Evaluating Service Characteristics of Working Surfaces of Car Parts by Microgeometric Quality Parameters

Abstract

1. Introduction

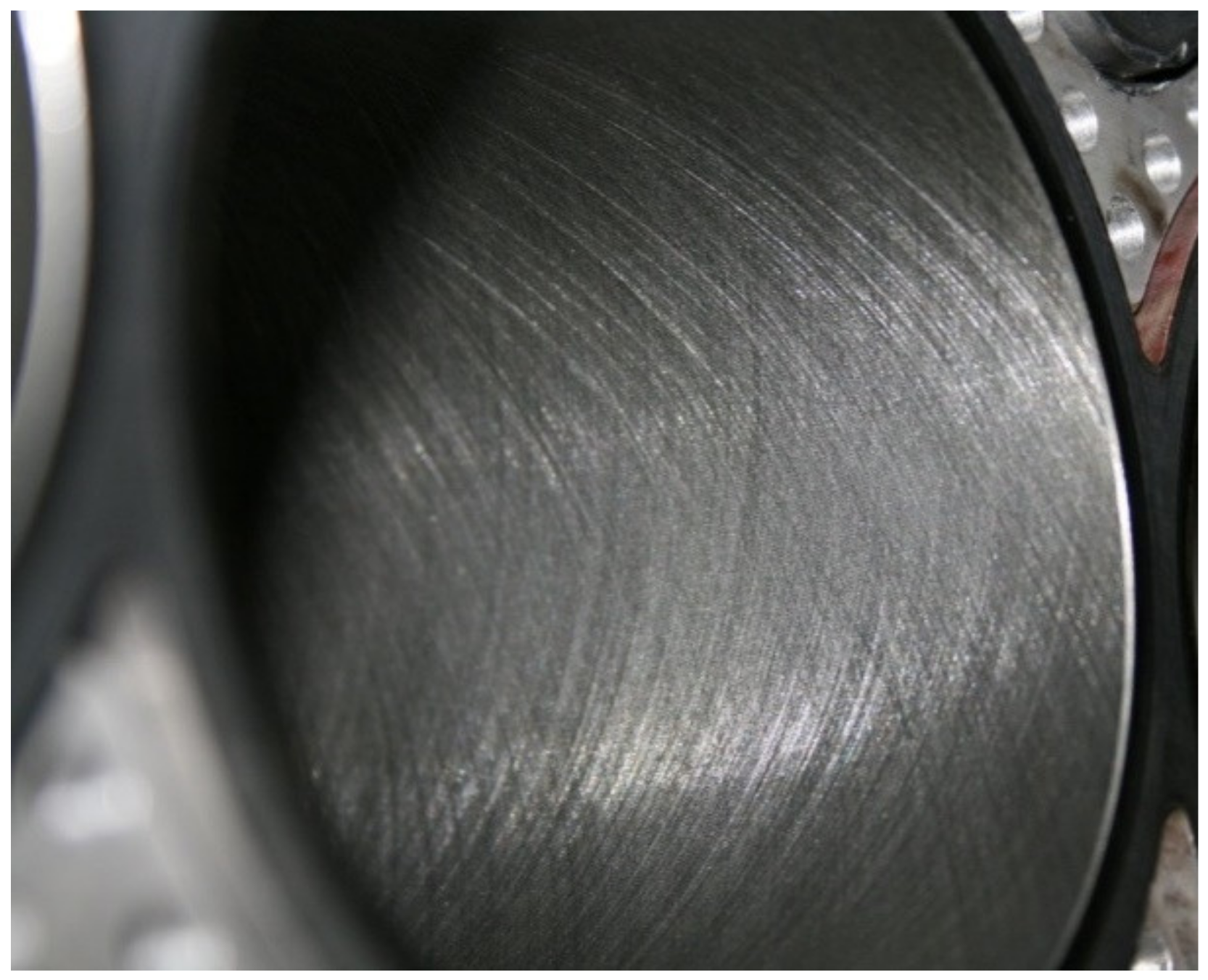

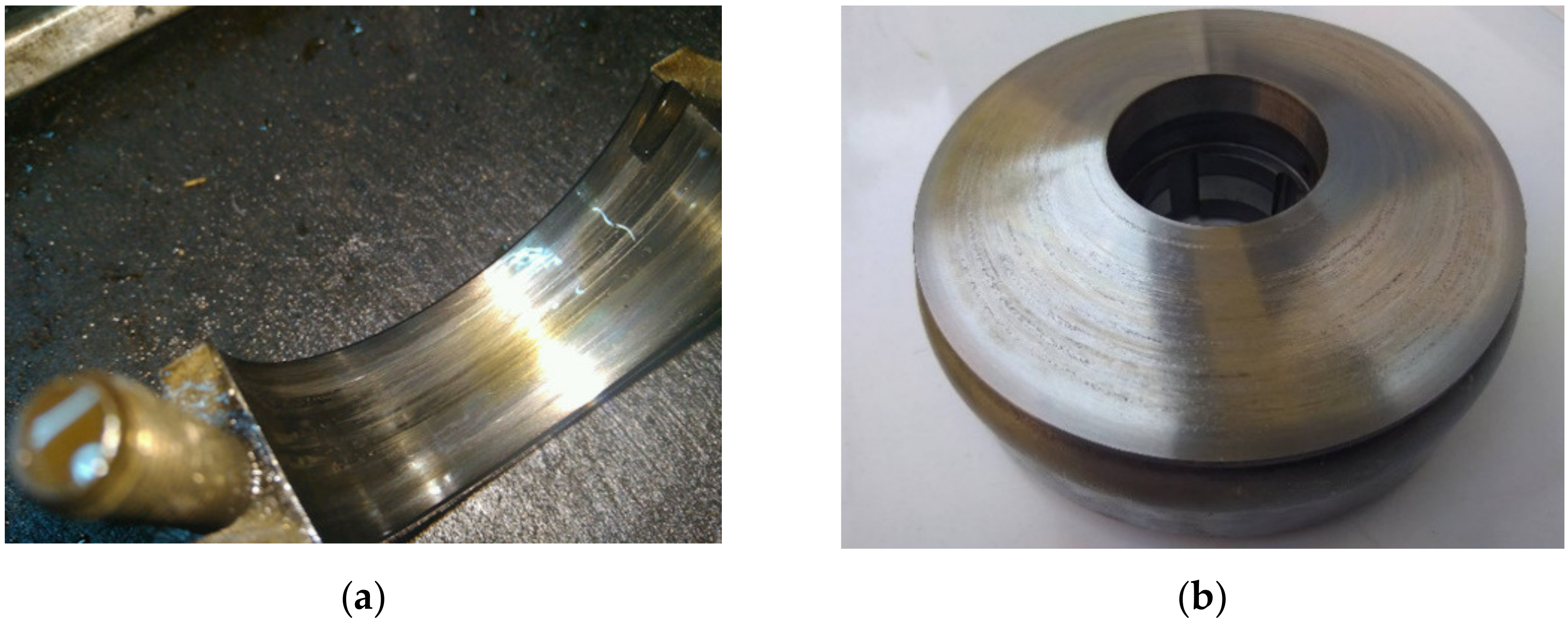

2. In-Service Analysis of Damage and Failures of Rotary Bodies

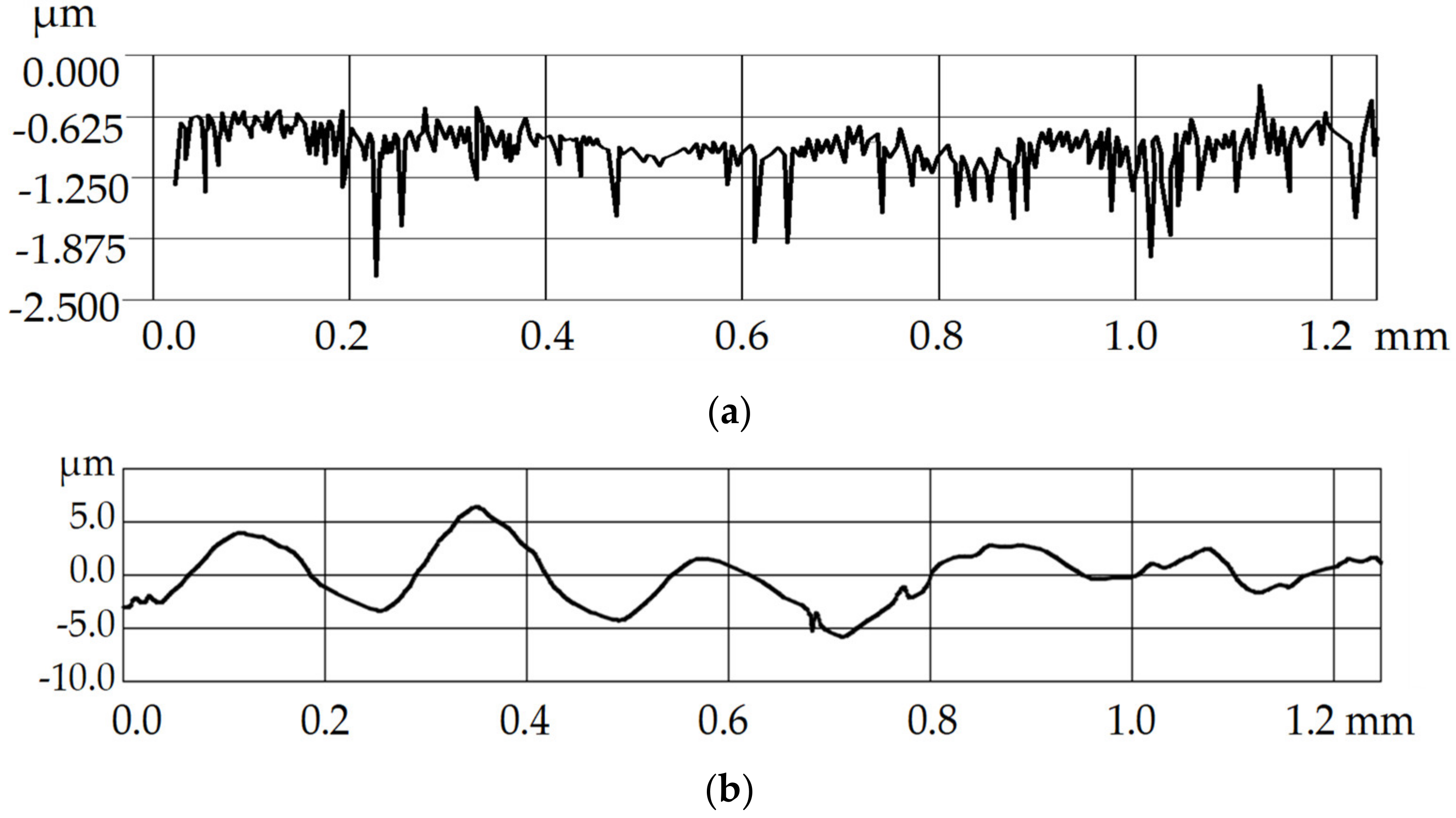

2.1. In-Service Wear and Damage of Rotary Bodies

- -

- Deviation of the working surface microgeometry;

- -

- Deviation of the working surface macrogeometry;

- -

- Non-optimal service characteristics of the surface;

- -

- Violation of operating conditions.

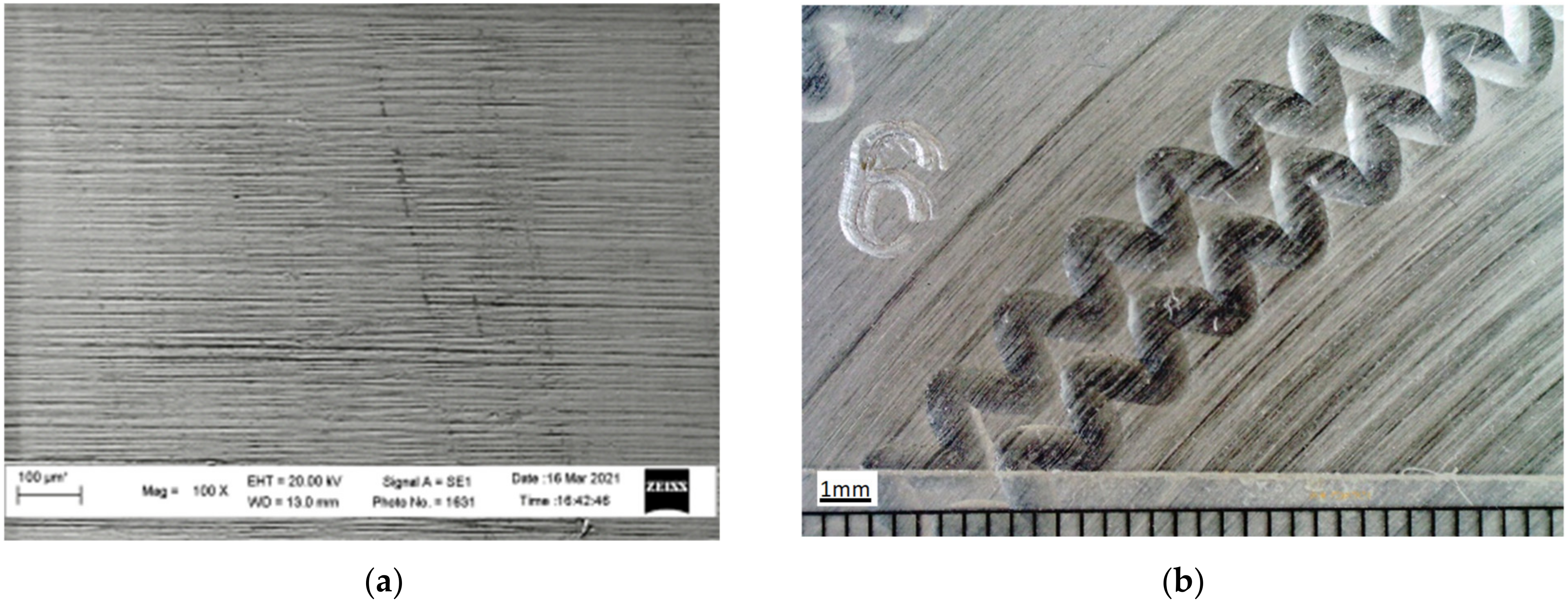

2.2. Relationship between Process Operations and the Oil-Absorption Power of the Surface

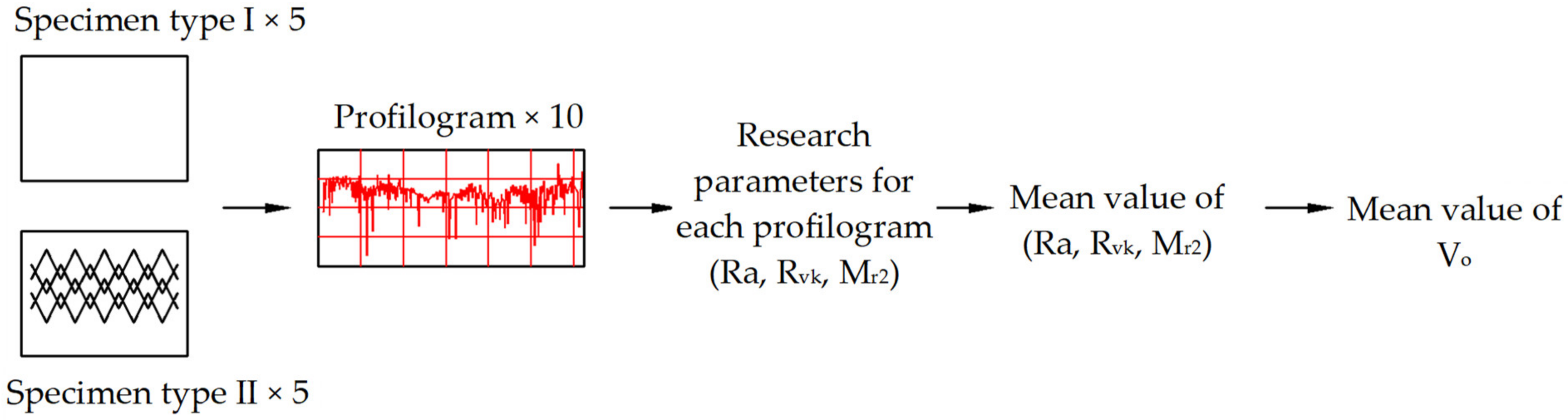

3. Materials and Methods

- -

- Type I were samples whose surface was machined with subsequent rolling.

- -

- Type I were samples for which the surface was processed by turning, with the subsequent formation of a regular microrelief.

4. Results

5. Discussion of Research Findings

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aimukhanbet, B.A. Influence of the Stress-Strain State of the Surface on Its Quality Indicators at Processing Cylindrical Parts by Plastic Deformation Methods. Ph.D. Thesis, Satbayev University, Almaty, Kazakhstan, 2019; p. 159. (In Russian). [Google Scholar]

- ISO 1302:2002. Geometrical Product Specifications (GPS)—Indication of Surface Texture in Technical Product Documentation; ISO: Geneva, Switzerland, 2002. [Google Scholar]

- ISO 13565-2:1996. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 2: Height Characterization Using the Linear Material Ratio Curve; ISO: Geneva, Switzerland, 1996. [Google Scholar]

- GOST 2789-73. Surface Roughness. Parameters and Characteristics; State Committee of Standards of the Council of Ministers of the USSR: Moscow, Russia, 1975; p. 7. (In Russian) [Google Scholar]

- GOST R ISO 4287-2014. Geometrical Product Specifications (GPS). Surface Texture. Profile Method. Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Moscow, Russia, 2015; p. 18. (In Russian) [Google Scholar]

- DSTU GOST 25142: 2009. Surface Roughness. Terms and Definitions; State Committee for Technical Regulation and Consumer Policy: Kyiv, Ukraine, 2009; p. 22. (In Ukrainian) [Google Scholar]

- Tabenkin, A.N.; Tarasov, S.B.; Stepanov, A.N. Sherokhovatost’, Volnistost’, Profil’. Mezhdunarodnyyopyt [Roughness, Waviness, and Profile, International Experience]; Izd-voPolitekhn. Un-ta: Saint Petersburg, Russia, 2007; p. 136. (In Russian) [Google Scholar]

- Stupnytskyy, V.V. Structural-parametric optimization of the technological processes for the assurance of part’s service properties. East. Eur. J. Enterp. Technol. 2014, 2, 9–16. [Google Scholar] [CrossRef]

- Nagorkin, M.N. Reliability of Technological Support of Roughness and Wear Resistance of Surfaces of Parts with Tools Made of Synthetic Superhard Materials. Ph.D. Thesis, Bryansk State Technical University, Bryansk, Russia, 2020; p. 337. (In Russian). [Google Scholar]

- Gamez-Montero, P.J.; Salazar, E.; Castilla, R.; Freire, J.; Khamashta, M.; Codina, E. Friction effects on the load capacity of a column and a hydraulic cylinder. Int. J. Mech. Sci. 2009, 51, 141–151. [Google Scholar] [CrossRef]

- Qin, P.; Yang, C.; Huang, W.; Xu, G.; Liu, C. Honing process of hydraulic cylinder bore for remanufacturing. In Proceedings of the 4th International Conference on Sensors, Measurement and Intelligent Materials, Shenzhen, China, 27–28 December 2015; Atlantis Press: Paris, France, 2016; pp. 64–68. [Google Scholar] [CrossRef]

- Kim, E.-S.; Kim, S.-M.; Lee, Y.-Z. The effect of plateau honing on the friction and wear of cylinder liners. Wear 2018, 400–401, 207–212. [Google Scholar] [CrossRef]

- Voitov, V.A.; Zakharchenko, M.B. Modeling the processes of friction and wear in tribosystems under boundary lubrication conditions. Part 2. Simulation results. Probl. Tribol. 2015, 76, 36–45. (In Russian) [Google Scholar]

- Aulin, V.; Hrynkiv, A.; Lysenko, S.; Dykha, A.; Zamota, T.; Dzyura, V. Exploring a possibility to control the stressed-strained state of cylinder liners in diesel engines by the tribotechnology of alignment. East. Eur. J. Enterp. Technol. 2019, 99, 6–16. [Google Scholar] [CrossRef]

- Castro, R.; Rocha, A.; Curi, E.M.; Peruch, F. A Comparison of microstructural, mechanical and tribological properties of WC-10Co4Cr—HVOF coating and hard chrome to use in hydraulic cylinders. Am. J. Mater. Sci. 2018, 8, 15–26. [Google Scholar] [CrossRef]

- Dzyura, V.; Maruschak, P. Optimizing the formation of hydraulic cylinder surfaces, taking into account their microrelief topography analyzed during different operations. Machines 2021, 9, 116. [Google Scholar] [CrossRef]

- Zhang, Y.; Zeng, L.; Wu, Z.; Ding, X.; Chen, K. Synergy of surface textures on a hydraulic cylinder piston. Micro Nano Lett. 2019, 14, 424–429. [Google Scholar] [CrossRef]

- Radionenko, O.; Kindrachuk, M.; Tisov, O.; Kryzhanovskyi, A. Features of transition modes of friction surfaces with partially regular microrelief. Aviation 2018, 22, 86–92. [Google Scholar] [CrossRef]

- Kindrachuk, M.; Radionenko, O.; Kryzhanovskyi, A.; Marchuk, V. The friction mechanism between surfaces with regular micro grooves under boundary lubrication. Aviation 2014, 18, 64–71. [Google Scholar] [CrossRef]

- Honing Cylinders: Technology Overview and Quality Criteria. Available online: https://rad-star.ru/pressroom/articles/khoningovanie-tsilindrov (accessed on 12 December 2021). (In Russian).

- Slavov, S.; Iliev, I. Design and fem static analysis of an instrument for surface plastic deformation of non-planar functional surfaces of machine parts. Fiability Durab. 2016, 2, 3–9. [Google Scholar]

- Sotnykov, O.; Rodionov, M.; Maruschak, P.; Brezinová, J.; Guzanová, A.; Apostol, Y. Failure analysis of the hingelever mould oscillator bearings of the continuous casting machine. Strength Fract. Complex. 2014, 8, 135–143. [Google Scholar] [CrossRef]

- Dzyura, V.O.; Maruschak, P.O.; Zakiev, I.M.; Sorochak, A.P. Analysis of inner surface roughness parameters of load-carrying and support elements of mechanical systems. Int. J. Eng. Trans. B Appl. 2017, 30, 1170–1175. [Google Scholar] [CrossRef]

- Dzyura, V.; Maruschak, P.; Tkachenko, I.; Kuchvara, I. Ensuring a stable relative area of burnishing of partially regular microrelief formed on end surfaces of rotary bodies. Stroj. Časopis J. Mech. Eng. 2021, 71, 41–50. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional importance of surface texture parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef] [PubMed]

- Dzierwa, A.; Markopoulos, A.P. Influence of ball-burnishing process on surface topography parameters and tribological properties of hardened steel. Machines 2019, 7, 11. [Google Scholar] [CrossRef]

- Sedlaček, M.; Gregorčič, P.; Podgornik, B. Use of the roughness parameters Ssk and Sku to control friction—A method for designing surface texturing. Tribol. Trans. 2017, 60, 260–266. [Google Scholar] [CrossRef]

- Zeng, Q.; Qin, Y.; Chang, W.; Luo, X. Correlating and evaluating the functionality-related properties with surface texture parameters and specific characteristics of machined components. Int. J. Mech. Sci. 2018, 149, 62–72. [Google Scholar] [CrossRef]

- Swirad, S.; Pawlus, P. The effect of ball burnishing on dry fretting. Materials 2021, 14, 7073. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Liu, Z.; Du, J.; Su, G.; Zhang, J.; Xu, C. On machinability and surface integrity in subsequent machining of additively-manufactured thick coatings: A review. J. Manuf. Process. 2020, 53, 123–143. [Google Scholar] [CrossRef]

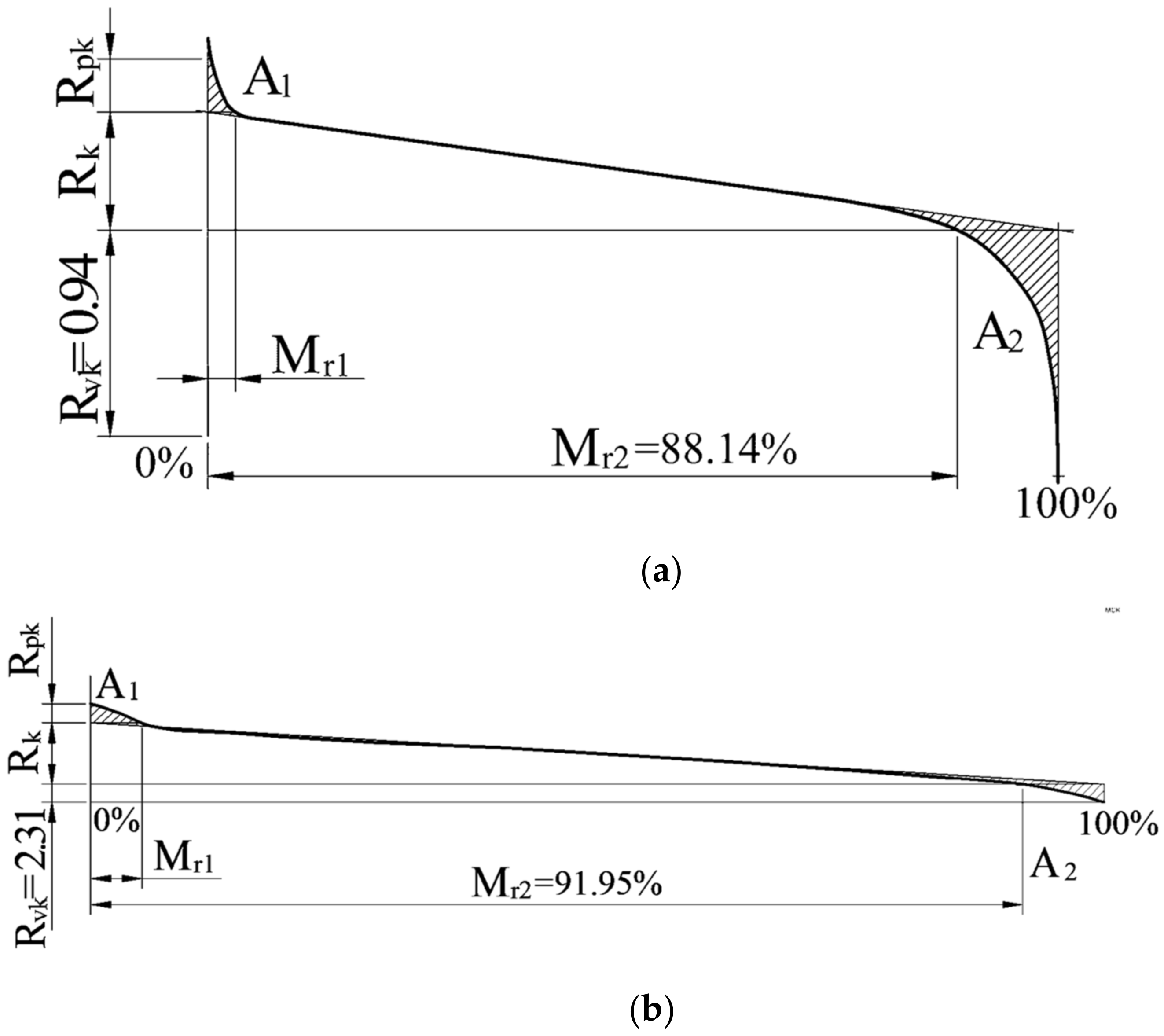

| Finishing Method | № | Measured and Calculated Roughness Parameters | ||||||

|---|---|---|---|---|---|---|---|---|

| Rai, µm | Mean Ra, µm | Rvk, µm | Mean Rvk, µm | Mr2, % | Mean Mr2, % | Volume of Oil, V0, mm3/cm2 | ||

| Rolling | 1 | 0.165 | 0.165 | 0.94 | 0.956 | 88.14 | 88.784 | 0.054 |

| 2 | 0.162 | 0.96 | 86.29 | |||||

| 3 | 0.197 | 0.87 | 90.08 | |||||

| 4 | 0.154 | 1.02 | 89.23 | |||||

| 5 | 0.146 | 0.99 | 90.18 | |||||

| Ball burnishing | 1 | 1.11 | 1.114 | 2.31 | 2.312 | 91.95 | 91.92 | 0.093 |

| 2 | 1.29 | 2.19 | 90.72 | |||||

| 3 | 1.17 | 2.22 | 92.38 | |||||

| 4 | 0.97 | 2.45 | 92.61 | |||||

| 5 | 1.03 | 2.39 | 91.94 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzyura, V.; Maruschak, P.; Slavov, S.; Gurey, V.; Prentkovskis, O. Evaluating Service Characteristics of Working Surfaces of Car Parts by Microgeometric Quality Parameters. Machines 2021, 9, 366. https://doi.org/10.3390/machines9120366

Dzyura V, Maruschak P, Slavov S, Gurey V, Prentkovskis O. Evaluating Service Characteristics of Working Surfaces of Car Parts by Microgeometric Quality Parameters. Machines. 2021; 9(12):366. https://doi.org/10.3390/machines9120366

Chicago/Turabian StyleDzyura, Volodymyr, Pavlo Maruschak, Stoyan Slavov, Volodymyr Gurey, and Olegas Prentkovskis. 2021. "Evaluating Service Characteristics of Working Surfaces of Car Parts by Microgeometric Quality Parameters" Machines 9, no. 12: 366. https://doi.org/10.3390/machines9120366

APA StyleDzyura, V., Maruschak, P., Slavov, S., Gurey, V., & Prentkovskis, O. (2021). Evaluating Service Characteristics of Working Surfaces of Car Parts by Microgeometric Quality Parameters. Machines, 9(12), 366. https://doi.org/10.3390/machines9120366