Impact of Electronic Radiation on the Morphology of the Fine Structure of the Surface Layer of R6M5 Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

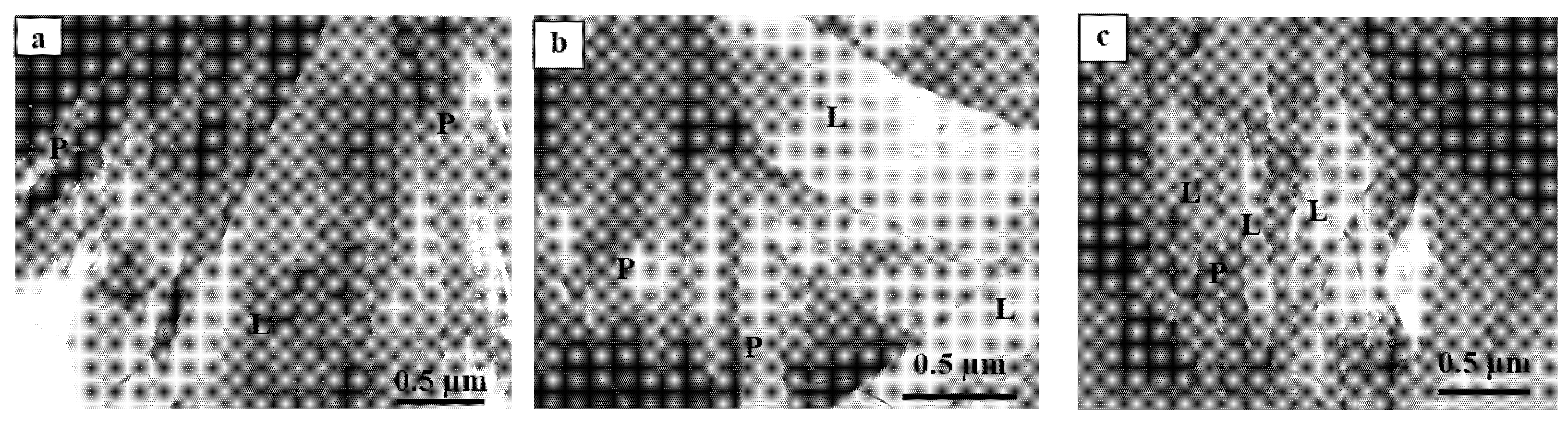

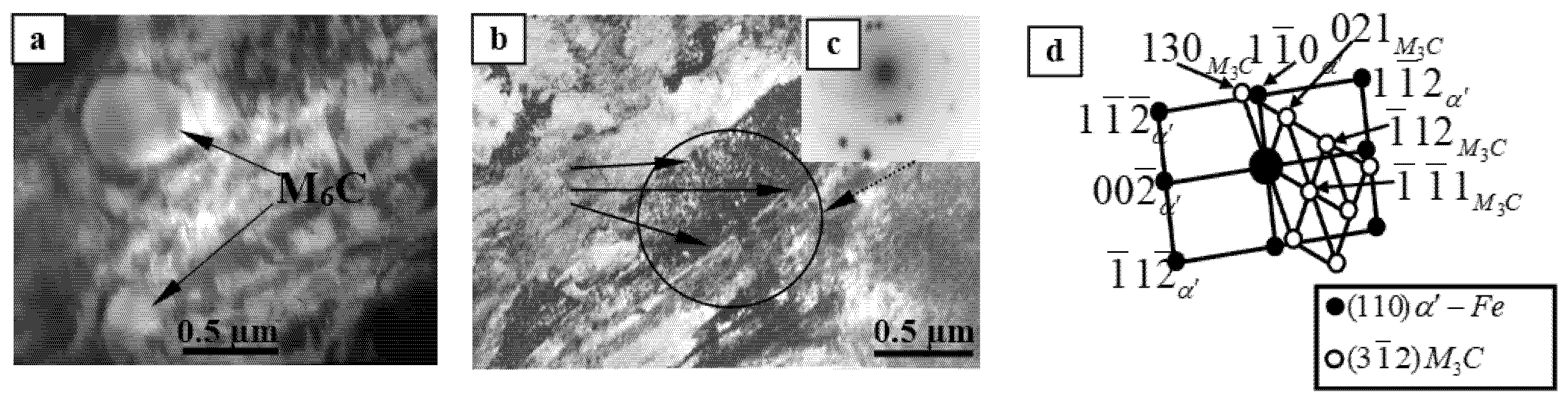

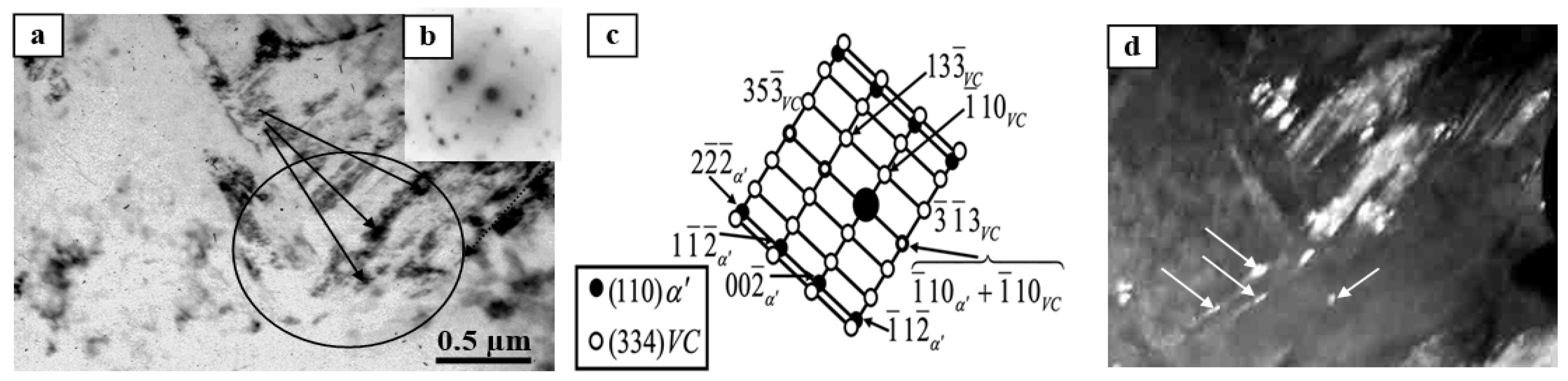

3.1. Structure and Phase Composition before Irradiation

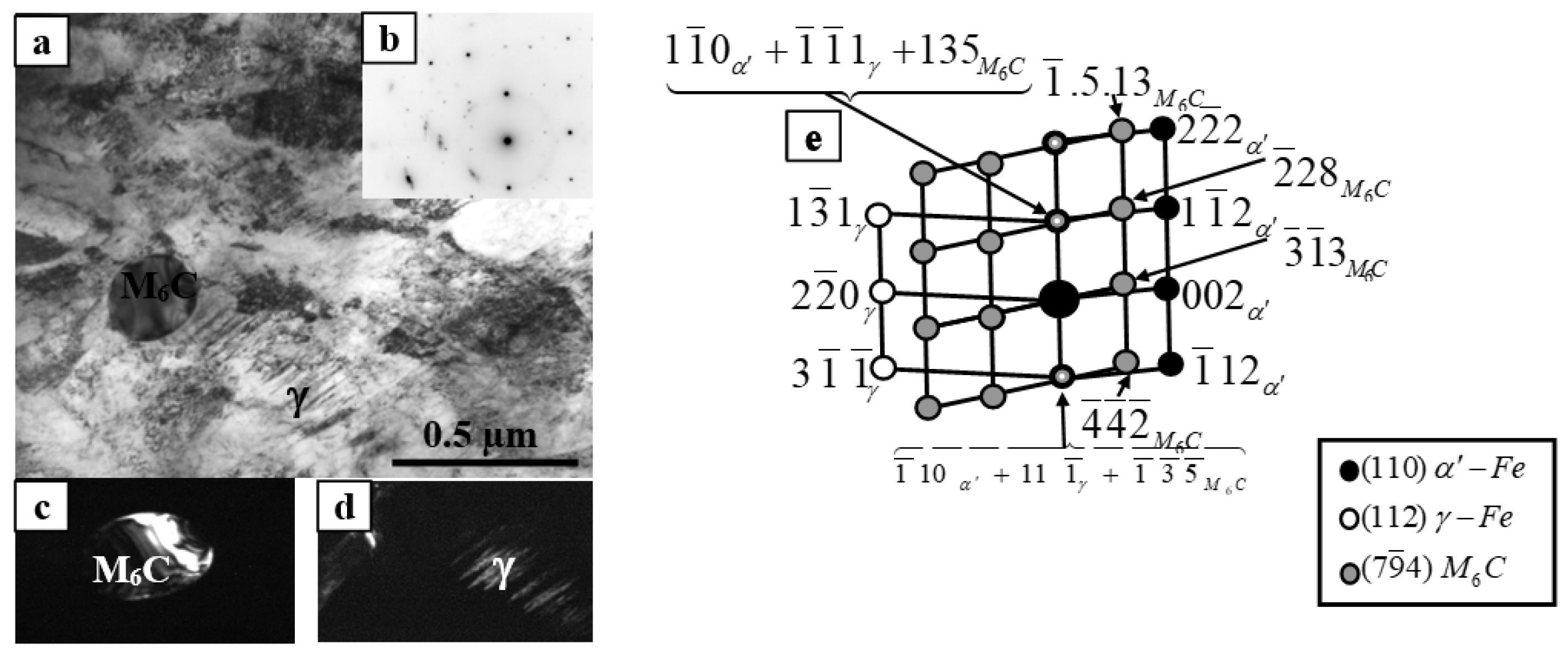

3.2. Structure and Phase Composition after Irradiation

4. Conclusions

- -

- in the initial state and after exposure to an electron beam, R6M5 steel is a multiphase material containing an α-phase, a γ-phase (residual austenite) and a carbide phase;

- -

- according to the morphological feature, α′-martensite in the initial state and after exposure to an electron beam is represented by lamellar and packet martensite;

- -

- the γ—phase (residual austenite) is present inside martensitic plates in the form of twin-type colonies consisting of separate parallel thin plates with an average size of ~10 × 250 nm and a volume fraction in the material of ~6%;

- -

- in the initial state and after exposure to the electron beam, the material also contains particles of M6C-type carbide of globular shape, which has a complex composition (Fe,W,Mo)6C, with an average size of ~0.5 microns and a volume fraction of 5%;

- -

- the scalar dislocation density plate and packet martensite after processing equal to the amount ρ = 4.5 × 1010 cm−2, which is 2-2. 5 times higher than in the initial state that has values for plate martensite ρ = 1.8 × 1010 cm−2 and packet martensite ~ρ = 3.5 × 1010 cm−2

- -

- after exposure to the electron beam, the amplitude of the internal long-range stresses equal σ∂ = 280 MPa, and the amplitude of the shear stresses equal σL = 420 MPa, that is, the condition σL > σ∂ is fulfilled, which confirms the plastic nature of the bending-torsion of the crystal lattice of α′-martensite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, X.G.; Li, D.Y. Effects of the sub-zero treatment condition on microstructure, mechanical behavior and wear resistance of W9Mo3Cr4V high speed steel. Wear 2013, 302, 854–862. [Google Scholar] [CrossRef]

- Yadav, V.K.; Kumar, P.; Dvivedi, A. Effect of tool rotation in near-dry EDM process on machining characteristics of HSS. Mater. Manuf. Process. 2019, 34, 779–790. [Google Scholar] [CrossRef]

- Enomoto, T.; Sugihara, T.; Yukinaga, S.; Hirose, K.; Stake, U. Highly wear-resistant cutting tools with textured surfaces in steel cutting. CIRP Ann. 2012, 61, 571. [Google Scholar] [CrossRef]

- Kim, J.; Narayanan, T.S.N.S.; Park, H.W. Reducing the pitting susceptibility of AISI 304 stainless steel using a hybrid treatment of high-power diode laser and large pulsed electron beam irradiation. Surf. Coat. Tech. 2020, 381, 1. [Google Scholar] [CrossRef]

- Konovalov, S.V.; Kormyshev, V.E.; Ivanov, Y.F.; Teresov, A.D. Electron-beam processing of the hardened layer formed on Hardox 450 steel electric-wire welding system Fe-C-V-Cr-Nb-W. Lett. Mater. 2016, 6, 350. [Google Scholar] [CrossRef][Green Version]

- Ormanova, M.; Petrov, P.; Kovacheva, D. Electron beam surface treatment of tool steels. Vacuum 2017, 135, 7. [Google Scholar] [CrossRef]

- Skakov, M.; Rakhadilov, B.; Scheffler, E.M. Microstructure and tribological properties of electrolytic plasma nitrided high-speed steel. Mater. Test. 2015, 57, 360. [Google Scholar] [CrossRef]

- Wang, X.; Han, X.G.; Lei, M.K.; Zhang, J.S. Effect of high-intensity pulsed ion beams irradiation on corrosion resistance of 316L stainless steel. Mater. Sci. Eng. A 2007, 457, 84. [Google Scholar] [CrossRef]

- Wang, R.; Cui, H.; Huang, J.; Jiang, H. Effect of the continuous electron beam process treatment in the surface modification of T10 steel. Nucl. Instrum. Methods Phys. Res. 2018, 436, 29. [Google Scholar] [CrossRef]

- Wang, R.; Yu, J.; Wei, D.; Meng, C. Surface microstructures and improved mechanical property of 40CrMn steel induced by continuous scanning electron beam process. Nucl. Instrum. Methods Phys. Res. B 2019, 459, 130–136. [Google Scholar] [CrossRef]

- Bessonov, D.A.; Vorobev, S.V.; Ivanov, F.Y. Povysheniye ustalostnoy dolgovechnosti stali 20KH13 elektronno-puchkovoy obrabotki. News Univ. Ferr. Metall. 2011, 10, 48–49. (In Russian) [Google Scholar]

- Ivanov, Y.F.; Gromov, V.E.; Vorobyov, S.V.; Bessonov, D.A.; Kolubaeeva, Y.A.; Konovalov, S.V. Structural-phase state of a 20CR13 steel surface layer irradiated by a high-intensity electron beam. Phys. Mesomech. 2011, 14, 111–116. (In Russian) [Google Scholar]

- Rykalin, N.N.; Zuev, I.V.; Uglov, A.A. Osnovy elektronno-luchevoy obrabotki materialov. Mech. Eng. 1978, 32–35. (In Russian) [Google Scholar]

- Denisova, Y.A. Strukturno-fazovyye prevrashcheniya v stalyakh, obrabotannykh nizkoenergeticheskim intensivnym elektronnym puchkom mikrosekundnoy dlitelnosti. Dis. K.F.M. Sci. Tomsk 2012, 220. (In Russian) [Google Scholar]

- Kozlov, I.V.; Popova, N.A.; Koneva, N.A. Scalar dislocation density in fragments with different substructure types. Lett. Mater. 2011, 1, 15. (In Russian) [Google Scholar] [CrossRef]

- Kubin, L.P.; Fressengeas, C.; Ananthakrishna, G. Collective behaviour of dislocations in plasticity. Dislocation Solids 2002, 11, 101. [Google Scholar] [CrossRef]

- GOST 19265-73 Bars and Strips of High-Speed Steel. Technical Specifications. GOST №. 19265-73 from 10 December 1973. Available online: http://vsegost.com/Catalog/83/8322.shtml (accessed on 22 January 2021).

- Guliaev, A.P. Physical metallurgy. M Metall. 1986, 6, 544. (In Russian) [Google Scholar]

- Tazhibayeva, I.; Kenzhin, E.; Shestakov, V.; Chikhray, Y.; Kulsartov, T.; Azizov, E.; Filatov, O.; Chernov, V. Material science activities for fusion reactors in Kazakhstan. J. Nucl. Mater. 2009, 386, 15–18. [Google Scholar] [CrossRef]

- Rahadilov, B.K.; Skakov, M.K.; Tulenbergenov, T.R. Structural Modification and Erosion of Plasma-Irradiated Tungsten and Molybdenum Surfaces. Key Eng. Mater. 2017, 736, 46. [Google Scholar] [CrossRef]

- Tulenbergenov, T.; Skakov, M.; Kolodeshnikov, A.; Zuev, V.; Rakhadilov, B.; Sokolov, I.; Ganovichev, D.; Miniyazov, A.; Bukina, O. Interaction between nitrogen plasma and tungsten. Nucl. Mater. Energy 2017, 13, 63. [Google Scholar] [CrossRef]

- Skakov, M.; Rakhadilov, B.; Karipbayeva, G. Specifics of microstructure and phase composition of high-speed steel R6M5. Appl. Mech. Mater. 2013, 404, 20–24. [Google Scholar] [CrossRef]

- Zuo, J.M.; Spence, J.C.H. Advanced Transmission Electron Microscopy. Imaging and Diffraction in Nanoscience; Springer: New York, NY, USA, 2017; p. 729. [Google Scholar]

- Matsukawa, Y.; Liu, G.S. In-situ TEM study on elastic interaction between a prismatic loop and a gliding dislocation. J. Nucl. Mater. 2012, 425, 54–59. [Google Scholar] [CrossRef]

- Hirsh, P.; Hovi, A.; Nicolson, R.; Peshli, D.; Yelan, M. Electron Microscopy of Fine Crystals; Ytevski, L.M., Ed.; Mir Publ.: Moscow, Russia, 1968; p. 574. [Google Scholar]

- Zisman, A.A.; Nikolaev, D.I.; Lychagina, T.A.; Yashina, E.A. On the Size Effect for Neutron Diffraction by Two-Phase Structures and Applicability of Composite Standards in Analysis of Residual Austenite in Steels. Tech. Phys. 2018, 63, 1696–1702. [Google Scholar] [CrossRef]

- Kozlov, I.V.; Ivanov, I.F.; Simonov, P.C. Phase composition and fine structure of R6M5 steel. Polzunovskii Alm. 2004, 4, 47–51. (In Russian) [Google Scholar]

- Shtremel, M.A. Prochnost splavov. Chast 1. Defekty reshetki, 3rd ed.; M.-MICIC: Moscow, Russia, 1999; p. 384. (In Russian) [Google Scholar]

- Ivanov, Y.F.; Gromov, V.E.; Glezer, A.M.; Peregudov, O.A.; Morozov, K.V. Nature of the structural degradation rail surfaces during operation. Bull. Russ. Acad. Sci. Phys. 2016, 80, 1483–1488. [Google Scholar] [CrossRef]

- Lipson, H.; Petch, N.J. The crystal structure of cementite Fe3C. J. Iron Steel Inst. 1940, 142, 95–103. [Google Scholar]

- Dunđer, M.; Vuherer, T.; Samardžić, I. Analysis of heat-affected zone microstructures of steel P92 after welding and after post-weld heat treatment. Int. J. Adv. Manuf. Technol. 2019, 102, 3801–3812. [Google Scholar] [CrossRef]

- Le, K.C.; Piao, Y. Thermodynamic dislocation theory: Size effect in torsion. Int. J. Plast. 2019, 115, 56–70. [Google Scholar] [CrossRef]

- Kormyshev, V.E.; Ivanov, Y.F.; Gromov, V.E. Formation of Fine Surface of Long Rails on Differentiated Hardening. J. Synch. Investig. 2020, 14, 1187–1190. [Google Scholar] [CrossRef]

- Koneva, N.A.; Popova, N.A.; Nikonenko, E.L. Internal Stresses and their Sources in BCC and FCC Steels. Solid State Phenom. 2020, 303, 128–142. [Google Scholar] [CrossRef]

| Phase | The Average Quantitative Parameters of Fine Structure | |||||

|---|---|---|---|---|---|---|

| PV | ρ, cm−2 | ρ ±, cm−2 | χ, cm−1 | σ∂, MPa | σL, MPa | |

| After surface irradiation | ||||||

| Packet martensite | 10% | 4.5 × 1010 | 2 × 1010 | 500 | 280 | 420 |

| Lamellar martensite | 90% | |||||

| Initial state | ||||||

| Packet martensite | 80% | 3.5 × 1010 | 1.7 × 1010 | 436 | 260 | 350 |

| Lamellar martensite | 20% | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakhadilov, B.; Kengesbekov, A.; Zhurerova, L.; Kozhanova, R.; Sagdoldina, Z. Impact of Electronic Radiation on the Morphology of the Fine Structure of the Surface Layer of R6M5 Steel. Machines 2021, 9, 24. https://doi.org/10.3390/machines9020024

Rakhadilov B, Kengesbekov A, Zhurerova L, Kozhanova R, Sagdoldina Z. Impact of Electronic Radiation on the Morphology of the Fine Structure of the Surface Layer of R6M5 Steel. Machines. 2021; 9(2):24. https://doi.org/10.3390/machines9020024

Chicago/Turabian StyleRakhadilov, Bauyrzhan, Aidar Kengesbekov, Laila Zhurerova, Rauan Kozhanova, and Zhuldyz Sagdoldina. 2021. "Impact of Electronic Radiation on the Morphology of the Fine Structure of the Surface Layer of R6M5 Steel" Machines 9, no. 2: 24. https://doi.org/10.3390/machines9020024

APA StyleRakhadilov, B., Kengesbekov, A., Zhurerova, L., Kozhanova, R., & Sagdoldina, Z. (2021). Impact of Electronic Radiation on the Morphology of the Fine Structure of the Surface Layer of R6M5 Steel. Machines, 9(2), 24. https://doi.org/10.3390/machines9020024