Lubrication Performance and Mechanism of Water-Based TiO2 Nanolubricants in Micro Deep Drawing of Pure Titanium Foils

Abstract

1. Introduction

2. Experimental Procedure

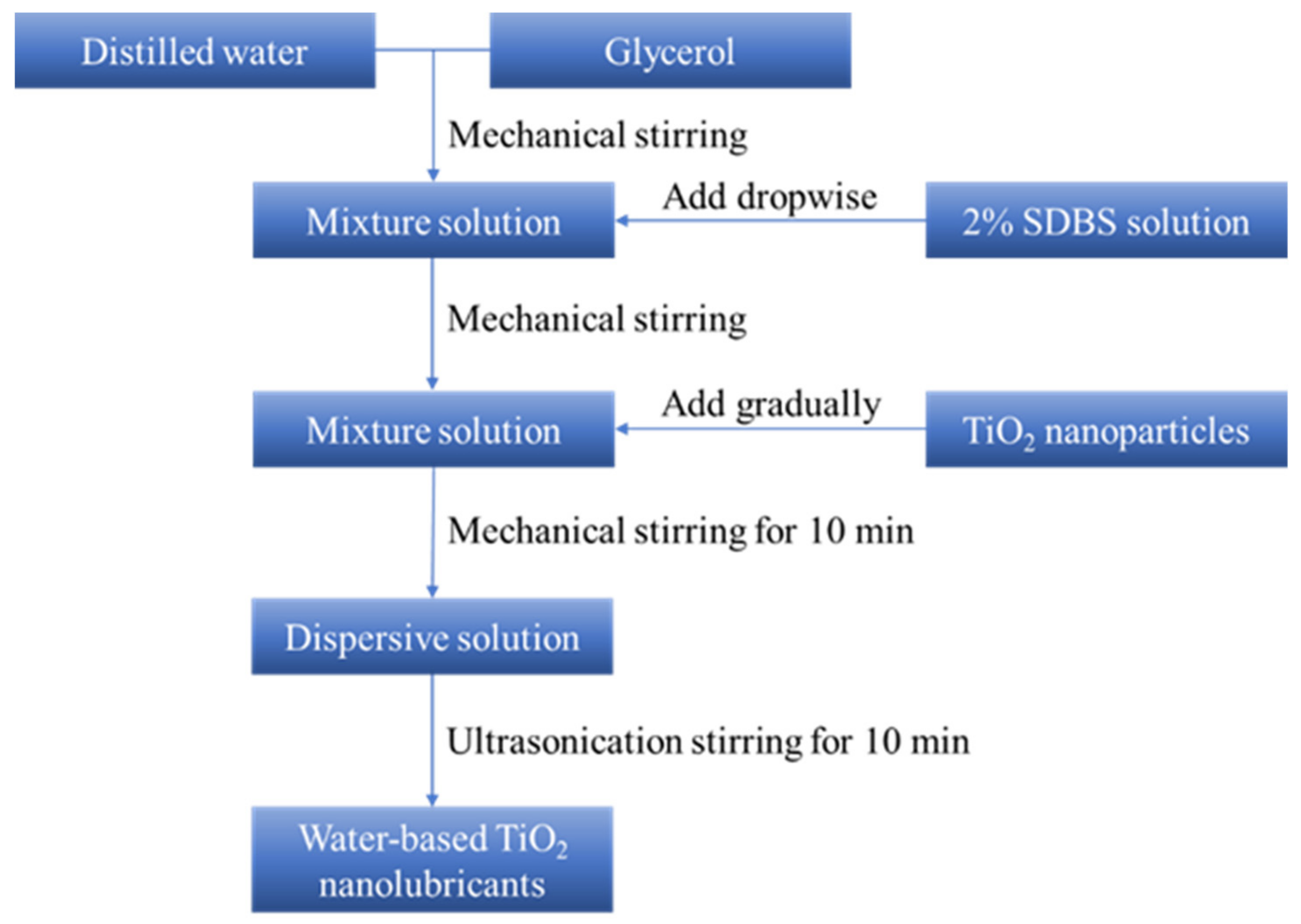

2.1. Material Preparation

2.2. Micro Deep Drawing

2.3. Observations

3. Results and Discussion

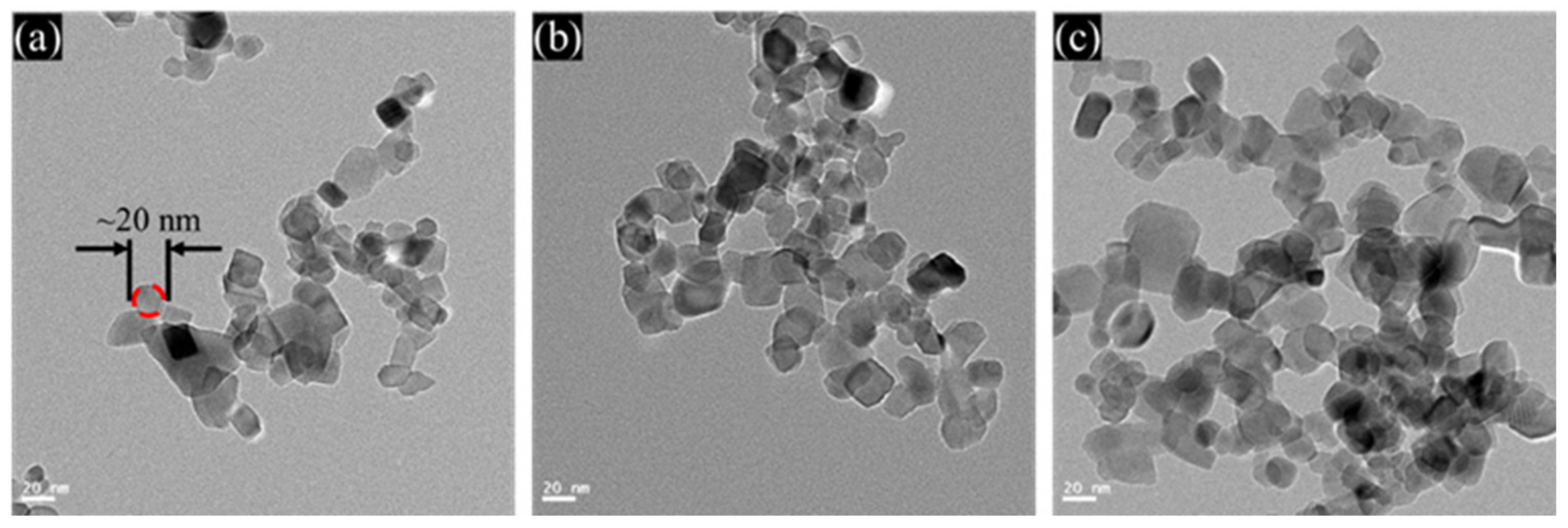

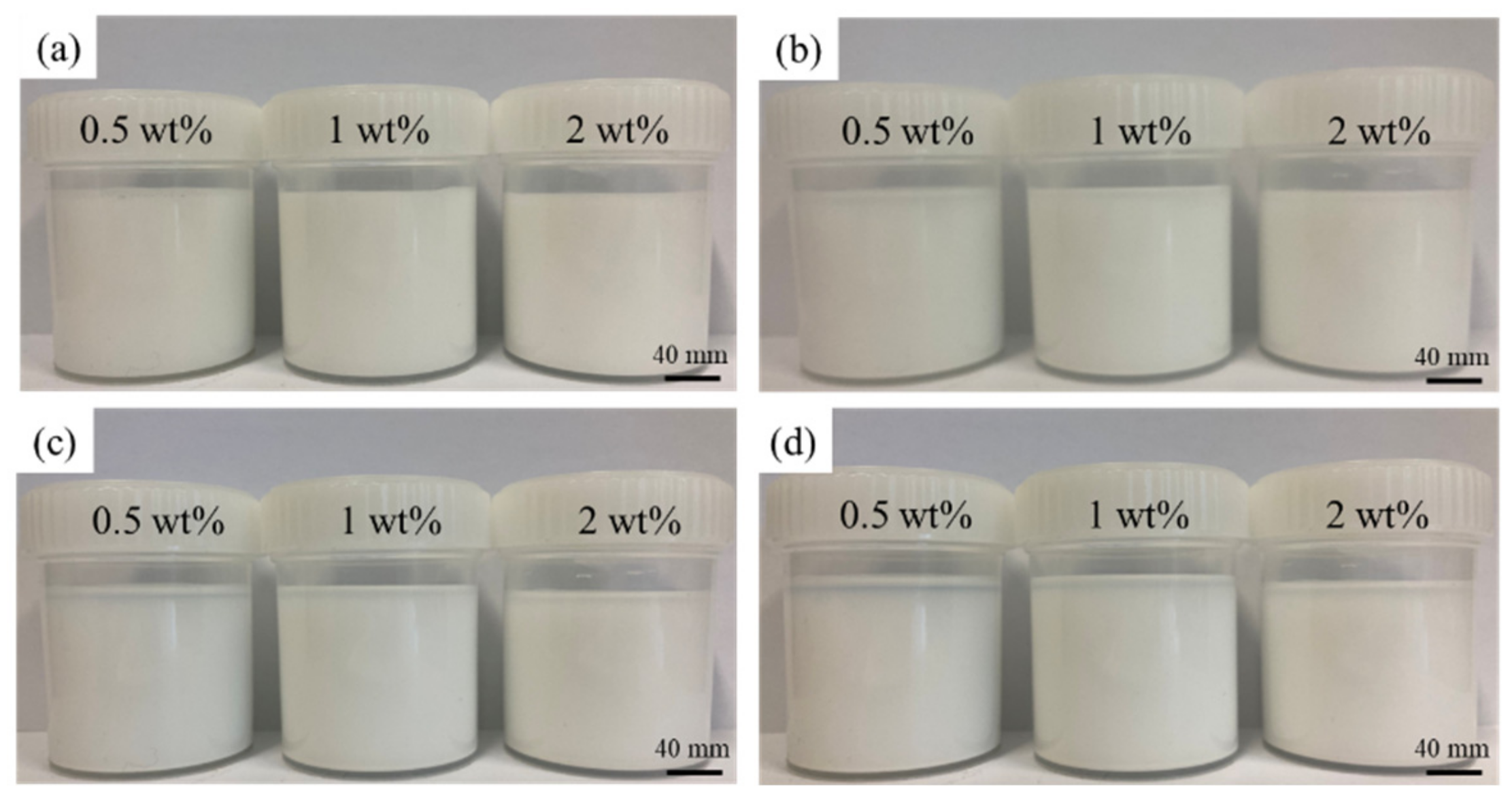

3.1. Material Characterisation

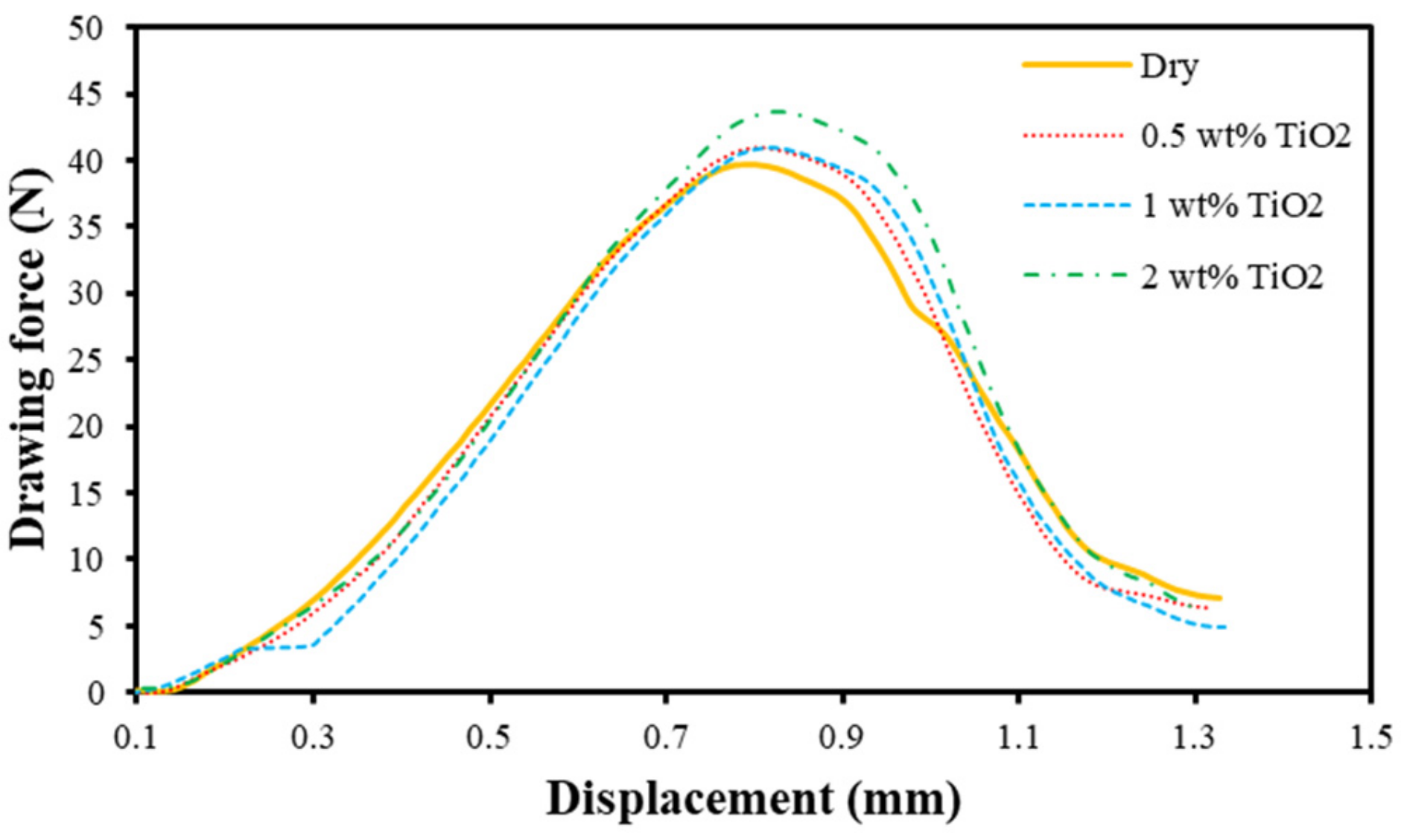

3.2. Drawing Force

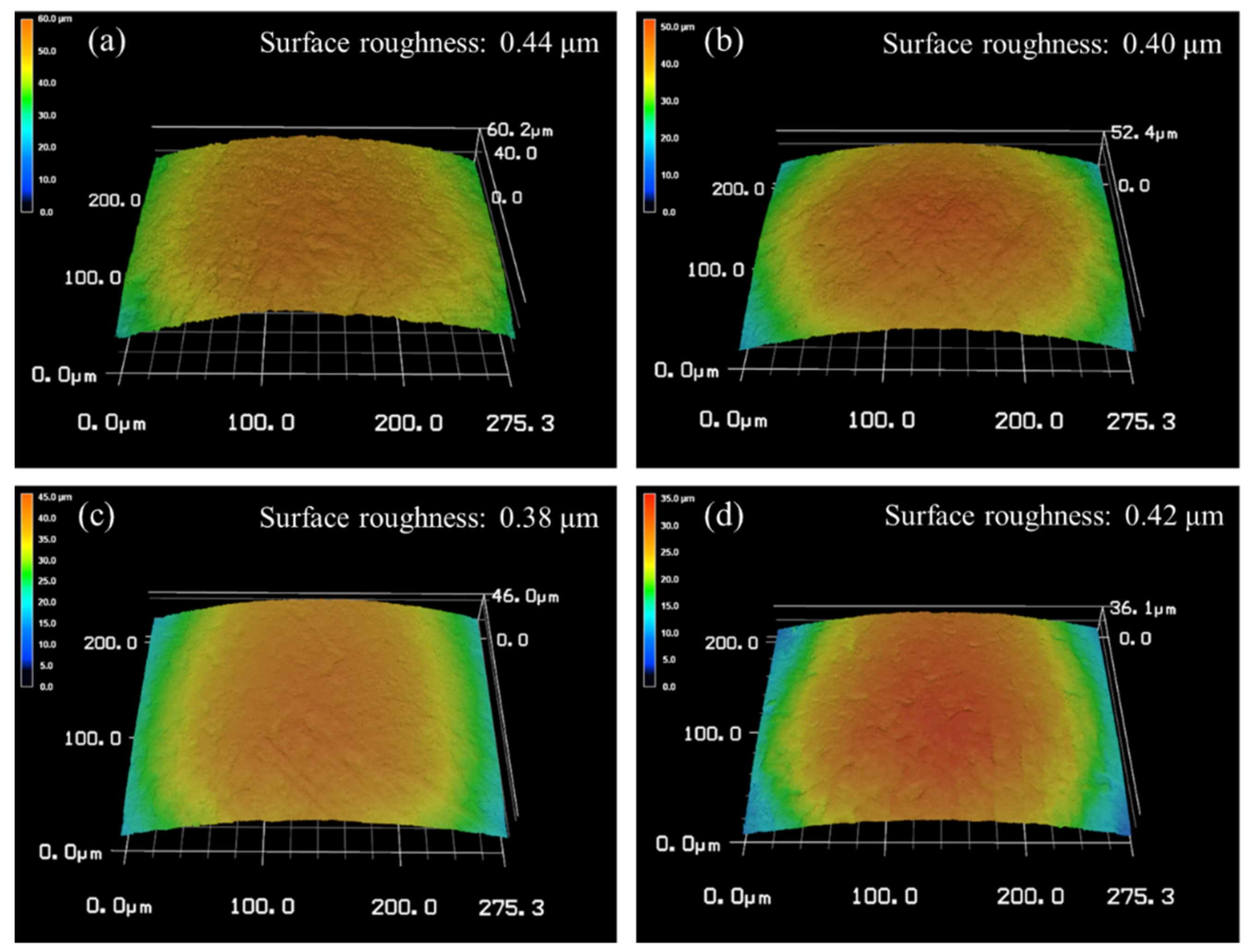

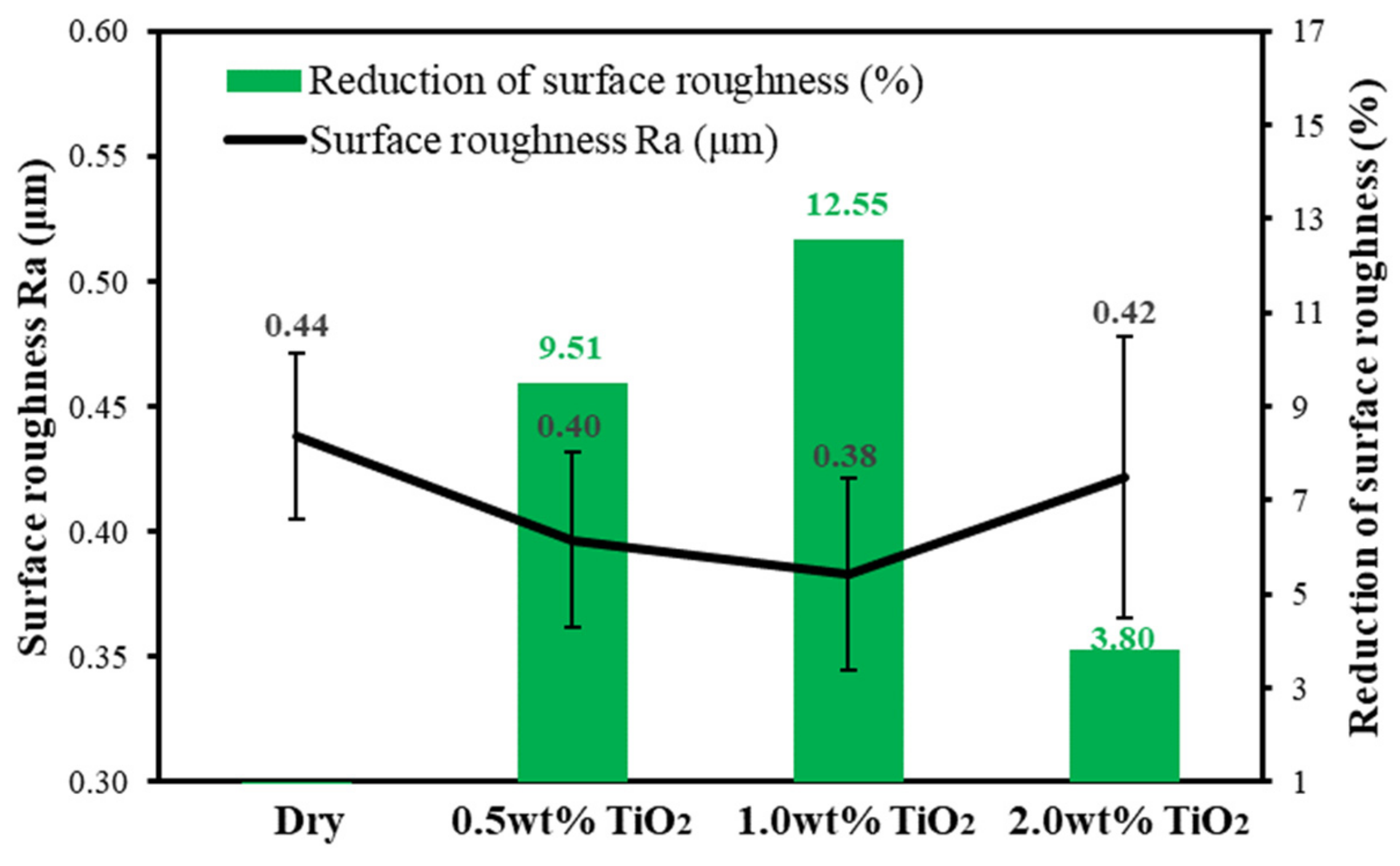

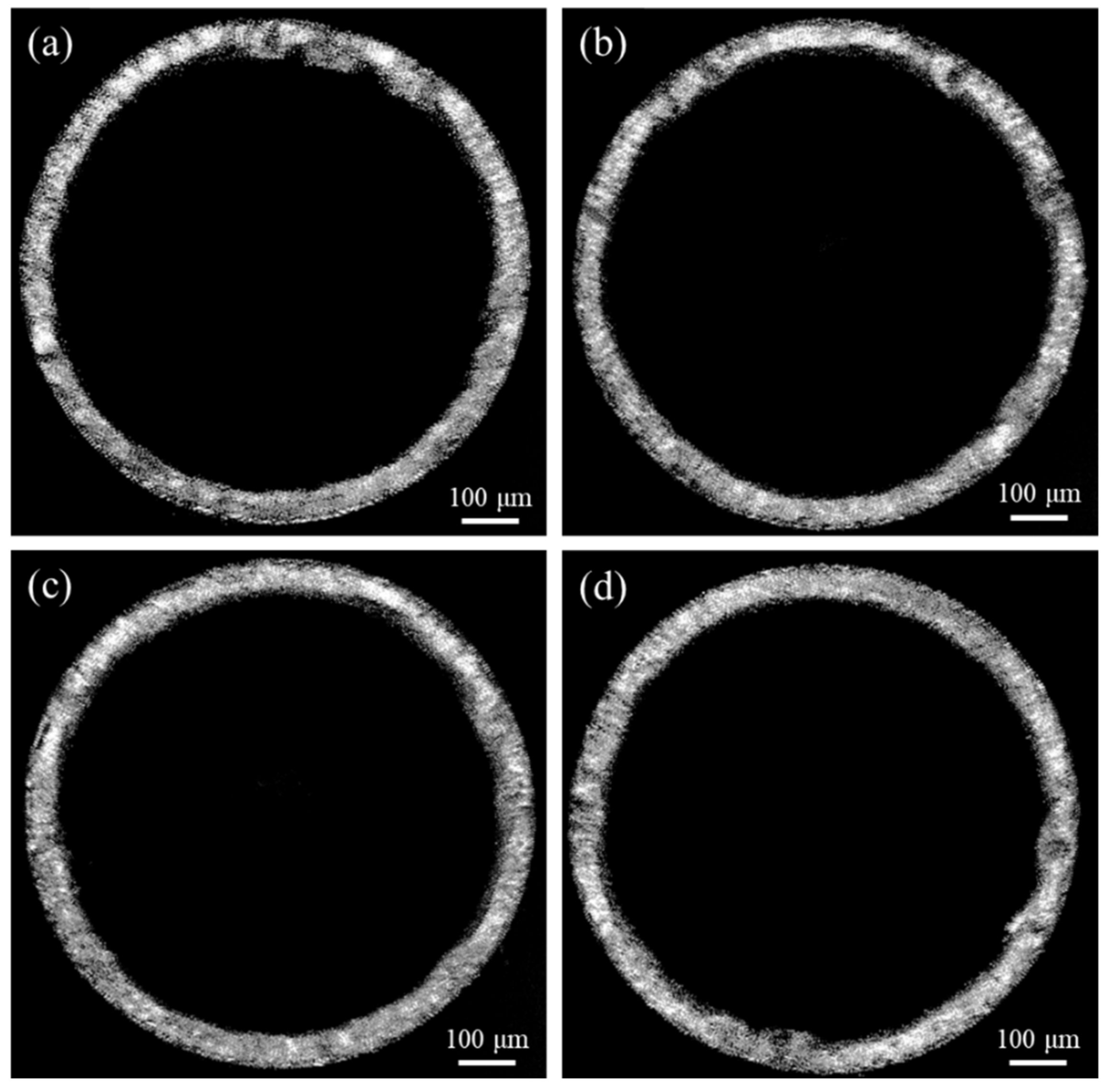

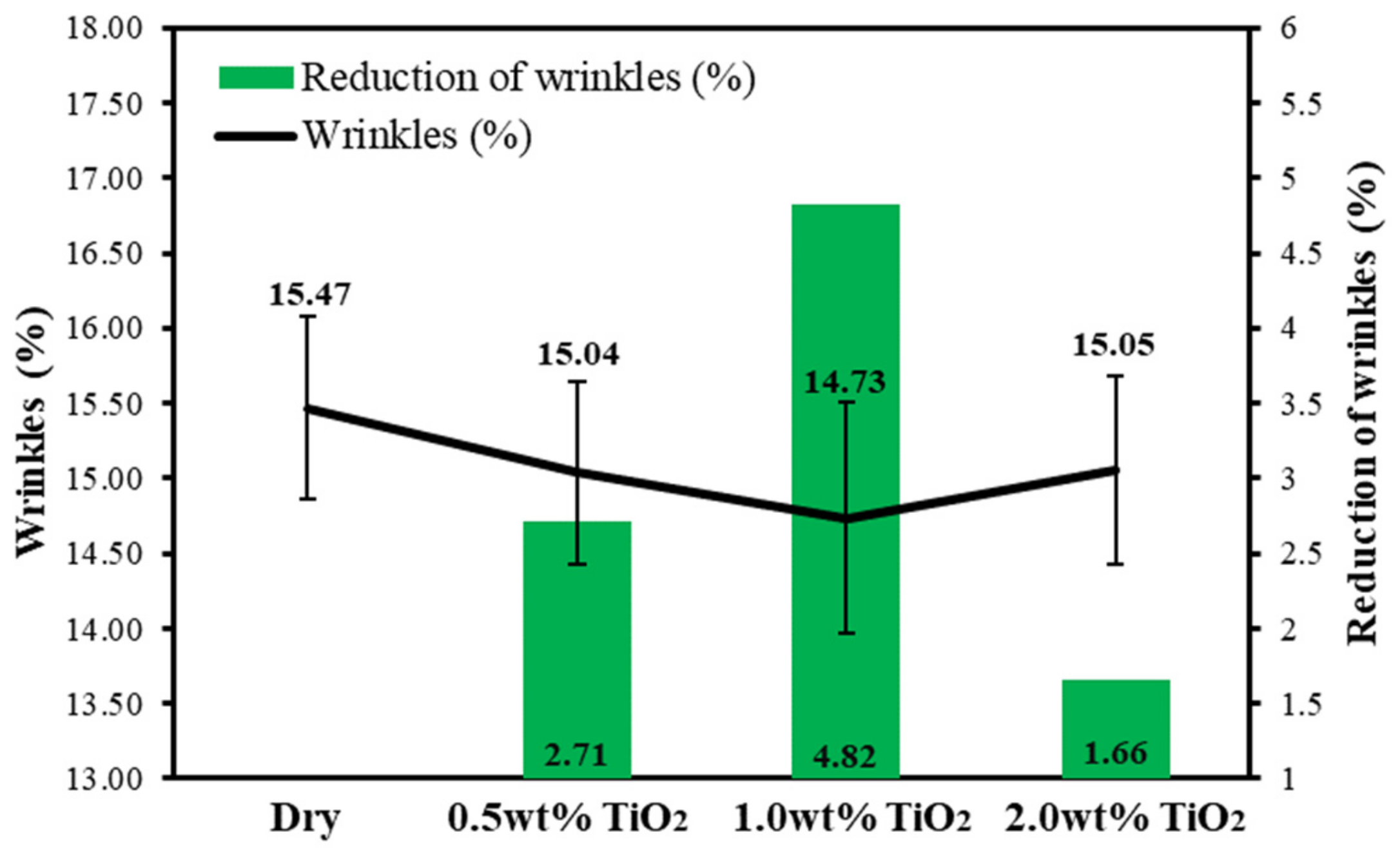

3.3. Quality Evaluation of Micro Cups

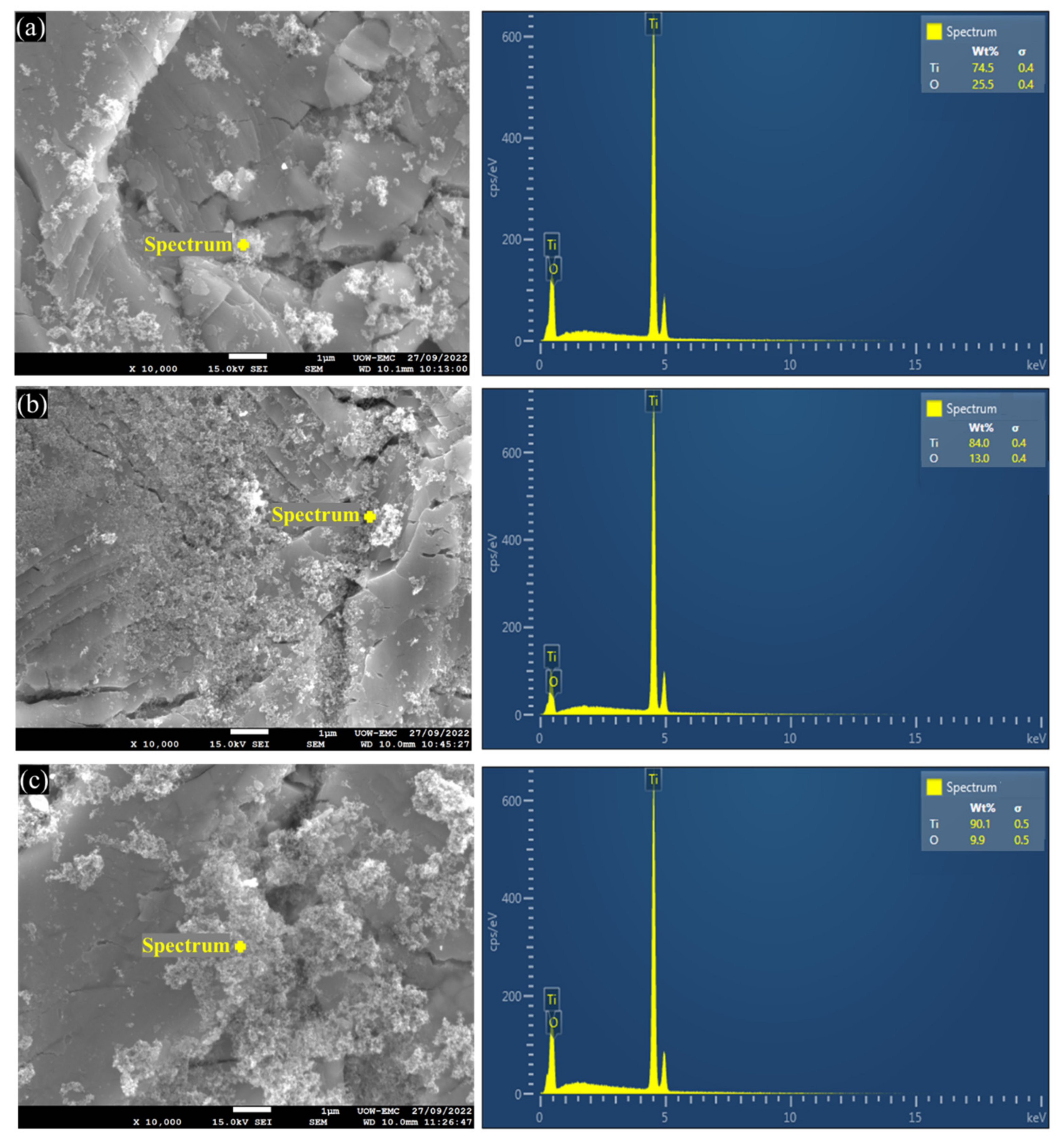

3.4. Surface Observation

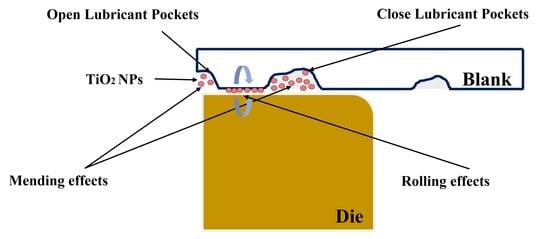

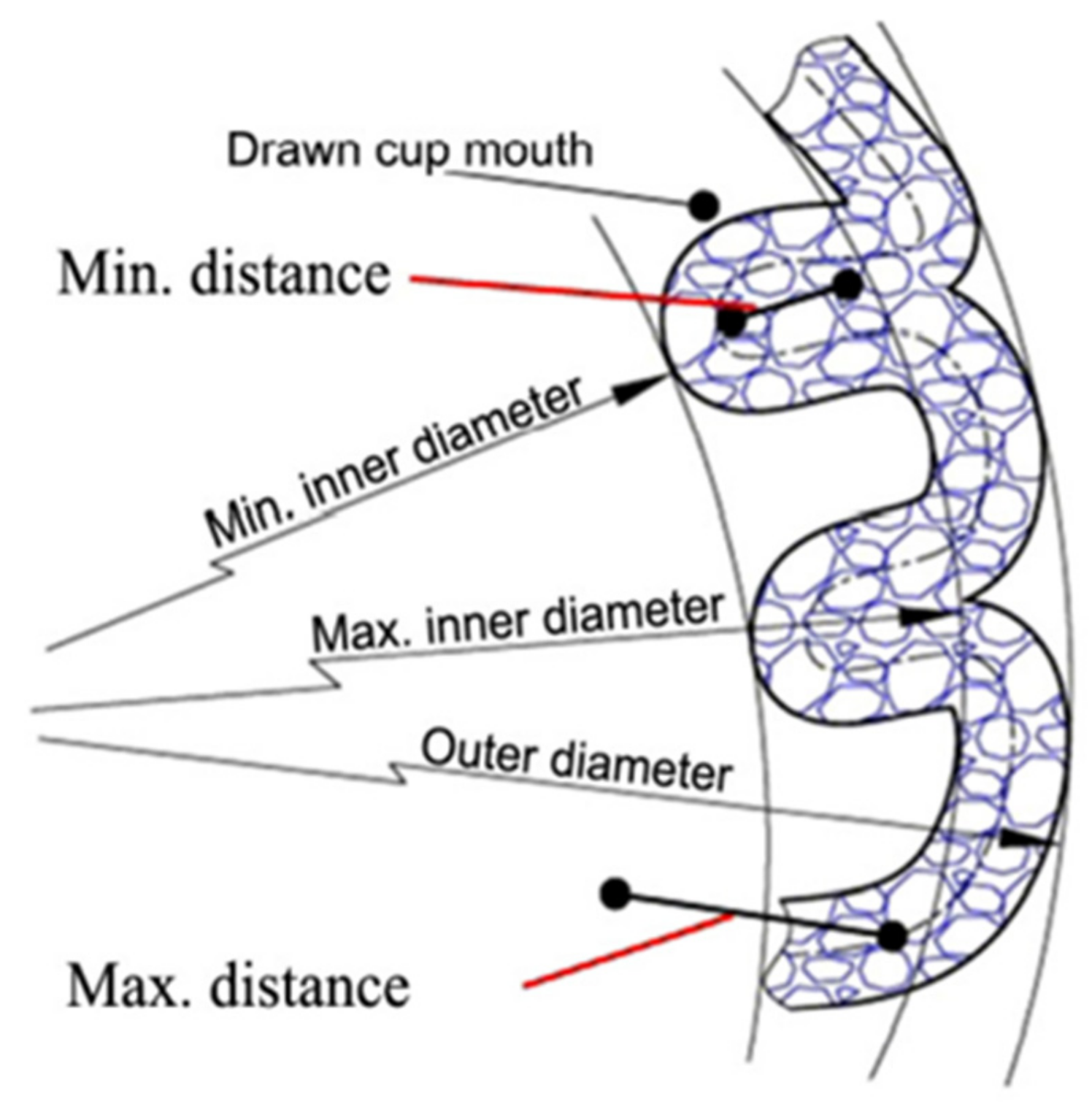

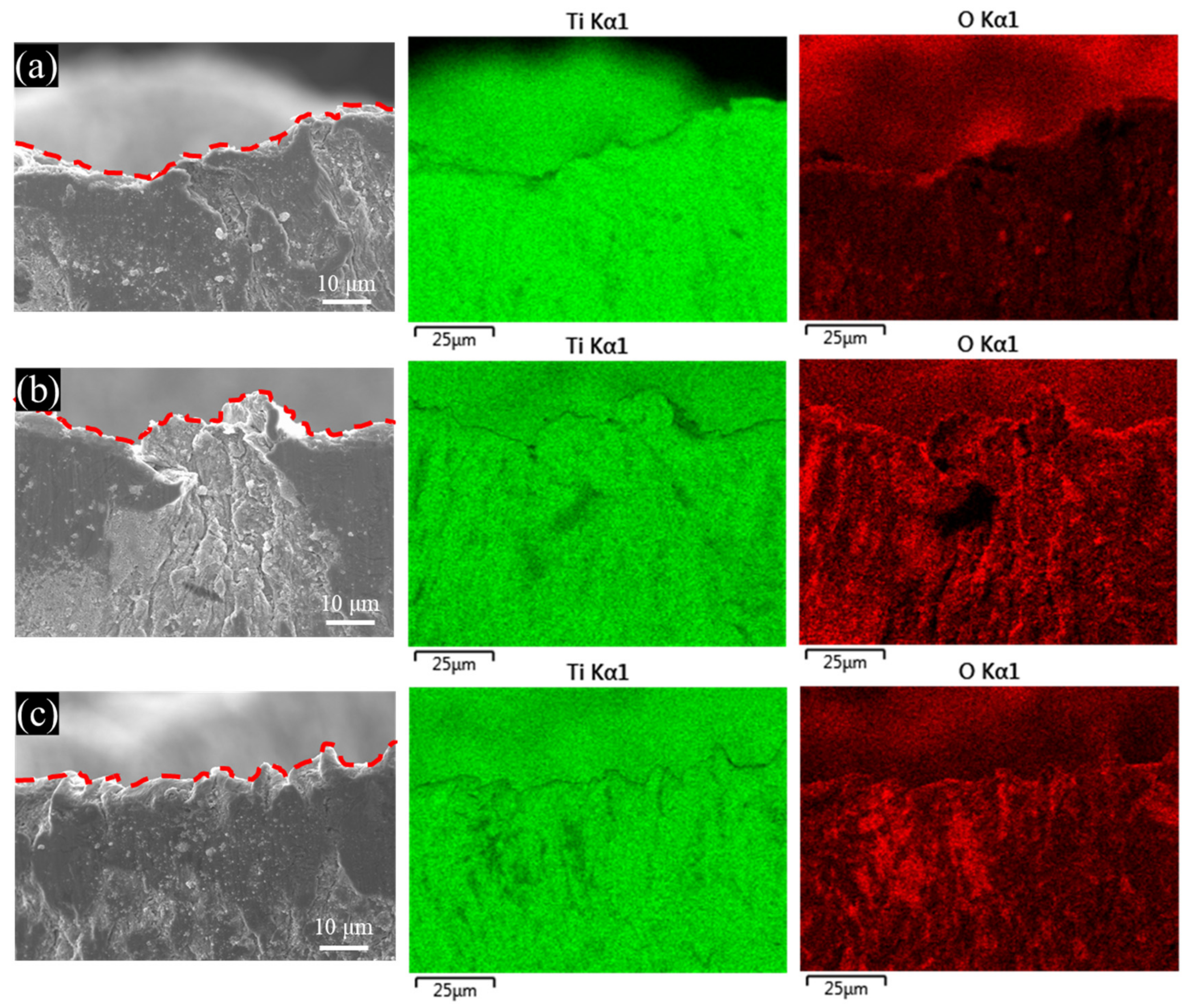

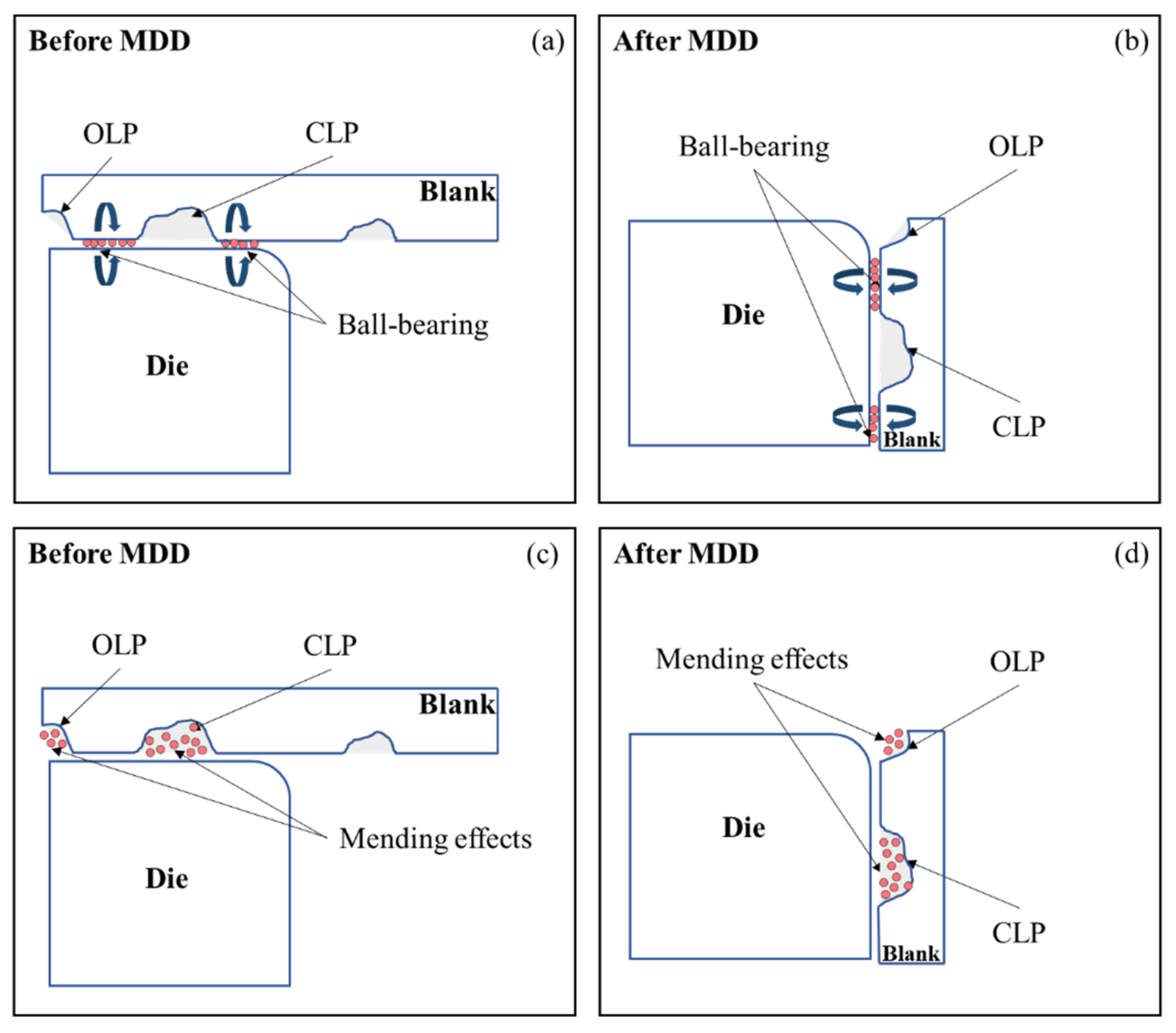

3.5. Lubrication Mechanism

4. Conclusions

- (1)

- The TEM images and sedimentation observations indicate the novel water-based TiO2 nanolubricants possess excellent dispersion stability.

- (2)

- As for the final drawing force, the 1.0 wt% nanolubricants exhibit the best lubrication performance, resulting in a 24.2% reduction in the final drawing force compared to the dry condition.

- (3)

- The 1.0 wt% nanolubricants show a significant improvement in the quality of the micro cups. There is a 12.55% reduction in the surface roughness compared to the dry condition. The wrinkles are decreased from 15.46% (dry conditions) to 14.73%.

- (4)

- The TiO2 NPs can fill in the OLPs area and therefore provide load bearing capacity, resulting in a reduction in friction during MDD. At the CLPs area, the lubrication mechanism can be contributed by the synergistic effect of ball bearing and mending effect of the TiO2 NPs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, J.; Wang, T.; Jia, F.; Li, Z.; Zhou, C.; Huang, Q.; Jiang, Z. Experimental Investigation on Micro Deep Drawing of Stainless Steel Foils with Different Microstructural Characteristics. Chin. J. Mech. Eng. 2021, 34, 11. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhao, J.; Xie, H. Microforming Technology Theory, Simulation and Practice, 1st ed.; Academic Press: London, UK, 2017. [Google Scholar]

- Hasan, M.; Zhao, J.; Jiang, Z. Micromanufacturing of composite materials: A review. Int. J. Extreme Manuf. 2019, 1, 26. [Google Scholar] [CrossRef]

- Luo, L.; Jiang, Z.; Wei, D.; Manabe, K.-I.; Zhao, X.; Wu, D.; Furushima, T. Effects of surface roughness on micro deep drawing of circular cups with consideration of size effects. Finite Elements Anal. Des. 2016, 111, 46–55. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Kolte, Y. A review on experimental and numerical studies on micro deep drawing considering size effects and key process parameters. Aust. J. Mech. Eng. 2022, 14. [Google Scholar] [CrossRef]

- Gong, F.; Guo, B.; Wang, C.; Shan, D. Micro deep drawing of micro cups by using DLC film coated blank holders and dies. Diam. Relat. Mater. 2011, 20, 196–200. [Google Scholar] [CrossRef]

- Vollertsen, F.; Hu, Z. Analysis of punch velocity dependent process window in micro deep drawing. Prod. Eng. 2010, 4, 553–559. [Google Scholar] [CrossRef]

- Luo, L.; Wei, D.; Wang, X.; Zhou, C.; Huang, Q.; Xu, J.; Wu, D.; Jiang, Z. Effects of hydraulic pressure on wrinkling and earing in micro hydro deep drawing of SUS304 circular cups. Int. J. Adv. Manuf. Technol. 2016, 90, 189–197. [Google Scholar] [CrossRef]

- Luo, L.; Wei, D.; Zu, G.; Jiang, Z. Influence of blank holder-die gap on micro-deep drawing of SUS304 cups. Int. J. Mech. Sci. 2020, 191, 106065. [Google Scholar] [CrossRef]

- Tan, X. Comparisons of friction models in bulk metal forming. Tribol. Int. 2002, 35, 385–393. [Google Scholar] [CrossRef]

- Peng, L.; Lai, X.; Lee, H.-J.; Song, J.-H.; Ni, J. Friction behavior modeling and analysis in micro/meso scale metal forming process. Mater. Des. 2010, 31, 1953–1961. [Google Scholar] [CrossRef]

- Vollertsen, F.; Hu, Z.; Niehoff, H.; Theiler, C. State of the art in micro forming and investigations into micro deep drawing. J. Mater. Process. Technol. 2004, 151, 70–79. [Google Scholar] [CrossRef]

- Han, J.; Zheng, W.; Wang, G.; Yu, M. Experimental study on size effect of dry friction in meso/micro-upsetting process. Int. J. Adv. Manuf. Technol. 2017, 95, 1127–1133. [Google Scholar] [CrossRef]

- Engel, U. Tribology in microforming. Wear 2006, 260, 265–273. [Google Scholar] [CrossRef]

- Chan, W.; Fu, M.; Lu, J. The size effect on micro deformation behaviour in micro-scale plastic deformation. Mater. Des. 2011, 32, 198–206. [Google Scholar] [CrossRef]

- Hu, Z.; Schubnov, A.; Vollertsen, F. Tribological behaviour of DLC-films and their application in micro deep drawing. J. Mater. Process. Technol. 2012, 212, 647–652. [Google Scholar] [CrossRef]

- Wang, C.; Guo, B.; Shan, D.; Bai, X. Experimental research on micro-deep drawing processes of pure gold thin sheet using DLC-coated female die. Int. J. Adv. Manuf. Technol. 2012, 67, 2477–2487. [Google Scholar] [CrossRef]

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Ding, W.; Chen, Y.; Mao, C.; Xu, X.; Liu, B.; Wang, D.; Li, H.N.; Zhang, Y.; et al. Minimum quantity lubrication machining of aeronautical materials using carbon group nanolubricant: From mechanisms to application. Chin. J. Aeronaut. 2021, 35, 85–112. [Google Scholar] [CrossRef]

- He, Y.; Wang, L.; Wu, T.; Wu, Z.; Chen, Y.; Yin, K. Facile fabrication of hierarchical textures for substrate-independent and durable superhydrophobic surfaces. Nanoscale 2022, 14, 9392–9400. [Google Scholar] [CrossRef] [PubMed]

- He, A.; Huang, S.; Yun, J.-H.; Wu, H.; Jiang, Z.; Stokes, J.; Jiao, S.; Wang, L.; Huang, H. Tribological Performance and Lubrication Mechanism of Alumina Nanoparticle Water-Based Suspensions in Ball-on-Three-Plate Testing. Tribol. Lett. 2017, 65, 40. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Xia, W.; Cheng, X.; He, A.; Yun, J.H.; Wang, L.; Huang, H.; Jiao, S.; Huang, L.; et al. A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol. Int. 2017, 109, 398–408. [Google Scholar] [CrossRef]

- Wu, H.; Jia, F.; Li, Z.; Lin, F.; Huo, M.; Huang, S.; Sayyar, S.; Jiao, S.; Huang, H.; Jiang, Z. Novel water-based nanolubricant with superior tribological performance in hot steel rolling. Int. J. Extreme Manuf. 2020, 2, 025002. [Google Scholar] [CrossRef]

- Wu, H.; Wei, D.; Hee, A.C.; Huang, S.; Xing, Z.; Jiao, S.; Huang, H.; Jiang, Z. The influence of water-based nanolubrication on mill load and friction during hot rolling of 304 stainless steel. Int. J. Adv. Manuf. Technol. 2022, 121, 7779–7792. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Cheng, X.; Xia, W.; He, A.; Yun, J.-H.; Huang, S.; Wang, L.; Huang, H.; Jiao, S.; et al. Friction and wear characteristics of TiO2 nano-additive water-based lubricant on ferritic stainless steel. Tribol. Int. 2018, 117, 24–38. [Google Scholar]

- Wu, H.; Zhao, J.; Luo, L.; Huang, S.; Wang, L.; Zhang, S.; Jiao, S.; Huang, H.; Jiang, Z. Performance Evaluation and Lubrication Mechanism of Water-Based Nanolubricants Containing Nano-TiO2 in Hot Steel Rolling. Lubricants 2018, 6, 57. [Google Scholar] [CrossRef]

- Kamali, H.; Xie, H.; Jia, F.; Wu, H.; Zhao, H.; Zhang, H.; Li, N.; Jiang, Z. Effects of nano-particle lubrication on micro deep drawing of Mg-Li alloy. Int. J. Adv. Manuf. Technol. 2019, 104, 4409–4419. [Google Scholar] [CrossRef]

- Haus, F.; German, J.; Junter, G.-A. Primary biodegradability of mineral base oils in relation to their chemical and physical characteristics. Chemosphere 2001, 45, 983–990. [Google Scholar] [CrossRef]

- Kamali, H.; Xie, H.; Zhao, H.; Jia, F.; Wu, H.; Jiang, Z. Frictional Size Effect of Light-Weight Mg–Li Alloy in Micro Deep Drawing under Nano-Particle Lubrication Condition. Mater. Trans. 2020, 61, 239–243. [Google Scholar] [CrossRef]

- Huo, M.; Wu, H.; Xie, H.; Zhao, J.; Su, G.; Jia, F.; Li, Z.; Lin, F.; Li, S.; Zhang, H.; et al. Understanding the role of water-based nanolubricants in micro flexible rolling of aluminium. Tribol. Int. 2020, 151, 106378. [Google Scholar] [CrossRef]

- Sun, J.L.; Zhu, Z.X.; Xu, P.F. Study on the Lubricating Performance of Nano-TiO2 in Water-Based Cold Rolling Fluid. Mater. Sci. Forum 2015, 817, 219–224. [Google Scholar] [CrossRef]

- Wu, H.; Kamali, H.; Huo, M.; Lin, F.; Huang, S.; Huang, H.; Jiao, S.; Xing, Z.; Jiang, Z. Eco-Friendly Water-Based Nanolubricants for Industrial-Scale Hot Steel Rolling. Lubricants 2020, 8, 96. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, Y.; Ge, F.; Huang, X.; Ge, H.H.; Zhao, Y.Z.; Meng, X.J.; Dou, B.L. Corrosion behavior of brass in SCW-SDBS-TiO2 nanofluid. J. Alloy. Compd. 2021, 855, 9. [Google Scholar] [CrossRef]

- Luo, L.; Jiang, Z.; Wei, D.; Manabe, K.-I.; Sato, H.; He, X.; Li, P. An experimental and numerical study of micro deep drawing of SUS304 circular cups. Manuf. Rev. 2015, 2, 27. [Google Scholar] [CrossRef][Green Version]

- Luo, L.; Jiang, Z.; Wei, D. Influences of micro-friction on surface finish in micro deep drawing of SUS304 cups. Wear 2017, 374, 36–45. [Google Scholar] [CrossRef]

- Wei, D.; Luo, L.; Sato, H.; Jiang, Z.; Manabe, K. Simulations of hydro-mechanical deep drawing using Voronoi model and real microstructure model. Procedia Eng. 2017, 207, 1033–1038. [Google Scholar] [CrossRef]

- Wu, Y.; Tsui, W.; Liu, T. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

| Type | Description |

|---|---|

| Group 1 | Dry condition |

| Group 2 | 0.5 wt% TiO2 + 10 wt% Glycerol + 0.1 wt% SDBS + Balanced water |

| Group 3 | 1.0 wt% TiO2 + 10 wt% Glycerol + 0.1 wt% SDBS + Balanced water |

| Group 4 | 2.0 wt% TiO2 + 10 wt% Glycerol + 0.1 wt% SDBS + Balanced water |

| Materials | Fe | C | N | H | O |

|---|---|---|---|---|---|

| Pure titanium | 0.20 | 0.08 | 0.03 | 0.015 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Jia, F.; Yan, J.; Wu, H.; Jiang, Z. Lubrication Performance and Mechanism of Water-Based TiO2 Nanolubricants in Micro Deep Drawing of Pure Titanium Foils. Lubricants 2022, 10, 292. https://doi.org/10.3390/lubricants10110292

Zhou M, Jia F, Yan J, Wu H, Jiang Z. Lubrication Performance and Mechanism of Water-Based TiO2 Nanolubricants in Micro Deep Drawing of Pure Titanium Foils. Lubricants. 2022; 10(11):292. https://doi.org/10.3390/lubricants10110292

Chicago/Turabian StyleZhou, Muyuan, Fanghui Jia, Jingru Yan, Hui Wu, and Zhengyi Jiang. 2022. "Lubrication Performance and Mechanism of Water-Based TiO2 Nanolubricants in Micro Deep Drawing of Pure Titanium Foils" Lubricants 10, no. 11: 292. https://doi.org/10.3390/lubricants10110292

APA StyleZhou, M., Jia, F., Yan, J., Wu, H., & Jiang, Z. (2022). Lubrication Performance and Mechanism of Water-Based TiO2 Nanolubricants in Micro Deep Drawing of Pure Titanium Foils. Lubricants, 10(11), 292. https://doi.org/10.3390/lubricants10110292