A Bearing Fault Diagnosis Method Using Multi-Branch Deep Neural Network

Abstract

:1. Introduction

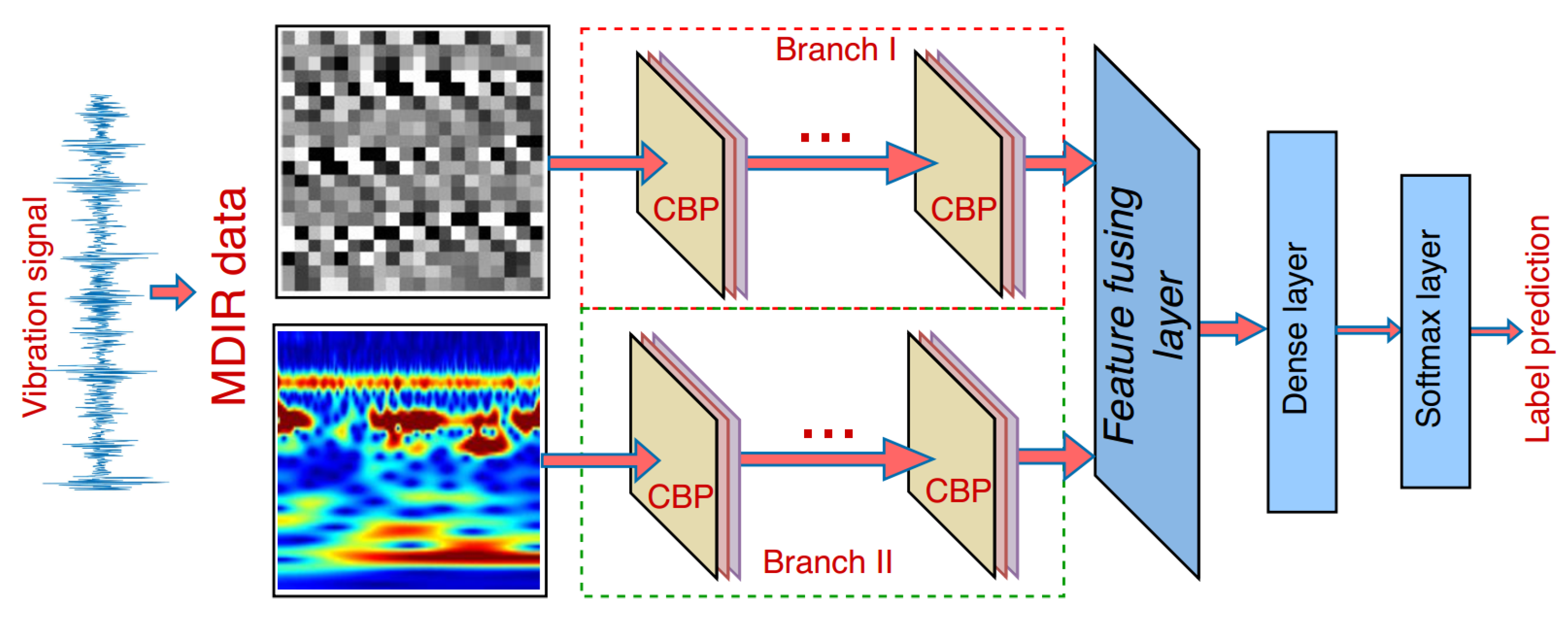

- Proposing a method to represent vibration signals in high dimensional form;

- Proposing an MB-DNN with a multi-branch structure to handle the new representation of vibration signal in the high-dimensional domain;

- Transforming the task of signal-based fault diagnosis into the task of image classification;

- The proposed fault diagnosis method achieves significant classification accuracy.

2. Multiple-Domain Image-Representation of Vibration Signal

- It may be easier to understand and mine information in high-dimensional data [30].

- CNN and its variants are suitable for the task of recognizing two-dimensional visual patterns [31].

- By transforming the signal into visual data, the task of fault diagnosis can be converted into the task of image classification.

3. Proposed Multi-Branch Deep Neural Network

4. Experiments and Results

4.1. Data Preparation

4.2. Signal Pre-Processing

4.3. Design and Train the Proposed DNN

4.4. Fault Diagnosis Result

4.5. Evaluation under Noisy Conditions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shahriar, M.R.; Borghesani, P.; Tan, A.C.C. Electrical signature analysis-based detection of external bearing faults in electromechanical drivetrains. IEEE Trans. Ind. Electron. 2017, 65, 5941–5950. [Google Scholar] [CrossRef]

- Van, M.; Hoang, D.T.; Kang, H.J. Bearing fault diagnosis using a particle swarm optimization-least squares wavelet support vector machine classifier. Sensors 2020, 20, 3422. [Google Scholar] [CrossRef] [PubMed]

- Hoang, D.T.; Tran, X.T.; Van, M.; Kang, H.J. A Deep Neural Network-Based Feature Fusion for Bearing Fault Diagnosis. Sensors 2021, 21, 244. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Hou, D.; Qi, H.; Bo, L. High-speed train wheel set bearing fault diagnosis and prognostics: A new prognostic model based on extendable useful life. Mech. Syst. Signal. Proc. 2021, 146, 107050. [Google Scholar] [CrossRef]

- Azamfar, M.; Singh, J.; Bravo-Imaz, I.; Lee, J. Multisensor data fusion for gearbox fault diagnosis using 2-D convolutional neural network and motor current signature analysis. Mech. Syst. Signal. Proc. 2020, 144, 106861. [Google Scholar] [CrossRef]

- Hoang, D.T.; Kang, H.J. A motor current signal-based bearing fault diagnosis using deep learning and information fusion. IEEE Trans. Instrum. Meas. 2019, 69, 3325–3333. [Google Scholar] [CrossRef]

- Kharche, P.P.; Kshirsagar, S.V. Review of fault detection in rolling element bearing. Int. J. Innov. Res. Adv. Eng. 2014, 1, 169–174. [Google Scholar]

- Rauber, T.W.; de Assis Boldt, F.; Varejão, F.M. Heterogeneous feature models and feature selection applied to bearing fault diagnosis. IEEE Trans. Ind. Electron. 2014, 62, 637–646. [Google Scholar] [CrossRef]

- Li, C.; Sanchez, V.; Zurita, G.; Lozada, M.C.; Cabrera, D. Rolling element bearing defect detection using the generalized synchrosqueezing transform guided by time--frequency ridge enhancement. ISA Trans. 2016, 60, 274–284. [Google Scholar] [CrossRef]

- Zhou, D.-X. Universality of deep convolutional neural networks. Appl. Comput. Harmon. Anal. 2020, 48, 787–794. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Zhang, W.; Ma, H.; Luo, Z.; Li, X. Degradation Alignment in Remaining Useful Life Prediction Using Deep Cycle-Consistent Learning. IEEE Trans. Neural Netw. Learn. Syst. 2021, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Saravanakumar, R.; Krishnaraj, N.; Venkatraman, S.; Sivakumar, B.; Prasanna, S.; Shankar, K. Hierarchical symbolic analysis and particle swarm optimization based fault diagnosis model for rotating machineries with deep neural networks. Measurement 2021, 171, 108771. [Google Scholar] [CrossRef]

- Alabsi, M.; Liao, Y.; Nabulsi, A.-A. Bearing fault diagnosis using deep learning techniques coupled with handcrafted feature extraction: A comparative study. J. Vib. Control. 2021, 27, 404–414. [Google Scholar] [CrossRef]

- Choudhary, A.; Mian, T.; Fatima, S. Convolutional neural network based bearing fault diagnosis of rotating machine using thermal images. Measurement 2021, 176, 109196. [Google Scholar] [CrossRef]

- Wang, C.; Xu, Z. An intelligent fault diagnosis model based on deep neural network for few-shot fault diagnosis. Neurocomputing 2021, 456, 550–562. [Google Scholar] [CrossRef]

- LeCun, Y.; Ranzato, M. Deep learning tutorial. In Proceedings of the Tutorials in International Conference on Machine Learning (ICML’13), Atlanta, GA, USA, 16–21 June 2013; pp. 1–29. [Google Scholar]

- Nguyen, C.D.; Prosvirin, A.E.; Kim, C.H.; Kim, J.-M. Construction of a sensitive and speed invariant gearbox fault diagnosis model using an incorporated utilizing adaptive noise control and a stacked sparse autoencoder-based deep neural network. Sensors 2021, 21, 18. [Google Scholar] [CrossRef] [PubMed]

- Salimans, T.; Goodfellow, I.; Zaremba, W.; Cheung, V.; Radford, A.; Chen, X. Improved techniques for training gans. Adv. Neural Inf. Proc. Syst. 2016, 29, 2234–2242. [Google Scholar]

- Pham, M.T.; Kim, J.-M.; Kim, C.H. Efficient Fault Diagnosis of Rolling Bearings Using Neural Network Architecture Search and Sharing Weights. IEEE Access 2021, 9, 98800–98811. [Google Scholar] [CrossRef]

- Zan, T.; Wang, H.; Wang, M.; Liu, Z.; Gao, X. Application of multi-dimension input convolutional neural network in fault diagnosis of rolling bearings. Appl. Sci. 2019, 9, 2690. [Google Scholar] [CrossRef] [Green Version]

- Pham, M.-T.; Kim, J.-M.; Kim, C.-H. 2D CNN-Based Multi-Output Diagnosis for Compound Bearing Faults under Variable Rotational Speeds. Machines 2021, 9, 199. [Google Scholar] [CrossRef]

- Wei, Y.; Xia, W.; Lin, M.; Huang, J.; Ni, B.; Dong, J.; Zhao, Y.; Yan, S. HCP: A flexible CNN framework for multi-label image classification. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 38, 1901–1907. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, X.; Yao, J.; Xu, Z.; Meng, D. Hyperspectral image classification with convolutional neural network and active learning. IEEE Trans. Geosci. Remote Sens. 2020, 58, 4604–4616. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network-Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2018, 65, 5990–5998. [Google Scholar] [CrossRef]

- Wang, J.; Mo, Z.; Zhang, H.; Miao, Q. A deep learning method for bearing fault diagnosis based on time-frequency image. IEEE Access 2019, 7, 42373–42383. [Google Scholar] [CrossRef]

- Eren, L. Bearing fault detection by one-dimensional convolutional neural networks. Math. Probl. Eng. 2017, 2017, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal. Proc. 2016, 72, 303–315. [Google Scholar] [CrossRef]

- Yuan, L.; Lian, D.; Kang, X.; Chen, Y.; Zhai, K. Rolling bearing fault diagnosis based on convolutional neural network and support vector machine. IEEE Access 2020, 8, 137395–137406. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal. Proc. 2015, 64, 100–131. [Google Scholar] [CrossRef]

- Ding, X.; He, Q. Energy-fluctuated multiscale feature learning with deep convnet for intelligent spindle bearing fault diagnosis. IEEE Trans. Instrum. Meas. 2017, 66, 1926–1935. [Google Scholar] [CrossRef]

- Phung, S.L.; Bouzerdoum, A. Visual and Audio Signal Processing Lab. University of Wollongong. 2009. Available online: https://documents.uow.edu.au/~phung/docs/cnn-matlab/cnn-matlab.pdf (accessed on 9 December 2021).

- Nguyen, D.; Kang, M.; Kim, C.-H.; Kim, J.-M. Highly reliable state monitoring system for induction motors using dominant features in a two-dimension vibration signal. New Rev. Hypermedia Multimed. 2013, 19, 248–258. [Google Scholar] [CrossRef]

- Bolós, V.J.; Ben’itez, R. The wavelet scalogram in the study of time series. In Advances in Differential Equations and Applications; Springer: Berlin/Heidelberg, Germany, 2014; pp. 147–154. [Google Scholar]

- LeCun, Y.; Haffner, P.; Bottou, L.; Bengio, Y. Object recognition with gradient-based learning. In Shape, Contour and Grouping in Computer Vision; Springer: Berlin/Heidelberg, Germany, 1999; pp. 319–345. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Proc. Syst. 2012, 25, 1097–1105. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Huang, G.; Liu, Z.; Van Der Maaten, L.; Weinberger, K.Q. Densely connected convolutional networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 4700–4708. [Google Scholar]

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. In Proceedings of the International Conference on Machine Learning, Lille, France, 6–11 July 2015; pp. 448–456. [Google Scholar]

- Loparo, K.A. Case Western Reserve University Bearing Data Center. Available online: http://csegroups.case.edu/bearingdatacenter/pages/download-data-file (accessed on 9 December 2021).

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.-C.; Liu, Z.; Yang, G.; Wu, C.-C.; Ye, Q. An Improved Fault Diagnosis Using 1D-Convolutional Neural Network Model. Electronics 2021, 10, 59. [Google Scholar] [CrossRef]

| Bearing Fault | Fault Size (mils) | Label |

|---|---|---|

| No fault | 0 | |

| Inner race fault | 7 | 1 |

| Inner race fault | 14 | 2 |

| Inner race fault | 21 | 3 |

| Ball fault | 7 | 4 |

| Ball fault | 14 | 5 |

| Ball fault | 21 | 6 |

| Outer race | 7 | 7 |

| Outer race | 14 | 8 |

| Outer race | 21 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.-C.; Hoang, D.-T.; Tran, X.-T.; Van, M.; Kang, H.-J. A Bearing Fault Diagnosis Method Using Multi-Branch Deep Neural Network. Machines 2021, 9, 345. https://doi.org/10.3390/machines9120345

Nguyen V-C, Hoang D-T, Tran X-T, Van M, Kang H-J. A Bearing Fault Diagnosis Method Using Multi-Branch Deep Neural Network. Machines. 2021; 9(12):345. https://doi.org/10.3390/machines9120345

Chicago/Turabian StyleNguyen, Van-Cuong, Duy-Tang Hoang, Xuan-Toa Tran, Mien Van, and Hee-Jun Kang. 2021. "A Bearing Fault Diagnosis Method Using Multi-Branch Deep Neural Network" Machines 9, no. 12: 345. https://doi.org/10.3390/machines9120345

APA StyleNguyen, V.-C., Hoang, D.-T., Tran, X.-T., Van, M., & Kang, H.-J. (2021). A Bearing Fault Diagnosis Method Using Multi-Branch Deep Neural Network. Machines, 9(12), 345. https://doi.org/10.3390/machines9120345