Improvement in Methane Production from Pelagic Sargassum Using Combined Pretreatments

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Enzymes

2.3. Inoculum

2.4. Sample Characterization

2.5. Biochemical Methane Potential (BMP) Test

2.6. Physical Pretreatment

2.7. Chemical Pretreatment

2.8. Enzymatic Pretreatment

2.9. Combined Pretreatments

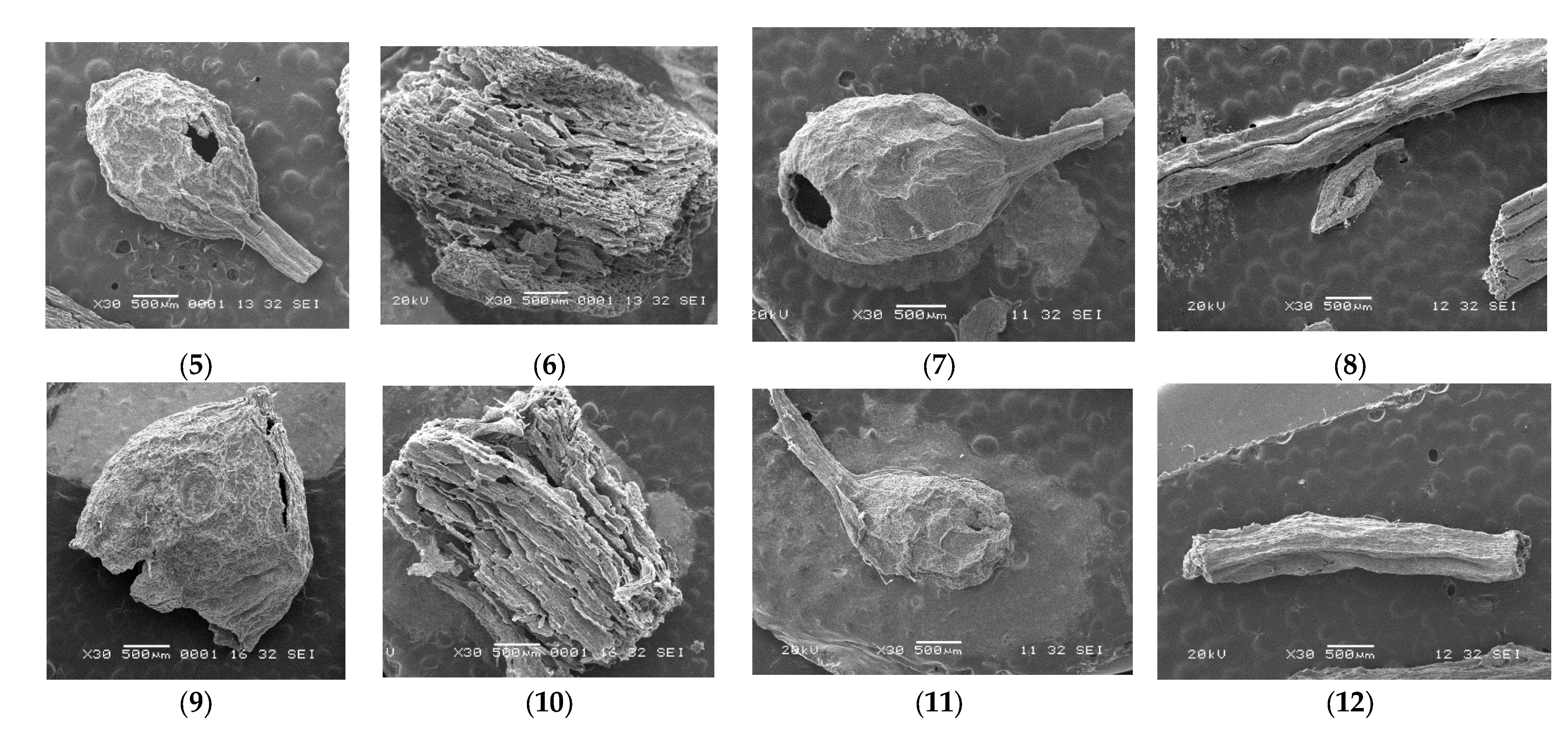

2.10. Scanning Electron Microscopy (SEM)

2.11. Statistical Analysis

3. Results

3.1. Compositional Analysis

CHNS/O

3.2. Biochemical Methane Potential (BMP)

3.2.1. Methane Yield

3.2.2. Concentration of Methane

3.2.3. Biodegradability Index

3.3. Scanning Electron Microscopy (SEM)

4. Discussion

4.1. Composition of Sargassum spp.

4.2. Elemental Analysis

4.3. BMP

4.3.1. Physical Pretreatment

4.3.2. Chemical Pretreatments

4.3.3. Enzymatic Pretreatment

4.3.4. Combined Pretreatments

4.3.5. DIET with Granular Activated Carbon (GAC)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smetacek, V.; Zingone, A. Green and golden seaweed tides on the rise. Nature 2013, 504, 84–88. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Hu, C.; Barnes, B.B.; Mitchum, G.; Lapointe, B.; Montoya, J.P. The great Atlantic Sargassum belt. Science 2019, 364, 83–87. [Google Scholar] [CrossRef] [PubMed]

- Louime, C.; Fortune, J.; Gervais, G. Sargassum Invasion of Coastal Environments: A Growing Concern. Am. J. Environ. Sci. 2017, 13, 58–64. [Google Scholar] [CrossRef]

- Rasher, D.B.; Hay, M.E. Chemically rich seaweeds poison corals when not controlled by herbivores. Proc. Natl. Acad. Sci. USA 2010, 107, 9683–9688. [Google Scholar] [CrossRef]

- Chávez, V.; Uribe-Martínez, A.; Cuevas, E.; Rodríguez-Martínez, R.E.; van Tussenbroek, B.I.; Francisco, V.; Estévez, M.; Celis, L.B.; Monroy-Velázquez, L.V.; Leal-Bautista, R.; et al. Massive influx of pelagic Sargassum spp. On the coasts of the mexican caribbean 2014–2020: Challenges and opportunities. Water 2020, 12, 2908. [Google Scholar] [CrossRef]

- De Jesus Raposo, M.F.; De Morais, A.M.M.B.; De Morais, R.M.S.C. Emergent sources of prebiotics: Seaweeds and microalgae. Mar. Drugs 2016, 14, 27. [Google Scholar] [CrossRef]

- Oyesiku, O.; Egunyomi, A. Identification and chemical studies of pelagic masses of Sargassum natans (Linnaeus) Gaillon and S. fluitans (Borgessen) Borgesen (brown algae), found offshore in Ondo State, Nigeria. Afr. J. Biotechnol. 2014, 13, 1188–1193. [Google Scholar]

- Alzate-Gaviria, L.; Domínguez-Maldonado, J.; Chablé-Villacís, R.; Olguin-Maciel, E.; Leal-Bautista, R.M.; Canché-Escamilla, G.; Caballero-Vázquez, A.; Hernández-Zepeda, C.; Barredo-Pool, F.A.; Tapia-Tussell, R. Presence of polyphenols complex aromatic “Lignin” in Sargassum Spp. From Mexican Caribbean. J. Mar. Sci. Eng. 2021, 9, 6. [Google Scholar] [CrossRef]

- Tapia-Tussell, R.; Avila-Arias, J.; Maldonado, J.D.; Valero, D.; Olguin-Maciel, E.; Pérez-Brito, D.; Alzate-Gaviria, L. Biological pretreatment of mexican caribbean macroalgae consortiums using Bm-2 strain (trametes hirsuta) and its enzymatic broth to improve biomethane potential. Energies 2018, 11, 494. [Google Scholar] [CrossRef]

- Milledge, J.J.; Maneein, S.; Arribas López, E.; Bartlett, D. Sargassum Inundations in Turks and Caicos: Methane potential and proximate, ultimate, lipid, amino acid, metal and metalloid analyses. Energies 2020, 13, 1523. [Google Scholar] [CrossRef]

- Thompson, T.M.; Young, B.R.; Baroutian, S. Efficiency of hydrothermal pretreatment on the anaerobic digestion of pelagic Sargassum for biogas and fertiliser recovery. Fuel 2020, 279, 118527. [Google Scholar] [CrossRef]

- Barbot, Y.N.; Al-Ghaili, H.; Benz, R. A review on the valorization of macroalgal wastes for biomethane production. Mar. Drugs 2016, 14, 120. [Google Scholar] [CrossRef]

- Bruhn, A.; Dahl, J.; Nielsen, H.B.; Nikolaisen, L.; Rasmussen, M.B.; Markager, S.; Olesen, B.; Arias, C.; Jensen, P.D. Bioenergy potential of Ulva lactuca: Biomass yield, methane production and combustion. Bioresour. Technol. 2011, 102, 2595–2604. [Google Scholar] [CrossRef]

- Li, H.; Kjerstadius, H. Evaluation of pretreatment methods for increased biogas production from macro algae. SGC Rapprot 2013, 278, 34. [Google Scholar]

- Morrison, M.; Gray, D. Anaerobic Digestion Economic Feasibility Study: Generating Energy from Waste, Sewage and Sargassum Seaweed in the OECS. Caribbean Council. 2017. Available online: https://www.caribbean-council.org/wp-content/uploads/2017/02/CPI-The-Caribbean-Council-Anaerobic-Digestion-Sargassum-Economic-Feasibility-Study-January-2017.pdf (accessed on 20 June 2022).

- Tabassum, M.R.; Xia, A.; Murphy, J.D. Potential of seaweed as a feedstock for renewable gaseous fuel production in Ireland. Renew. Sustain. Energy Rev. 2017, 68, 136–146. [Google Scholar] [CrossRef]

- Tabassum, M.R.; Wall, D.M.; Murphy, J.D. Biogas production generated through continuous digestion of natural and cultivated seaweeds with dairy slurry. Bioresour. Technol. 2016, 219, 228–238. [Google Scholar] [CrossRef]

- Tedesco, S.; Marrero Barroso, T.; Olabi, A.G. Optimization of mechanical pre-treatment of Laminariaceae spp. biomass-derived biogas. Renew. Energy 2014, 62, 527–534. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P.N.L. Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- Ben Yahmed, N.; Carrere, H.; Marzouki, M.N.; Smaali, I. Enhancement of biogas production from Ulva sp. by using solid-state fermentation as biological pretreatment. Algal Res. 2017, 27, 206–214. [Google Scholar] [CrossRef]

- Jard, G.; Dumas, C.; Delgenes, J.P.; Marfaing, H.; Sialve, B.; Steyer, J.P.; Carrère, H. Effect of thermochemical pretreatment on the solubilization and anaerobic biodegradability of the red macroalga Palmaria palmata. Biochem. Eng. J. 2013, 79, 253–258. [Google Scholar] [CrossRef]

- Yuhendra, A.P.; Farghali, M.; Mohamed, I.M.; Iwasaki, M.; Tangtaweewipat, S.; Ihara, I.; Sakai, R.; Umetsu, K. Potential of biogas production from the anaerobic digestion of Sargassum fulvellum macroalgae: Influences of mechanical, chemical, and biological pretreatments. Biochem. Eng. J. 2021, 175, 108140. [Google Scholar] [CrossRef]

- Jeong, G.T.; Kim, S.K.; Park, D.H. Application of solid-acid catalyst and marine macro-algae Gracilaria verrucosa to production of fermentable sugars. Bioresour. Technol. 2015, 181, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.J.; Fathoni, A.; Jeong, G.T.; Jeong, H.D.; Nam, T.J.; Kong, I.S.; Kim, J.K. Microbacterium oxydans, a novel alginate- and laminarin-degrading bacterium for the reutilization of brown-seaweed waste. J. Environ. Manag. 2013, 130, 153–159. [Google Scholar] [CrossRef] [PubMed]

- Gerken, H.G.; Donohoe, B.; Knoshaug, E.P. Enzymatic cell wall degradation of Chlorella vulgaris and other microalgae for biofuels production. Planta 2013, 237, 239–253. [Google Scholar] [CrossRef]

- Jegatheesan, A.; Sudhakar, M.P.; Poonam, C.; Perumal, K.; Arunkumar, K. Isolation and characterization of alginate-degrading bacteria Sinomicrobium oceani. Biomass Convers. Biorefinery 2017, 7, 51–58. [Google Scholar] [CrossRef]

- Pazarlioǧlu, N.K.; Sariişik, M.; Telefoncu, A. Laccase: Production by Trametes versicolor and application to denim washing. Process Biochem. 2005, 40, 1673–1678. [Google Scholar] [CrossRef]

- Wesenberg, D.; Buchon, F.; Agathos, S.N. Degradation of dye-containing textile effluent by the agaric white-rot fungus Clitocybula dusenii. Biotechnol. Lett. 2002, 24, 989–993. [Google Scholar] [CrossRef]

- Vanegas, C.H.; Hernon, A.; Bartlett, J. Enzymatic and organic acid pretreatment of seaweed: Effect on reducing sugars production and on biogas inhibition. Int. J. Ambient Energy 2015, 36, 2–7. [Google Scholar] [CrossRef]

- Ganesh Saratale, R.; Kumar, G.; Banu, R.; Xia, A.; Periyasamy, S.; Dattatraya Saratale, G. A critical review on anaerobic digestion of microalgae and macroalgae and co-digestion of biomass for enhanced methane generation. Bioresour. Technol. 2018, 262, 319–332. [Google Scholar] [CrossRef]

- Holmes, D.E.; Dang, Y.; Walker, D.J.F.; Lovley, D.R. The electrically conductive pili of Geobacter species are a recently evolved feature for extracellular electron transfer. Microb. Genom. 2016, 2, e000072. [Google Scholar] [CrossRef]

- Malvankar, N.S.; Lovley, D.R. Microbial nanowires for bioenergy applications. Curr. Opin. Biotechnol. 2014, 27, 88–95. [Google Scholar] [CrossRef]

- Rotaru, A.E.; Shrestha, P.M.; Liu, F.; Shrestha, M.; Shrestha, D.; Embree, M.; Zengler, K.; Wardman, C.; Nevin, K.P.; Lovley, D.R. A new model for electron flow during anaerobic digestion: Direct interspecies electron transfer to Methanosaeta for the reduction of carbon dioxide to methane. Energy Environ. Sci. 2014, 7, 408–415. [Google Scholar] [CrossRef]

- Valero, D.; Alzate-Gaviria, L.; Montes, J.A.; Rico, C. Influence of a Conductive Material and Different Anaerobic Inocula on Biochemical Methane Potential of Substrates from Alcoholic Beverage Production. Waste Biomass Valorization 2020, 11, 5957–5964. [Google Scholar] [CrossRef]

- Shanmugam, S.R.; Adhikari, S.; Wang, Z.; Shakya, R. Treatment of aqueous phase of bio-oil by granular activated carbon and evaluation of biogas production. Bioresour. Technol. 2017, 223, 115–120. [Google Scholar] [CrossRef]

- Poggi-Varaldo, H.M.; Valdés, L.; Esparza-García, F.; Fernández-Villagómez, G. Solid substrate anaerobic co-digestion of paper mill sludge, biosolids, and municipal solid waste. Water Sci. Technol. 1997, 35, 197–204. [Google Scholar] [CrossRef]

- Ward, A.J.; Lewis, D.M.; Green, F.B. Anaerobic digestion of algae biomass: A review. Algal Res. 2014, 5, 204–214. [Google Scholar] [CrossRef]

- Valero, D.; Montes, J.A.; Rico, J.L.; Rico, C. Influence of headspace pressure on methane production in Biochemical Methane Potential (BMP) tests. Waste Manag. 2016, 48, 193–198. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, L.; Kong, X.; Zhen, F.; Wang, Z.; Sun, Y.; Dong, P.; Lv, P. Inhibition Effect of Sodium Concentrations on the Anaerobic Digestion Performance of Sargassum Species. Energy Fuels 2017, 31, 7101–7109. [Google Scholar] [CrossRef]

- McKennedy, J.; Sherlock, O. Anaerobic digestion of marine macroalgae: A review. Renew. Sustain. Energy Rev. 2015, 52, 1781–1790. [Google Scholar] [CrossRef]

- Jung, K.A.; Lim, S.R.; Kim, Y.; Park, J.M. Potentials of macroalgae as feedstocks for biorefinery. Bioresour. Technol. 2013, 135, 182–190. [Google Scholar] [CrossRef]

- Marinho-Soriano, E.; Fonseca, P.C.; Carneiro, M.A.A.; Moreira, W.S.C. Seasonal variation in the chemical composition of two tropical seaweeds. Bioresour. Technol. 2006, 97, 2402–2406. [Google Scholar] [CrossRef]

- Milledge, J.J.; Harvey, P.J. Golden Tides: Problem or golden opportunity? The valorisation of Sargassum from beach inundations. J. Mar. Sci. Eng. 2016, 4, 60. [Google Scholar] [CrossRef]

- Nielsen, H.B.; Heiske, S. Anaerobic digestion of macroalgae: Methane potentials, pre-treatment, inhibition and co-digestion. Water Sci. Technol. 2011, 64, 1723–1729. [Google Scholar] [CrossRef]

- Xia, A.; Cheng, J.; Murphy, J.D. Innovation in biological production and upgrading of methane and hydrogen for use as gaseous transport biofuel. Biotechnol. Adv. 2016, 34, 451–472. [Google Scholar] [CrossRef]

- Thompson, T.M.; Young, B.R.; Baroutian, S. Pelagic Sargassum for energy and fertiliser production in the Caribbean: A case study on Barbados. Renew. Sustain. Energy Rev. 2020, 118, 109564. [Google Scholar] [CrossRef]

- Kwietniewska, E.; Tys, J. Process characteristics, inhibition factors and methane yields of anaerobic digestion process, with particular focus on microalgal biomass fermentation. Renew. Sustain. Energy Rev. 2014, 34, 491–500. [Google Scholar] [CrossRef]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar] [CrossRef]

- Allen, E.; Wall, D.M.; Herrmann, C.; Xia, A.; Murphy, J.D. What is the gross energy yield of third generation gaseous biofuel sourced from seaweed? Energy 2015, 81, 352–360. [Google Scholar] [CrossRef]

- Maneein, S.; Milledge, J.J.; Harvey, P.J.; Nielsen, B.V. Methane production from Sargassum muticum: Effects of seasonality and of freshwater washes. Energy Built Environ. 2021, 2, 235–242. [Google Scholar] [CrossRef]

- López-Aguilar, H.; Kennedy-Puentes, G.; Gómez, J.; Huerta-Reynoso, E.; Peralta-Pérez, M.D.R.; de la Serna, F.Z.D.; Pérez-Hernández, A. Practical and theoretical modeling of anaerobic digestion of Sargassum spp. In the mexican caribbean. Pol. J. Environ. Stud. 2021, 30, 3151–3161. [Google Scholar] [CrossRef]

- Botheju, D.; Lie, B.; Bakke, R. Oxygen effects in anaerobic digestion—II. Model. Identif. Control 2010, 31, 55–65. [Google Scholar] [CrossRef]

- Song, M.; Pham, H.D.; Seon, J.; Woo, H.C. Marine brown algae: A conundrum answer for sustainable biofuels production. Renew. Sustain. Energy Rev. 2015, 50, 782–792. [Google Scholar] [CrossRef]

- Oliveira, J.V.; Alves, M.M.; Costa, J.C. Optimization of biogas production from Sargassum sp. using a design of experiments to assess the co-digestion with glycerol and waste frying oil. Bioresour. Technol. 2015, 175, 480–485. [Google Scholar] [CrossRef] [PubMed]

- Nadaleti, W.C.; Przybyla, G. Emissions and performance of a spark-ignition gas engine generator operating with hydrogen-rich syngas, methane and biogas blends for application in southern Brazilian rice industries. Energy 2018, 154, 38–51. [Google Scholar] [CrossRef]

- Thompson, T.M.; Young, B.R.; Baroutian, S. Advances in the pretreatment of brown macroalgae for biogas production. Fuel Process. Technol. 2019, 195, 106151. [Google Scholar] [CrossRef]

- Tabassum, M.R.; Xia, A.; Murphy, J.D. The effect of seasonal variation on biomethane production from seaweed and on application as a gaseous transport biofuel. Bioresour. Technol. 2016, 209, 213–219. [Google Scholar] [CrossRef]

- Barbot, Y.N.; Thomsen, L.; Benz, R. Thermo-acidic pretreatment of beach macroalgae from rügen to optimize biomethane production—Double benefit with simultaneous bioenergy production and improvement of local beach and waste management. Mar. Drugs 2015, 13, 5681–5705. [Google Scholar] [CrossRef]

- Barbot, Y.N.; Falk, H.M.; Benz, R. Thermo-acidic pretreatment of marine brown algae Fucus vesiculosus to increase methane production—A disposal principle for macroalgae waste from beaches. J. Appl. Phycol. 2015, 27, 601–609. [Google Scholar] [CrossRef]

- Ehimen, E.A.; Holm-Nielsen, J.B.; Poulsen, M.; Boelsmand, J.E. Influence of different pre-treatment routes on the anaerobic digestion of a filamentous algae. Renew. Energy 2013, 50, 476–480. [Google Scholar] [CrossRef]

- Hom-Diaz, A.; Passos, F.; Ferrer, I.; Vicent, T.; Blánquez, P. Enzymatic pretreatment of microalgae using fungal broth from Trametes versicolor and commercial laccase for improved biogas production. Algal Res. 2016, 19, 184–188. [Google Scholar] [CrossRef]

- Li, Y.; Cui, J.; Zhang, G.; Liu, Z.; Guan, H.; Hwang, H.; Aker, W.G.; Wang, P. Optimization study on the hydrogen peroxide pretreatment and production of bioethanol from seaweed Ulva prolifera biomass. Bioresour. Technol. 2016, 214, 144–149. [Google Scholar] [CrossRef]

- Cabrera, E.; Muñoz, M.J.; Martín, R.; Caro, I.; Curbelo, C.; Díaz, A.B. Alkaline and alkaline peroxide pretreatments at mild temperature to enhance enzymatic hydrolysis of rice hulls and straw. Bioresour. Technol. 2014, 167, 1–7. [Google Scholar] [CrossRef]

- Rabelo, S.C.; Andrade, R.R.; Maciel Filho, R.; Costa, A.C. Alkaline hydrogen peroxide pretreatment, enzymatic hydrolysis and fermentation of sugarcane bagasse to ethanol. Fuel 2014, 136, 349–357. [Google Scholar] [CrossRef]

- Messerschmidt, A.; Huber, R. The blue oxidases, ascorbate oxidase, laccase and ceruloplasmin modelling and structural relationships. Eur. J. Biochem. 1990, 187, 341–352. Available online: http://onlinelibrary.wiley.com/doi/10.1111/j.1432-1033.1990.tb15311.x/pdf (accessed on 20 June 2022). [CrossRef]

- Strong, P.J.; Claus, H. Laccase: A review of its past and its future in bioremediation. Crit. Rev. Environ. Sci. Technol. 2011, 41, 373–434. [Google Scholar] [CrossRef]

- Wong, D.W.S. Structure and action mechanism of ligninolytic enzymes. Appl. Biochem. Biotechnol. 2009, 157, 174–209. [Google Scholar] [CrossRef]

- Kudanga, T.; Nemadziva, B.; Le Roes-Hill, M. Laccase catalysis for the synthesis of bioactive compounds. Appl. Microbiol. Biotechnol. 2017, 101, 13–33. [Google Scholar] [CrossRef]

- Carlsson, M.; Lagerkvist, A.; Morgan-Sagastume, F. The effects of substrate pre-treatment on anaerobic digestion systems: A review. Waste Manag. 2012, 32, 1634–1650. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef]

- Baldrian, P. Fungal laccases-occurrence and properties. FEMS Microbiol. Rev. 2006, 30, 215–242. [Google Scholar] [CrossRef]

- Lenihan, P.; Orozco, A.; O’Neill, E.; Ahmad, M.N.M.; Rooney, D.W.; Walker, G.M. Dilute acid hydrolysis of lignocellulosic biomass. Chem. Eng. J. 2010, 156, 395–403. [Google Scholar] [CrossRef]

- Ma, L.; Li, A.; Li, T.; Li, M.; Wang, X.; Hussain, M.A.; Qayum, A.; Jiang, Z.; Hou, J. Structure and characterization of laccase-crosslinked α-lactalbumin: Impacts of high pressure homogenization pretreatment. LWT 2020, 118, 108843. [Google Scholar] [CrossRef]

- Riva, S. Laccases: Blue enzymes for green chemistry. Trends Biotechnol. 2006, 24, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Valero, D.; Rico, C.; Canto-Canché, B.; Domínguez-Maldonado, J.A.; Tapia-Tussell, R.; Cortes-Velazquez, A.; Alzate-Gaviria, L. Enhancing biochemical methane potential and enrichment of specific electroactive communities from nixtamalization wastewater using granular activated carbon as a conductive material. Energies 2018, 11, 2101. [Google Scholar] [CrossRef]

- Arami-Niya, A.; Wan Daud, W.M.A.; Mjalli, F.S.; Abnisa, F.; Shafeeyan, M.S. Production of microporous palm shell based activated carbon for methane adsorption: Modeling and optimization using response surface methodology. Chem. Eng. Res. Des. 2012, 90, 776–784. [Google Scholar] [CrossRef]

- Hesas, R.H.; Arami-Niya, A.; Daud, W.M.A.W.; Sahu, J. Preparation and characterization of activated carbon from apple waste by microwave-assisted phosphoric acid activation: Application in methylene blue adsorption. BioResources 2013, 8, 2950–2966. [Google Scholar]

- Cheng, Q.; De Los Reyes, F.L.; Call, D.F. Amending anaerobic bioreactors with pyrogenic carbonaceous materials: The influence of material properties on methane generation. Environ. Sci. Water Res. Technol. 2018, 4, 1794–1806. [Google Scholar] [CrossRef]

- Freitas, A.F.; Mendes, M.F.; Coelho, G.L.V. Thermodynamic study of fatty acids adsorption on different adsorbents. J. Chem. Thermodyn. 2007, 39, 1027–1037. [Google Scholar] [CrossRef]

- Da Silva, A.H.; Miranda, E.A. Adsorption/desorption of organic acids onto different adsorbents for their recovery from fermentation broths. J. Chem. Eng. Data 2013, 58, 1454–1463. [Google Scholar] [CrossRef]

- Bernard, O.; Polit, M.; Hadj-Sadok, Z.; Pengov, M.; Dochain, D.; Estaben, M.; Labat, P. Advanced monitoring and control of anaerobic wastewater treatment plants: Software sensors and controllers for an anaerobic digester. Water Sci. Technol. 2018, 2, 175–182. [Google Scholar] [CrossRef]

- Milquez-Sanabria, H.; Blanco-Cocom, L.; Alzate-Gaviria, L. A fast linear predictive adaptive model of packed bed coupled with UASB reactor treating onion waste to produce biofuel. Microb. Cell Fact. 2016, 15, 167. [Google Scholar] [CrossRef][Green Version]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Florentino, A.P.; Xu, R.; Zhang, L.; Liu, Y. Anaerobic digestion of blackwater assisted by granular activated carbon: From digestion inhibition to methanogenesis enhancement. Chemosphere 2019, 233, 462–471. [Google Scholar] [CrossRef] [PubMed]

- Johnravindar, D.; Liang, B.; Fu, R.; Luo, G.; Meruvu, H.; Yang, S.; Yuan, B.; Fei, Q. Supplementing granular activated carbon for enhanced methane production in anaerobic co-digestion of post-consumer substrates. Biomass Bioenergy 2020, 136, 105543. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Fazzino, F.; Folino, A.; Scibetta, S.; Sidari, R. Improvement of semi-continuous anaerobic digestion of pre-treated orange peel waste by the combined use of zero valent iron and granular activated carbon. Biomass Bioenergy 2019, 129, 105337. [Google Scholar] [CrossRef]

- Martínez, E.J.; Rosas, J.G.; Sotres, A.; Moran, A.; Cara, J.; Sánchez, M.E.; Gómez, X. Codigestion of sludge and citrus peel wastes: Evaluating the effect of biochar addition on microbial communities. Biochem. Eng. J. 2018, 137, 314–325. [Google Scholar] [CrossRef]

| Parameter (%) | Sargassum spp. |

|---|---|

| Moisture% | 12.98 ± 4.34 |

| TS% | 87.02 ± 4.34 |

| VS% | 77.78 ± 1.95 |

| Ash | 22.22 ± 1.95 |

| VS/TS | 0.89 |

| Parameter (%) | Sargassum spp. |

|---|---|

| Ash% | 22.22 ± 1.95 |

| C% | 33.84 ± 1.05 |

| H% | 4.71 ± 0.22 |

| N% | 1.39 ± 0.22 |

| S% | 1.21 ± 0.22 |

| O% | 36.62 ± 3.37 |

| C:N | 24.26 |

| Pretreatment | Test | BI |

|---|---|---|

| PHYSICAL | C | 0.55 |

| CC | 0.38 | |

| CHEMICAL | P | 0.57 |

| PC | 0.59 | |

| ENZYMATIC | E | 0.42 |

| EC | 0.44 | |

| COMBINED | PE | 0.95 |

| PEC | 0.95 | |

| PTE | 0.88 | |

| PTEC | 0.78 |

| Pretreatment | Substrate | Operating Conditions | Pretreatment Characteristics | Yield (L CH4/kg VS) | % Methane | Literature |

|---|---|---|---|---|---|---|

| Physical | Sargassum spp. (C) | 40 °C Inoculum: substrate: 2:1 | Washed, dried (80 °C), and particle size > 1 mm | 224.19 ±9.45 | 46.44% ± 1.69 | This study |

| Sargassum spp. (CC) | 152.89 ± 2.00 | 48.86% ± 3.41 | ||||

| Sargassum fulvellum | 38 °C | 0.075–0.85 mm | 350 | 44% | [22] | |

| Laminaria spp. | 50 °C | Particle size 0.075 mm | 229 | 52% | [18] | |

| 40 °C | 0.075 mm | 210 | 51% | |||

| 30 °C | 0.075 mm | 220 | ||||

| Ulva lactuca | 55 °C | Wash and cut | 271 | - | [13] | |

| S. latissima | Inoculum:substrate: 1:1 | Wash, dried (80 °C), and 2-3 mm | 422 | - | [15] | |

| A. nodosum (brown seaweed) | Diary slurry and grass silage (37 °C and I:S;2:1) | Wash and 4 mm | 215-217 | - | [57] | |

| L. Digitata | Diary slurry and grass silage (37 °C and I:S;2:1) | Wash and 4 mm | 267 | - | [17] | |

| S. latissimi | 258 | |||||

| F. vesiculosos | 37 °C | 1000 bar 1 × 10 mm in the end (1 cm) | 92 | - | [14] | |

| U. lactuca | 53 °C | Wash and macerated | 255 | - | [44] | |

| Chemical | Sargassum spp. (P) | 40 °C Inoculum: substrate: 2:1 | Washed, dried (60 °C), and particle size > 1 mm+ peroxide | 230.82 ±11.65 | 51.55% ± 3.77 | This study |

| Sargassum spp. (PC) | 240.32 ±3.04 | 51.11% ± 0.56 | ||||

| S. fulvellum | 38 °C | 0.075–0.85 mm HCl 40 mL/L | 312 | 40% | [22] | |

| Ulva sp. | 35 °C Inoculum: substrate: 2:1 | 4% HCl a 150 °C | 77 | 61% | [20] | |

| Mixture of red and green macroalgae | 35–40 °C | 5–20 mm 0.05 M HCl 80 °C | 66 | - | [58] | |

| 5–20 mm 0.2 M HCl 80 °C 20 min | 90 | - | ||||

| F. vesiculosus | 37 °C | 0.2 M HCl | 52 | - | [59] | |

| L. digitata and S. latissima | 35 °C | 1% lactic acid | 161 | - | [29] | |

| Ulva sp. | 35 °C Inoculum: substrate: 2:1 | 4% NaOH 20 °C | 148 | 57% | [20] | |

| S. fulvellum | 38 °C | 0.075–0.85 mm NaOH 10mL/L | 282 | 43% | [22] | |

| Palmaria palmata | 35 °C Inoculum: substrate: 2:1 | 0.04 g NaOH gTS−1 at 20 °C | 365 | - | [21] | |

| Enzymatic | Sargassum spp. (E) | 40 °C Inoculum: substrate: 2:1 | Washed, dried (60 °C,) and particle size > 1 mm T. hirsuta | 172.57 ± 0.56 | 84.56% ± 0.15 | This study |

| Sargassum spp. (EC) | 179.56 ± 0.50 | 81.49% ± 1.02 | ||||

| S. fulvellum | 38 °C | 1 mL/L Viscamyl™ Flow cellulase enzyme | 133.27 | 44% | [22] | |

| pelagic Sargassum spp. | 38 °C | Enzymes from T. hirsuta | 104 | 52% | [9] | |

| Ulva sp. | 35 °C Inoculum: substrate: 2:1 | Enzymes from Aspergillus fumigatus | 153 | 58% | [20] | |

| L. digitata and S. latissima | 35 °C | Cellulase | 232 | [29] | ||

| Alginate lyase | 225 | - | ||||

| Celluclast | 72 | |||||

| Rhizoclonium | 53 °C | Lipase | 97 | [60] | ||

| Xylanase | 77 | - | ||||

| α-amylase | 79 | |||||

| Oocystis sp. | Inoculum: substrate:2:1 | Commercial lacasse | 100 | - | [61] | |

| Lacasse from T. versicolor | 144 | - | ||||

| F. vesiculosos | 37 °C | Hemicellulase, pectinase, protease, and cellulase | 49 | - | [14] | |

| Combined | Sargassum spp. (PE) | Washed, 60 °C particle size > 1 mm, peroxide and enzymes from Trametes hirsuta | 387.64 ±1.41 | 86.41% ± 0.04 | This study | |

| Sargassum spp. (PEC) | 385.73 ± 4.76 | 76.04% ± 0.80 | ||||

| Sargassum spp. (PTE) | Washed, 60 °C particle size > 1 mm, thermal 120 °C, peroxide and Enzymes from Trametes hirsuta | 364.95 ± 8.18 | 87.69% ± 1.49 | |||

| Sargassum spp. (PTEC) | 318.06 ± 10.24 | 85.26% ± 0.10 | ||||

| L. digitata and S. latissima | 35 °C | Cellulase 1% lactic acid | 161 | - | [29] | |

| F. vesiculosos | 37 °C | 1000 bar + Hemicellulase, pectinase, protease, and cellulase | 49 | - | [14] | |

| F. vesiculosus | 37 °C | 80 °C and 0.2 M HCl | 116 | - | [59] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chikani-Cabrera, K.D.; Fernandes, P.M.B.; Tapia-Tussell, R.; Parra-Ortiz, D.L.; Hernández-Zárate, G.; Valdez-Ojeda, R.; Alzate-Gaviria, L. Improvement in Methane Production from Pelagic Sargassum Using Combined Pretreatments. Life 2022, 12, 1214. https://doi.org/10.3390/life12081214

Chikani-Cabrera KD, Fernandes PMB, Tapia-Tussell R, Parra-Ortiz DL, Hernández-Zárate G, Valdez-Ojeda R, Alzate-Gaviria L. Improvement in Methane Production from Pelagic Sargassum Using Combined Pretreatments. Life. 2022; 12(8):1214. https://doi.org/10.3390/life12081214

Chicago/Turabian StyleChikani-Cabrera, Karla Daniela, Patricia Machado Bueno Fernandes, Raúl Tapia-Tussell, David Leonardo Parra-Ortiz, Galdy Hernández-Zárate, Ruby Valdez-Ojeda, and Liliana Alzate-Gaviria. 2022. "Improvement in Methane Production from Pelagic Sargassum Using Combined Pretreatments" Life 12, no. 8: 1214. https://doi.org/10.3390/life12081214

APA StyleChikani-Cabrera, K. D., Fernandes, P. M. B., Tapia-Tussell, R., Parra-Ortiz, D. L., Hernández-Zárate, G., Valdez-Ojeda, R., & Alzate-Gaviria, L. (2022). Improvement in Methane Production from Pelagic Sargassum Using Combined Pretreatments. Life, 12(8), 1214. https://doi.org/10.3390/life12081214