Dual Resource Constrained Flexible Job Shop Scheduling Based on Improved Quantum Genetic Algorithm

Abstract

:1. Introduction

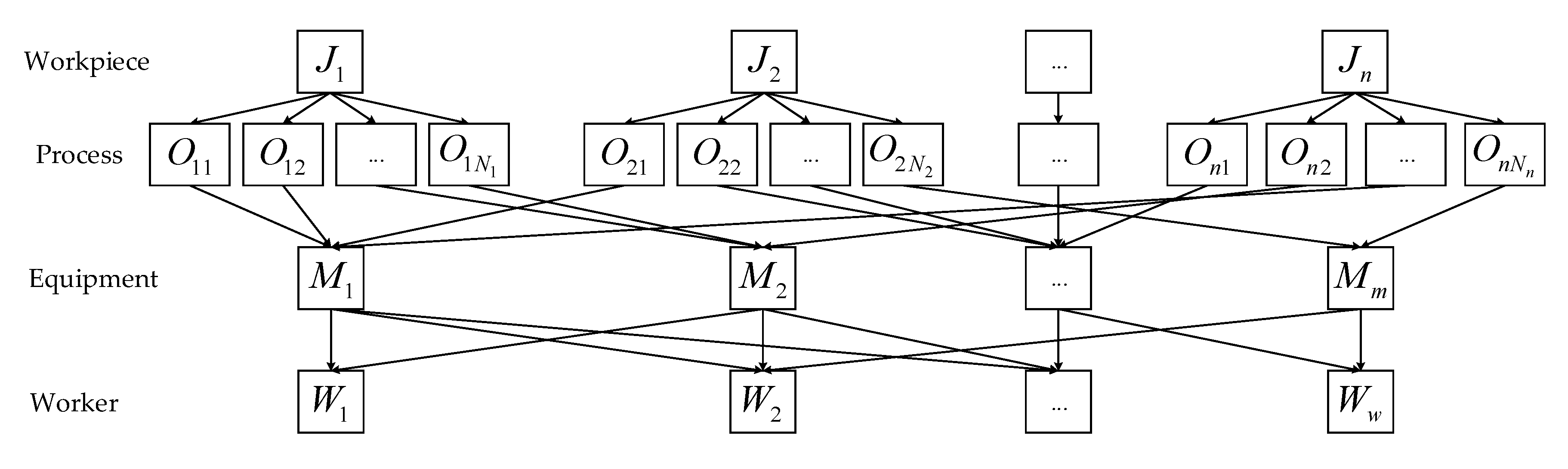

2. Research on DRCFJSP

2.1. DRCFJSP Problem Description

- (1)

- Each workpiece is not allowed to be interrupted while being processed on the equipment;

- (2)

- Each piece of equipment can only process one of the processes of a workpiece at the same time;

- (3)

- Each process must be completed in accordance with the processing sequence, that is, the next process of the process route can be processed after one process is completed;

- (4)

- No priority restrictions between artifacts;

- (5)

- The transportation time in the production process is not considered;

- (6)

- Workers are responsible for the loading and unloading operations of process processing, and the processing time is determined by the standard working hours of the machine tool;

- (7)

- A worker can only operate one piece of equipment at a time.

2.2. Mathematical Model

2.3. Improved Quantum Genetic Algorithm to Solve DRCFJSP

2.3.1. Quantum Coding

2.3.2. Niche Initialization Population

2.3.3. Adaptive Rotation Angle Adjustment

2.3.4. Quantum Mutation

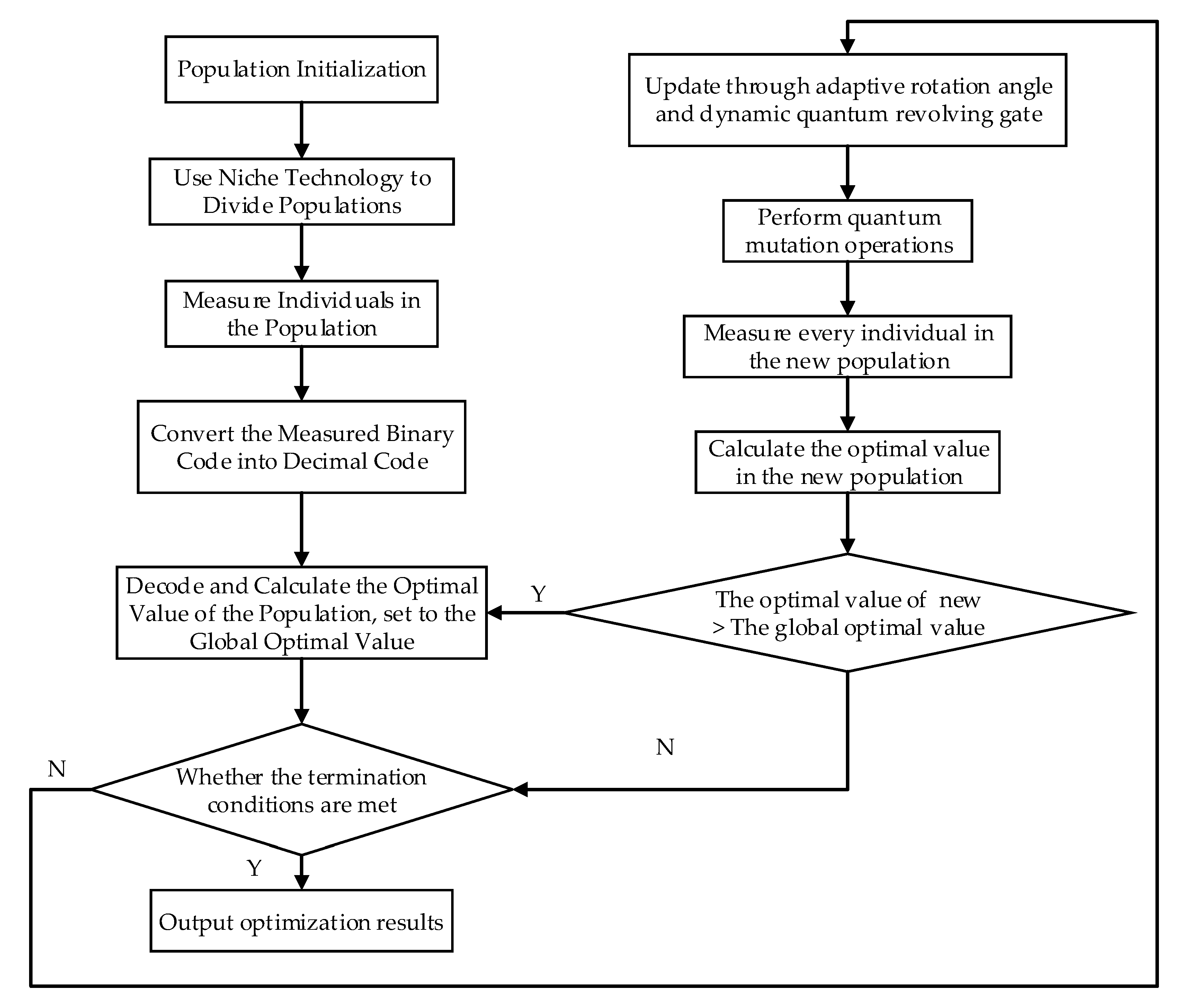

2.4. Algorithm Steps

- Step 1: Initialize the parameters, determine the population size , the maximum algebra , the number of quantum chromosomes and the quantum mutation probability , and the niche technology initializes the population;

- Step 2: Measure the population, get the binary code, and get the observation state according to the initial state of the population;

- Step 3: Calculate and save, convert the observation state into a decimal code, obtain a process-based code, obtain a set of solution vectors through decoding technology, evaluate it through the fitness function, and set the population optimal to the global optimal value;

- Step 4: Judge whether the termination condition is satisfied, the termination algorithm is satisfied, and Step5 is executed if it is not satisfied;

- Step 5: Update. Calculate the rotation angle of the quantum revolving gate according to the dynamic quantum rotation angle method and perform quantum mutation operation to update the population ;

- Step 6: Observe and decode the new population, determine whether the optimal value of the new population is greater than the global optimal value, and set the optimal value of the population to the global optimal value if it is satisfied, then return to Step 4.

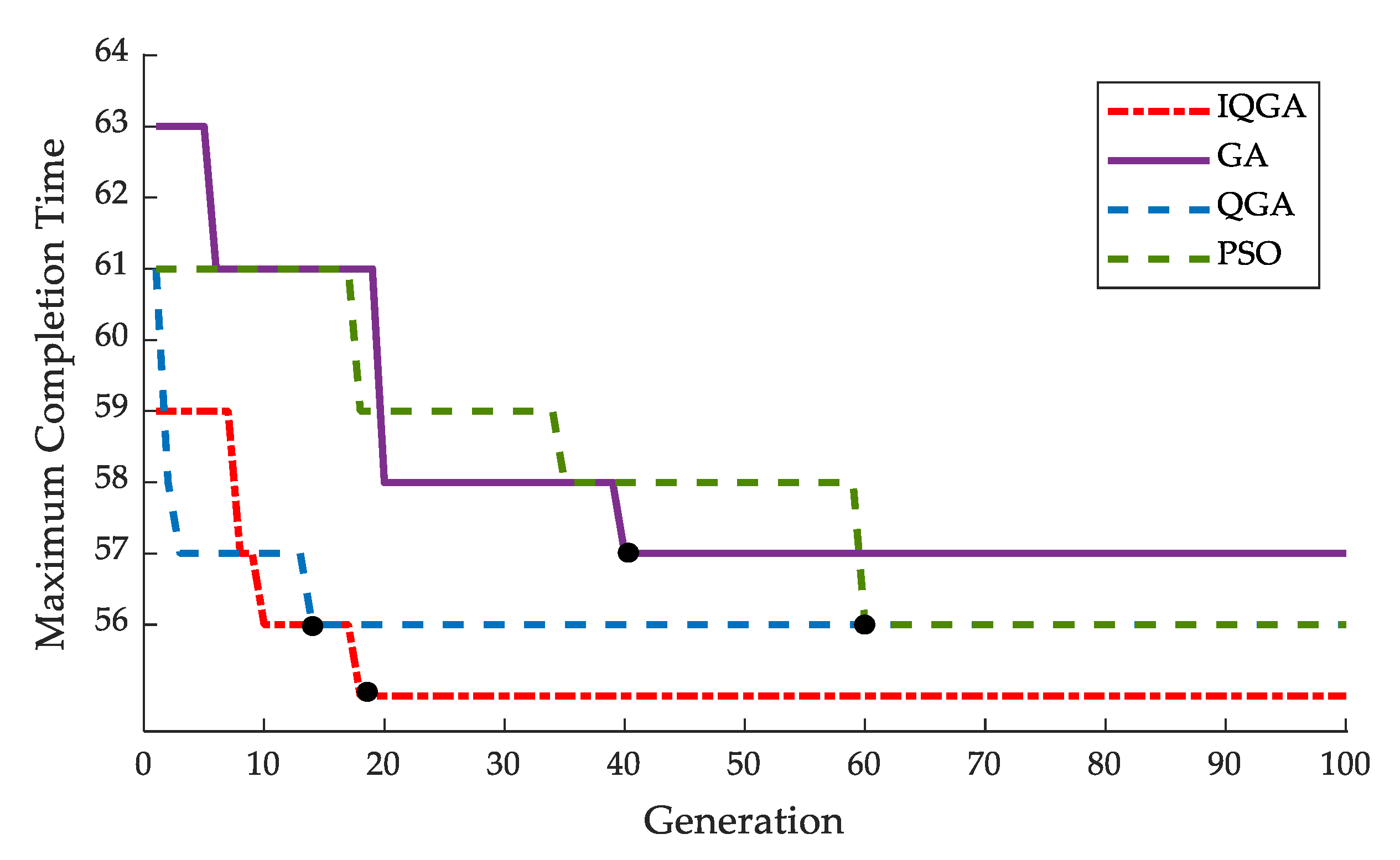

3. Results

3.1. Standard Calculation Examples

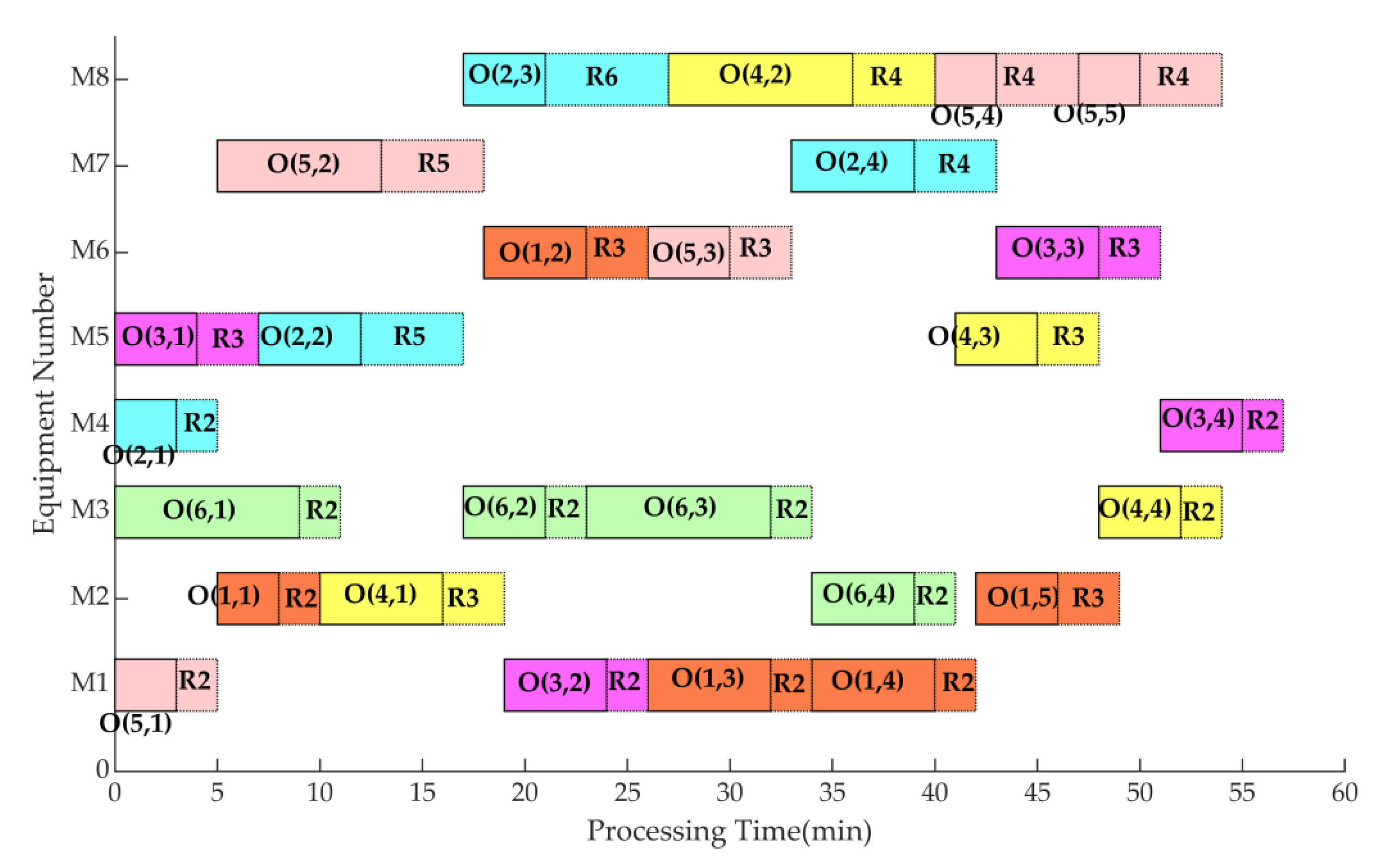

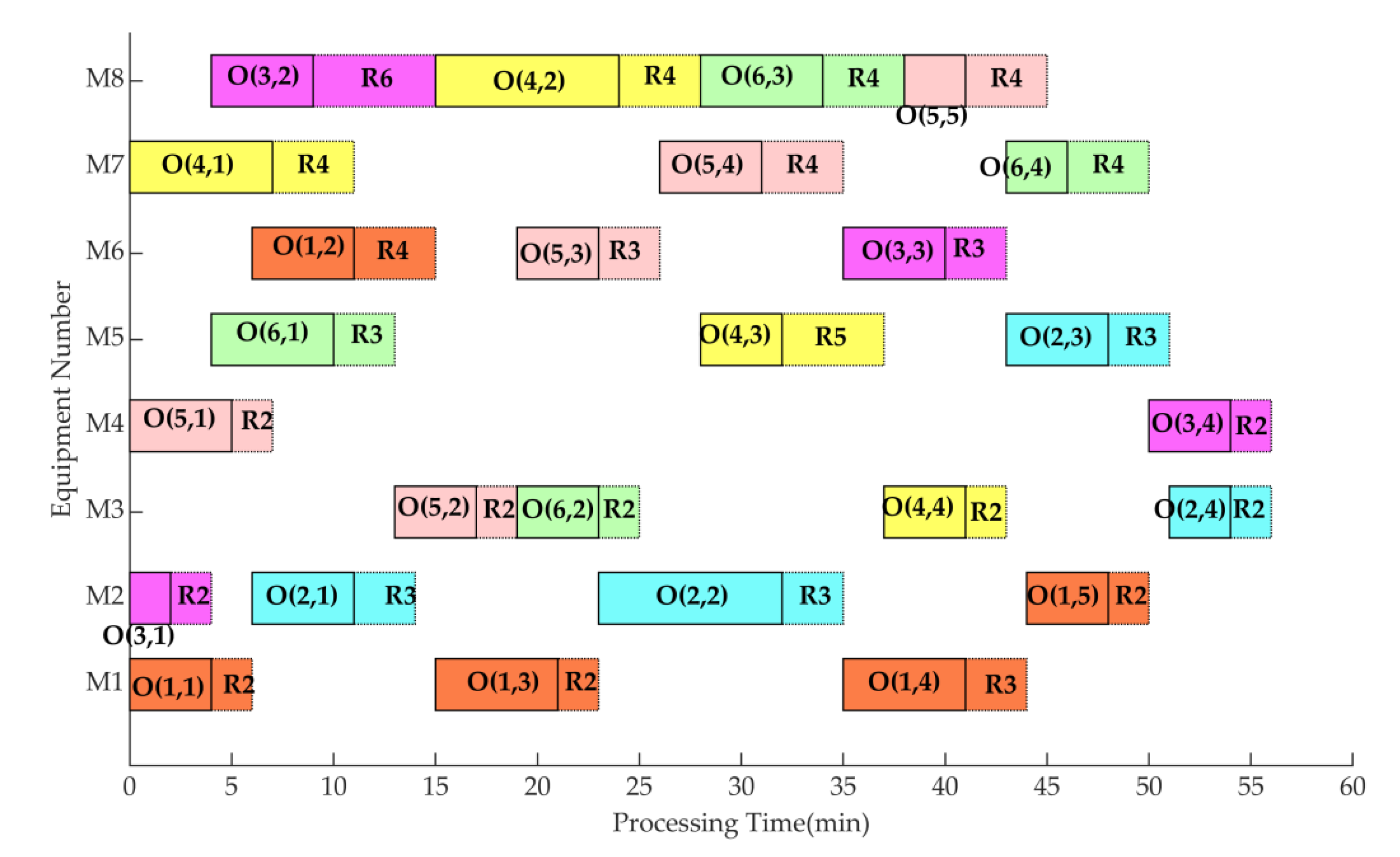

3.2. Actual Calculation Example

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Liu, C.; Chang, C.; Tseng, C. Actor-Critic Deep Reinforcement Learning for Solving Job Shop Scheduling Problems. IEEE Access 2020, 8, 71752–71762. [Google Scholar] [CrossRef]

- Qamhan, A.A.; Ahmed, A.; Al-Harkan, I.M.; Badwelan, A.; Al-Samhan, A.M.; Hidri, L. An Exact Method and Ant Colony Optimization for Single Machine Scheduling Problem with Time Window Periodic Maintenance. IEEE Access 2020, 8, 44836–44845. [Google Scholar] [CrossRef]

- Berti, N.; Finco, S.; Battaia, O.; Delorme, X. Ageing workforce effects in Dual-Resource Constrained Job-Shop Scheduling. Int. J. Prod. Econ. 2021, 237, 108151. [Google Scholar] [CrossRef]

- Kumar, P.; Gupta, S.; Gunda, Y. Estimation of Human Error Rate in Underground Coal Mines through Retrospective Analysis of Mining Accident Reports and Some Error Reduction Strategies. Saf. Sci. 2020, 123, 104555. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Ren, Y.; Zhang, B.; Lv, C. Mixed-integer Linear Programming and Constraint Programming Formulations for Solving Distributed Flexible Job Shop Scheduling Problem. Comput. Ind. Eng. 2020, 142, 106347. [Google Scholar] [CrossRef]

- Wang, Y.; Cen, H.; Yang, O. Optimal Configuration for Workshop Manufacturing System under Dual Resource Constraints. Int. J. Simul. Model. 2018, 17, 180–189. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Niu, X. A Branch Population Genetic Algorithm for Dual-Resource Constrained Job Shop Scheduling Problem. Comput. Ind. Eng. 2016, 102, 113–131. [Google Scholar] [CrossRef]

- Zhong, Q.; Yang, H.; Tang, T. Optimization Algorithm Simulation for Dual-Resource Constrained Job-Shop Scheduling. Int. J. Simul. Model. 2018, 17, 147–158. [Google Scholar] [CrossRef]

- Gong, G.; Deng, Q.; Gong, X.; Liu, W.; Ren, Q. A New Double Flexible Job-Shop Scheduling Problem Integrating Processing Time, Green Production, and Human Factor Indicators. J. Clean. Prod. 2018, 174, 560–576. [Google Scholar] [CrossRef]

- Wu, R.; Li, Y.; Guo, S.; Xu, W. Solving the Dual-Resource Constrained Flexible Job Shop Scheduling Problem with Learning Effect by a Hybrid Genetic Algorithm. Adv. Mech. Eng. 2018, 10, 1–14. [Google Scholar] [CrossRef]

- Zhang, J.; Jie, J.; Wang, W.; Xu, X. A Hybrid Particle Swarm Optimisation for Multi-Objective Flexible Job-Shop Scheduling Problem with Dual-Resources Constrained. Int. J. Comput. Sci. Math. 2017, 8, 526–532. [Google Scholar] [CrossRef]

- Gong, X.; Deng, Q.; Gong, G.; Wei, L.; Qing, R. A Memetic Algorithm for Multi-Objective Flexible Job-Shop Problem with Worker Flexibility. Int. J. Prod. Res. 2018, 56, 2506–2522. [Google Scholar] [CrossRef]

- Geng, K.; Ye, C.; Liu, L. Research on Multi-Objective Hybrid Flow Shop Scheduling Problem with Dual Resource Constraints Using Improved Memetic Algorithm. IEEE Access 2020, 8, 104527–104542. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, L. A Knowledge-Guided Fruit Fly Optimization Algorithm for Dual Resource Constrained Flexible Job-Shop Scheduling Problem. Int. J. Prod. Res. 2016, 54, 5554–5566. [Google Scholar] [CrossRef]

- Yang, G.; Chung, B.; Lee, S. Limited Search Space-Based Algorithm for Dual Resource Constrained Scheduling Problem with Multilevel Product Structure. Appl. Sci. 2019, 9, 4005. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Yi, L. Approach of Solving Dual Resource Constrained Multi-Objective Flexible Job Shop Scheduling Problem Based on MOEA/D. Int. J. Online Eng. 2018, 14, 75–89. [Google Scholar]

- Andrade-Pineda, J.; Canca, D.; Gonzalez-R, P.; Calle, M. Scheduling a Dual-Resource Flexible Job Shop with Makespan and Due Date-Related Criteria. Ann. Oper. Res. 2020, 291, 5–35. [Google Scholar] [CrossRef]

- Yazdani, M.; Zandieh, M.; Tavakkoli-Moghaddam, R. A hybrid meta-heuristic algorithm for dual resource constrained flexible job shop scheduling problem. Ind. Manag. Stud. 2014, 12, 43–74. [Google Scholar]

- Yazdani, M.; Zandieh, M.; Tavakkoli-Moghaddam, R.; Jolai, F. Two meta-heuristic algorithms for the dual-resource constrained flexible job-shop scheduling problem. Sci. Iran. 2015, 22, 1242–1257. [Google Scholar]

- Defersha, F.; Obimuyiwa, D.; Yimer, A. Multiple-Trial/Best-Move Simulated Annealing for Flexible Job Shop Scheduling with Scarce Setup-Operators. In Proceedings of the 2020 7th International Conference on Soft Computing & Machine Intelligence (ISCMI), Stockholm, Sweden, 14–15 November 2020; pp. 61–67. [Google Scholar]

- Chatzikonstantinou, I.; Giakoumis, D.; Tzovaras, D. A new shopfloor orchestration approach for collaborative human-robot device disassembly. In Proceedings of the 2019 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), Leicester, UK, 19–23 August 2019; pp. 225–230. [Google Scholar]

- Gong, G.; Chiong, R.; Deng, Q.; Gong, X. A Hybrid Artificial Bee Colony Algorithm for Flexible Job Shop Scheduling with Worker Flexibility. Int. J. Prod. Res. 2020, 58, 4406–4420. [Google Scholar] [CrossRef]

- Li, H.; Zhu, H. Modified Water Wave Optimization for Energy-Conscious Dual-Resource Constrained Flexible Job Shop Scheduling. Int. J. Perform. Eng. 2020, 16, 916. [Google Scholar]

- Xu, H.; Bao, Z.; Zhang, T. Solving Dual Flexible Job-Shop Scheduling Problem Using a Bat Algorithm. Adv. Prod. Eng. Manag. 2017, 12, 5–16. [Google Scholar] [CrossRef] [Green Version]

- Narayanan, A.; Moore, M. Quantum-Inspired Genetic Algorithms. In Proceedings of the IEEE International Conference on Evolutionary Computation, Nagoya, Japan, 20–22 May 1996; pp. 61–66. [Google Scholar]

- Gao, L.; Liu, R.; Wang, F.; Wu, W.; Bai, B.; Yang, S.; Yao, L. An Advanced Quantum Optimization Algorithm for Robot Path Planning. J. Circuits Syst. Comput. 2020, 29, 4–13. [Google Scholar] [CrossRef]

- Sabahi, F. Quantum Genetic LMI-based H∞ Control with Time Delay. Int. J. Ind. Electron. Control Optim. 2020, 3, 1–10. [Google Scholar]

- Tian, Y.; Hu, W.; Du, B.; Hu, S.; Nie, C.; Zhang, C. IQGA: A Route Selection Method Based on Quantum Genetic Algorithm-Toward Urban Traffic Management under Big Data Environment. World Wide Web 2019, 22, 2129–2151. [Google Scholar] [CrossRef]

- Sun, J.; Xu, L. Cloud-Based Adaptive Quantum Genetic Algorithm for Solving Flexible Job Shop Scheduling Problem. In Proceedings of the 2019 IEEE 7th International Conference on Computer Science and Network Technology, Dalian, China, 19–20 October 2019; pp. 1–5. [Google Scholar]

- Li, H.; Zou, P.; Huang, Z.; Zeng, C.; Liu, X. Multimodal optimization using whale optimization algorithm enhanced with local search and niching technique. Math. Biosci. Eng. MBE 2019, 17, 1–27. [Google Scholar] [CrossRef]

- Ning, T.; Guo, C.; Chen, R.; Jin, H. A Novel Hybrid Method for Solving Flexible Job-Shop Scheduling Problem. Open Cybern. Syst. J. 2016, 10, 13–19. [Google Scholar] [CrossRef] [Green Version]

- Kacem, I.; Hammadi, S.; Borne, P. Approach by localization and Multi-objective Evolutionary Optimization for Flexible Job-Shop Scheduling Problems. IEEE Trans. Syst. Man Cybern. Part C 2002, 32, 1–13. [Google Scholar] [CrossRef]

- Nouiri, M.; Bekrar, A.; Jemai, A.; Niar, S.; Ammari, A. An Effective and Distributed Particle Swarm Optimization Algorithm for Flexible Job-Shop Scheduling Problem. J. Intell. Manuf. 2018, 29, 603–615. [Google Scholar] [CrossRef]

- Ziaee, M. A Heuristic Algorithm for Solving Flexible Job Shop Scheduling Problem. Int. J. Adv. Manuf. Technol. 2014, 71, 519–528. [Google Scholar] [CrossRef]

- Luan, F.; Cai, Z.; Wu, S.; Ma, J.; Li, F.; Yang, J. Improved Whale Optimization Algorithm of Scheduling Problem for Low Carbon Workshop. Mech. Sci. Technol. Aerosp. Eng. 2020, 39, 721–728. [Google Scholar]

- Cui, Q.; Wu, X.; Yu, J. Improved Genetic Algorithm Variable Neighborhood Search for Solving Hybrid Flow Shop Scheduling Problem. Comput. Integr. Manuf. Syst. 2017, 23, 1917–1927. [Google Scholar]

| Parameter | Description |

|---|---|

| The maximum completion time | |

| The start time of process | |

| The processing time of | |

| The end time of | |

| The loading and unloading time of worker on equipment | |

| When the value is 1, it means that the process of the workpiece is processed by the worker on the equipment. |

| Xi | bi | f(Xi) > f(bi) | Δθ | S(αi, βi) | |||

|---|---|---|---|---|---|---|---|

| αiβi > 0 | αiβi < 0 | αi = 0 | βi = 0 | ||||

| 0 | 0 | False | 0 | - | - | - | - |

| 0 | 0 | True | 0 | - | - | - | - |

| 0 | 1 | False | δ | +1 | −1 | 0 | ±1 |

| 0 | 1 | True | δ | −1 | +1 | ±1 | 0 |

| 1 | 0 | False | δ | −1 | +1 | ±1 | 0 |

| 1 | 0 | True | δ | +1 | −1 | 0 | ±1 |

| 1 | 1 | False | 0 | - | - | - | - |

| 1 | 1 | True | 0 | - | - | - | - |

| Examples | n × m | Standard Solution | Particle Swarm Algorithm | Heuristic Algorithm | Meta-Heuristic Algorithm | IQGA |

|---|---|---|---|---|---|---|

| Kacem01 | 4 × 5 | 11 | 11 | 11 | 11 | 11 |

| Kacem02 | 8 × 8 | 14 | 17 | 15 | 14 | 14 |

| Kacem03 | 10 × 7 | 11 | - | 13 | 13 | 12 |

| Kacem04 | 10 × 10 | 7 | 8 | 7 | 7 | 7 |

| Kacem05 | 15 × 10 | 11 | - | 12 | 14 | 12 |

| Equipment Number | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | ||

| J1 | O11 | 4 | 3 | — | 6 | — | — | — | — |

| O12 | — | — | 5 | — | — | 5 | — | 7 | |

| O13 | 6 | — | 8 | — | — | 6 | — | 7 | |

| O14 | 6 | — | 5 | — | — | 8 | 7 | — | |

| O15 | — | 4 | 9 | — | — | — | 4 | — | |

| J2 | O21 | 6 | 5 | — | 3 | — | — | — | — |

| O22 | — | 9 | 4 | — | 5 | — | 6 | — | |

| O23 | — | — | — | — | 5 | — | 7 | 4 | |

| O24 | 3 | — | 3 | — | — | 5 | 6 | — | |

| J3 | O31 | — | 2 | 6 | — | 4 | — | 5 | — |

| O32 | 5 | — | 8 | — | — | 7 | — | 5 | |

| O33 | 8 | — | 6 | — | — | 5 | 5 | — | |

| O34 | — | — | — | 4 | 8 | — | — | 4 | |

| J4 | O41 | — | 6 | 8 | — | 6 | — | 7 | — |

| O42 | — | — | 7 | — | — | 2 | — | 9 | |

| O43 | — | — | — | — | 4 | — | 4 | 4 | |

| O44 | — | 7 | 4 | — | — | — | 5 | — | |

| J5 | O51 | 3 | 5 | — | 5 | — | — | — | — |

| O52 | — | 6 | 4 | — | 7 | — | 8 | — | |

| O53 | 3 | — | 7 | — | — | 4 | — | 8 | |

| O54 | — | — | — | — | 4 | — | 5 | 3 | |

| O55 | — | — | — | 3 | 8 | — | — | 3 | |

| J6 | O61 | — | 5 | 9 | — | 6 | — | 9 | — |

| O62 | — | — | 4 | — | — | 3 | — | 8 | |

| O63 | 5 | — | 9 | — | — | 6 | — | 6 | |

| O64 | — | 5 | 6 | — | — | — | 3 | — | |

| Worker | M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 |

|---|---|---|---|---|---|---|---|---|

| W1 | 2 | 3 | — | — | — | — | — | — |

| W2 | — | 2 | 3 | — | 5 | — | — | — |

| W3 | — | — | — | 3 | — | 4 | 5 | — |

| W4 | 3 | — | — | — | 3 | — | — | 6 |

| W5 | — | — | 2 | — | — | — | 4 | 4 |

| W6 | — | — | — | 2 | — | 3 | — | — |

| Algorithm | Population Size | Number of Iterations | Other Parameters |

|---|---|---|---|

| GA | 100 | 100 | Crossover rate 0.8, mutation rate 0.05 |

| PSO | 100 | 100 | Inertia weight w = 0.73, learning factor c1 = 2, c2 = 2.1 |

| QGA | 100 | 100 | Mutation rate 0.05 |

| IQGA | 100 | 100 | Mutation rate 0.05 |

| Number of Runs | Algorithm | ||||

|---|---|---|---|---|---|

| GA | PSO | QGA | IQGA | ||

| maxCi | 1 | 58 | 59 | 57 | 55 |

| 2 | 59 | 56 | 56 | 56 | |

| 3 | 59 | 57 | 56 | 56 | |

| 4 | 59 | 57 | 56 | 55 | |

| 5 | 58 | 56 | 57 | 55 | |

| 6 | 57 | 56 | 57 | 56 | |

| 7 | 58 | 56 | 56 | 55 | |

| 8 | 57 | 56 | 56 | 55 | |

| 9 | 59 | 56 | 56 | 55 | |

| 10 | 59 | 57 | 56 | 55 | |

| Best | 57 | 56 | 56 | 55 | |

| Worst | 59 | 59 | 57 | 56 | |

| Average | 58.3 | 56.6 | 56.3 | 55.3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Du, H.; Borucki, S.; Jin, S.; Hou, T.; Li, Z. Dual Resource Constrained Flexible Job Shop Scheduling Based on Improved Quantum Genetic Algorithm. Machines 2021, 9, 108. https://doi.org/10.3390/machines9060108

Zhang S, Du H, Borucki S, Jin S, Hou T, Li Z. Dual Resource Constrained Flexible Job Shop Scheduling Based on Improved Quantum Genetic Algorithm. Machines. 2021; 9(6):108. https://doi.org/10.3390/machines9060108

Chicago/Turabian StyleZhang, Shoujing, Haotian Du, Sebastian Borucki, Shoufeng Jin, Tiantian Hou, and Zhixiong Li. 2021. "Dual Resource Constrained Flexible Job Shop Scheduling Based on Improved Quantum Genetic Algorithm" Machines 9, no. 6: 108. https://doi.org/10.3390/machines9060108

APA StyleZhang, S., Du, H., Borucki, S., Jin, S., Hou, T., & Li, Z. (2021). Dual Resource Constrained Flexible Job Shop Scheduling Based on Improved Quantum Genetic Algorithm. Machines, 9(6), 108. https://doi.org/10.3390/machines9060108