and partitioning process. Int. J. Fatigue 2017, 104, 397–407. [Google Scholar] [CrossRef]

- Andriollo, T.; Zhang, Y.; Fæster, S.; Kouznetsova, V. Analysis of the correlation between micro-mechanical fields and fatigue crack propagation path in nodular cast iron. Acta Mater. 2020, 188, 302–314. [Google Scholar] [CrossRef]

- Du, Y.; Wang, X.; Zhang, D.; Wang, X.; Ju, C.; Jiang, B. A superior strength and sliding-wear resistance combination of ductile iron with nanobainitic matrix. J. Mater. Res. Technol. 2021, 11, 1175–1183. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Liu, C.; Du, Y.; Wang, X.; Zhu, X.; Jiang, B. Effects of Tempering Temperature on Mechanical and Tribological Behavior of Ductile Iron. Lubricants 2022, 10, 326. https://doi.org/10.3390/lubricants10120326

Hu Z, Liu C, Du Y, Wang X, Zhu X, Jiang B. Effects of Tempering Temperature on Mechanical and Tribological Behavior of Ductile Iron. Lubricants. 2022; 10(12):326. https://doi.org/10.3390/lubricants10120326

Chicago/Turabian StyleHu, Zhitao, Chen Liu, Yuzhou Du, Xin Wang, Xinyu Zhu, and Bailing Jiang. 2022. "Effects of Tempering Temperature on Mechanical and Tribological Behavior of Ductile Iron" Lubricants 10, no. 12: 326. https://doi.org/10.3390/lubricants10120326

APA StyleHu, Z., Liu, C., Du, Y., Wang, X., Zhu, X., & Jiang, B. (2022). Effects of Tempering Temperature on Mechanical and Tribological Behavior of Ductile Iron. Lubricants, 10(12), 326. https://doi.org/10.3390/lubricants10120326